Agricultural machinery gear machining device and machining method thereof

A processing device and agricultural machinery technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of affecting output and lowering processing efficiency, and achieve the effect of reducing circulation time, reducing manual operation, improving processing efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

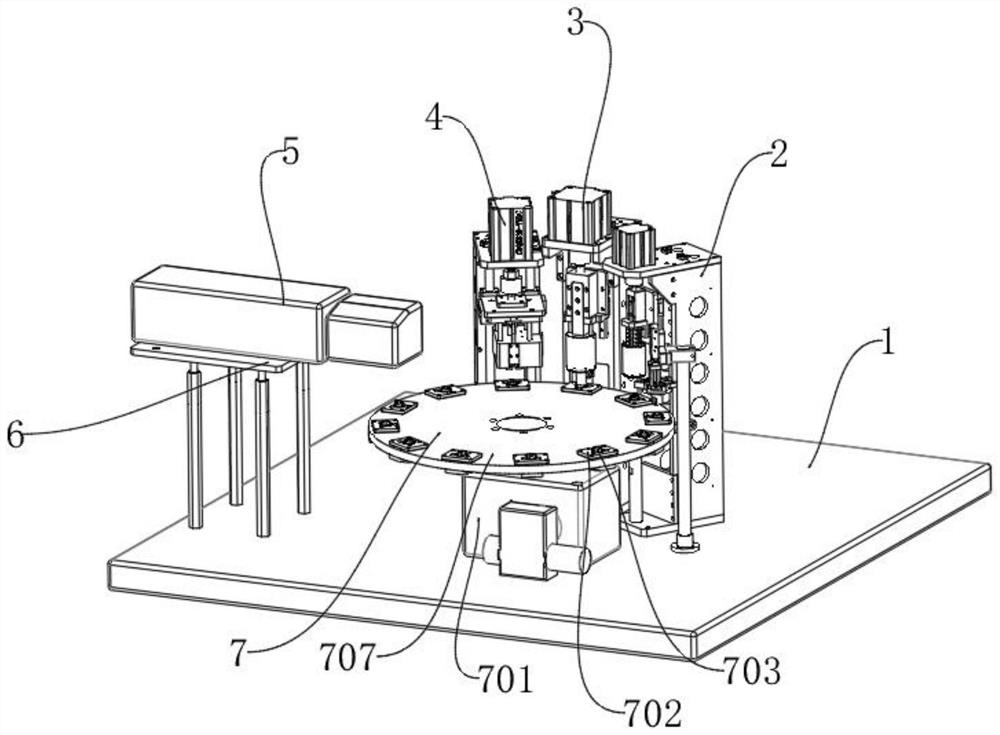

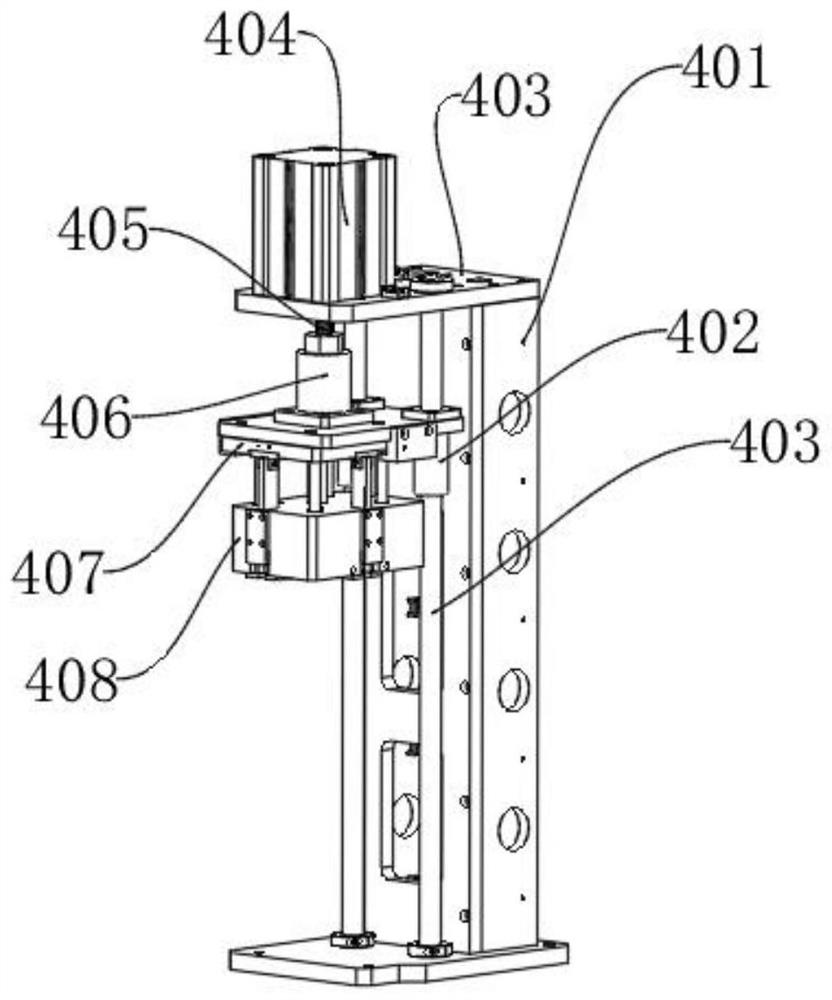

[0032] Such as Figure 1-Figure 5 As shown, an agricultural machinery gear processing device of the present invention includes a base plate 1, a feeding assembly 7 for automatic feeding is installed above the base plate 1, and a punching assembly 2 for processing the connecting holes of agricultural machinery gears is installed in sequence on the outside of the feeding assembly 7 , the inner hole grinding assembly 3 for grinding the connection hole and the cleaning assembly 4 for cleaning the connection hole of the agricultural machinery gear and the burr on the outer wall, the marking machine mounting seat 6 is installed on the outside of the cleaning assembly 4, and the marking machine mounting seat 6 is installed Marking machine5.

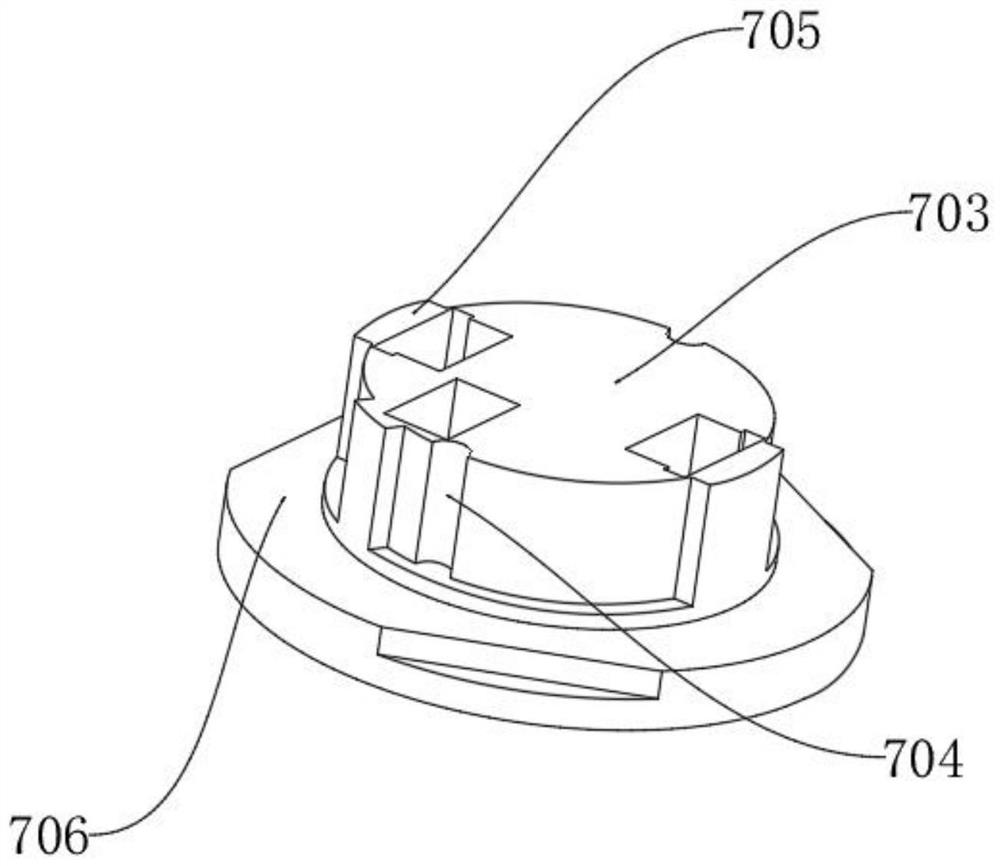

[0033] Preferably, the feeding assembly 7 includes a feeding motor 701, a receiving plate 707 and a connecting seat 703, the feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com