Large circular plate high-pressure automatic filter press

A filter press and disc technology, applied in the field of large disc high pressure automatic filter press, can solve the problems of low filtration pressure, small filtration pressure, long pressing time, etc. The effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

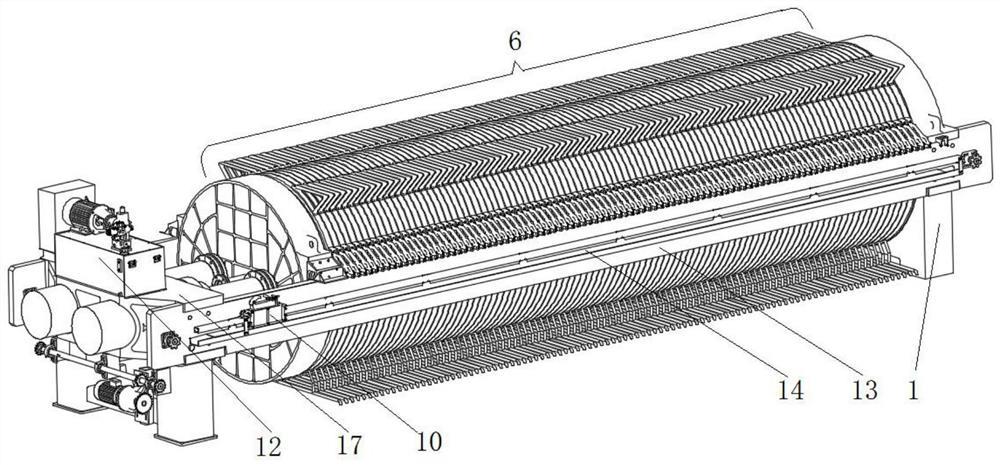

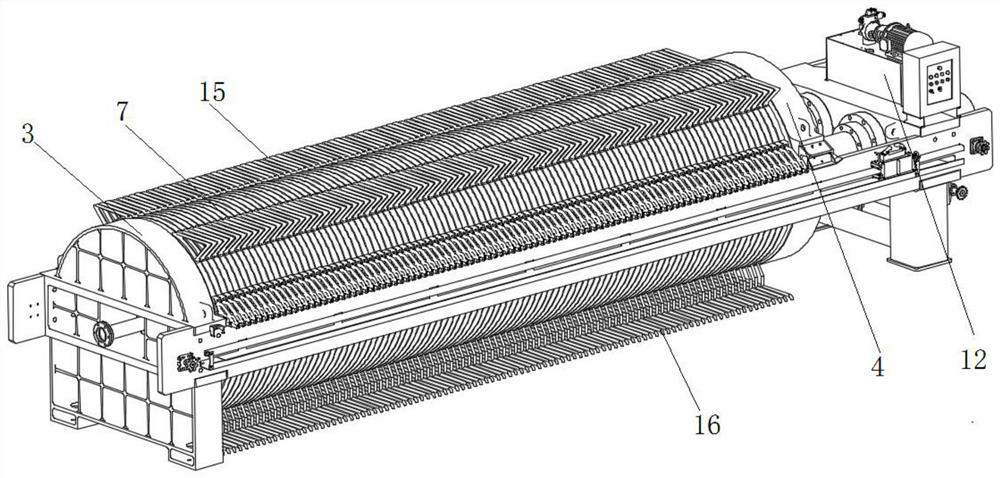

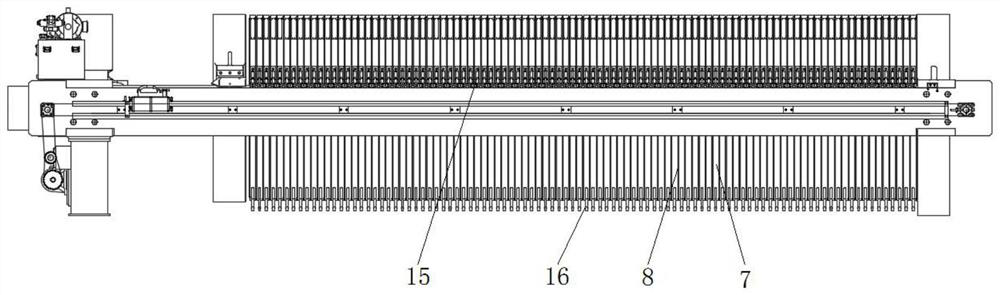

[0039] Such as Figure 1-7 As shown, the present embodiment provides a large-scale disc high-pressure automatic filter press, the automatic filter press can reach two meters in length, and compared with the existing filter press, it belongs to a large-scale filter press; on this basis, The area of the circular filter plate is also larger than that of the existing filter plate, so as to increase the output of a single machine. The large circular plate high-pressure automatic filter press of this embodiment mainly includes a frame part, a filter part, a hydraulic system, an automatic plate pulling device and an electrical control system. in:

[0040] The frame part includes a frame 1, and the frame 1 includes a frame 2, and the two ends of the frame 2 are respectively provided with a thrust plate 3 and a pushing plate 4, and one side of the pushing plate 4 is connected with two pushing oil cylinders 5 side by side. The piston rod on the oil cylinder pushes the push plate 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com