Combined mold-core insert core full-automatic feeding, discharging and detachment mechanism in cooperation with injection molding machine

A technology for inserting mold cores and injection molding machines, applied in the direction of coating, etc., can solve problems such as reducing production efficiency, increasing production costs, and damaging molds, and achieves the goals of improving production efficiency and automation, improving circulation efficiency, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

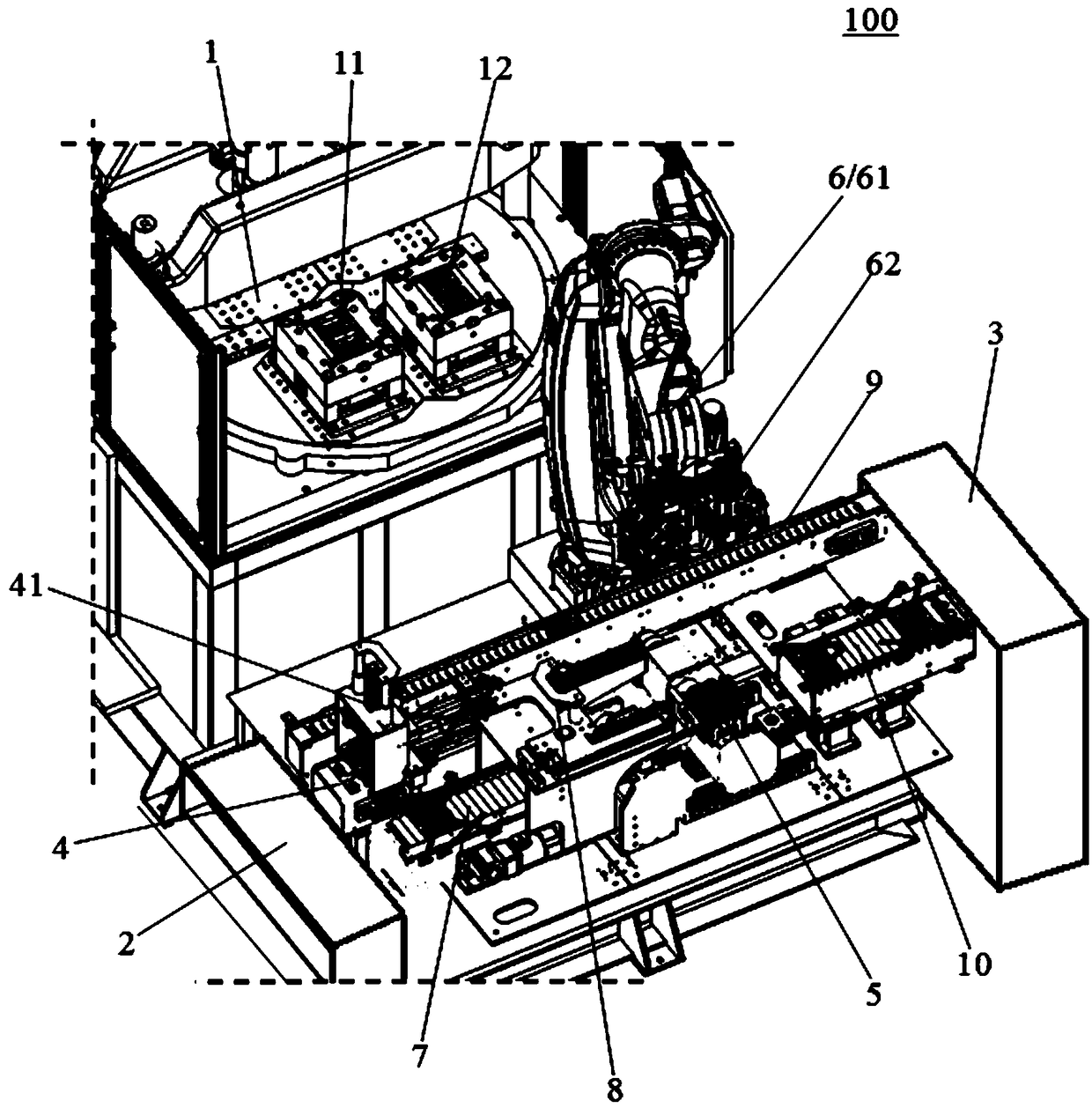

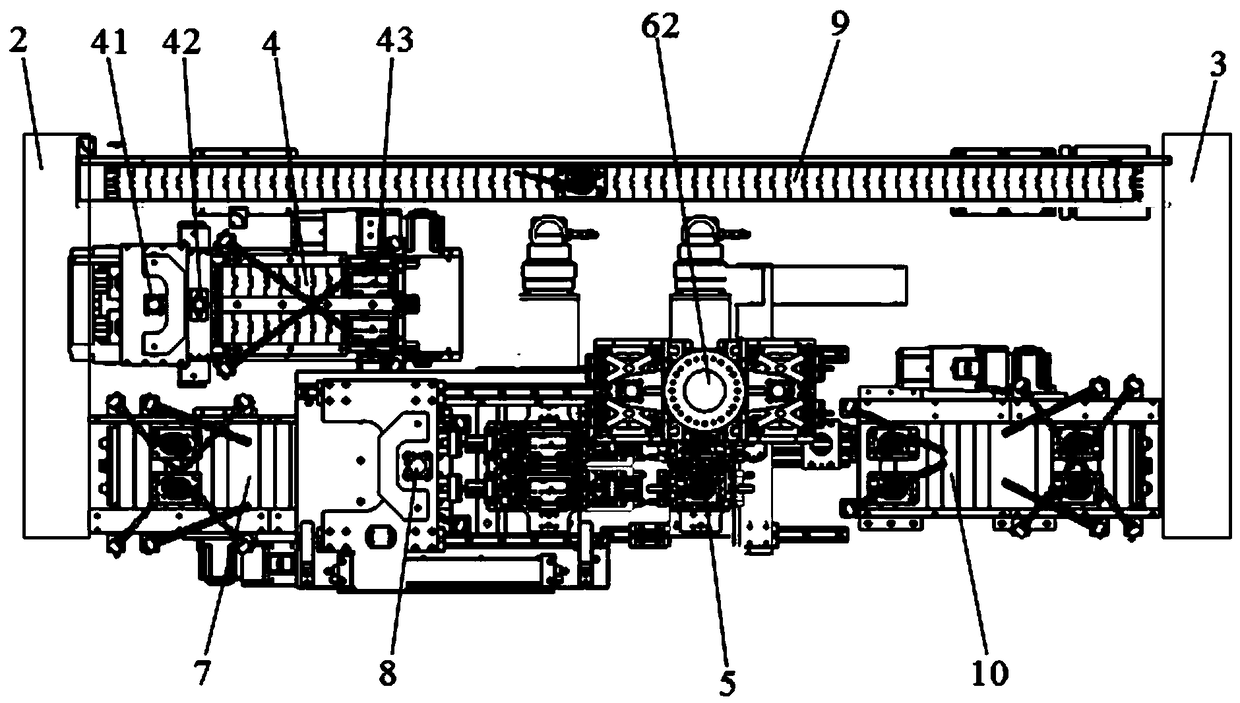

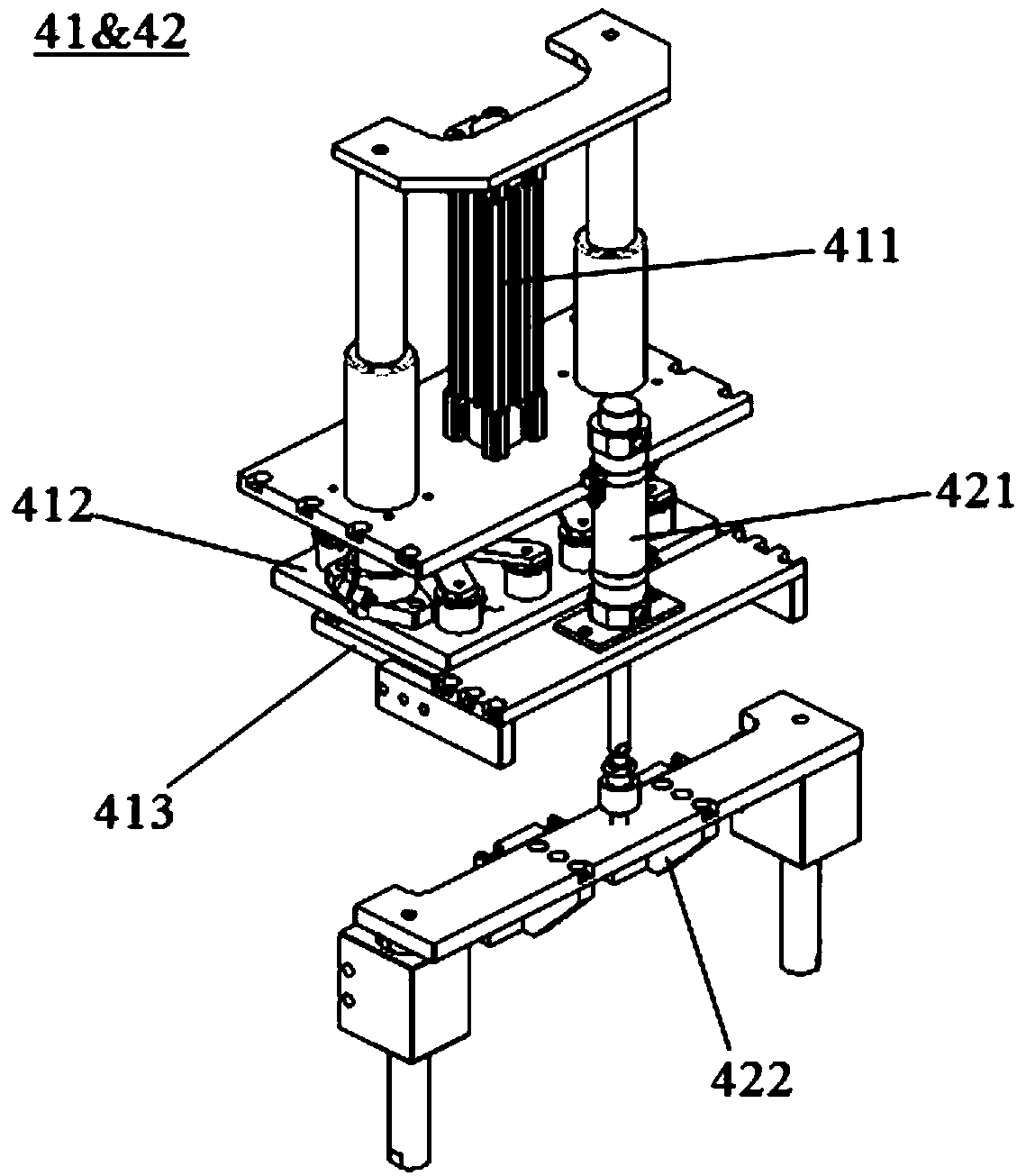

[0043] Please refer to Figure 1-Figure 10 , the present embodiment is an injection molding machine combined mold insert fully automatic loading and unloading and dismantling mechanism 100, which includes an injection molding machine 1, a combined insert assembly station 2, a molded product blanking station 3, and a docking assembly insert Assembling station 2 assembly material feeding conveying device 4, assembly dismantling mechanism 5 for disassembling assembly A and assembly B, assembly assembly from assembly feeding conveying device 4 Grabbing into the injection molding machine 1 and grabbing the molded assembly from the injection molding machine 1 to the robot clamping mechanism 6 in the assembly disassembly mechanism 5, and transporting it to the assembly station 2. Insertion A return conveying line 7, gripper mechanism 8 for grabbing insert A from the combined insert dismantling mechanism 5 to the insert A return conveying line 7, docking combined insert assembly stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com