Feeding and discharging equipment

A technology of equipment and processing equipment, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low degree of automation and low efficiency of tool loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

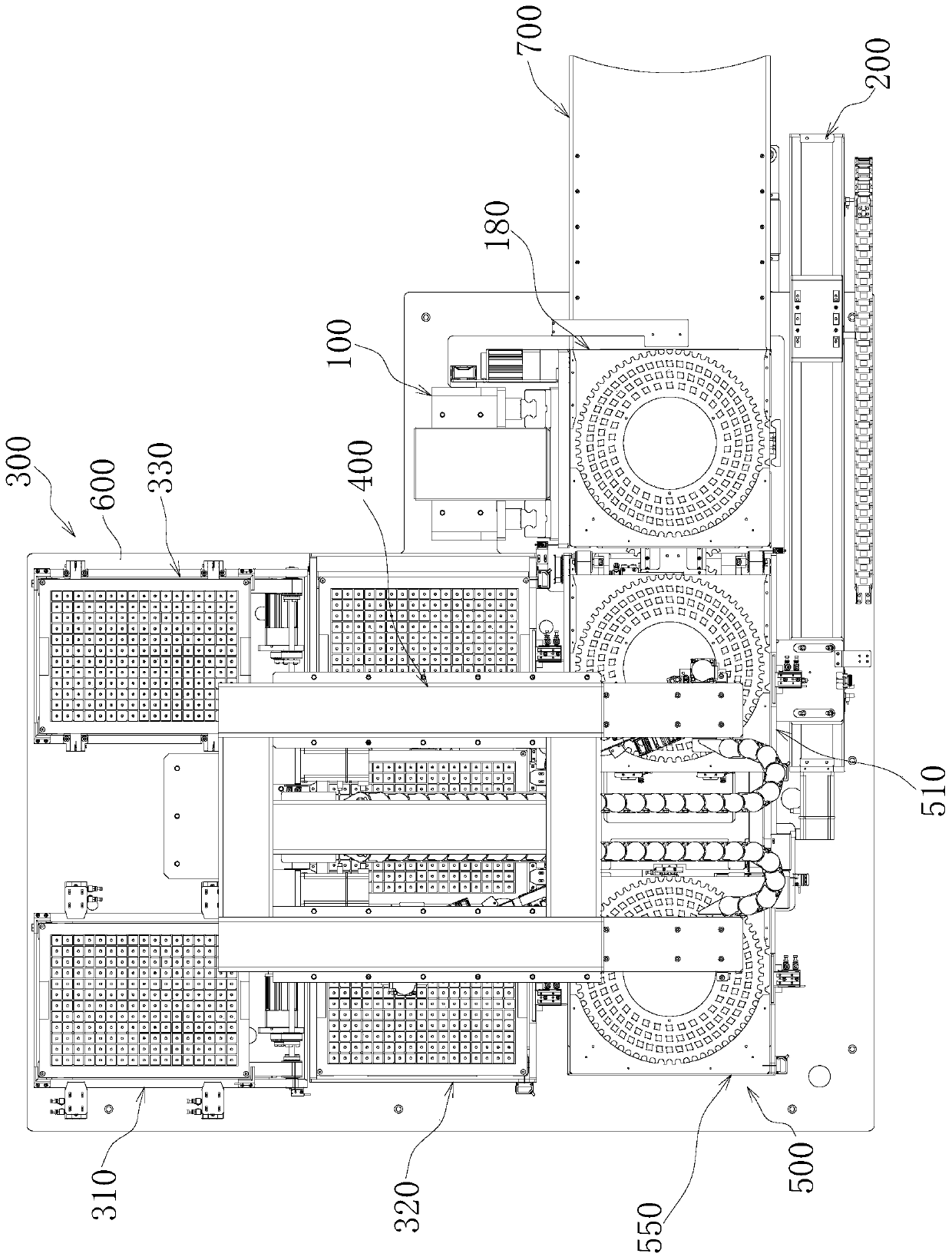

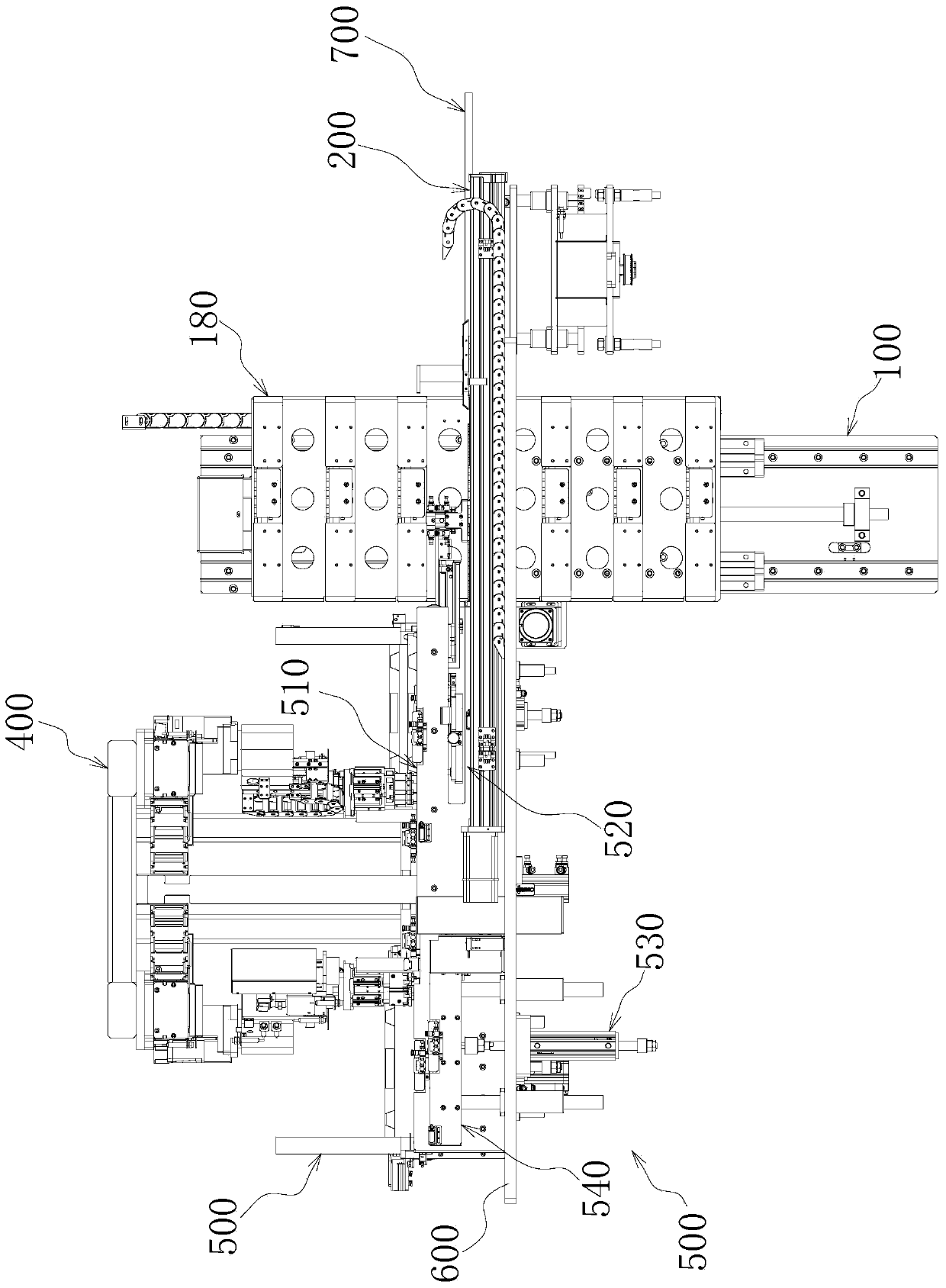

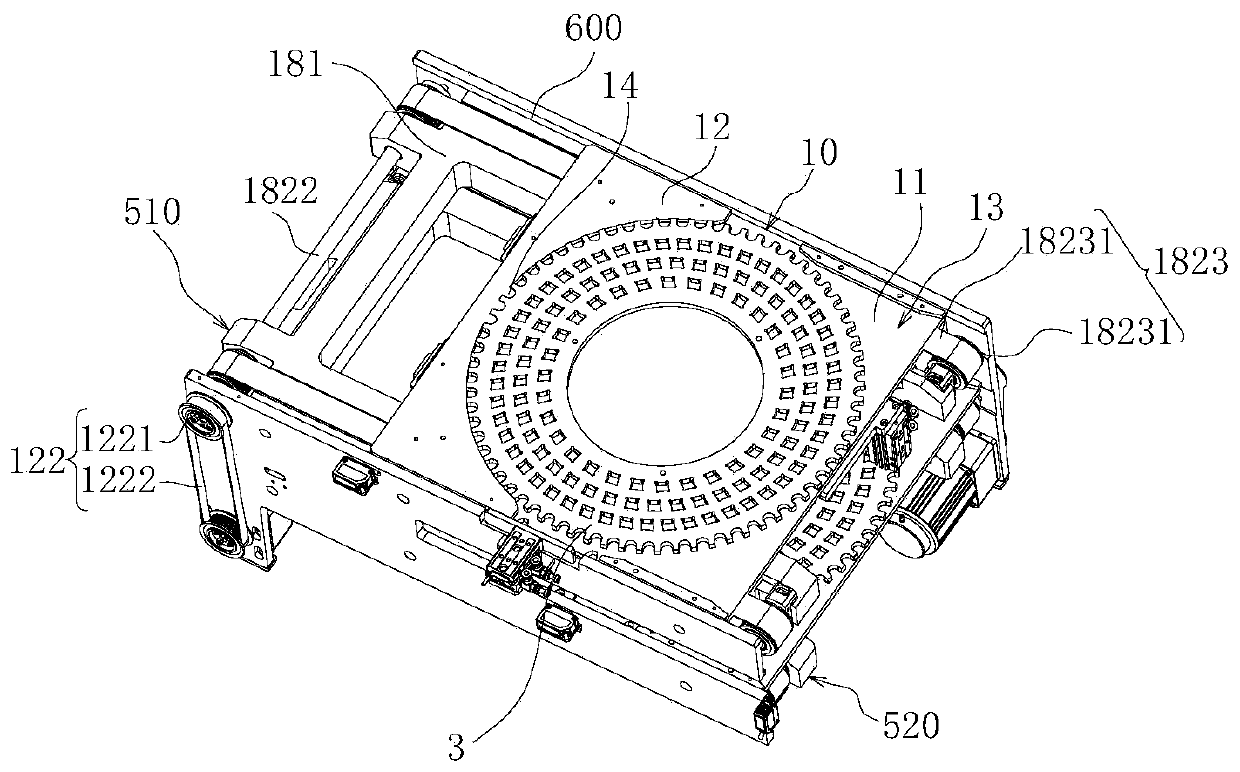

[0008] Embodiments of the present invention are described in detail below, and by referring to the attached Figure 1-34 The described embodiments illustrate the invention, but reference is made to the appended Figure 1-34 The content shown in should not be construed as limiting the present invention.

[0009] Such as Figure 1-34 As shown, in one embodiment of the present invention, a kind of loading and unloading equipment is provided, which is used in conjunction with processing equipment. The processing equipment is mainly used for grinding tools or passivating tools. The tools can be indexable tools, milling cutters, drills Wait.

[0010] The loading and unloading equipment: includes a frame 600, a carrier circulation device 500, a jig manipulator 200, a tray circulation device 300 and a tool loading and unloading device 400; the carrier circulation device 500 is installed on the frame 600, and the carrier circulation device 500 The carrier 1 for carrying the jig 2 ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com