Preparation method of high-content carbon black master batch

A carbon black masterbatch, high-content technology, applied in chemical instruments and methods, dyeing polymer organic compound treatment, compounds of group 5/15 elements of the periodic table, etc., can solve the problem of low carbon black content, masterbatch flame retardancy Poor effect and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of preparation method of high-content carbon black masterbatch, specifically comprises the steps:

[0045] Step S1: weighing 100 parts of raw material modified polystyrene, 600 parts of modified carbon black particles, 2 parts of liquid paraffin, 10 parts of graphite, 3 parts of kaolin powder, and 5 parts of sodium dodecylbenzenesulfonate;

[0046] Step S2: Dissolve modified polystyrene in N,N-dimethylformamide, add modified carbon black particles and triethylamine, and carry out the reaction at a speed of 300r / min and a temperature of 80°C After 5h, the solvent was distilled off to obtain the substrate;

[0047] Step S3: After mixing the substrate, liquid paraffin, graphite, kaolin powder, and sodium dodecylbenzenesulfonate evenly, add it to the extruder at the temperature of 190, 205, 215, 220, and 215°C in each section , extruded, cooled and granulated to produce high-content carbon black masterbatches.

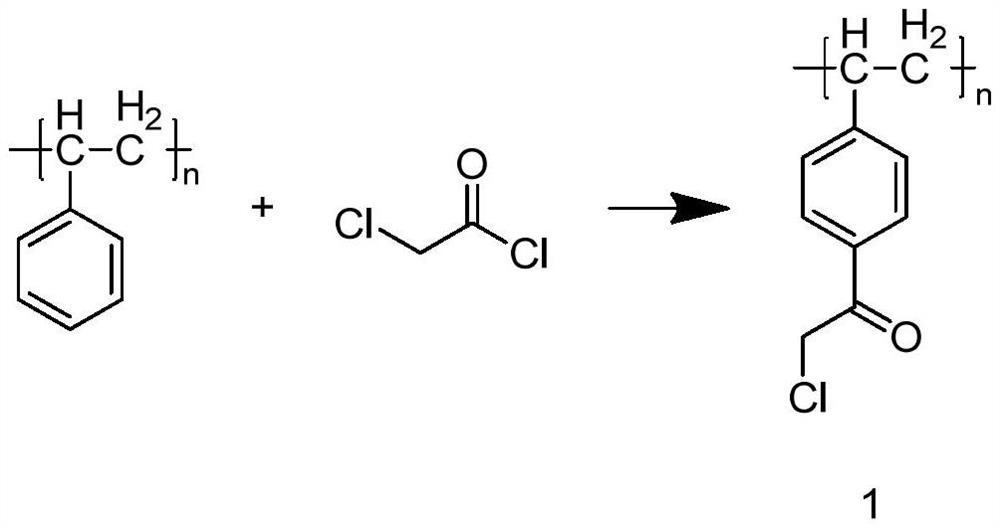

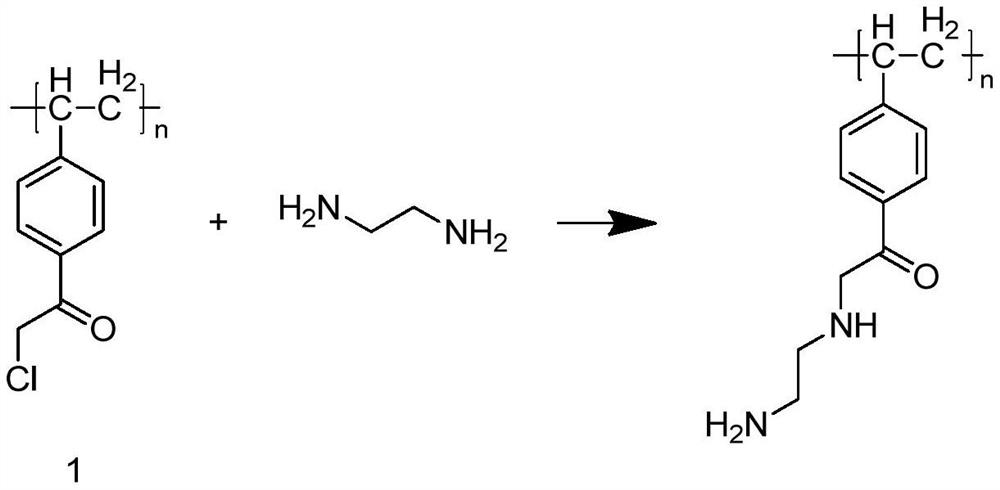

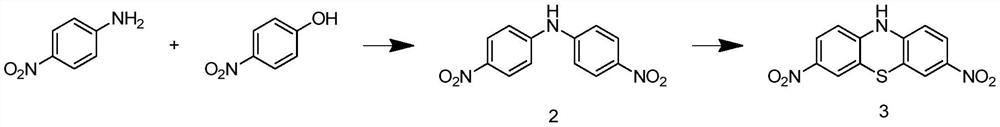

[0048] Described modified polystyrene is made by foll...

Embodiment 2

[0058] A kind of preparation method of high-content carbon black masterbatch, specifically comprises the steps:

[0059] Step S1: weighing 130 parts of raw materials modified polystyrene, 700 parts of modified carbon black particles, 3 parts of liquid paraffin, 13 parts of graphite, 5 parts of kaolin powder, and 7 parts of sodium dodecylbenzenesulfonate;

[0060] Step S2: Dissolve the modified polystyrene in N,N-dimethylformamide, add modified carbon black particles and triethylamine, and carry out the reaction at a speed of 400r / min and a temperature of 85°C After 6h, the solvent was distilled off to obtain the substrate;

[0061] Step S3: After mixing the substrate, liquid paraffin, graphite, kaolin powder, and sodium dodecylbenzenesulfonate evenly, add it to the extruder at the temperature of 190, 205, 215, 220, and 215°C in each section , extruded, cooled and granulated to produce high-content carbon black masterbatches.

[0062] Described modified polystyrene is made by...

Embodiment 3

[0072] A kind of preparation method of high-content carbon black masterbatch, specifically comprises the steps:

[0073] Step S1: weighing 150 parts of raw materials modified polystyrene, 800 parts of modified carbon black particles, 5 parts of liquid paraffin, 15 parts of graphite, 8 parts of kaolin powder, and 8 parts of sodium dodecylbenzenesulfonate;

[0074] Step S2: Dissolve the modified polystyrene in N,N-dimethylformamide, add modified carbon black particles and triethylamine, and carry out the reaction at a speed of 500r / min and a temperature of 90°C After 7h, the solvent was removed by distillation to obtain the substrate;

[0075] Step S3: After mixing the substrate, liquid paraffin, graphite, kaolin powder, and sodium dodecylbenzenesulfonate evenly, add it to the extruder at the temperature of 190, 205, 215, 220, and 215°C in each section , extruded, cooled and granulated to produce high-content carbon black masterbatches.

[0076] Described modified polystyrene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com