Composition for anisotropic conductive adhesive film, anisotropic conductive adhesive film and semiconductor device

A conductive adhesion, anisotropic technology, applied in conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, semiconductor devices, etc., can solve problems such as reduced dimensional stability and insufficient adhesion of glass substrates , to improve the filling rate, improve connection reliability and stability, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

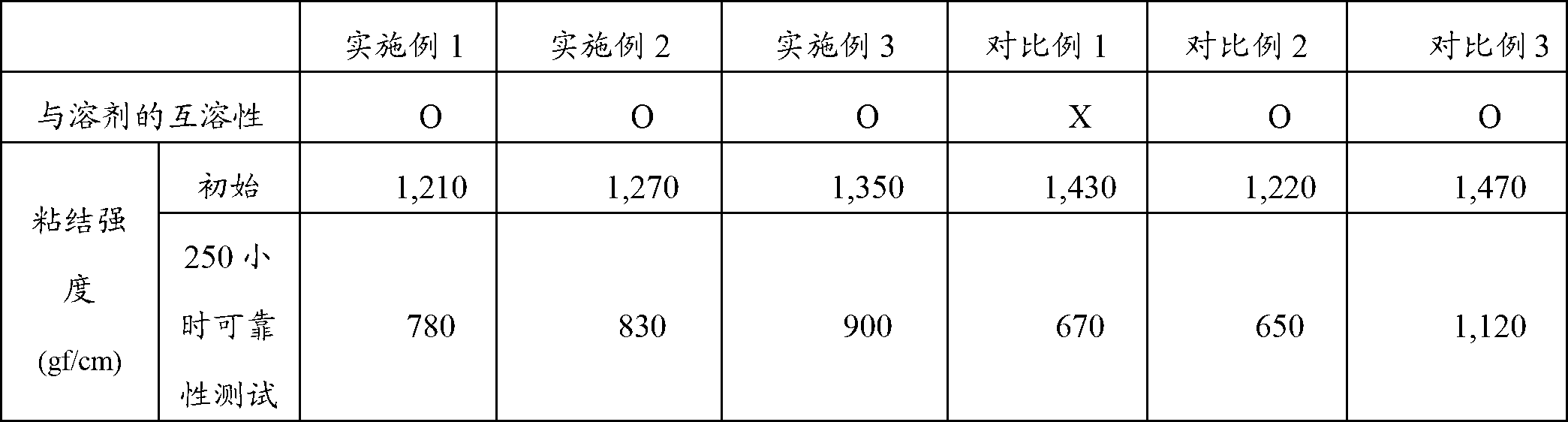

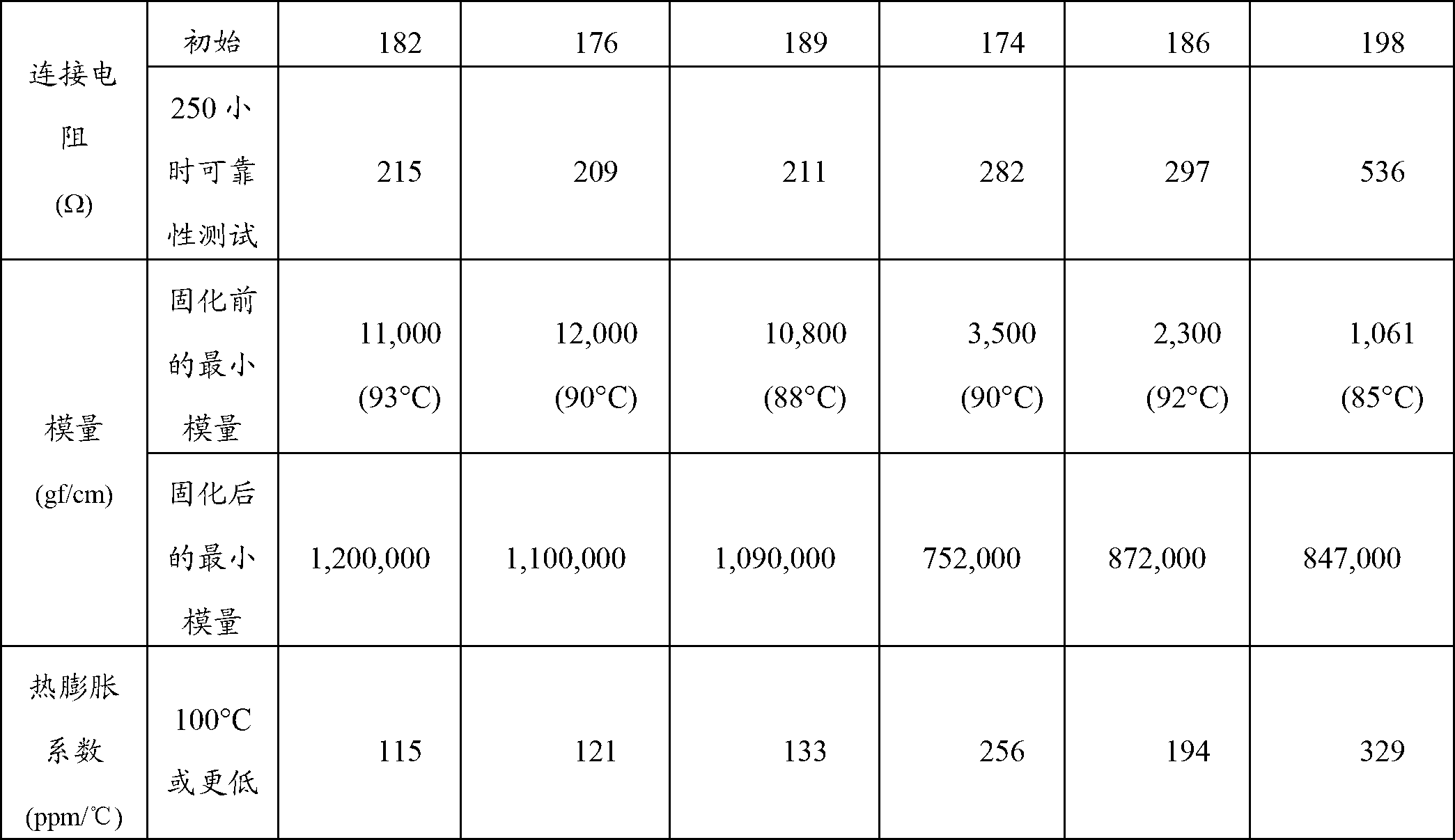

[0138] Example 1: Preparation of anisotropic conductive adhesive film

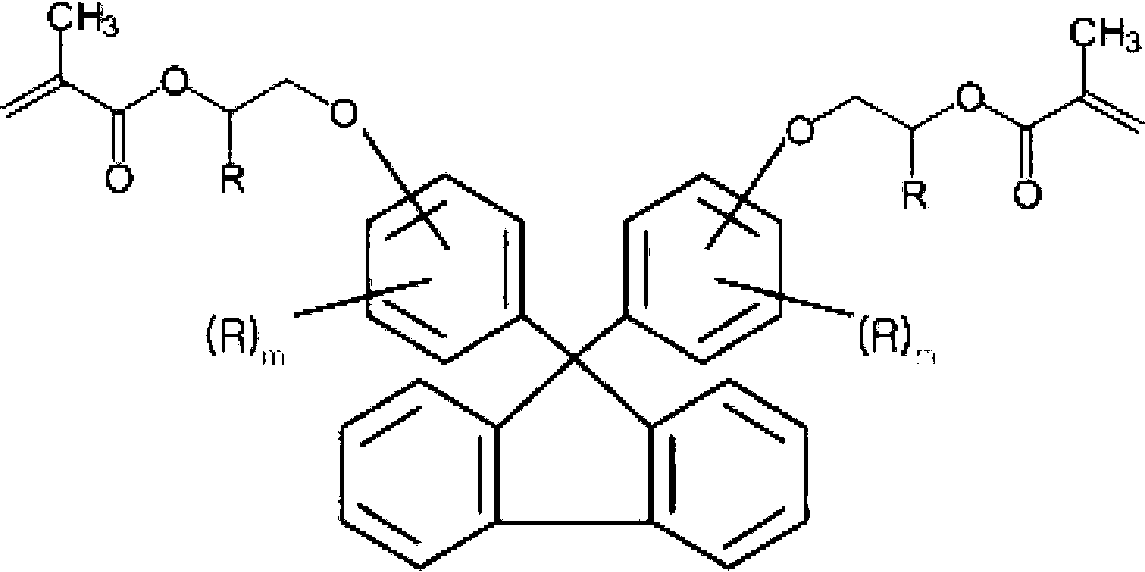

[0139] (1) Preparation of anisotropic conductive adhesive composition

[0140] By mixing 30 wt% epoxy-functional acrylate copolymer (solids content: 18%), 5 wt% carboxyl-modified acrylonitrile butadiene rubber dissolved in toluene and methyl ethyl ketone (MEK) (solid content: 25%, weight average molecular weight: 240,000g / mol, Nipol NBR, Zeon Co., Ltd.), 15wt% styrene-acrylonitrile resin dissolved in MEK (solid content: 50%, Tg: 120°C , weight average molecular weight: 100,000g / mol), 20wt% isocyanurate ethylene oxide modified diacrylate (DSC exothermic peak: 92°C to 95°C), 20wt% bisphenol fluorene diacrylate (weight-average molecular weight: 1,400g / mol), 1.5wt% acidified phosphoethyl methacrylate, 2.5wt% phosphate acrylate (weight-average molecular weight: 12,000g / mol), 1.0wt% as Organic peroxide lauroyl peroxide (solid content: 10%) dissolved in toluene and 2.0 wt% benzoyl peroxide (solid content: 10%) ...

Embodiment 2

[0145] In the same manner as in Example 1, except that the contents of acrylate copolymer, oxirane-isocyanurate-modified diacrylate and bisphenol fluorene diacrylate were changed to 35wt%, 15wt% and 25wt% respectively An anisotropic conductive film according to Example 2 was prepared.

Embodiment 3

[0147] An anisotropic conductive film of Example 3 was prepared in the same manner as in Example 1, except that the following urethane acrylate resin was used instead of the carboxy-modified acrylonitrile butadiene rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com