Heat exchanger flow circuit arranging method and device

A layout method and heat exchanger technology, which is applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of heat flow layout without using the field synergy principle, lack of comprehensive consideration, etc., and achieve volume reduction , cost reduction, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

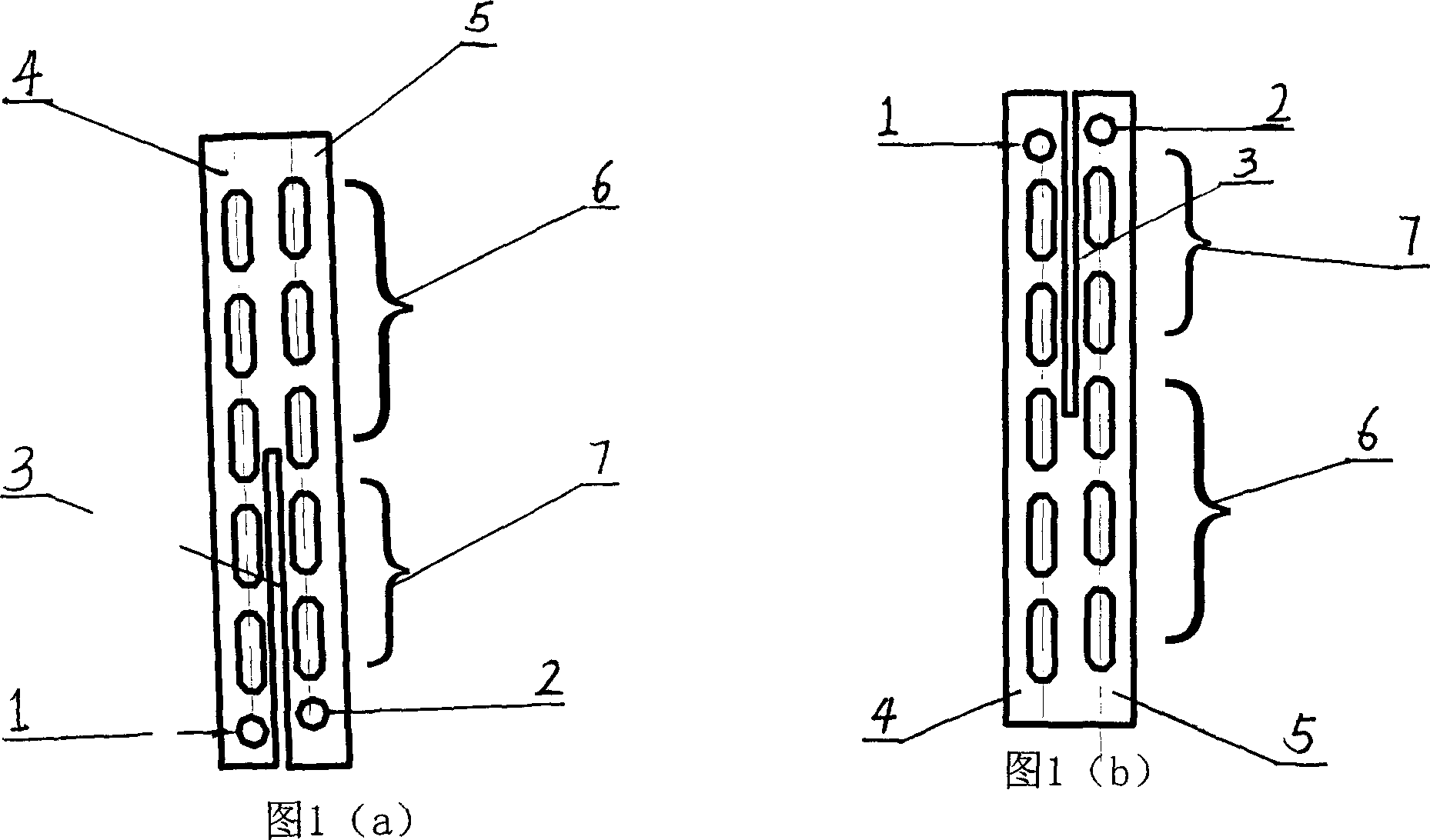

[0023] see figure 1 , the flow path arrangement method of the present invention is as follows:

[0024] 1) Pure countercurrent arrangement

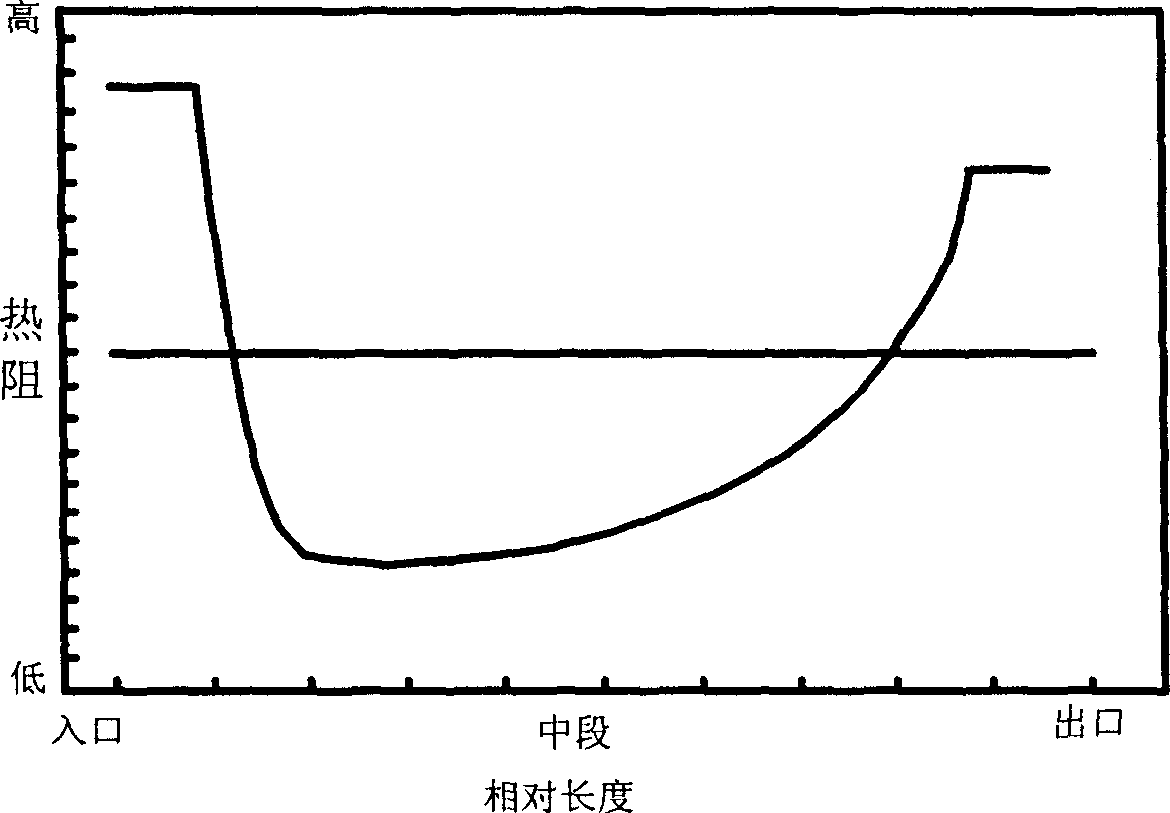

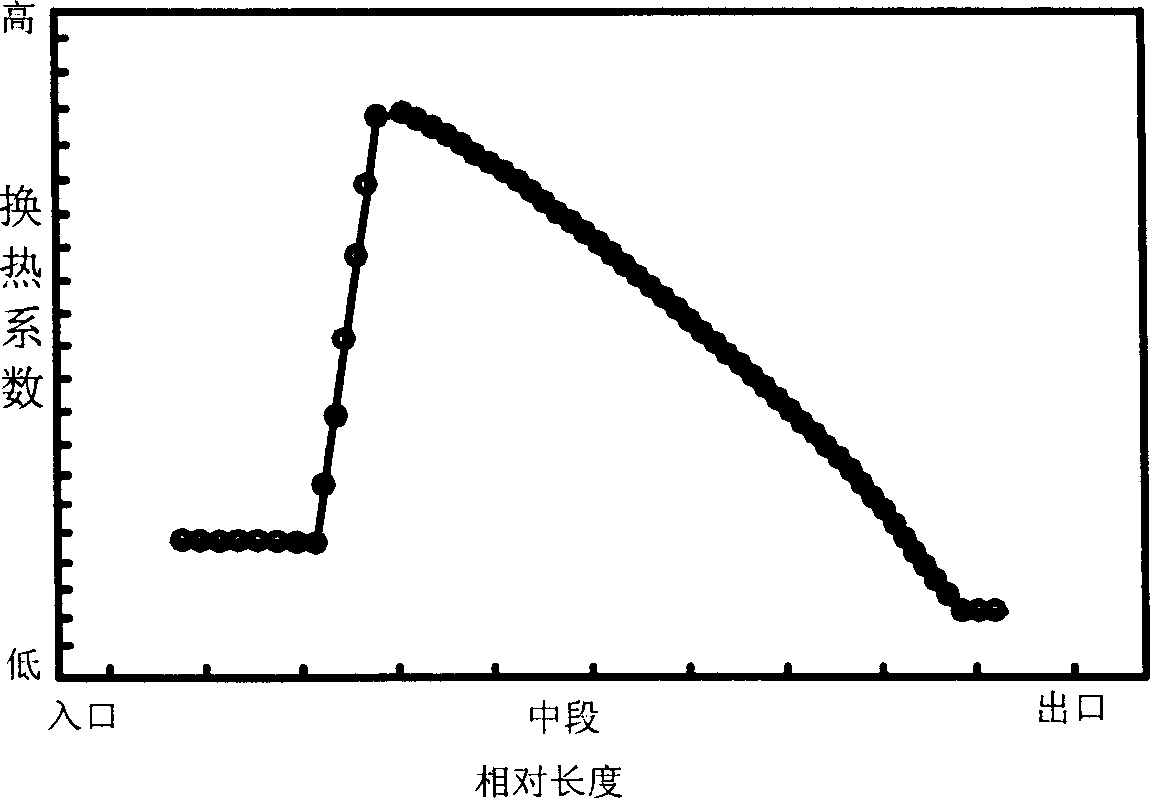

[0025] According to the basic principle of heat transfer, under the same inlet and outlet temperature conditions, the average temperature and pressure of countercurrent flow is the largest, and the average temperature and pressure of downstream flow is the smallest. Therefore, at the same temperature of the hot and cold fluids, the countercurrent arrangement is better than the forward flow arrangement, that is, the flow direction of the refrigerant is opposite to the flow direction of the air;

[0026] 2) Prevent reverse heat conduction in fins

[0027] The inlet and outlet of the refrigerant are both at one end of the heat exchanger, where there is a large temperature difference in the fins, and reverse heat conduction will inevitably occur. In order to avoid reverse heat conduction, the method adopted is to slit the middle part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com