Fireproof aluminium-plastic panel containing nanometer flame retardant and core material special for fireproof aluminium-plastic panel containing nanometer flame retardant

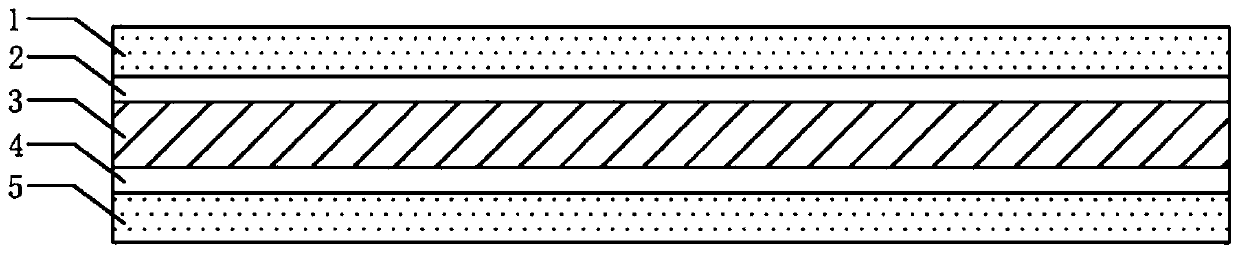

A nano flame retardant, aluminum-plastic board technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problem of failing to meet the flame retardant performance requirements of core materials and unsatisfactory flame retardant performance , single flame retardant performance and other problems, to achieve the effect of not easy to damage and deformation, good flame retardant and fire performance, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

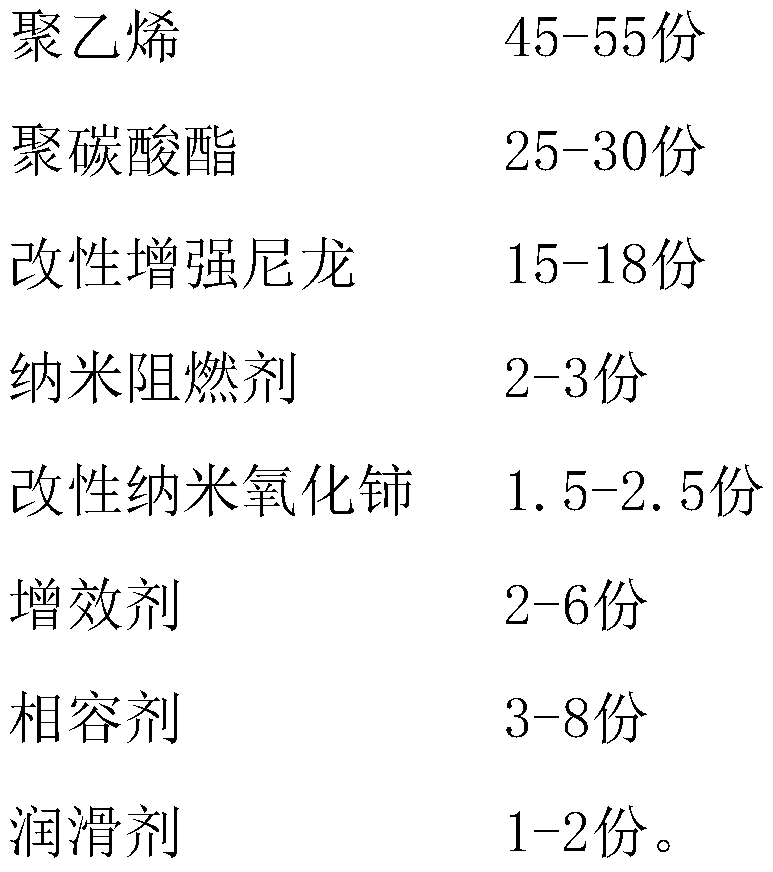

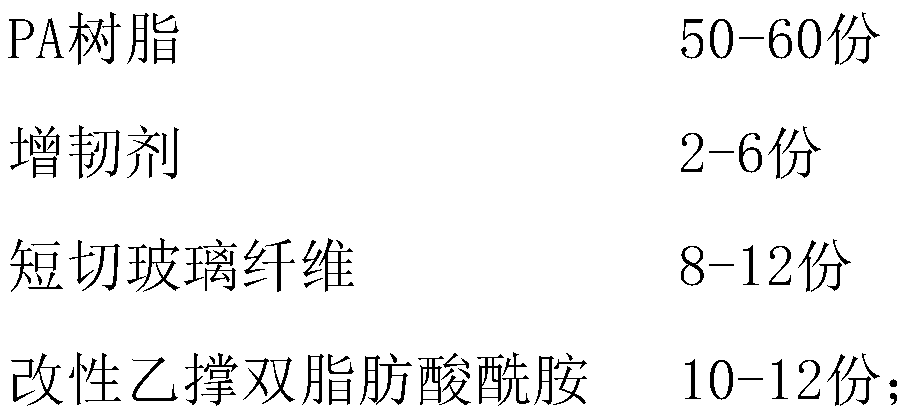

[0056] A special core material for fire-resistant aluminum-plastic panels containing a nano-flame retardant, the core material comprising the following raw materials in parts by weight:

[0057]

[0058]

[0059] Each part of the nano flame retardant includes 8 parts of hexaphenoxycyclotriphosphazene, 3 parts of nano silicon dioxide, 2 parts of ammonium polyphosphate, 2 parts of nano magnesium hydroxide powder and 5 parts of nano glass powder.

[0060] Described hexaphenoxy cyclotriphosphazene is prepared by following steps:

[0061]Step (1): adding ammonium chloride powder into chlorobenzene, stirring evenly to obtain mixture A;

[0062] Step (2): Heat the mixture A prepared in step (1) to 75°C, add ZnO, then add phosphorus pentachloride while stirring, and feed chlorine gas at the same time, heat, stir and reflux for 12 hours, cool after the reaction, and pump the pressure Filter and wash to obtain hexachlorocyclotriphosphazene;

[0063] Step (3): dissolving phenol i...

Embodiment 2

[0085] A special core material for fire-resistant aluminum-plastic panels containing a nano-flame retardant, the core material comprising the following raw materials in parts by weight:

[0086]

[0087] Each part of the nano flame retardant includes 8.5 parts of hexaphenoxycyclotriphosphazene, 3.5 parts of nano silicon dioxide, 2.5 parts of ammonium polyphosphate, 2.5 parts of nano magnesium hydroxide powder and 5.2 parts of nano glass powder.

[0088] Described hexaphenoxy cyclotriphosphazene is prepared by following steps:

[0089] Step (1): adding ammonium chloride powder into chlorobenzene, stirring evenly to obtain mixture A;

[0090] Step (2): Heat the mixture A prepared in step (1) to 80°C, add ZnO, then add phosphorus pentachloride while stirring, and feed chlorine gas at the same time, heat, stir and reflux for 13 hours, cool after the reaction, and pump the pressure Filter and wash to obtain hexachlorocyclotriphosphazene;

[0091] Step (3): dissolving phenol in...

Embodiment 3

[0113] A special core material for fire-resistant aluminum-plastic panels containing a nano-flame retardant, the core material comprising the following raw materials in parts by weight:

[0114]

[0115] Each part of the nano flame retardant includes 9 parts of hexaphenoxycyclotriphosphazene, 4 parts of nano silicon dioxide, 3 parts of ammonium polyphosphate, 3 parts of nano magnesium hydroxide powder and 5.5 parts of nano glass powder.

[0116] Described hexaphenoxy cyclotriphosphazene is prepared by following steps:

[0117] Step (1): adding ammonium chloride powder into chlorobenzene, stirring evenly to obtain mixture A;

[0118] Step (2): Heat up the mixture A prepared in step (1) to 85°C, add ZnO, then add phosphorus pentachloride while stirring, and at the same time pass in chlorine gas, heat, stir and reflux for 14 hours, cool after the reaction, and pump the pressure Filter and wash to obtain hexachlorocyclotriphosphazene;

[0119] Step (3): dissolving phenol in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com