Multi-level flipping type proteopexy cooking machine and fishmeal machine

A protein fixation, multi-level technology, applied in application, food preparation, food science and other directions, can solve the problems of insufficient heating, loss of fish meal protein, insufficient protein fixation, etc., achieve high processing yield, purify production environment, shorten pressing effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

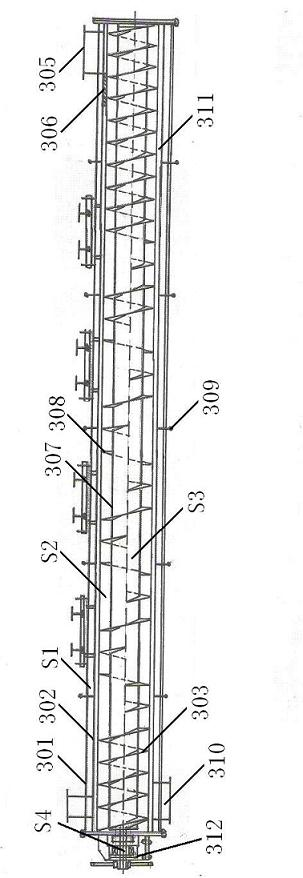

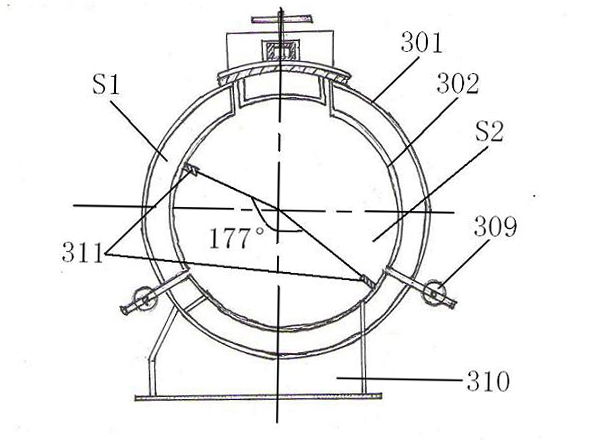

[0029] refer to Figure 1 to Figure 3 , in this embodiment, a multi-level flipping protein fixed cooking machine, including: a cylindrical coaxial shell 301 and an inner shell 302, an auger shaft 307, a material inlet 305 and a material outlet 310; A closed space S1 is formed between the inner shell 302 and the outer shell 301, which is used for passing in heating gas; both ends of the auger shaft 307 are respectively connected to a shaft head 312; the feeding port 305 is arranged at one end of the outer shell 301 , communicated with the inner cavity S2; the discharge port 310 is arranged at the other end of the shell 301, and communicated with the inner cavity S2; the auger shaft 307 is provided with 7 whole-leaf helical blades in sequence from the feed port end to the discharge port end 303, 18 half-leaf helical blades 308 and 4 whole-leaf helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com