Semiautomatic settling type pickle squeezer

A settling type, press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of long pressing and dehydration time, many manual operation links, increase work intensity, etc., achieve simple and effective structure, high degree of automation, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

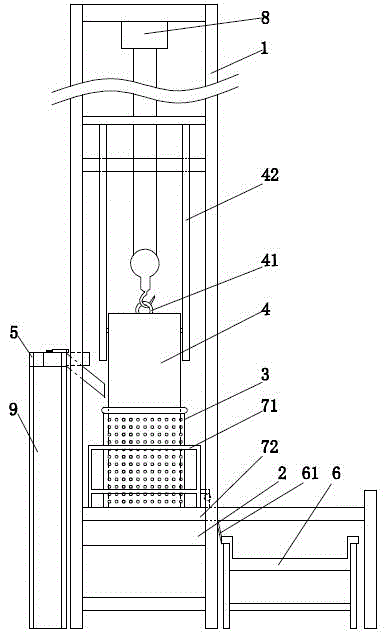

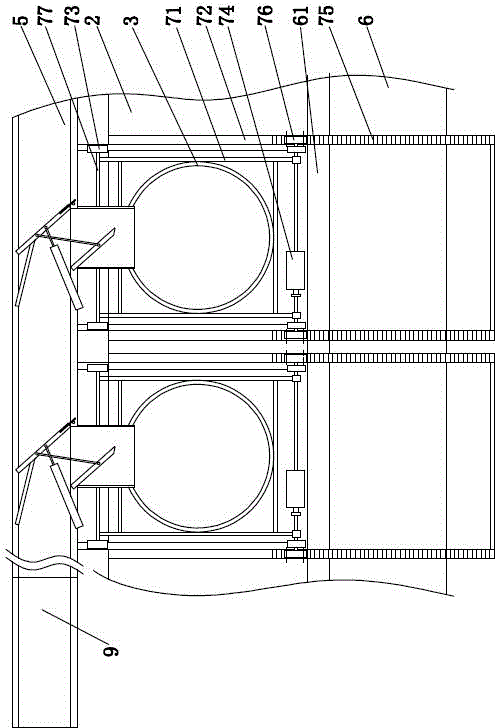

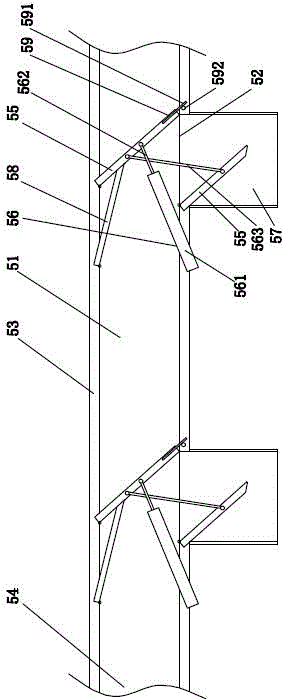

[0027] Figure 1 to Figure 5 Shows the semi-automatic sinking type kimchi press machine provided by the present invention, including a frame 1, a pressing platform 2 for bearing the pressing force on the frame 1, a bottomless filter cartridge 3 on the pressing platform 2, and a bottomless filter cartridge 3 Adapted solid press cylinder 4, feeding device 5 for feeding into the bottomless filter cylinder 3, collecting device 6 seamlessly connected with the pressing platform 2, and moving the bottomless filter cartridge 3 to the collecting device 6 The upper filter cartridge moving device 7; the solid press cylinder 4 is connected with a lifting device 8 that drives it up and down.

[0028] The solid squeeze cylinder 4 is a steel cylinder filled with concrete to make it very heavy. Specifically, a solid squeeze cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com