Flame-retardant PVC material and preparation method thereof

A technology of PVC material and PVC resin, which is applied in the field of flame-retardant PVC material and its preparation, can solve the problems of reducing PVC mechanical properties, limited improvement effect, and uneven dispersion, so as to delay thermal degradation speed, slow down or inhibit combustion, and improve dispersion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

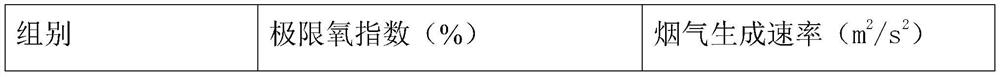

[0027] This embodiment provides a flame-retardant PVC material.

[0028] Composition of raw materials (parts by weight): 100 parts of PVC resin, 10 parts of surface-modified porous aluminum hydroxide microspheres, 5 parts of SbOCl, 2 parts of smoke suppressant, 2 parts of diisobutyl phthalate, bis(3,5 - 1 part of tertiary butyl-4-hydroxyphenyl) sulfide. The smoke suppressant is a compound mixture of zinc borate and molybdenum trioxide with a mass ratio of 3:1.

[0029] Surface modified porous aluminum hydroxide microspheres are prepared by the following method:

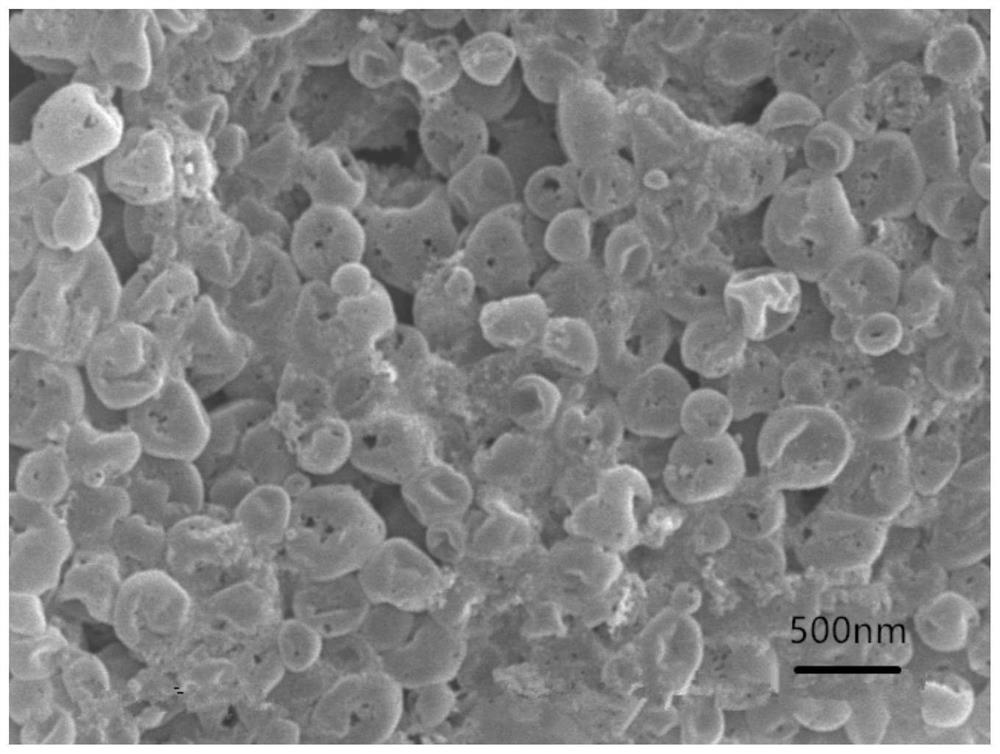

[0030] S1. Preparation of porous nano-aluminum hydroxide microspheres: adding pseudo-boehmite powder into water to obtain a suspension with a mass fraction of 15 wt%, adding 2 mol / L hydrochloric acid, adjusting the pH value to 4, heating to 70°C, and obtaining The sol is spray-dried after cooling to obtain porous nano-aluminum hydroxide microspheres;

[0031] S2. Porous nano-aluminum hydroxide microspheres loaded w...

Embodiment 2

[0035] This embodiment provides a flame-retardant PVC material.

[0036] Composition of raw materials (parts by weight): 120 parts of PVC resin, 10-15 parts of surface-modified porous aluminum hydroxide microspheres, 10 parts of SbOCl, 3 parts of smoke suppressant, 2-5 parts of di-n-octyl phthalate, 2, 3 parts of 6-tertiary butyl-4-methylphenol. The smoke suppressant is a compound mixture of zinc borate and molybdenum trioxide, with a mass ratio of 3:2.

[0037] Surface modified porous aluminum hydroxide microspheres are prepared by the following method:

[0038] S1. Preparation of porous nano-aluminum hydroxide microspheres: adding pseudo-boehmite powder into water to obtain a suspension with a mass fraction of 15 wt%, adding 0.5 mol / L of sulfuric acid, adjusting the pH value to 5, heating to 80°C, Obtain sol, spray dry after cooling, obtain porous nano-aluminum hydroxide microsphere;

[0039] S2. Porous nano-aluminum hydroxide microspheres loaded with adipic acid: Dissolv...

Embodiment 3

[0043] This embodiment provides a flame-retardant PVC material.

[0044] Composition of raw materials (parts by weight): 110 parts of PVC resin, 12 parts of surface-modified porous aluminum hydroxide microspheres, 7 parts of SbOCl, 2.5 parts of smoke suppressant, 3.5 parts of dioctyl phthalate, tetrakis [β-( 2 parts of 3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester. The smoke suppressant is a compound mixture of zinc borate and molybdenum trioxide with a mass ratio of 3:1.5.

[0045] Surface modified porous aluminum hydroxide microspheres are prepared by the following method:

[0046] S1. Preparation of porous nano-aluminum hydroxide microspheres: adding pseudo-boehmite powder into water to obtain a suspension with a mass fraction of 20 wt%, adding 1 mol / L nitric acid, adjusting the pH to 4.5, heating to 75°C, and obtaining The sol is spray-dried after cooling to obtain porous nano-aluminum hydroxide microspheres;

[0047] S2. Porous nano-aluminum hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com