Double-vacuum superconducting tube based on metal tubes

A double vacuum, metal tube technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems that thermal efficiency cannot be reached quickly, local high temperature is prone to occur, uneven heat conduction, etc. Short heating time and fast thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

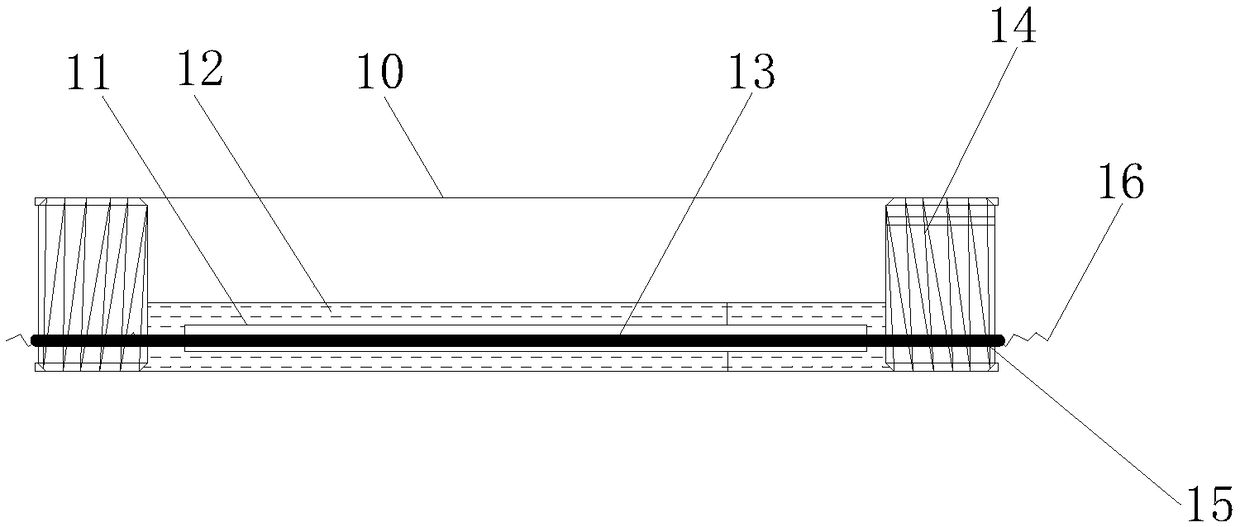

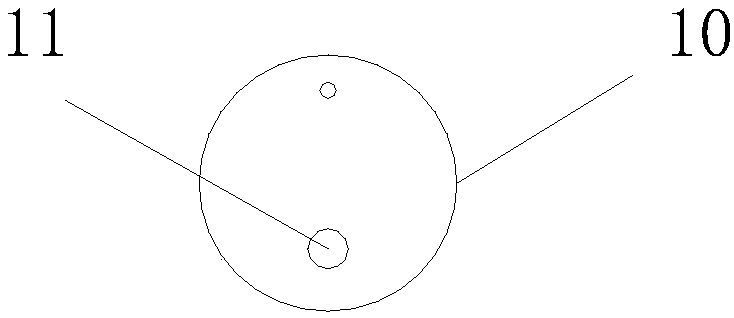

[0022] A dual vacuum superconductor based on metal tubes, see appendix figure 1 As shown, it includes a first outer tube 10, a second outer tube 11, a nano metal rod 13 and a sealing plug 14, the first outer tube 10 is provided with a superconducting chamber, and the sealing plugs 14 are respectively located at The two ends of the first outer tube 10 make the superconducting chamber of the first outer tube 10 form a closed space, and the superconducting chamber is divided into a vacuum layer and a superconducting liquid layer 12 from top to bottom; The outer tube 11 is embedded in the center of the superconducting liquid layer 12, and the nano-metal rods 13 pass through the second outer tube 11 and the superconducting liquid layer 12, and are connected to the sealing plugs 14 arranged at both ends of the first outer tube 10. The nano metal rod 13 is tightly wound with a silica gel heating wire; the silica gel heating wire passes through the wire hole 15 on the sealing plug, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com