Patents

Literature

75results about How to "Realize automatic circulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for business data processing

ActiveCN102970353ANo cloggingImprove circulation speedData switching networksMessage queueBusiness data

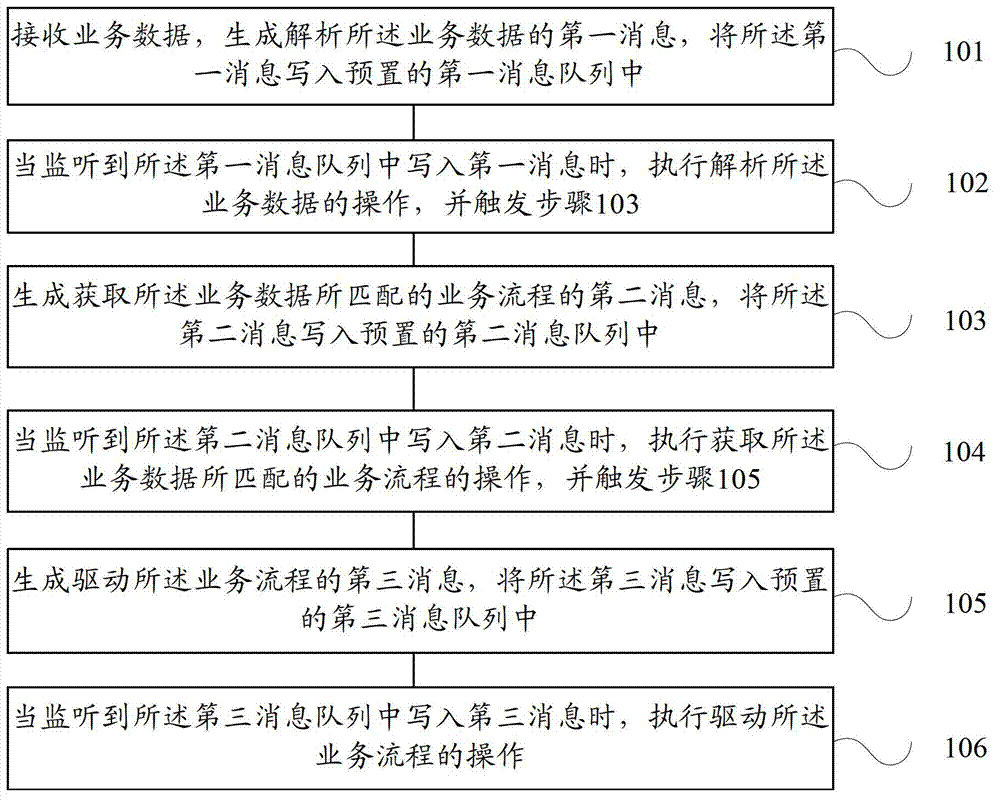

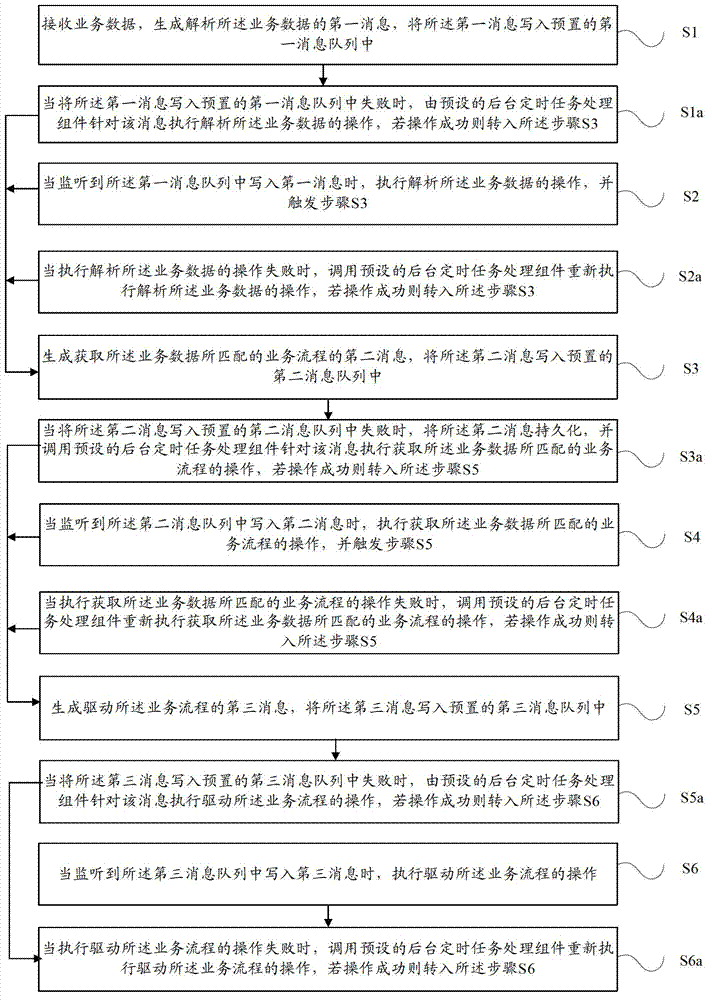

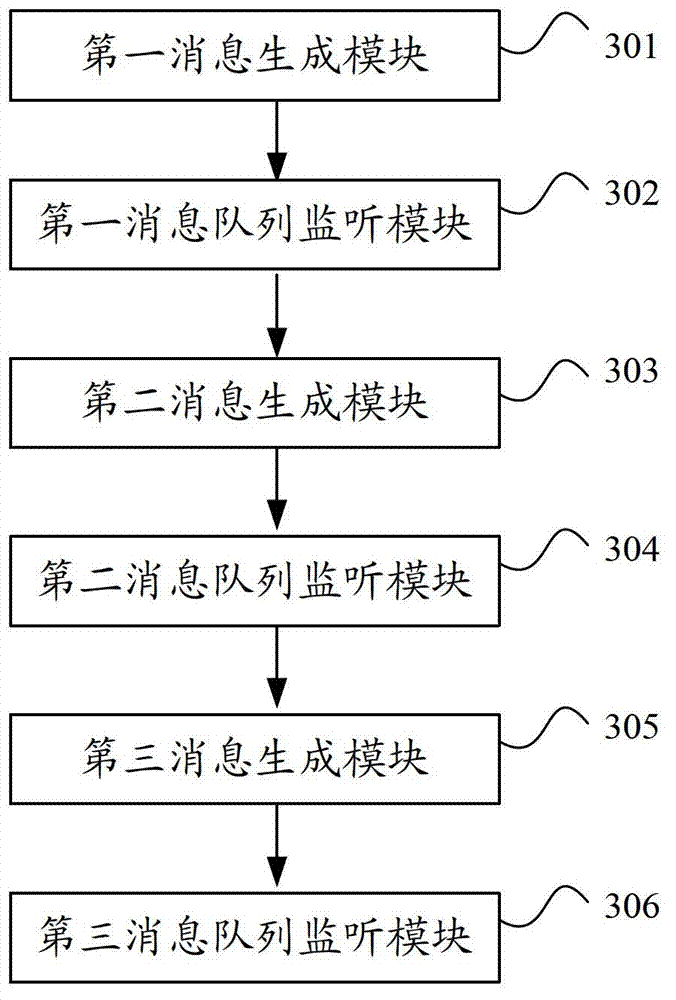

The invention provides a method and system for business data processing. The method comprises receiving business data, generating a first message for analyzing the business data, and writing the first message into a preset first message queue; carrying out operation for analyzing the business data when monitoring writing in of the first message, generating a second message for obtaining business process matched with the business data, and writing the second message in a preset second message queue; carrying out operation for obtaining the business process matched with the business data when monitoring writing in of the second message, generating a third message driving the business process, and writing the third message in a preset third message queue; and carrying out operation for driving the business process when monitoring writing in of the third message. According to the method and system for business data processing, promptness and safety of business processing can be improved, resource cost is reduced, and service paralysis is avoided.

Owner:DATANG SOFTWARE TECH

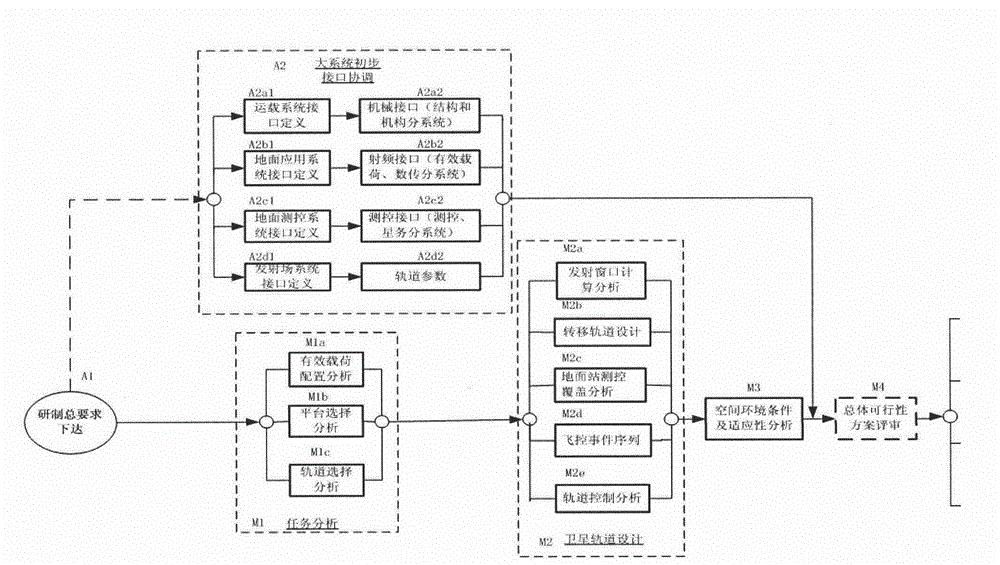

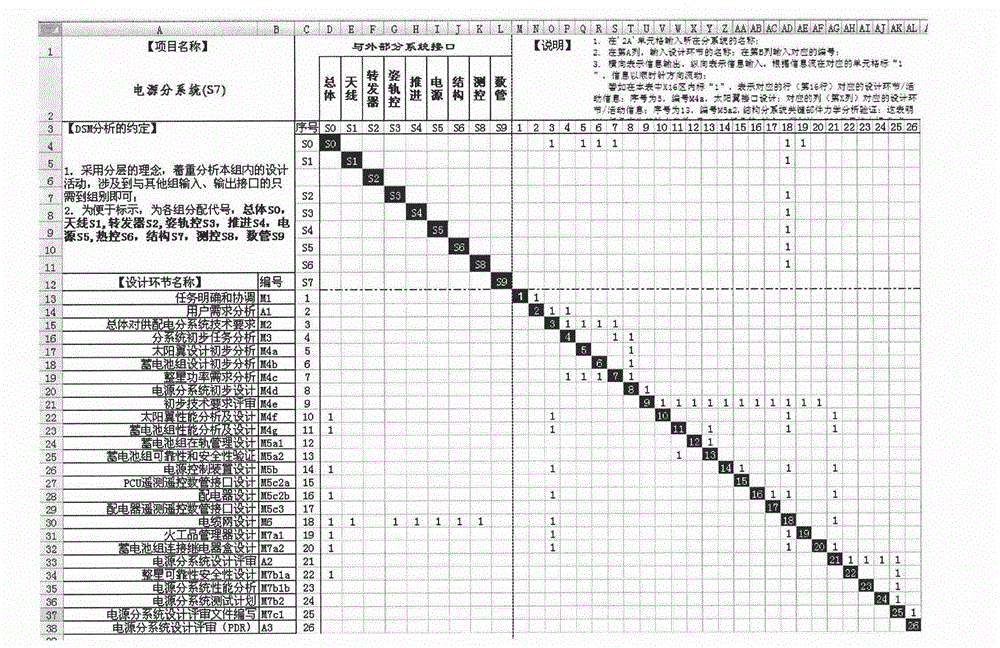

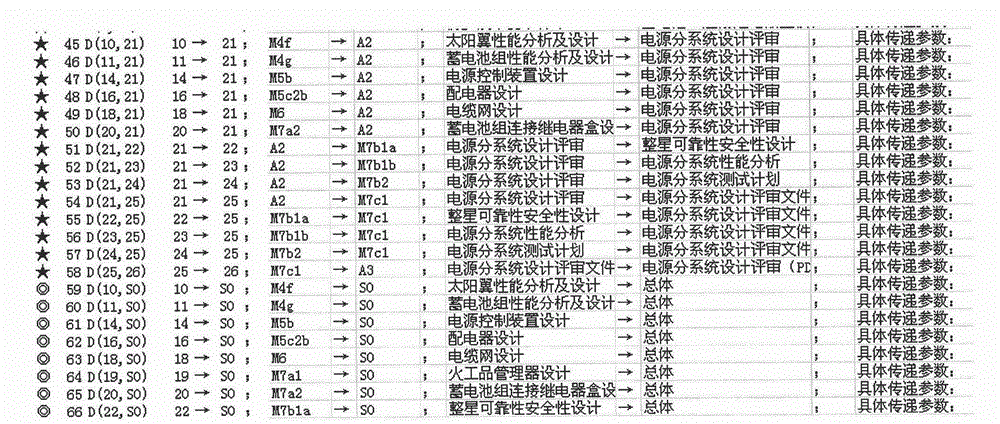

DSM-based satellite coupling design flow structured analysis and retrieval method

InactiveCN103942349AImplement strand analysisSolve the coupling problemSpecial data processing applicationsStructure analysisCoupling

The invention relates to a DSM-based satellite coupling design flow structured analysis and retrieval method and belongs to the field of design of spacecrafts. The method includes the first step of sorting and summarizing the general flow of designing remote sensing satellites or other types of spacecrafts on the basis of a traditional process expression mode, the second step of conducting mapping to generate a DSM matrix, conducting statistics on DSM items and conducting structured quantitative analysis item by item to obtain a perfect parameter correlation list, and the third step of utilizing the spreadsheet-based middleware technology to achieve storage of a spreadsheet in a database, and retrieving the coupling design process of the satellites according to the storage information about DSM correlation subitems in the database. According to the DSM-based satellite coupling design flow structured analysis and retrieval method, on the basis of the existing design process of the spacecrafts, the design process is mapped to generate a DSM, the DSM is stored into the database for maintenance, the Excel spreadsheet is used as a front-end interface, and consequently a foundation is laid for follow-up optimization.

Owner:中国空间技术研究院神舟学院

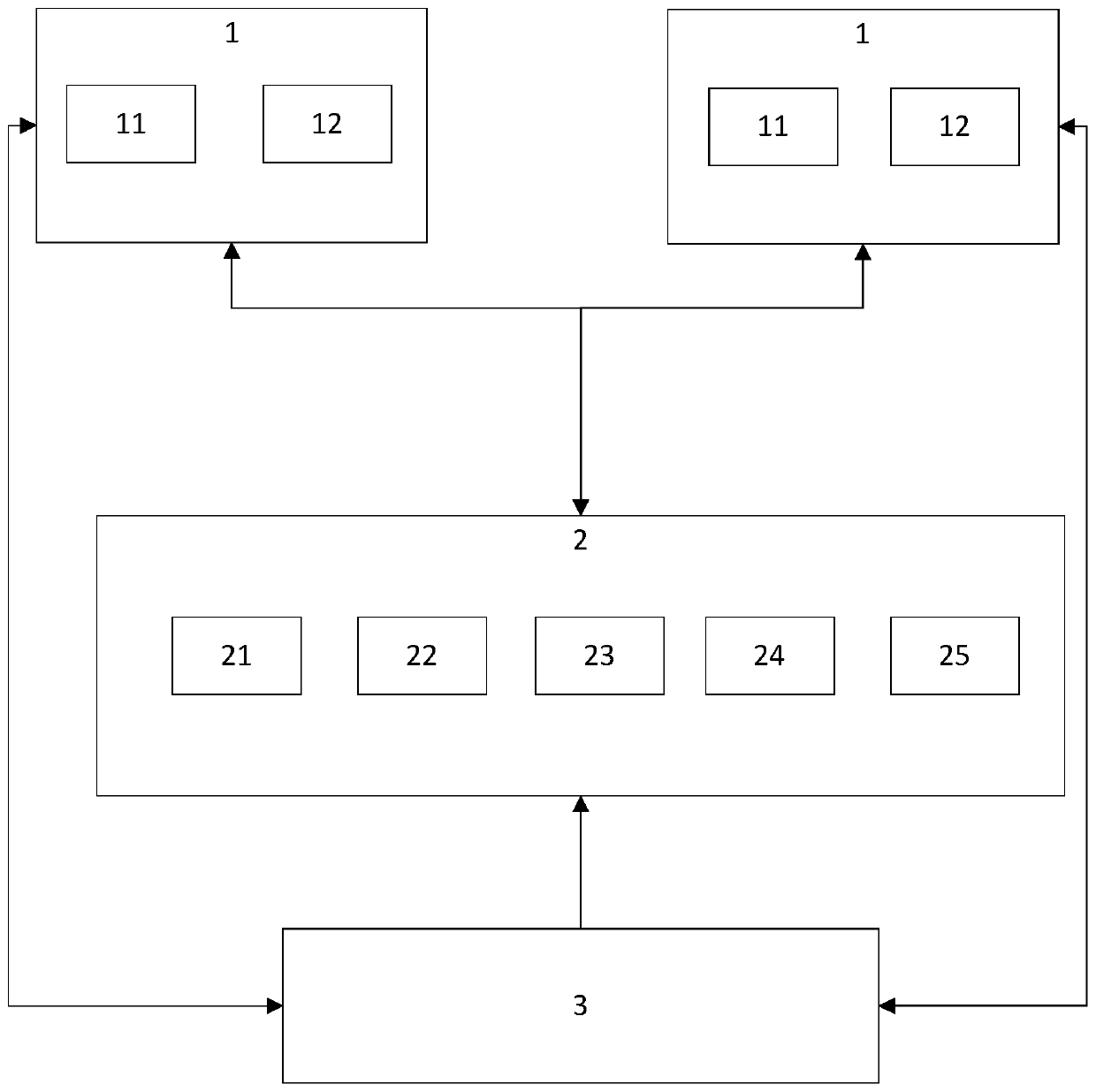

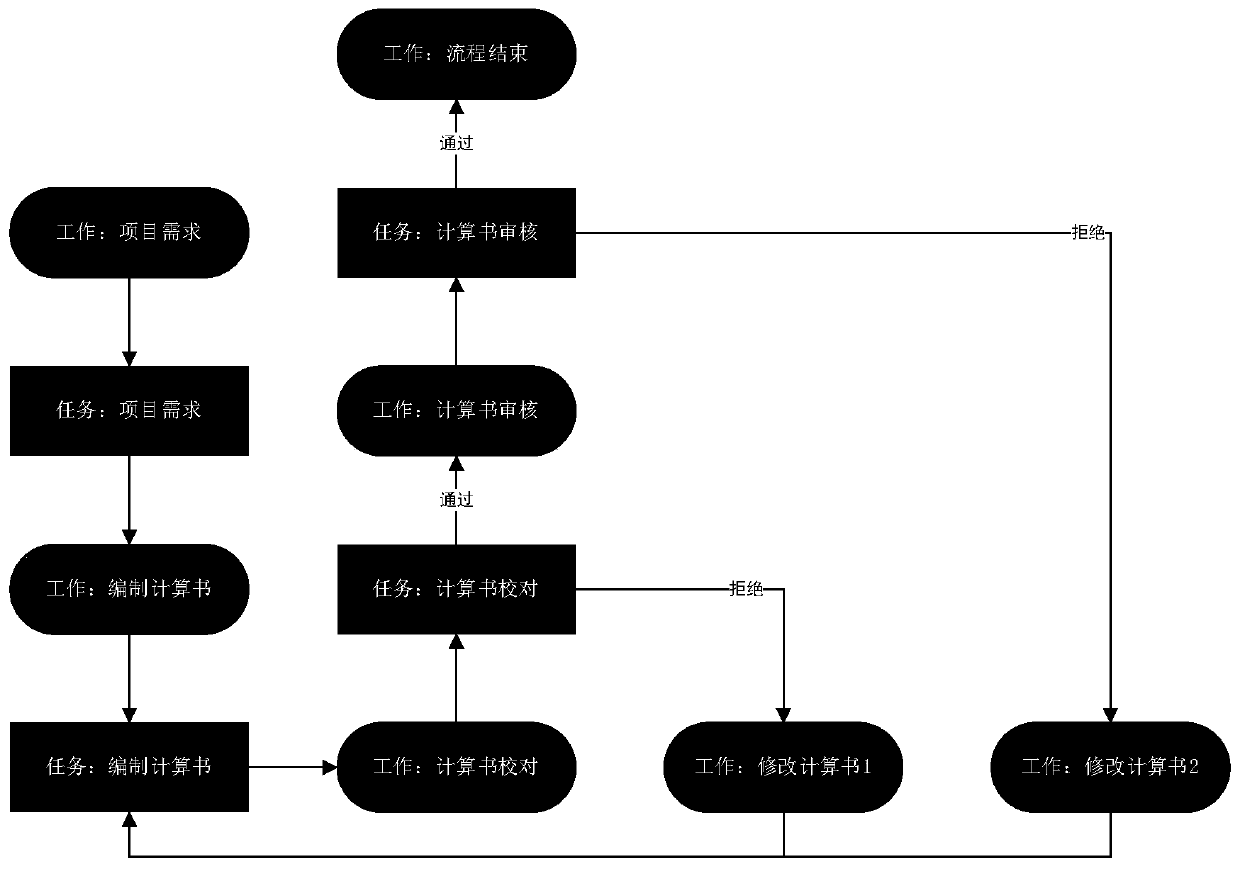

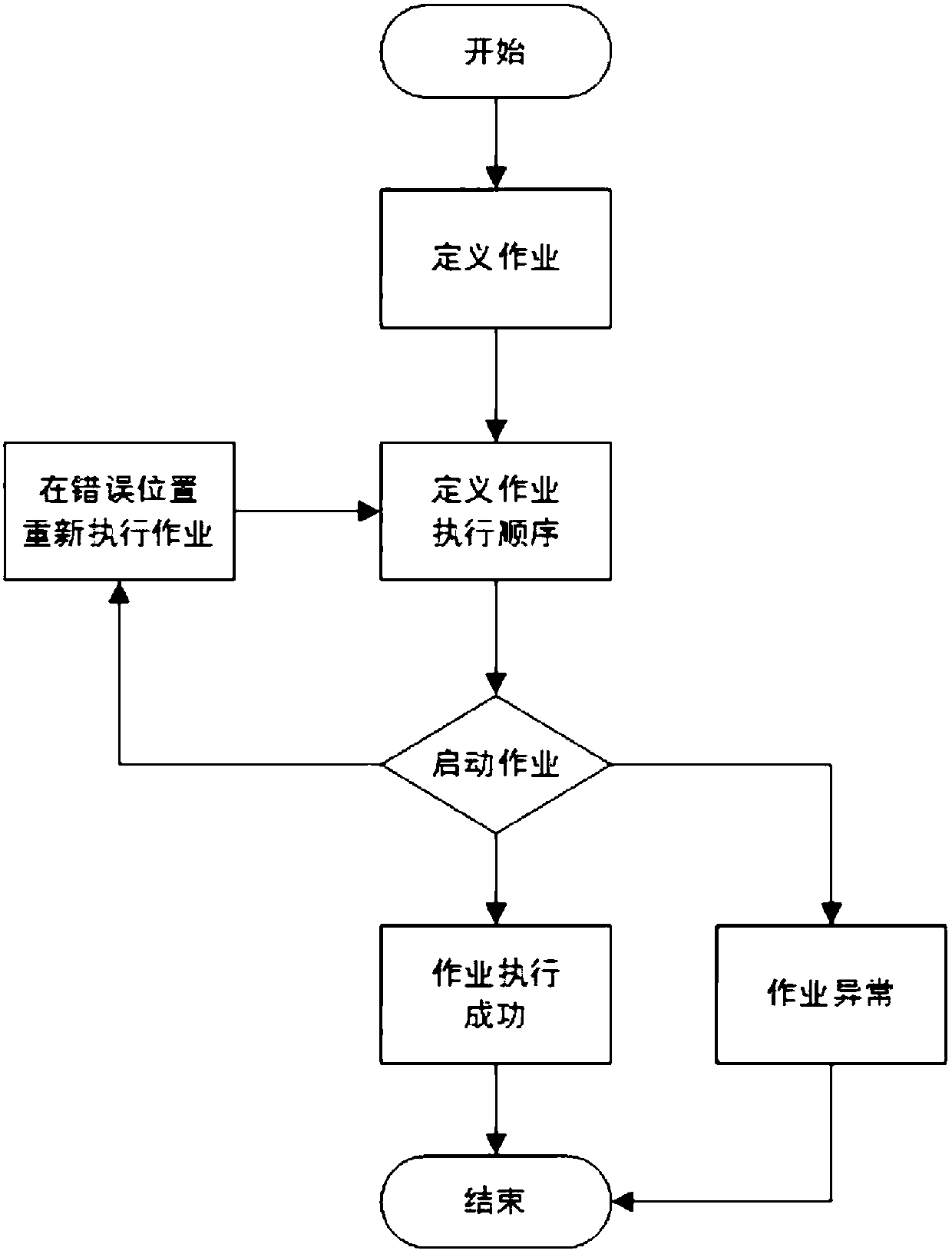

Workflow construction system and method for working platform

InactiveCN110717656ARealize automatic circulationAchieve interactionOffice automationResourcesData descriptionSoftware engineering

The invention discloses a workflow construction system for a working platform and a construction system. The system comprises at least one client, at least one server and at least one metadata storageserver. Each client is used for carrying out workflow construction operation by a user and comprises a workflow definition module and a workflow starting module. Each server is used for executing workflow construction and workflow operation according to the transmission information of the client, and comprises a client communication module, a storage communication module, a data description module, an engine generation module and a workflow operation module; and the storage server is used for storing the workflow engine metadata and the task system metadata. The workflow definition specification with the allocation mode attribute is designed for the business characteristics of the working platform, so that task design management personnel can construct the custom task which can be published, allocated and executed on the working platform.

Owner:武汉空心科技有限公司

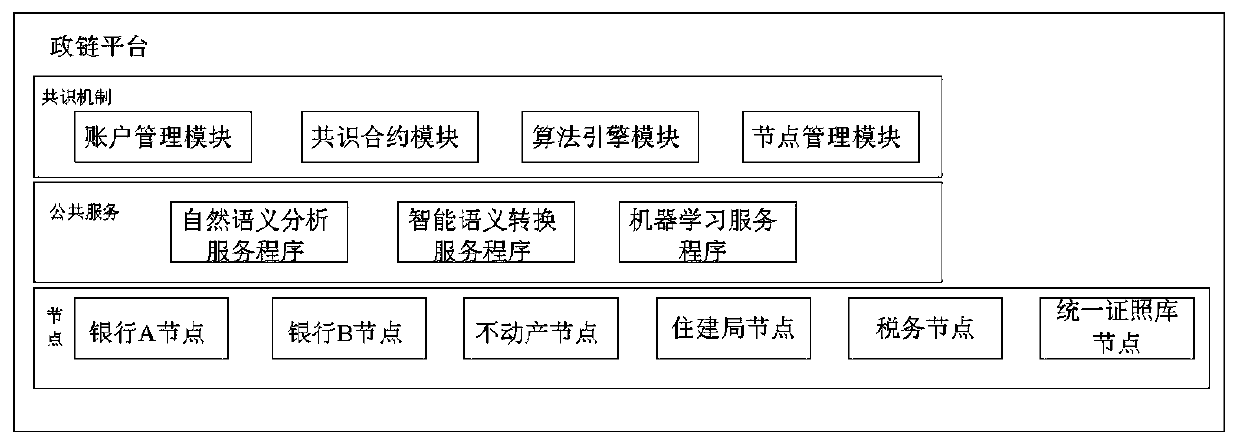

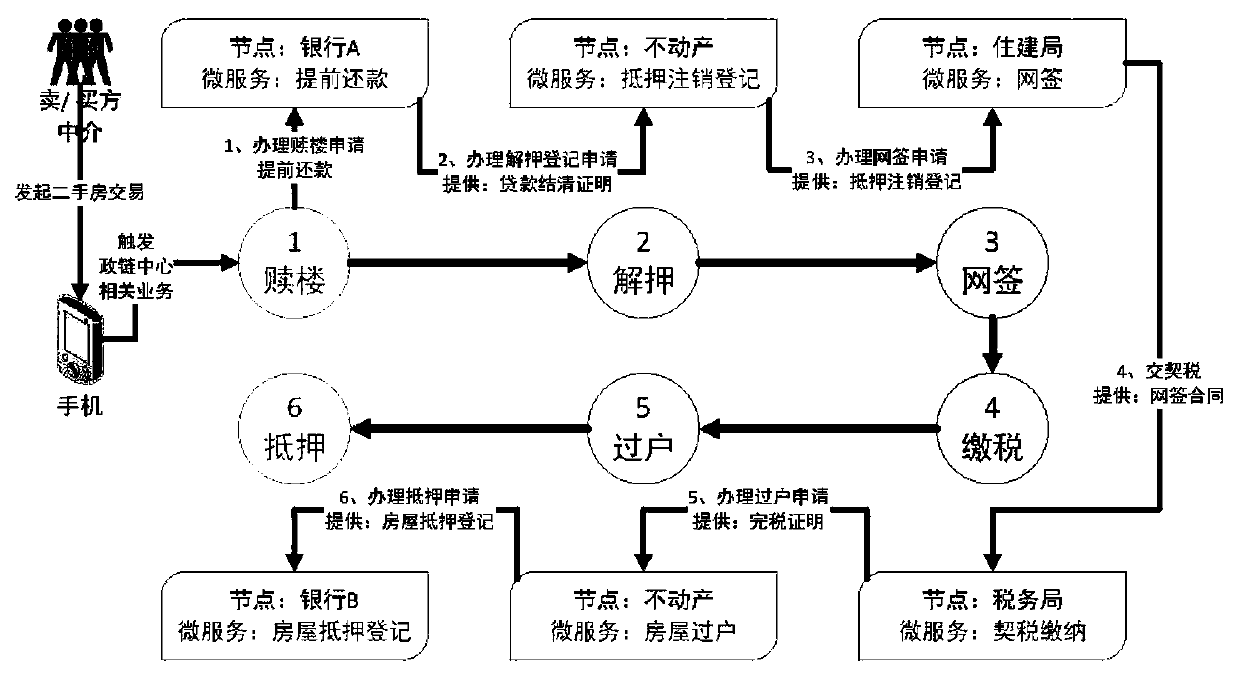

A real estate service administration chain platform based on a block chain technology

InactiveCN109559255AAvoid silosInhibition of differentiationData processing applicationsResidenceThe Internet

The invention relates to a real estate service administration chain platform based on a block chain technology. The real estate service administration chain platform comprises at least one bank node,at least one real estate node, at least one residence bureau node, at least one tax node and a unified certificate library node, wherein the bank node, the real estate node, the residence bureau node,the tax node and the unified license library node are all provided with micro-service systems used for carrying out data reading / writing service with other nodes which belong to the real estate service administration chain platform and are not the nodes of the micro-service systems; and the micro-service system of each node in the real estate service administration chain platform is realized according to a consensus mechanism in the real estate service administration chain platform when reading / writing data. According to the real estate service administration chain platform, a user does not need to run more among functional departments, data running can be achieved, and the smart government affair internet convenience service under the block chain is completed.

Owner:GUANGDONG KAMFU TECH CO LTD

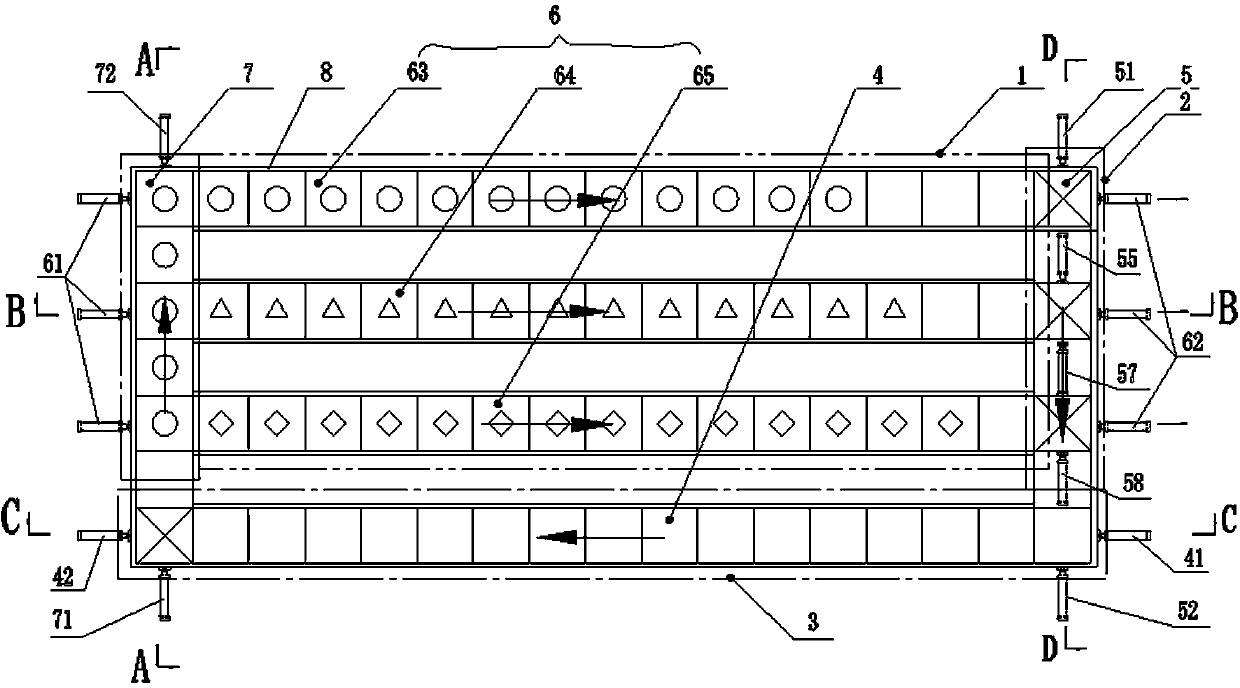

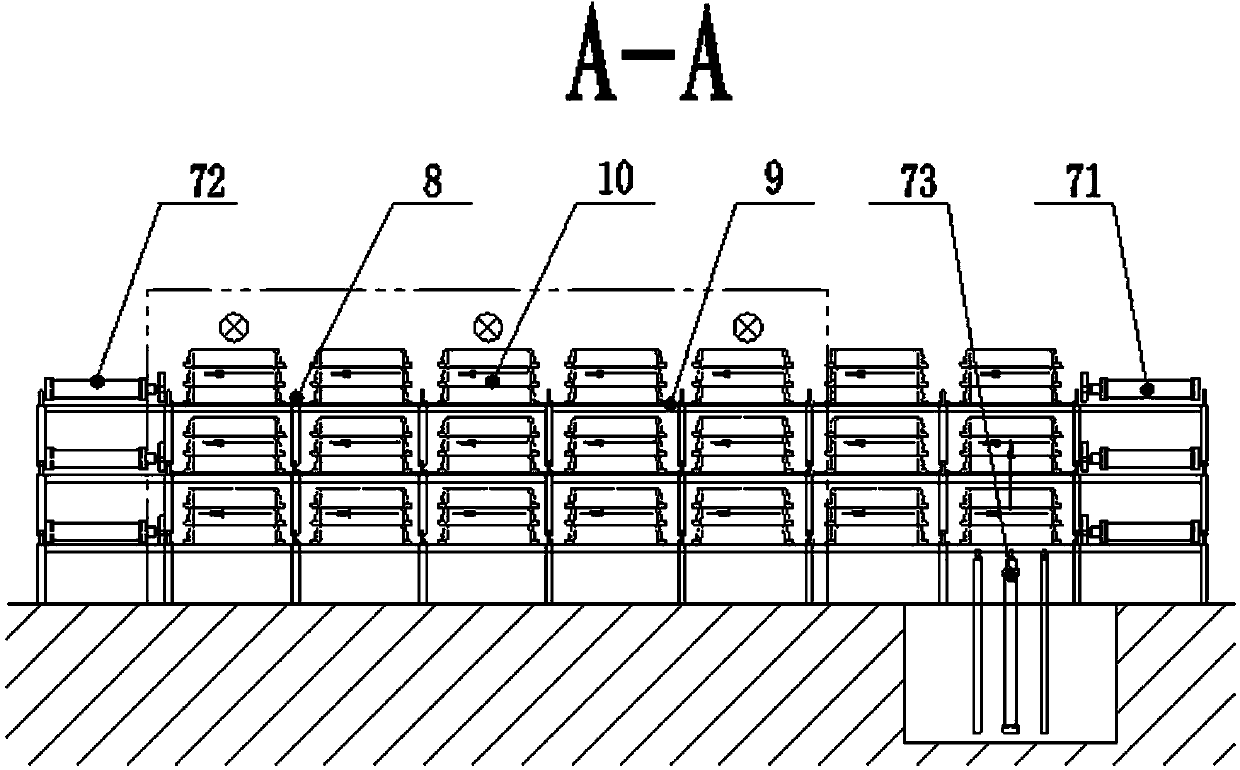

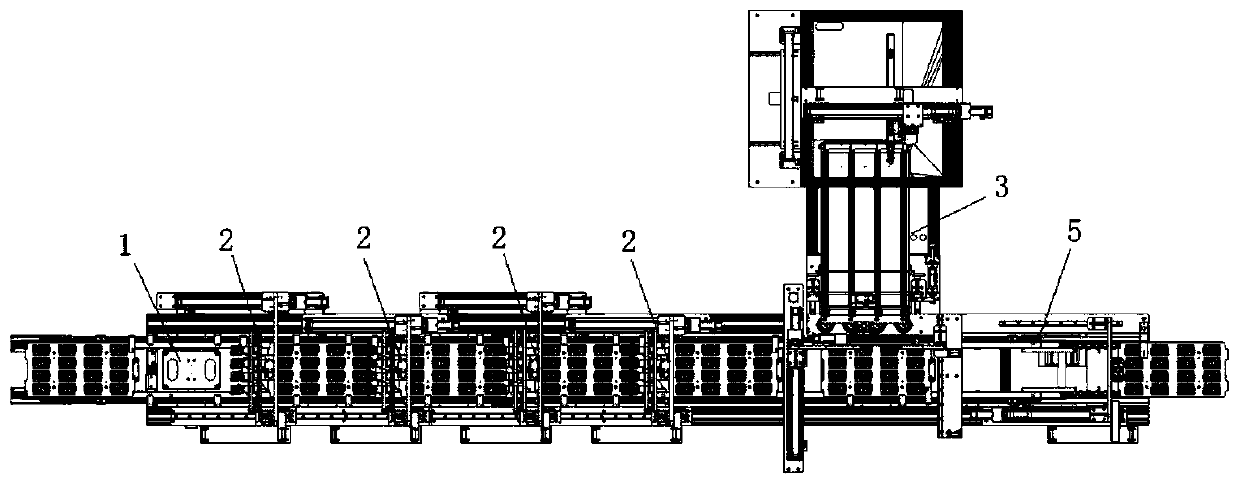

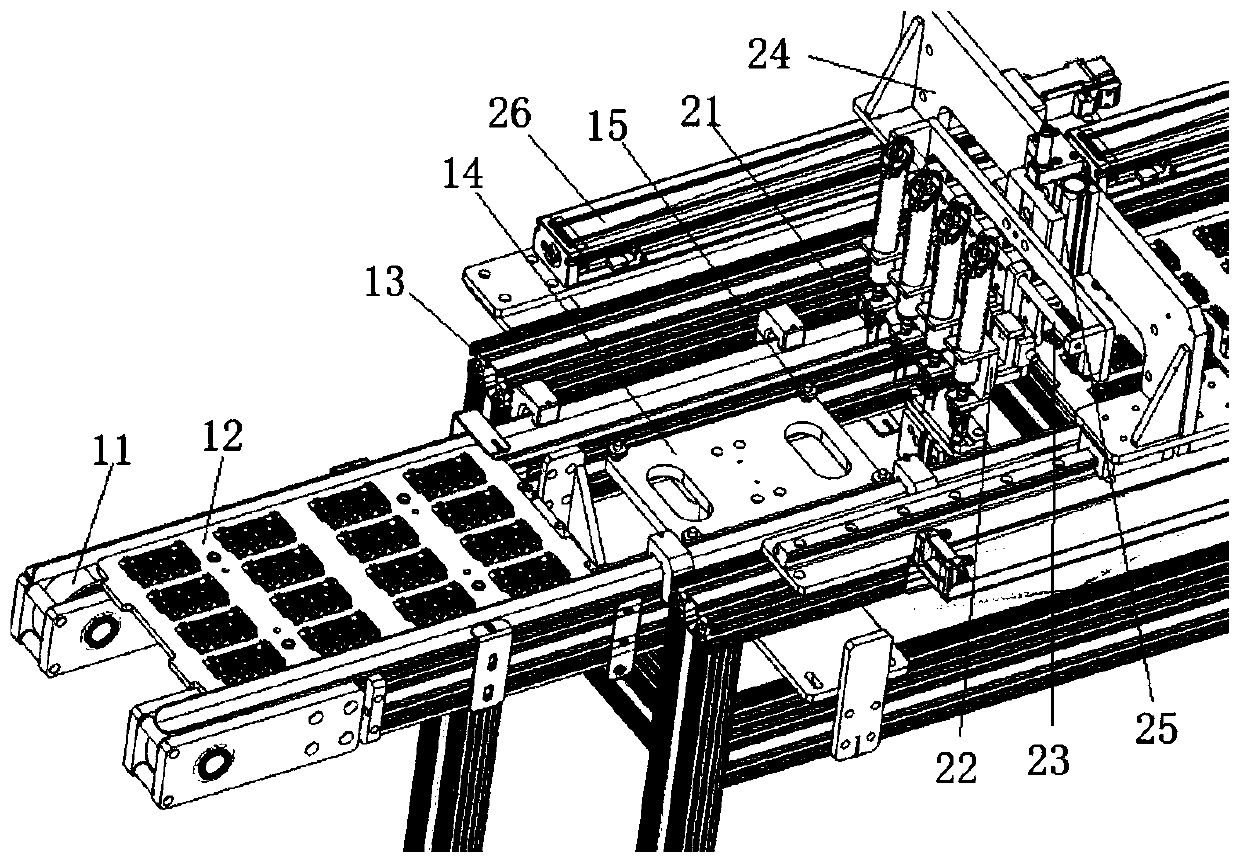

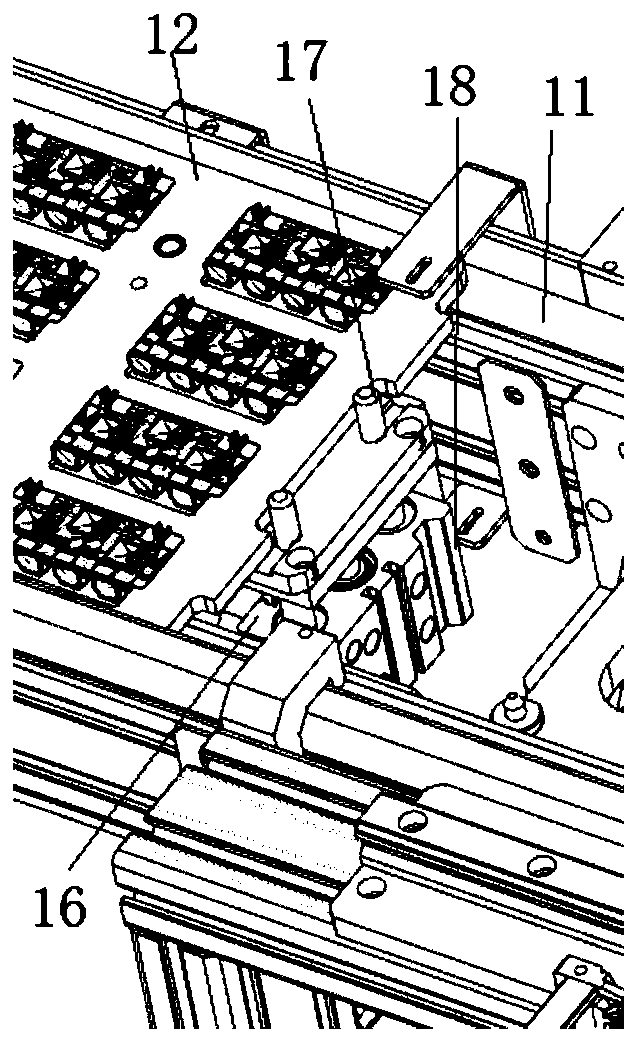

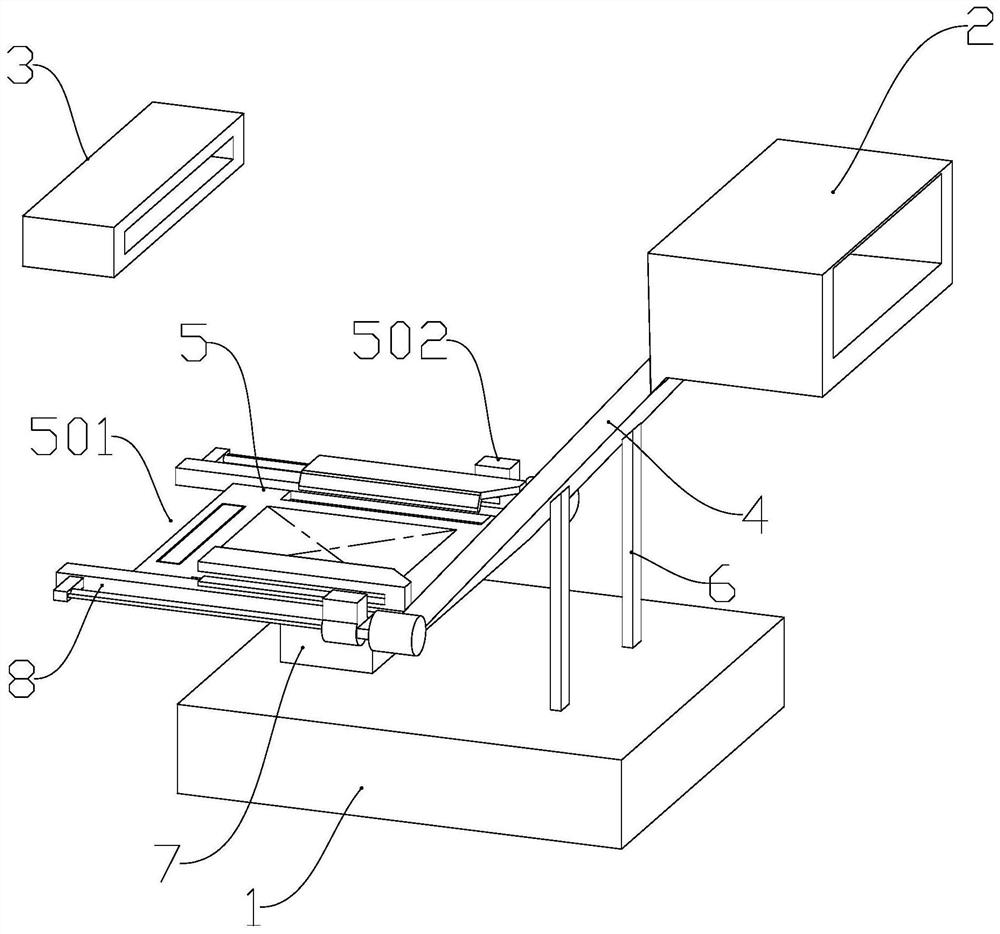

Integrated sand core feeding and discharging device for drying room

ActiveCN103736934ARealize in and outRealize automatic circulationFoundry mouldsFoundry coresNuclear engineering

The invention discloses an integrated sand core feeding and discharging device for a drying room, and relates to the technical field of cast molding core treatment. The device comprises more than two core storing channels which are formed in parallel, and flowing and rotating channels which are connected with core feeding channels, wherein two ends of each core storing channel are respectively connected with the core feeding channels and core discharging channels; the flowing and rotating channels are parallel to the core storing channels; the flowing and rotating channels, the core feeding channels, the core storing channels and the core discharging channels are the same in the structure and respectively comprise brackets; tracks are arranged on the brackets; sand core trays are arranged on the tracks; sand core tray jacking mechanisms are respectively arranged at the inlet ends of the flowing and rotating channels, the core feeding channels, the core storing channels and the core discharging channels; the sand core trays in which sand cores are placed are promoted by the sand core tray jacking mechanisms to sequentially enter the flowing and rotating channels, the core feeding channels and the core storing channels, then the sand cores are taken out from the core discharging channels, and the empty trays are pushed to the flowing and rotating channels. The device is simple in structure, convenient to operate and high in working efficiency, and can be used for guaranteeing the drying quality and lightening the working intensity of a worker.

Owner:XINXING HEBEI ENG & RES INC

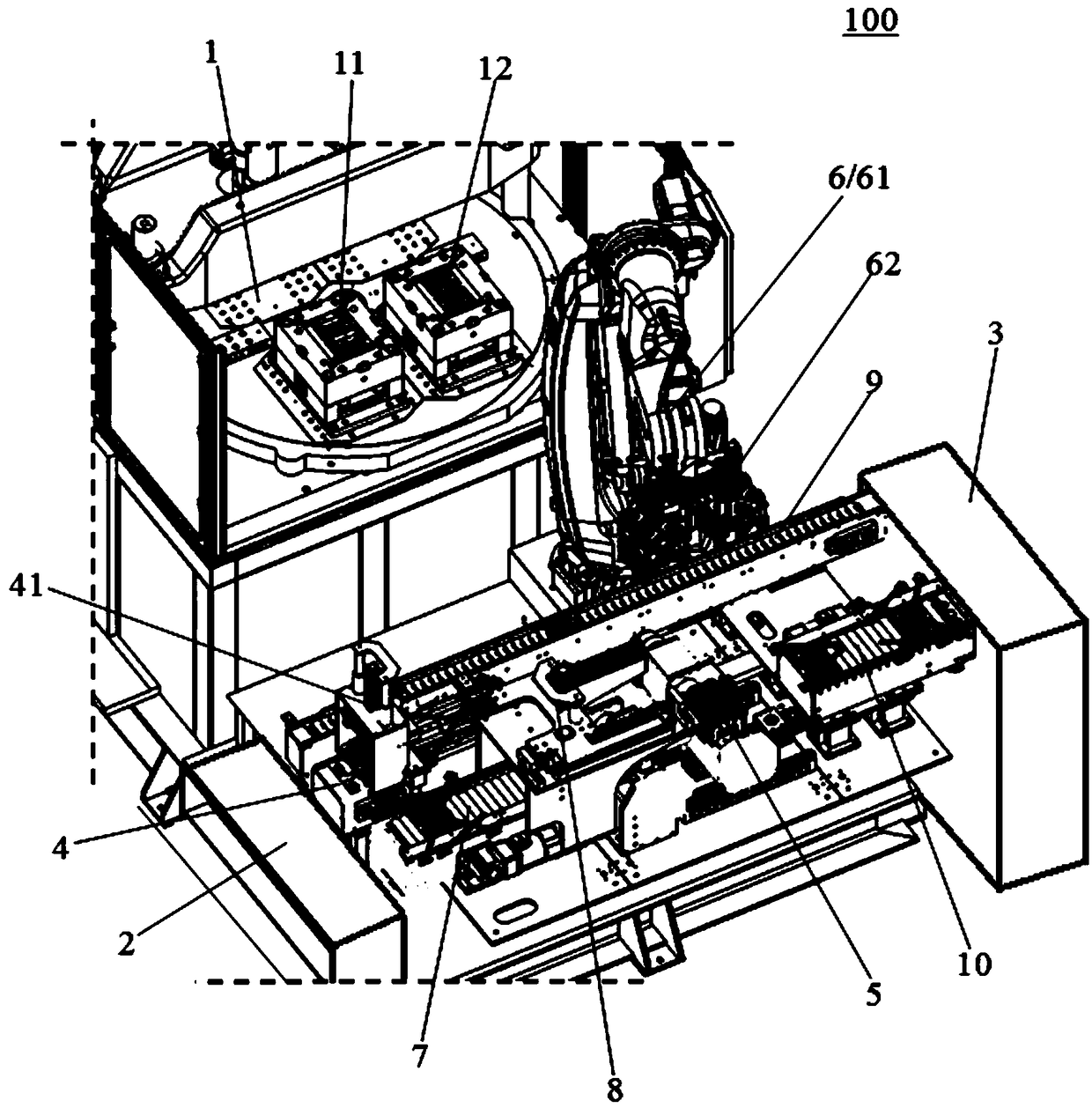

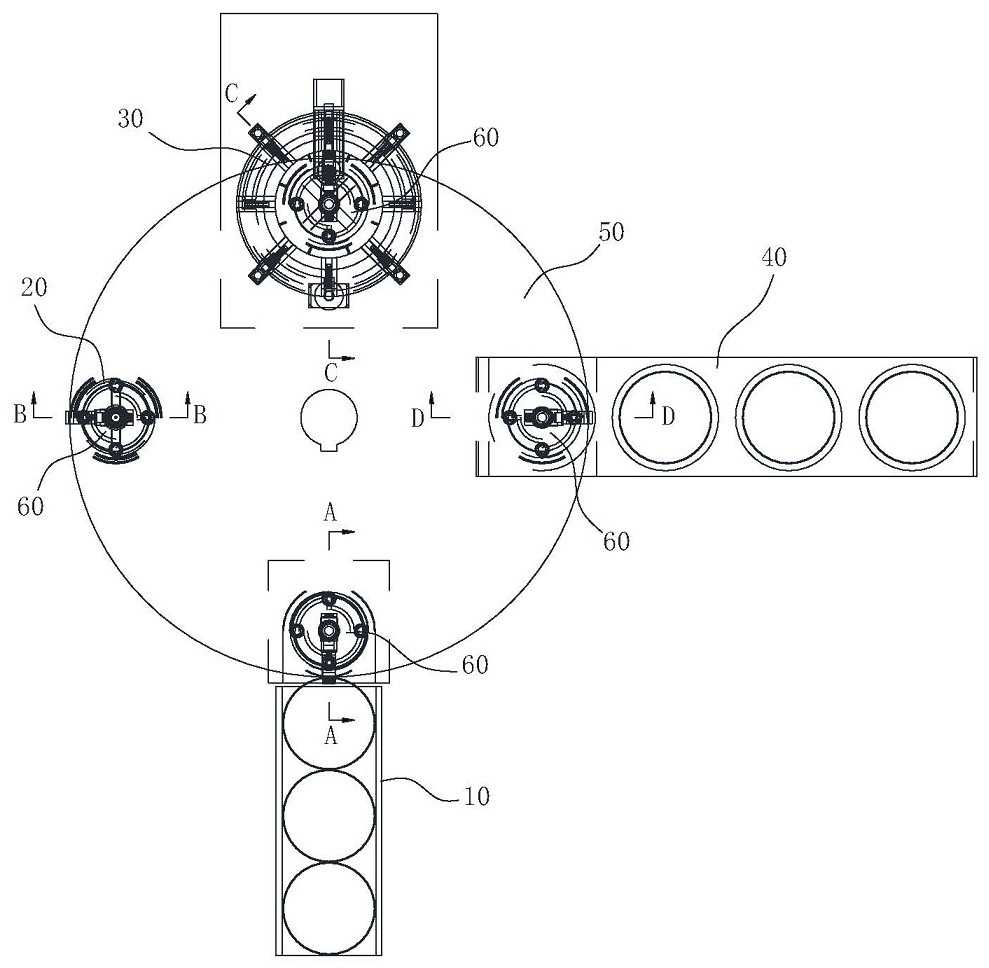

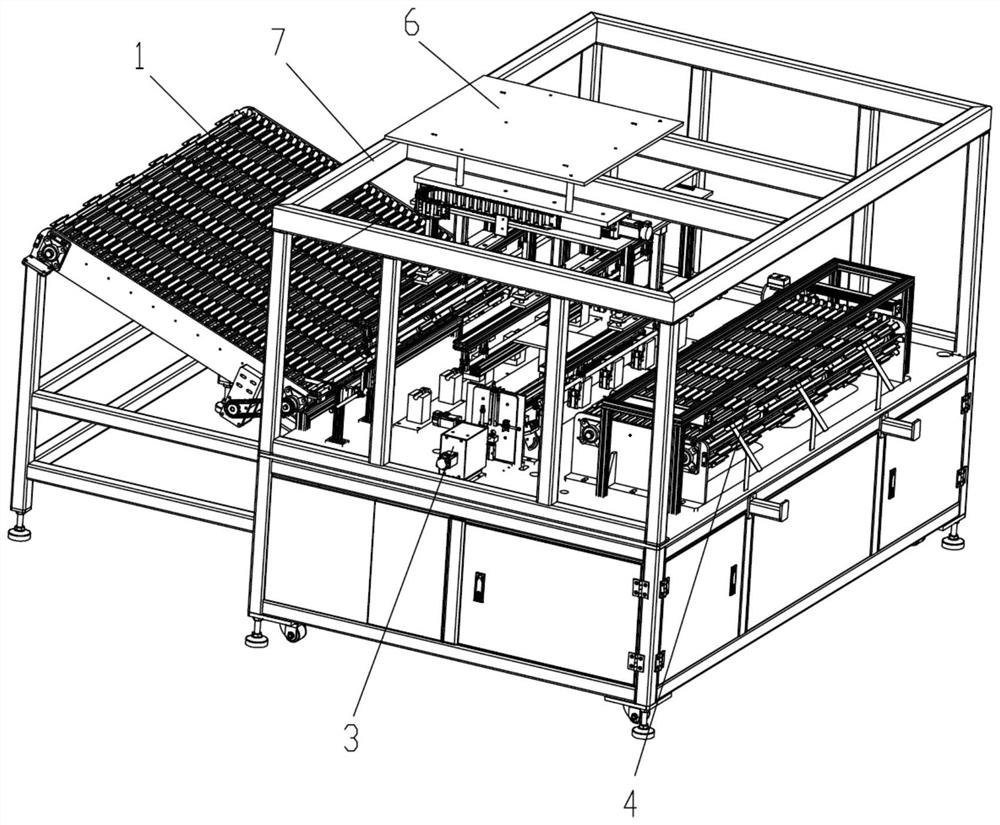

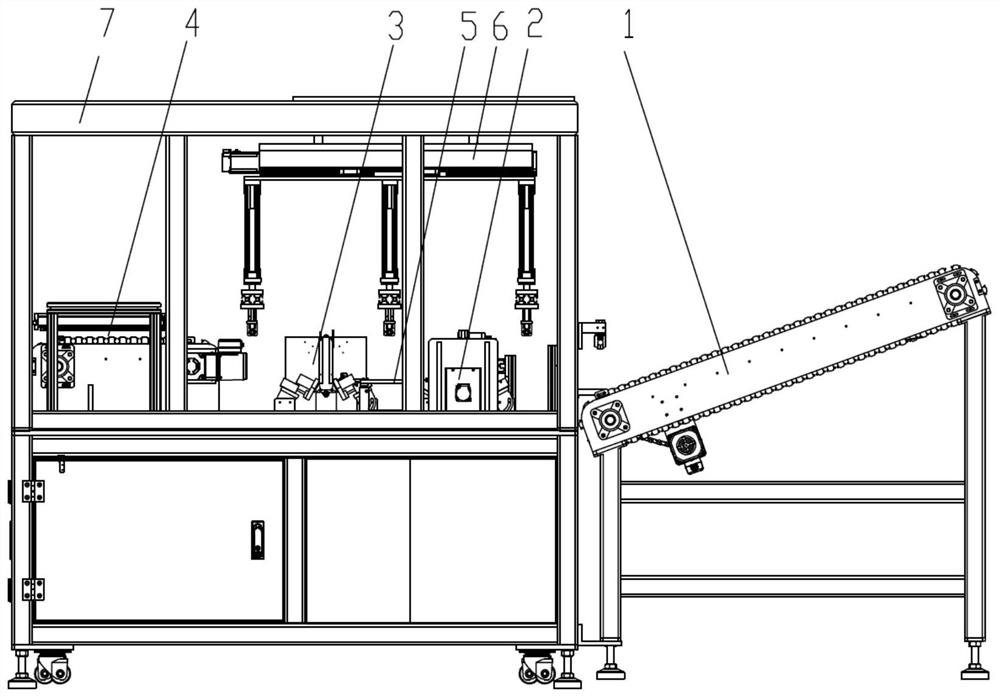

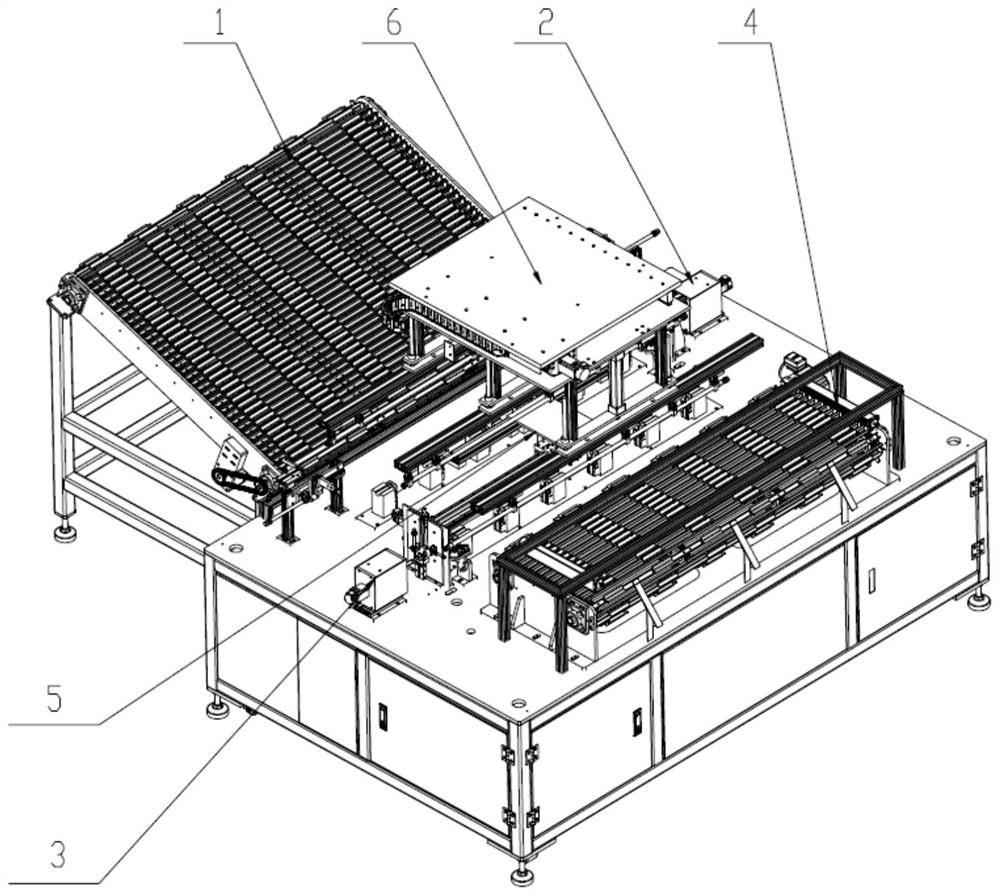

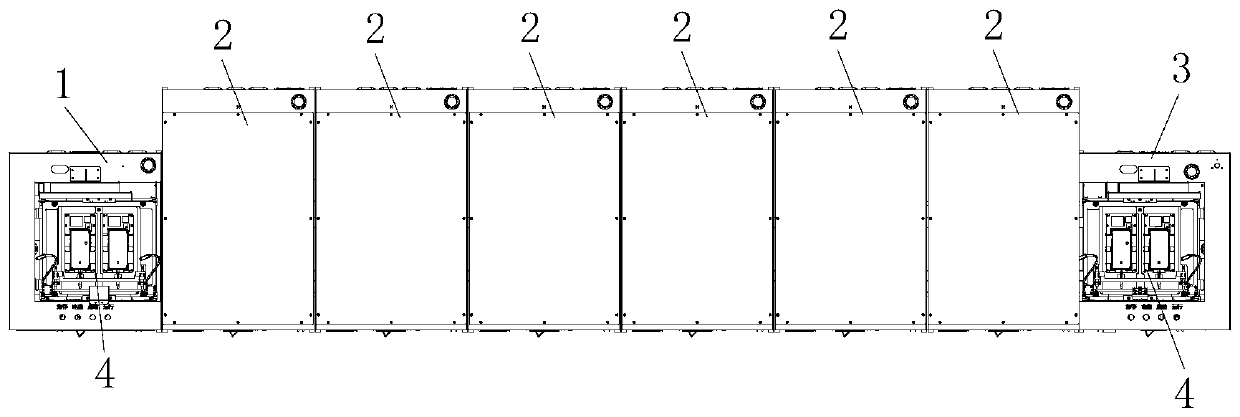

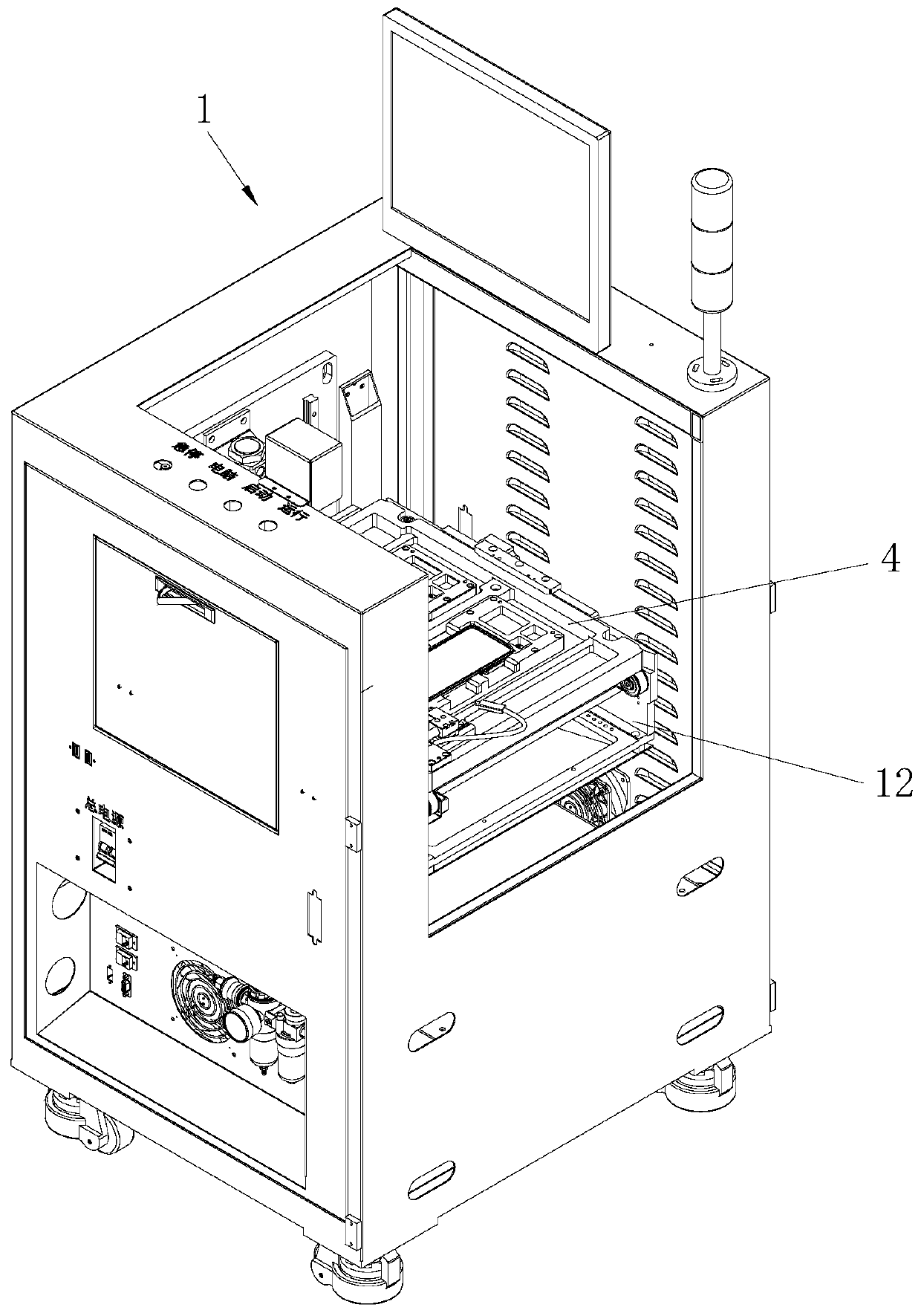

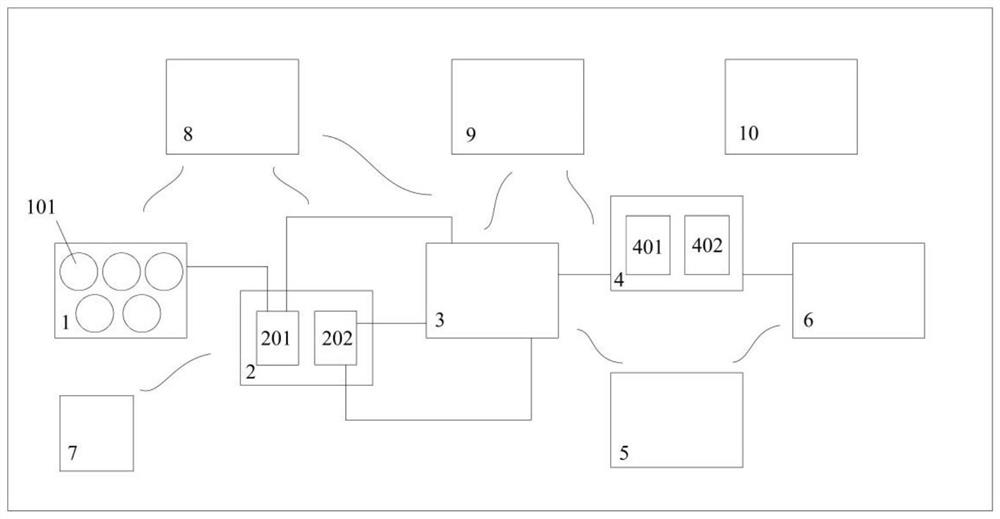

Battery pack optical detection system

ActiveCN110567975AImprove accuracyRealize automatic circulationOptically investigating flaws/contaminationConveyor partsPhysical hard workEngineering

The invention discloses a battery pack optical detection system, comprising a long side shooting group, a top shooting mechanism, a bottom shooting mechanism and a short side shooting group which areused for shooting a battery pack, and a circulation mechanism which is used for circulating the battery pack among the shooting mechanisms. According to the battery pack optical detection system, theimage information of all the surfaces of the battery pack are acquired through the long side shooting group, the top shooting mechanism, the bottom shooting mechanism and the short side shooting group, whether the battery pack is complete or not is judged by means of image comparison, and the detection accuracy is improved. The circulation mechanism realizes automatic circulation of the battery pack in the detection process, greatly reduces the physical labor of workers, and improves the detection efficiency.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

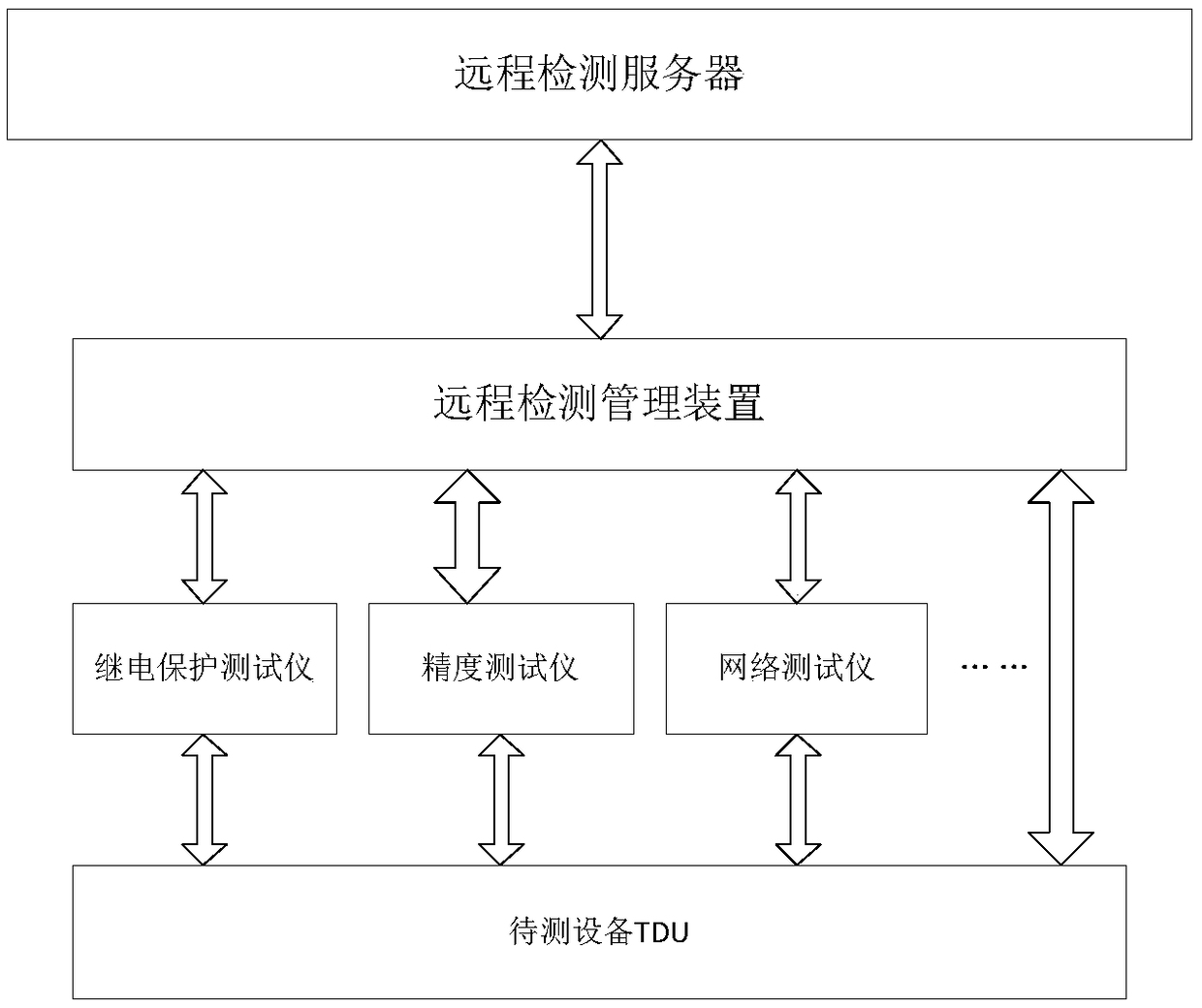

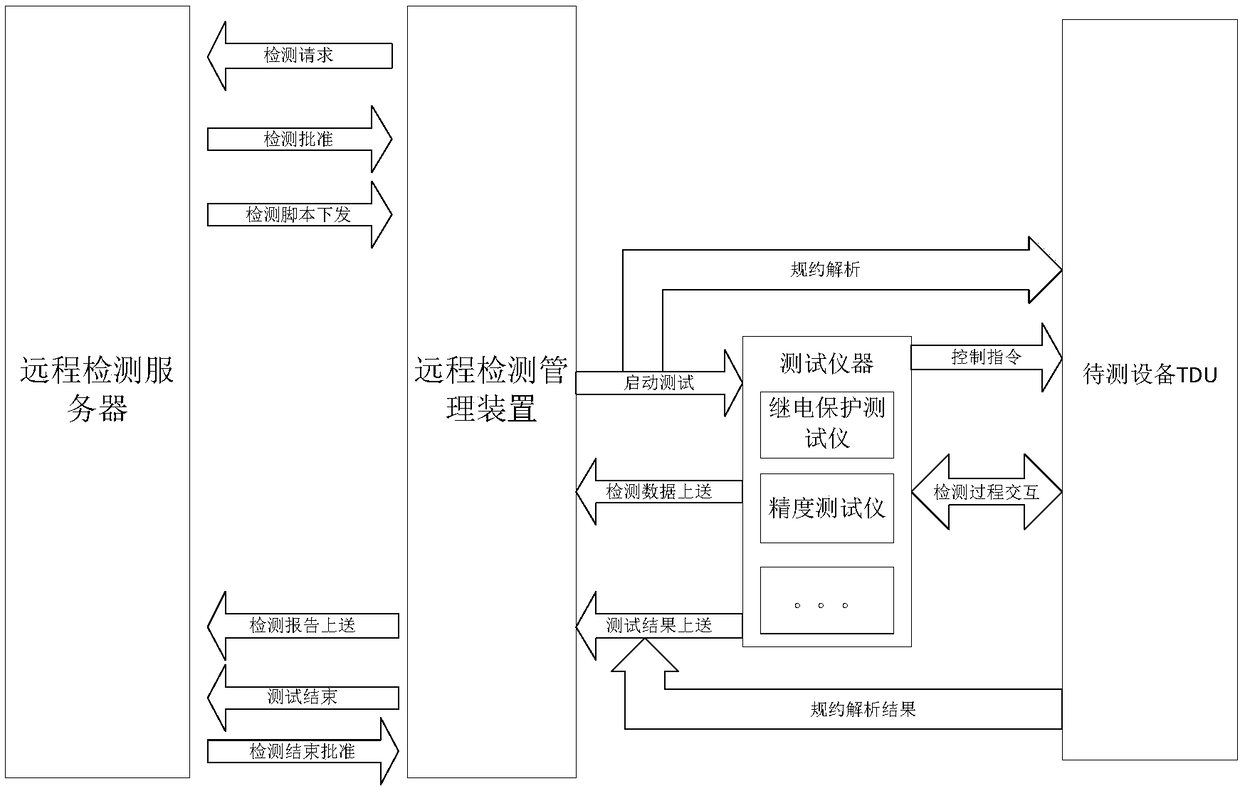

Remote detection system and method for transformer substation automation device

InactiveCN108964280AReduce manual operationsReduce dependencyCircuit arrangementsInformation technology support systemInstrumentationOperating system

The invention discloses a remote detection system and method for a transformer substation automation device. The system comprises a remote detection server and a remote detection management device. The remote detection management device sends a remote detection data request to the remote detection server; a detection script and a detection control instruction are sent to the remote detection management device corresponding to the request and a device to be detected after the request is approved via the remote detection server. The remote detection management device is used for controlling a specialized detection instrument to perform detection service; the remote detection management device is used for detecting the device to be detected according to the control instruction, and a detection result is sent to the remote detection server. Remote automatic detection of the automation device is realized, automatic circulation between individual detection tasks can be realized through control of the detection script and detection use cases; all types of specification data forms at all levels is automatically received and analyzed so as to realize automatic closed-loop recording of detection data and automatic generation of detection reports; dependence of detection sites on technicians can be lowered, and work efficiency can be improved.

Owner:广州思泰信息技术有限公司

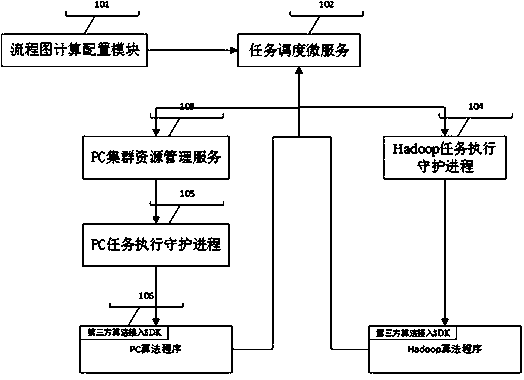

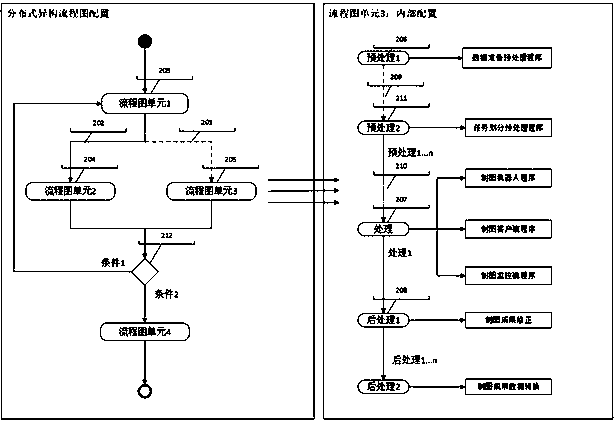

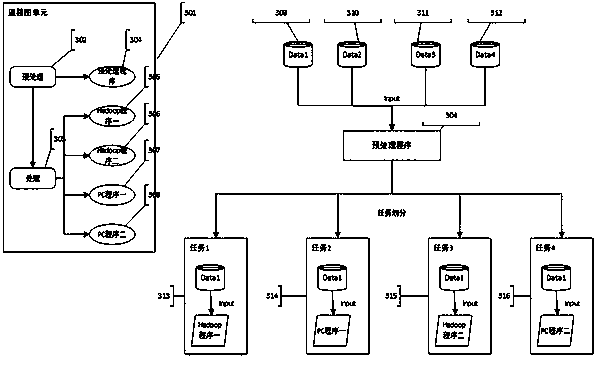

Distributed flow chart heterogeneous computing scheduling method

InactiveCN110287016ARealize automatic circulationSolve adaptation problemsProgram initiation/switchingResource allocationStreaming dataMulti language

The invention relates to the technical field of computers. The method is used for solving the problems of heterogeneous algorithm execution scheduling, data seamless circulation between heterogeneous algorithms, fine-grained division of parallel tasks, streaming data dynamic processing and the like in the current distributed cluster job processing flow. The invention provides a distributed flow chart heterogeneous computing scheduling method. The method comprises the steps of self-customrizing calculation flow chart configuration and then comprises the steps of manging computing process through centralized scheduling; carrying out hybrid scheduling on a heterogeneous algorithm; managing input and output data of a calculation program in the flow chart and forming a streaming data processing mechanism; providing a multi-language heterogeneous algorithm to access the SDK; configuring and executing a preprocessing algorithm program to process a data seamless circulation problem between heterogeneous algorithms, and configuring and executing the preprocessing algorithm program to carry out fine-grained division and the like on parallel tasks, thereby forming a complete solution for scheduling, executing and managing a heterogeneous algorithm computing process in a distributed cluster operation mode.

Owner:武汉兆格信息技术有限公司

Method for automatic circulation of inter-process product production information

PendingCN113469510ARealize automatic circulationFull recordCo-operative working arrangementsOffice automationInformatizationTerminal equipment

A method for automatic circulation of inter-process product production information belongs to the technical field of intelligent manufacturing, is used for solving the problems of high difficulty and high cost of informatization reconstruction of old factories, and comprises the following steps: 1) determining a circulation mode of inter-process product production; (2) setting the circulation mode of product production in a production management system; 3) generating a two-dimensional code of a product to be produced according to the identification number of the product to be produced in the production management system; and 4) issuing the two-dimensional code to each process, after the current process is completed, scanning the two-dimensional code by an operator through terminal equipment on a process position, and filling process information of the product in the current process on the terminal equipment. By setting the two-dimensional code recorded with the production information of the product, the production information and order information of each process are recorded on a circulation card, so that automatic circulation of the production information of the product between the processes is realized, and the problems of loss and inconvenience of manual recording are avoided.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

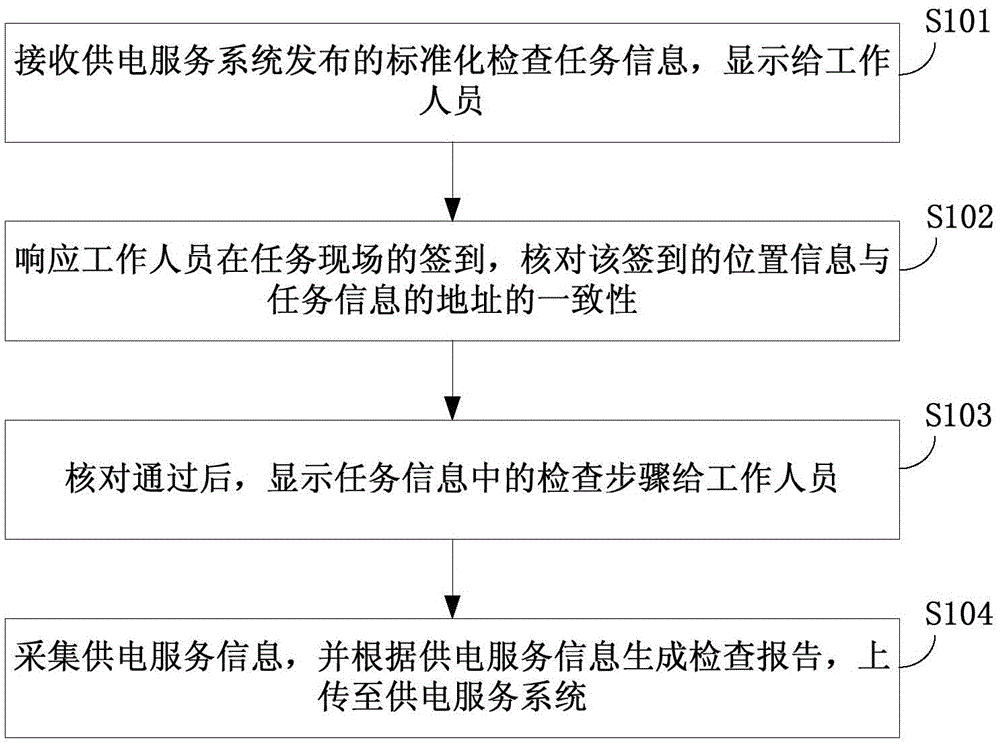

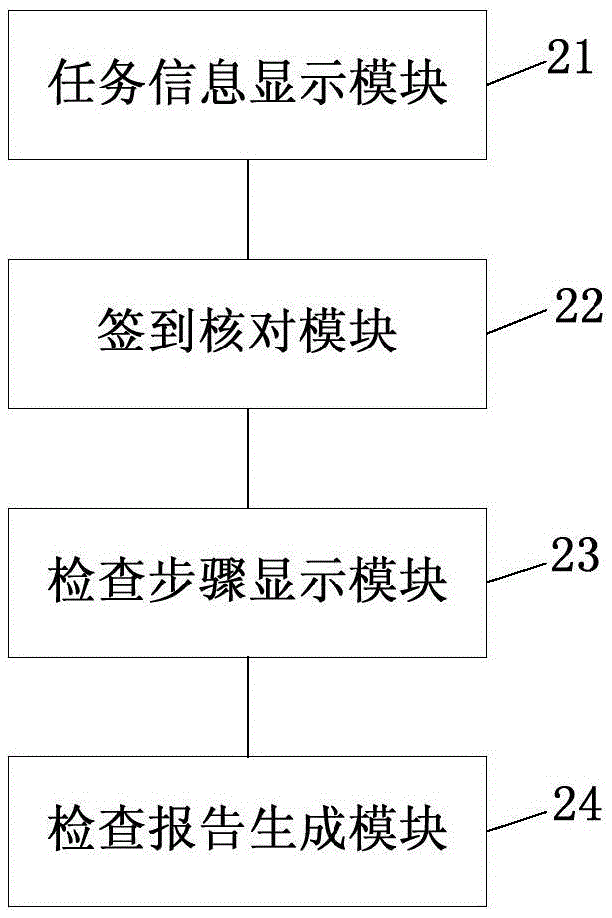

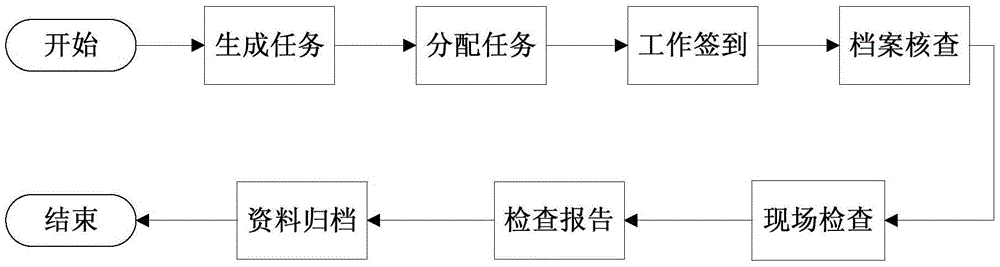

Handheld terminal for checking power supply service and method of checking power supply service

InactiveCN105469323ARealize automatic circulationReduce laborData processing applicationsEmbedded systemService system

The invention provides a handheld terminal for checking power supply service and a method of checking power supply service, wherein the method comprises the following steps of: receiving task information issued by a power supply service system, displaying the task information for a worker; responding to signing in of the worker at a task site, verifying consistency of position information of signing in and address of the task information; after the position information passes through verification, displaying checking steps in the task information for the worker; acquiring power supply service information, generating a check report according to the power supply service information, and uploading the generated report to the power supply service system.

Owner:STATE GRID CORP OF CHINA +2

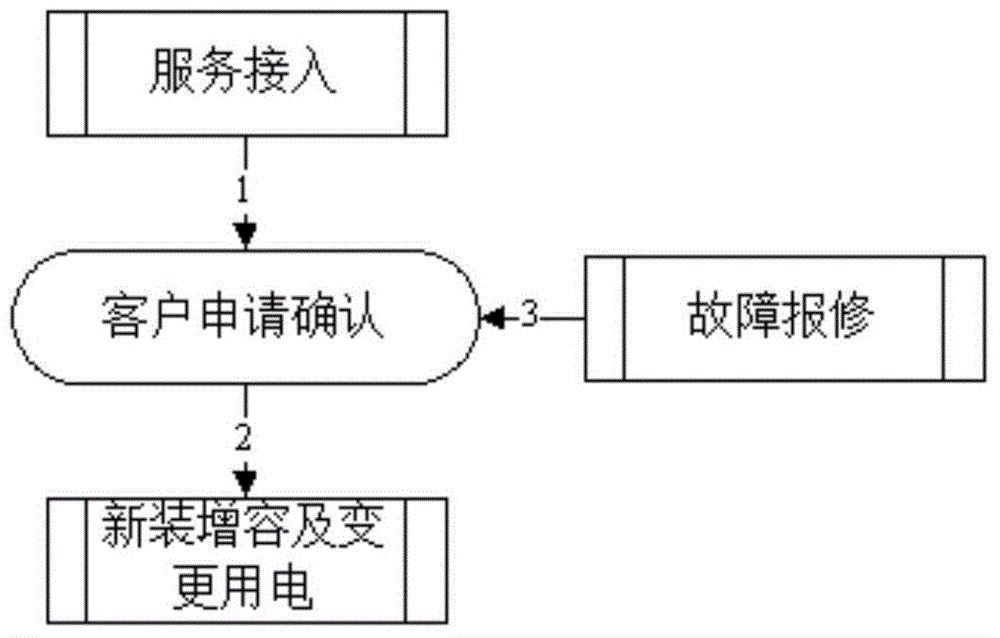

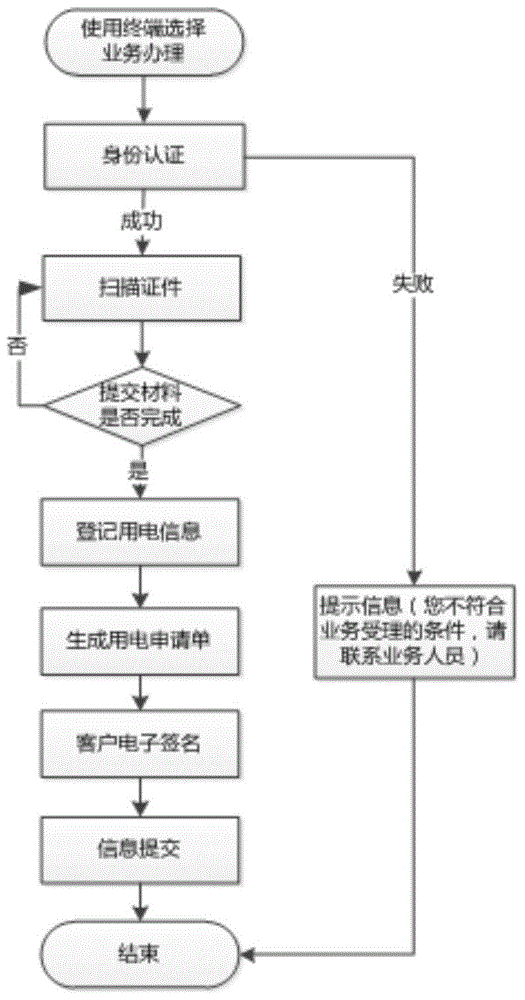

Method for performing business expansion service handling of power interactive service terminal based on electronic signature technology

InactiveCN104899792ARealize automatic circulationGuaranteed accuracyData processing applicationsElectricityService domain

The invention relates to the field of power services, and particularly relates to a method for performing business expansion service handling of a power interactive service terminal based on an electronic signature technology. The method comprises the following steps: (1) authenticating identity: an electricity customer entering the homepage of a power self-help service system on the power interactive service terminal, selecting a service option to be handled, then entering an identity authentication link, and putting the identity card on an authentication module of the terminal for acknowledging; wherein if the authentication fails, the system will prompt information (you are not qualified for service acceptance, please contact servicers); if the authentication succeeds, the system stores customer information and enters next operation procedure; (2) submitting and scanning materials; (3) applying a service; (4) acknowledging an electronic signature; and (5) submitting information. The method fulfills the purpose of automatically processing marketing business expansion service handling procedures by using the power interactive service terminal. By introducing the electronic signature technology, the consumption of massive paper forms is reduced, the consumption of resources is reduced, and unnecessary loss caused by damage or loss of paper is effectively avoided.

Owner:STATE GRID CORP OF CHINA +3

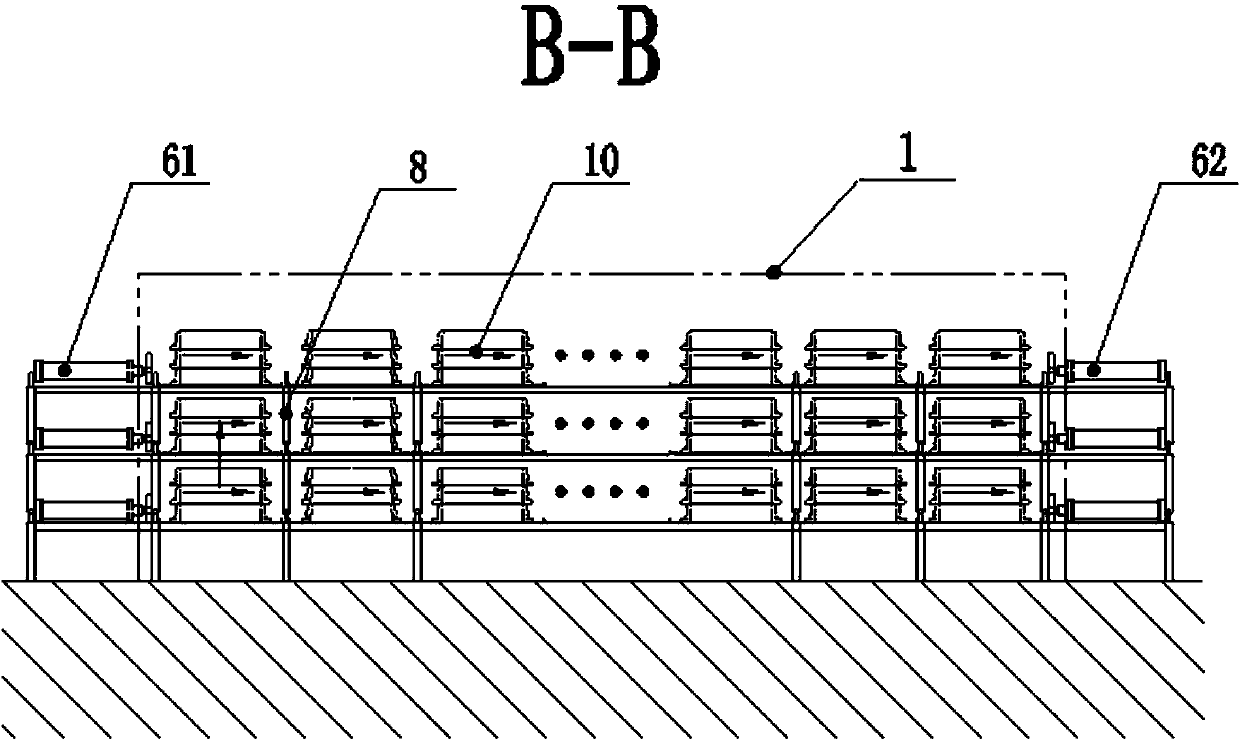

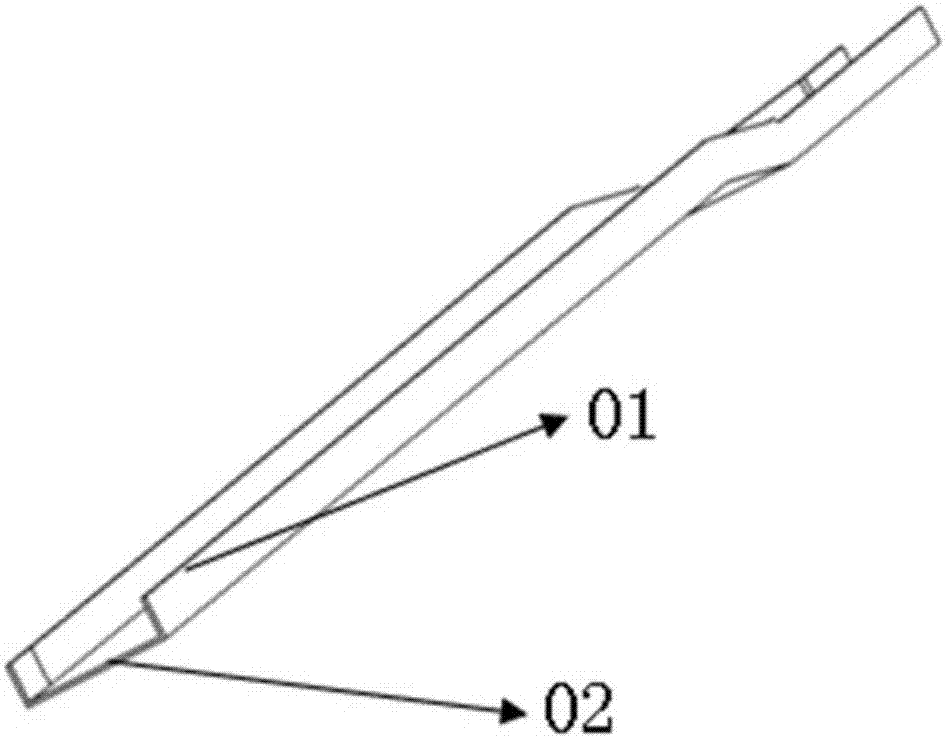

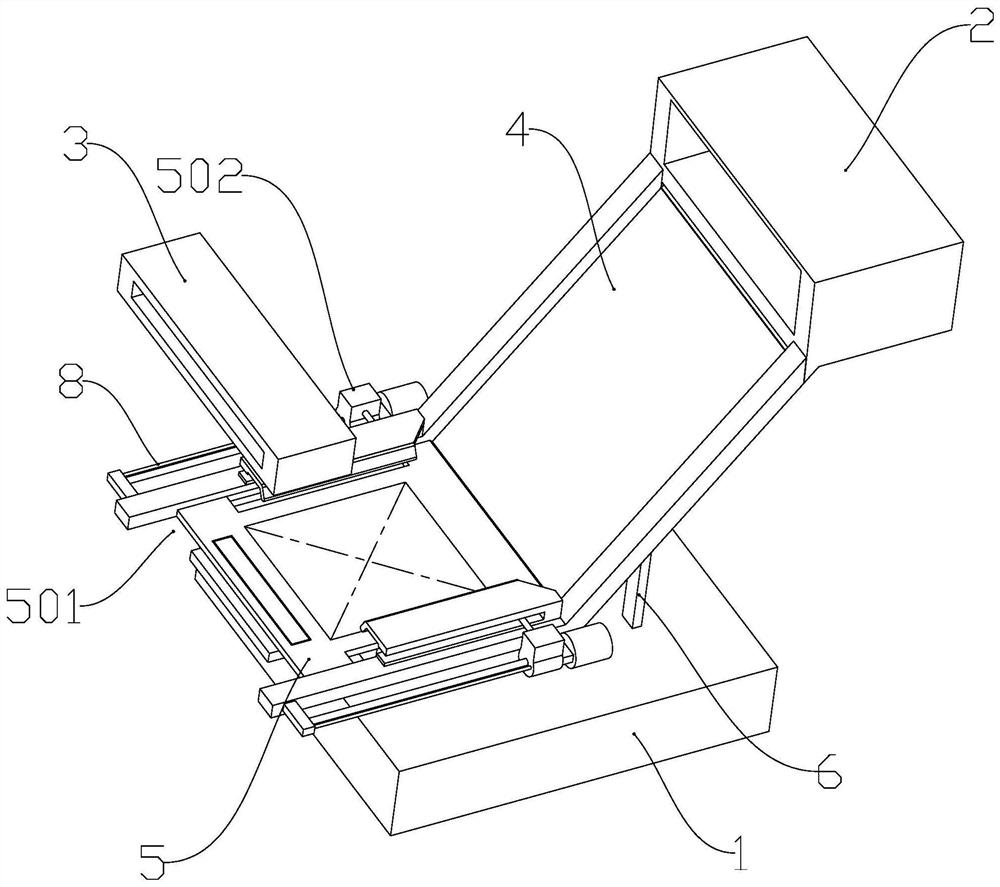

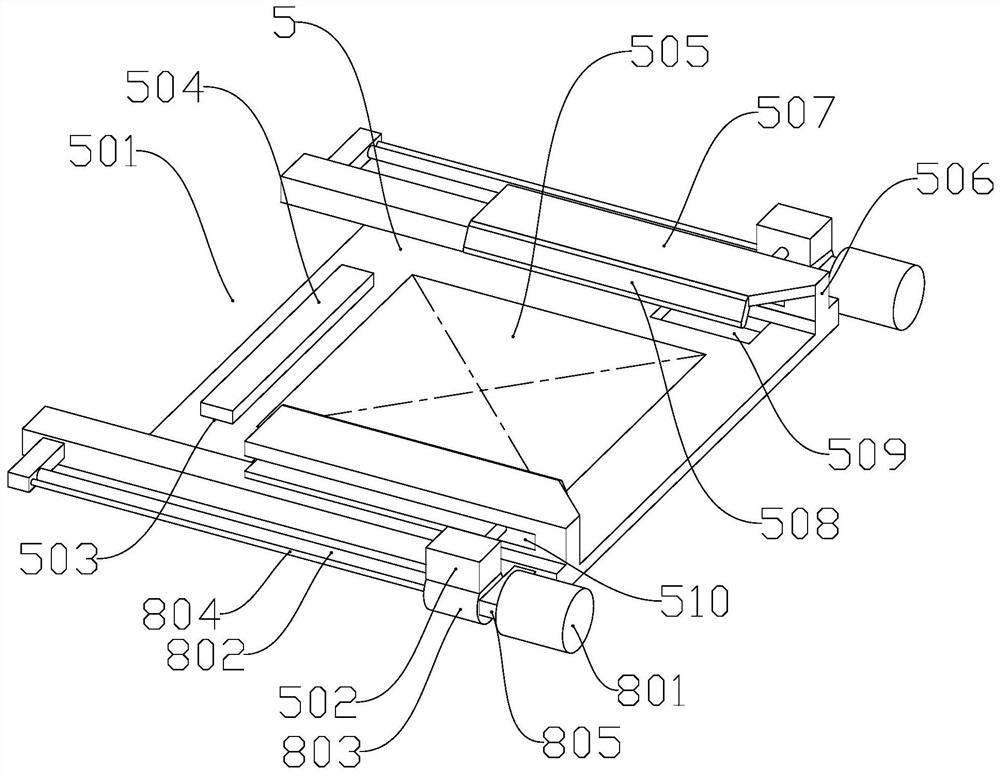

Combined mold-core insert core full-automatic feeding, discharging and detachment mechanism in cooperation with injection molding machine

PendingCN109397618ARealization of automatic disassemblyRealize automatic unloadingCoatingsButt jointEngineering

The invention discloses a combined mold-core insert core full-automatic feeding, discharging and detachment mechanism in cooperation with an injection molding machine. The mechanism comprises the injection molding machine, a combined insert core assembly working station, a formed product discharging working station, a combined insert core feeding conveying device of a butt joint combined insert core assembly working station, a combined insert core detachment mechanism, a robot clamping mechanism, a sub insert core A return stroke conveying line conveyed to the combined insert core assembly working station, sub insert core B return stroke conveying lines of the butt joint combined insert core assembly working station and the formed product discharging working station and a sub insert core Bdischarging conveying line conveyed to the formed product discharging working station, wherein the robot clamping mechanism grabs a combined insert core from the combined insert core feeding conveying device to the interior of the injection molding machine and grabs the formed combined insert core from the injection molding machine to the combined insert core detachment mechanism. According to the combined mold-core insert core full-automatic feeding, discharging and detachment mechanism in cooperation with the injection molding machine, automatic feeding, discharging, detachment and circulation of a combined insert core in a secondary injection molding formation technology can be achieved, the production efficiency is greatly improved, and the safety of operators is improved.

Owner:YUANTAI AUTOMATION TECH SUZHOU

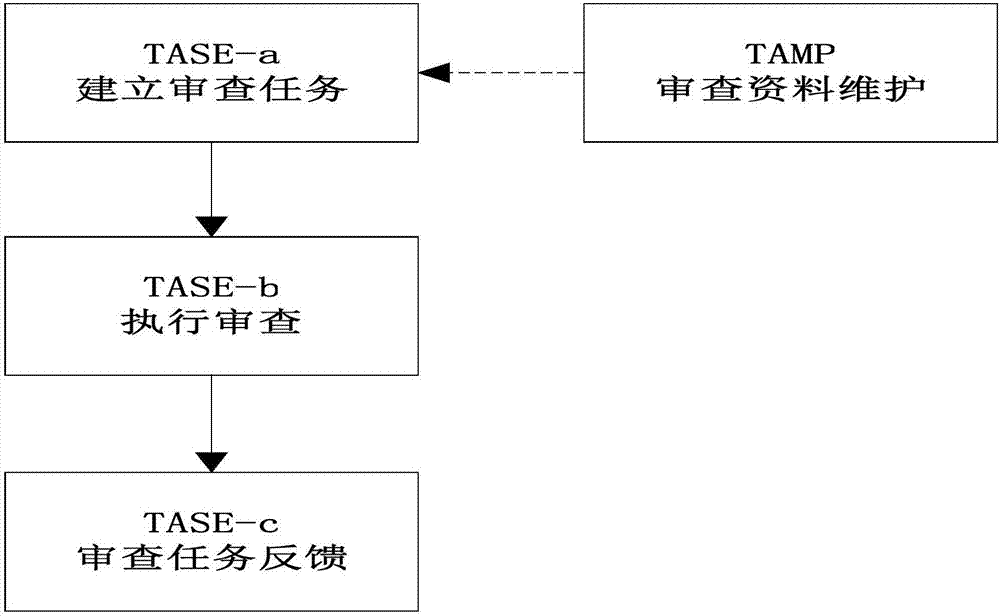

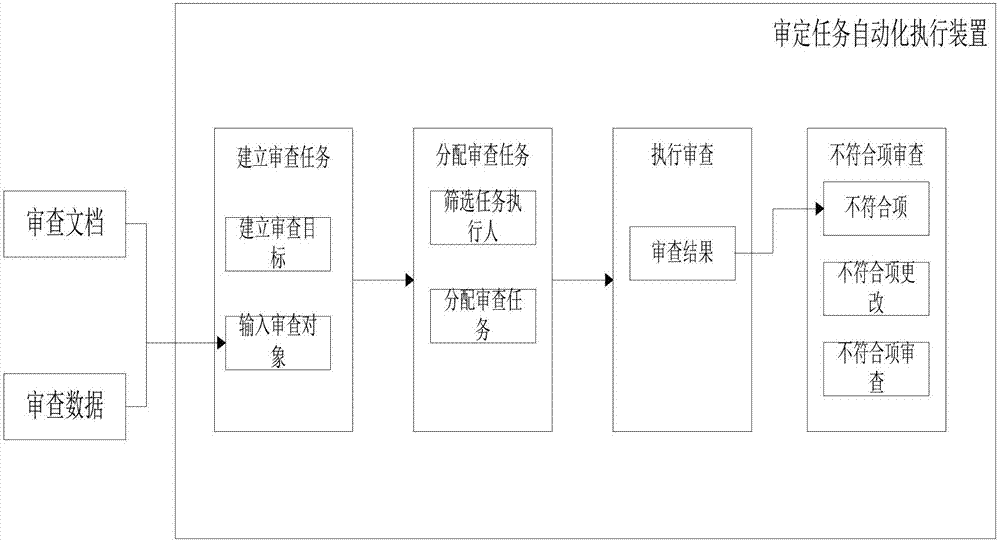

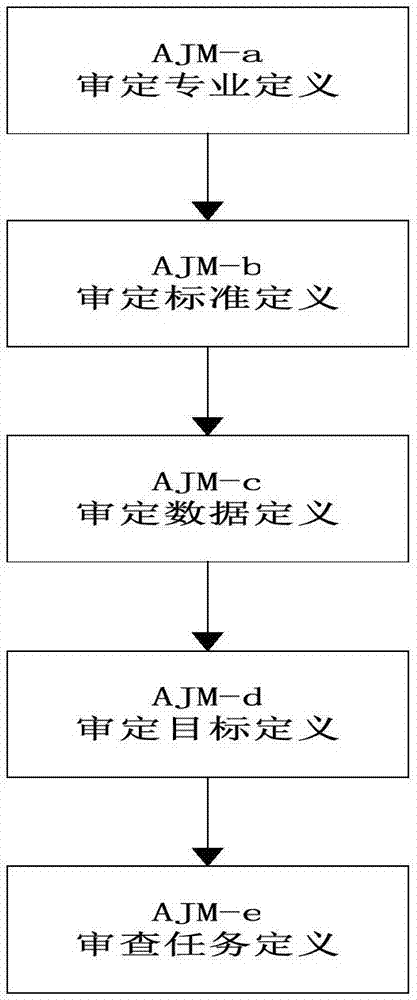

Method and system for automation execution of inspection task

InactiveCN106971253ARealize automatic circulationReview status clearOffice automationResourcesComputer scienceAutomation

The invention discloses a method and device for automation execution of an inspection task. According to the category of inspection projects, related standards / specifications are automatically matched, inspection targets are established, the standards / specifications are regarded as the bases for determining whether an inspection object is in accordance with the standards, and the inspection object is input according to the established inspection targets; then the inspection device automatically screens an inspection task executor in accordance with the condition to allow a project person in charge to make a choice, and when the person in charge of the inspection project distributes the inspection task to the screened task executor, the device automatically drives the inspection task according to the inspection targets and the related inspection object; and the inspection task executor executes specific inspection according to the related inspection targets and the inspection object and provides an inspection result, and the device automatically establishes a link of the inspection task and the inspection result. According to the device, automatic turning of the inspection task process can be realized, the association relation between inspection data is established, support data and inspection states of all the inspection targets are clear, and the inspection work is simplified.

Owner:上海爱韦讯信息技术股份有限公司

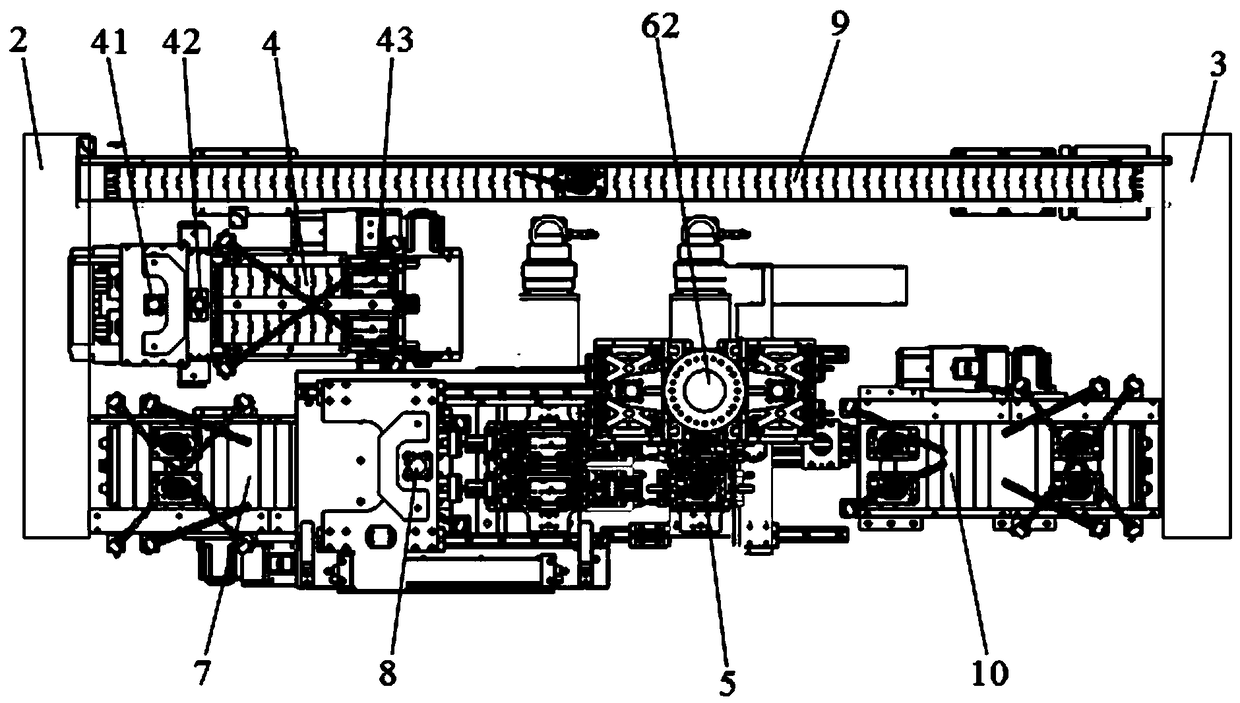

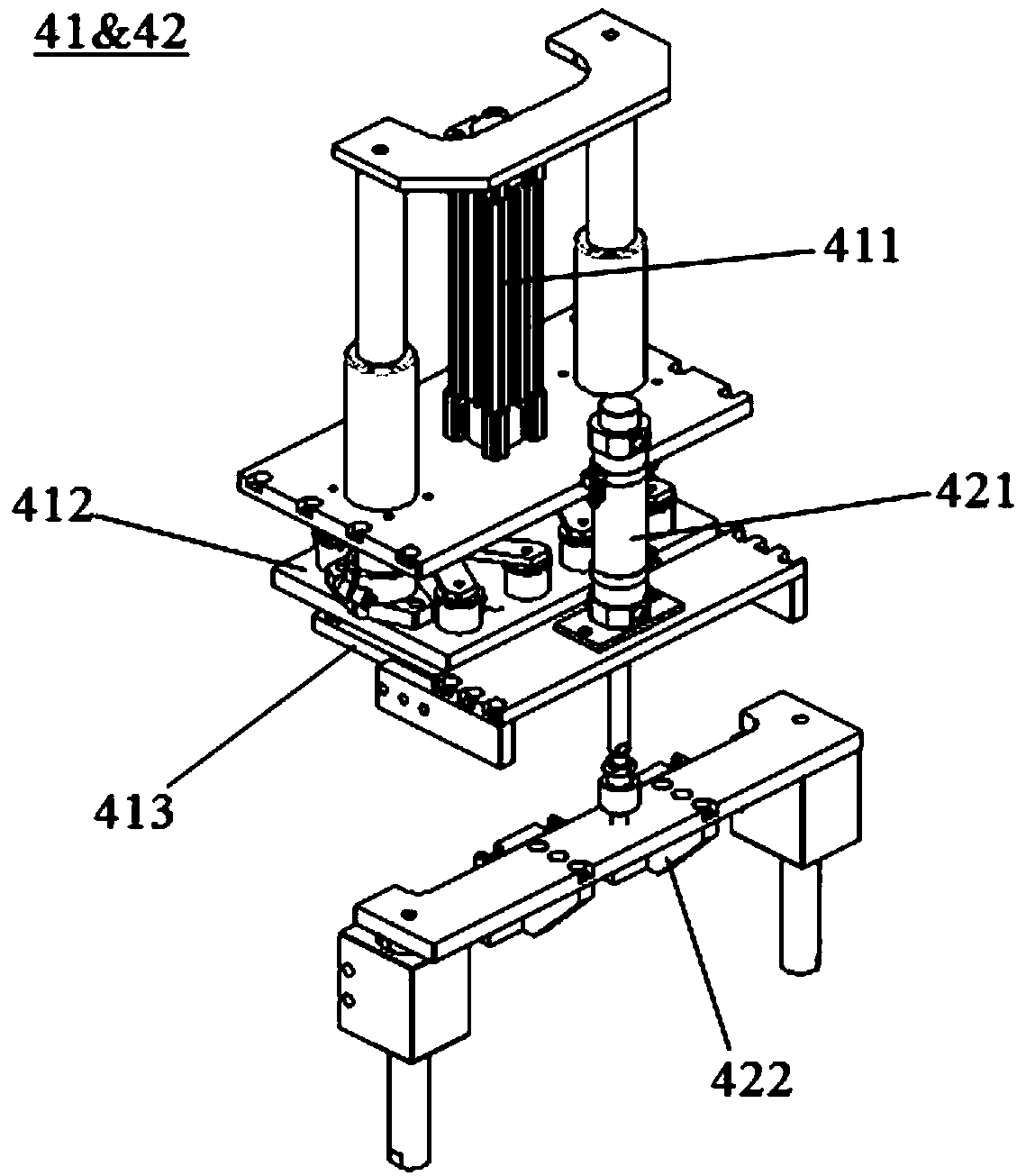

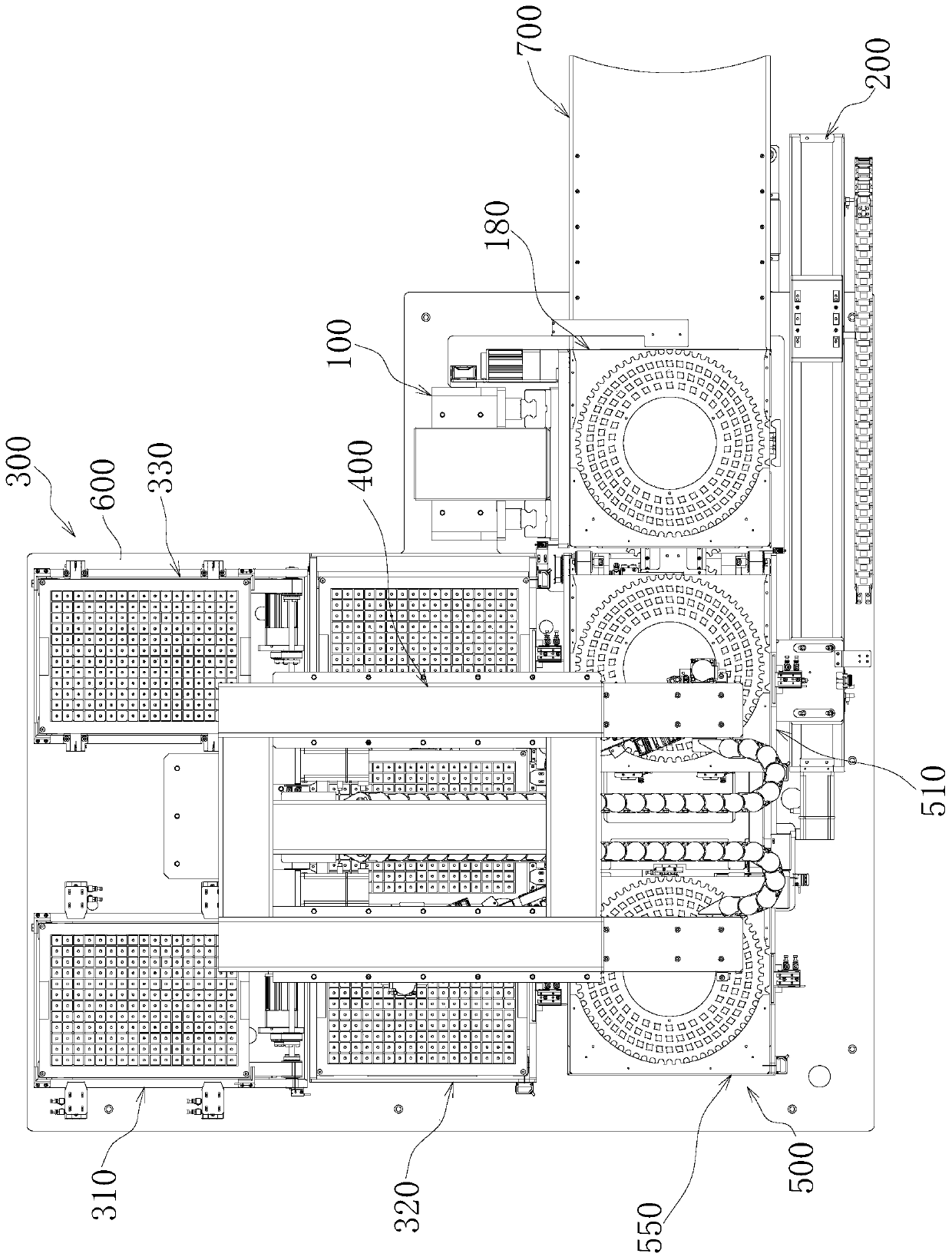

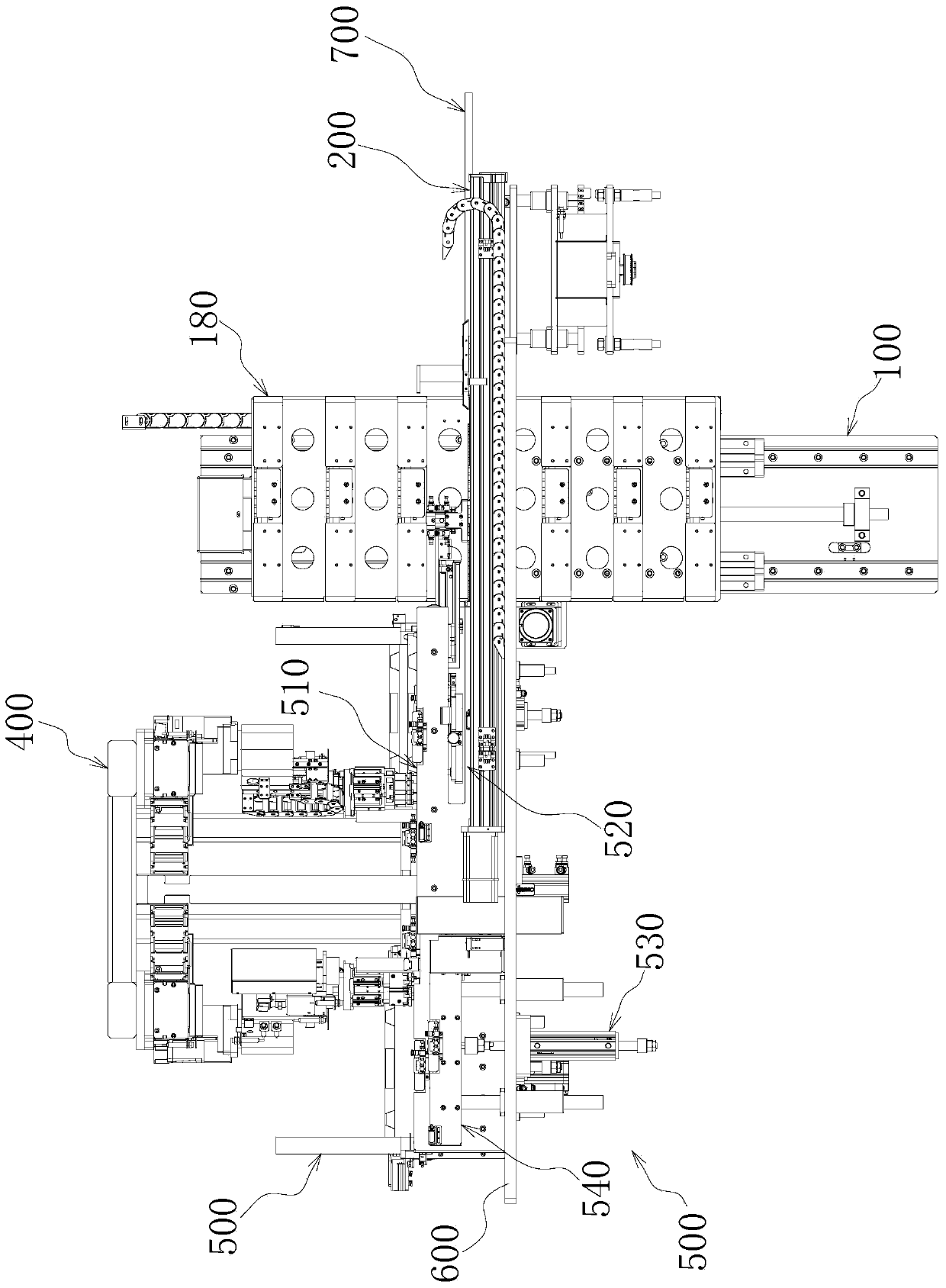

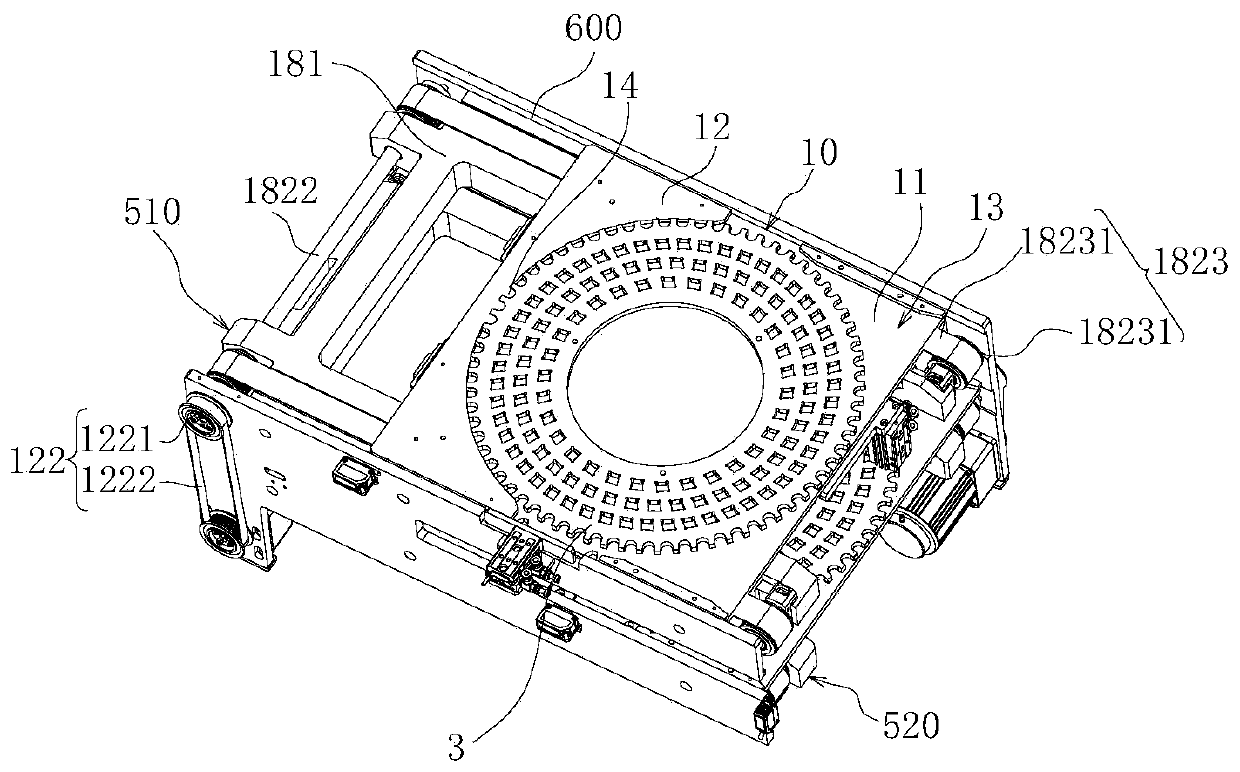

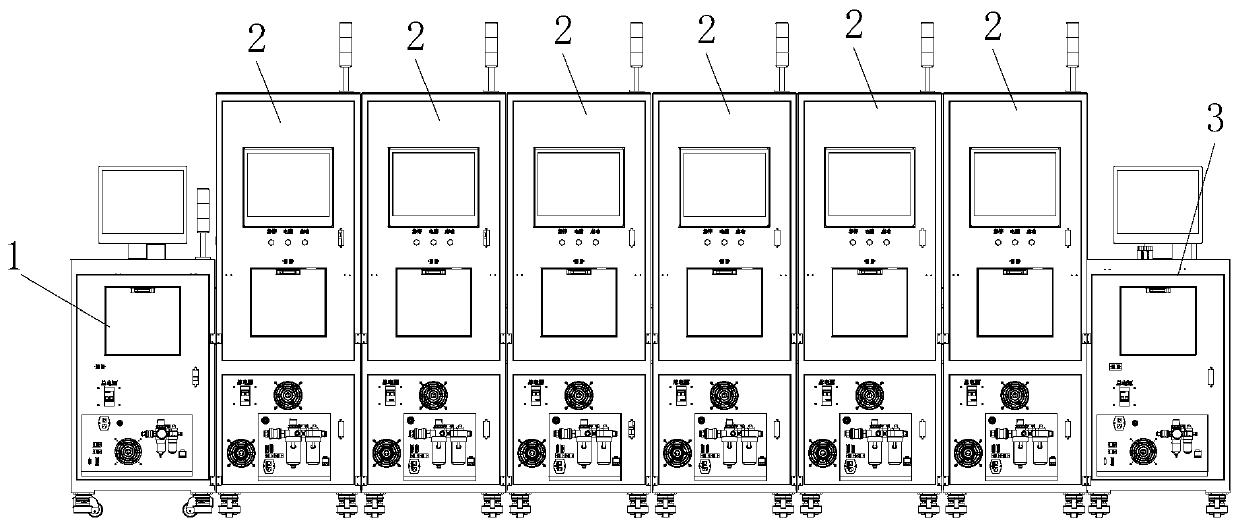

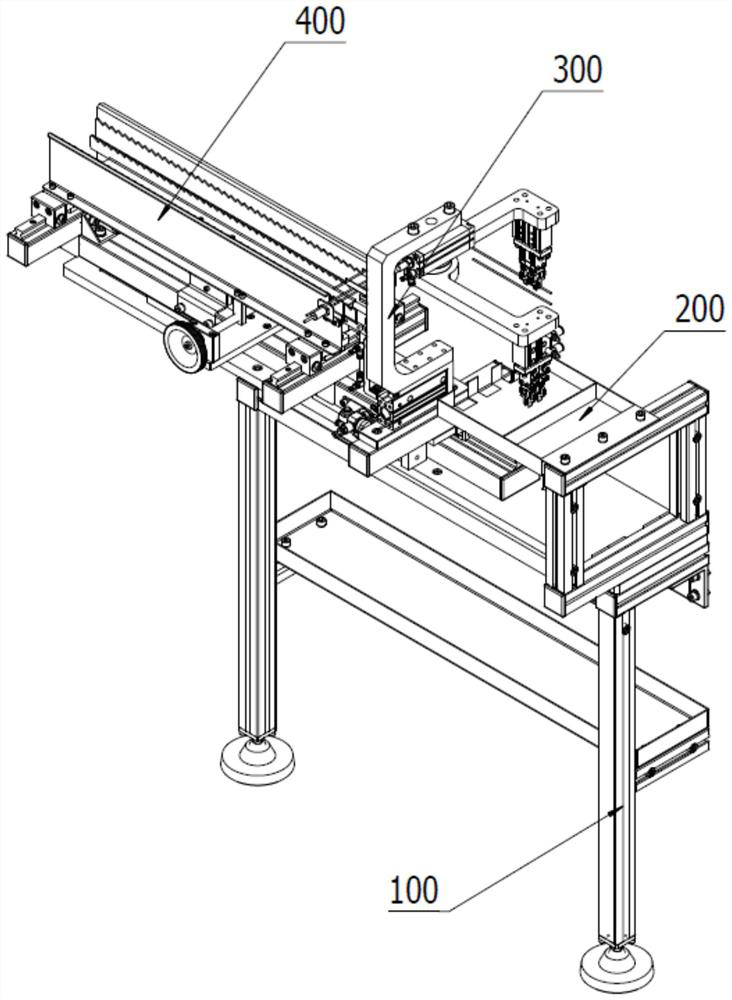

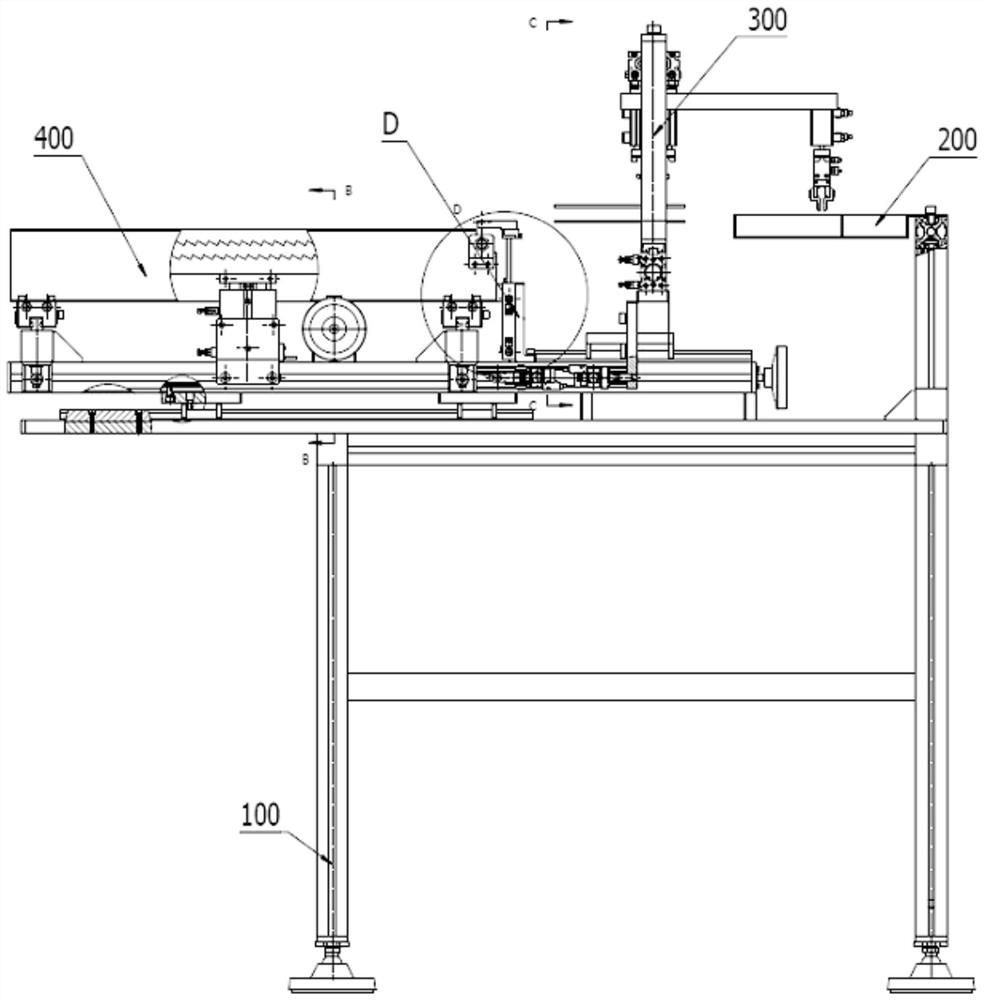

Feeding and discharging equipment

ActiveCN111169985ARealize automatic circulationHigh degree of automationSupporting framesMechanical conveyorsManufacturing engineeringAutonomation

The invention belongs to the technical field of machining equipment, and particularly relates to feeding and discharging equipment which comprises a rack, a carrier circulation device, a jig mechanical arm, a material disc circulation device and a cutter feeding and discharging device. The carrier circulation device is installed on the rack and used for circularly conveying carriers for loading jigs back and forth; the jig mechanical arm is mounted on the rack and is used for moving the jigs back and forth between machining equipment and the carrier circulation device; the material disc circulation device is installed on the rack, located on the side of the carrier circulation device and used for conveying material discs to the cutter discharging position on the carrier circulation devicefrom the cutter feeding position on the carrier circulation device; and the cutter feeding and discharging device is installed on the rack and comprises a feeding mechanical arm and a discharging mechanical arm. According to the feeding and discharging equipment, in the automatic feeding and discharging process of cutters, automatic circulation of the material discs and the jigs can be achieved, the automation degree is high, the labor intensity is greatly relieved, and the production efficiency is high.

Owner:CHENGDU BANGPU CUTTING TOOLS CO LTD

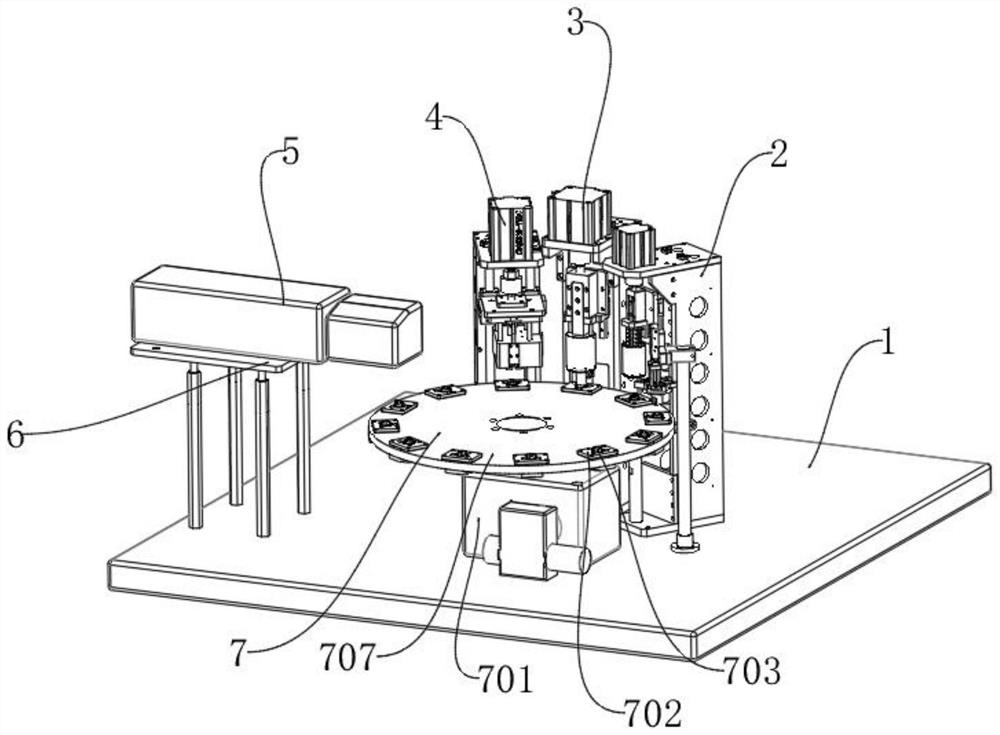

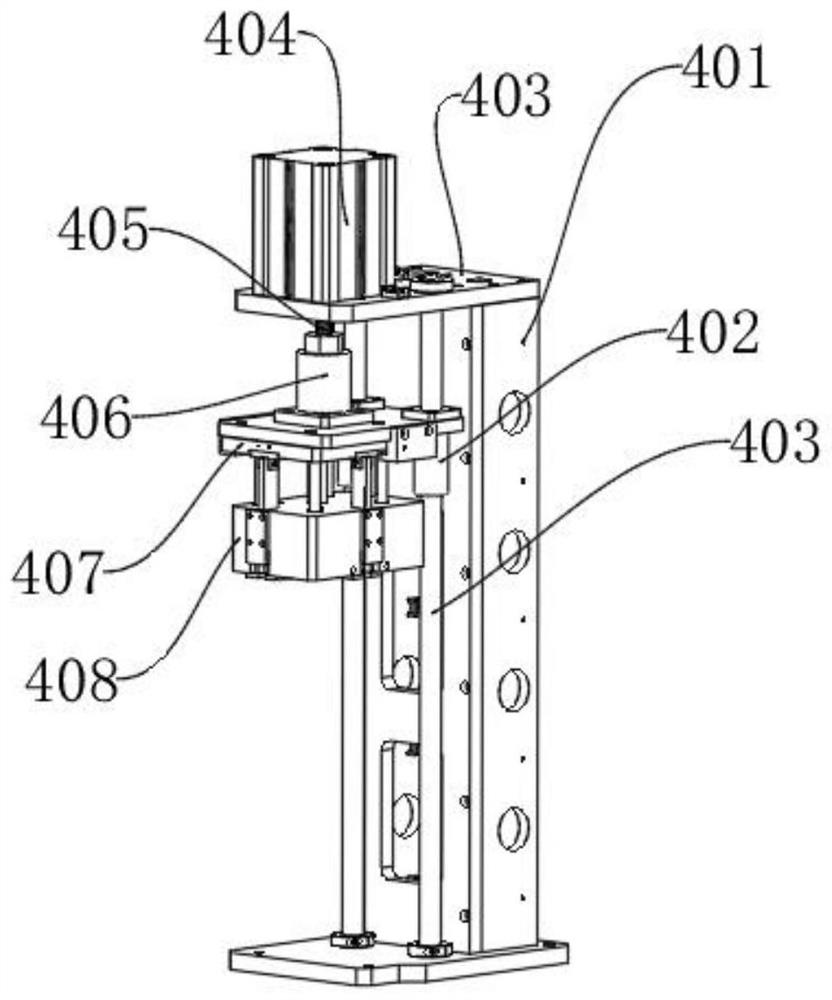

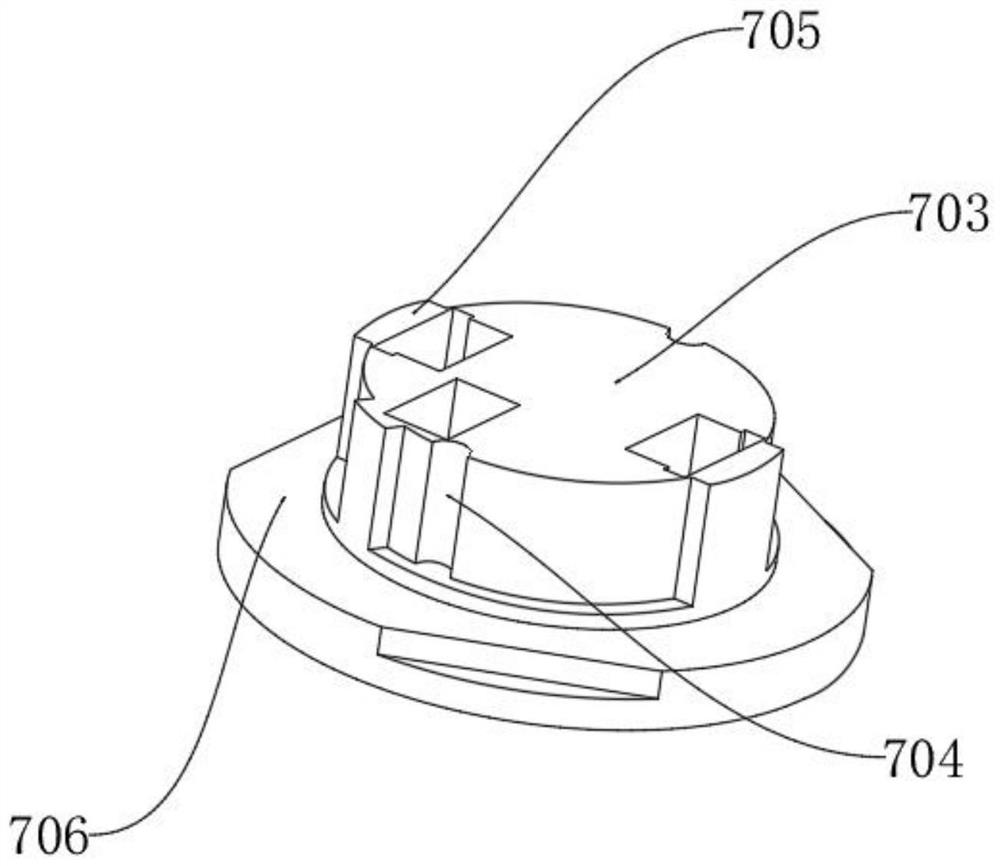

Automatic chip mounting mechanism

PendingCN110191593AReduce settingsAvoid repeated start-up energy consumptionPrinted circuit assemblingElectrical componentsRotary stageSoldering

The present invention discloses an automatic chip mounting mechanism. The mechanism comprises a feeding device, a plurality of tin-soldering devices matched with the feeding device, and a chip mounting device. A material ejection component comprises a top plate arranged at the lower portion of a conveyer belt and used for extending and top connection with a product carrier to break away the product carrier from the conveyer belt, a material blocking component comprises a blocking post extended to the side of the product carrier to limit the movement of the product carrier along the conveyer belt, each tin-soldering device comprises a plurality of tin-soldering needle tips horizontally and vertically moving arranged at the upper portion of the product carrier, the chip mounting device comprises a material taking component configured to convey a chip, a rotation component configured to rotate and locate the chip and an attaching component, the material taking component comprises a lifting material taking sucking disc, the rotation component comprises a rotationally arranged rotation platform, the material taking sucking disc sucks the chip to be located at the rotation platform, andthe attaching component comprises an attaching sucking disc configured to absorb the chip on the rotation platform in a lifting movement mode and transmit the chip onto the product carrier in the conveyer belt. The automatic chip mounting mechanism achieves automatic product feeding and chip mounting, and improves the processing efficiency.

Owner:苏州睿立汇自动化科技有限公司

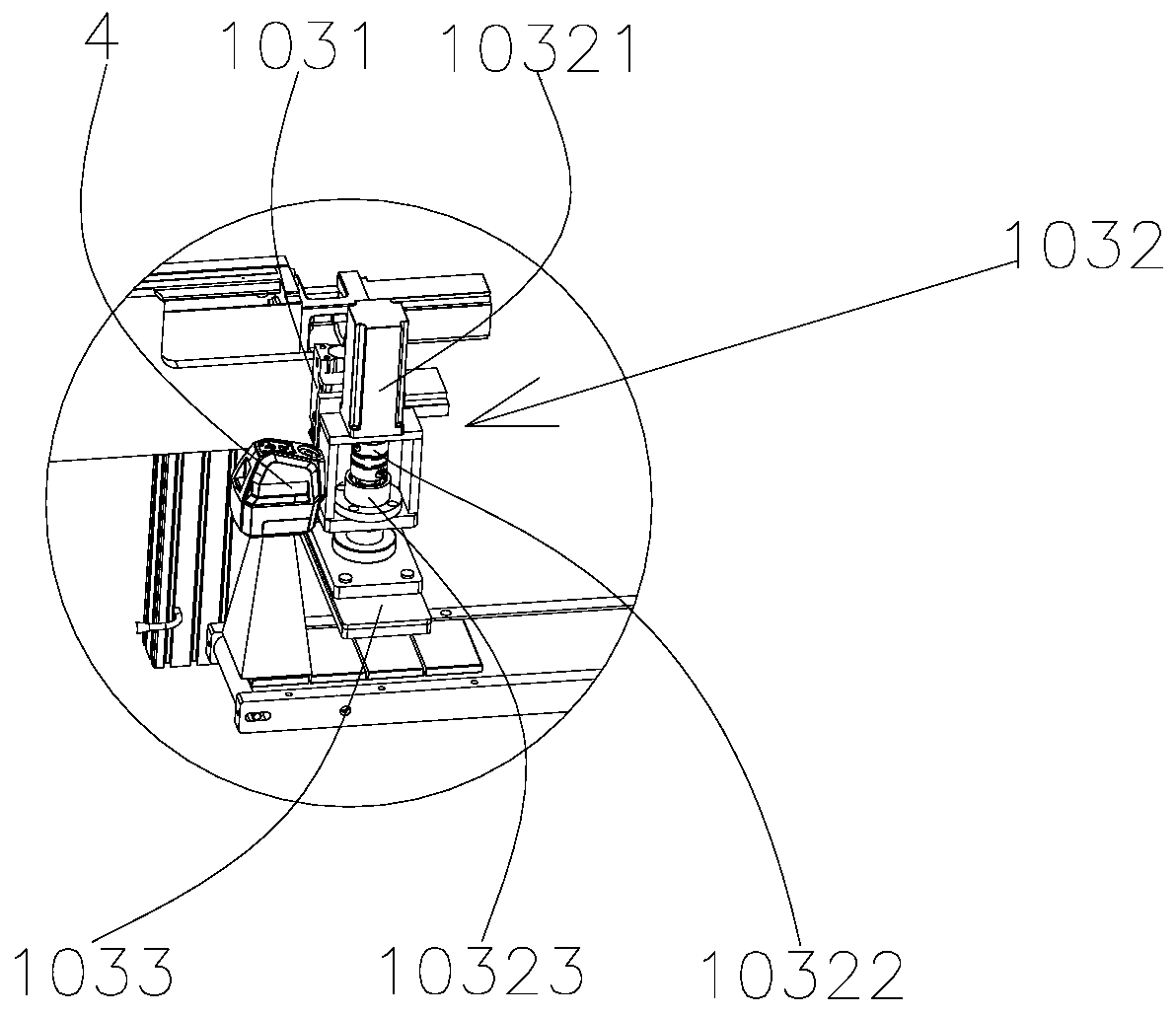

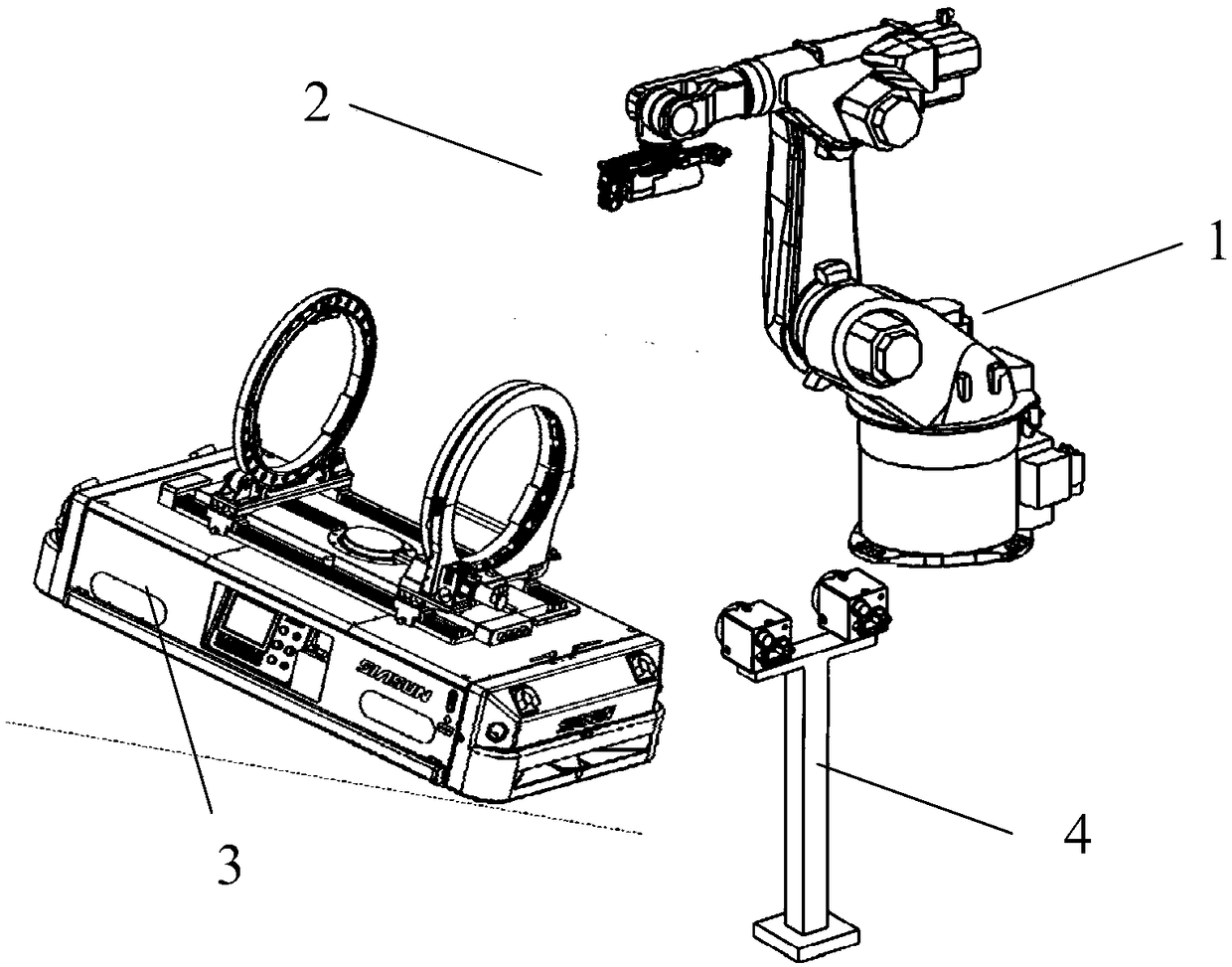

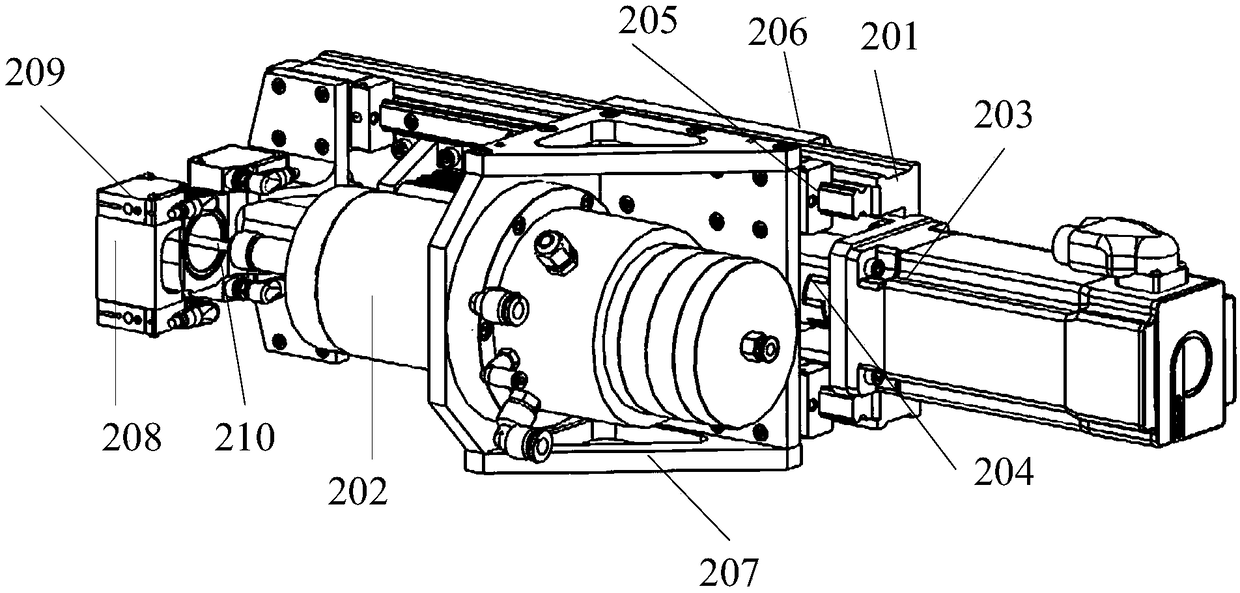

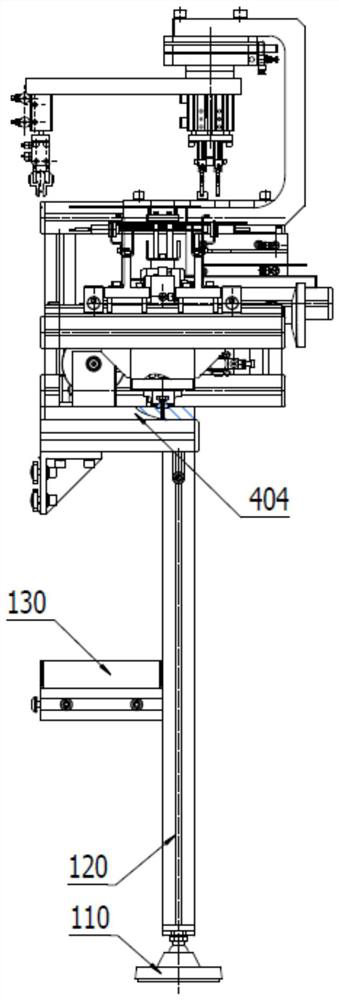

Mechanical arm drilling device and drilling method adapting to automatic logistics

ActiveCN108858218ARealize automatic circulationImprove positioning accuracy and measurement efficiencyProgramme-controlled manipulatorDrilling systemTransfer function

The invention discloses a mechanical arm drilling device and drilling method adapting to automatic logistics, and used for carrying out product drilling working with high accuracy and high automationdegree. The mechanical arm drilling device comprises a series mechanical arm (1), a drilling end executer (2), an automatic logistics vehicle (3) and a vision measurement assembly (4). By realizing anautomatic transfer function of the drilling end executer (2) and the automatic logistics vehicle (3) in a drilling process, the problems that timely adjustment for the positions and the distances ofcomponents during a drilling process for a drilling product cannot be realized, and the drilling accuracy is low, in an existing drilling system, are solved; and the mechanical arm drilling device isstable in drilling structure and high in drilling efficiency.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

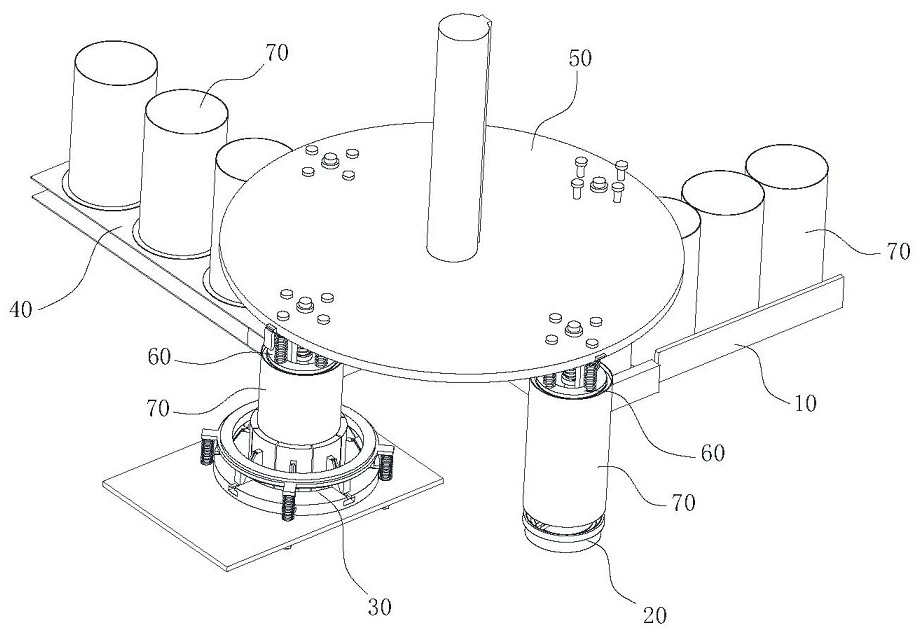

Material transferring method for cylinder sleeve machining

InactiveCN111842698ARealize automatic circulationAvoid damageShaping toolsLiquid surface applicatorsAirbagManipulator

The invention belongs to the technical field of engine cylinder sleeve machining, and particularly relates to a material transferring method for cylinder sleeve machining. A manipulator is adopted toclamp a cylinder sleeve from the inside of the cylinder sleeve, the cylinder sleeve is transferred to pass through an oil painting station, a face turning station, and an unloading station successively, and is released on the unloading station, the manipulator includes a circular mounting plate, and clamping units are arranged on the edge of the mounting plate. According to the method, airbag typemanipulator is utilized to achieve the flexible clamping and transferring of the cylinder sleeve, the damage to the inner wall of the cylinder sleeve can be reduced, meanwhile the automatic transferring of the cylinder sleeve between the stations can be achieved, and the production efficiency can be improved.

Owner:ANHUI PROVINCE YUEXI CYLINDER

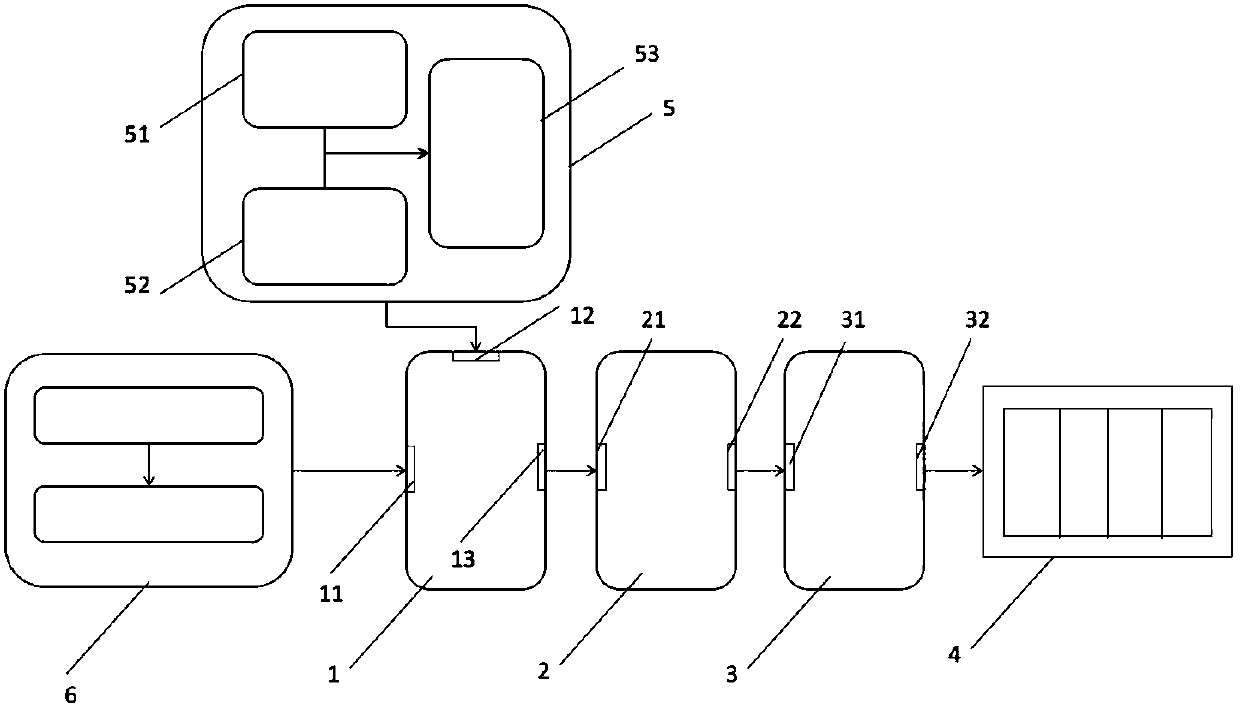

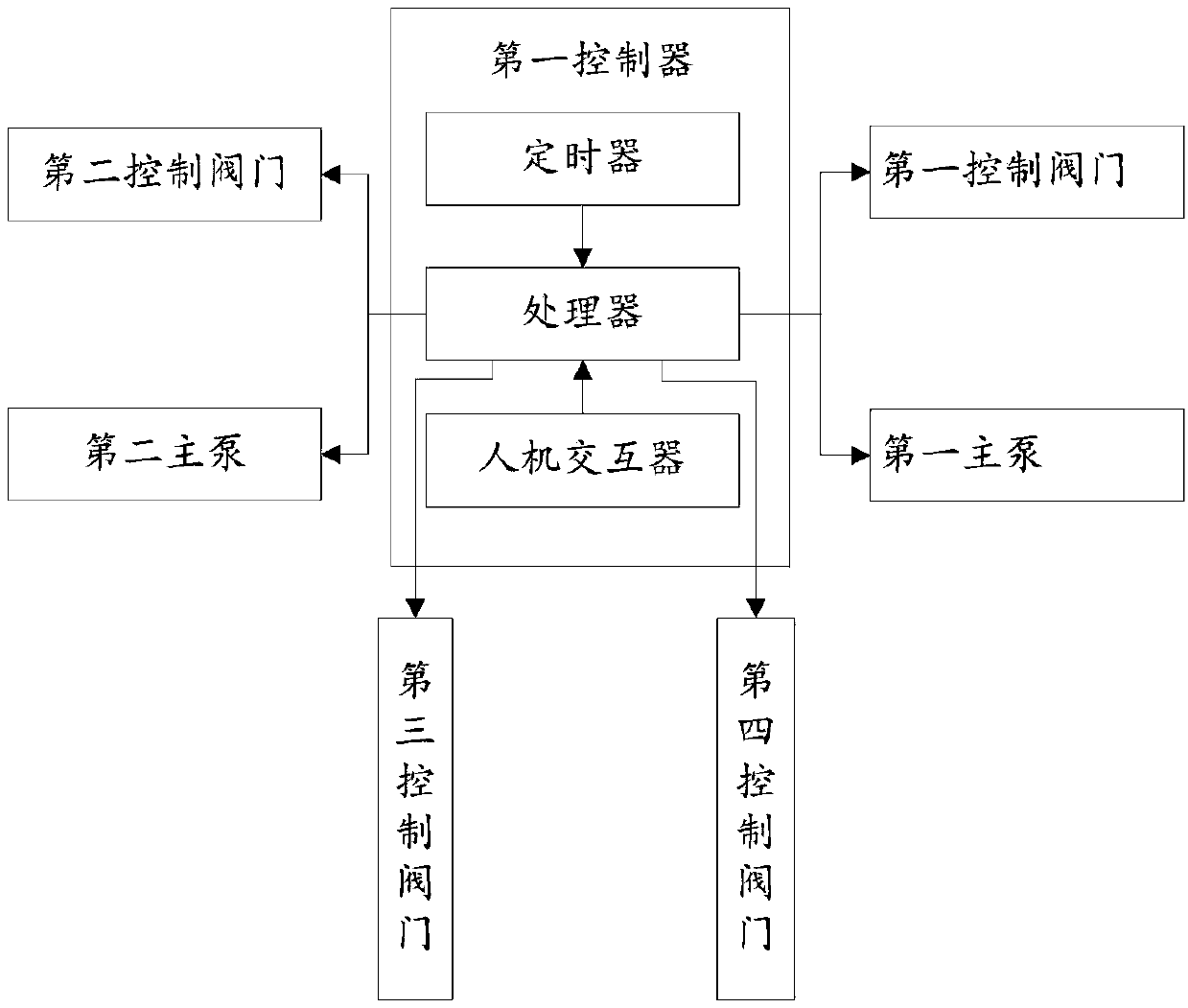

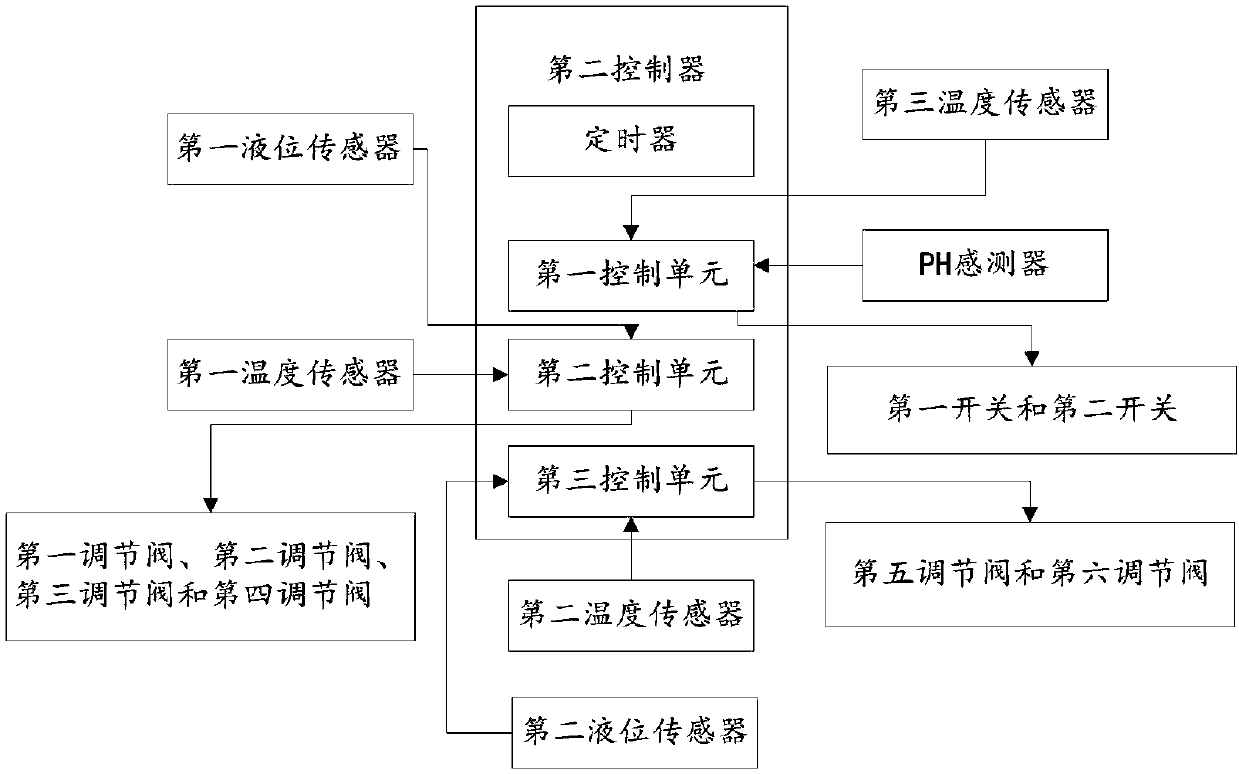

Automated dyeing system

InactiveCN107630305ARealize automatic circulationRealize full automationTextile treatment containersTextile treatment machine arrangementsAutomatic controlControl system

The invention provides an automated dyeing system, which comprises a mechanical device and a control system, wherein the mechanical device comprises a first dyeing barrel, a second dyeing barrel and athird dyeing barrel which are sequentially arranged in series, and the first dyeing barrel is provided with a first dye liquid inlet and a second dye liquid inlet; the first dye liquid inlet is in communication with a first dye acquisition device, and the second dye liquid inlet is in communication with a second dye acquisition device; the control system comprises a first controller for controlling control elements arranged in the first dyeing barrel, the second dyeing barrel and the third dyeing barrel which are sequentially arranged in series. The automated dyeing system provided by the invention realizes the automated circulation of dye and the front to end automation of a dyeing process. The dyeing is controlled by the control system in the whole process so as to minimize manual intervention, and the dyeing efficiency can be obviously enhanced by the sensor-based automated control and the use of various sensors.

Owner:汪辉

Automatic circulation device for metal hose manufacturing process

PendingCN114044310ARealize automatic circulationIncrease productivityConveyorsLifting framesTransmission beltEngineering

The invention relates to an automatic circulation device for a metal hose manufacturing process, and belongs to the technical field of metal hose manufacturing. The device comprises an output end of a feeding device, a first joint welding station, a second joint welding station, a workpiece clamping and transferring device capable of moving above a cooling device, and a position conversion device arranged between the first joint welding station and the second joint welding station. The workpiece clamping and transferring device comprises a top plate assembly forming a horizontal moving pair with a support, a horizontal suspender driven by a lifting air cylinder is mounted on the lower surface of the top plate assembly, and at least two clamping jaws which are distributed at intervals and driven by an opening and closing air cylinder respectively are mounted on the bottom face of the suspender; the position conversion device comprises a rail mounted on the bottom plate and a sliding seat forming a moving pair with the rail, and the sliding seat is connected with a transmission belt; the sliding seat is provided with a horizontal bracket driven by a jacking cylinder; and supporting claws are distributed on the horizontal bracket at intervals. The production efficiency is remarkably improved, the quality can be guaranteed, and the device is suitable for metal hoses of various lengths and has good adaptability.

Owner:AEROSUN CORP

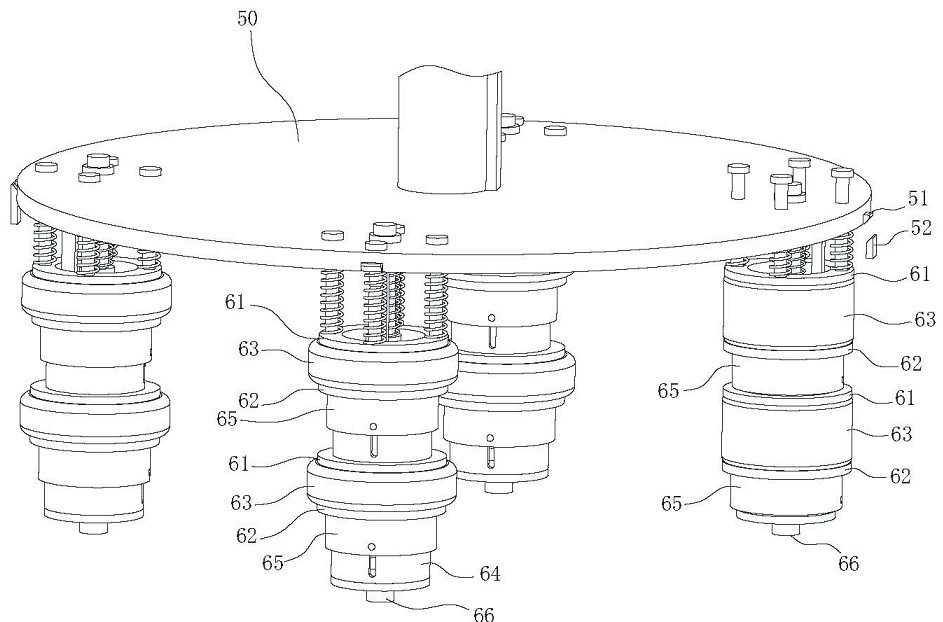

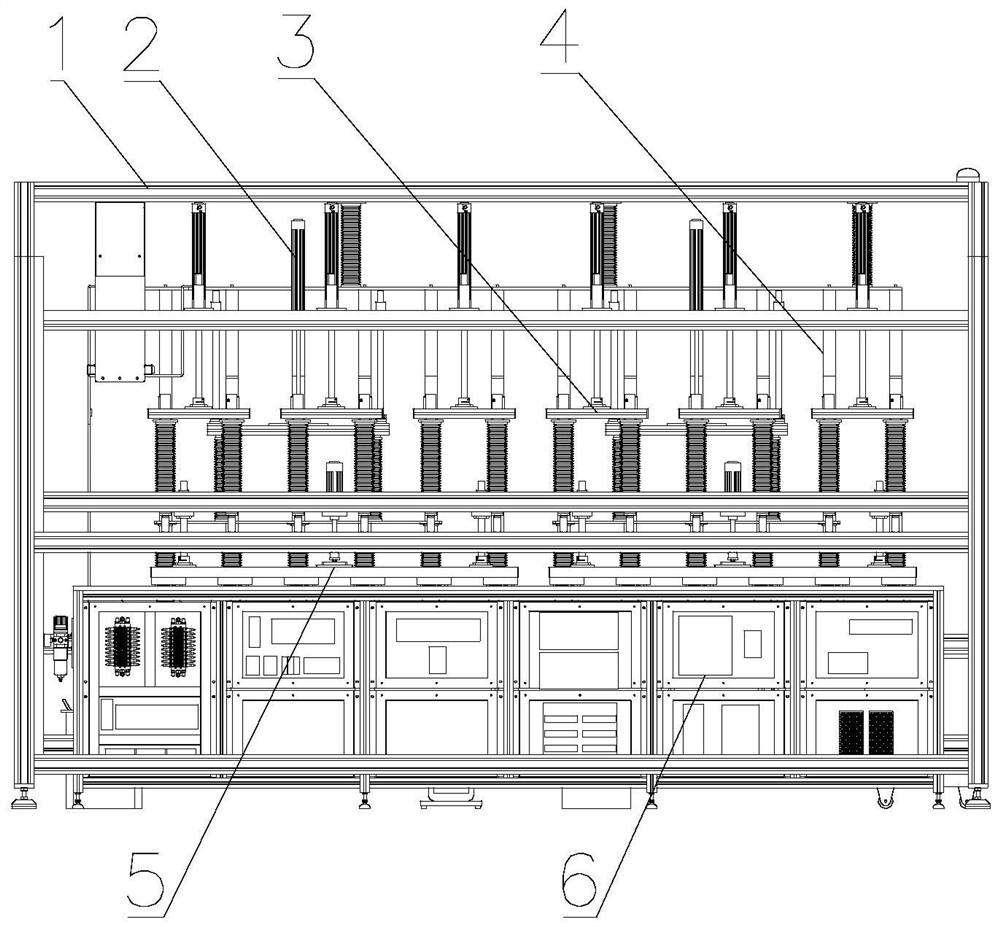

Full-automatic high-voltage transformer insulation withstand voltage testing device

PendingCN112051491AEfficient integrationSmall footprintTesting dielectric strengthVery high resistance measurementsSmall footprintMechanical engineering

The invention discloses a full-automatic high-voltage transformer insulation withstand voltage testing device, which comprises an aluminum profile frame, and is characterized in that the aluminum profile frame is provided with a high-voltage switching pneumatic device, a transformer primary side wiring mechanism, a high-voltage conductive copper bar, a transformer secondary side wiring mechanism,an electrical testing function module, a roller conveying line and an electrical testing instrument. The device is efficient in integration and small in occupied area. The device provided by the scheme can sequentially carry out insulation resistance measurement and a power frequency withstand voltage test on the high-voltage current transformer and the high-voltage voltage transformer, and considers an induction withstand voltage test, an error test and an excitation characteristic test of the high-voltage voltage transformer. A current transformer insulation withstand voltage test and a voltage transformer full-inspection test are integrated into one body. The device is suitable for calibrating the high-voltage transformer.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

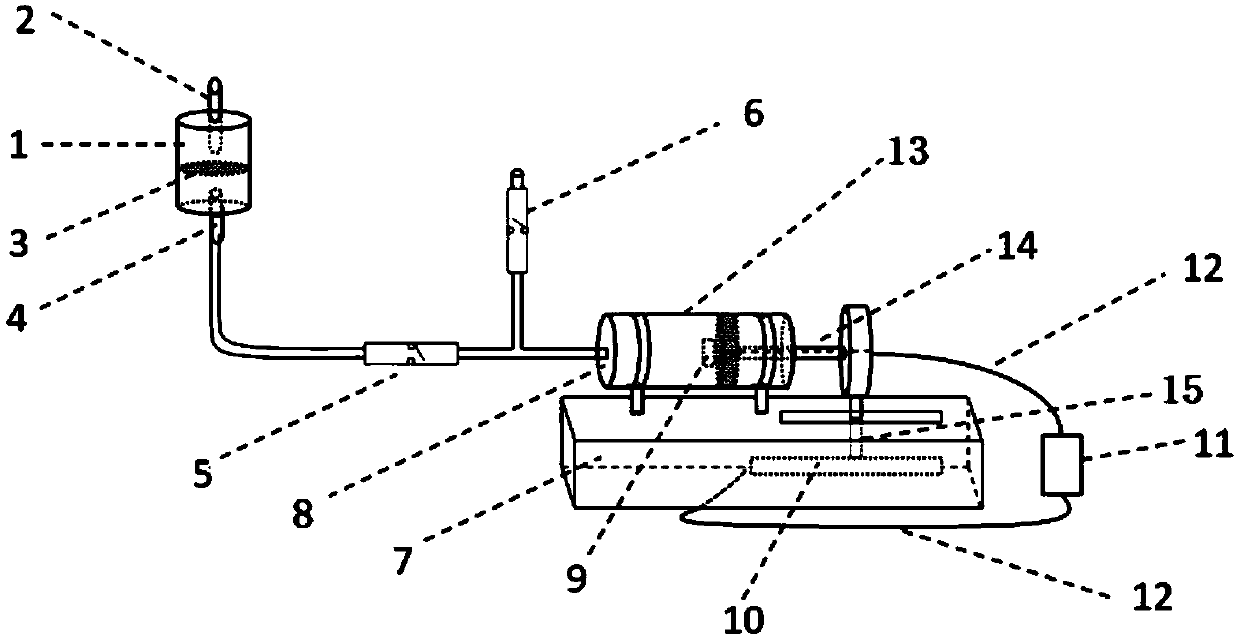

Gastrointestinal digestive fluid circulation instrument

PendingCN111249540ATimely and safe circulationRealize full closed circulationIntravenous devicesSuction drainage systemsAutomatic controlEngineering

The invention provides a gastrointestinal digestive fluid circulation instrument. The instrument consists of a fluid storage bottle (1), a fluid inlet pipe (2), a fluid outlet pipe (4), a one-way fluid inlet valve (5), a one-way fluid outlet valve (6), a base (7), a suction-propulsion device (8), a bidirectional translation motor (10) and an automatic control device (11), wherein the fluid inlet pipe (2) and the fluid outlet pipe (4) are connected with the upper end and the lower end of the fluid storage bottle (1) respectively; the other end of the fluid outlet pipe (4) is connected with thesuction-propulsion device (8); the suction-propulsion device (8) consists of an outer sleeve (13) and a suction-propulsion rod (14); a pressure sensor (9) is arranged in a tube cavity of the suction-propulsion device (8); the automatic control device (11) controls the bidirectional translation motor (10) to drive the suction-propulsion rod (14) to perform suction or propulsion motion according toa set control program and a command, so a digestive fluid retained at the upper section of an obstruction part can be timely and safely input back to the digestive tract at the lower section of the obstruction part, gastrointestinal digestive fluid circulation is realized, and loss of a large amount of components such as water, electrolytes and proteins is avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

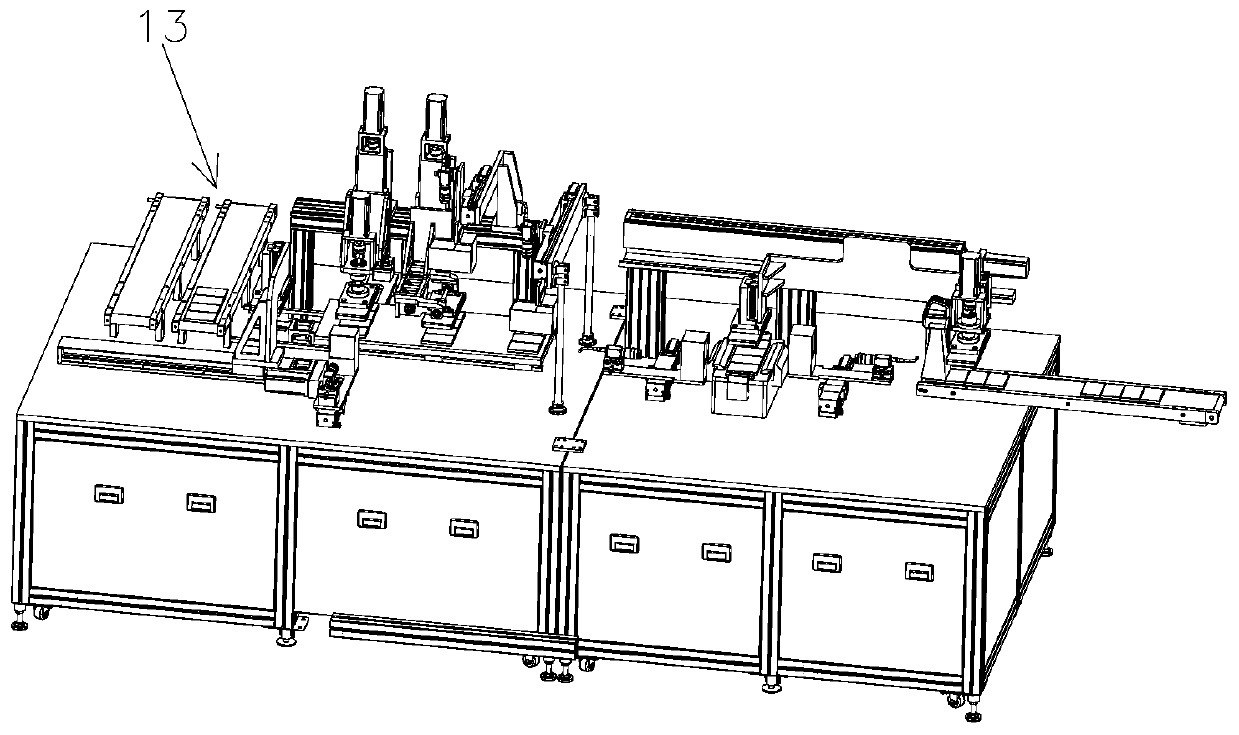

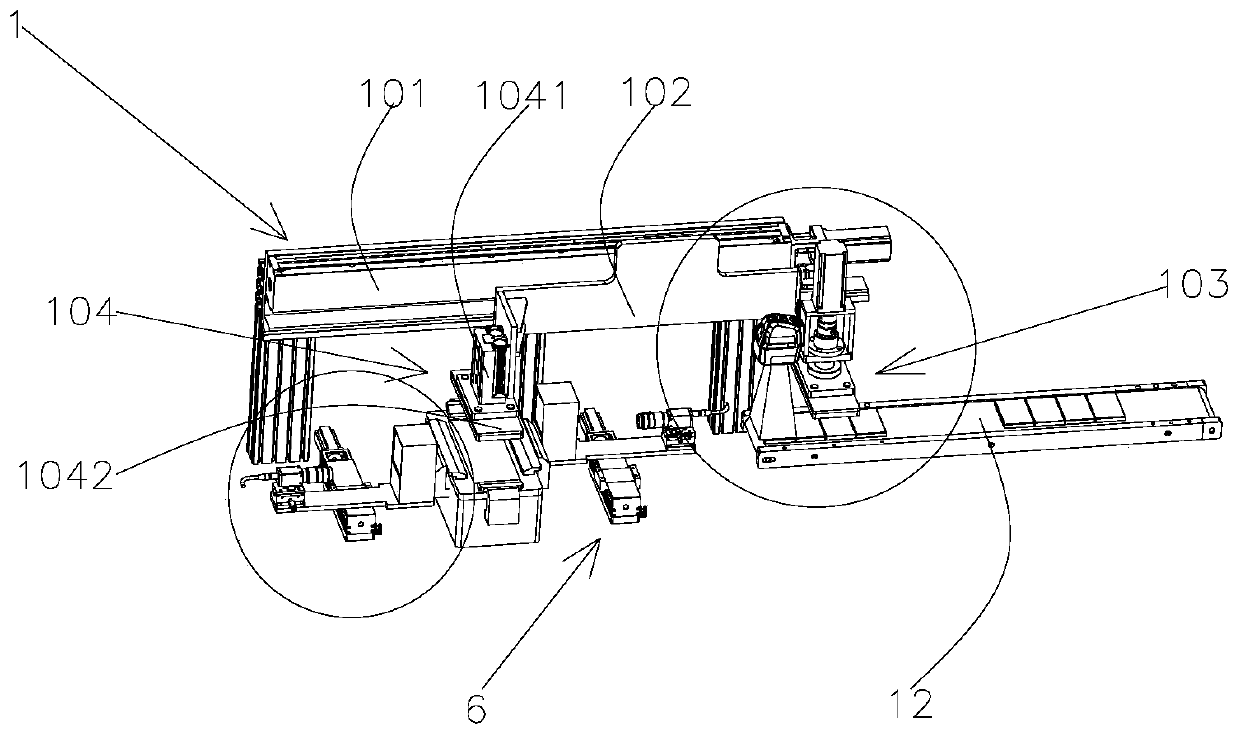

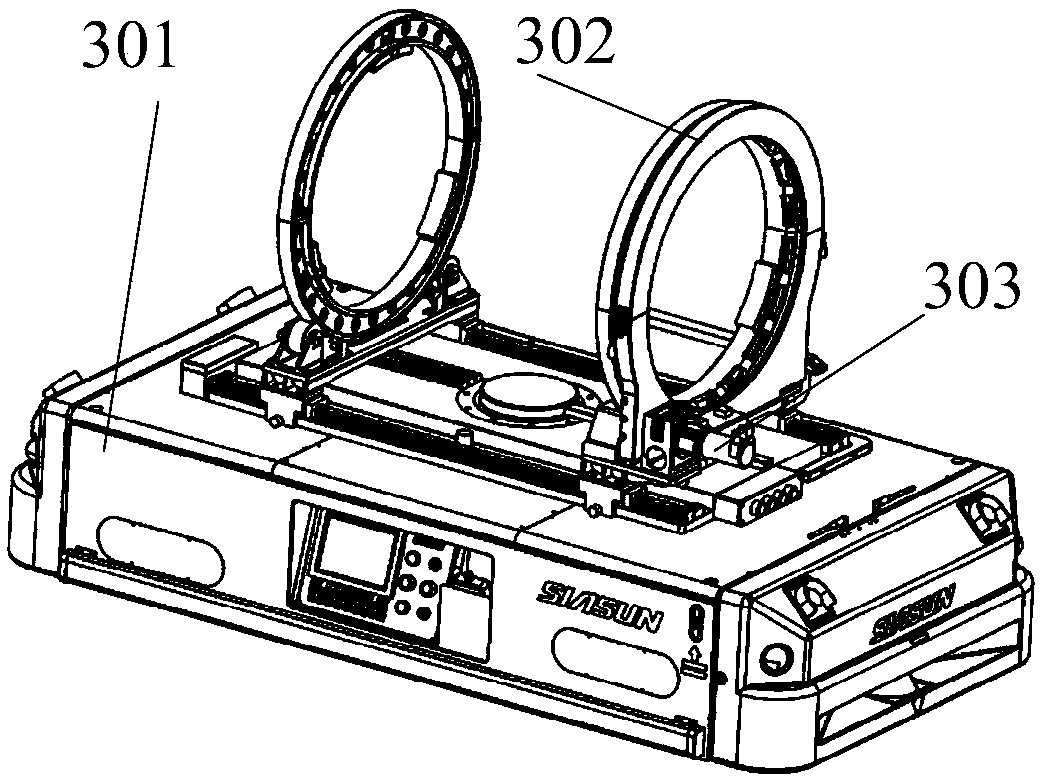

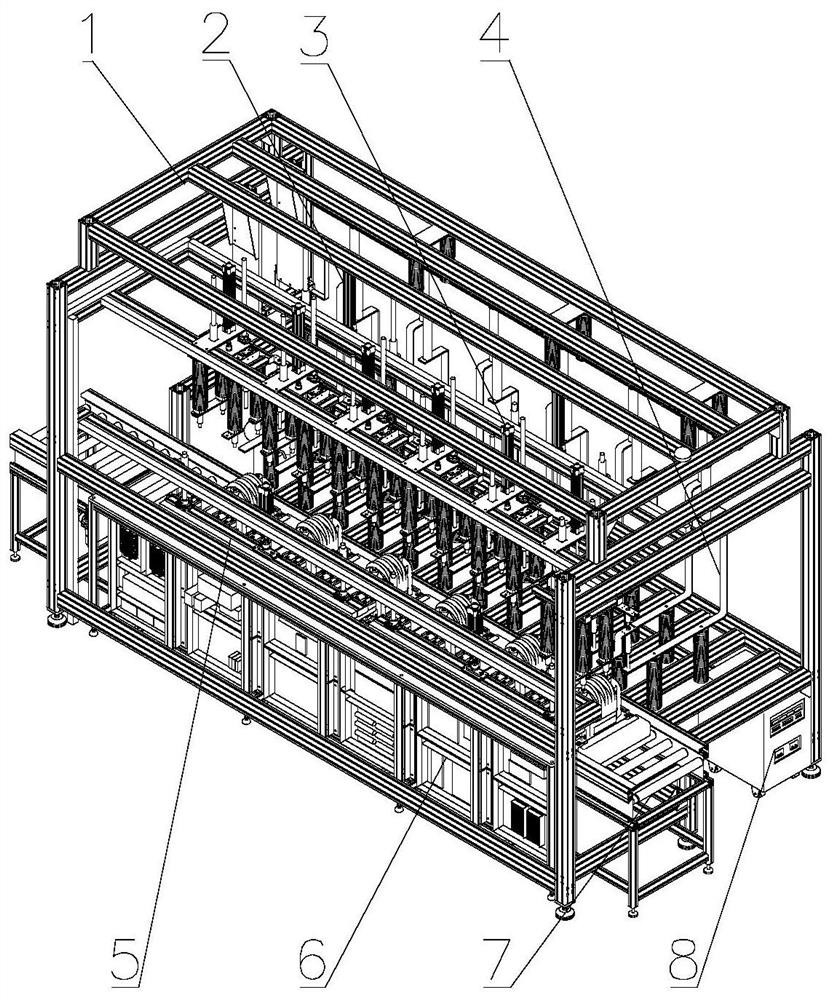

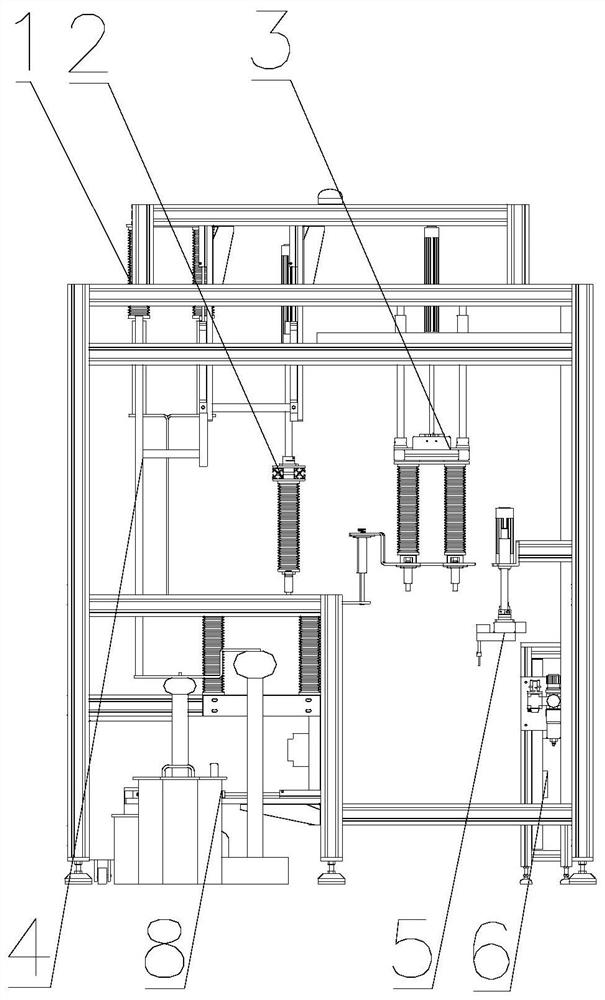

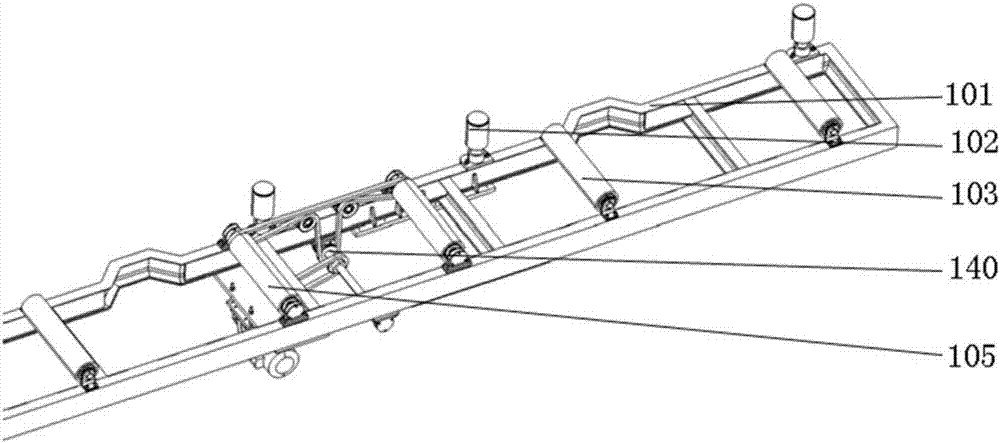

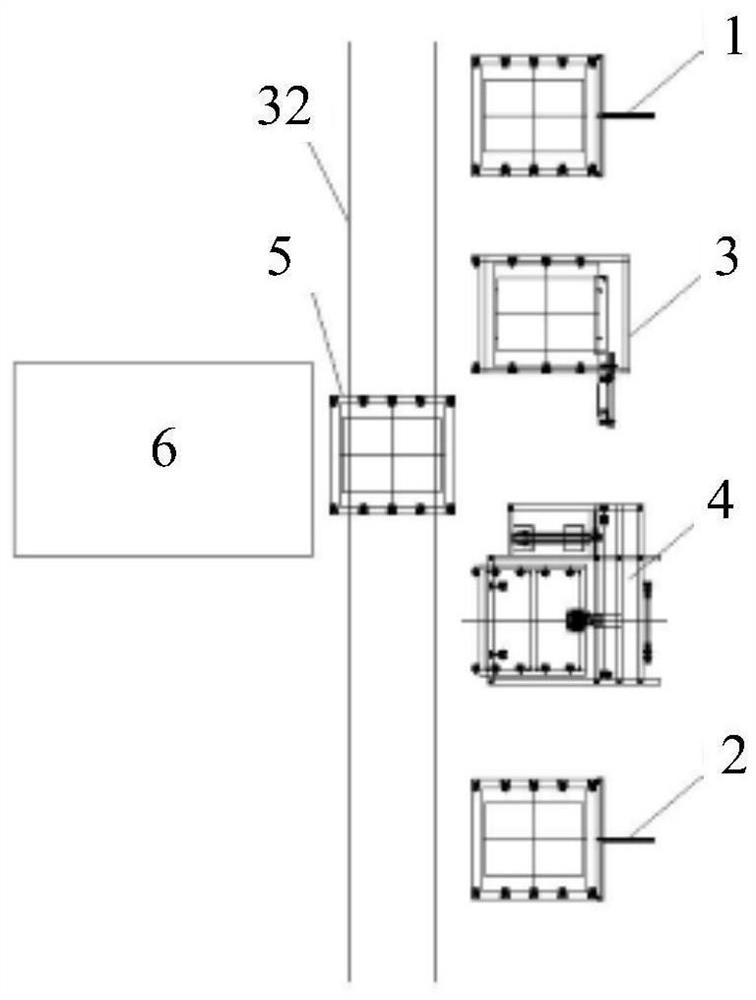

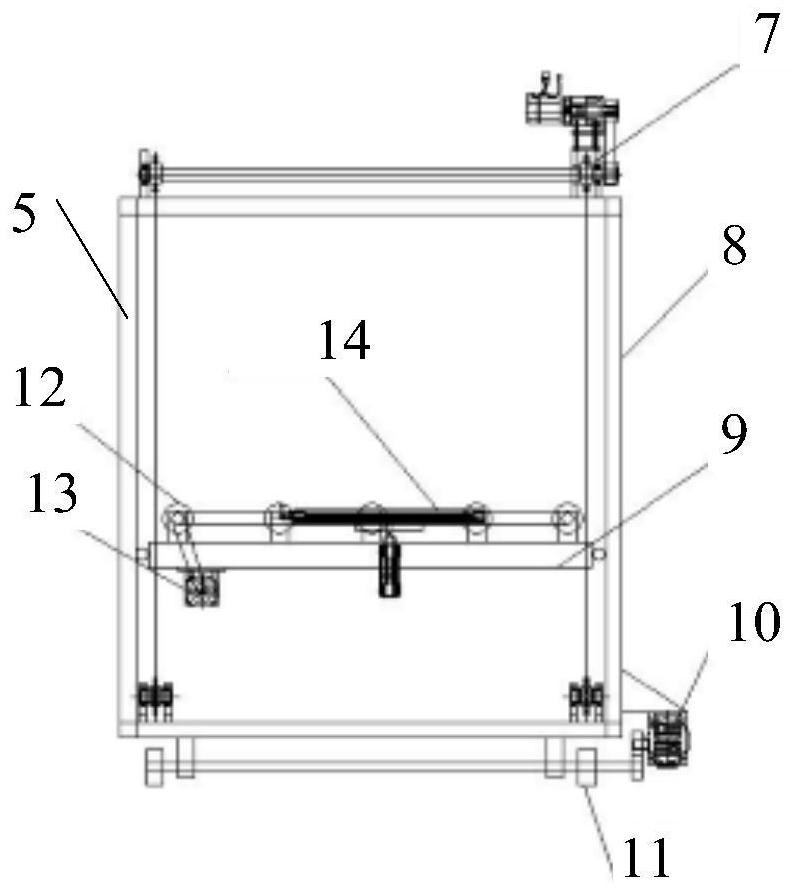

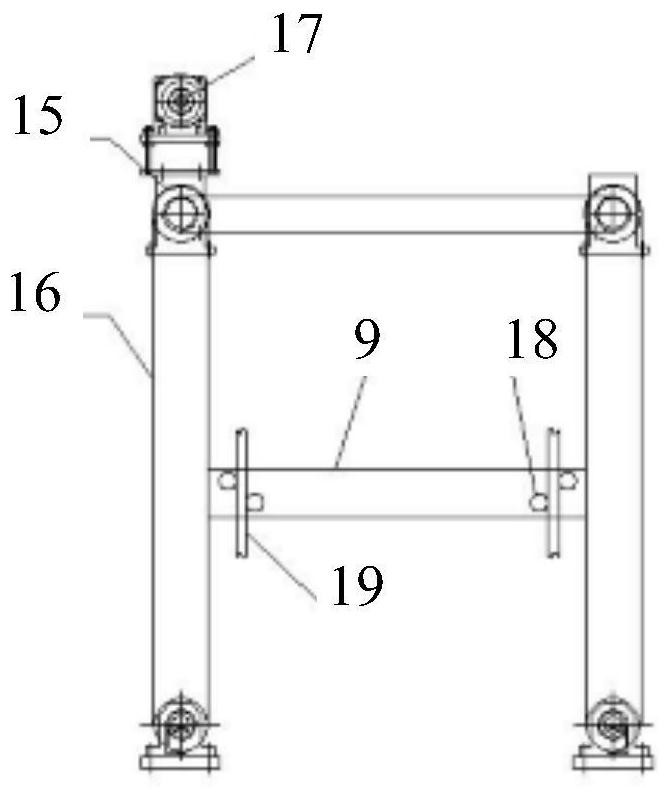

Jig circulation system and terminal testing system

PendingCN109761014AAchieve circulationRealize automatic circulationConveyor partsMechanical conveyorsEngineeringTraining set

The invention provides a jig circulation system and a terminal testing system. The jig circulation system comprises jigs, a feeding device, testing devices and a discharging device, the feeding devicecomprises a first lifting mechanism which drives the jigs to move in the vertical direction, and a first translation mechanism which is used for carrying and translating the jigs; the testing devicescomprises upper-layer translation mechanisms and lower-layer translation mechanisms, wherein the upper-layer translation mechanisms and the lower-layer translation mechanisms are both used for carrying and translating the jigs; and the discharging device comprises a second lifting mechanism which drives the jigs to move in the vertical direction, and s second translation mechanism which is used for carrying and translating the jigs. According to the jig circulation system and the terminal testing system, the jigs sequentially pass through the upper-layer first translation mechanism, the upper-layer translation mechanism, the second translation mechanism and the lower-layer translation mechanism, and finally returns to the first translation mechanism to realize automatic circulation of thejigs.

Owner:SHENZHEN ITC TECH

Feeding and discharging device of miniature straightening machine

InactiveCN112407921ARealize automatic feeding processRealize automatic unloading and storageLifting framesConveyor partsStructural engineeringMachine

The invention discloses a feeding and discharging device of a miniature straightening machine. The feeding and discharging device comprises a frame, a first fixed plate, a second fixed plate, a movable plate mechanism, a movable plate air cylinder, a lifting mechanism, a grabbing mechanism and a workpiece storage box; the first fixed plate and the second fixed plate are arranged at one end of theframe, and the first fixed plate and the second fixed plate can move relatively and move in the horizontal direction; the movable plate mechanism is arranged between the two fixed plates; the movableplate air cylinder is arranged at the bottom of a fixed plate mechanism; the lifting mechanism is arranged on one sides of the two fixed plates; the grabbing mechanism is arranged on one side of the lifting mechanism, and the grabbing mechanism can move horizontally and longitudinally along the frame; and the workpiece storage box is arranged at the other end of the frame in a supporting mode andlocated on one side of the grabbing mechanism. Workpieces are fed through mutual cooperation of the sawtooth-shaped fixed plate mechanism and two movable plates, sorting of the workpieces is completedthrough cooperation of the lifting mechanism and the grabbing mechanism, and unattended operation of micro shaft straightening is achieved.

Owner:中机试验装备股份有限公司

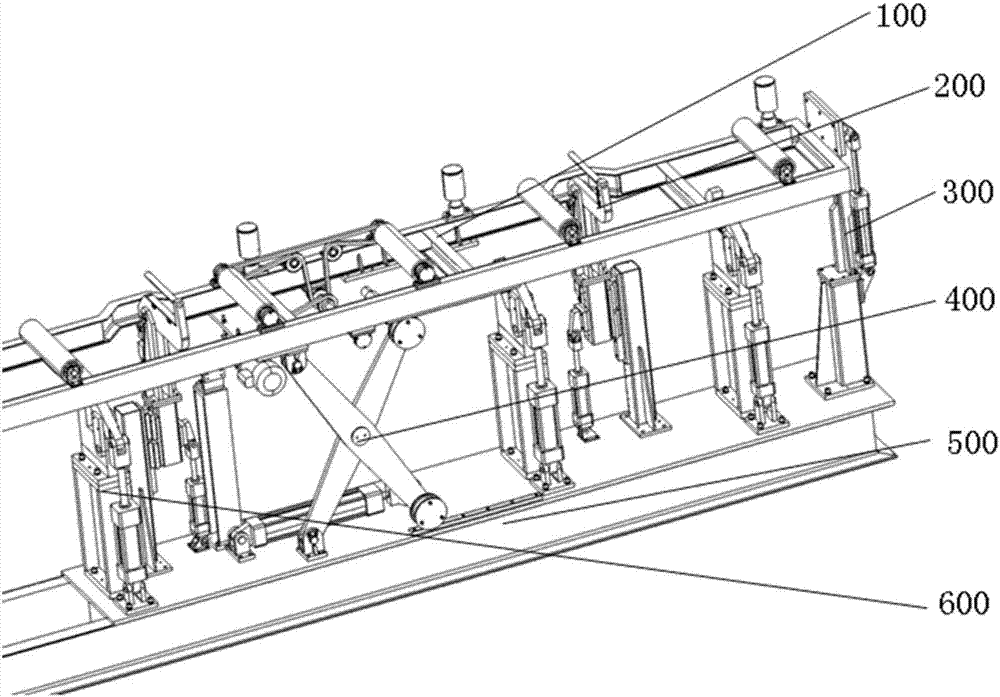

Circulating system of automotive frame

InactiveCN107052644ARealize automatic circulationWelding/cutting auxillary devicesAuxillary welding devicesPositioning systemRivet

The invention relates to a circulating system of an automotive frame. The circulating system comprises a circulating system body, an overturning system, a limiting system, a jacking system, a bottom plate system and a clamping and positioning system. The jacking system, the limiting system, the overturning system and the clamping and positioning system are fixedly arranged on the bottom plate system. The circulating system and the jacking system are connected in a sliding and overlapping manner, and in the moving process, the jacking system drives the circulating system body to synchronously move. According to the technical scheme, free posture switching of the automotive frame in the circulating and rivet welding process is achieved through the circulating system body, the jacking system and the overturning system, and automatic circulating of the automotive frame among all working procedures is achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

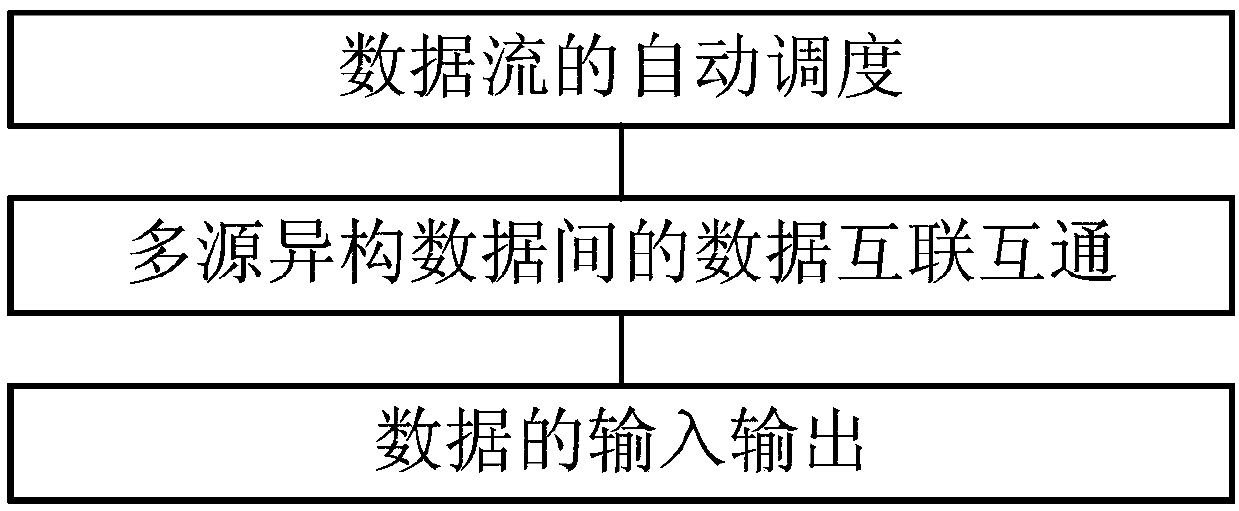

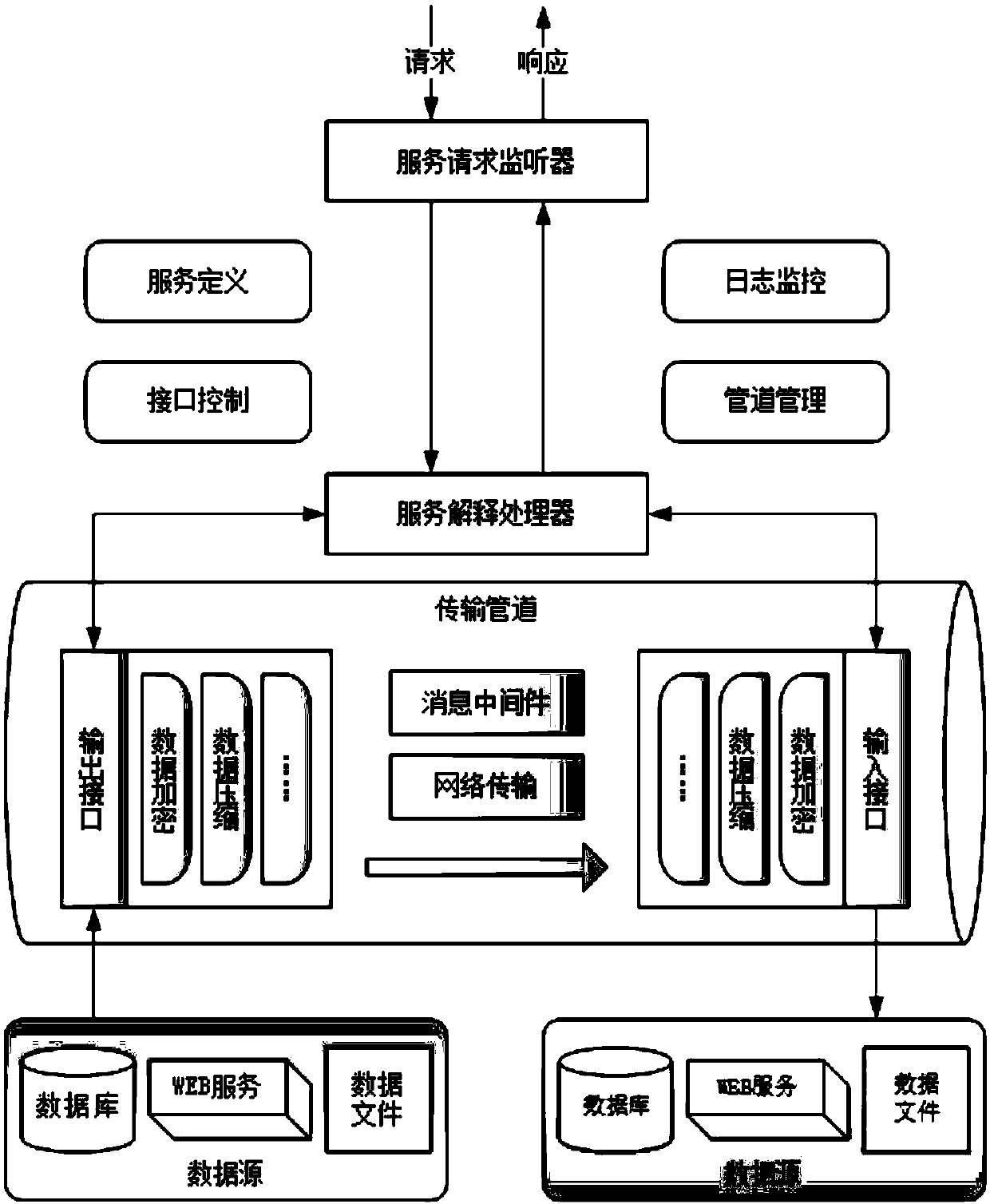

A Data Exchange Method Based on Service Bus

ActiveCN106709016BRealize automatic circulationEffective input and outputDatabase distribution/replicationData miningData streamData source

The invention discloses a data exchange method based on a service bus, which includes the following processes: automatic scheduling of data streams: automatic scheduling of multiple data sources in the form of data streams; data interconnection among heterogeneous data from multiple sources: The source heterogeneous data is extracted and transformed, and the processed data is exchanged with the source data; data input and output: effective input and output of multi-source heterogeneous data. The present invention automatically schedules, extracts, and transforms multiple data sources in the form of data streams, exchanges or forwards processed data with source data to other target locations, effectively inputs and outputs multi-source heterogeneous data, and realizes data streams by using The service bus for automatic scheduling and exchange uses the data exchange engine to collect and process data call service requests, and realizes data sharing and exchange through data interfaces. Make all business data interconnected, realize the automatic flow of data in the system, and facilitate participation in the upper-level business process.

Owner:山东麦港数据系统有限公司

Material transfer conveying device for constructing automatic production line

InactiveCN111776684APrevent slippingWhen sliding to the transfer table, the limit table is in the sliding position of the material to avoidConveyorsControl devices for conveyorsProduction lineDrive shaft

The invention relates to a material transfer conveying device for constructing automatic production line. The material transfer conveying device comprises a base, a front leading port, a rear leadingport, a guiding plate and a transfer table, wherein a lifting drive device is arranged at the top of the base, a drive shaft of the lifting drive device is connected with the bottom of the transfer table, and a butt joint notch is formed in the left end of the transfer table; and an adjusting air cylinder and an electric screw rod assembly are arranged on each of two sides of the transfer table, and a clamp part is detachably connected onto an air cylinder shaft of each adjusting air cylinder. According to the material transfer conveying device, the guiding plate guides a material of front equipment to reach the transfer table, the material is subjected to position adjusting and correcting on the transfer table, then the transfer table is lifted to correspond to the rear leading port, thematerial is transferred to rear equipment in a fixed state, accurate and order processing for the material is conveniently performed in the rear equipment, meanwhile, automatic circulation of the material is realized, and production efficiency and production quality of the automatic production line are effectively improved.

Owner:CHENGDU HENGLIDA TECH

Agricultural machinery gear machining device and machining method thereof

PendingCN114131348ARealize automatic circulationReduce turnaround timeOther manufacturing equipments/toolsGear wheelAgricultural engineering

The invention discloses an agricultural machinery gear machining device and a machining method.The agricultural machinery gear machining device comprises a bottom plate, and a feeding assembly used for automatic feeding is installed above the bottom plate; a punching assembly used for machining the agricultural machine gear connecting hole, an inner hole grinding assembly used for grinding the connecting hole and a cleaning assembly used for cleaning burrs of the agricultural machine gear connecting hole and the outer wall are sequentially installed on the outer side of the feeding assembly. By installing the punching assembly, the inner hole grinding assembly, the cleaning assembly and the feeding assembly, agricultural machine gear blanks can be conveyed above the feeding assembly and sequentially machined through the punching assembly, the inner hole grinding assembly and the cleaning assembly, automatic circulation and automatic machining among all procedures are achieved, meanwhile, the machining process is stable, and the machining quality is high; the overall machining efficiency is improved, and the yield is improved.

Owner:盐城泽华精工机械有限公司

Automatic tray sequence transfer equipment

InactiveCN111824650ARealize automatic circulationSave human effortConveyorsStorage devicesEngineeringMechanical engineering

The invention discloses automatic tray sequence transfer equipment. The equipment comprises a sequence transfer vehicle and a temporary storage frame, wherein the sequence transfer vehicle comprises avehicle body, a conveying mechanism and a first lifting mechanism, the first lifting mechanism comprises a lifting frame which is arranged on the vehicle body in a liftable manner and a first liftingdriving mechanism which drives the lifting frame to ascend and descend, the conveying mechanism is arranged on the lifting frame, and the conveying mechanism is used for bearing trays and conveying the trays to the outside of the vehicle body through the side outlet of the vehicle body; and the temporary storage frame comprises a multi-layer frame body, a second pushing mechanism and a second lifting mechanism, wherein each layer of frame body is used for bearing one tray, the second pushing mechanism is arranged on one side of the multi-layer frame body in a liftable manner, the second lifting mechanism drives the second pushing mechanism to ascend or descend to the position of one layer of frame body, and the second pushing mechanism is used for pushing the tray carried on the one layerof frame body to the outside of the temporary storage frame via the side outlet on the other side of the temporary storage frame. According to the equipment, the automatic circulation of the trays among stations is realized, the manpower is saved, and the production efficiency is improved.

Owner:京磁材料科技股份有限公司

Full-automatic soil sample preparation system

PendingCN114018668ARealize automatic circulationPreparing sample for investigationSoil scienceDry soil

The invention provides a full-automatic soil sample preparation system. The system comprises a drying assembly used for drying a wet fresh soil sample to prepare a moisture-free dry soil sample, a screening assembly which is used for screening out impurities in the soil sample, a grinding assembly which is used for grinding the soil sample according to preparation requirements, so as to make the soil sample prepared into a soil sample with a proper particle size, a weighing assembly which is used for weighing the soil sample in at least one link of soil sample preparation, a transfer assembly which is used for enabling the soil sample in each link of soil sample preparation to flow among different assemblies, a sample loading assembly which is used for loading the soil sample in at least one link of soil sample preparation, and a monitoring assembly which is used for monitoring information and data generated in each link in the soil sample preparation process. By means of the system, automatic dry soil sample preparation can be achieved, and various problems of manual operation in the prior art are solved.

Owner:北京兰友科技有限公司

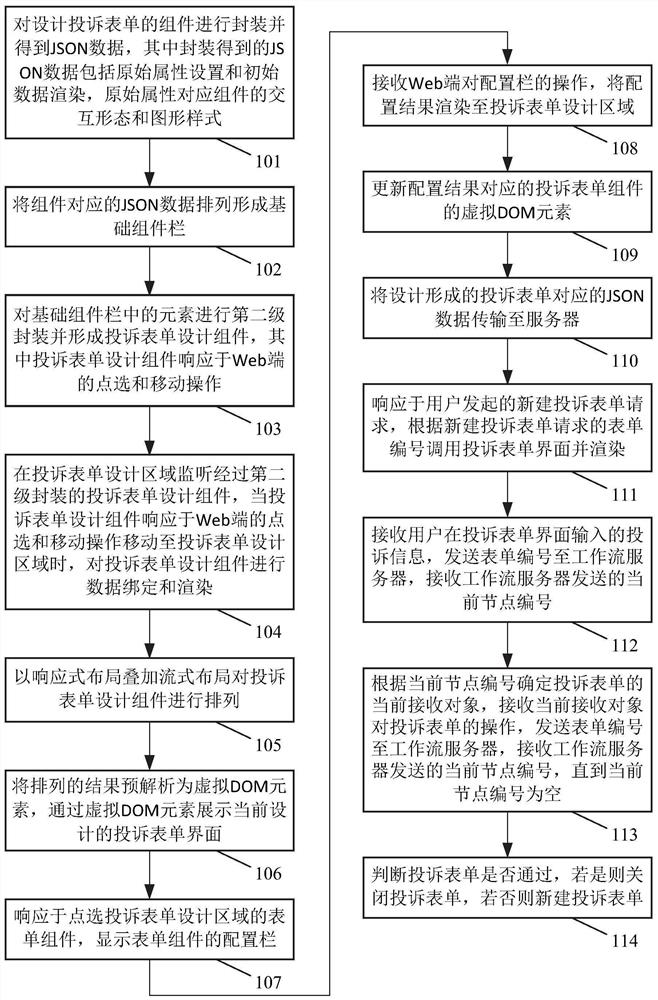

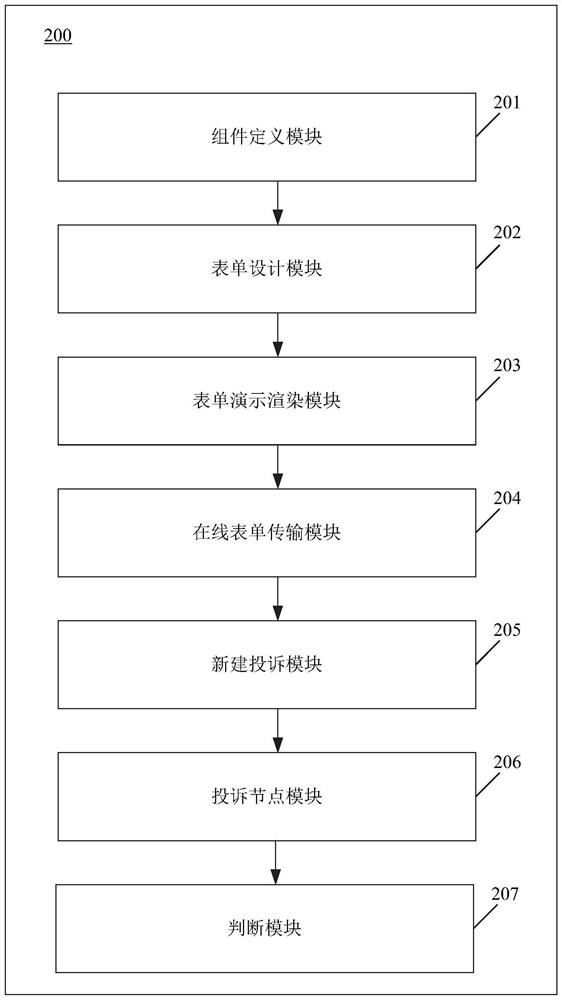

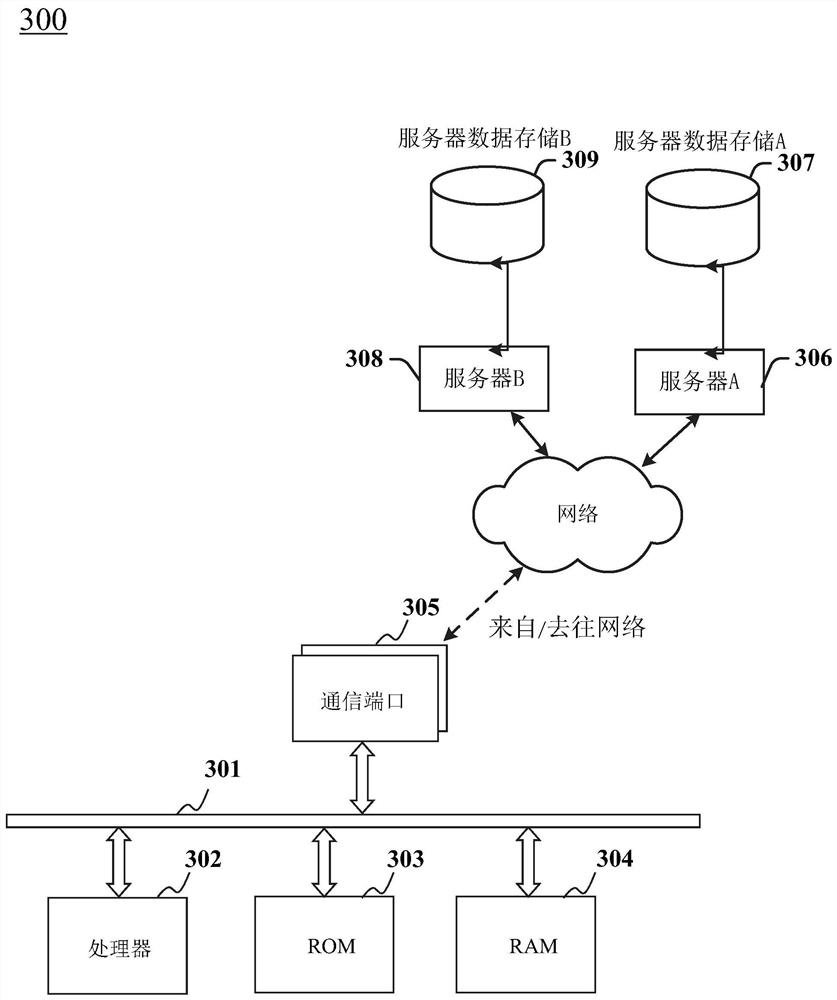

Implementation method, device and system of Web end complaint form designer

ActiveCN111930379AHigh degree of customizationHighly flexible design freedomSoftware engineeringCommerceSoftware engineeringServer

The invention provides an implementation method, device and system of a Web end complaint form designer. The implementation method comprises the steps of packaging and arranging the parts for designing a complaint form to form a basic part column; carrying out second-stage packaging on the elements; performing corresponding data binding and rendering on the complaint form design part; arranging the complaint form design parts, pre-analyzing the complaint form design parts into virtual DOM elements, and displaying an interface; receiving an operation of the Web side on the configuration bar, and rendering a configuration result to a complaint form design area; updating the virtual DOM elements and transmitting the virtual DOM elements to a server; calling a complaint form interface according to the request; complaint information is received, a form number is sent to a workflow server, and a current node number is received; determining a current receiving object, receiving an operation of the current receiving object, sending a form number to a workflow server, and receiving a current node number until the current node number is empty; judging whether the complaint form passes or not, if yes, closing the complaint form, and if not, creating a new complaint form.

Owner:上海太美星云数字科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com