Circulating system of automotive frame

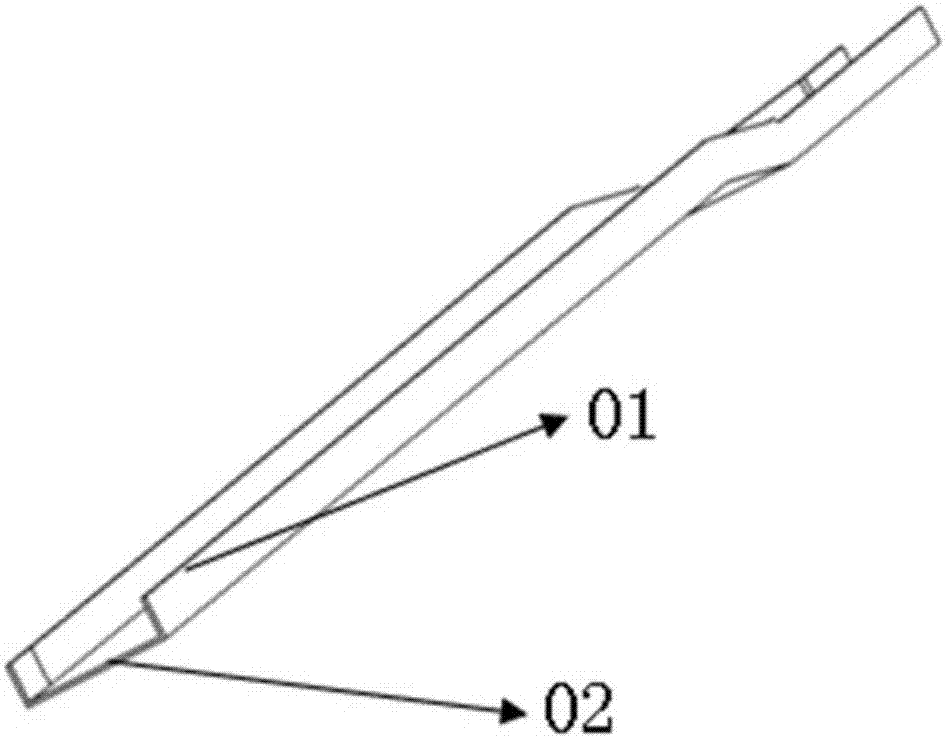

A technology for automobile girders and rotating plates, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as difficulty in maintaining the posture of automobile girders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

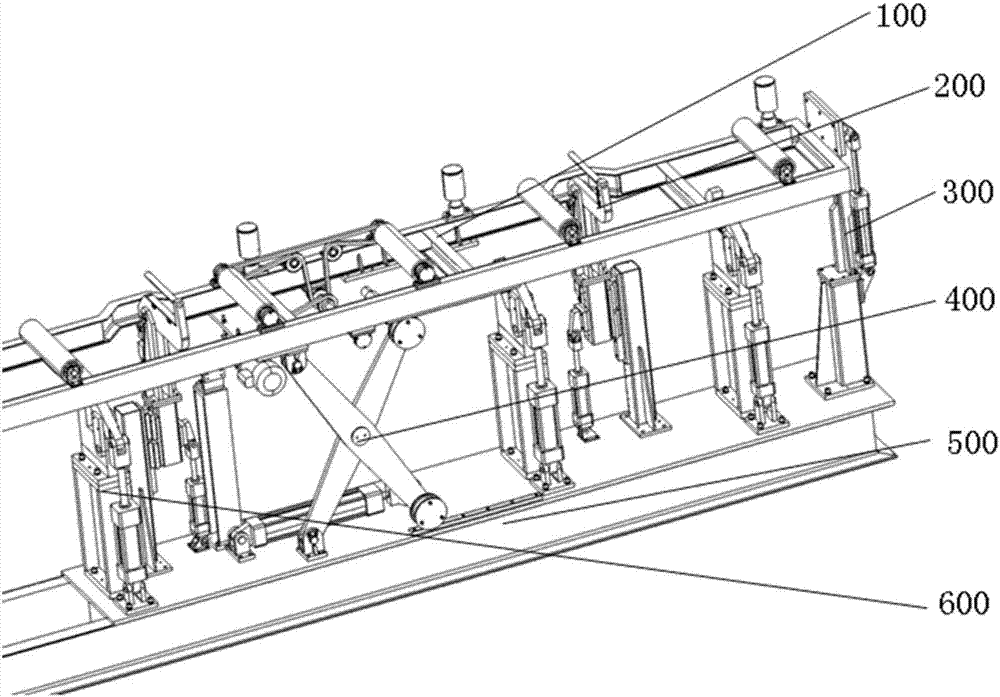

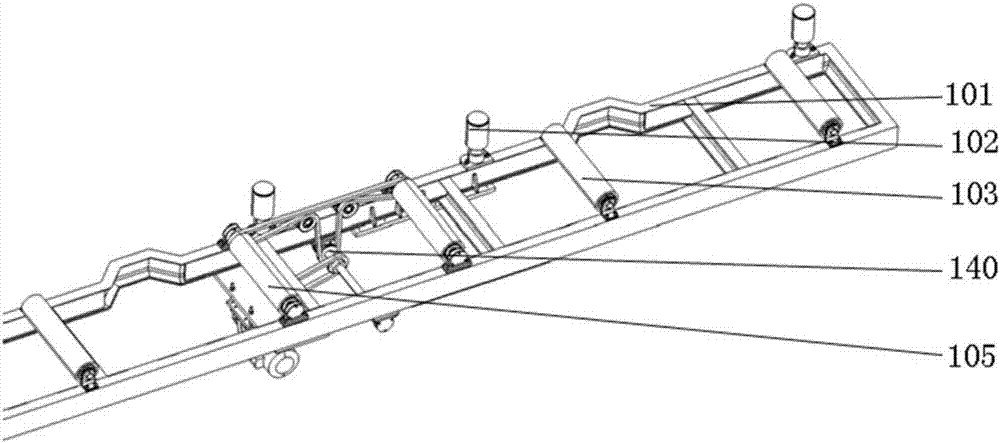

[0044] Such as figure 2 As shown, the present application provides a circulation system for an automobile frame, including a circulation system 100 , an overturning system 200 , a limit system 300 , a jacking system 400 , a floor system 500 and a clamping and positioning system 600 .

[0045] The jacking system 400, the limit system 300, the overturn system 200 and the clamping and positioning system 600 are all fixedly installed on the floor system 500; the overturn system can change the posture of the automobile frame, and the limit system is used to control the circulation process of the automobile frame The extreme position in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com