Environment-friendly flame-retardant high-temperature-resistant oil-resistant special flexible cable material and production method thereof

A flexible cable and high-temperature-resistant technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of poor high-temperature resistance and oil resistance of cable materials, easy to cause harm to people, and high hardness of cable materials, etc. Problems, to achieve the effect of improving visibility, excellent weathering resistance and mechanical strength, high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

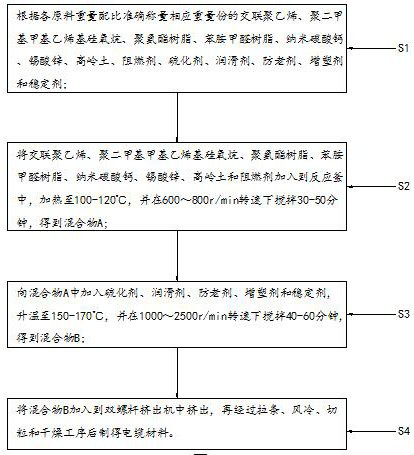

[0027] Such as figure 1 As shown, a green flame-retardant, high-temperature, oil-resistant, special flexible cable material proposed by an embodiment of the present invention includes the following weight ratio raw materials: 40 parts of cross-linked polyethylene, 20 parts of polydimethylmethylvinylsiloxane , 10 parts of polyurethane resin, 10 parts of aniline formaldehyde resin, 5 parts of nano-calcium carbonate, 2 parts of zinc stannate, 5 parts of kaolin, 15 parts of flame retardant, 3 parts of vulcanizing agent, 1 part of lubricant, 2 parts of anti-aging agent, 2 parts of plasticizer and 3 parts of stabilizer.

[0028] In this embodiment, the flame retardant is any one or combination of zinc borate, aluminum hydroxide, magnesium hydroxide and antimony trioxide.

[0029] In this embodiment, the vulcanizing agent is any one or a combination of dicumyl peroxide, tert-butylphenol formaldehyde resin, benzoyl peroxide, quinone oxime compound, isocyanate and urethane.

[0030] ...

Embodiment 2

[0041] Such as figure 1 As shown, a green flame-retardant, high-temperature, oil-resistant special flexible cable material proposed by an embodiment of the present invention includes the following weight ratio raw materials: 60 parts of cross-linked polyethylene, 30 parts of polydimethylmethylvinylsiloxane , 20 parts of polyurethane resin, 30 parts of aniline formaldehyde resin, 15 parts of nano-calcium carbonate, 6 parts of zinc stannate, 10 parts of kaolin, 25 parts of flame retardant, 5 parts of vulcanizing agent, 3 parts of lubricant, 3 parts of anti-aging agent, 6 parts of plasticizer and 5 parts of stabilizer.

[0042] In this embodiment, the flame retardant is any one or combination of zinc borate, aluminum hydroxide, magnesium hydroxide and antimony trioxide.

[0043] In this embodiment, the vulcanizing agent is any one or a combination of dicumyl peroxide, tert-butylphenol formaldehyde resin, benzoyl peroxide, quinone oxime compound, isocyanate and urethane.

[0044...

Embodiment 3

[0055] Such as figure 1 As shown, a green flame-retardant, high-temperature, oil-resistant special flexible cable material proposed by an embodiment of the present invention includes the following weight ratio raw materials: 50 parts of cross-linked polyethylene, 25 parts of polydimethylvinylsiloxane , 15 parts of polyurethane resin, 20 parts of aniline formaldehyde resin, 10 parts of nano-calcium carbonate, 4 parts of zinc stannate, 7.5 parts of kaolin, 20 parts of flame retardant, 4 parts of vulcanizing agent, 2 parts of lubricant, 2.5 parts of anti-aging agent, 4 parts of plasticizer and 4 parts of stabilizer.

[0056] In this embodiment, the flame retardant is any one or combination of zinc borate, aluminum hydroxide, magnesium hydroxide and antimony trioxide.

[0057] In this embodiment, the vulcanizing agent is any one or a combination of dicumyl peroxide, tert-butylphenol formaldehyde resin, benzoyl peroxide, quinone oxime compound, isocyanate and urethane.

[0058] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com