Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

A technology for oriented particle board and formaldehyde purification, applied to chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problems of decorative paper visual distortion and other problems, and achieve realistic surface decoration effect, good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

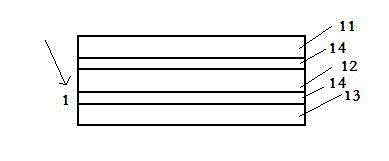

[0064] a. Substrate preparation: The substrate layer is an oriented strand board layer, and the substrate layer is an oriented strand board layer; The core shavings layer 12 arranged horizontally, the flame retardant layer 14 is arranged between the lower surface shavings layer 13 and the core shavings layer 12 and between the upper surface shavings layer 11 and the core shavings layer 12 . ; Wherein, the flame retardant layer 14 is impregnated with a flame retardant solution;

[0065] The flame retardant of the flame retardant solution is a compound nitrogen-phosphorus flame retardant;

[0066] The compound nitrogen-phosphorus flame retardant is ammonium polyphosphate, ammonium phosphate and ammonium sulfate according to the mass ratio of 1: 3: 1 to prepare a 25% aqueous solution with a mass concentration.

[0067] b. Formaldehyde decomposition glue preparation: fully mix the formaldehyde decomposition active ingredients and amino resin and stir evenly to obtain the formalde...

Embodiment 2

[0075] a. Substrate preparation: the substrate layer is an oriented strand board layer, and the oriented strand board layer includes two upper and lower surface layers in which the rubber-mixed shavings are arranged longitudinally according to their fiber directions and a core layer of shavings in which the rubber-mixed shavings are arranged horizontally according to their fiber directions. A flame retardant layer is provided between the wood particle layer of the lower surface layer and the wood particle layer of the core layer and between the wood particle layer of the upper surface layer and the core layer;

[0076] Among them, the flame-retardant layer is impregnated with a flame-retardant solution;

[0077] The flame retardant of the flame retardant solution is a compound nitrogen-phosphorus flame retardant;

[0078] The compound nitrogen and phosphorus flame retardant is ammonium polyphosphate, ammonium phosphate, and ammonium sulfate according to the mass ratio of 3:1:1...

Embodiment 3

[0086] a. Substrate preparation: the substrate layer is an oriented strand board layer, and the oriented strand board layer includes two upper and lower surface layers in which the rubber-mixed shavings are arranged longitudinally according to their fiber directions and a core layer of shavings in which the rubber-mixed shavings are arranged horizontally according to their fiber directions. A flame retardant layer is provided between the wood particle layer of the lower surface layer and the wood particle layer of the core layer and between the wood particle layer of the upper surface layer and the core layer;

[0087] Among them, the flame-retardant layer is impregnated with a flame-retardant solution;

[0088] The flame retardant of the flame retardant solution is a compound nitrogen-phosphorus flame retardant;

[0089] The compound nitrogen-phosphorus flame retardant is ammonium polyphosphate, ammonium phosphate and ammonium sulfate according to the mass ratio of 1:1:1 to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com