Friction material, brake pad with friction material and method for manufacturing brake pad

A technology of friction materials and raw materials, applied in friction linings, chemical instruments and methods, other chemical processes, etc., can solve problems such as thermal recession and wear, and achieve the effect of less material consumption, good thermal stability and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

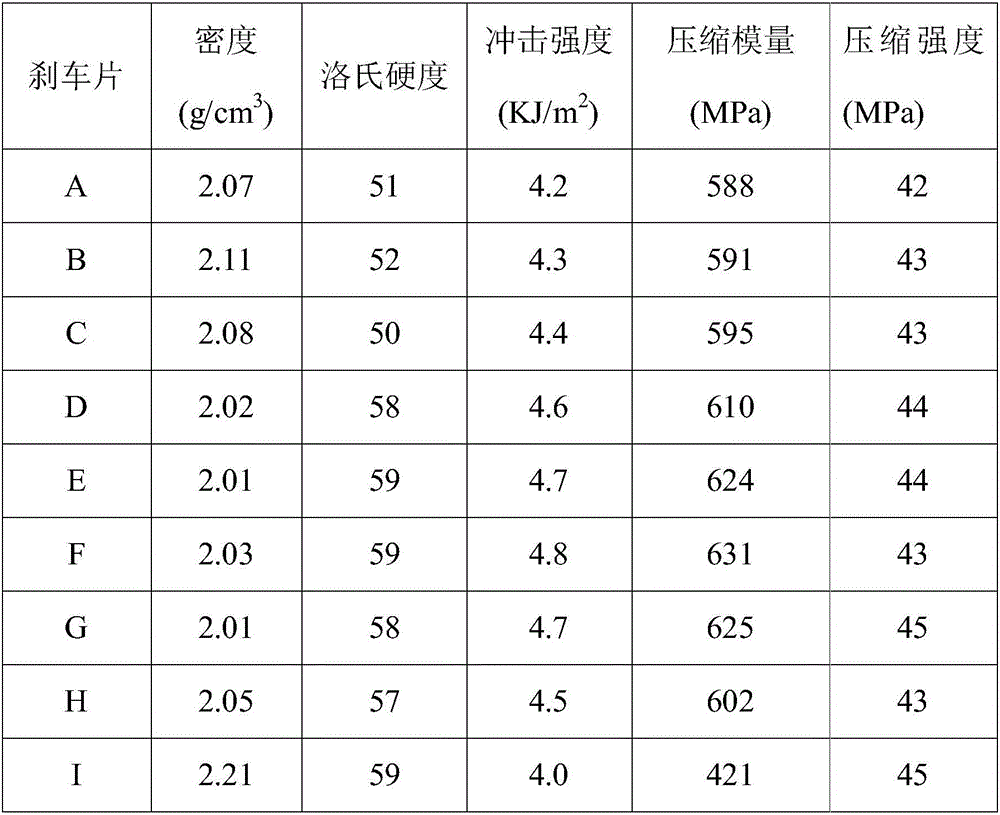

Examples

Embodiment 1

[0029] This embodiment provides a friction material whose raw materials include the following components:

[0030] Steel fiber 45g, modified phenolic resin 6.5g, nitrile rubber 8g, styrene-butadiene rubber 10g, graphite 5g, antimony sulfide 3g, potassium hexatitanate 6g, silicon dioxide 1g, aramid fiber 3g, calcium carbonate 1g, heavy oxide Magnesium 3.5g, white corundum 2g, silicon carbide 1.5g, carbon black 1g.

[0031] The method for manufacturing a brake pad by using the above-mentioned friction material includes the following steps:

[0032] The above-mentioned raw material components were weighed and mixed uniformly to form a mixture. The mixture was placed in a mold and pressed under a pressure of 10 MPa for 15 seconds to obtain a blank, and then the blank was heated to 160° C. for 24 hours to obtain a brake pad A.

Embodiment 2

[0034] This embodiment provides a friction material whose raw materials include the following components:

[0035] 50g of steel fiber, 5g of boron modified phenolic resin, 6.5g of nitrile rubber, 11g of styrene-butadiene rubber, 1g of graphite, 5g of antimony sulfide, 5g of potassium hexatitanate, 1.5g of silicon dioxide, 1g of aramid fiber, 1.5g of calcium carbonate, Heavy magnesium oxide 2g, white corundum 1g, silicon carbide 2g, carbon black 2g.

[0036] The method for manufacturing a brake pad by using the above-mentioned friction material includes the following steps:

[0037] The above-mentioned raw material components were weighed and mixed uniformly to form a mixture. The mixture was placed in a mold and pressed under a pressure of 9 MPa for 12 seconds to obtain a blank, and then the blank was heated to 180° C. for 22 hours to obtain a brake pad B.

Embodiment 3

[0039] This embodiment provides a friction material whose raw materials include the following components:

[0040] Steel fiber 55g, boron modified phenolic resin 8g, nitrile rubber 5g, styrene-butadiene rubber 12g, graphite 3g, antimony sulfide 1g, potassium hexatitanate 4g, silicon dioxide 2g, aramid fiber 5g, calcium carbonate 2g, heavy oxide Magnesium 5g, white corundum 1.5g, silicon carbide 1g, carbon black 1.5g.

[0041] The method for manufacturing a brake pad by using the above-mentioned friction material includes the following steps:

[0042] The above-mentioned raw material components were weighed and mixed uniformly to form a mixture. The mixture was placed in a mold and pressed under a pressure of 12 MPa for 10 seconds to obtain a blank, and then the blank was heated to 200° C. for 20 hours to obtain a brake pad C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com