Automatic chip mounting mechanism

An automatic patch and patch technology, applied in electrical components, printed circuit manufacturing, electrical components, etc., can solve the problems of product quality, dislocation of tin, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

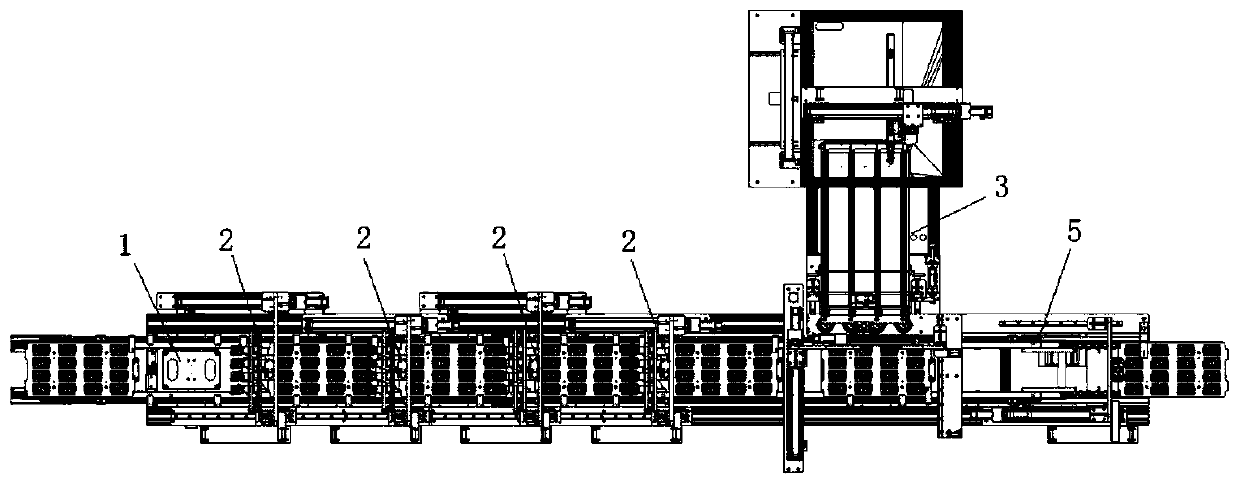

[0032] refer to Figure 1-9 As shown, the present embodiment is an automatic placement mechanism, including a feeding device 1 , several tin spotting devices 2 cooperating with the feeding device 1 , a placement device 3 , and a feeding device 5 .

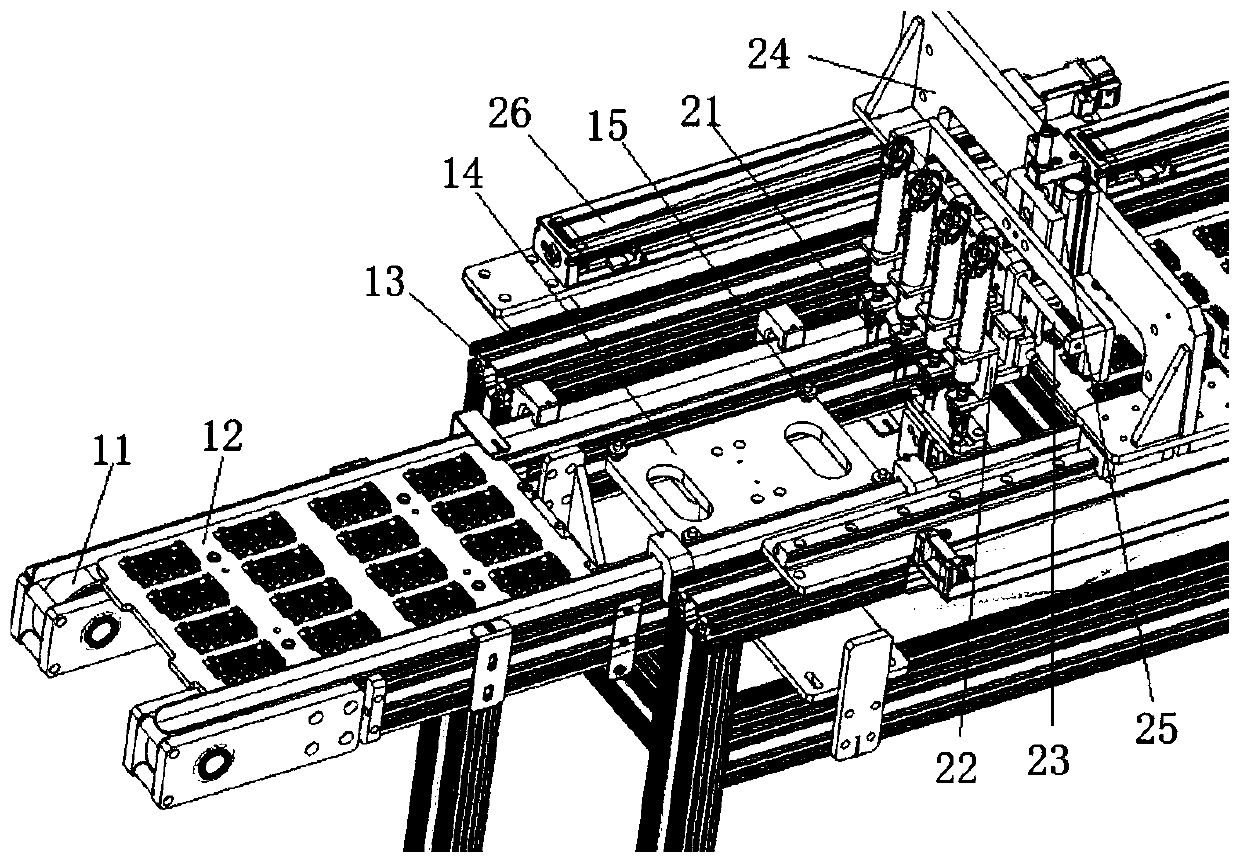

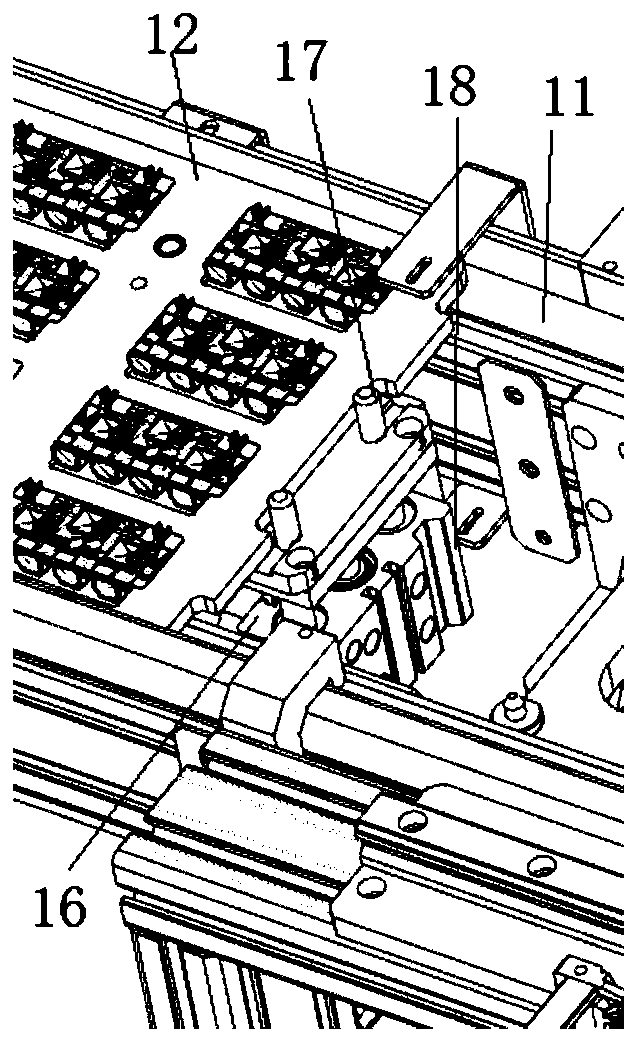

[0033] The feeding device 1 includes a conveyor belt 11 , a number of ejector components arranged at intervals below the conveyor belt 11 , and stopper assemblies arranged at both ends of each ejector assembly.

[0034] The inner side of the conveyor belt 11 carries and transports a number of product carriers 12, and the two sides of the conveyor belt 11 are symmetrically provided with a number of locking blocks 13, and the bottom of the locking blocks 13 is placed above the side of the product carrier 12 for limiting product loading. The position height of tool 12 in conveyor belt 11.

[0035] The ejector assembly includes an extended jacking product carrier 12 located below the conveyor belt 11 to separate it from the top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com