Patents

Literature

126 results about "Tube change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

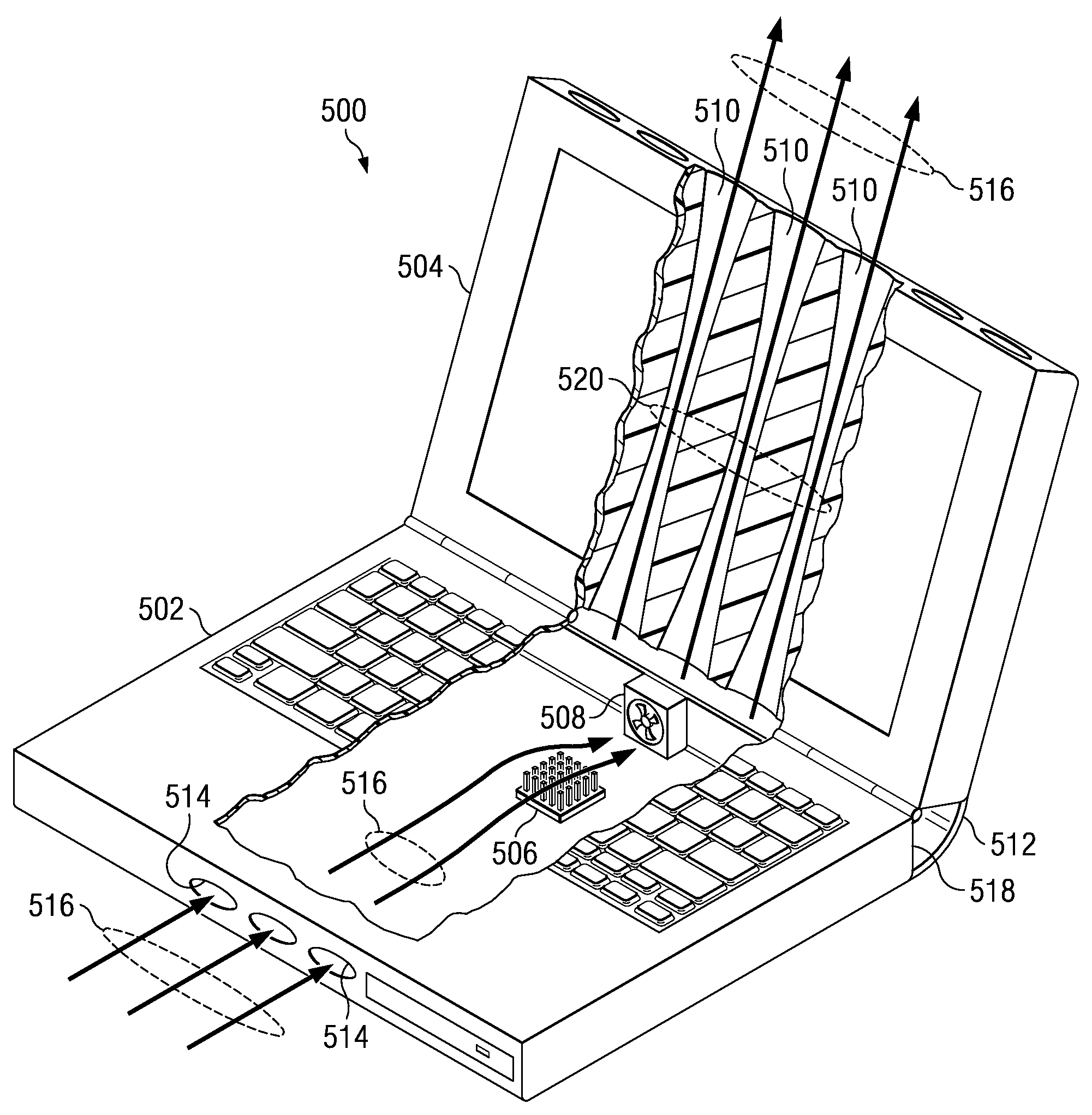

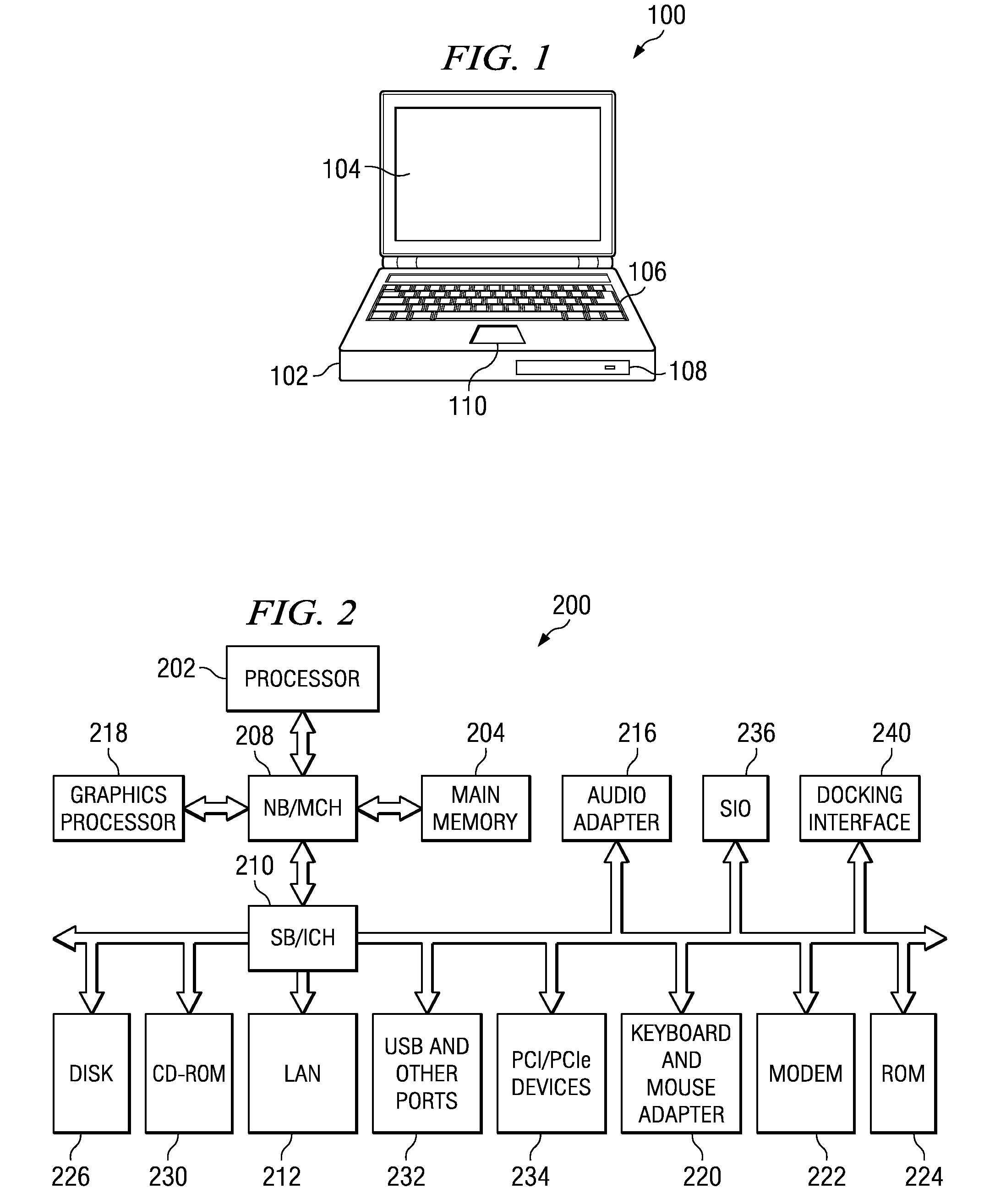

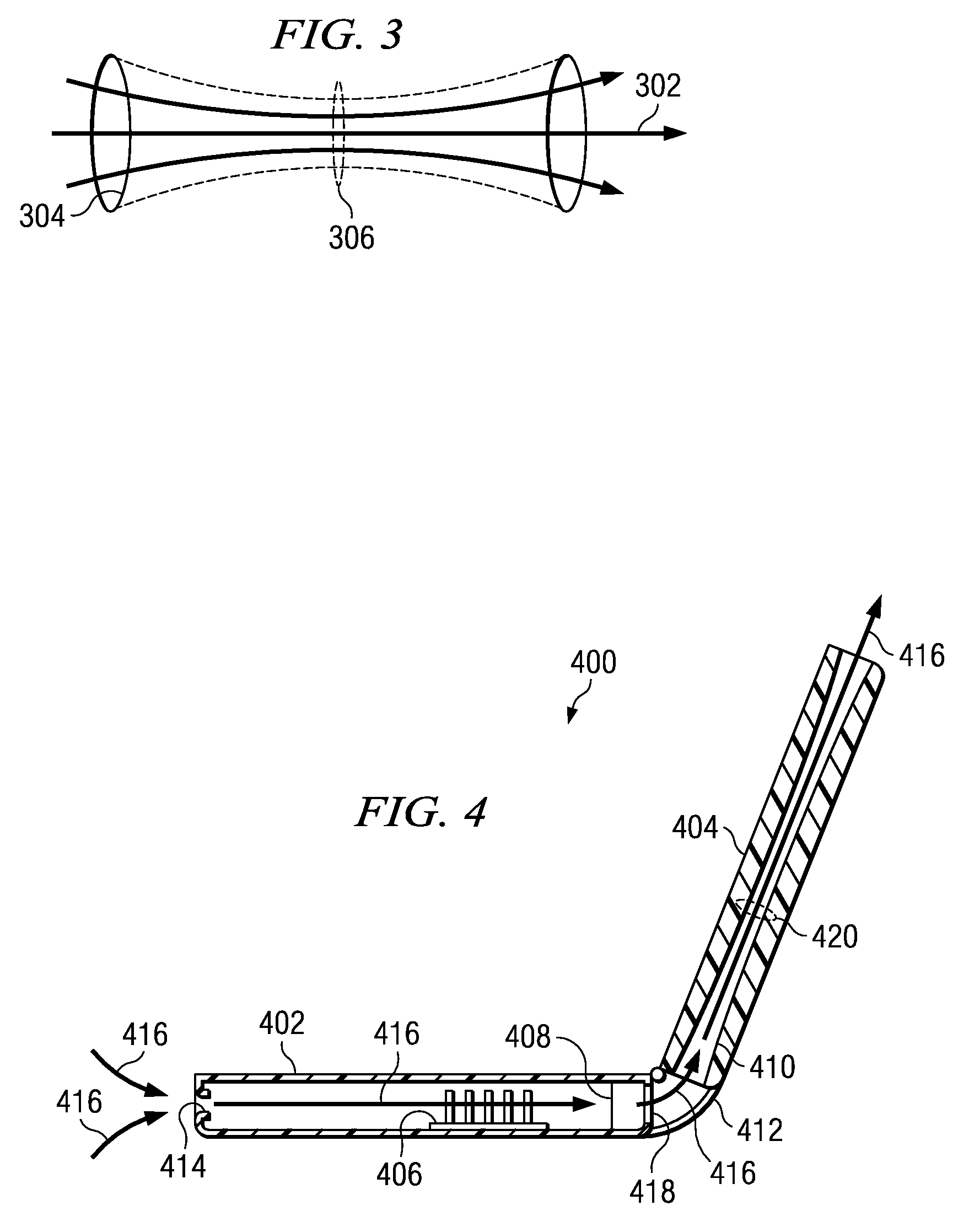

Venturi bernoulli heat extraction system for laptop computers

InactiveUS7457113B2Digital data processing detailsHeat exchange apparatusDisplay deviceMechanical engineering

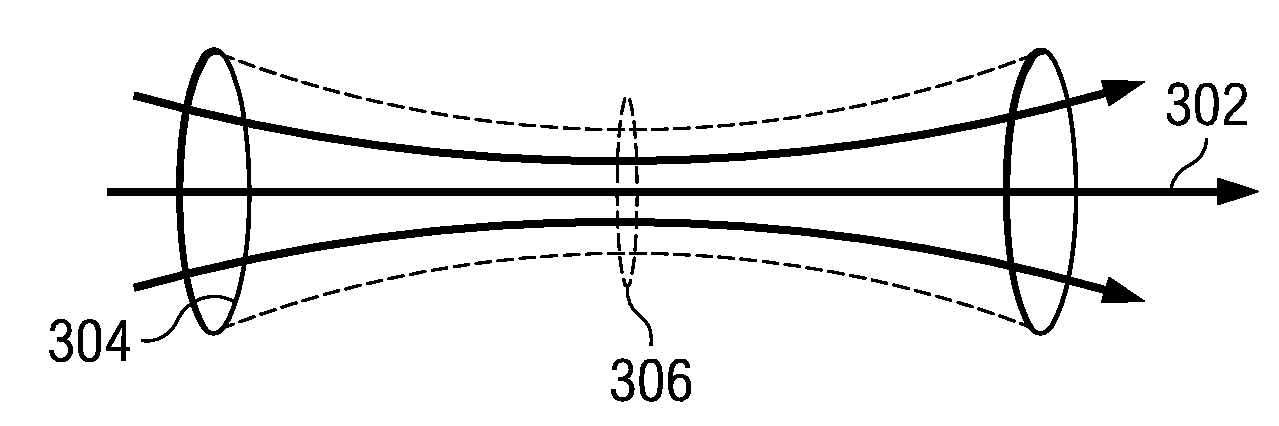

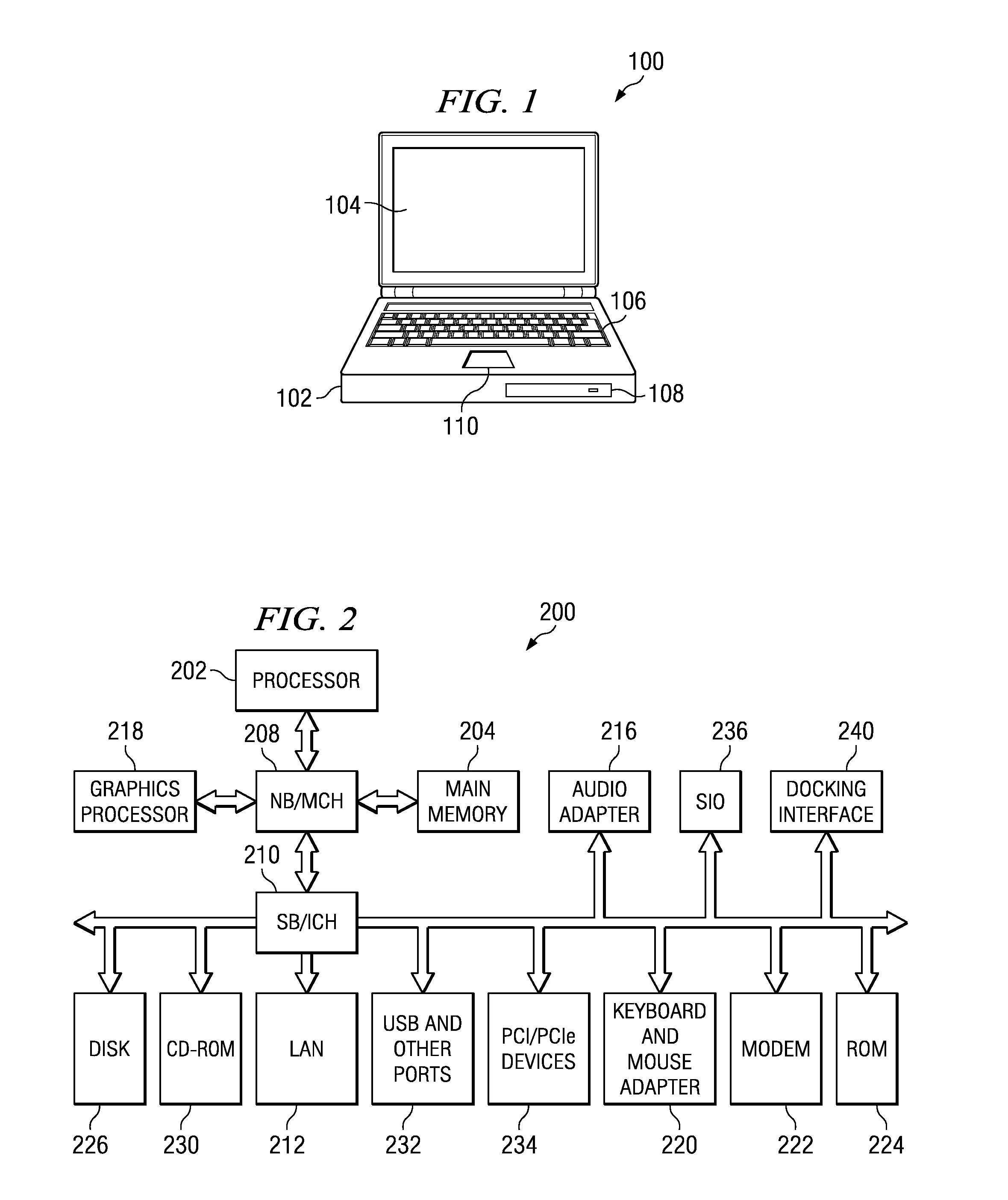

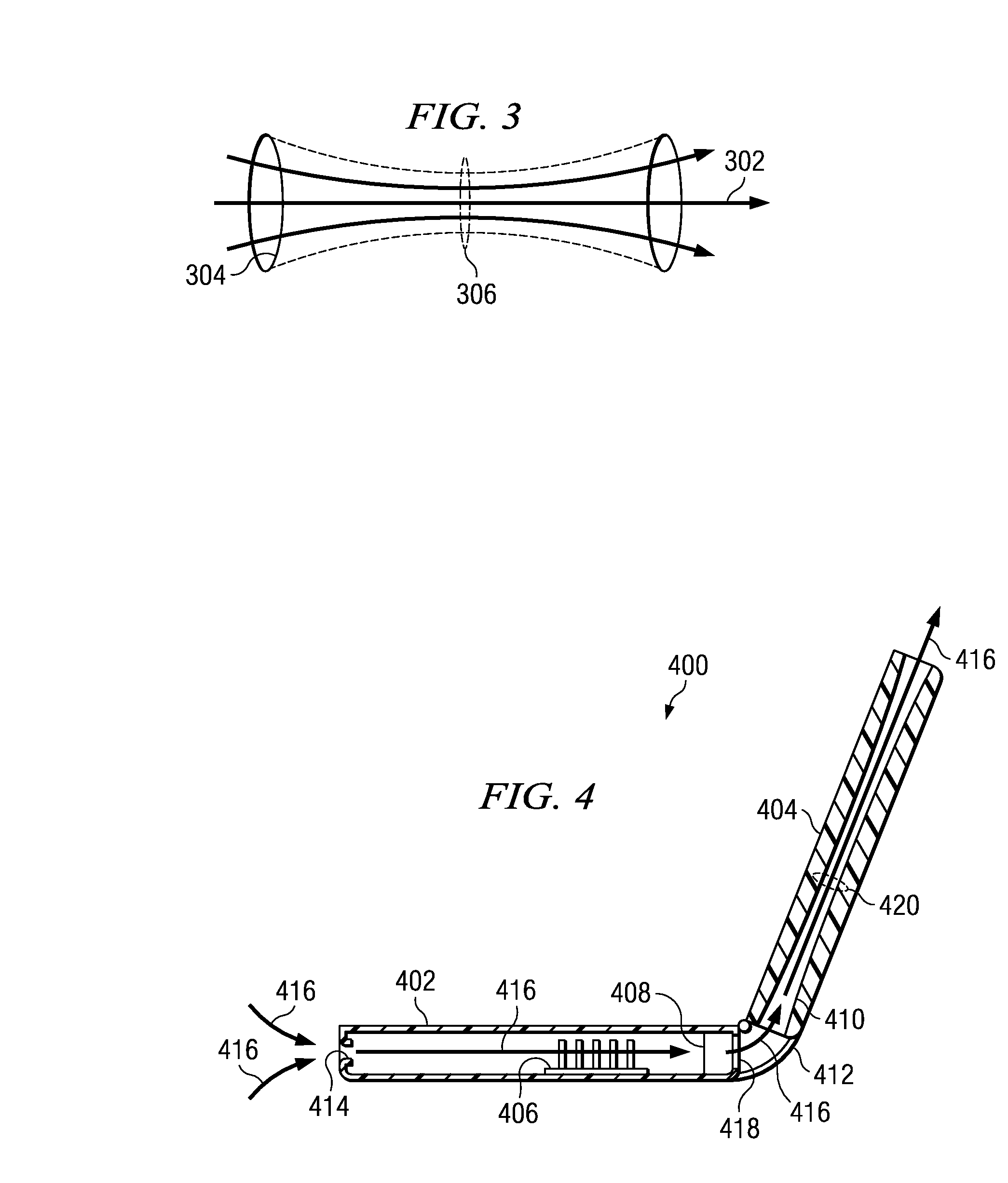

A heat extraction system is provided for a laptop computer that comprises a system unit that includes a set of heat sources and a video display unit that is movably attached to the system unit. The laptop computer has air inlets and air outlets that allow air to flow into the system unit, over the heat sources forming heated air, and exhaust the heated air. The laptop computer has a set of tubes, which have an inlet and an outlet, located behind a video display in the video display unit and an air connection from the air outlets to each inlet in the tubes. The set of tubes are formed such that heated air passing through a constriction in the set of tubes changes in velocity and pressure in order to satisfy the conservation of flow rate. Thus, heat produced by the heat sources is extracted from the laptop computer.

Owner:IBM CORP

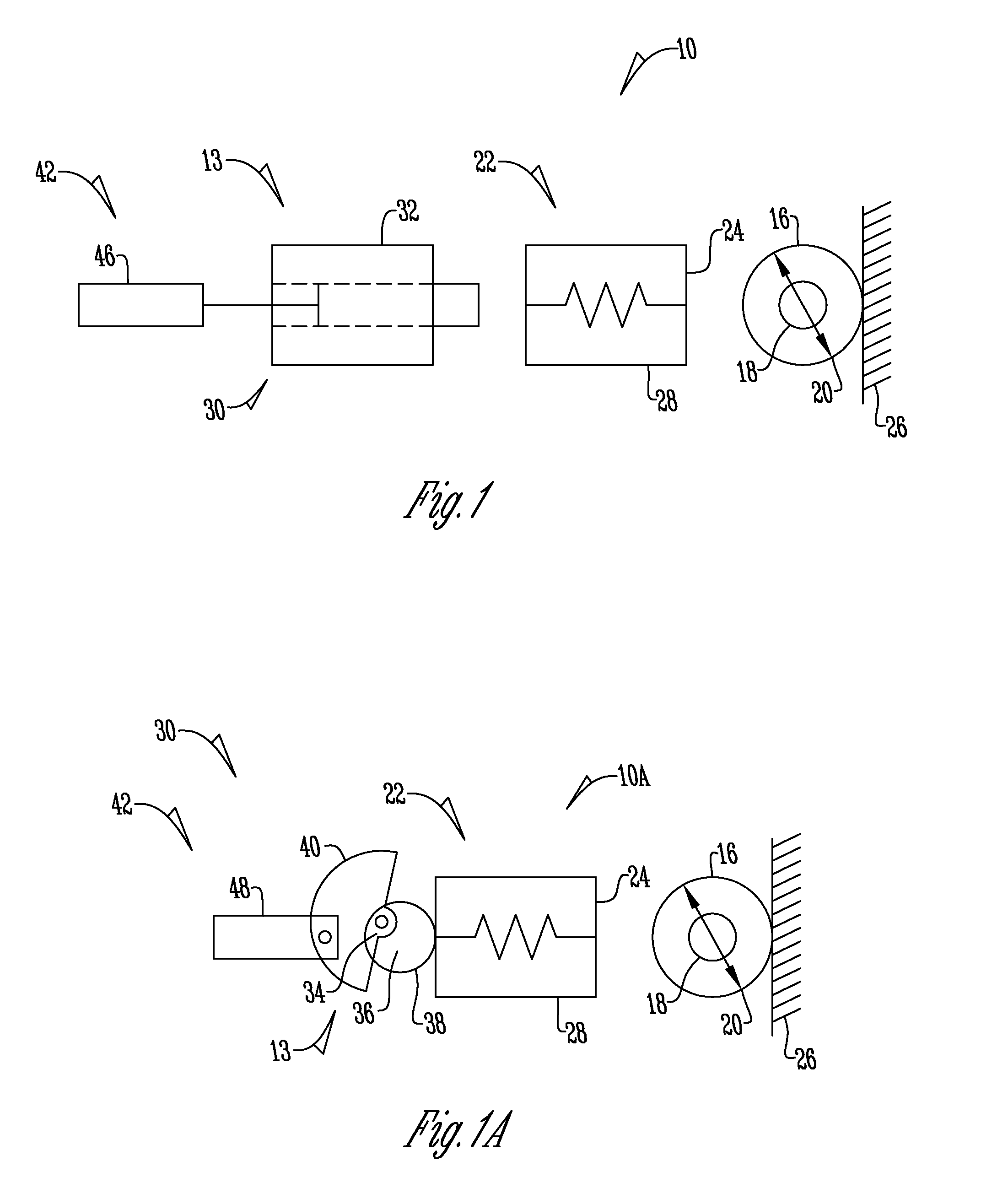

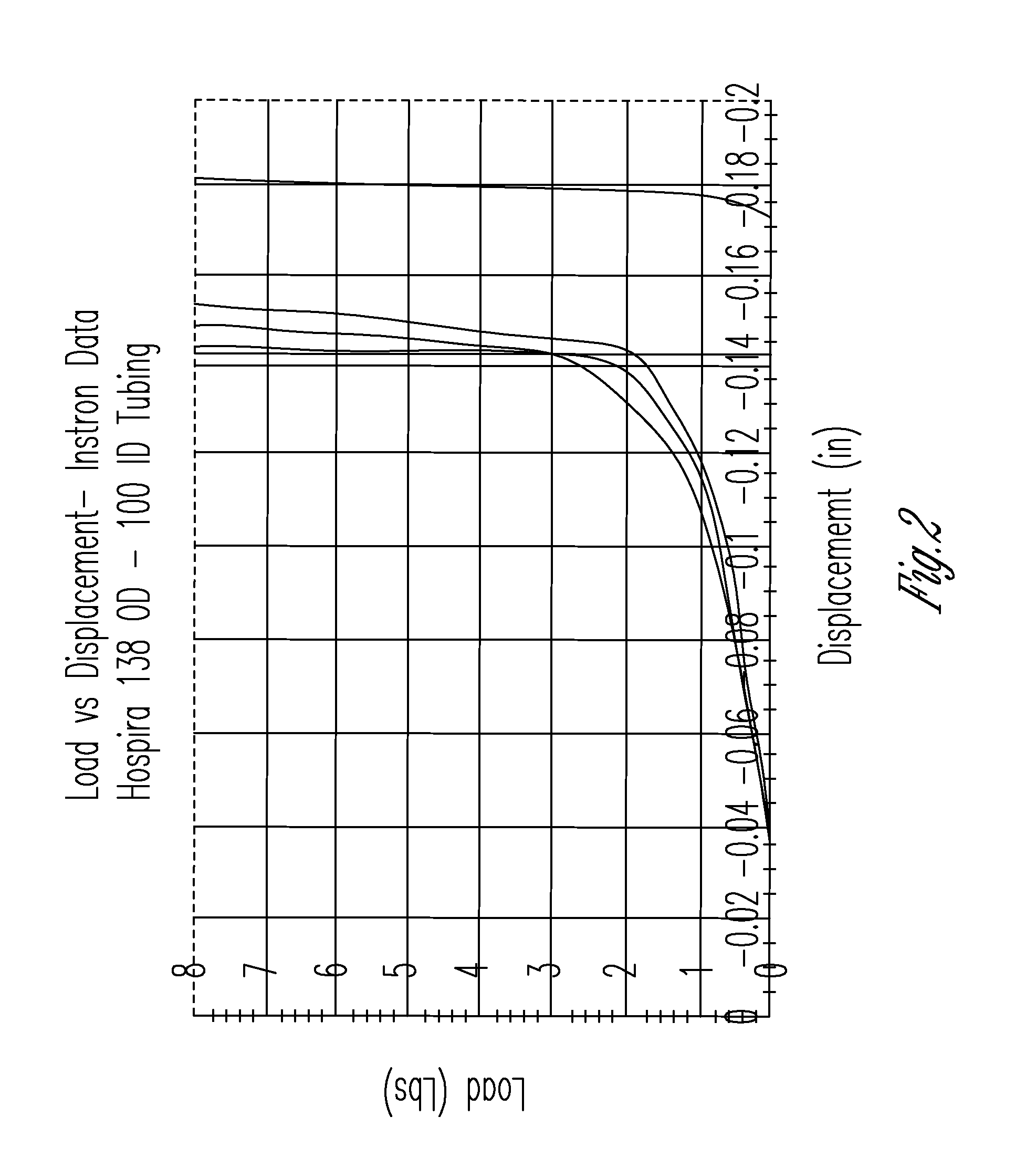

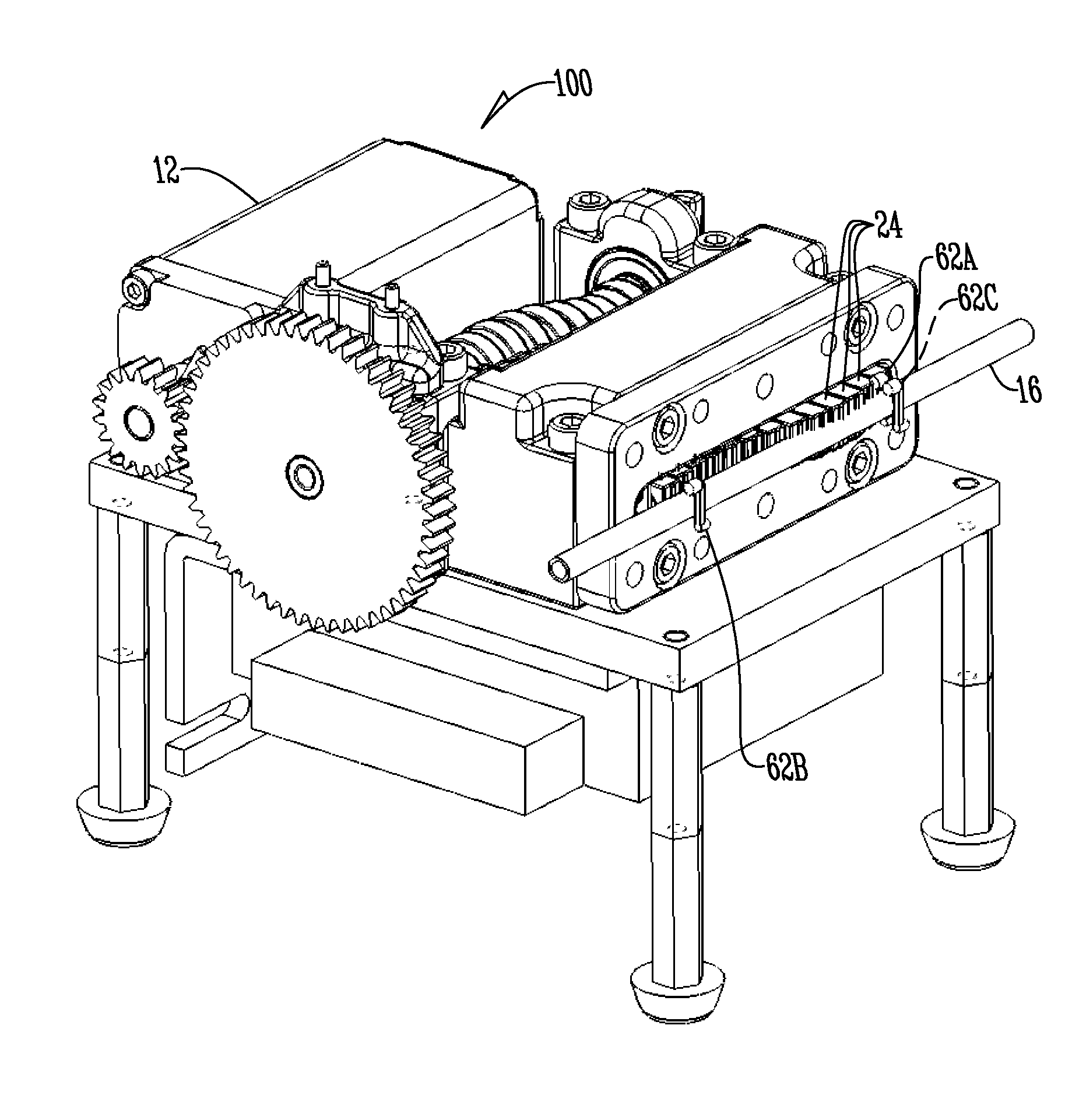

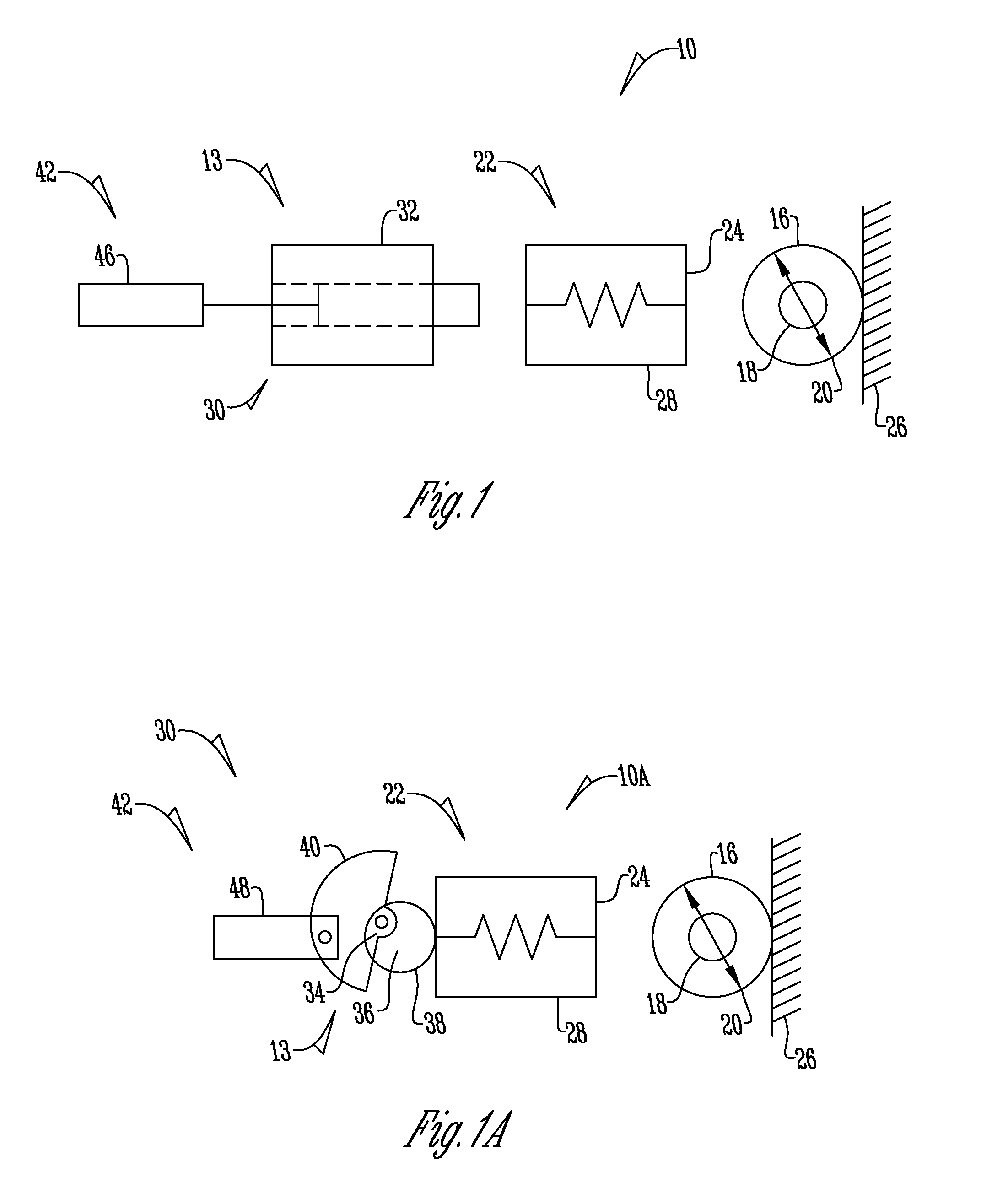

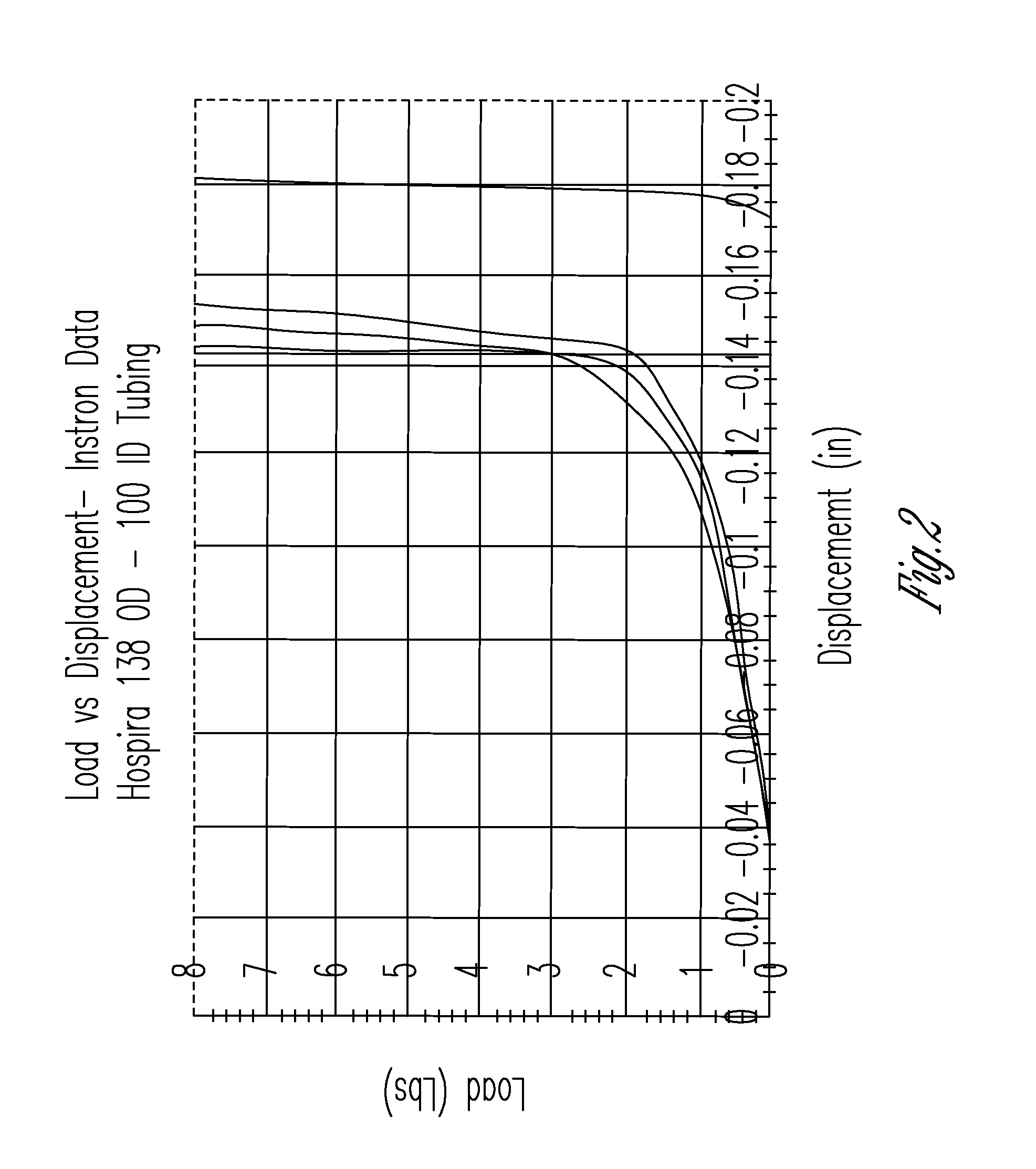

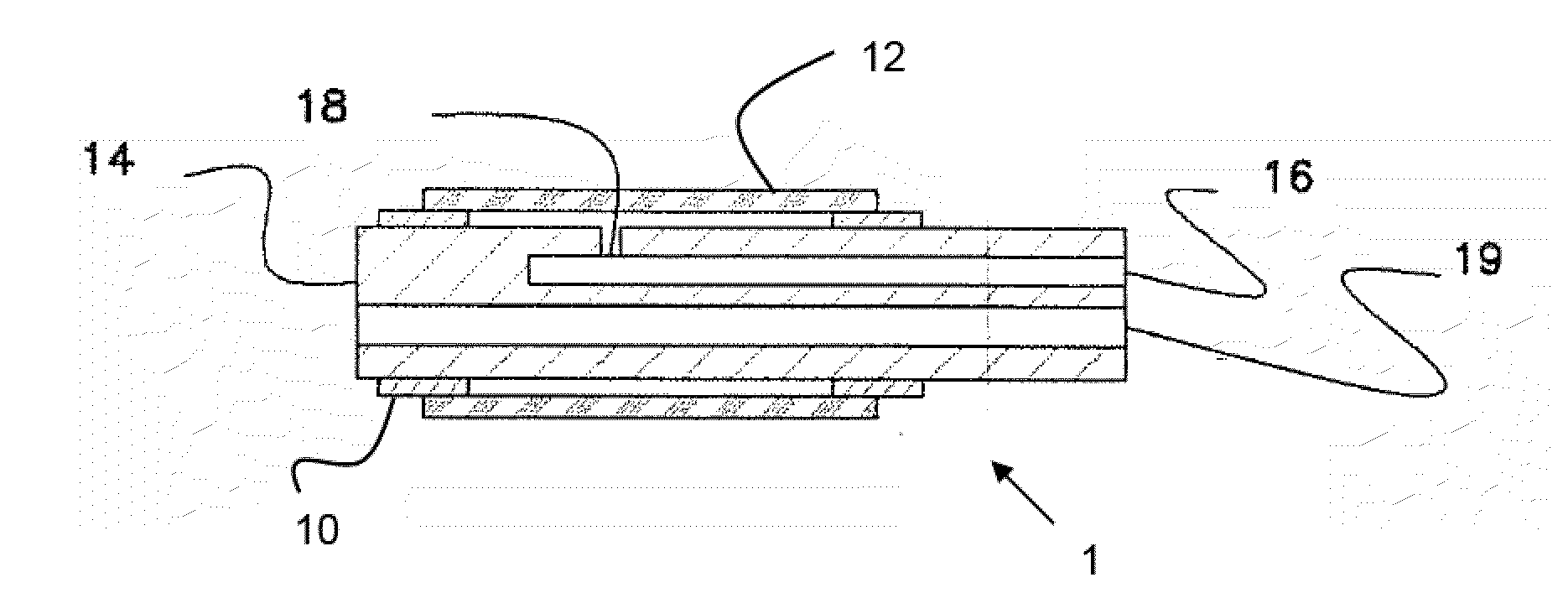

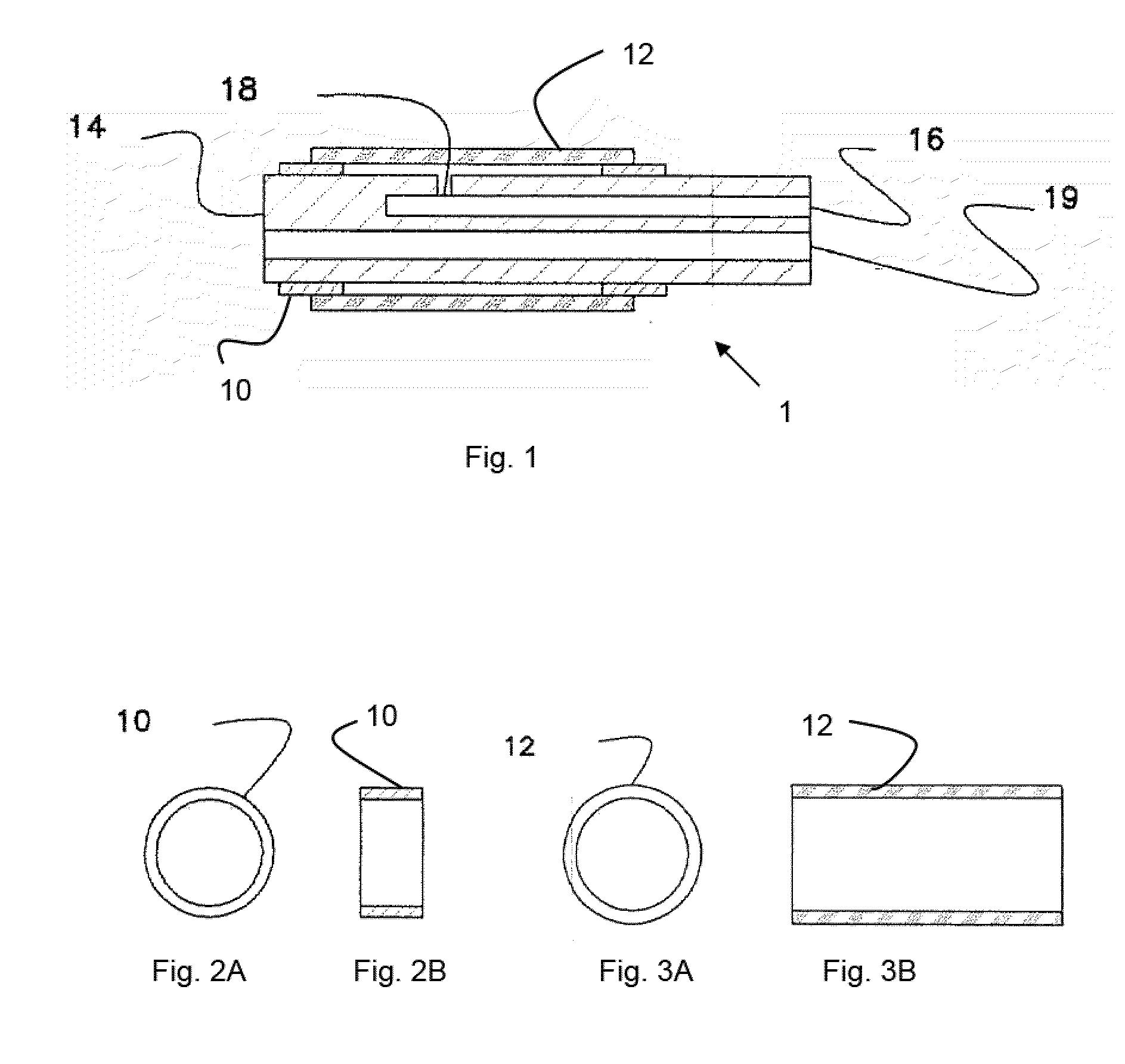

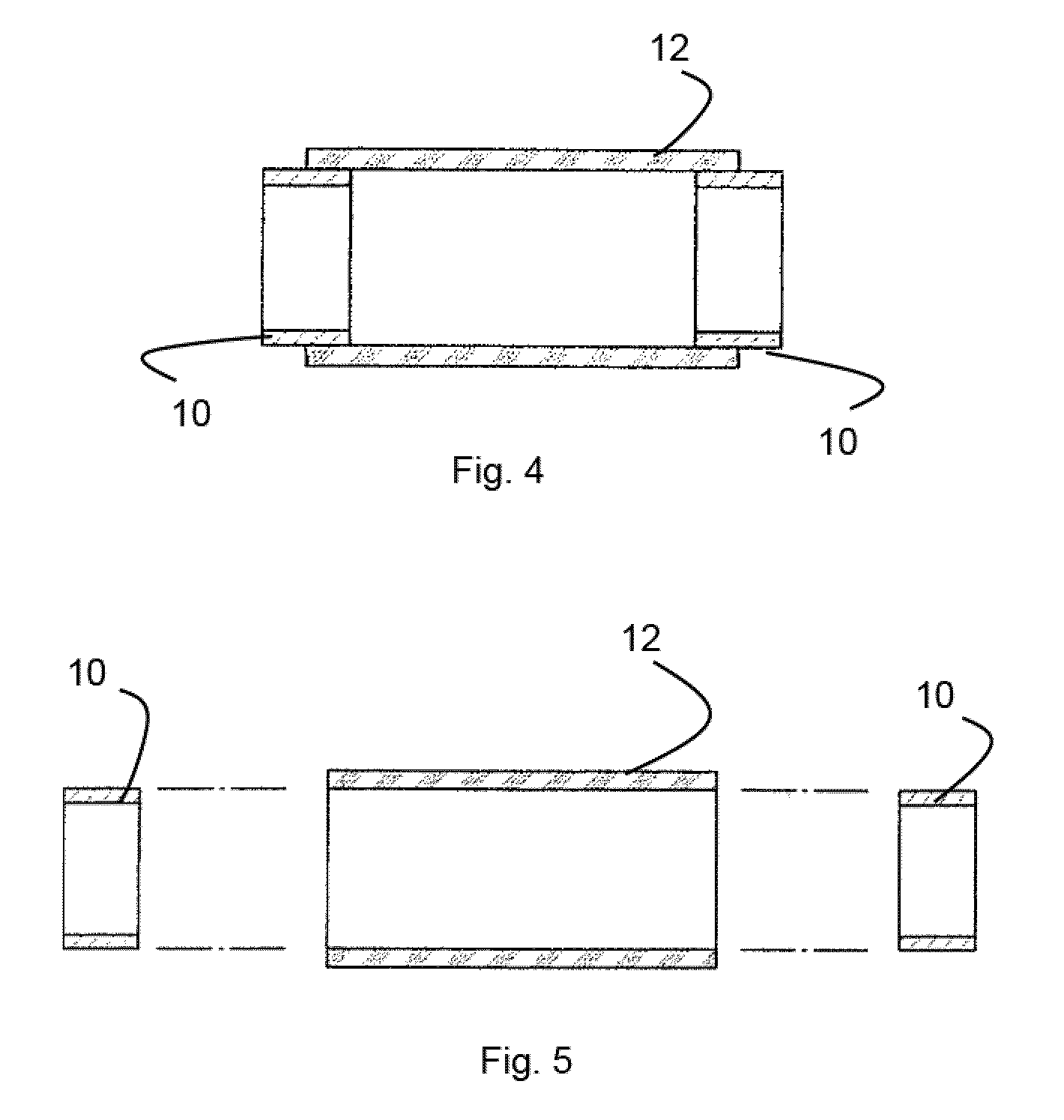

Fluid Flow Rate Compensation System Using an Integrated Conductivity Sensor to Monitor Tubing Changes

ActiveUS20110318198A1Consistent rateCompensate degradationFlexible member pumpsIntravenous devicesElectricityElectric signal

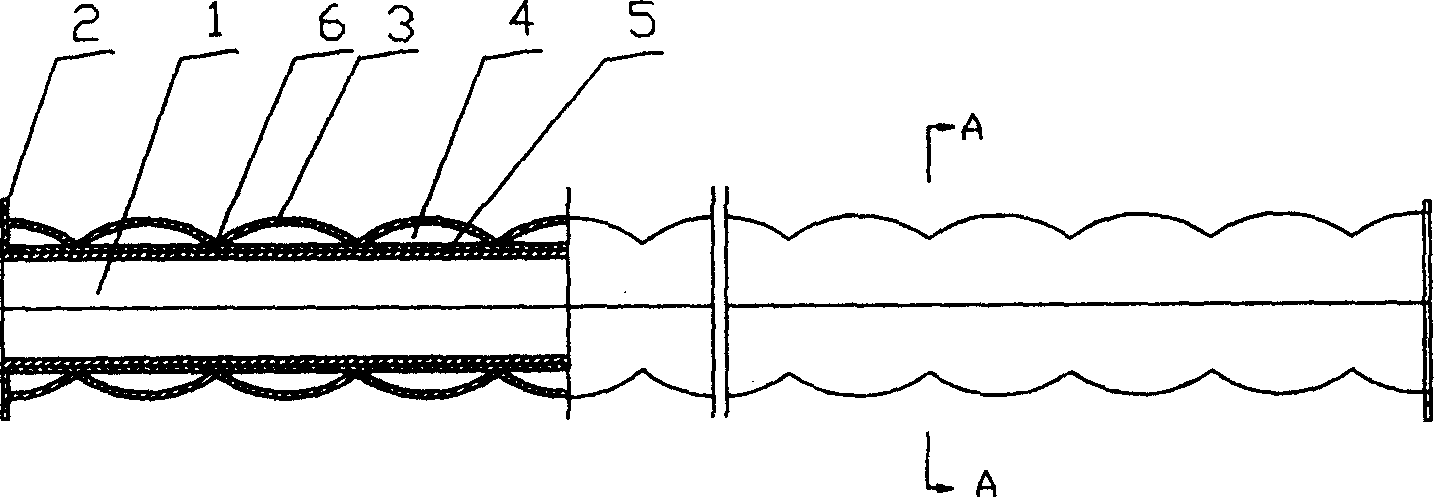

An infusion system and method for controlling the fluid flow from a pump includes a pump system that has a controller that utilizes an algorithm to control the flow rate of fluid through tubing. A plurality of electrodes operatively contacts an electrically conductive portion of the tubing that is also acted upon by the pump system. The electrodes monitor electrical properties of the tubing and provide an electric signal indicative thereof to the controller, which varies the flow rate of the fluid through the tubing as a result of the electric signal.

Owner:ICU MEDICAL INC

Fluid flow rate compensation system using an integrated conductivity sensor to monitor tubing changes

ActiveUS8858185B2Consistent rateCompensate degradationFlexible member pumpsIntravenous devicesElectricityElectric signal

An infusion system and method for controlling the fluid flow from a pump includes a pump system that has a controller that utilizes an algorithm to control the flow rate of fluid through tubing. A plurality of electrodes operatively contacts an electrically conductive portion of the tubing that is also acted upon by the pump system. The electrodes monitor electrical properties of the tubing and provide an electric signal indicative thereof to the controller, which varies the flow rate of the fluid through the tubing as a result of the electric signal.

Owner:ICU MEDICAL INC

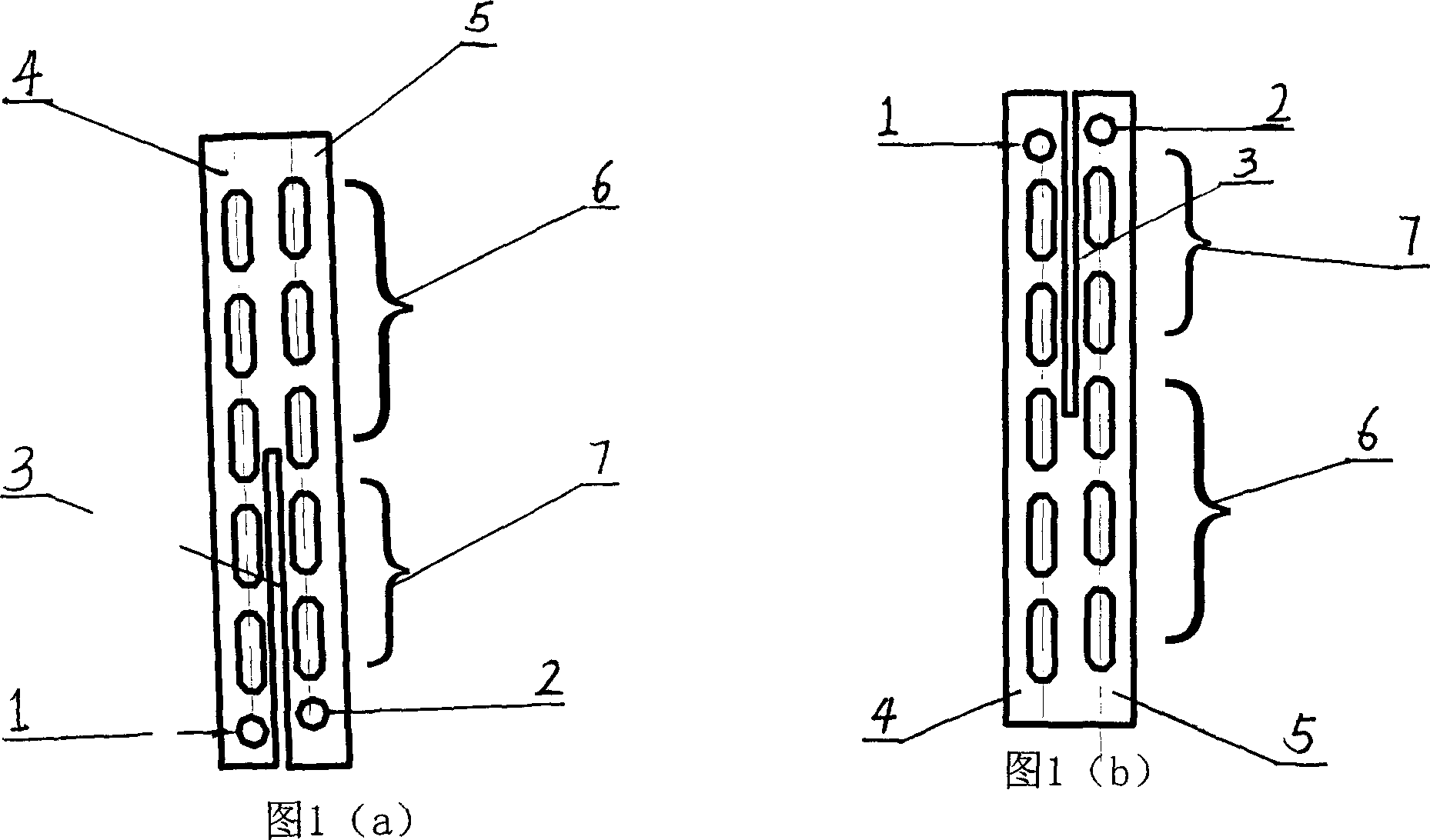

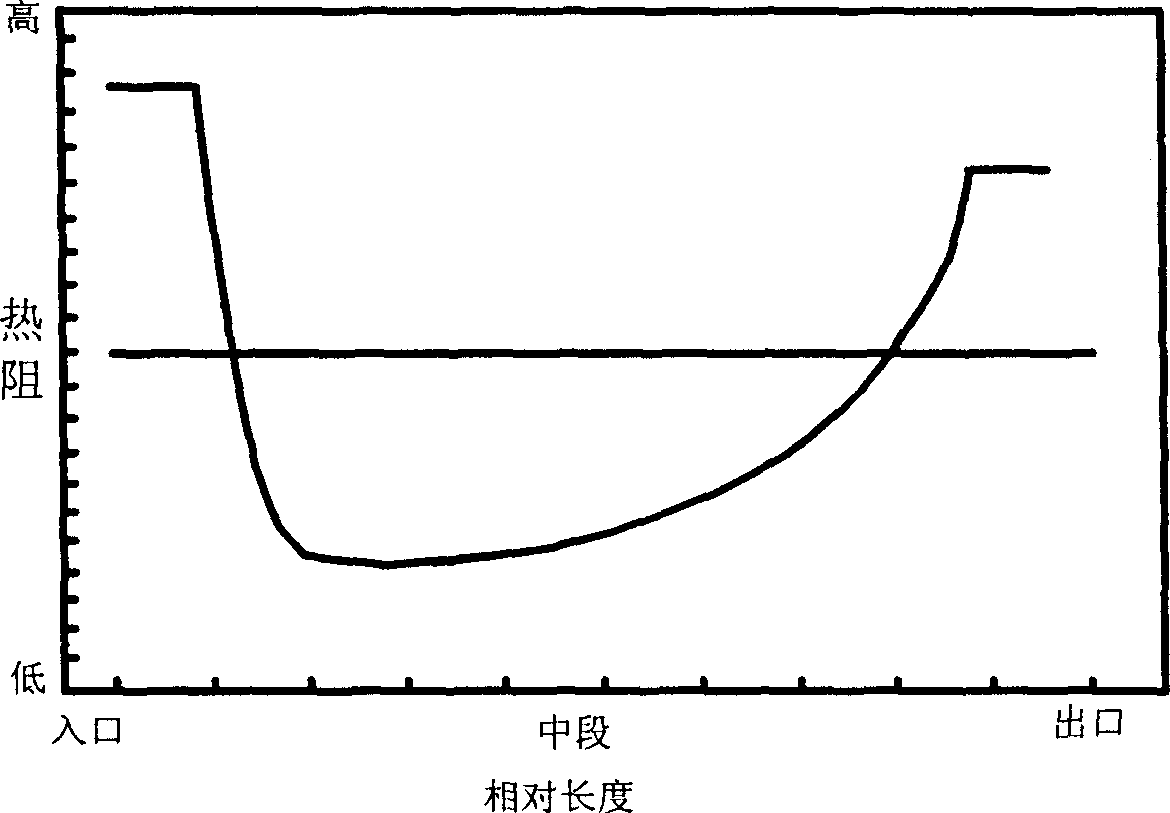

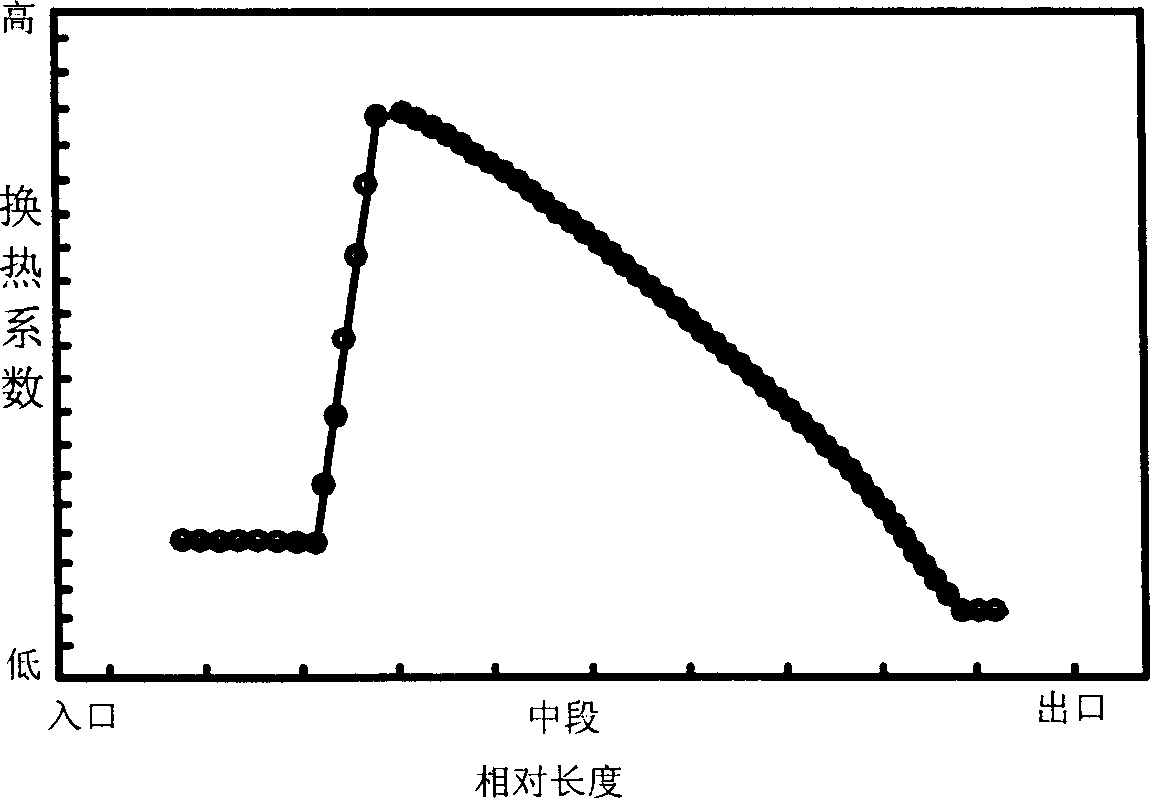

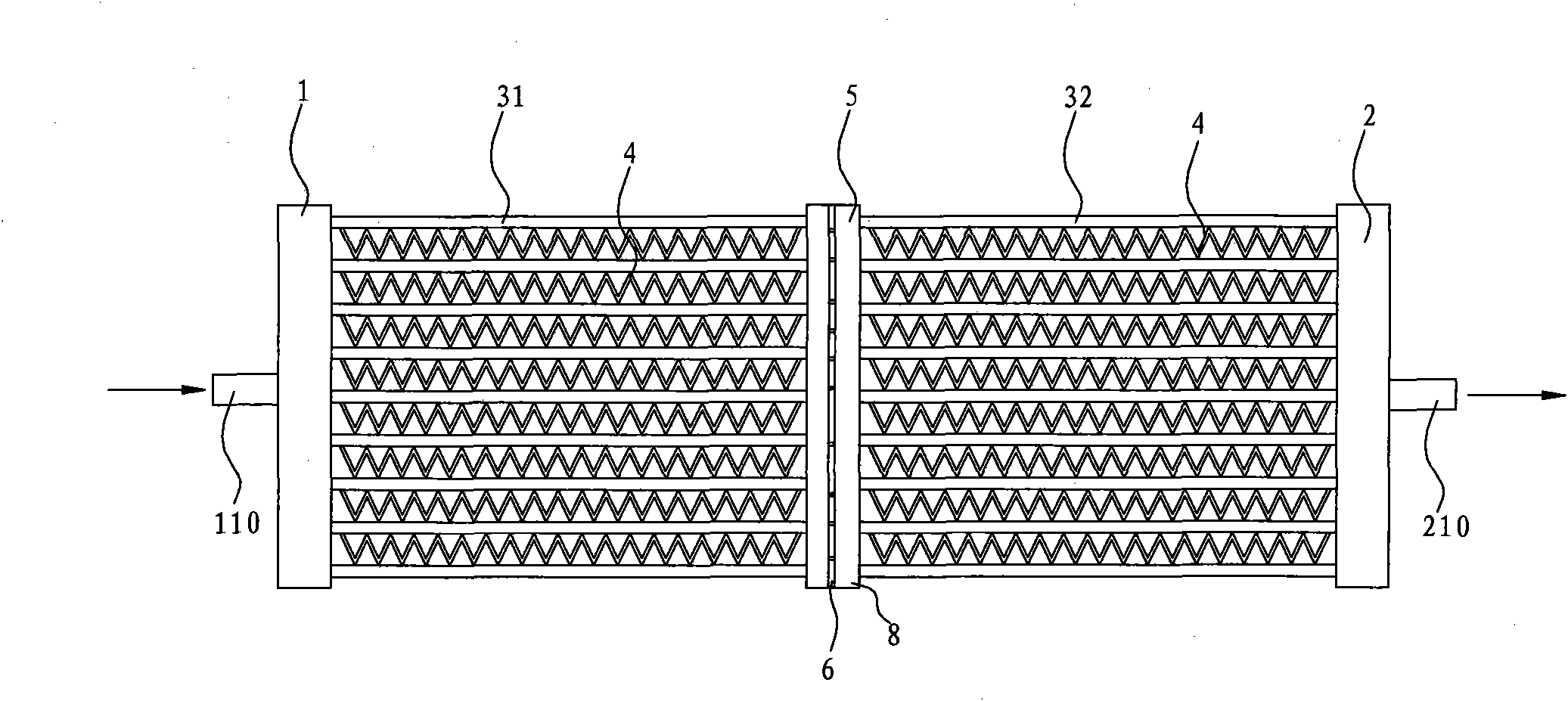

Heat exchanger flow circuit arranging method and device

InactiveCN1389702AImprove heat transfer effectReduce volumeHeat transfer modificationHeat flowEngineering

This invention relates to a design method for the flow circuit of a heat exchanger, which is suitable to the condenser and evaporator in refrigerator or air conditioner using single or mixed refrigerant. In said design multiple factors are comprehensively considered, such as constant heat flow principle and field coordination principle. It is provided that as the phase state of the refrigerant running in tube changes, the flow path number, the type of the fin out of tube and the reinforcing structure in tube should be changed, and suitable nodes should be selected to branch or interflow the flow. The heat exchange characteristic of refrigerating and air conditioning apparatus can be obviously raised.

Owner:XI AN JIAOTONG UNIV

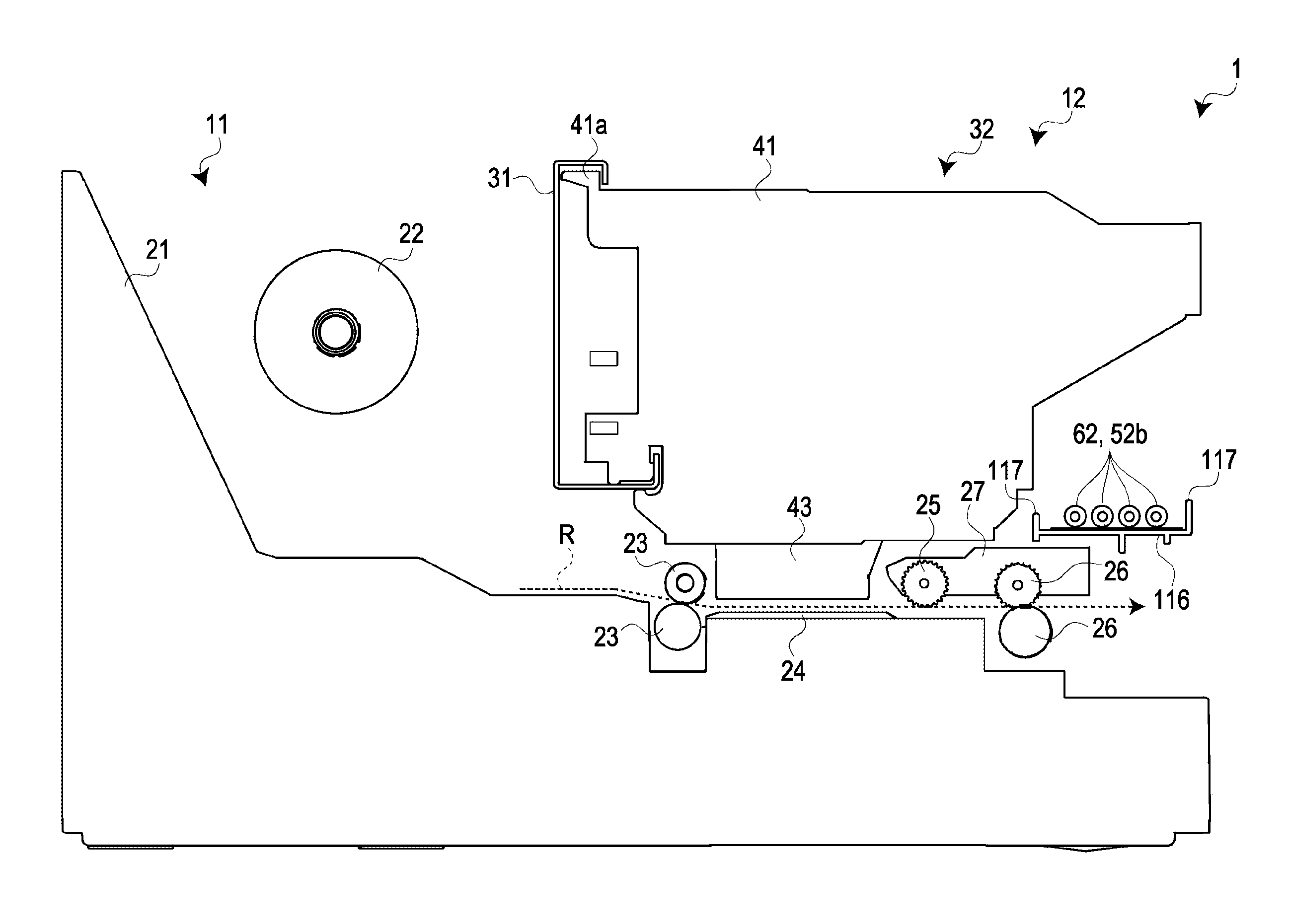

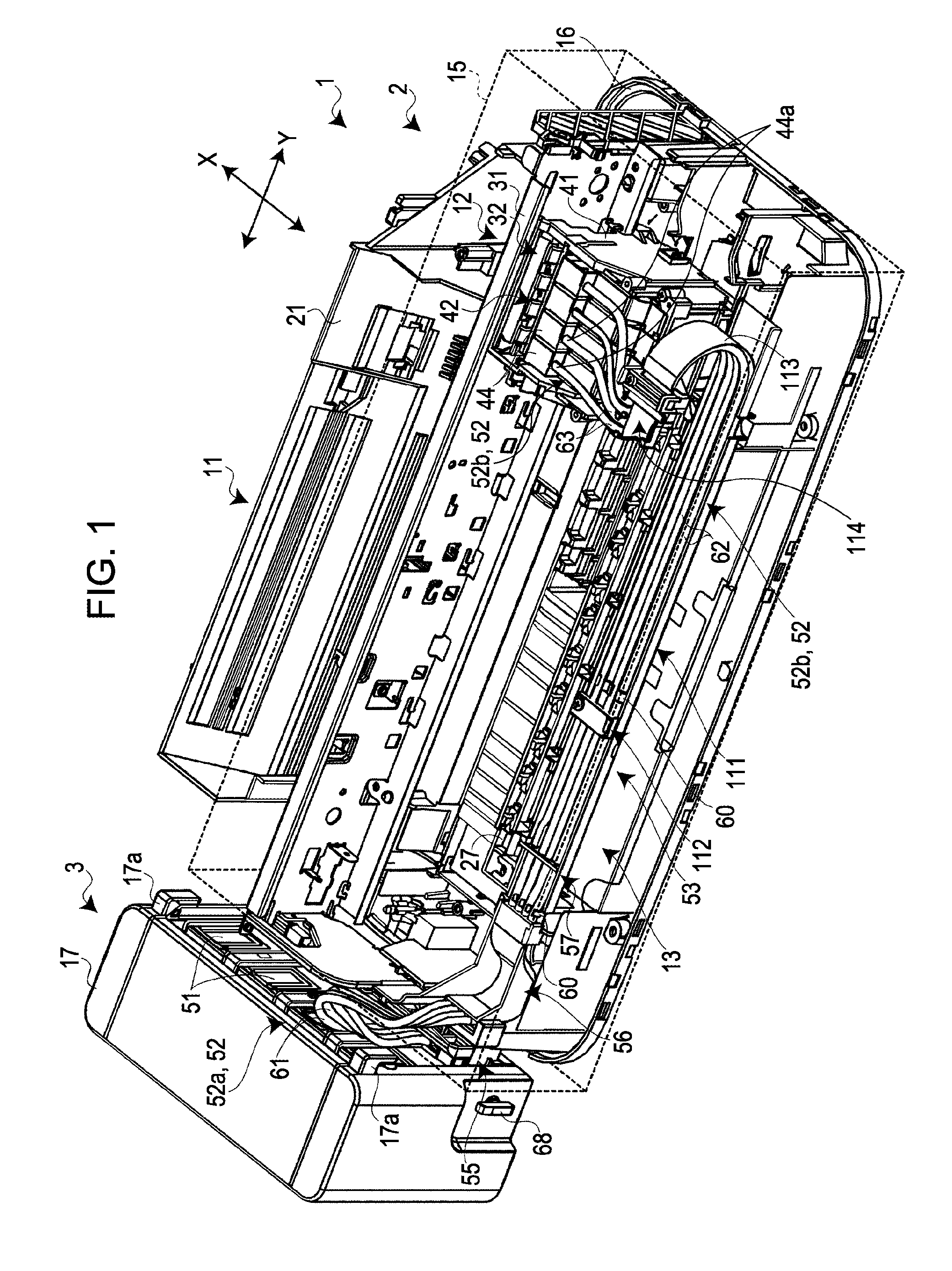

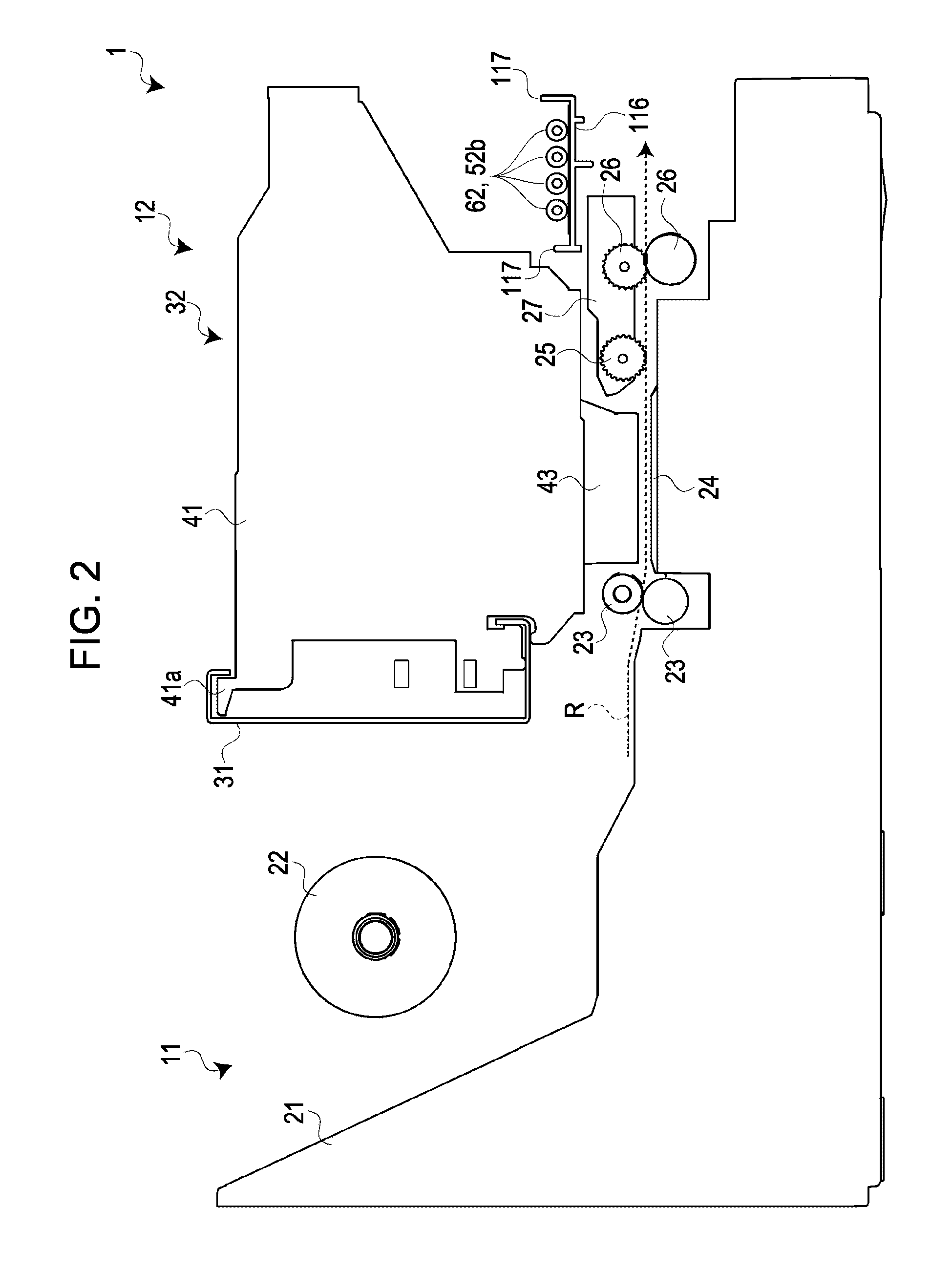

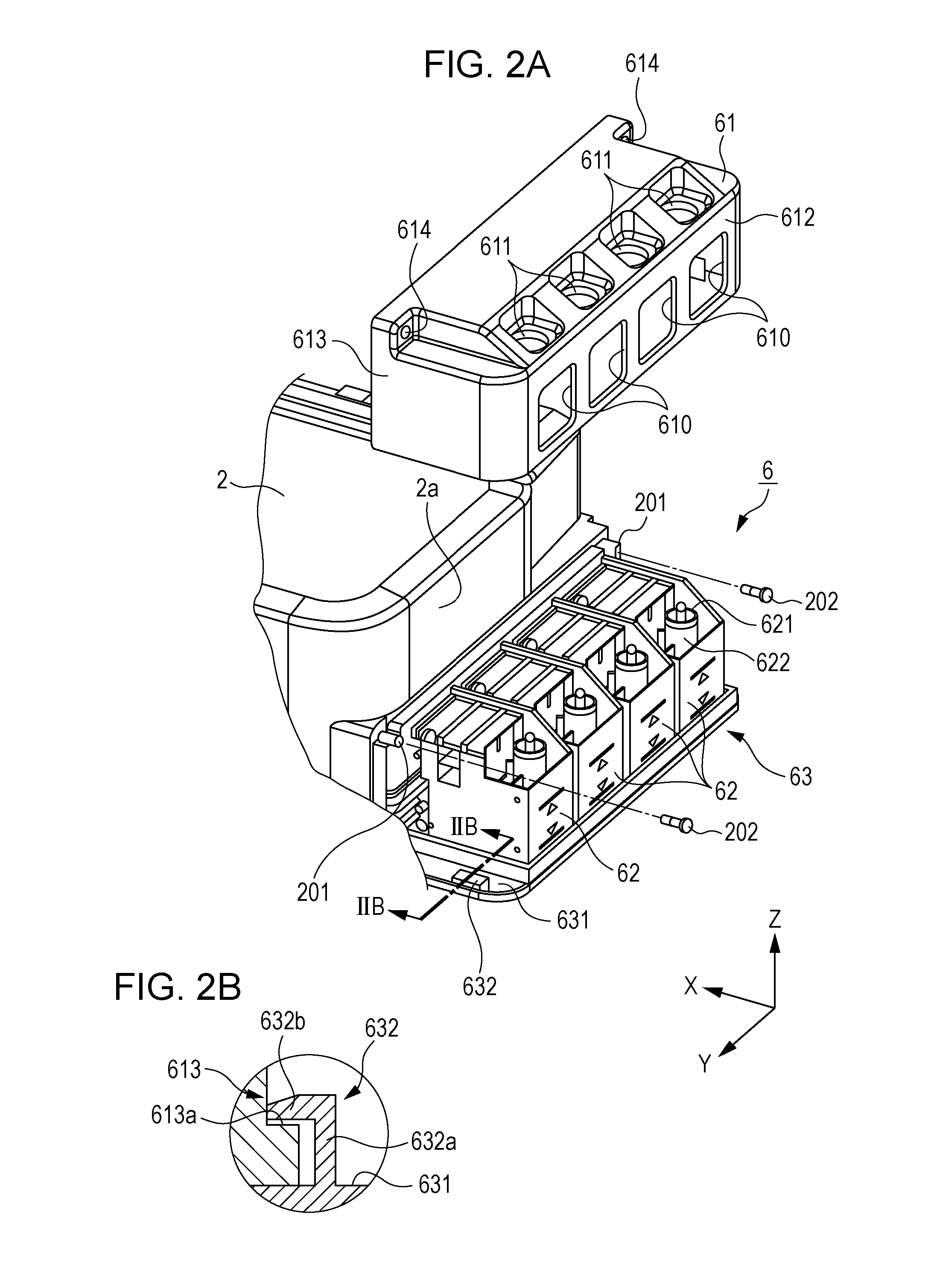

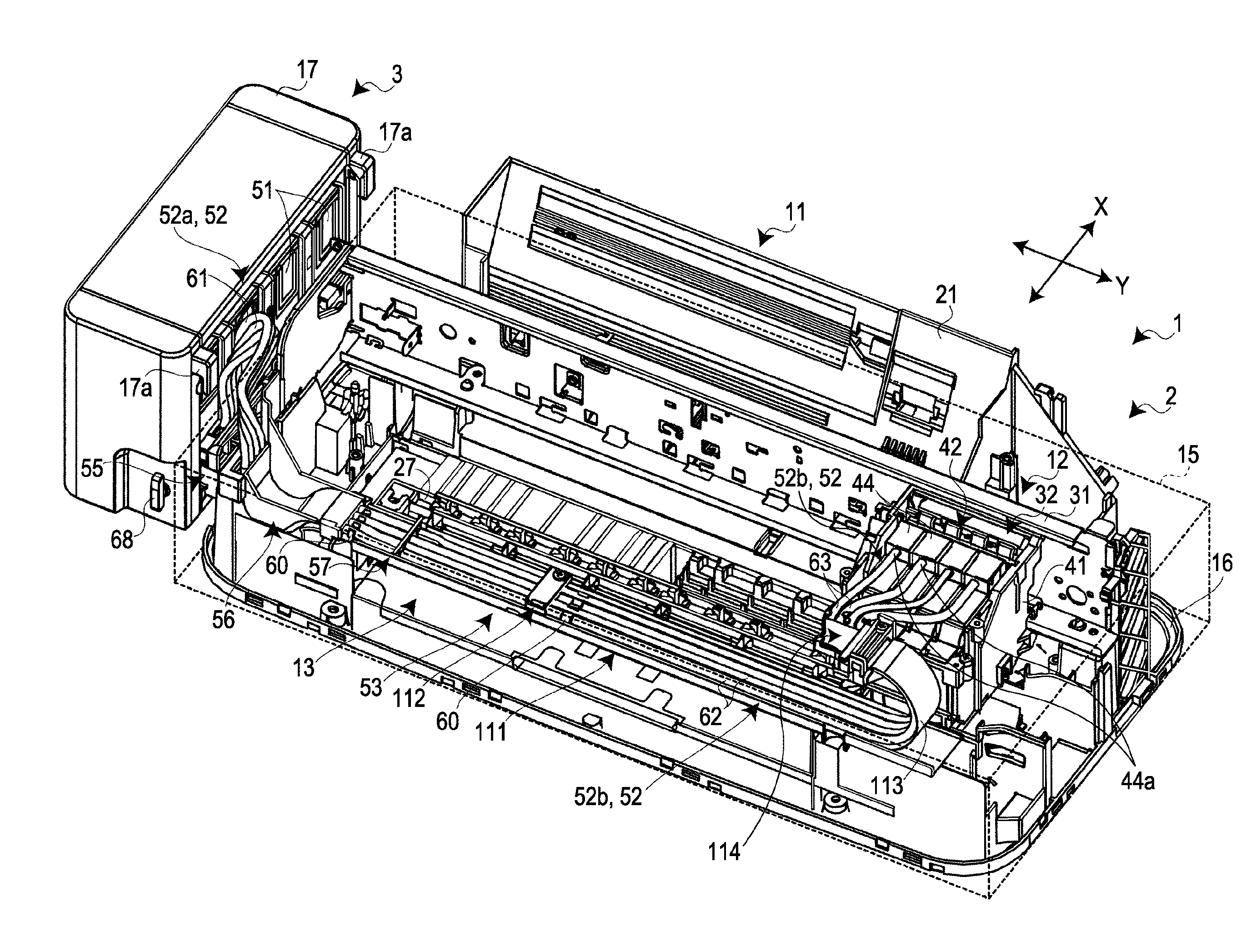

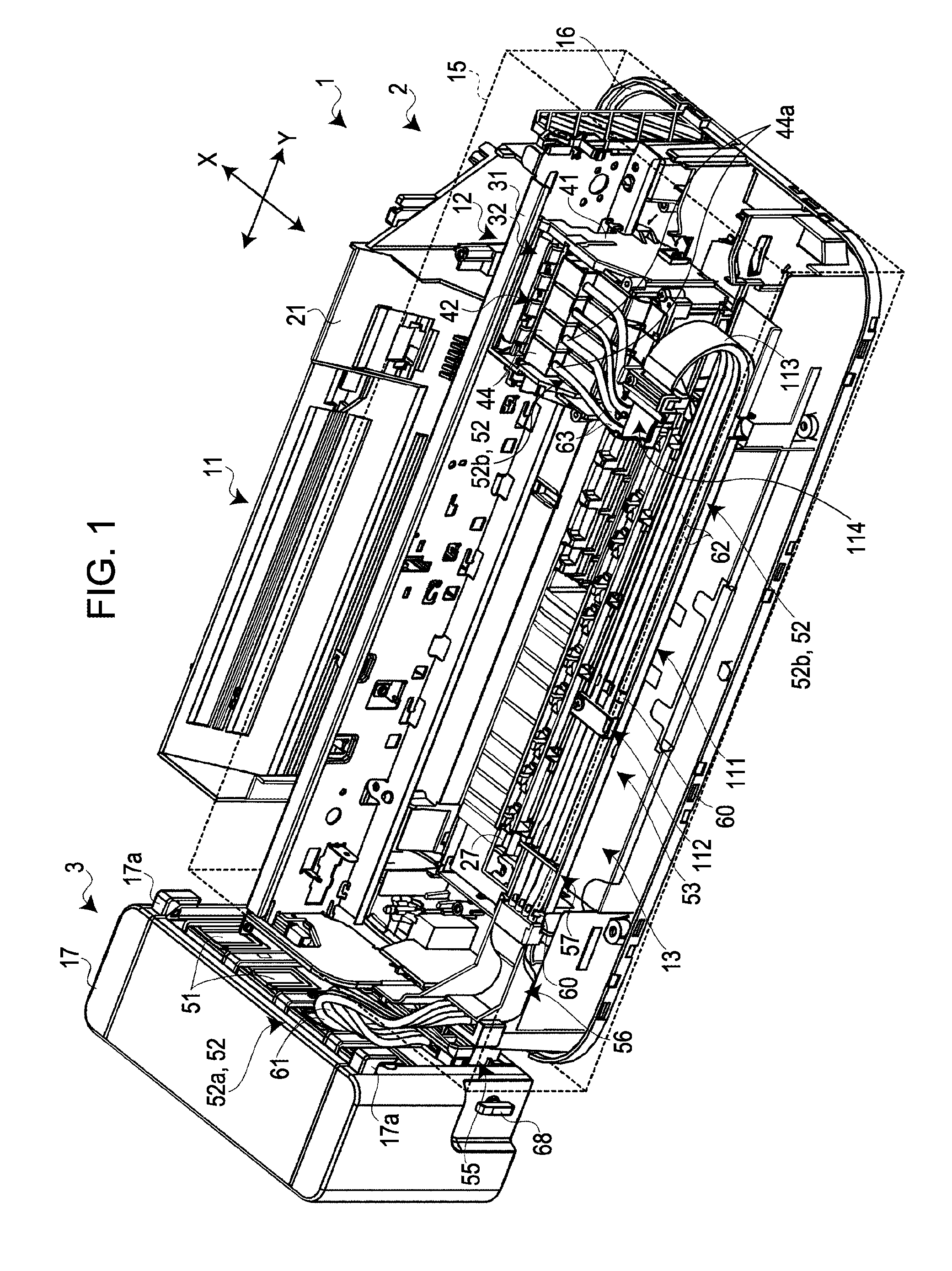

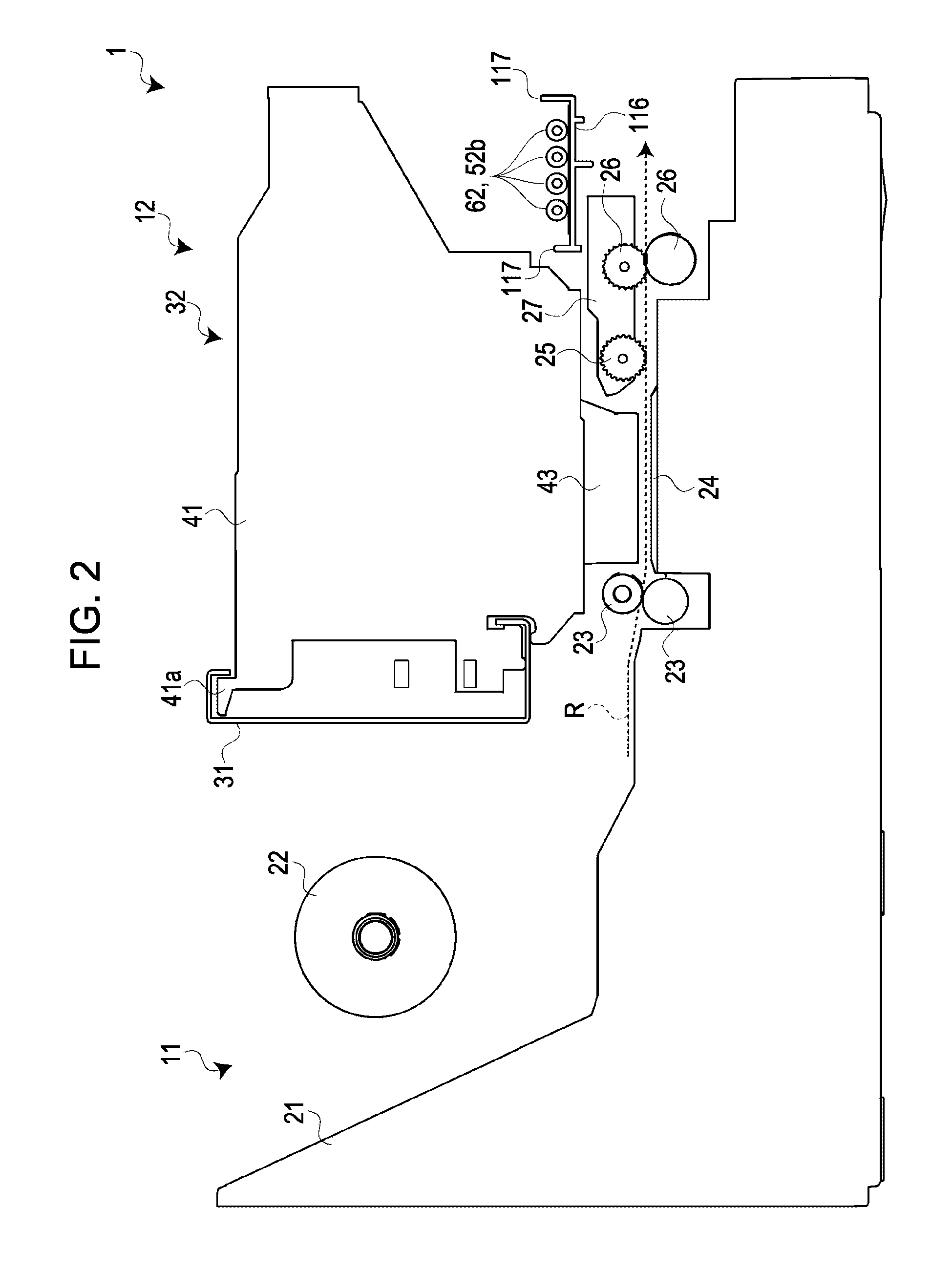

Ink jet recording apparatus

ActiveUS20120050416A1Effectively preventing a tube from movingIncrease frictionOther printing apparatusPull forceContact force

A tube support member that puts a tube connected to an ink jet head and an ink tank in a bent state is provided. Accordingly, when a pulling force acts between the bent support member and the tube, a component force acting as contact force occurs at the surface that makes contact with the tube, and a high degree of friction is generated in response to this component force. The tube is thus strongly supported in a state in which the tube does not shift with the dimensions of the tube changing. Meanwhile, when the pulling force is released, the component force is also eliminated, and the tube is freed; the dimensions of the tube return to normal, and the tension is eliminated.

Owner:SEIKO EPSON CORP

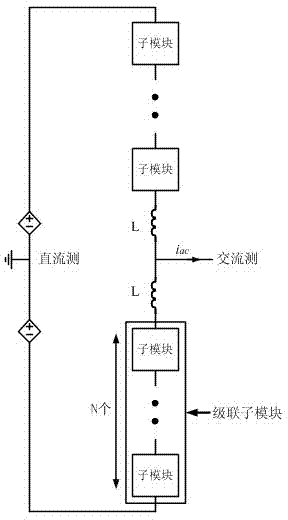

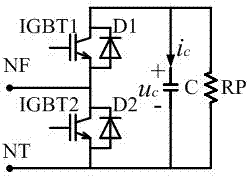

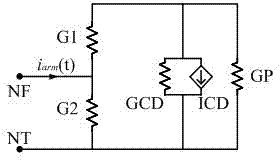

Equivalent simulation calculation modeling method for modularized multi-level converter

ActiveCN103593520AFast simulation calculationCalculations are reliableSpecial data processing applicationsTransient stateElectricity

The invention relates to an equivalent simulation calculation modeling method for a modularized multi-level converter. The modularized multi-level converter is composed of six bridge arms. Every two bridge arms form a phase unit. Each bridge arm is formed by connecting a cascade sub-module and a bridge arm reactance L in series. Each sub-module comprises an insulation gate double-pole thyristor IGBT1, an insulation gate double-pole thyristor IGBT2, a diode D1, a diode D2 and a capacitor C. Each insulation gate double-pole thyristor and one diode are connected in an anti-parallel mode for forming a switching component branch. According to the equivalent simulation calculation modeling method, equivalence is carried out on the sub-modules of the modularized multi-level converter and Dommel equivalent calculation models for the bridge arms, and additional switching component processing is adopted for solving the problem that the switching-on state of a switch tube changes during two simulation moments in the locking phase of the modularized multi-level converter. According to the modeling method, the calculation amount in the simulation operation can be reduced by reducing the number of variable impedance branches in the electromagnetic transient simulation calculation, and therefore simulation of the modularized multi-level converter is efficient, and the calculation result is stable and reliable.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

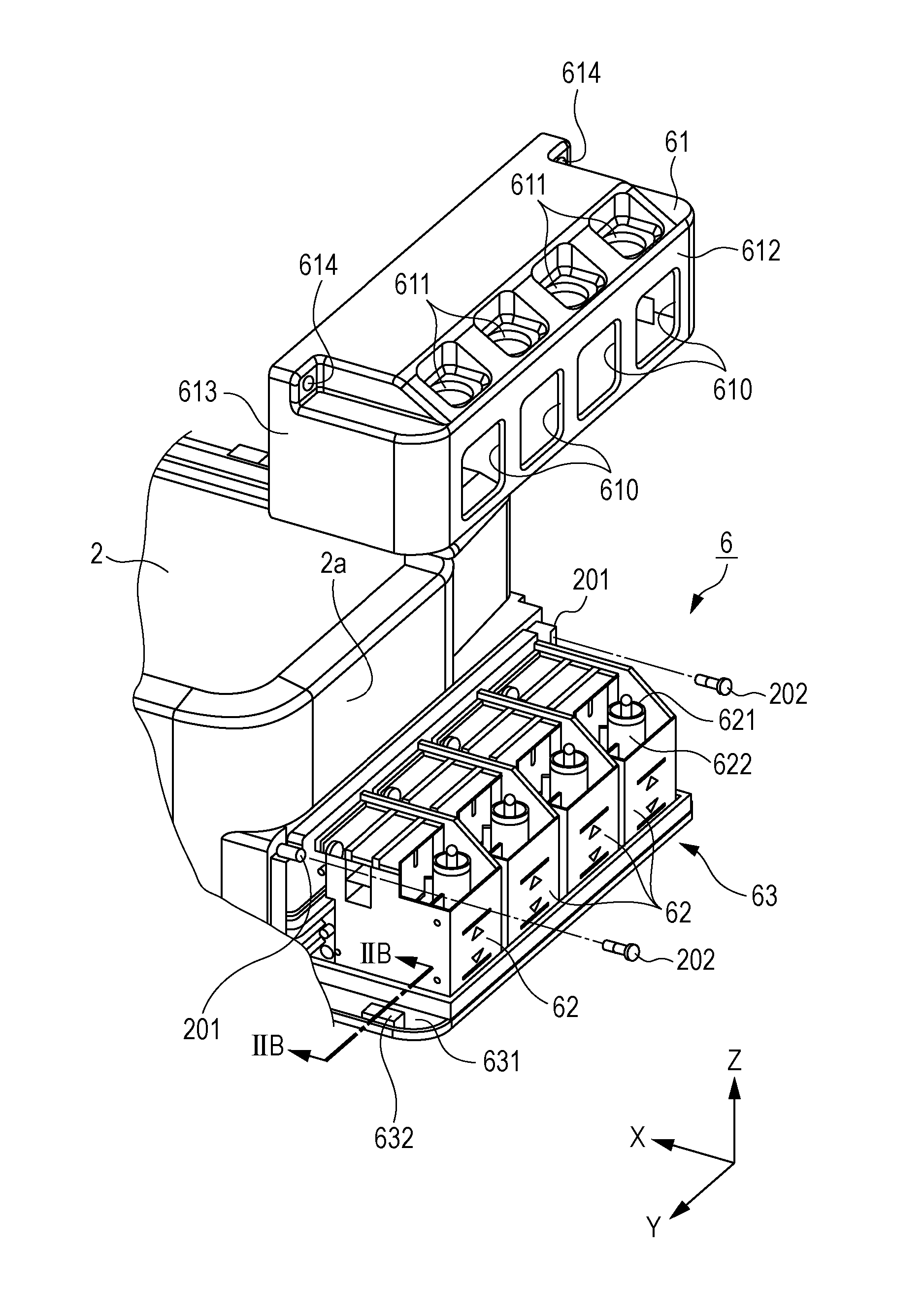

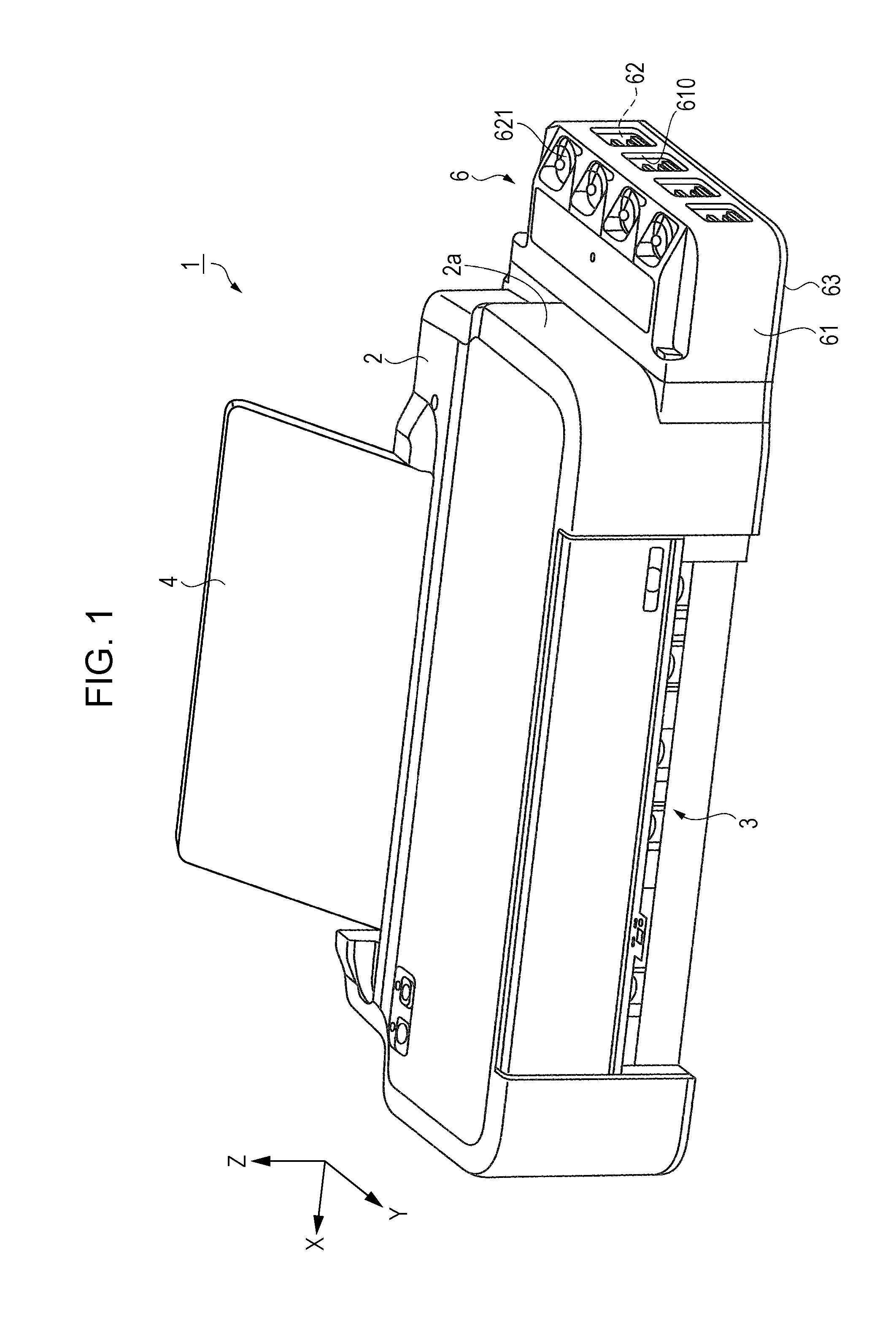

Liquid ejecting apparatus

ActiveUS20150174907A1Shorten the lengthSupply be preventedOther printing apparatusLiquid jetReciprocating motion

Provided is a liquid ejecting apparatus which includes a carriage which reciprocates in a state where a liquid ejecting head is mounted thereon, a tank unit which is provided outside the carriage and accommodates ink, four liquid supply tubes which communicate with the liquid ejecting head and the tank unit, and a tube support portion which supports the liquid supply tubes in a state where the liquid supply tubes are aligned in a horizontal direction, in which, in a case main body, the liquid supply tubes extend further to the tank unit side than a portion in which the liquid supply tubes are supported by the tube support portion, in a state where a parallel alignment direction of the four liquid supply tubes changes from the horizontal direction (a transporting direction) to a vertical direction.

Owner:SEIKO EPSON CORP

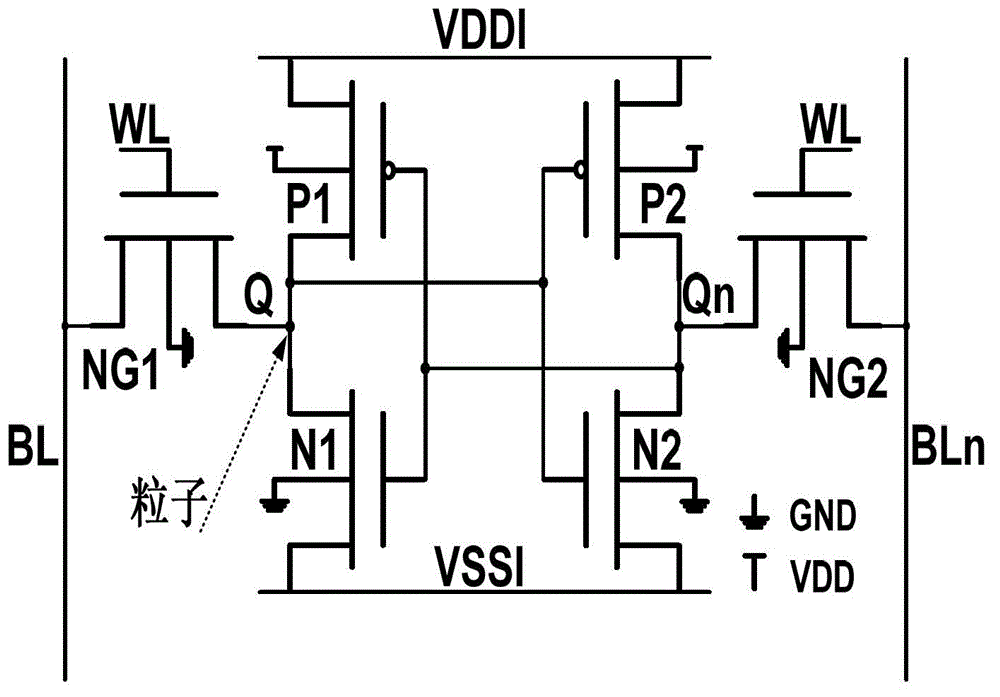

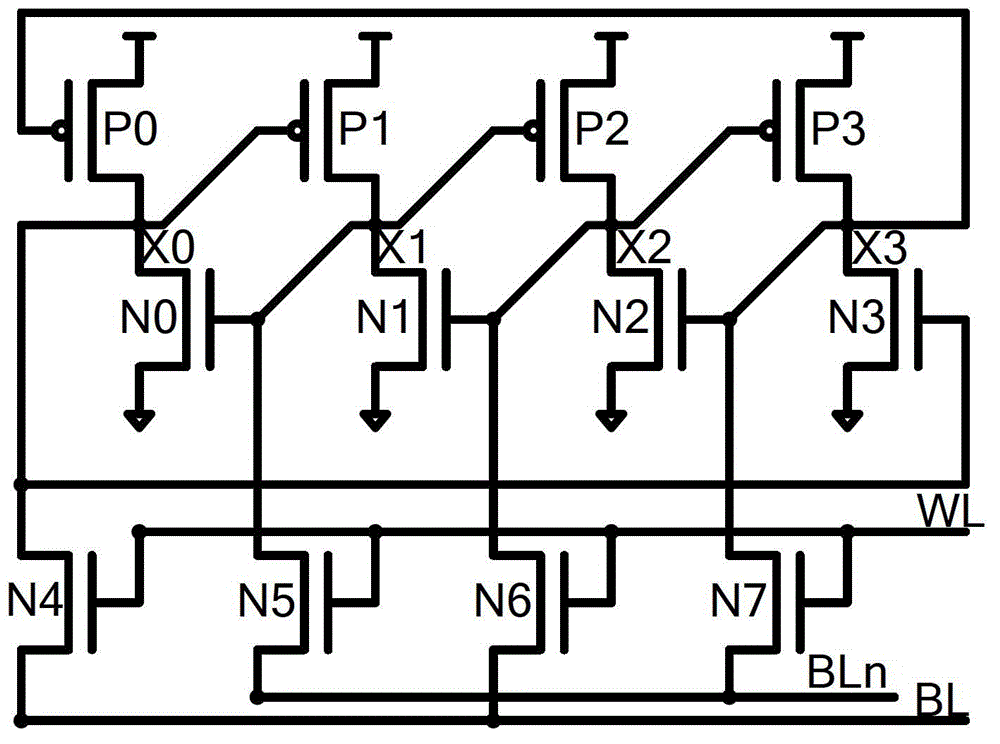

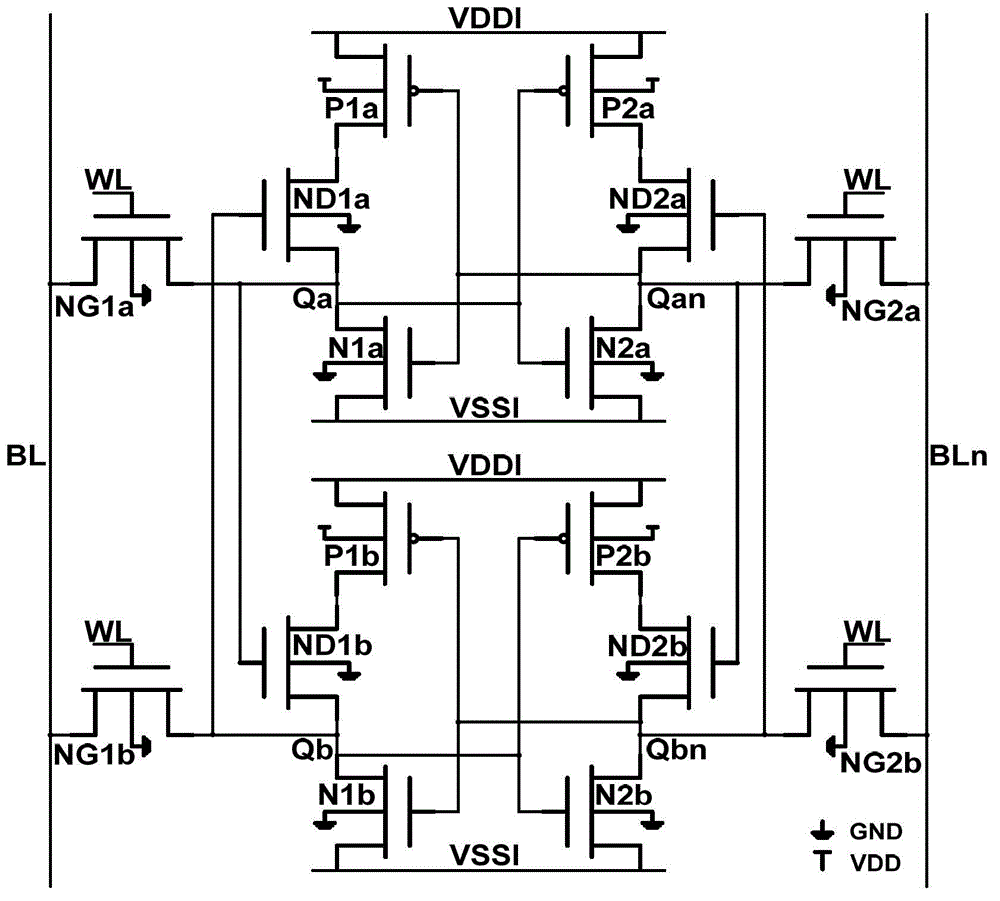

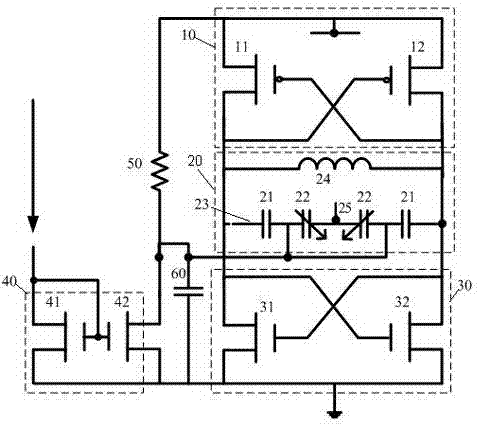

Static random access memory (SRAM) with redundant structure

InactiveCN103337252AImprove immunityImprove stabilityDigital storageStatic random-access memoryRandom access memory

The invention discloses a static random access memory (SRAM) with a redundant structure. The SRAM comprises first to fourth pull-up tubes, first to fourth pull-down tubes, first to fourth load tubes, and first to fourth gate tubes. On the basis of a conventional SRAM structure, the load tubes are added between drains of the pull-down tubes and the pull-up tubes; the threshold value of each load tube changes within a range of -VDDI / 2-0v, so that under the condition of no soft error, the load tubes are in a turn-on state all the time, and memory information is kept; under the condition of existence of soft errors, through the load tubes and a feedback mechanism of the redundant structure, the memory information can be recovered. The SRAM with the redundant structure has the advantages of high soft error resistance, high stability, low power consumption and compatibility with a commercial logic process.

Owner:TSINGHUA UNIV +1

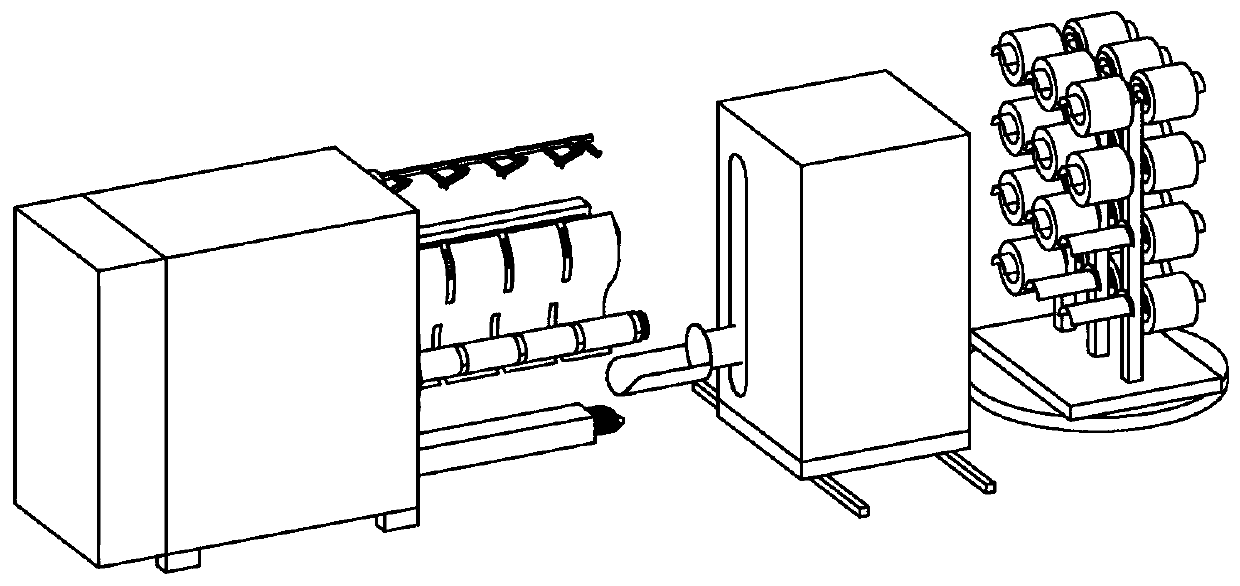

Intelligent glass fiber forming and winding device

An intelligent glass fiber forming and winding device comprises a winding head and a tube changing mechanism installed on a main frame, wherein the tube changing mechanism comprises a rotating disk and a yarn guide, at least one yarn winding tube is sleeved on the winding head and comprises a winding section and a tube changing section, and the tube changing section can be used to cut off and windthe yarn; the yarn guide can rotate clockwise or counterclockwise relative to the main frame and comprises a yarn guide rotating shaft and a tube changing yarn guiding rod and a loading yarn guidingrod that are fixed on the yarn guide rotating shaft, and both ends of the tube changing yarn guiding rod are inconsistent with respect to the axis of the yarn guide rotating shaft such that the yarn guide rotating shaft rotates during the tube changing process, and the yarn can slide from the highest end to the lowest end along the tube changing yarn guiding rod, thereby poking the yarn to the tube changing section on the corresponding winding tube. The intelligent glass fiber forming and winding device provided by the invention has reasonable structure and easy operation, and can effectivelyimprove the production efficiency and product quality of glass fiber.

Owner:ТАЙ'АНЬ ШУНЬМАО НЬЮ МЕТЕРИАЛ ТЕХНОЛОДЖИ КО., ЛТД.

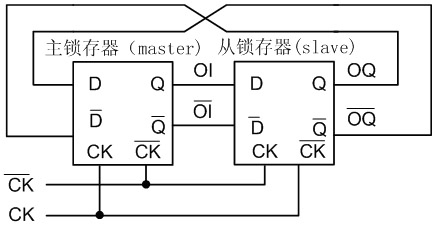

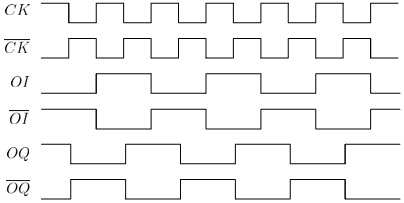

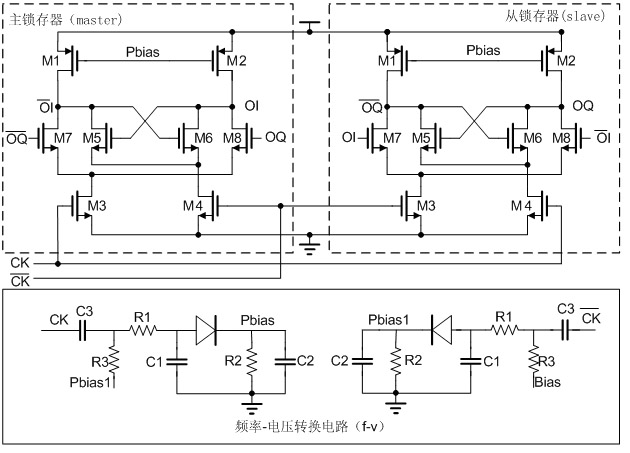

Complementary metal oxide semiconductor (CMOS) ultra-wide-band divide-by-2 frequency divider structure

InactiveCN101924553ALower RC constantReduce power consumptionPulse automatic controlP channelStructure based

The invention belongs to the technical field of clock frequency division, in particular relates to a divide-by-2 frequency divider structure based on a standard complementary metal oxide semiconductor (CMOS) process and suitable for an ultra-wide band. The divide-by-2 frequency divider consists of two primary and secondary differential analog D latches, wherein each D latch is a dynamic bias taking a pair of differential N-channel metal oxide semiconductor (NMOS) tubes as an amplifying part, a pair of crossly coupled positive feedback NMOS tubes as a latching part, a pair of p-channel metal oxide semiconductor (PMOS) tubes as a load and a pair of clocked NMOS tubes as the amplifying part and the latching part respectively; the magnitude of the bias voltage of the PMOS tubes changes along with frequencies; and a frequency-voltage converting circuit provides a bias for the PMOS tube load. The divide-by-2 frequency divider structure can effectively increase the working frequency range of a frequency divider; and the ratio of an upper limit frequency to a lower limit frequency of the divide-by-2 frequency divider structure can reach about 250. The circuit of the invention has the characteristics of low power consumption and noise, high speed and the like.

Owner:FUDAN UNIV

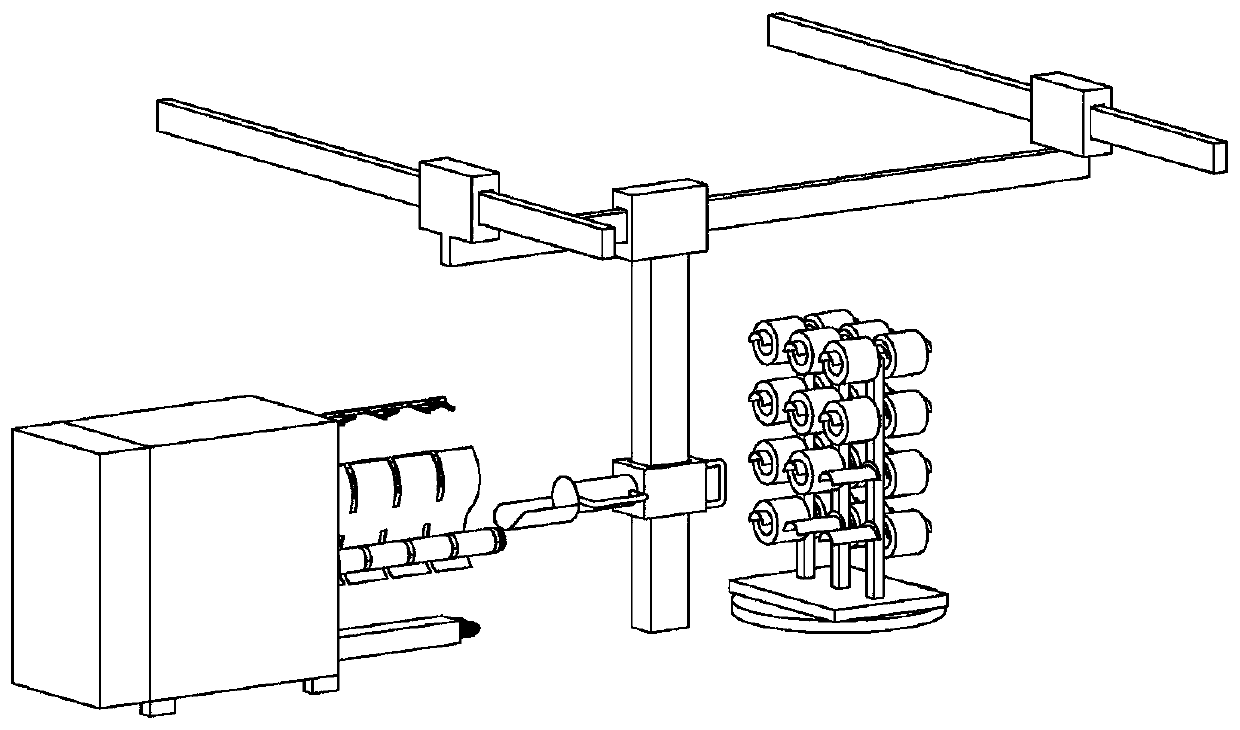

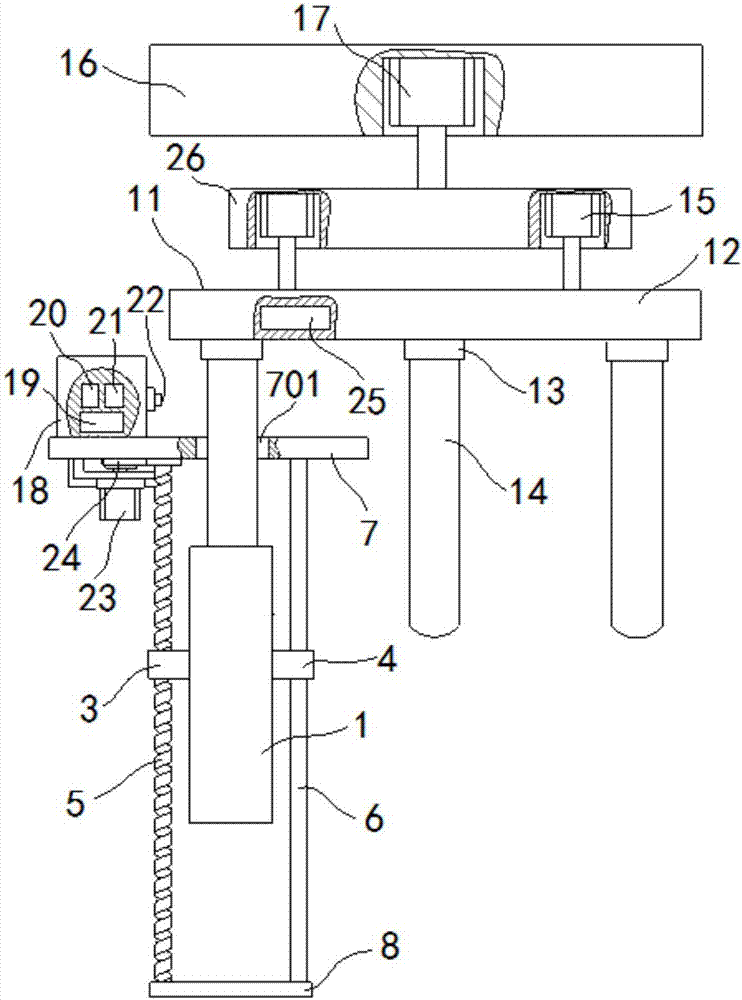

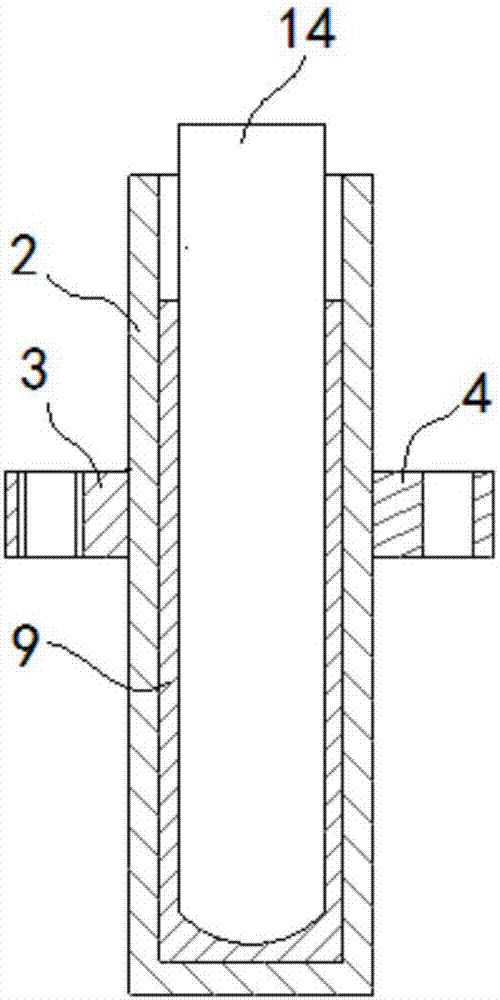

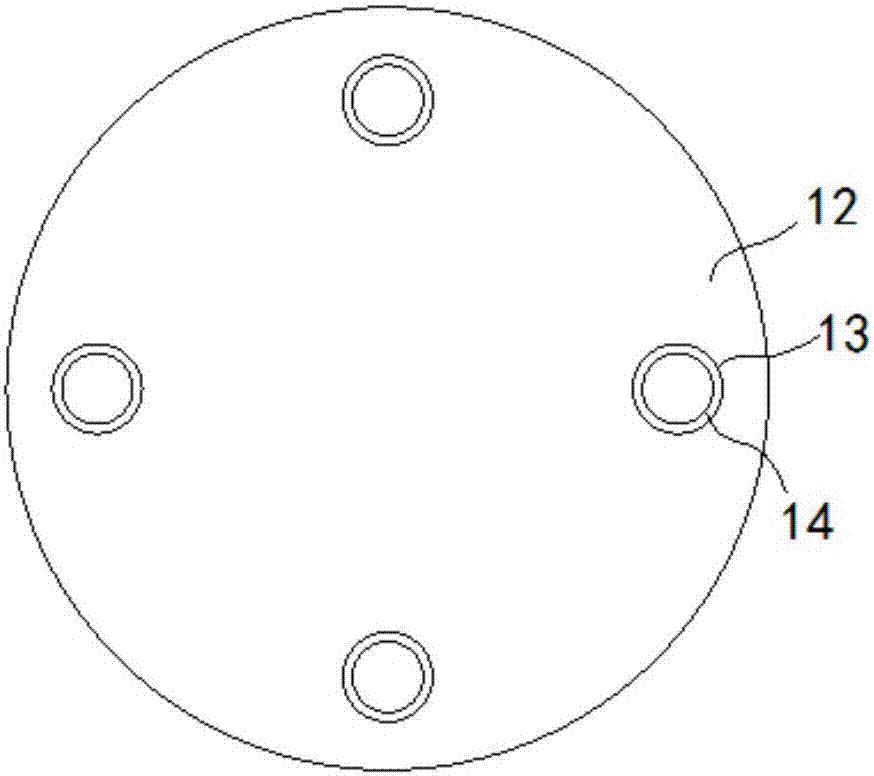

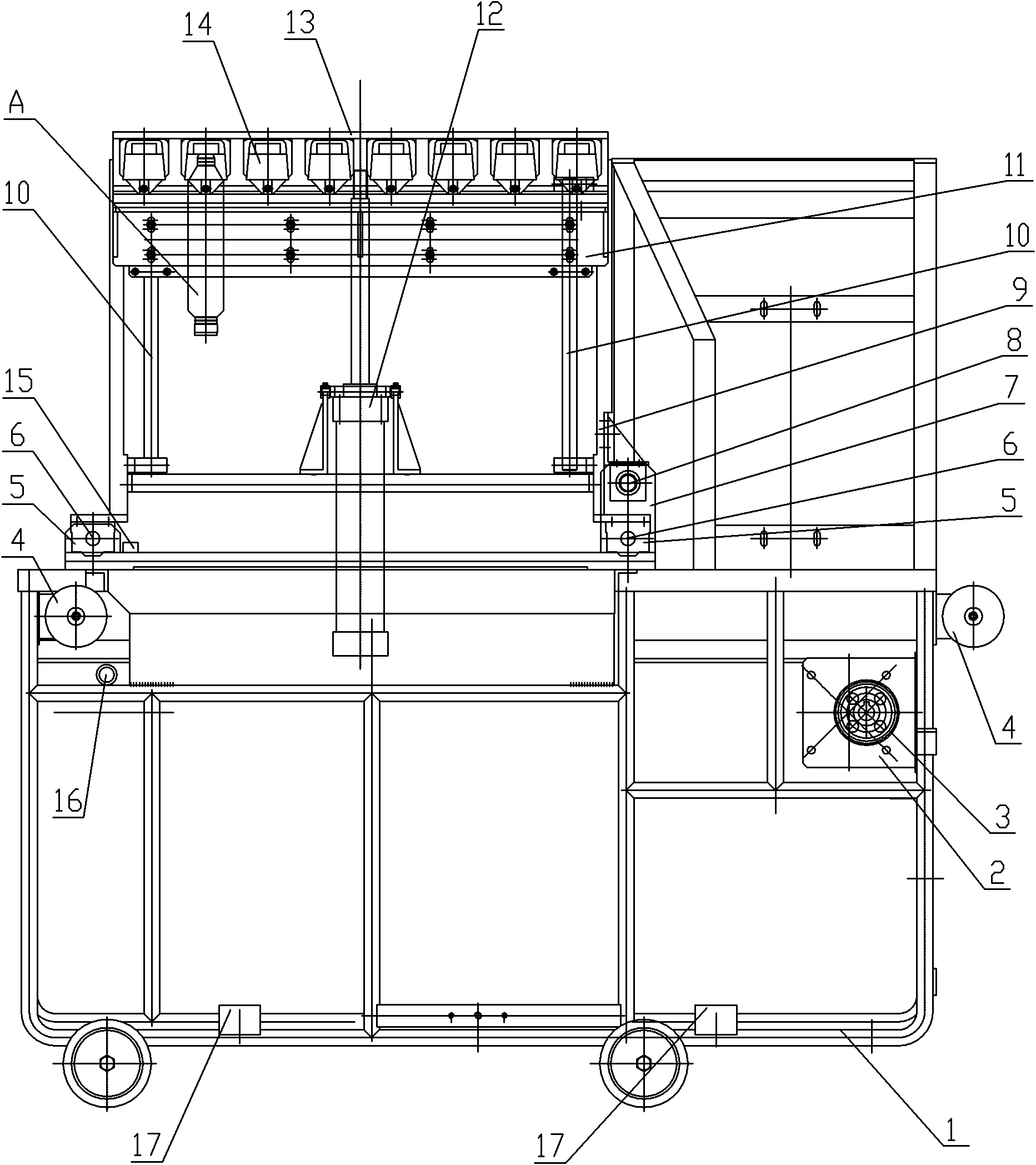

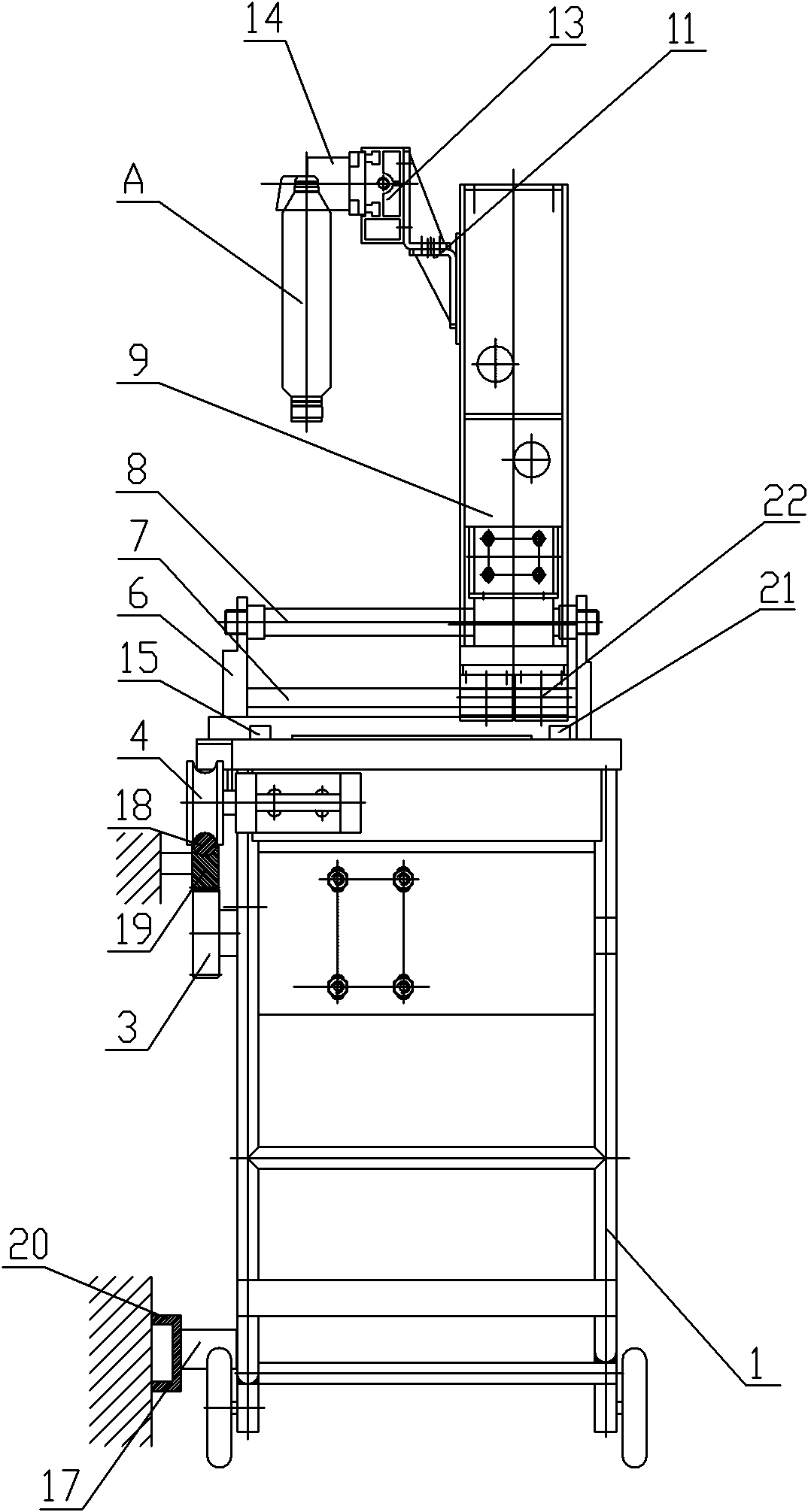

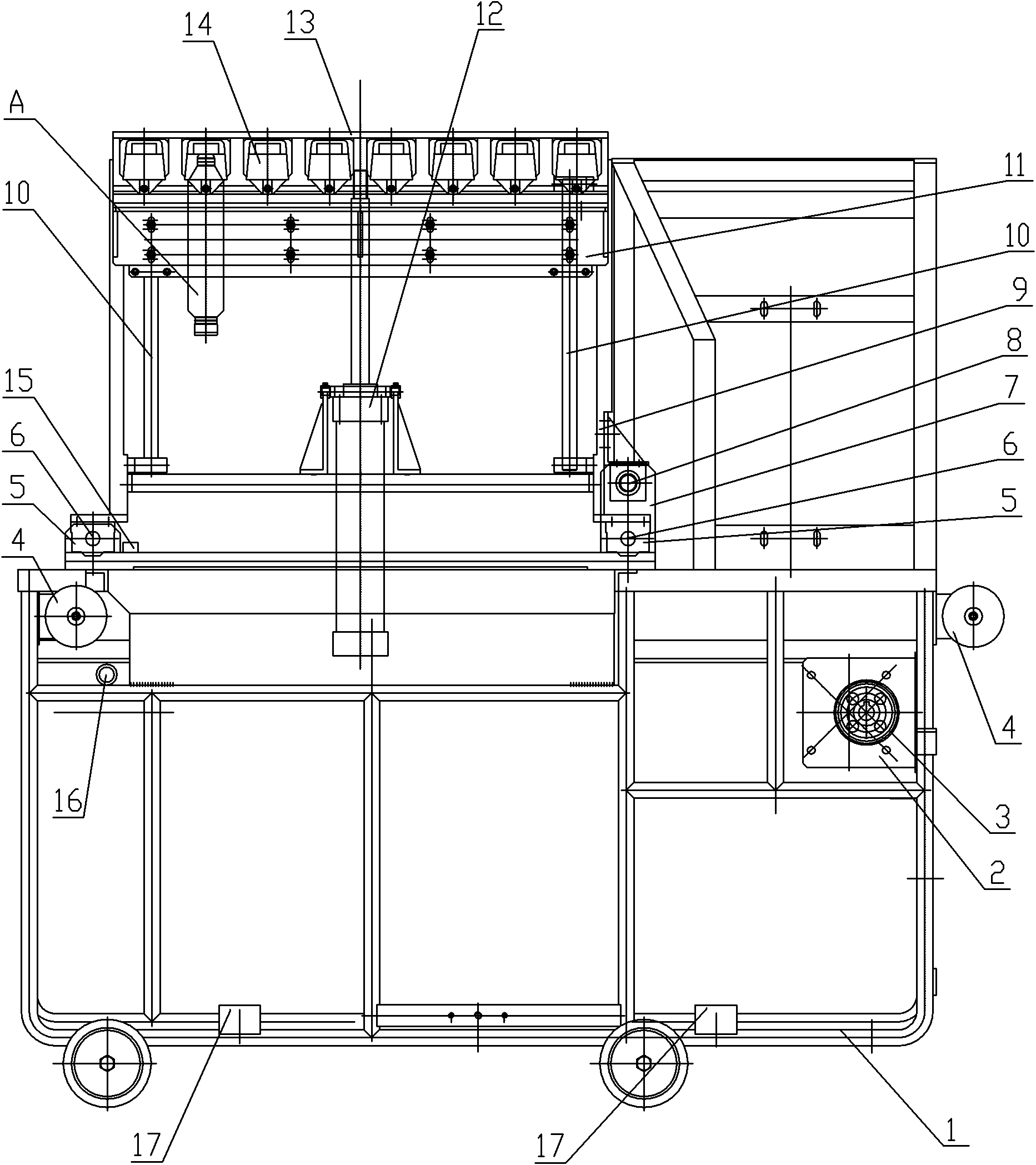

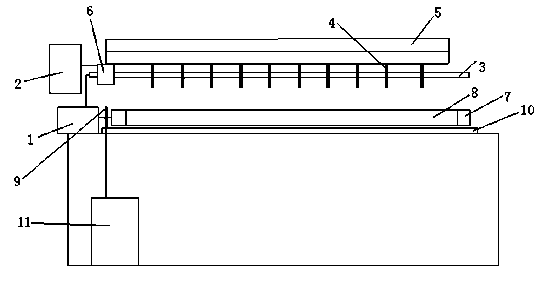

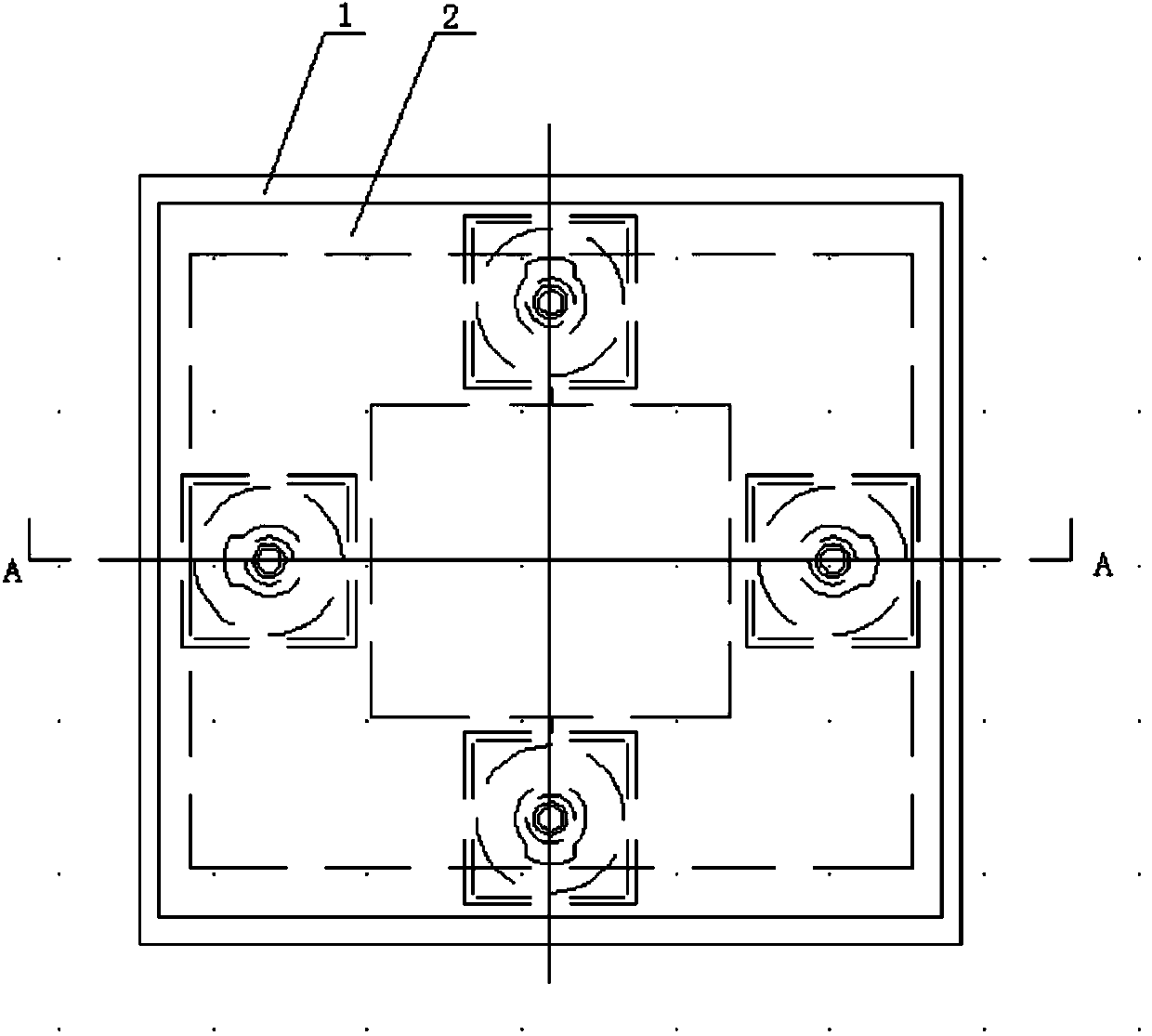

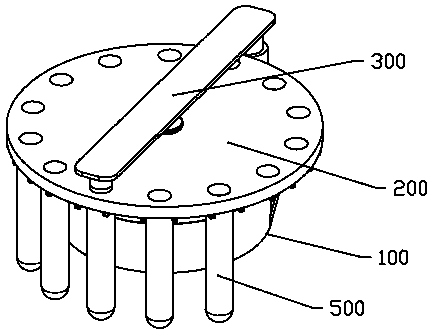

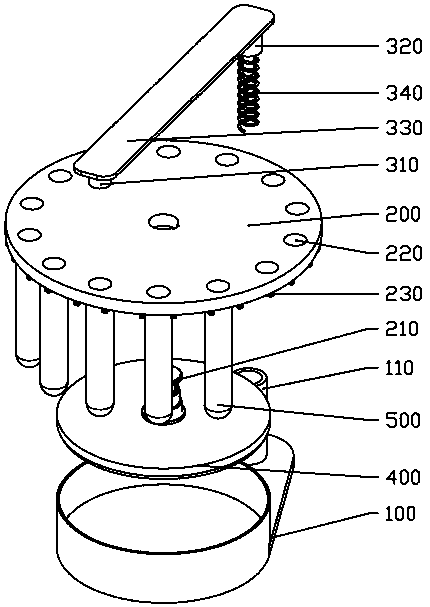

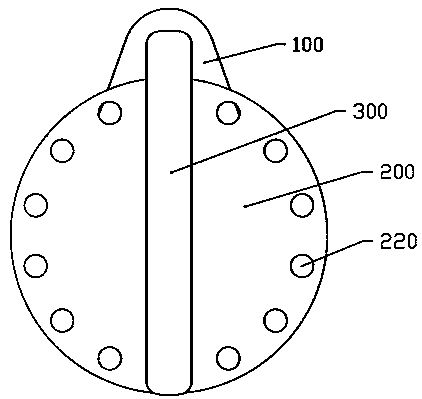

Water sample collection device provided with tube change mechanism

ActiveCN106932224AEasy to insertRealize automatic collectionWithdrawing sample devicesElectric machineryEngineering

The invention discloses a water sample collection device provided with a tube change mechanism. The water sample collection device comprises a collection tube, a screw rod, a guide rod, a mounting plate, a connecting plate, a rubber sleeve, a rotating table, test tube covers, sampling test tubes, a lifting motor, a rotating motor, a control box, a controller, a GPS (global position system) locator, a wireless communicator, a camera and the like. The collection mechanism and the tube change mechanism are arranged, so that each of the sampling test tubes can be conveniently inserted into a rubber tube in the collection tube for water sample collection work, the sampling test tubes are changed by the rotating table and the motors, water samples in lakes can be automatically collected, and the test tubes can be automatically changed. Therefore, the labor intensity of workers is effectively relieved, and the collection of the water samples of the lakes is facilitated; the GPS locator and the wireless communicator are arranged, so that position information of collection of the water samples is sent to a far-end server, so as to complete recording; the camera is arranged, so that the test tubes for collecting the water samples at different positions and different times can be photographed and recorded, so that the workers can conveniently distinguish a plurality of sampling test tubes in the rotating table.

Owner:JIANGSU TIANSHUI IRRIGATION & DRAINAGE EQUIP CO LTD

Catheter with pressure sensor

A pressure sensor assembly is disclosed which includes a flaccid tube having two mounting sleeve members that bond the tube to a distal end of a catheter. The catheter includes an aperture located beneath the tube and in communication with an air passage. As the pressure outside the tube changes, the tube moves relative to the catheter body, thereby communicating that pressure change to the sealed air passage within the catheter. This air passage is connected to an external transducer that can measure this pressure change and thereby determine a pressure at the distal end of the pressure catheter.

Owner:INNERSPACE

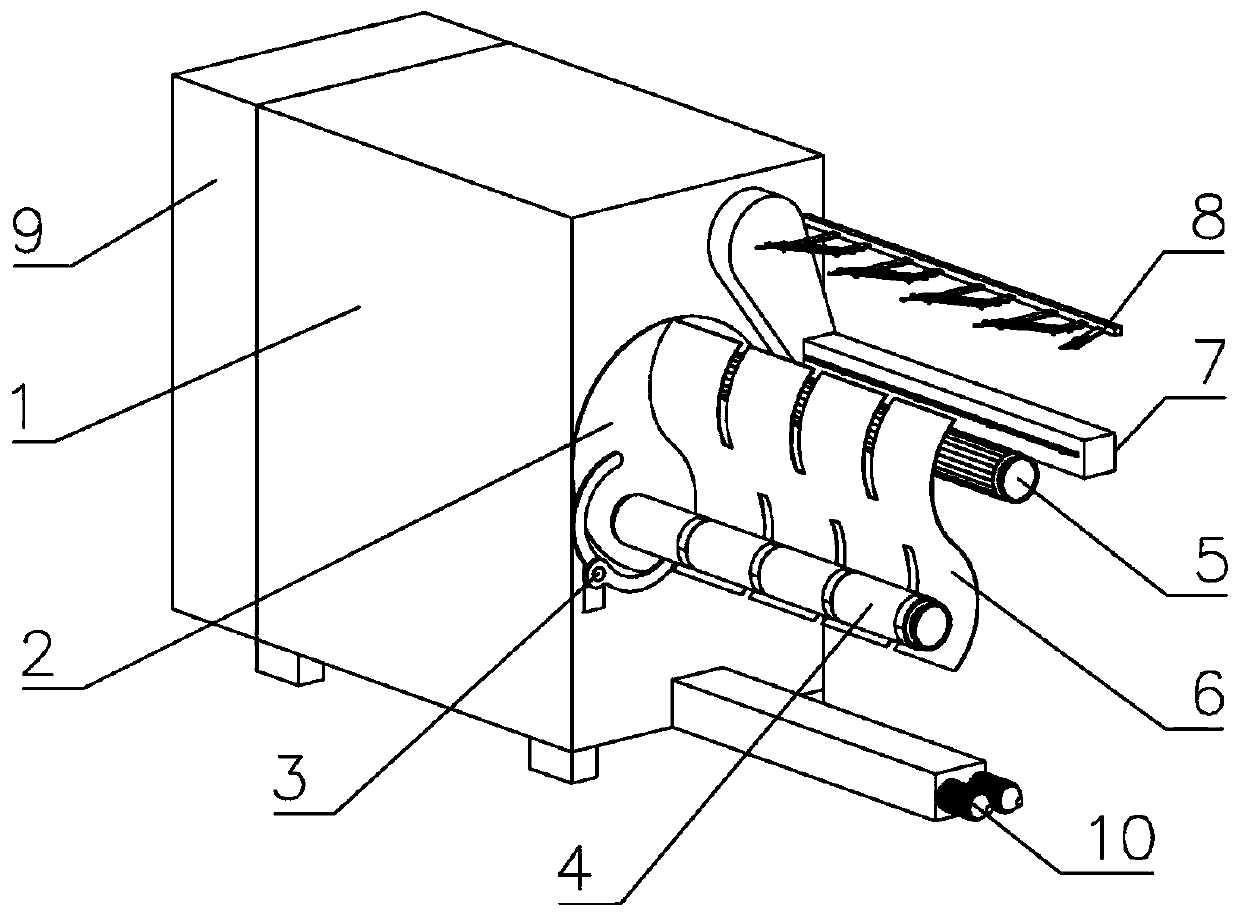

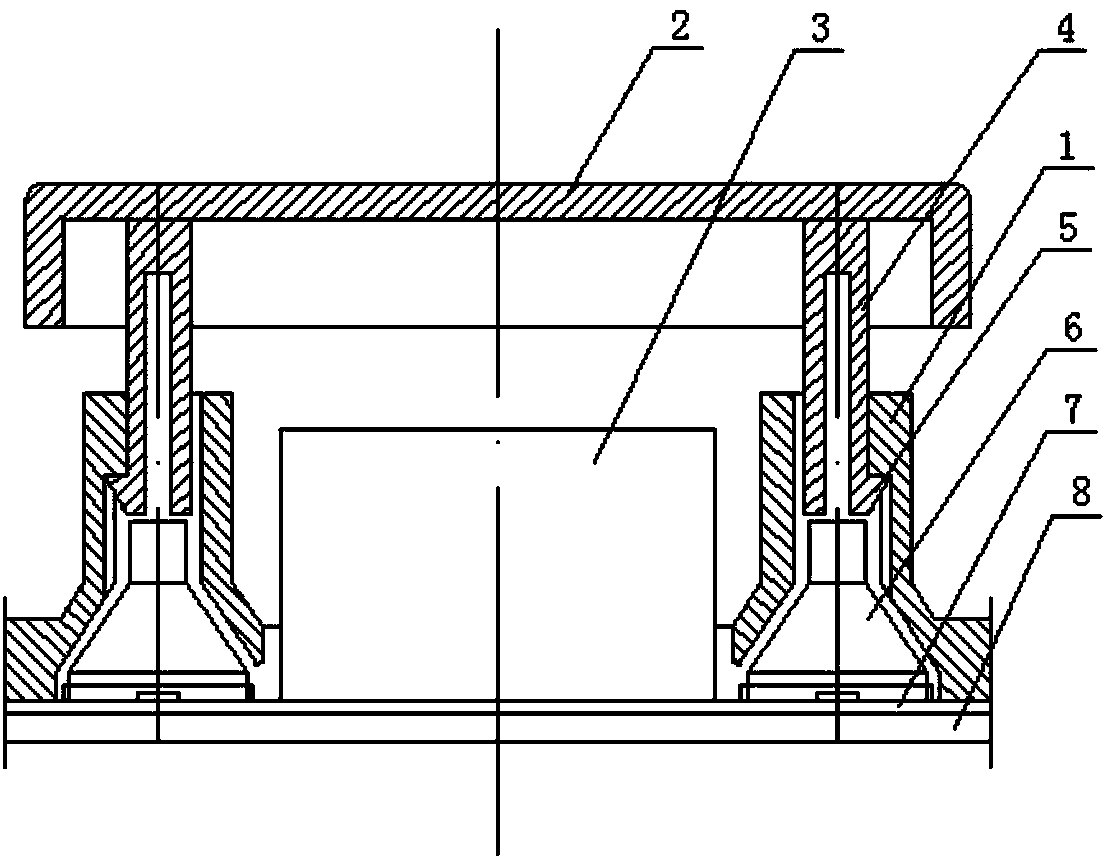

Intermittent automatic tube drawing device

The invention relates to an intermittent automatic tube drawing device which comprises a doffing trolley. The doffing trolley is arranged on a guide rail assembly and can travel, and the traveling route of the doffing trolley is parallel to the central line of a spindle of a spinning frame. The intermittent automatic tube drawing device is characterized in that the doffing trolley is provided with a traveling driving mechanism, a tube drawing mechanical arm and a control system, wherein the traveling driving mechanism is used for driving the doffing trolley to travel intermittently, the tube drawing mechanical arm is used for drawing yarn-loaded tubes on the spinning frame and collecting the yarn-loaded tubes, the control system is used for controlling the traveling driving mechanism and the tube drawing mechanical arm to act crossly, the tube drawing mechanical arm stops drawing tubes when the traveling driving mechanism drives the doffing trolley to travel, and the tube drawing mechanical arm starts to draw tubes when the traveling driving mechanism drives the doffing trolley to stop. The intermittent automatic tube drawing device has a smart structure and high automation degree, can realize automatic doffing so as to reduce labor intensity of workers, save the labor time, and improve the doffing efficiency, yarn collecting efficiency and empty tube changing efficiency, and has high action accuracy, lower production cost and low fault rate.

Owner:WUXI JIJU TEXTILE TOOLS

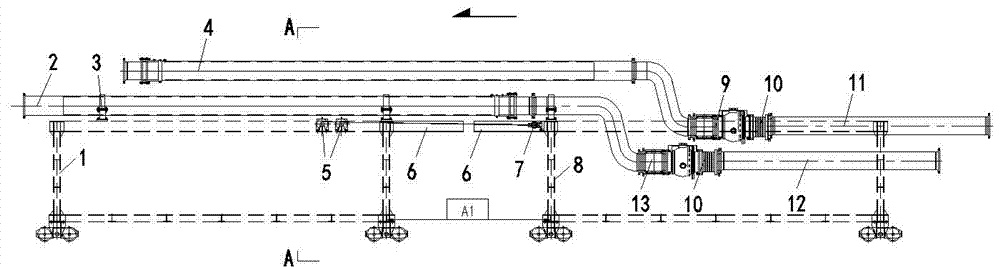

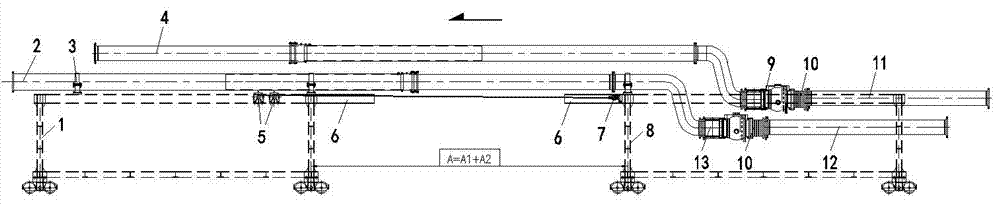

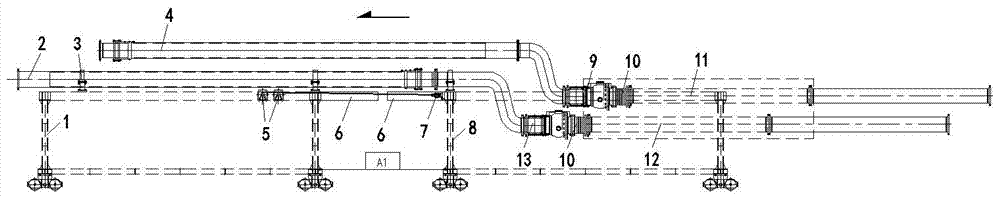

Novel small-diameter slurry shield tube-changing device

The invention provides a novel small-diameter slurry shield tube-changing device, and the problem that a tube-changing device is not suitable for a small-diameter slurry shield in the prior art is solved. The novel small-diameter slurry shield tube-changing device comprises a slurry-feeding extension tube and a slurry-discharging extension tube. The slurry-feeding extension tube is connected with a slurry-feeding tube, the slurry-discharging extension tube is connected with a slurry-discharging tube, and the slurry-feeding extension tube and the slurry-discharging extension tube are arranged on a first trolley; the slurry-discharging tube and the slurry-feeding tube are arranged on a second trolley, a hydraulic winch is arranged on the first trolley, and a hauling pulley is arranged on the second trolley; and a rope of the hydraulic winch is connected with the hauling pulley, a slurry-discharging ball valve and an expansion joint are arranged on the slurry-discharging tube, and a slurry-feeding ball valve and an expansion joint are arranged on the slurry-feeding tube. According to the novel small-diameter slurry shield tube-changing device, a muddy-water pipe is driven to move while shield excavation is achieved by adopting a trolley and an extension tube which move relatively, and the structural arrangement is simple; a constructor conducts the tunneling-tube adding-tunneling step repeatedly, synchronous lengthening of the muddy-water pipe can be achieved, and the operation is convenient; and a complete set of device is low in price, the cost is saved, the occupied space is small, and the novel small-diameter slurry shield tube-changing device is suitable for small-diameter shield tunneling machines.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

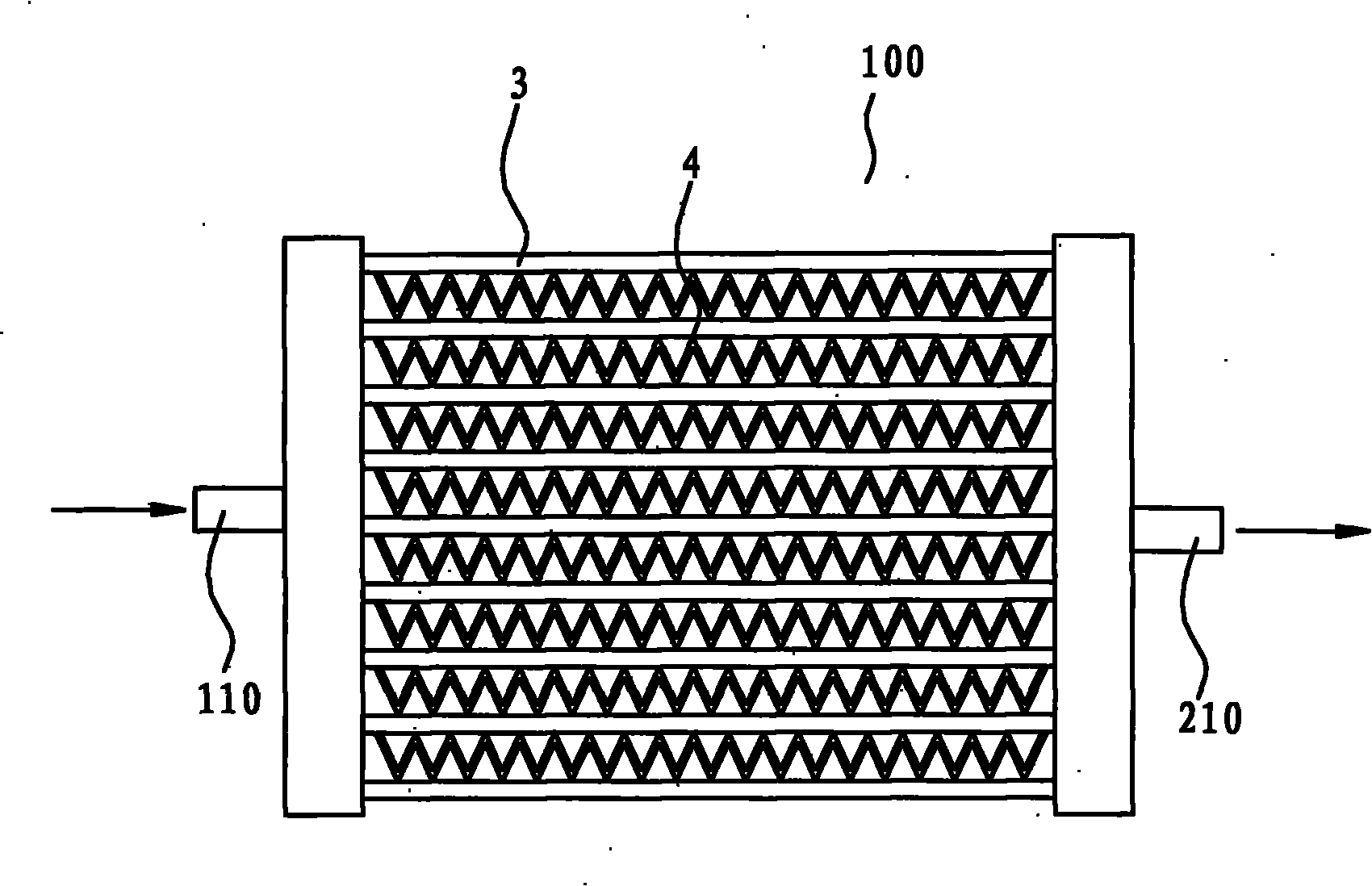

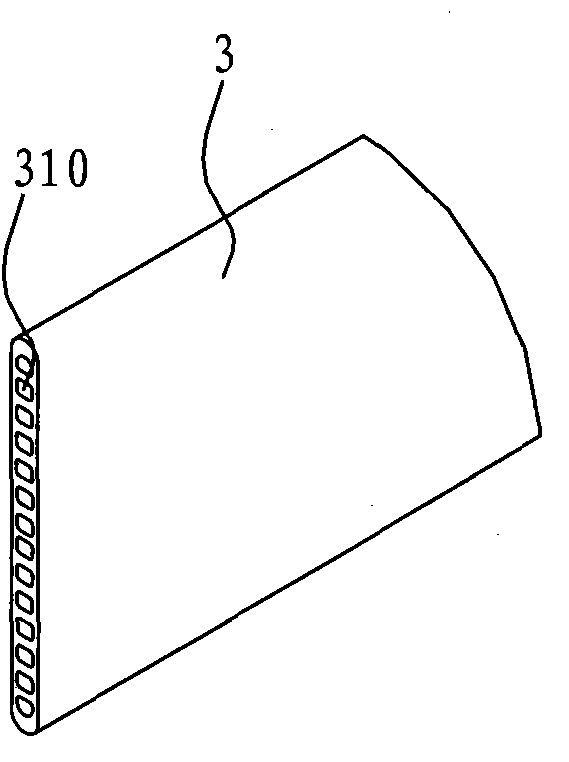

Heat exchanger with improved heat exchange property

ActiveCN101858672AImprove efficiencyExert heat exchange capacityEvaporators/condensersHeat exchanger casingsEngineeringRefrigerant

The invention discloses a heat exchanger, which comprises a first collecting pipe, a second collecting pipe separated from the first collecting pipe, heat exchange tubes and fins, wherein a refrigerant channel is arranged in each heat exchange tube; two ends of each heat exchange tube are respectively connected to the first and second collecting pipes so as to communicate with the first and second collecting pipes through the refrigerant channel; the whole cross section area of the refrigerant channel in the heat exchange tube changes along the flowing direction of the refrigerant in the heat exchange tube in order to keep the flowing speed of the refrigerant in the flowing direction thereof; and each fin is arranged between adjacent heat exchange tubes. In the heat exchanger of the embodiment of the invention, the whole cross section area of the heat exchange tubes at an inlet and outlet of the refrigerant changes following the state of the refrigerant and the flowing speed of the refrigerant in the heat exchange tube is kept even, so the whole efficiency of the heat exchanger is promoted and the heat exchange property of the heat exchanger can be better performed.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

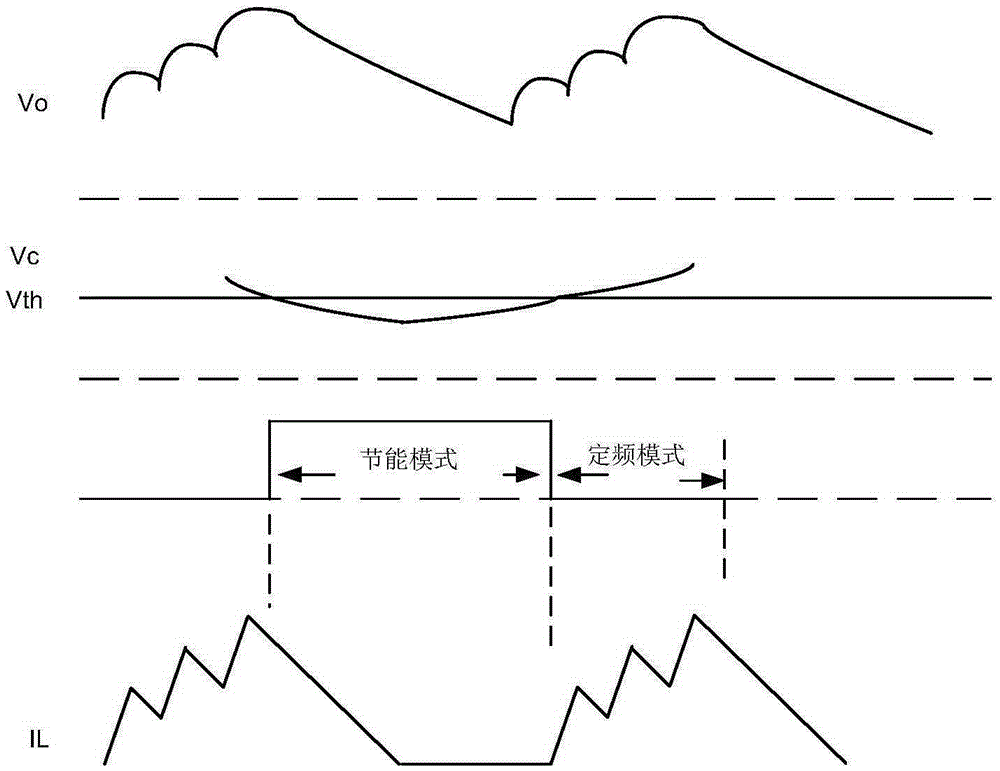

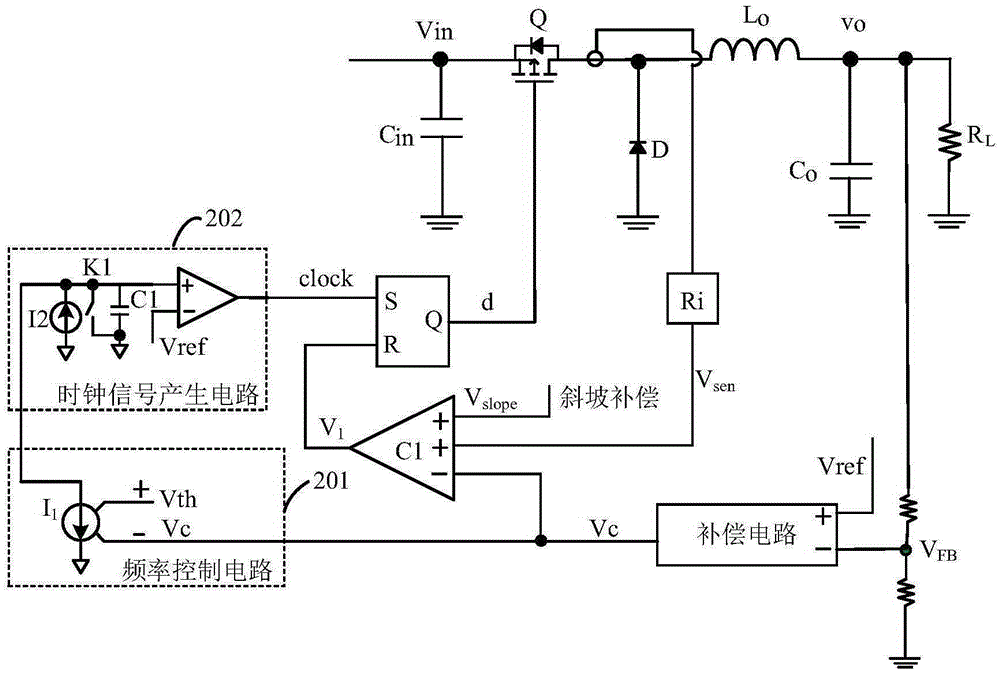

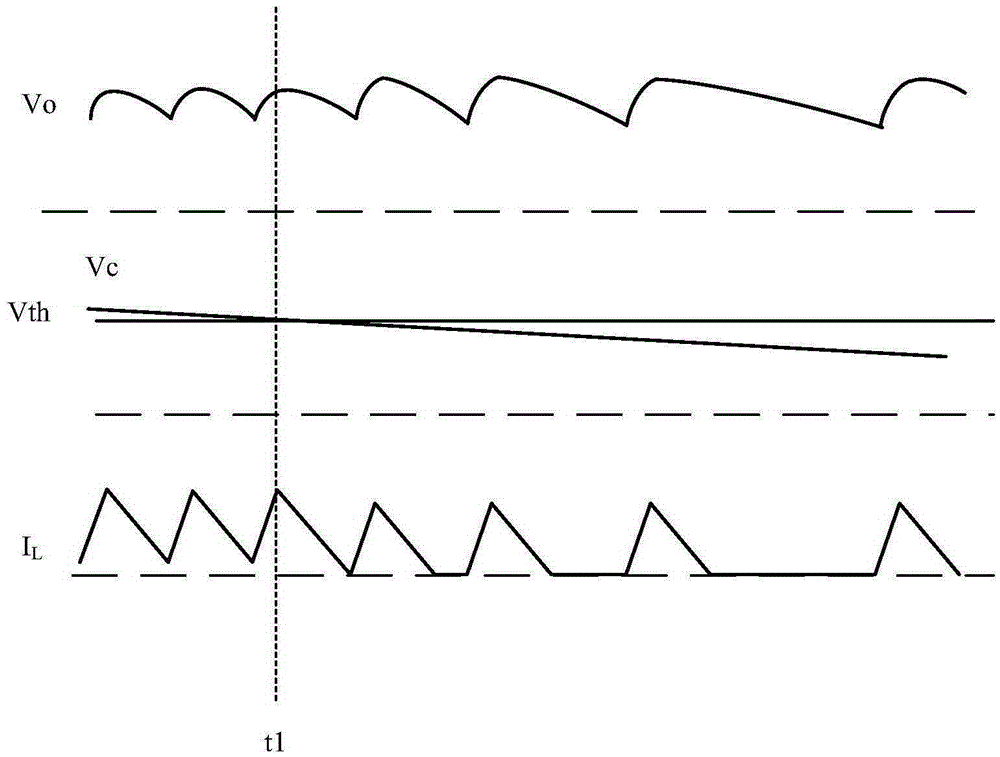

Switching power supply frequency reduction control circuit and control method

ActiveCN105262337AImprove stabilityNo mutationDc-dc conversionElectric variable regulationControl signalSwitching frequency

According to a switching power supply frequency reduction control circuit and a control method of the invention, a frequency control circuit generates a first current signal associated with a compensation control signal, and the first current signal changes the size of a first current source so as to make a first clock signal for controlling switching of a power switch tube change with the compensation control signal, and therefore, the switching frequency of the power switch tube is controlled by the compensation control signal. When the compensation control signal is greater than a threshold voltage signal, the switching frequency of the power switch tube is a preset switching frequency; and when the compensation control signal is smaller than the threshold voltage signal, the switching frequency of the power switch tube changes with the difference between the compensation control signal and the threshold voltage signal. The threshold voltage signal in the embodiment is set to represent the output voltage under a light-load or no-load state. The switching power supply makes the switching frequency of the power switch tube not change suddenly, and the output voltage is highly stable.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

Venturi bernoulli heat extraction system for laptop computers

InactiveUS20080089023A1Digital data processing detailsHeat exchange apparatusDisplay deviceEngineering

A heat extraction system is provided for a laptop computer that comprises a system unit that includes a set of heat sources and a video display unit that is movably attached to the system unit. The laptop computer has air inlets and air outlets that allow air to flow into the system unit, over the heat sources forming heated air, and exhaust the heated air. The laptop computer has a set of tubes, which have an inlet and an outlet, located behind a video display in the video display unit and an air connection from the air outlets to each inlet in the tubes. The set of tubes are formed such that heated air passing through a constriction in the set of tubes changes in velocity and pressure in order to satisfy the conservation of flow rate. Thus, heat produced by the heat sources is extracted from the laptop computer.

Owner:IBM CORP

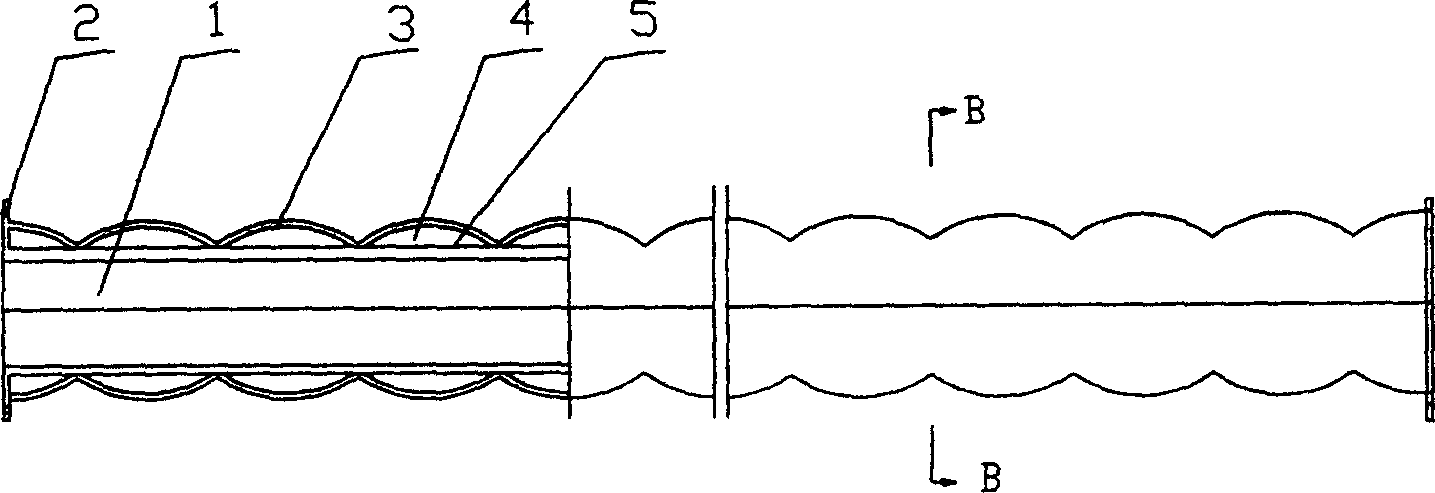

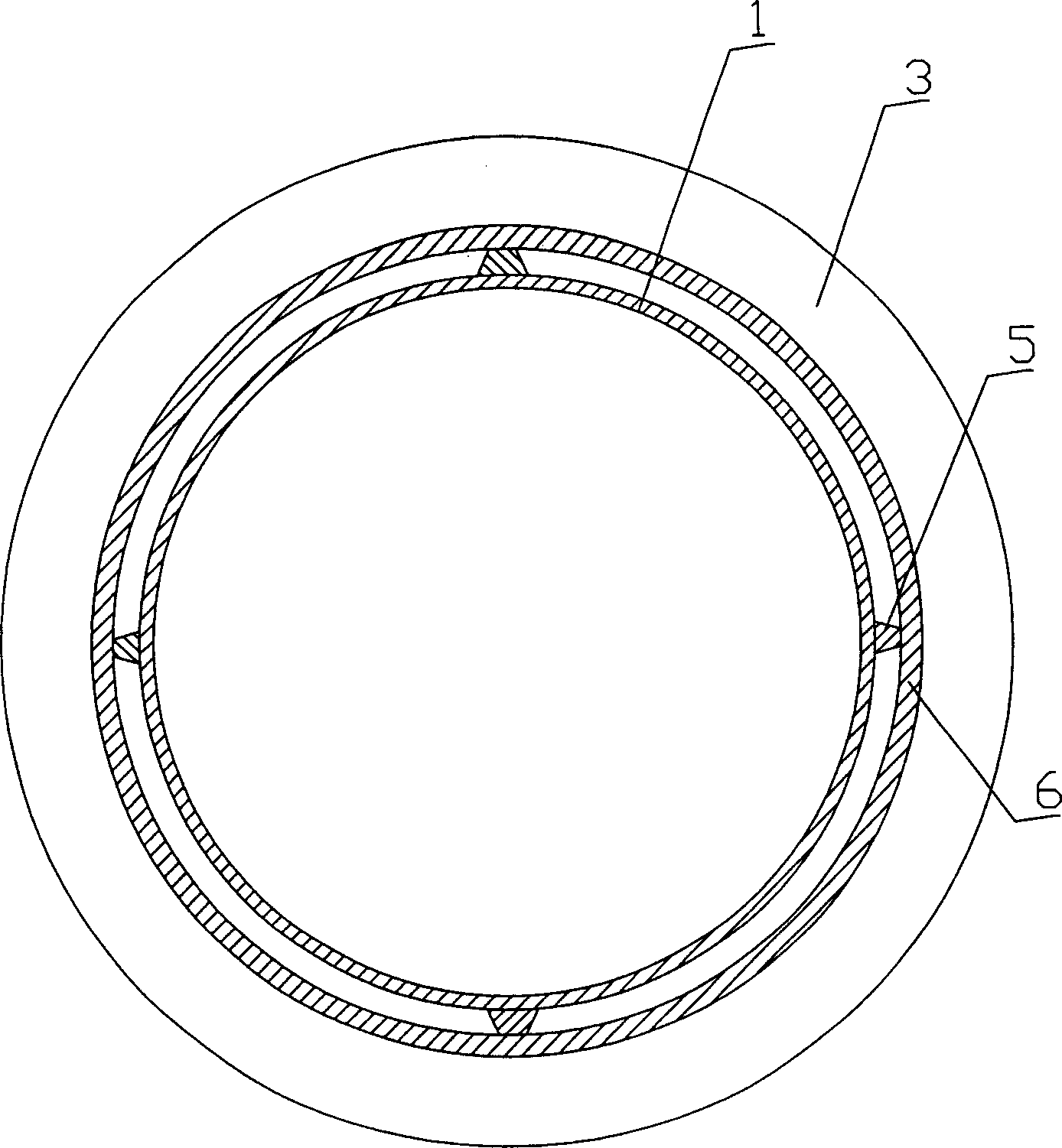

Vacuum heat-preserving tube

InactiveCN1837669ASimple structureEasy to manufactureThermal insulationPipe protection by thermal insulationTemperature differenceThermal expansion

The invention relates to a vacuum thermal-insulated tube, which comprises a tube whose two ends are connected with flanges. It is characterized in that: the tube is sheathed with a sheath with continuous ripple structure to form a vacuum chamber. The invention has simple structure and improved stress relation to avoid crack caused by the temperature difference between inner and outer tubes. And the ripple structure can release the tube change, to reduce the cost of connecting tube. The invention has lower cost and wider application for transmitting high-temperature water or steam.

Owner:张丽娟

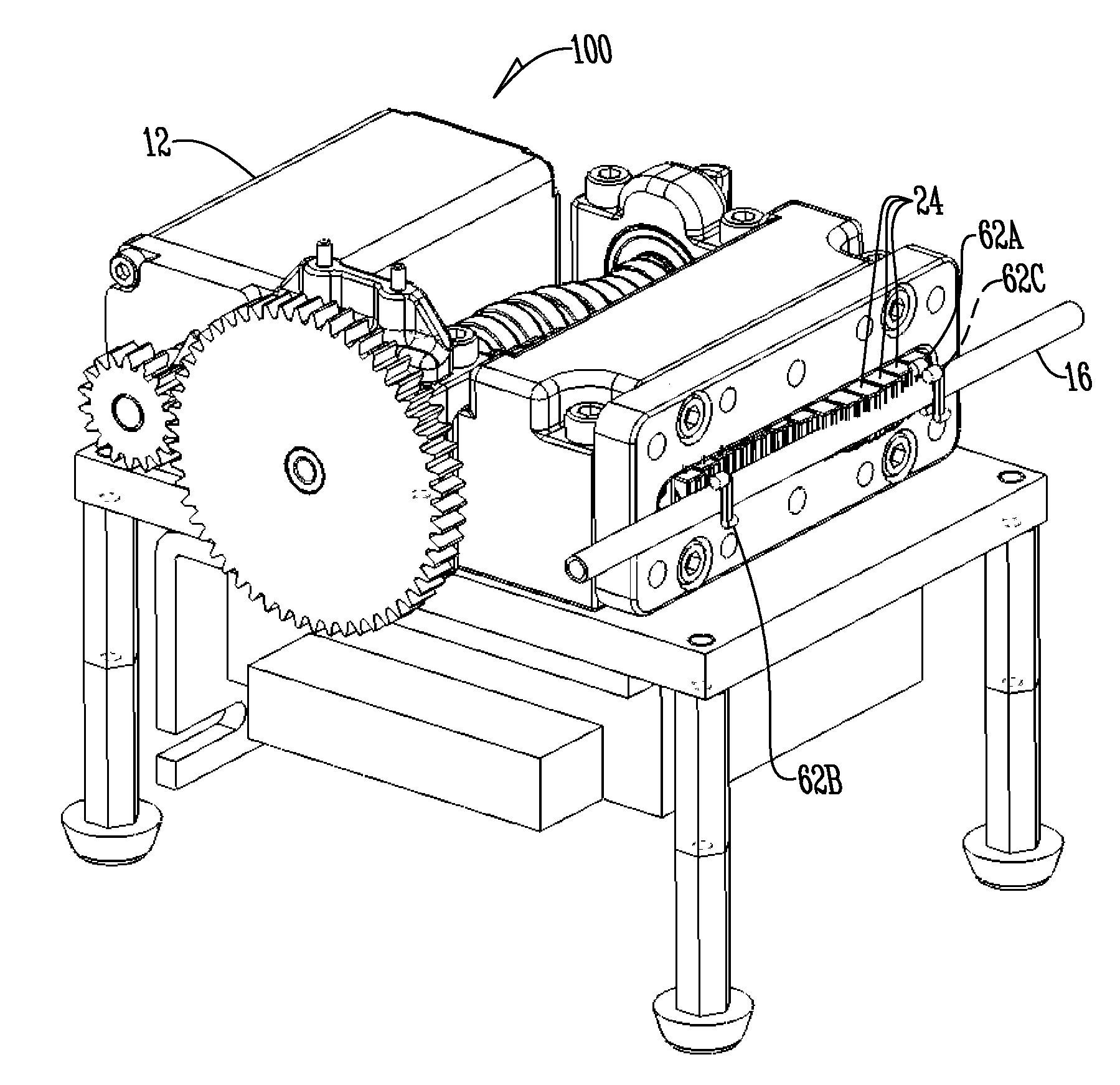

Paper tube cutting machine

ActiveCN104015216AImprove cleanlinessPhysical health effectsMetal working apparatusRotational axisElectric machinery

The invention discloses a paper tube cutting machine which comprises a driving unit and a cutting unit. The driving unit comprises a motor and an air cylinder. The air cylinder is connected with the cutting unit. The cutting unit specifically comprises round blades arranged on a cutting shaft in a sleeved mode, and a shell arranged above the blades. One side of the cutting shaft is provided with a bearing which is connected with an air cylinder, the rotation angle of the bearing is controlled through the air cylinder, and therefore the position of the cutting shaft is controlled. A rotation shaft is arranged below the blades, and the diameters of the two ends of the rotation shaft are large. The middle of the rotation shaft is sleeved with a rubber sleeve, and the rotation shaft is connected with a motor. In the machining process, a paper tube is arranged on the rotation shaft in a sleeved mode, the paper tube cutting machine is further provided with a material return unit which specifically comprises a material return ring and a guide rail. The guide rail is arranged below the rotation shaft, and the material return ring is arranged on the guide rail and driven by another air cylinder. According to the paper tube cutting machine, multiple sets of paper tubes can be machined at a time, efficiency is higher, cost is lower, and maintenance is more convenient. In addition, when the machining widths of the paper tubes change, only the distance of the round blades needs to be changed.

Owner:SUZHOU TIANZUAN MACHINERY EQUIP

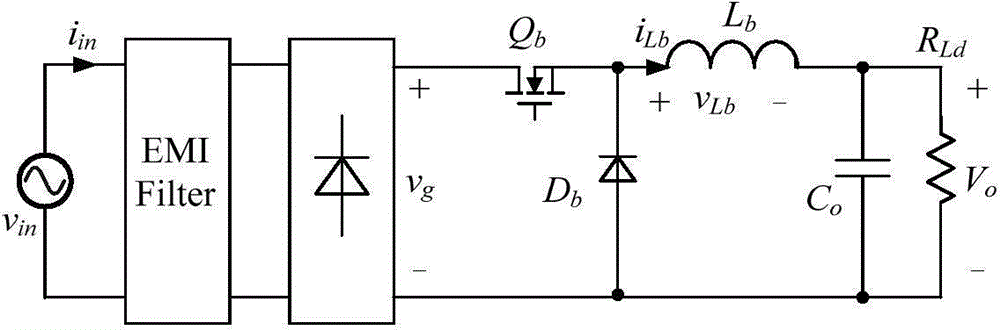

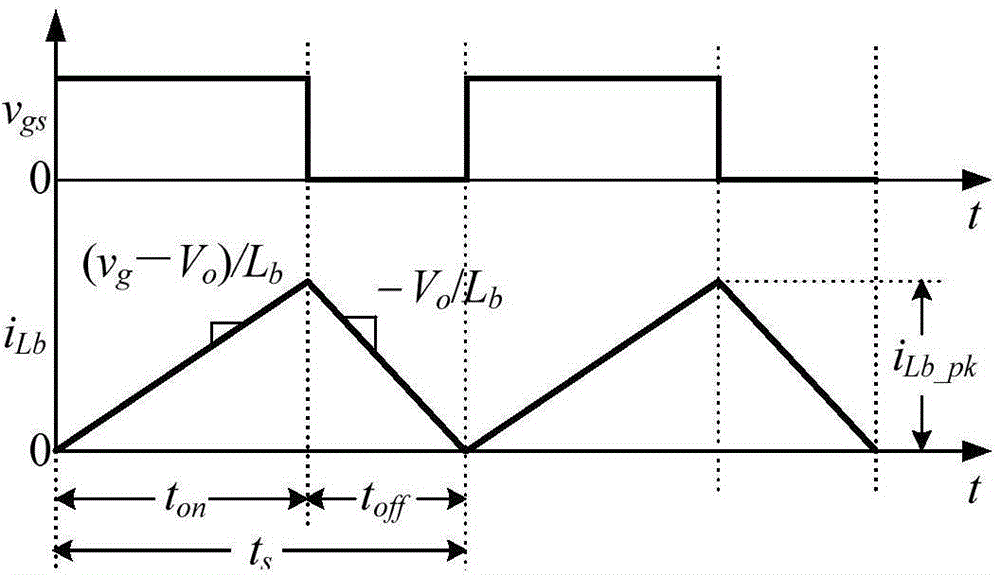

CRM Buck PFC convertor with optimal frequency variation range

InactiveCN104702131ASmall range of variationSmall rippleAc-dc conversion without reversalEfficient power electronics conversionFeedback circuitsEngineering

Owner:NANJING UNIV OF SCI & TECH

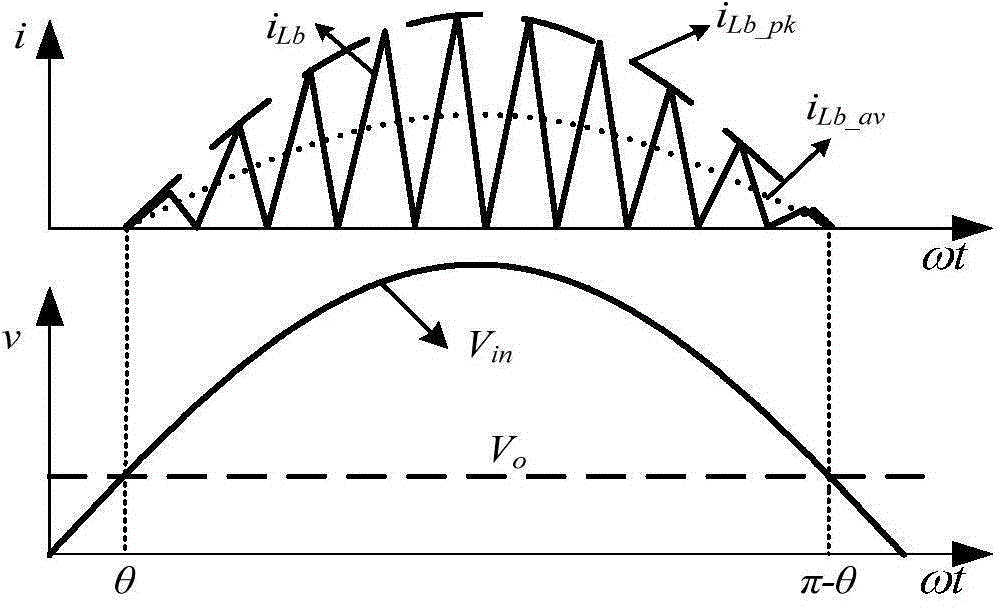

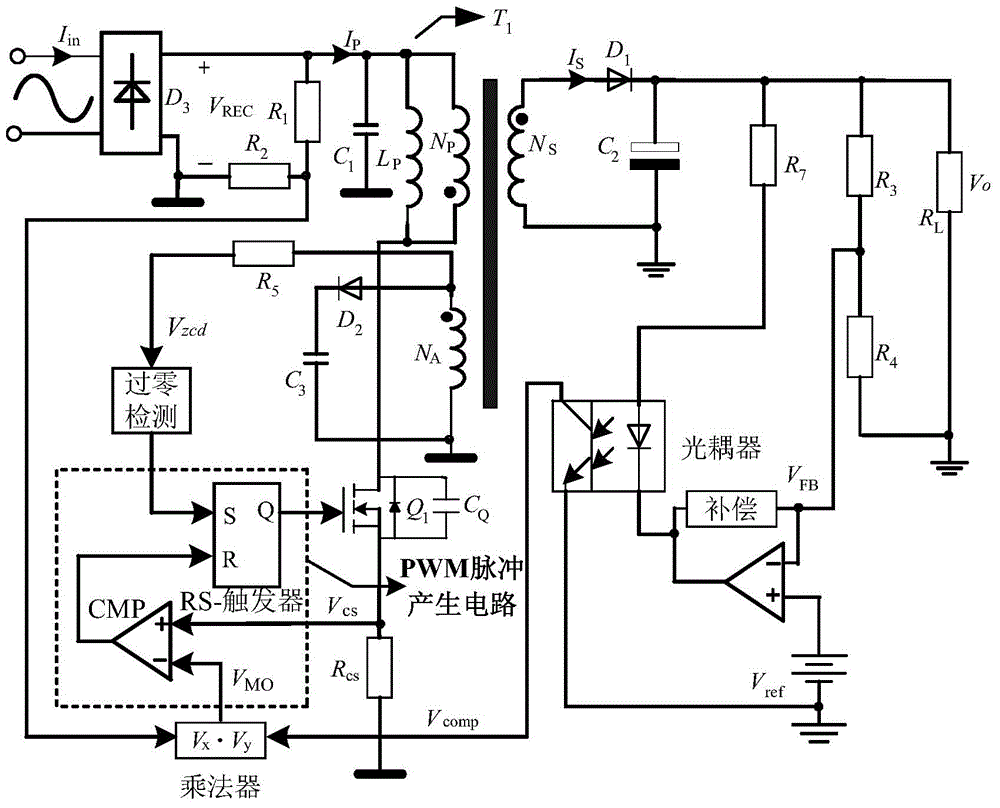

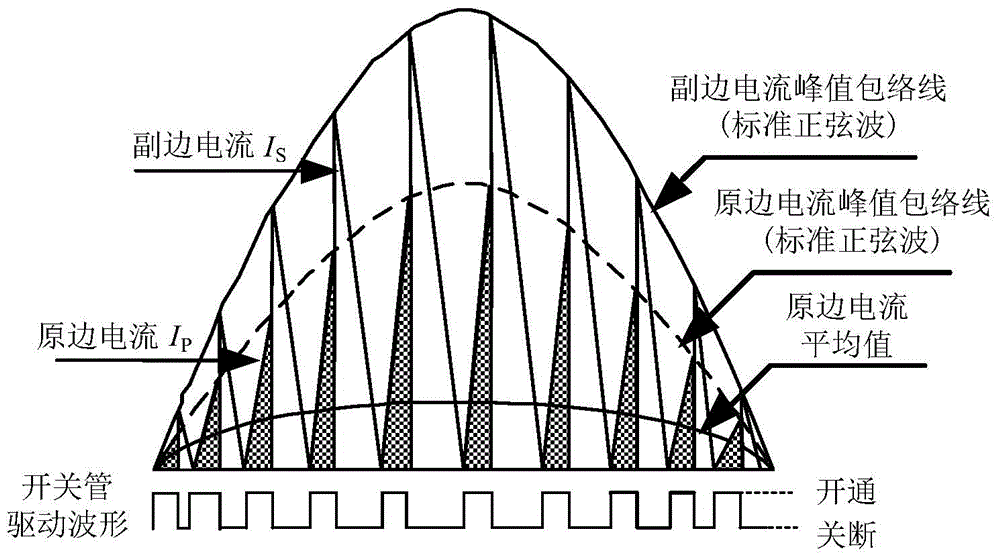

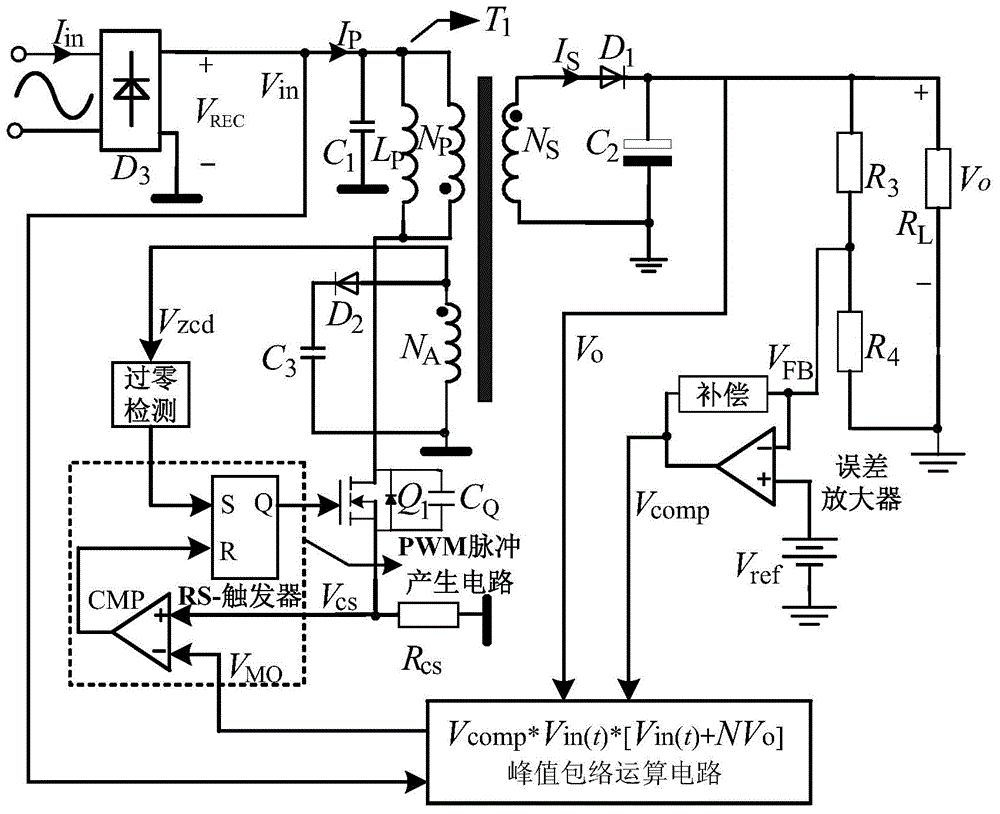

Method and device for controlling critical continuous mode unit power factor flyback converter

InactiveCN104467433AKeep high efficiencyReduce Harmonic DistortionEfficient power electronics conversionAc-dc conversionPeak valueVoltage range

The invention discloses a method and device for controlling a critical continuous mode unit power factor flyback converter. The method and device are used for improving the power factor of the critical continuous mode flyback converter. According to the method, the current peak envelope of a primary side switching tube of the critical continuous mode flyback converter is controlled, so that the current peak envelope of the switching tube changes along with changes of input voltage and output voltage within a power frequency cycle, and turn-off time of the switching tube is decided by the zero-crossing moment of a secondary side current of a transformer. Thus, the unit power factor of the critical continuous mode flyback converter can be obtained within the whole input voltage range.

Owner:SOUTHWEST JIAOTONG UNIV

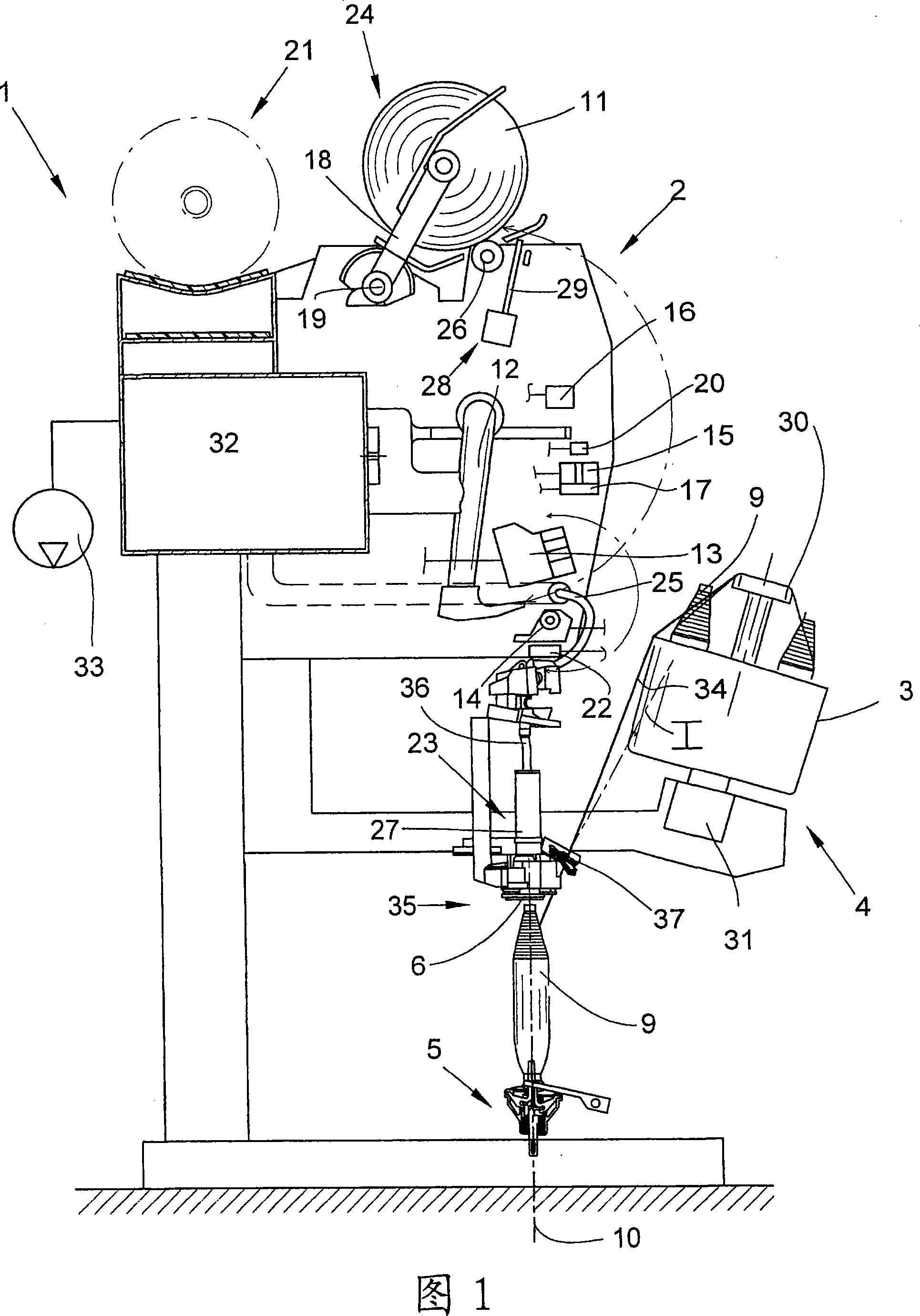

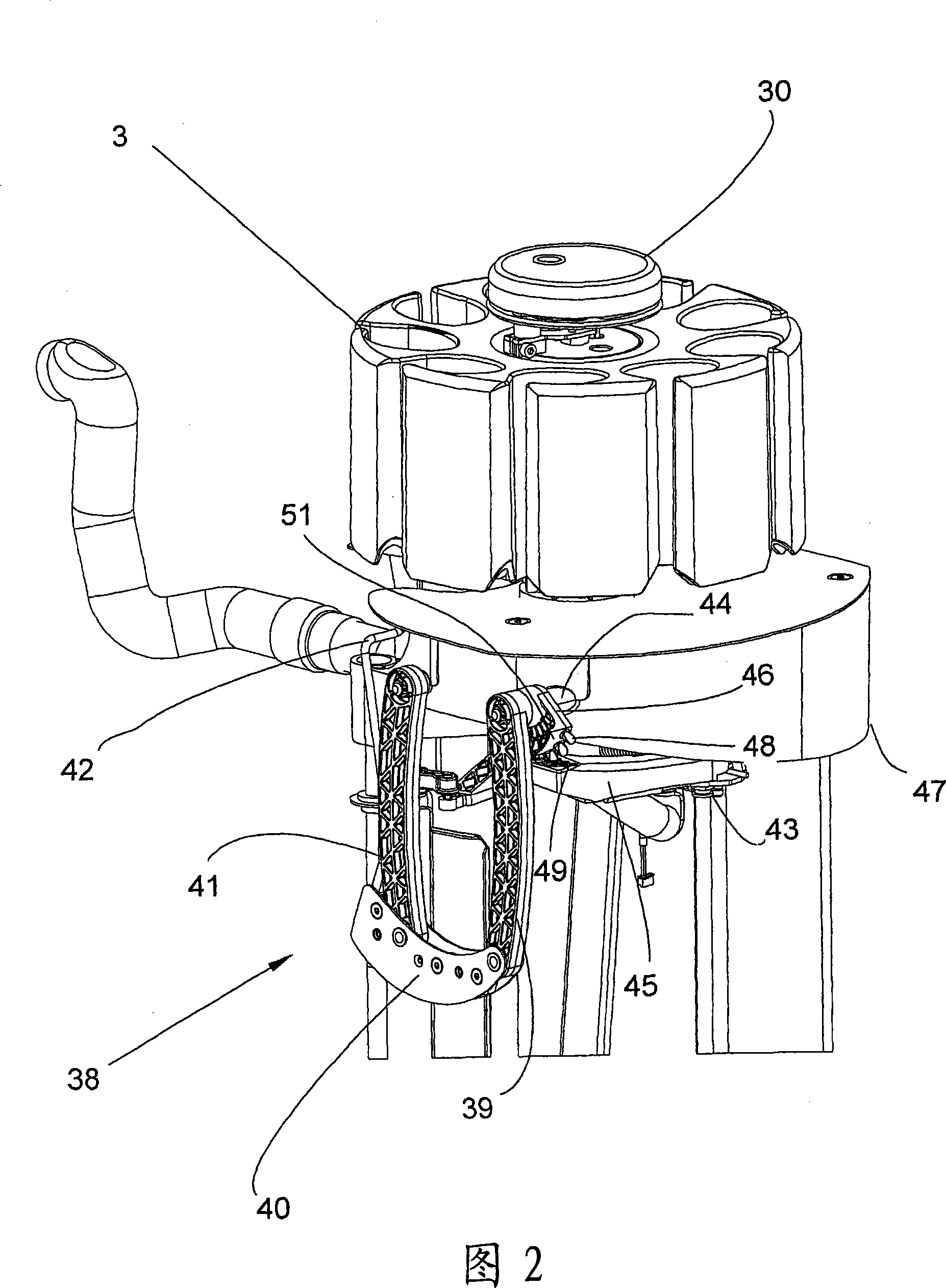

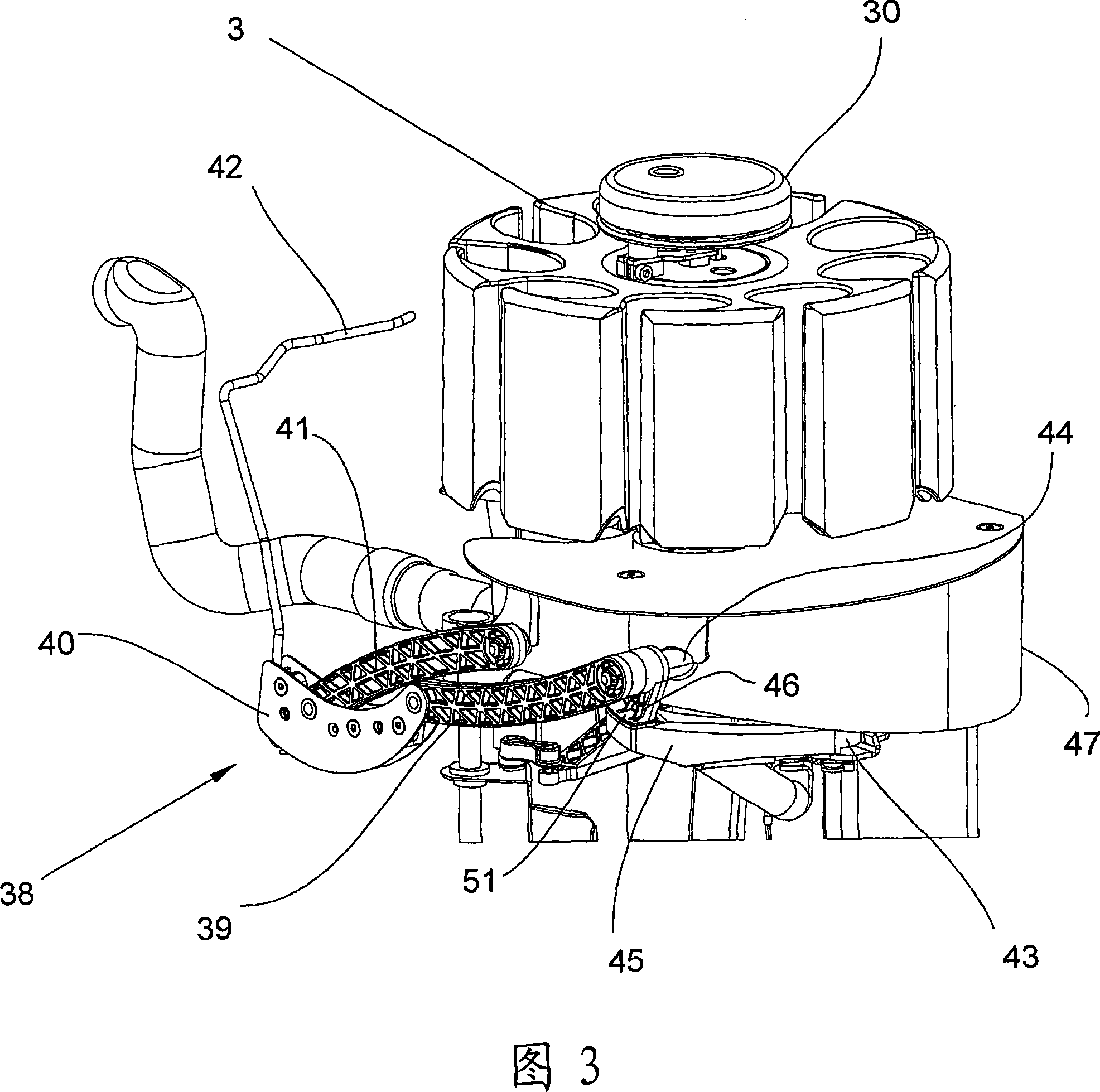

Textile mechanical station for manufacturing across winding reel

The present invention relates to a textile machine working station (2) for producing cross-wound bobbin, the working station (2) has a yarn tube changing device (4), the yarn tube changing device has a bobbin tube chamber (3) can be rotatable supported and store yarn tube (9), a lever mechanism (38) can be asway supported and used for delivering the yarn of yarn tube (9) to the yarn clamping tube (25) while splicing yarn or after changing yarn tube, and a driving electric motor (31) used for driving the bobbin tube chamber (3) and the lever mechanism (38), the electric motor delivers torque to the lever mechanism (38) by a driving shaft (43) and a driven shaft (44) arranged with mutually axle angle mode and having fall between them, here, the lever mechanism (38) can be transferred into yarn delivering location from static location, on the lever mechanism (38) there is a sector gear (46) capable of asway supporting on the driven shaft (44), the sector gear corresponding to a feeding lever (45), the feeding lever connects by the driving shaft (43) and the driving electric motor (31), the sector gear (46) and the feeding lever (45) forms as this, that is the torque acting on the lever mechanism (38) remains constant during the pivoting movement.

Owner:OERLIKON TEXTILE GMBH & CO KG

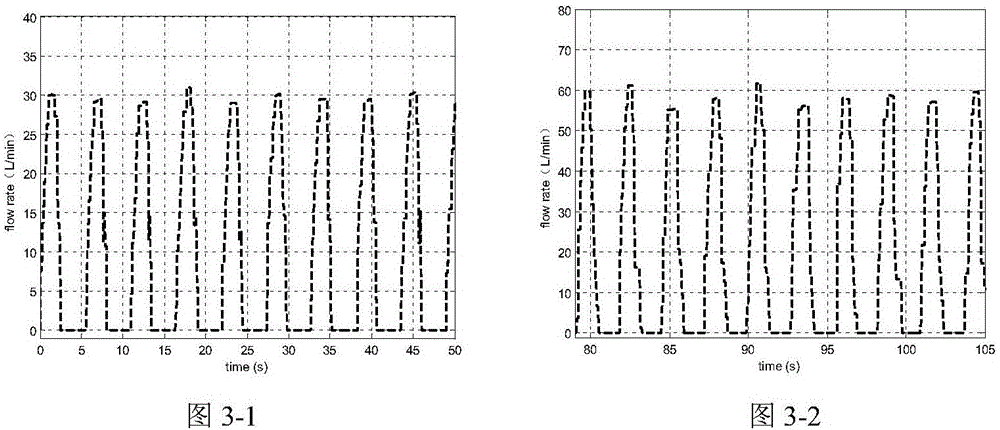

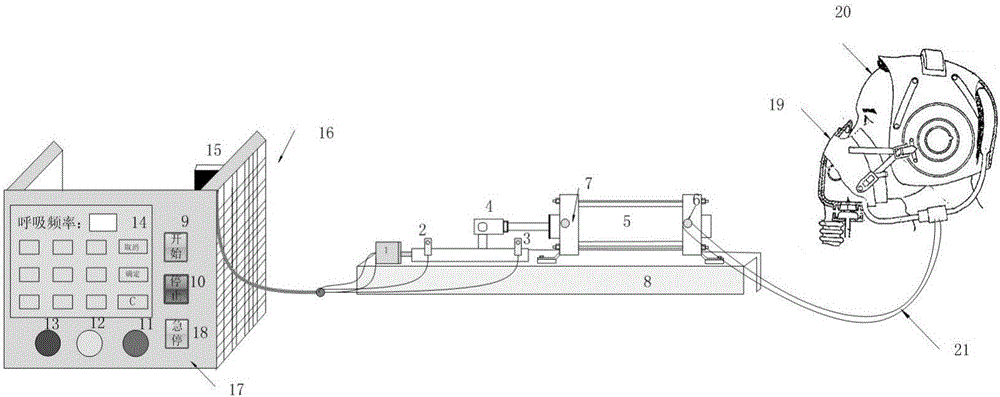

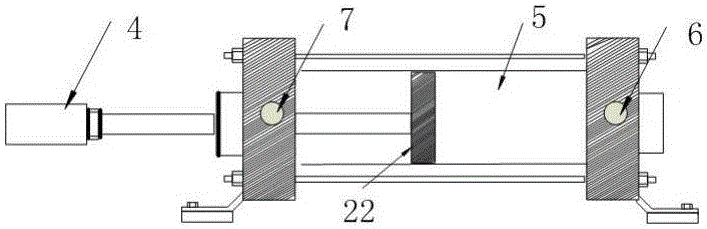

Breathing simulation device used for performance testing of oxygen supplying system

The invention discloses a breathing simulation device for performance testing of an oxygen supply system, which is suitable for the field of aviation personal protection. The device comprises: a control system, a power module, a cylinder structure, and a head mold structure. The control system controls the movement of the cylinder piston according to the sinusoidal law by controlling the rotation of the motor, so that the gas flow rate flowing through the air pipe of the head mold changes according to the sinusoidal law. The device can set the respiratory rate through the LCD touch screen, and change the respiratory tidal volume by adjusting the position of the photoelectric switch. The present invention truly and accurately simulates the changing law of human respiration in the design of an oxygen regulator for an oxygen mask, replaces the role of a human in an experiment, is simple and intuitive, and is convenient to operate, and has certain application value in the process of designing an oxygen supply system.

Owner:NANKAI UNIV

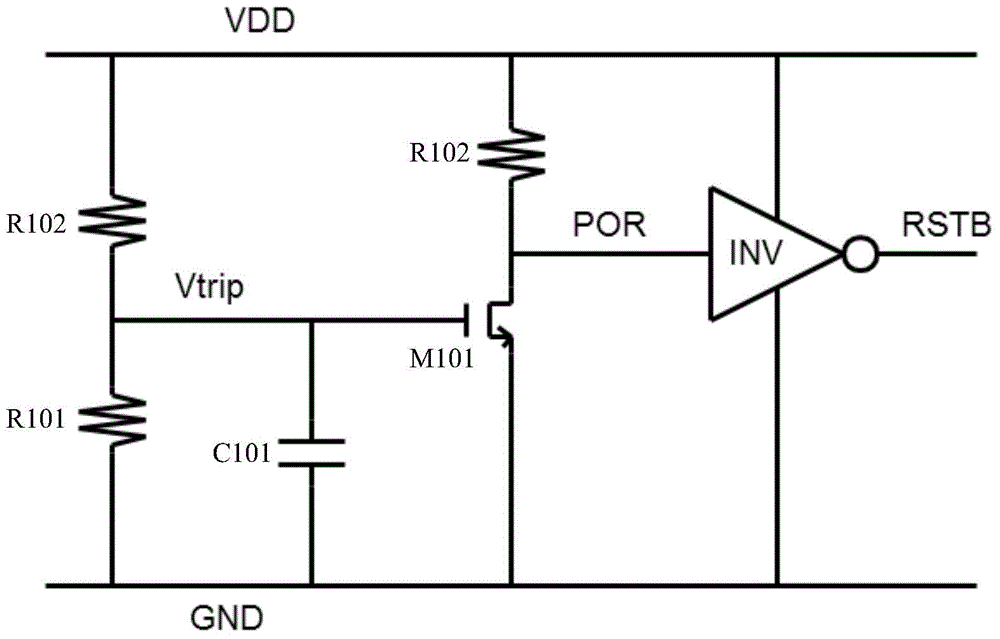

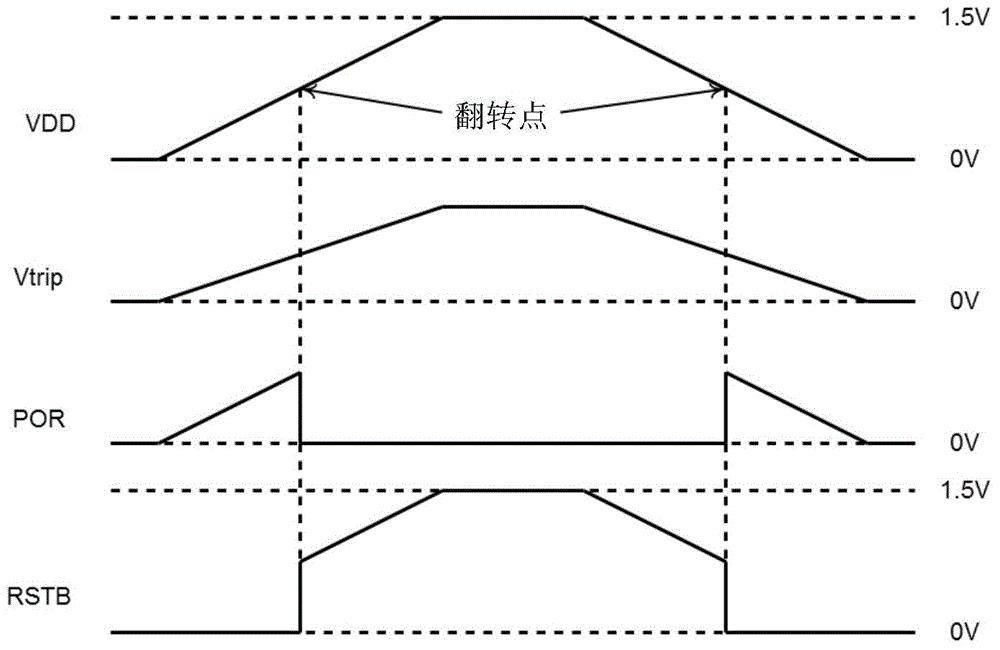

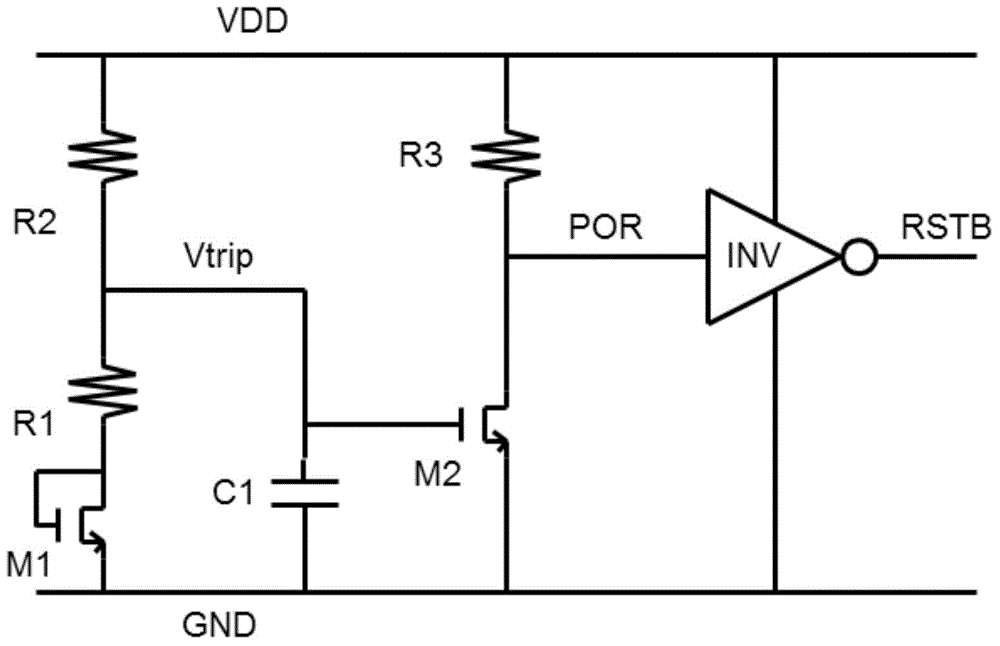

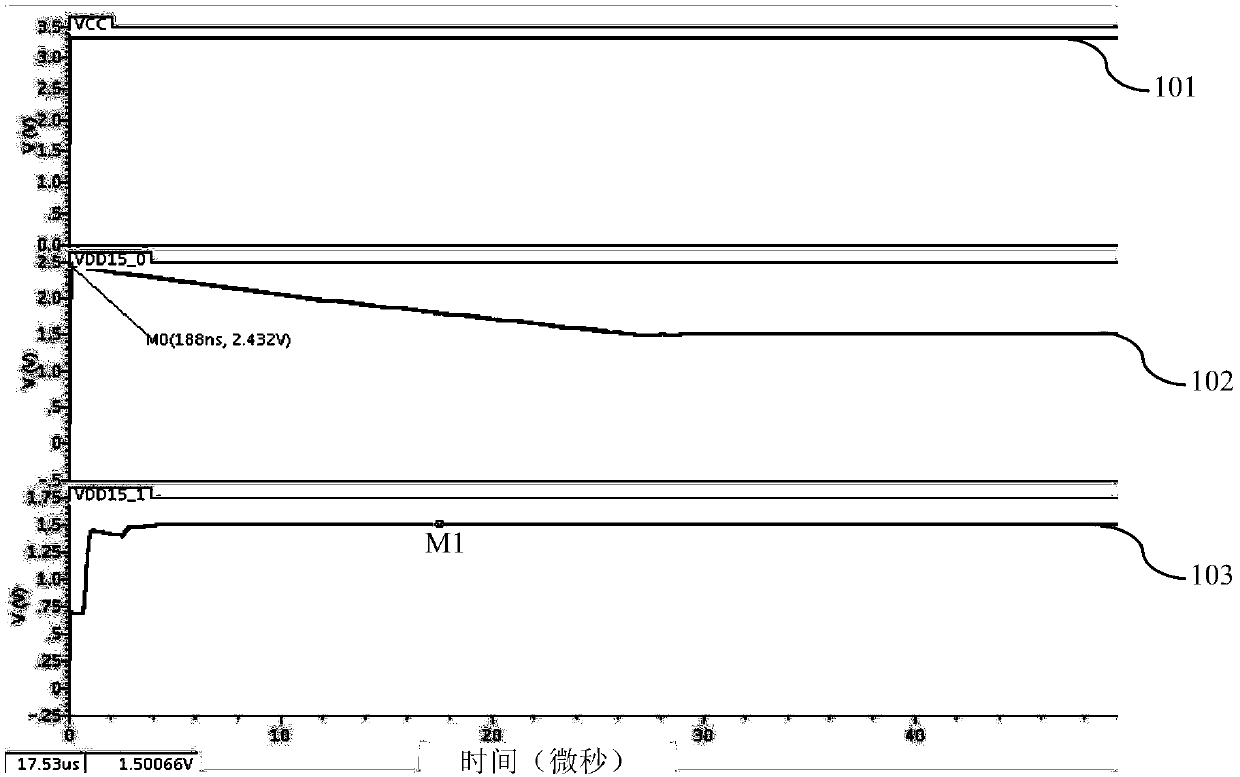

Power-on reset circuit

The invention discloses a power-on reset circuit. The circuit comprises a first voltage division circuit connected between a power supply voltage and the ground. A plurality of resistors and one first NMOS tube are serially connected to form the first voltage division circuit. A grid electrode and a drain electrode of the first NMOS tube are serially connected between an output end of the first voltage division circuit and the ground. A source electrode of a second NMOS tube is grounded, a grid electrode is connected with an overturn voltage output by the first voltage division circuit, and a drain electrode is connected with the power supply voltage through a third resistor. The drain electrode of the second NMOS tube outputs a power-on reset signal. The power-on reset signal is reversed by an inverter, and then a reset signal is output. According to the invention, the first NMOS tube is capable of compensating the threshold voltage of the second NMOS tube controlled by the overturn voltage, so that the influences of the threshold voltage of the second NMOS tube on the power-on process when the threshold voltage of the second NMOS tube changes along with PVT are reduced, and the discreteness of the overturn voltage is lowered.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

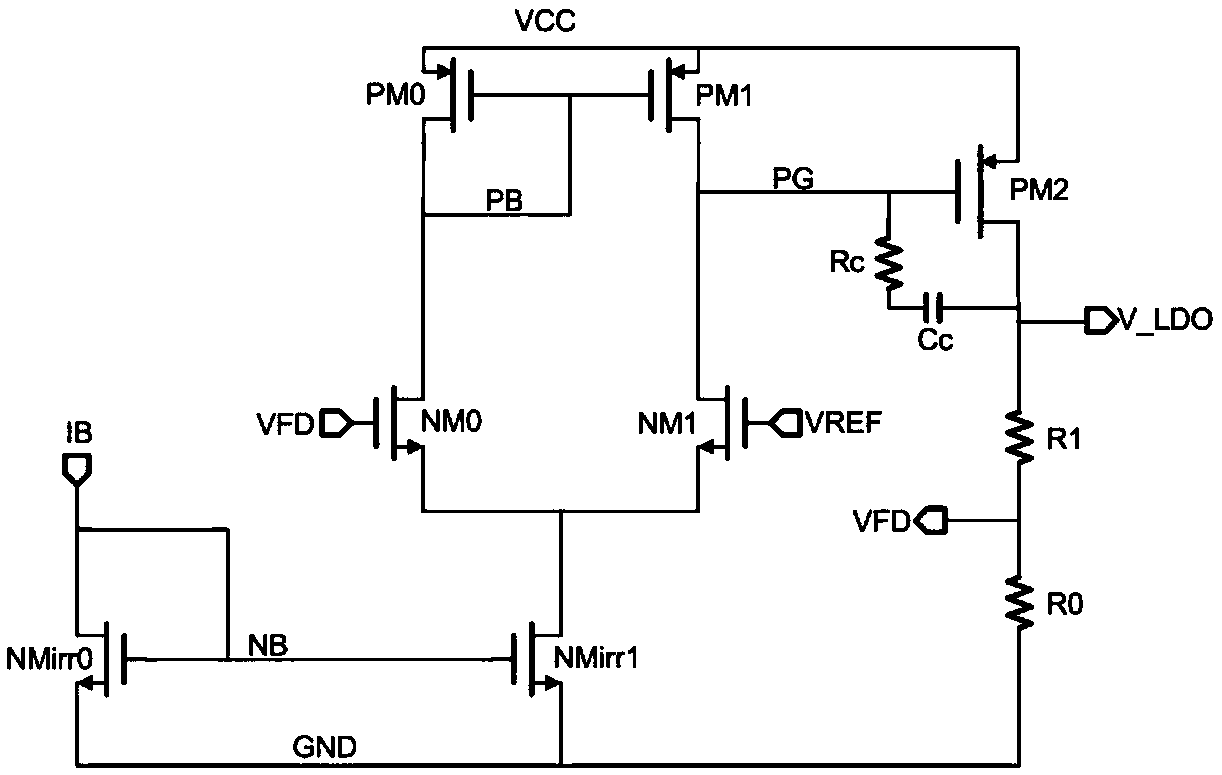

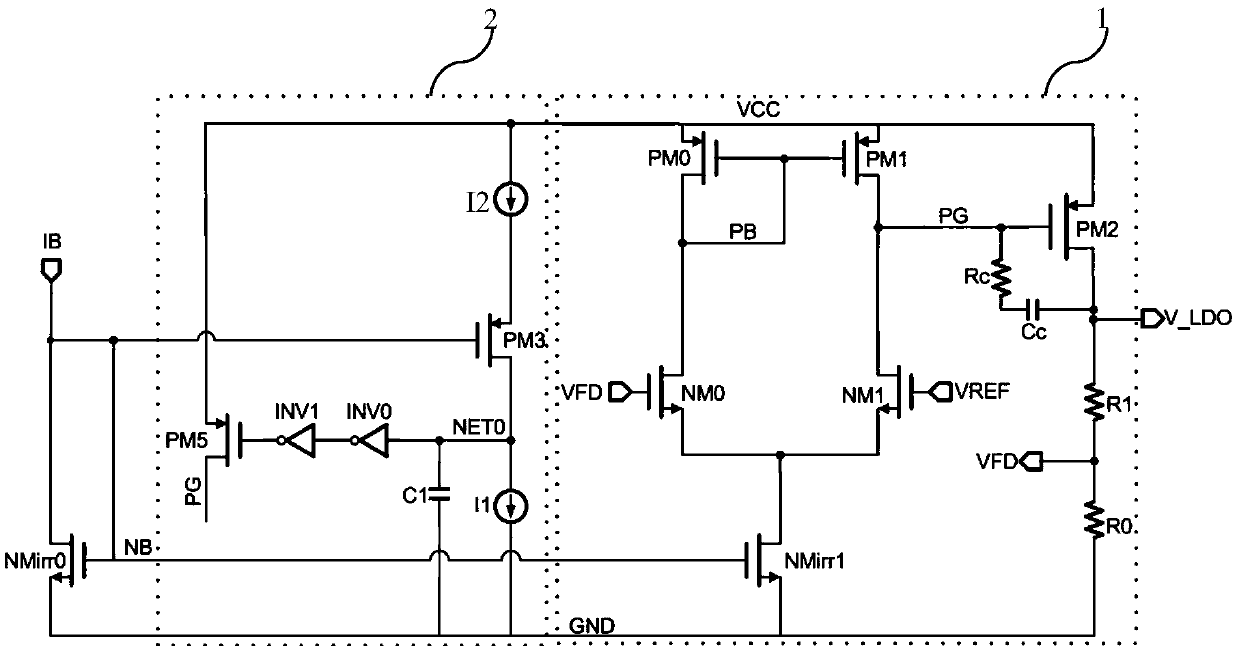

LDO circuit

ActiveCN109656299AEliminate overshootRate of ascentElectric variable regulationCapacitanceEngineering

The invention discloses an LDO circuit, which comprises an overshoot suppression circuit and an LDO main circuit; the overshoot suppression circuit comprises a current comparator, wherein the currentcomparator comprises two comparison current sources and a second PMOS tube serving as a switch between the two comparison current sources; and the grid electrode of the second PMOS tube is connected with the grid electrode of a mirror image NMOS tube corresponding to the tail current. The overshoot suppression circuit also includes a first capacitor and a third PMOS tube. The drain of the third PMOS tube is connected to the gate of the first PMOS tube of the LDO body circuit. In the electrifying process, before the power supply voltage rises to be less than or equal to the sum of the thresholdvoltages of the mirror NMOS tube and second PMOS tube, the second PMOS tube is turned off, the first comparison current source pulls down the gate voltage of the third PMOS tube so that the gate voltage of the first PMOS tube changes along with the power supply voltage, thereby preventing power-on overshoot; and the third PMOS tube is disconnected after the power-on is finished so as to avoid influencing the LDO main circuit.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

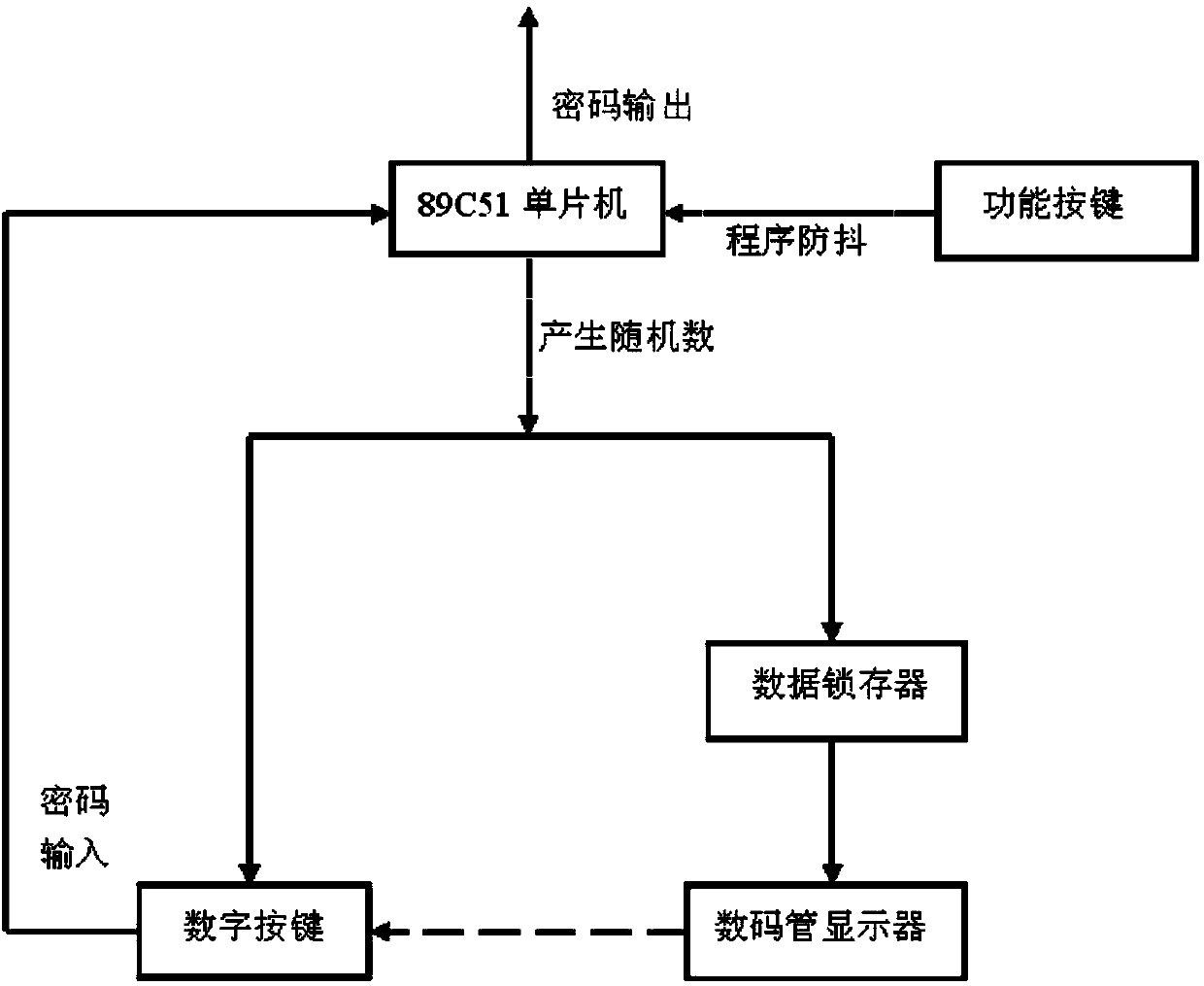

Password-stealing-preventing random-variation numeric keypad

InactiveCN103473517AIncrease flexibilityEnsure safetyInternal/peripheral component protectionDisplay deviceEngineering

The invention relates to a password-stealing-preventing random-variation numeric keypad comprising function keys, numeric keys and a control circuit. Each key comprises a keycap, a digital tube display, conductive rubber triggers, support sleeves, support pillars, a thin-film touch panel and a circuit board, the thin-film touch panel is fixedly mounted on the circuit board, the conductive rubber triggers are fixedly mounted on the thin-film touch panel, the keycap is mounted on the conductive rubber triggers through the support sleeves and the support pillars in a guiding and sliding manner, and digital tubes are fixedly mounted on the thin-film touch panel below the middle of the keycap. The keypad aims to overcome defects of a traditional password keypad, and an 89C51 single chip microcomputer generates random numbers by the aid of an internal timer and a method of interrupt coalescing; the dynamic random-number password-stealing-preventing keypad, allowing positions of numbers from 0 to 9 displayed by the LED seven-segment digital tubes changing randomly, can not only be applied to password entering of ATMs (automatic teller machines), but also be widely applied to various other devices, utilizing keypads for entering passwords, such as POSs (points of sales), safety boxes and antitheft doors, and is of great significance to development of national economy and protection of civil information.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Turntable type plant leaf sampler and sampling method

PendingCN109406193AEasy to useAvoid confusing situationsWithdrawing sample devicesEngineeringLaboratory facility

The invention relates to a detection sampling device in the field of agriculture, in particular to a turntable type plant leaf sampler and a sampling method. The sampler comprises a base, a rotating disc arranged on the base through a positioning disc and a cutting handle matched with the rotating disc; the rotating disc is arranged at the upper end of a central rotating shaft, the lower end of the central rotating shaft penetrates through the center of the positioning disc, and a cutting knife on the cutting handle is matched with a cutting hole formed in the edge of the rotating disc. The sampler can be used for efficiently completing plant leaf sampling, a plurality of leaves can be continuously sampled, continuous tube changing is achieved, and convenience and quickness are achieved. The situation that samples are mixed can be greatly avoided, and the sampler is small in size and low in weight and can be conveniently used in laboratories and carried for field sampling.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Ink jet recording apparatus

ActiveUS8646885B2Effectively preventing a tube from movingIncrease frictionOther printing apparatusPull forceEngineering

A tube support member that puts a tube connected to an ink jet head and an ink tank in a bent state is provided. Accordingly, when a pulling force acts between the bent support member and the tube, a component force acting as contact force occurs at the surface that makes contact with the tube, and a high degree of friction is generated in response to this component force. The tube is thus strongly supported in a state in which the tube does not shift with the dimensions of the tube changing. Meanwhile, when the pulling force is released, the component force is also eliminated, and the tube is freed; the dimensions of the tube return to normal, and the tension is eliminated.

Owner:SEIKO EPSON CORP

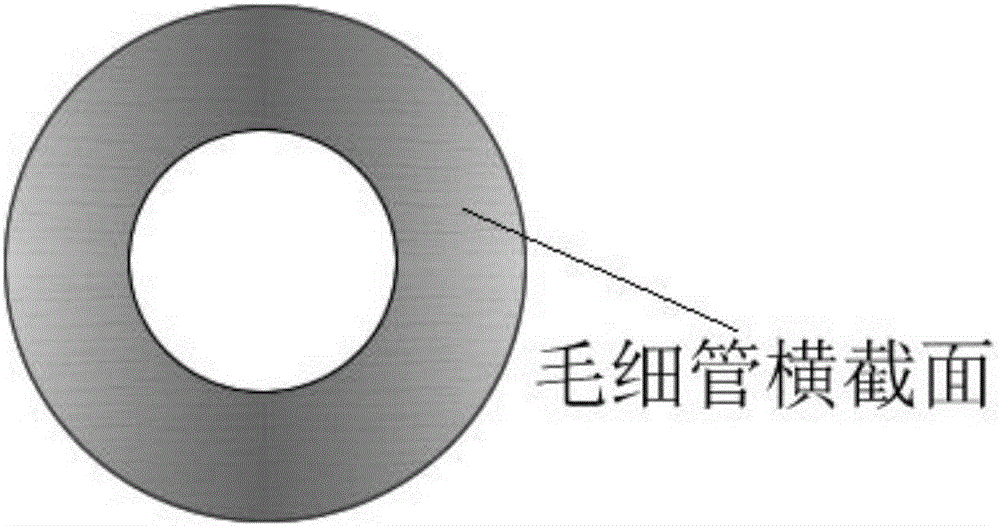

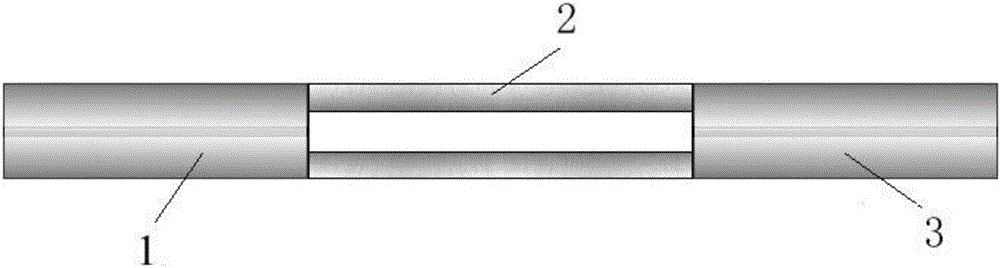

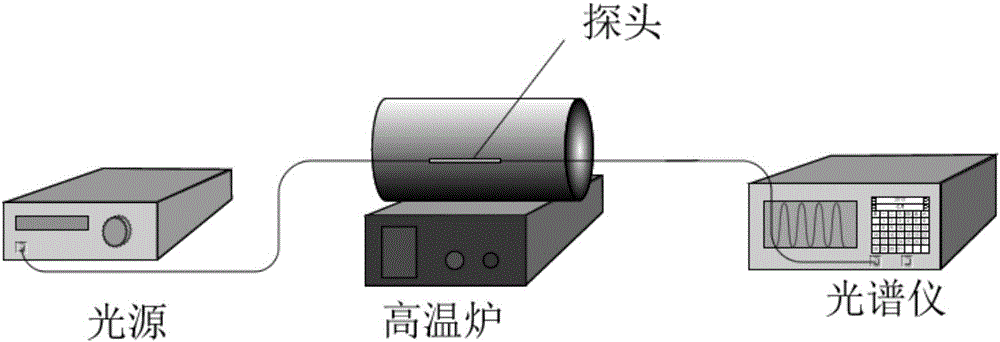

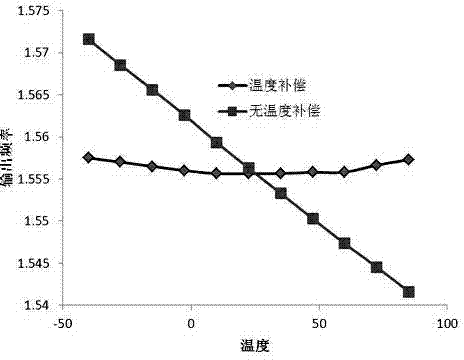

Capillary structure-based optical fiber high-temperature sensor and preparation method thereof

InactiveCN106644154AHigh precisionHigh measurement accuracyThermometers using physical/chemical changesSpectrographEngineering

The invention discloses a capillary structure-based optical fiber high-temperature sensor and a preparation method thereof. The sensor comprises a capillary tube. The two ends of the capillary tube are respectively provided with an input optical fiber and an output optical fiber. The input end of the optical fiber high-temperature sensor is connected with a light source through the input optical fiber. The output end of the optical fiber high-temperature sensor is connected with a spectrograph through the output optical fiber. The input optical fiber and the output optical fiber are single-mode optical fibers. The inner diameter of the capillary tube is 75 mum. The outer diameter of the capillary tube is 125 mum. The length of the capillary tube is 10 to 50 mm. when the ambient temperature of a detection area changes within the range of 0 to 1000 DEG C, the wavelength of each transmission peak in the capillary tube changes correspondingly. Through detecting the changing condition of the wavelength of the transmission peak by means of the spectrograph, the temperature change can be detected. The optical fiber high-temperature sensor is simple in structure, low in cost and high in measurement precision.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

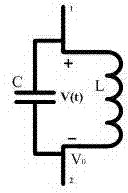

Voltage-controlled oscillator circuit with frequency not changing with temperature

InactiveCN104300967AThe output frequency does not changeGenerator stabilizationMirror imageFilter capacitor

The invention discloses a voltage-controlled oscillator circuit with frequency not changing with temperature. The circuit comprises a first cross coupling tube, an LC oscillating circuit connected with the two output ends of the first cross coupling tube in parallel, a second cross coupling tube connected with the LC oscillating circuit in parallel, a mirror image current source circuit, a divider resistor arranged between the first cross coupling tube and the output end of the mirror image current source circuit, and a filter capacitor connected with the output end of the mirror image current source circuit. Because a pair of variable capacitors are arranged on the LC oscillating circuit and negative temperature coefficient current with slope is input to the mirror image current source circuit, on the premise that the complexity and the power consumption of the circuit are not increased and high performance is achieved, it is avoided that because the working state of the first cross coupling tube and the working state of the second cross coupling tube change, the oscillating frequency at the signal output end of the VCO circuit changes, and finally, the frequency drift caused by temperature changes can be effectively overcome or counteracted.

Owner:HANGZHOU CANAANTEK COMM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com