Accumulator distribution type fuel injection pump

A fuel injection pump and pressure accumulator technology, which is applied in the direction of fuel injection pumps, fuel injection devices, variable displacement pump components, etc., can solve problems such as complex composition, difficulty in ensuring strength, and complex structure, so as to improve reliability and prevent Partial wear, the effect of improving durability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

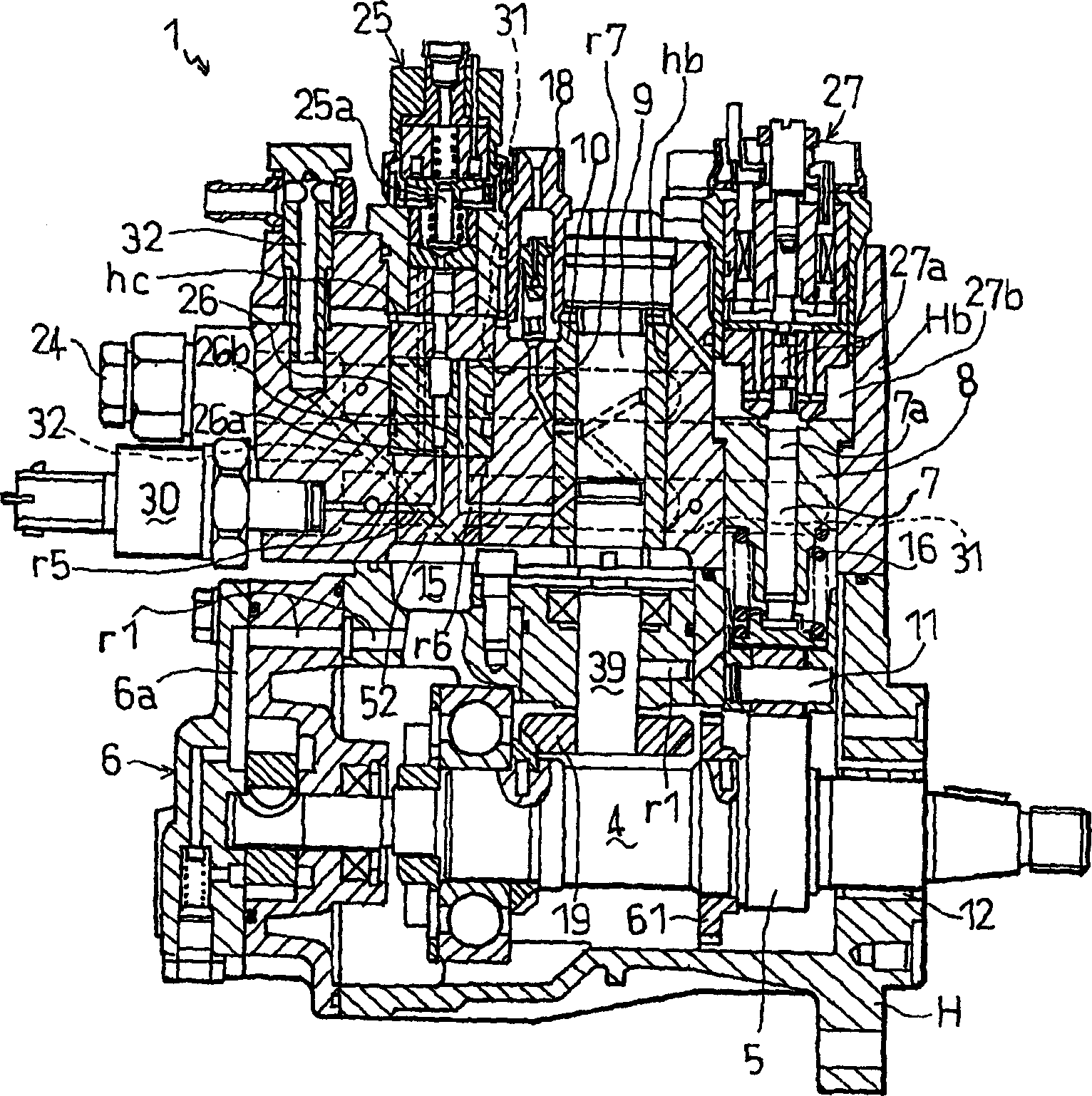

[0034] In order to illustrate the present invention in more detail, it is described below with reference to the accompanying drawings.

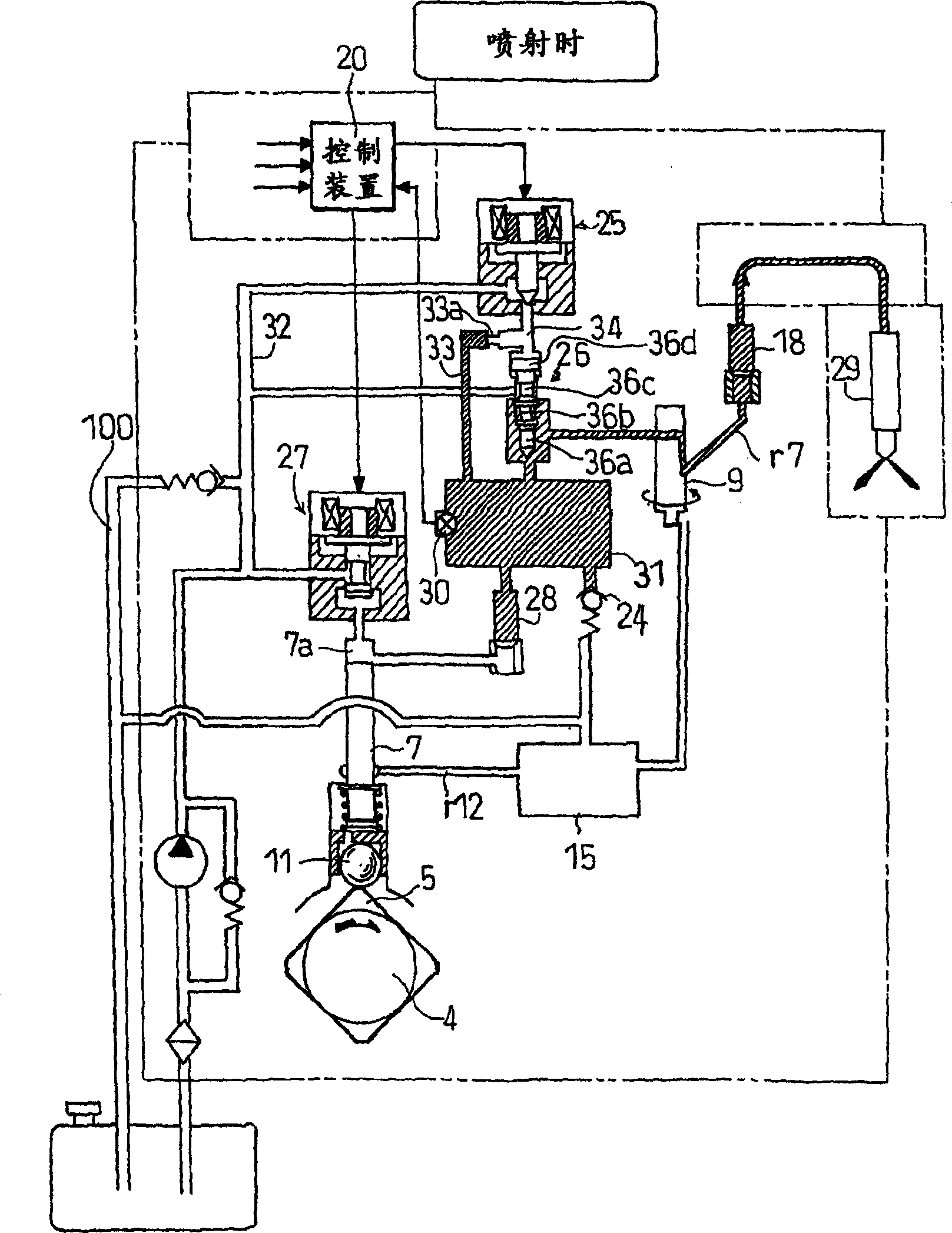

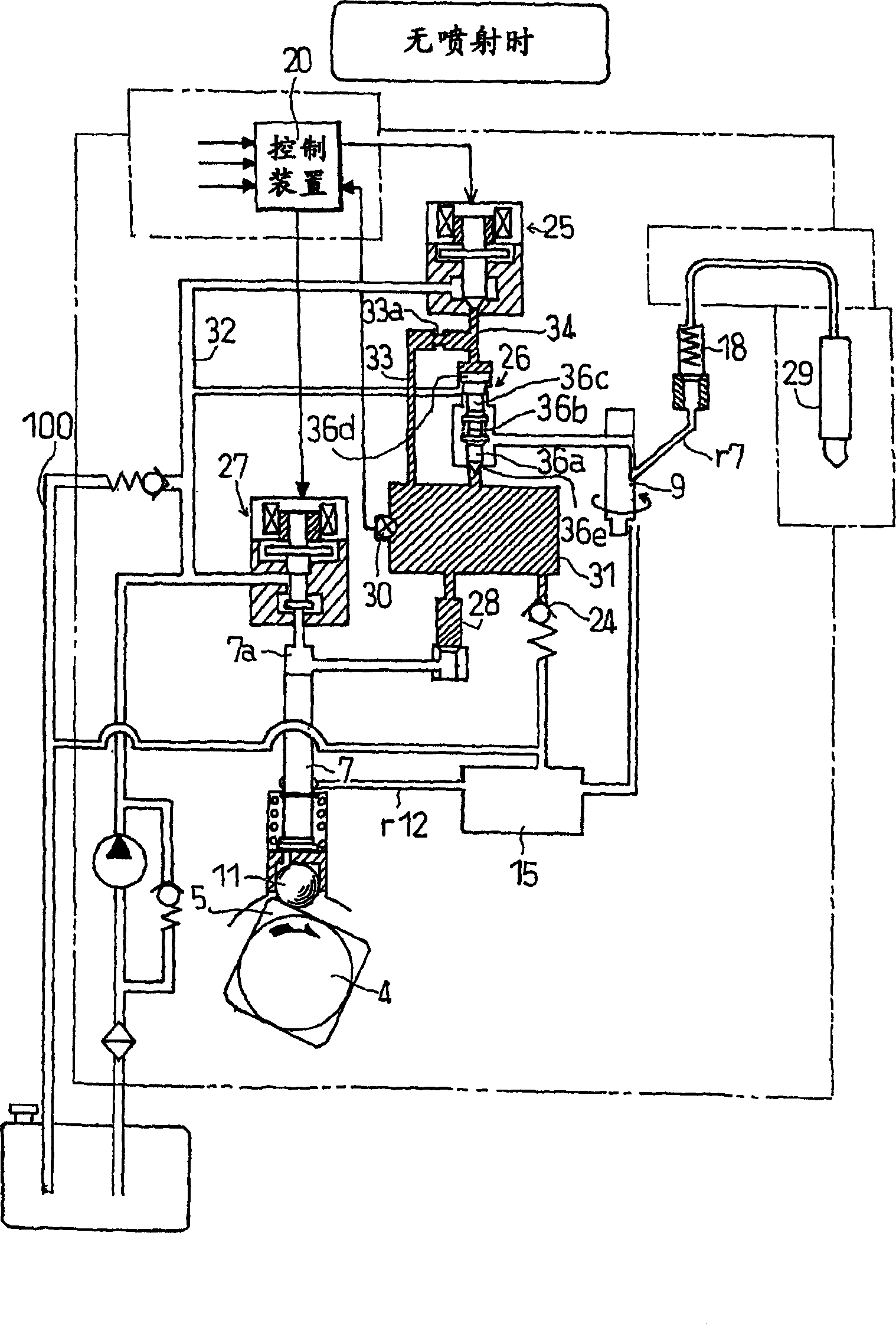

[0035] First, a schematic configuration of an accumulator-dispensing fuel injection pump of the present invention will be described. Such as figure 1 , figure 2 ,and Figure 3 ~ Figure 5 As shown, the fuel injection pump 1 configured as a pressure accumulator distribution type fuel injection pump includes an accumulator chamber 31 for accumulating high-pressure fuel, a plunger 7 for pumping fuel into the accumulator chamber 31, and The fuel pressure-fed by the pressure chamber 31 is distributed and supplied to the distribution shaft 9 and the like of the injection nozzle 29 of each cylinder.

[0036] The plunger 7 is driven to slide up and down by the cam 5 formed on the camshaft 4 through the plunger 11 , and the plunger chamber 7 a formed above the plunger 7 is connected to the accumulator chamber 31 through the check valve 28 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com