Automatic circulation device for metal hose manufacturing process

A metal hose and conversion device technology, which is applied in the direction of lifting device, loading/unloading, transportation and packaging, etc., can solve the problems of low production efficiency, variable length and specification of metal hose, and unfavorable product consistency, so as to improve production Efficiency, good adaptability, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

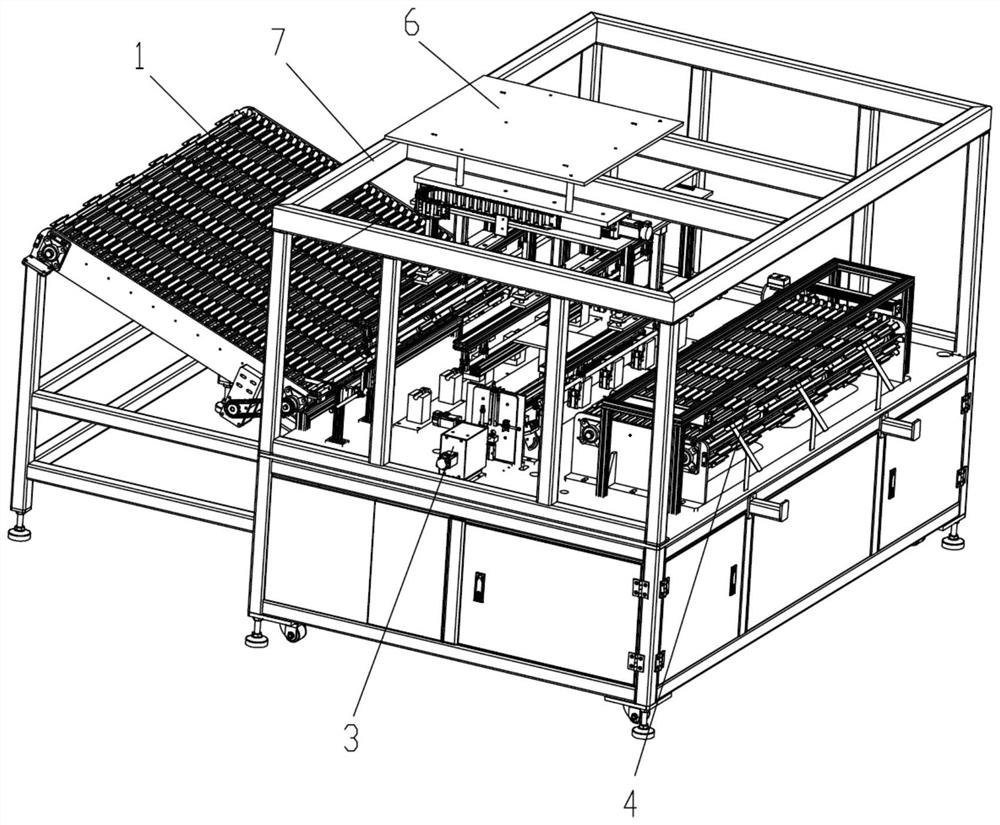

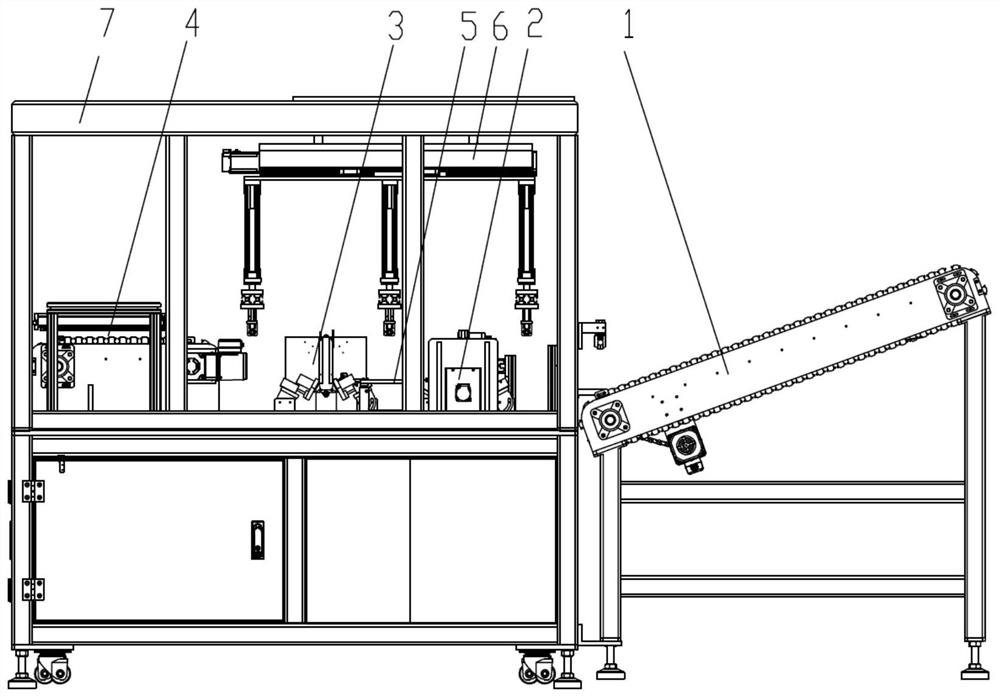

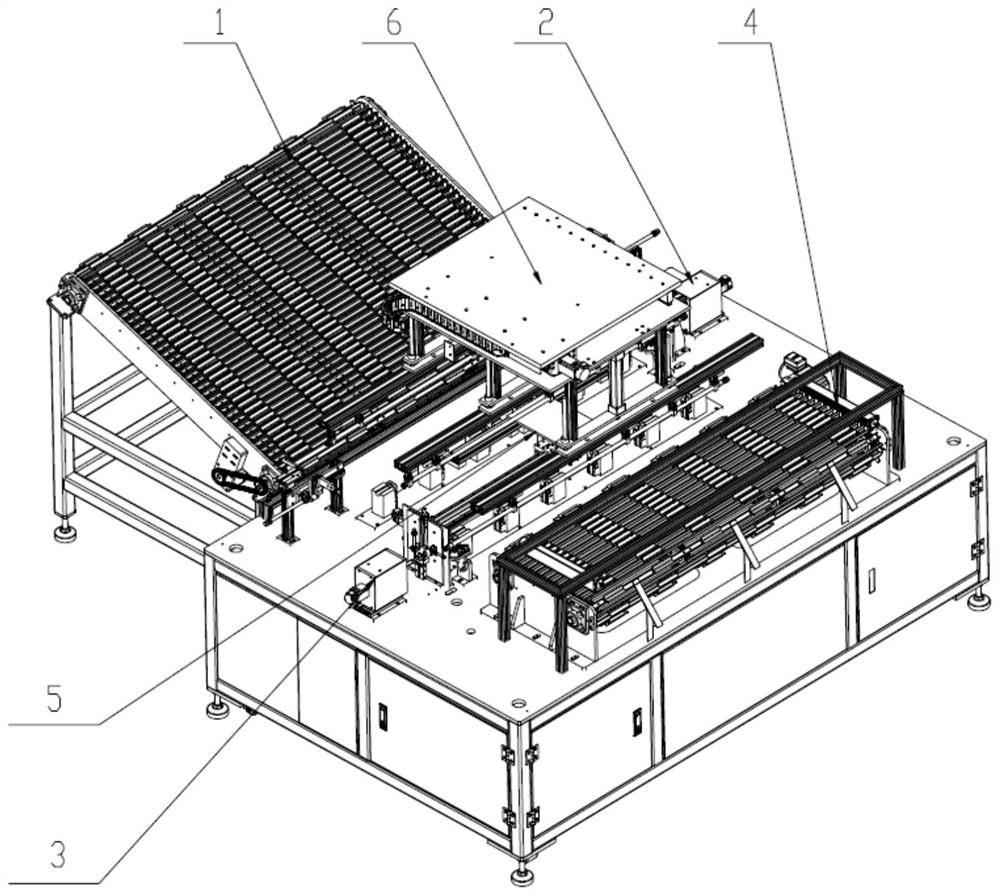

[0022] The automatic flow device of the metal hose manufacturing process of this embodiment is as follows: Figure 1 to Figure 3 As shown, the first joint welding station 2, the second joint welding station 3 and the cooling device 4, which are the same as those in the prior art, are arranged on the same workbench in an orderly interval. The bracket 7 of the frame structure is equipped with a workpiece clamping and circulating device 6 that can be displaced above the output end of the feeding device 1 , the first joint welding station 2 , the second joint welding station 3 and the cooling device 4 . A position changing device 5 is arranged on the workbench between the first joint welding station 2 and the second joint welding station 3 .

[0023] The specific structure of the workpiece clamping flow device 6 is as follows: Figure 4 As shown, it includes a top plate assembly 6.1 that forms a horizontal moving pair through the servo drive mechanism 601 and the guide rails on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com