Full-automatic high-voltage transformer insulation withstand voltage testing device

A high-voltage transformer and insulation withstand voltage technology, which is applied in the field of fully automatic high-voltage transformer insulation and withstand voltage test devices, can solve the problem of not forming a centralized integrated control scheme, increasing equipment purchase costs and labor costs, and increasing potential safety hazards. Error rate and other issues, to achieve the effect of improving equipment and line reuse, reducing manual participation, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

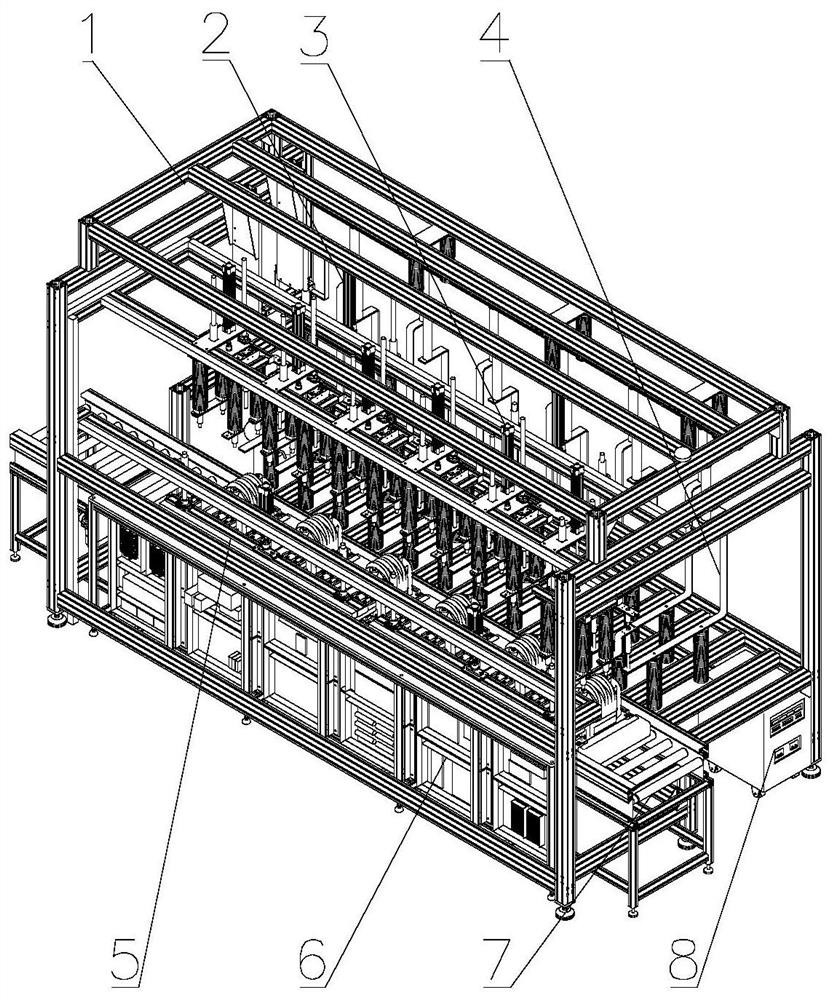

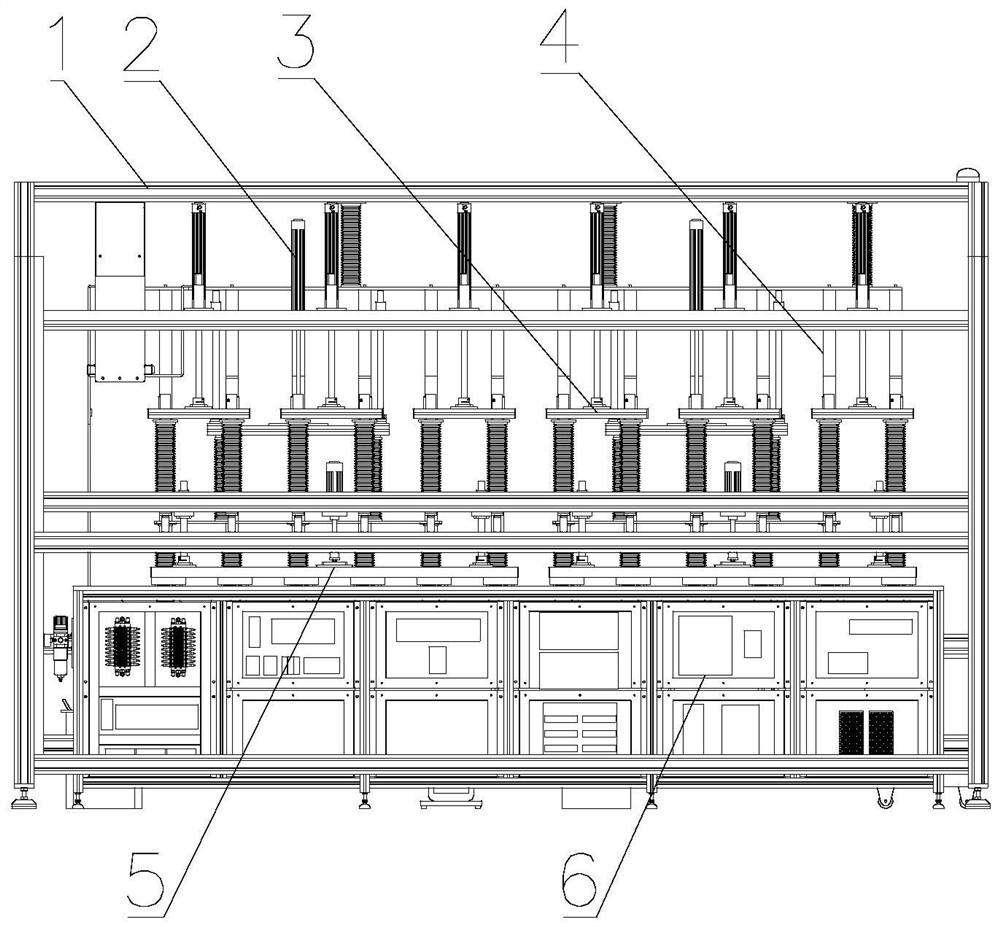

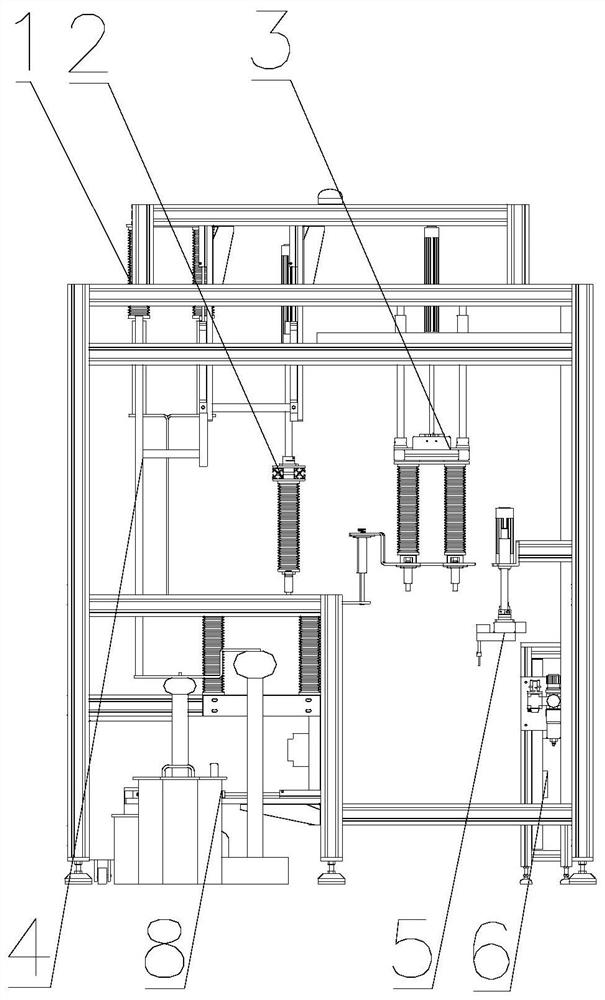

[0035] Such as Figure 1-8 As shown, the present invention provides a technical solution: a fully automatic high-voltage transformer insulation withstand voltage test device, including an aluminum profile frame 1, and the aluminum profile frame 1 is provided with a high-voltage switching pneumatic device 2 and a transformer primary side wiring mechanism 3 , high-voltage conductive copper bar 4, transformer secondary side wiring mechanism 5, electrical measurement function module 6, roller conveyor line 7 and electrical measuring instrument 8;

[0036] The high-voltage switching pneumatic device 2 is fixedly installed on the inner wall of the aluminum profile frame 1, and the high-voltage switching pneumatic device 2 is located above the electrical measuring instrument 8;

[0037] Transformer primary side wiring mechanism 3 includes guide rod one 31, guide rod cylinder one 32, crimping cylinder 33, insulator 34, insulation and voltage resistance contact terminal 35 and error te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com