Continuous twin-roll counter-pressure dewaterer

A dewatering machine and double-roller technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of short pressing time, large pressing force, and reduce the requirement of tension force of filter cloth, so as to improve the output of mud cake and The effect of solid content, small contact area, and shortening of pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

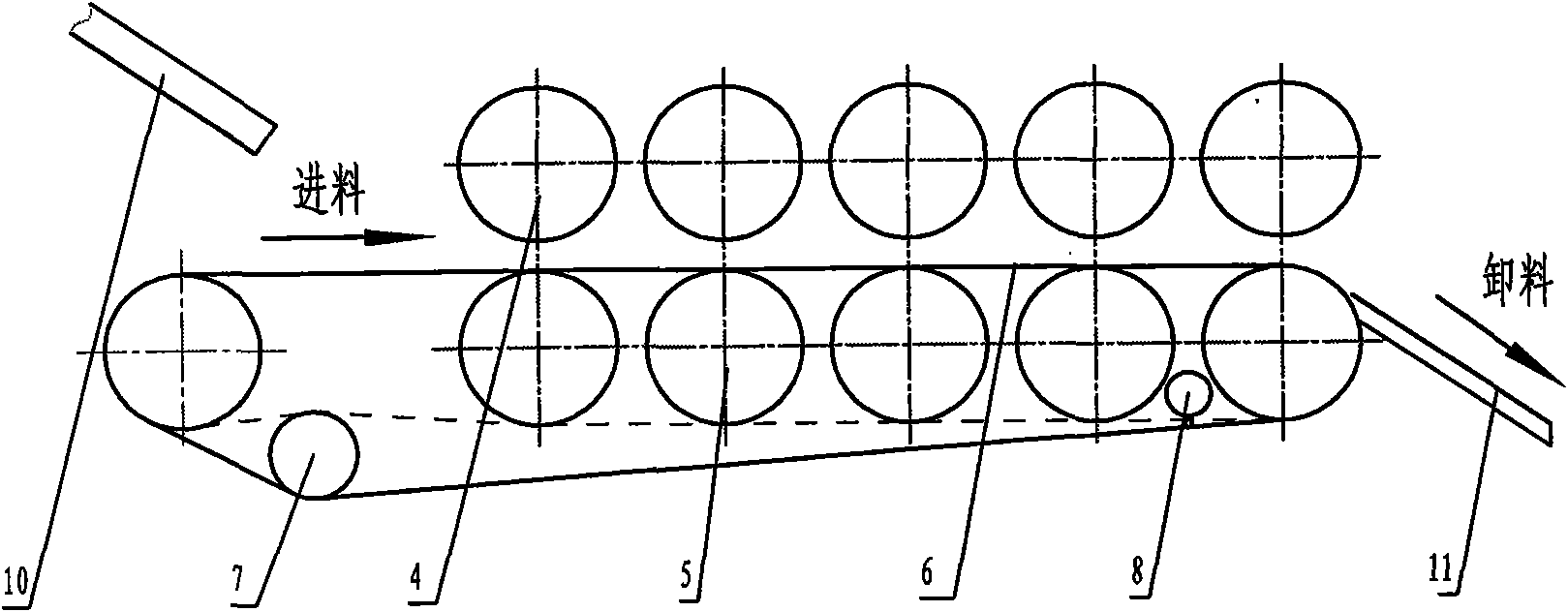

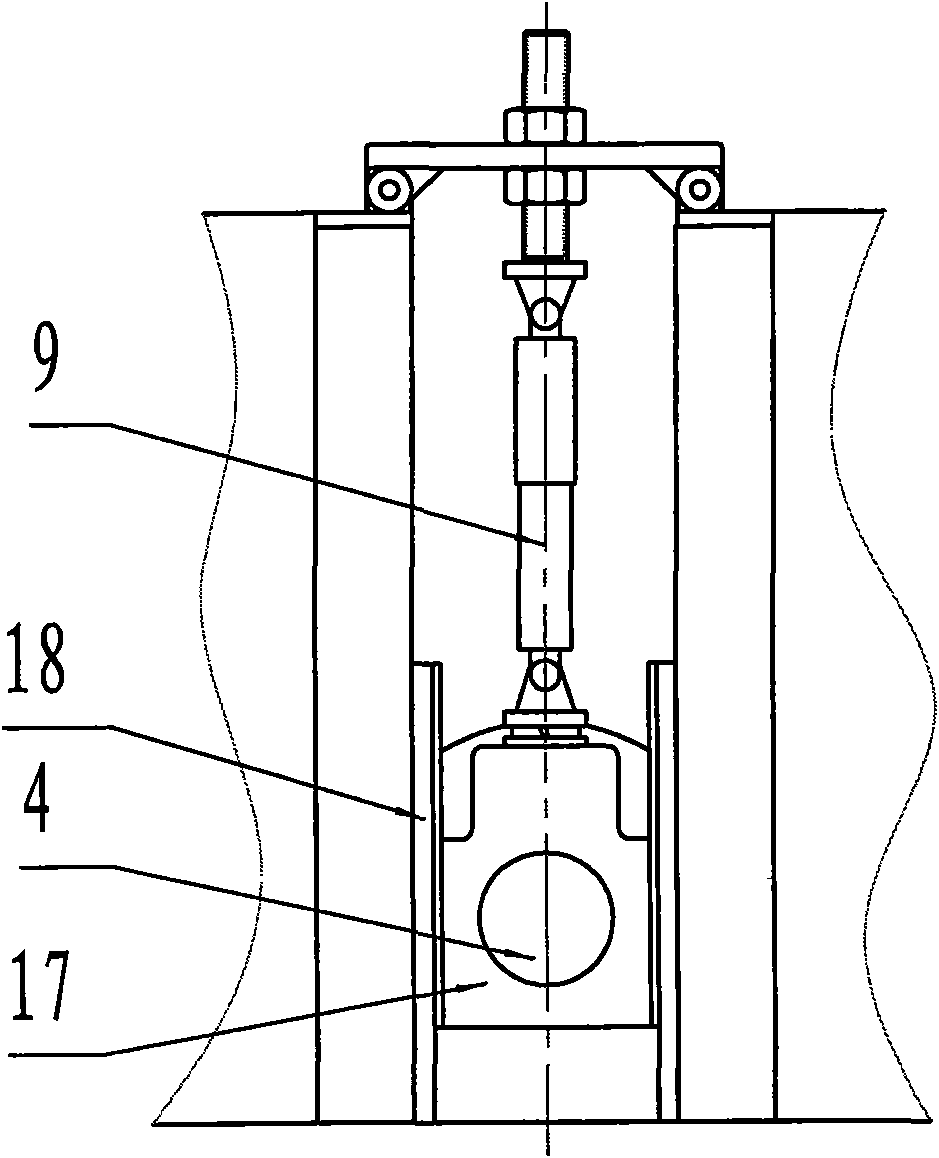

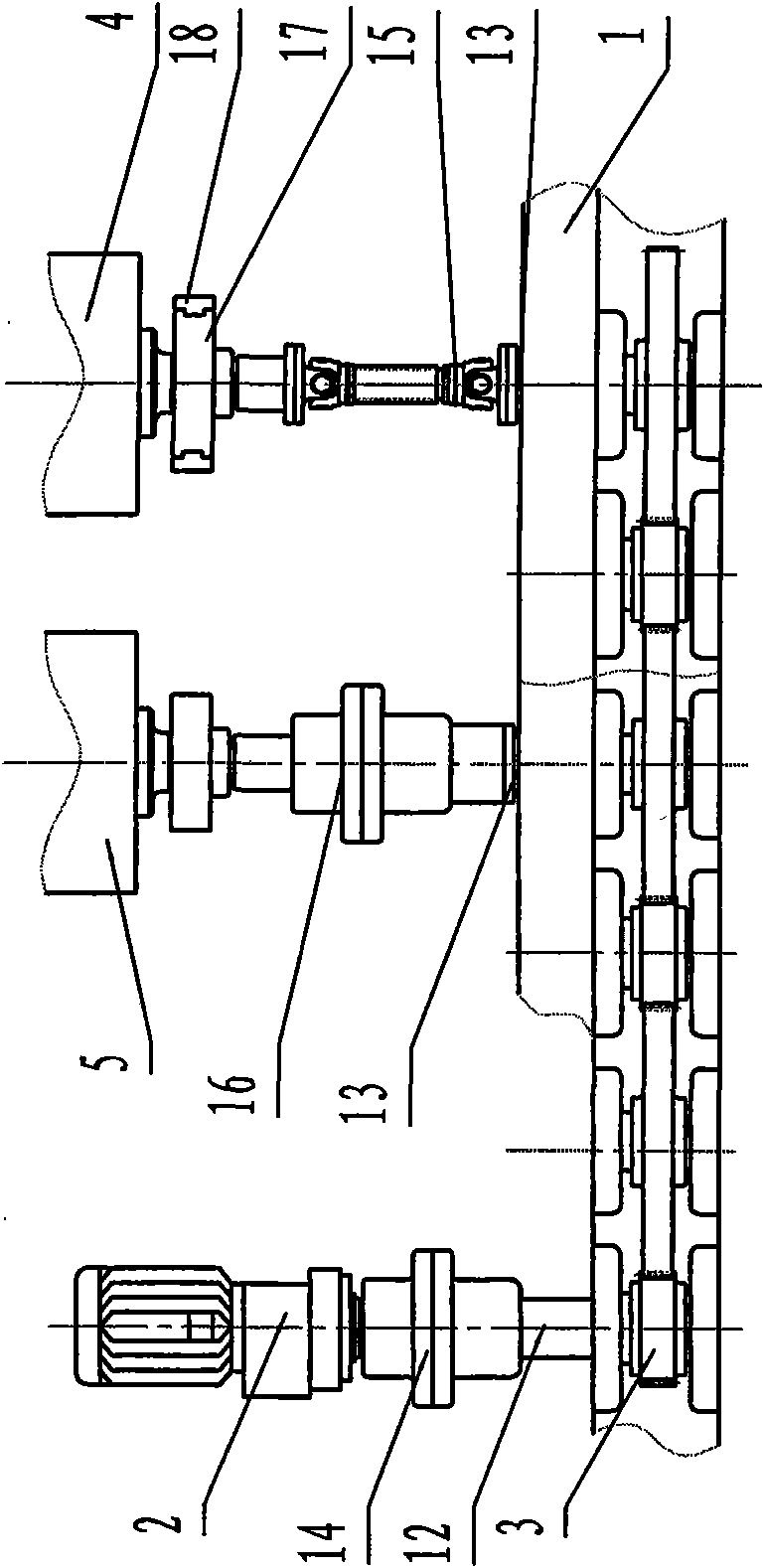

[0014] According to the accompanying drawings, the continuous double-roller counter-pressure dehydrator of the present invention is mainly composed of a frame 1, a power device 2, a transmission device 3, an upper roller part 4, a lower roller part 5, a filter cloth 6, and a tensioning device 7 , Washing device 8, automatic regulator 9, feeding device 10, and unloading device 11. All components are installed on the frame 1 to form a whole.

[0015] The transmission device 3 is provided with an input shaft 12 and several pairs of output shafts 13 arranged up and down. The input shaft 12 is connected with the power unit 2 through a coupling I 14, and the upper output shaft 13 is connected with the upper roller part 4 through a universal coupling 15. Connection, the output shaft 13 of the lower row is connected with the lower roller part 5 through the shaft coupling II 16, and the upper roller part 4 and the lower roller part 5 are rolled in a roll-to-roll rotary relay type. Tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com