Battery pack optical detection system

A technology for optical inspection and battery packs, which can be used in optical testing of flaws/defects, material analysis by optical means, measurement devices, etc., which can solve the problems of low accuracy and low efficiency of manual inspection of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

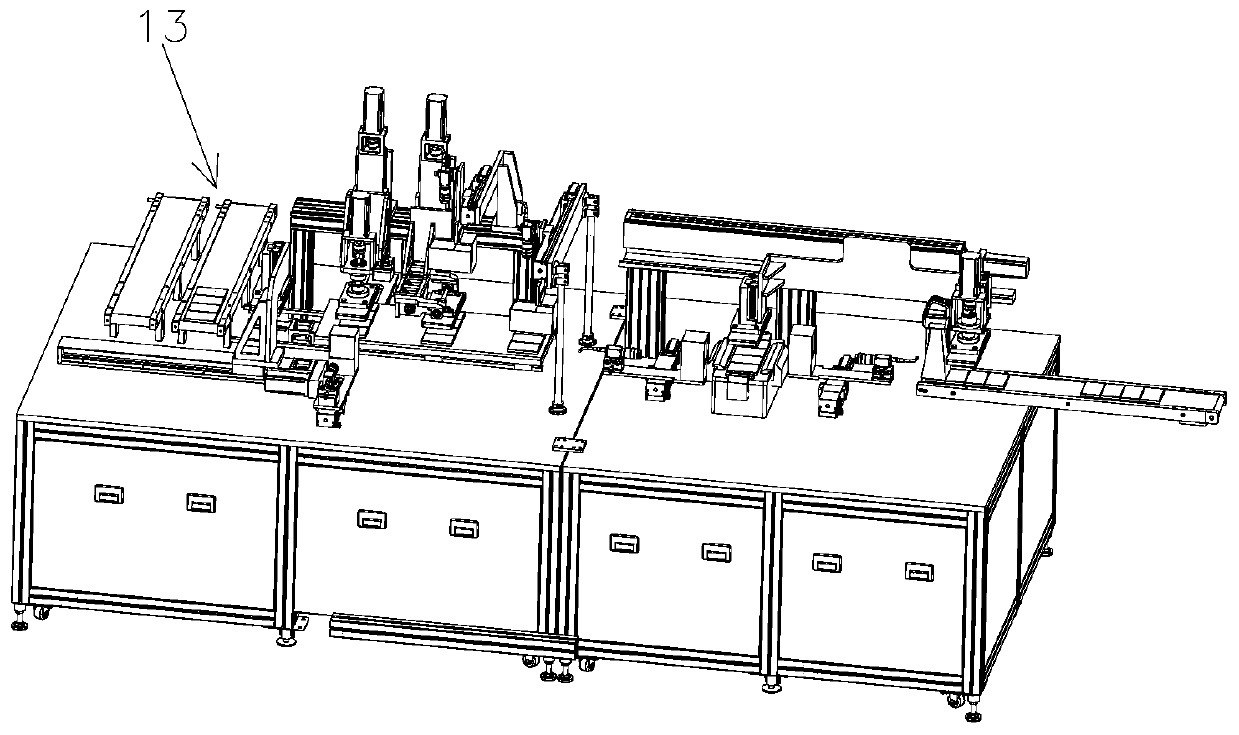

[0085] Workbench, the overall shape of the workbench is a cuboid, and there are several brake universal wheels under the workbench, so that the user can easily adjust the working position and placement direction of the workbench. The upper surface of the workbench is a table top arranged horizontally, and a first support frame and a second support frame are arranged on the table surface. The first support frame and the second support frame are both M-shaped structural frames, and the first support frame and the second support frame The racks are all arranged on the side of the table near the side of the table along the length direction of the workbench.

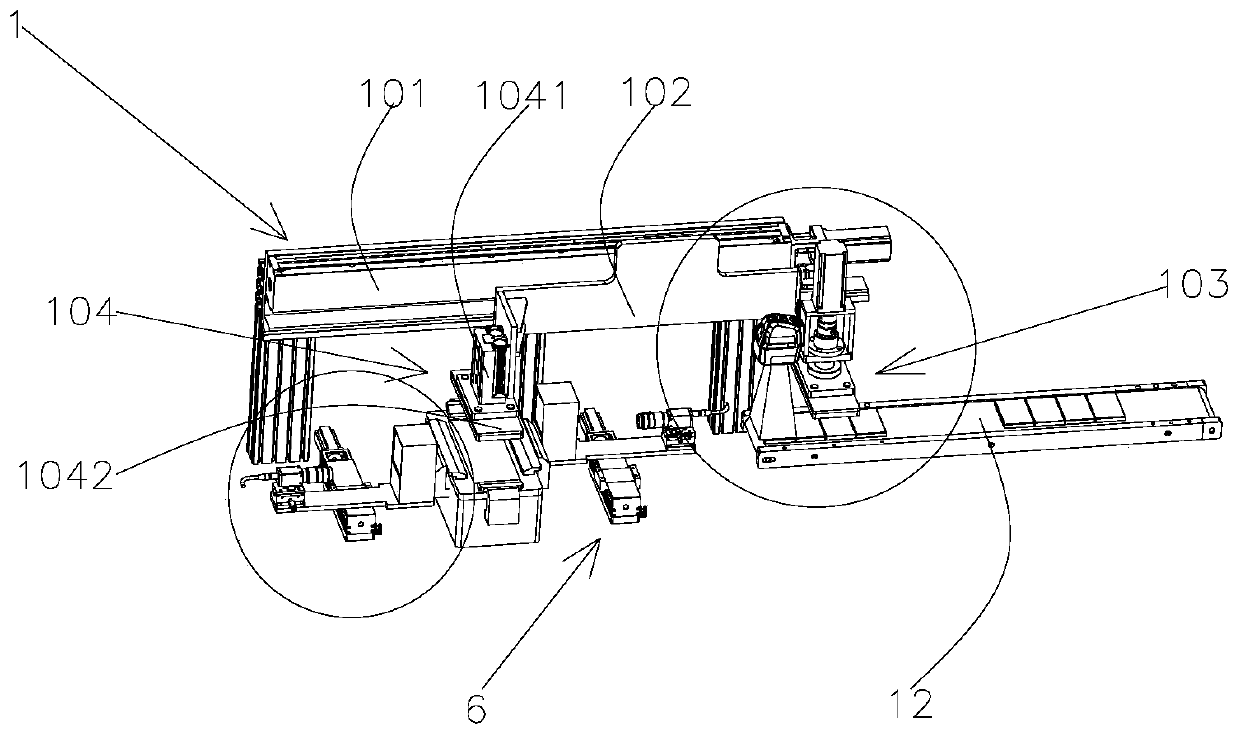

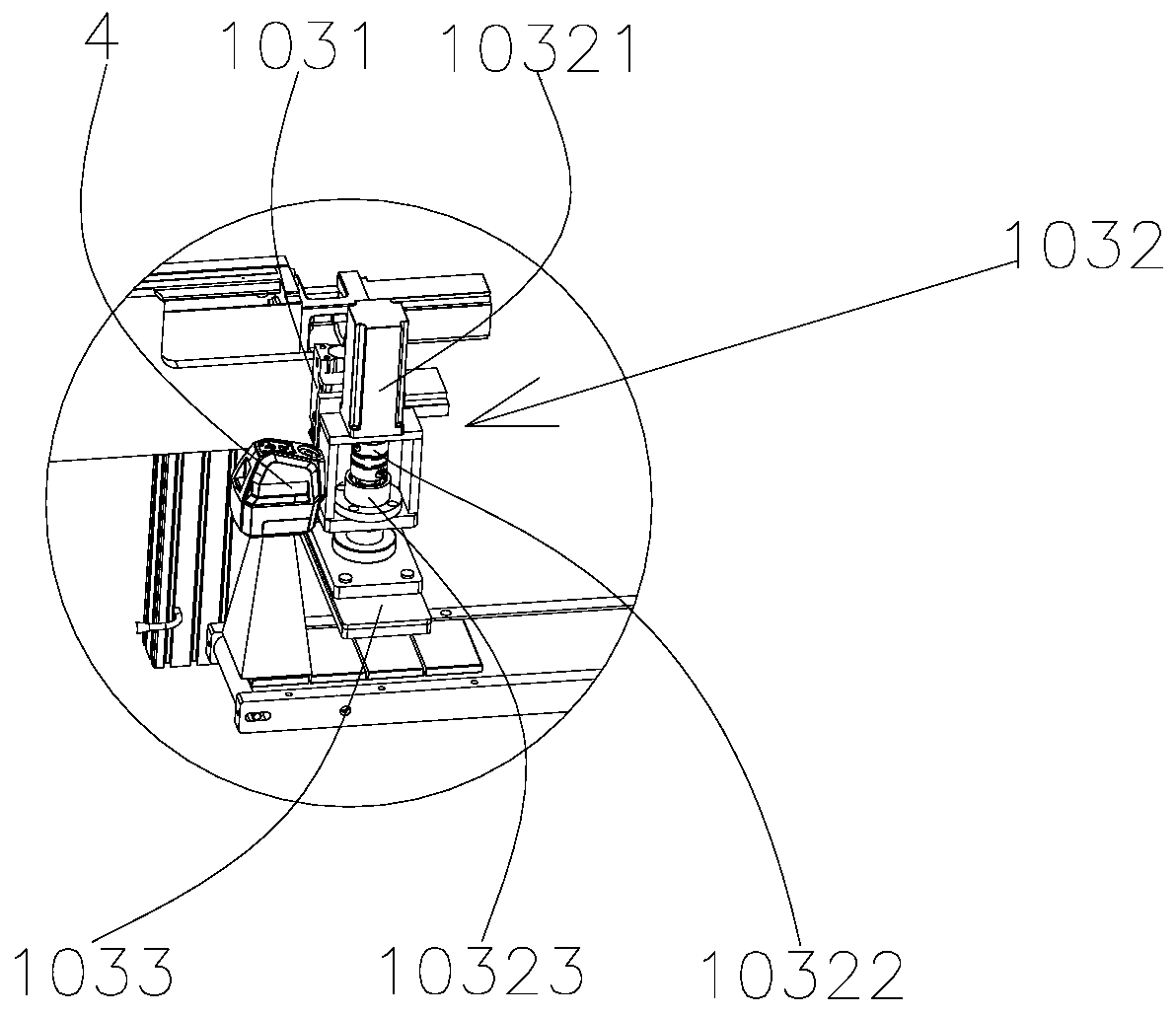

[0086] The feeding mechanism includes a feeding mechanism 12 and a discharging mechanism 13 for transporting the battery pack, and the shape of the battery pack is a flat cuboid. The feed mechanism 12 is a conveyor belt arranged along the length direction of the workbench, and the feed mechanism 12 is responsible for transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com