Pipe connection instant heating type heat exchanger with part of shell tubes storing water

A heat exchanger and connecting pipe technology, applied in the field of HVAC, can solve the problems of paying more water bills, increasing costs, and increasing product volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

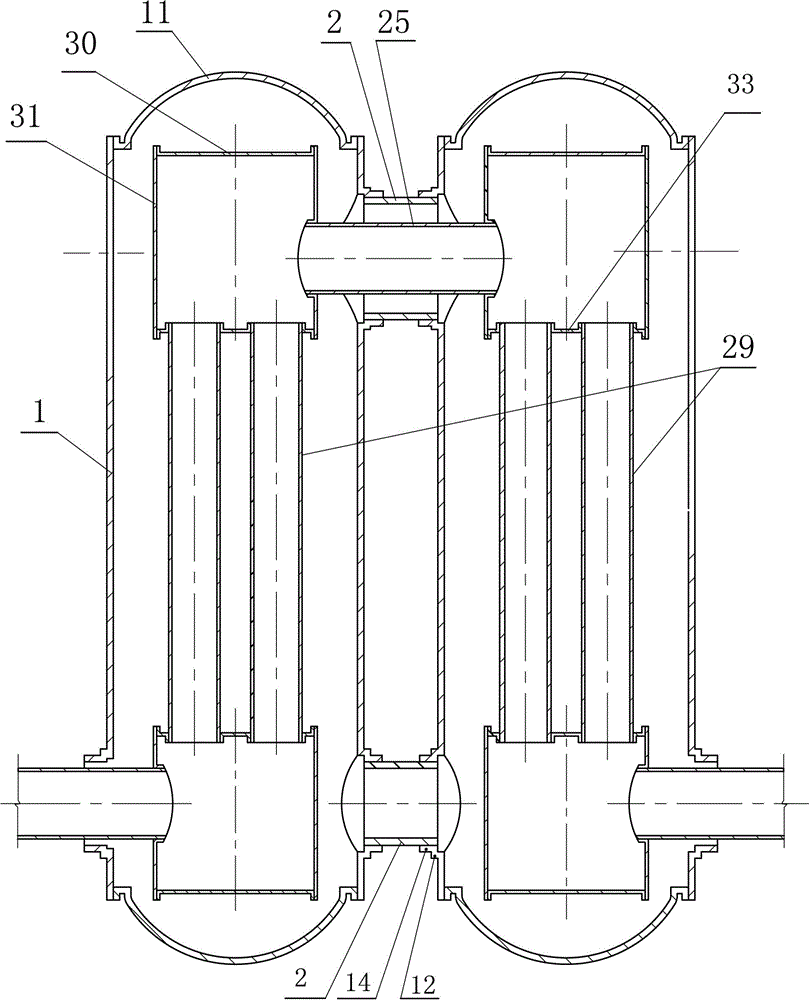

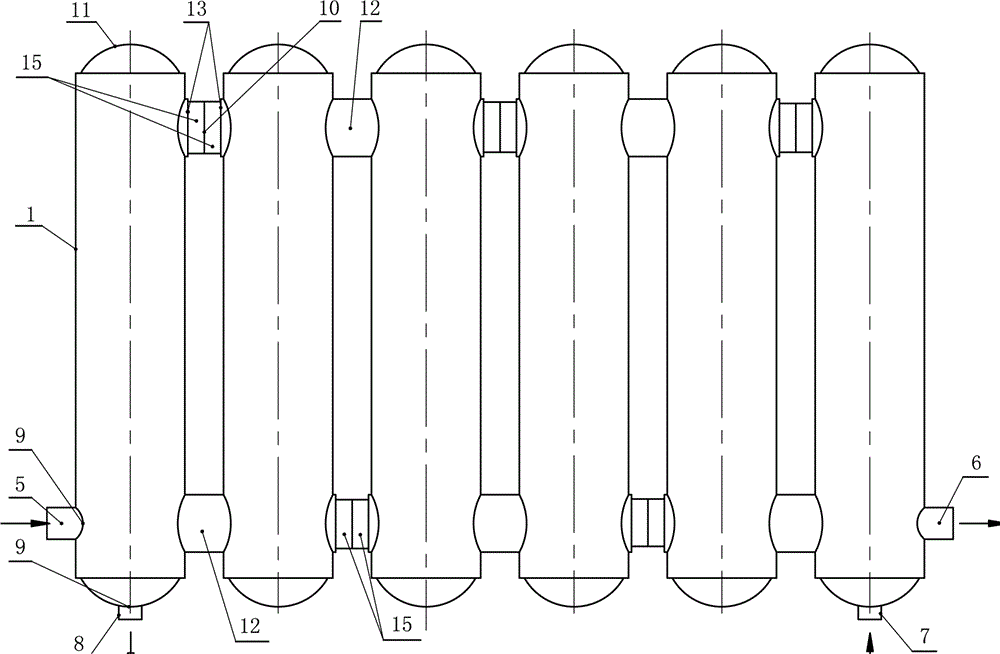

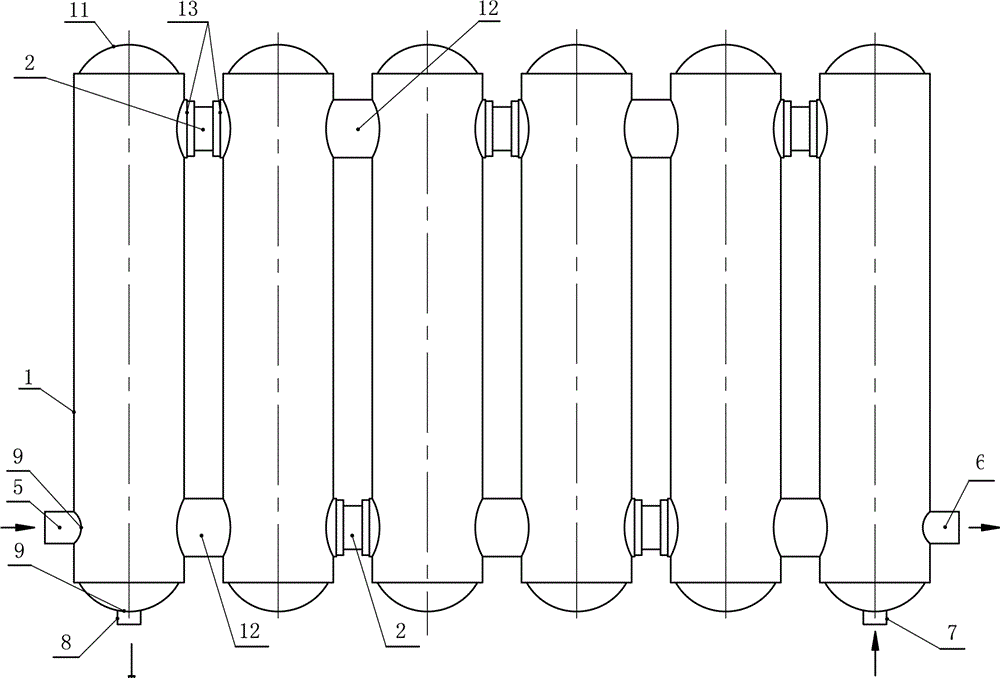

[0034] 1. The pipe of the present invention connects part of the shell-and-tube water storage heat exchanger, such as Figure 1 to Figure 25 As shown, it includes: shell tube 1, head blocking plate 11, cold water heat-absorbing pipe 3, heating pipe 24, heating connecting pipe 25, pipe connecting partition 26, pipe joints and other components assembled and welded to form a radiator-shaped heat exchanger; Ports of multiple shell tubes 1 are locally positioned and have shell tube Unicom welding holes 10 or notches 21 at the mouth of the tubes. The holes or slots on the shell tubes 1 are connected to the adjacent tubes by airtight welding. The cavity is connected to form a fluid heat conduction circulation channel; the port of the shell tube 1 is not perforated, and the wall of the tube is provided with a support 12 to support and fix the adjacent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com