Mechanical arm drilling device and drilling method adapting to automatic logistics

A technology of hole-making device and robotic arm, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as errors that cannot be eliminated, achieve the effects of improving work efficiency, realizing automatic circulation, improving positioning accuracy and measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

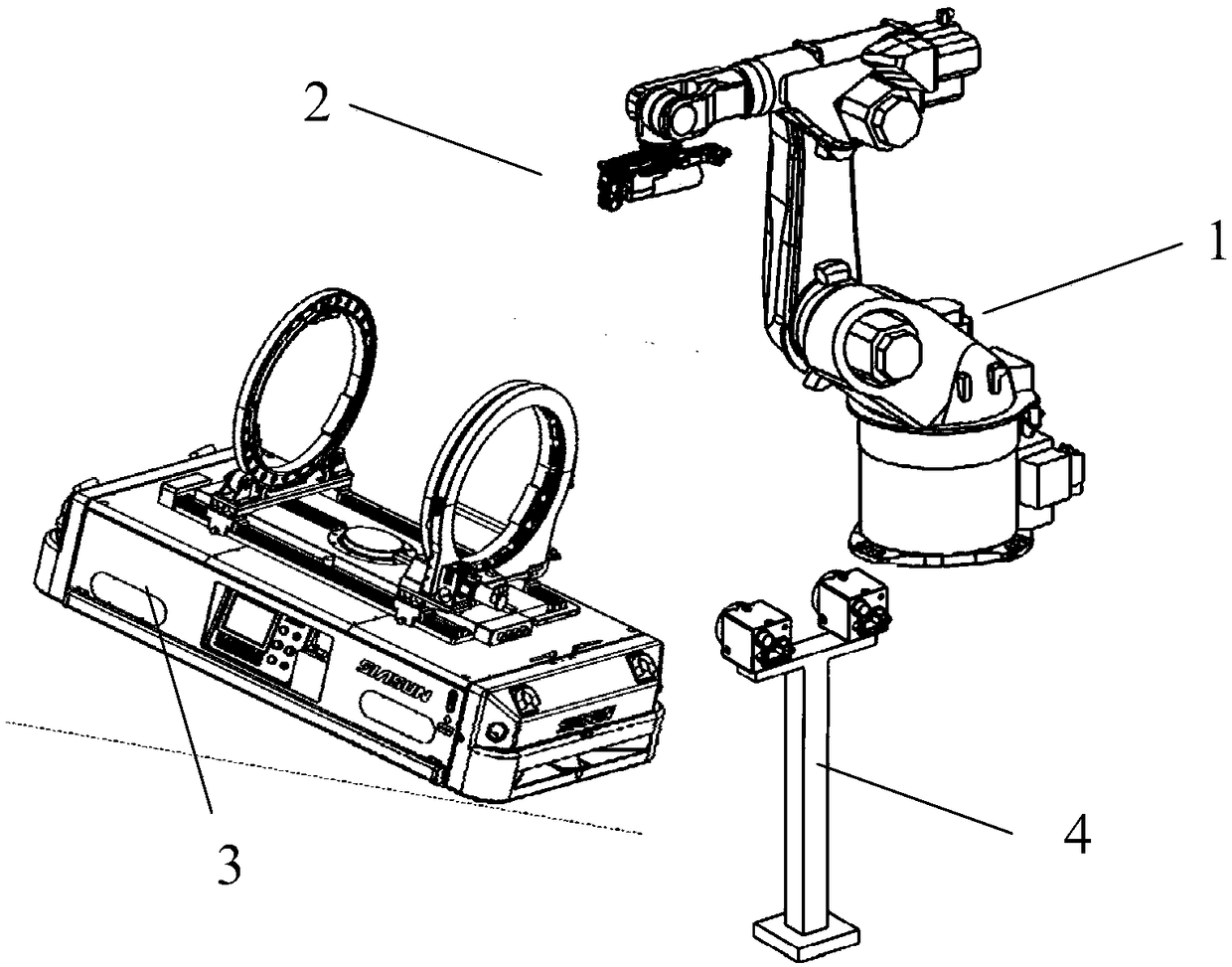

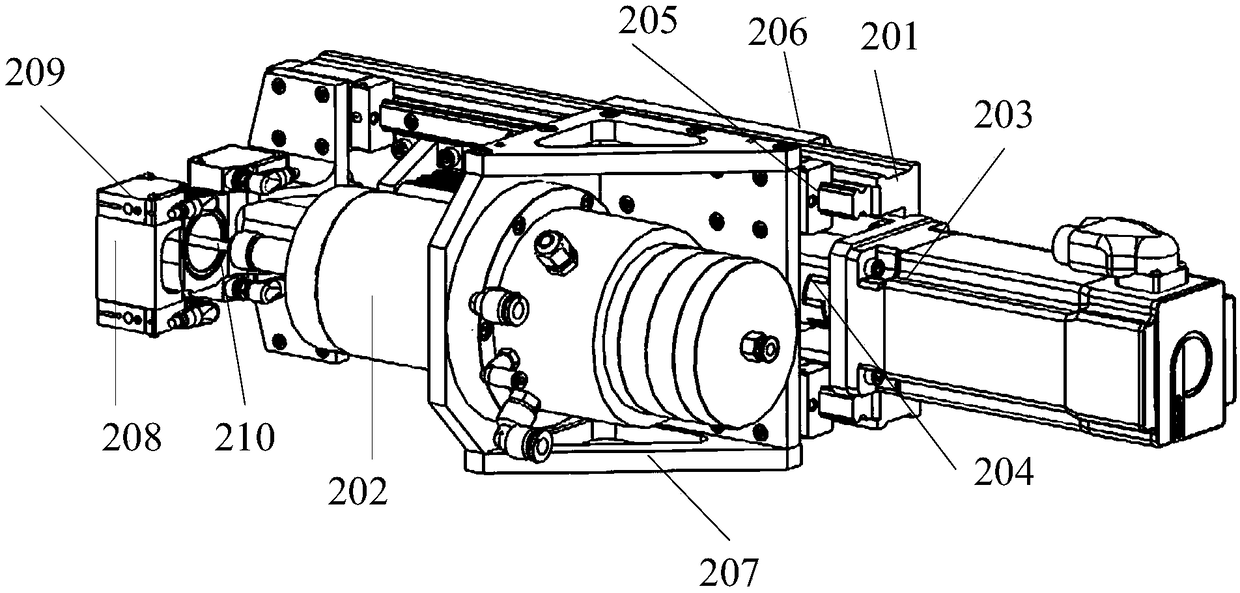

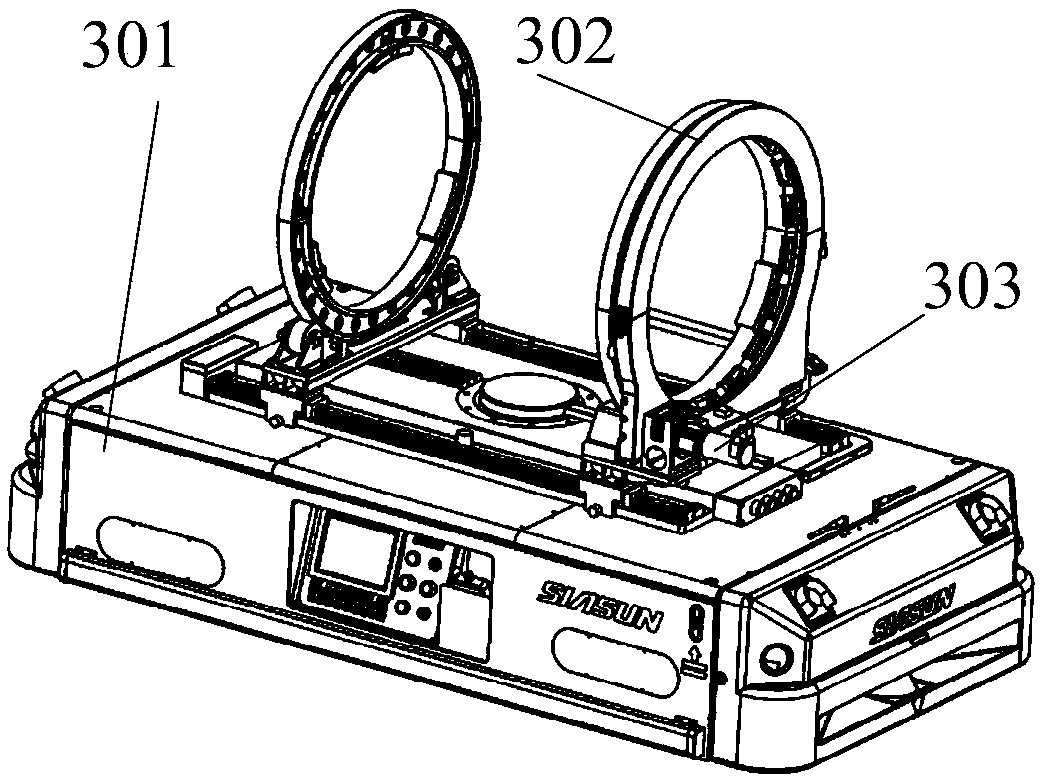

[0029] A mechanical arm hole-making device adapted to automatic logistics, such as figure 1 As shown, it includes a tandem robot arm 1, a hole-making end effector 2, an automatic logistics vehicle 3, a visual measurement component 4, and a controller. The hole-making end effector 2 is installed on the tandem machine for adapting the clamping position of the hole-making product. At the flange of the port of the arm 1, and driven by the mechanical arm 1 in series, the hole-making products are processed, and the automatic logistics vehicle 3, which is used to drive the hole-making products to perform full-circle rotation and position and spacing adjustment, is used for hole-making work. It is fixed under the tandem robot arm 1 and the hole-making end effector 2, and the visual measurement component 4 is fixedly installed on the ground on one side of the automatic logistics vehicle 3 to take pictures and measure the automatic logistics vehicle 3 in the designated position, and at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com