Intermittent automatic tube drawing device

An intermittent, automatic technology, applied in textiles and papermaking, etc., can solve the problems of high labor intensity, large number of workers, affecting product quality, etc., and achieve the effect of reducing labor intensity, high movement accuracy and saving labor time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

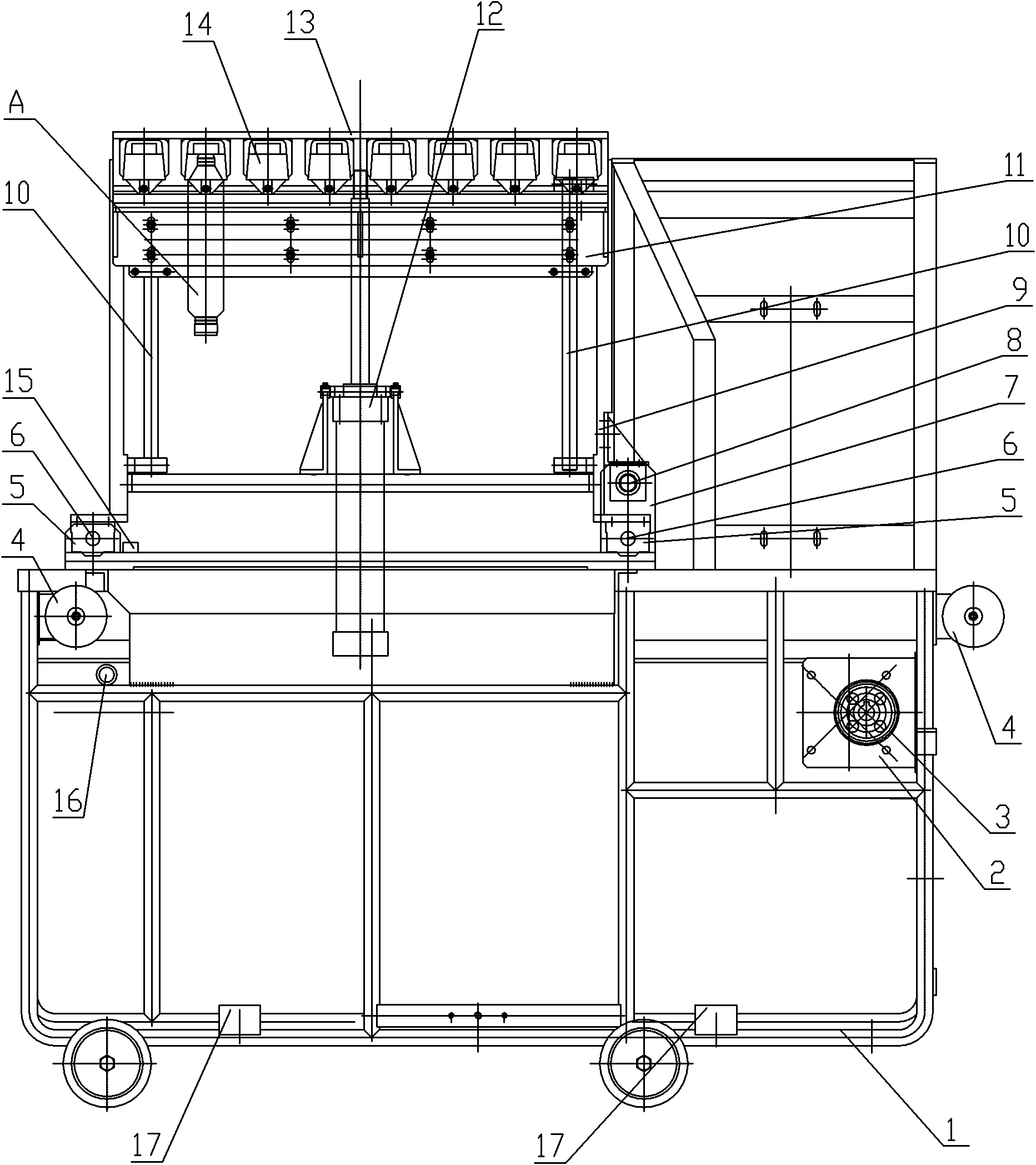

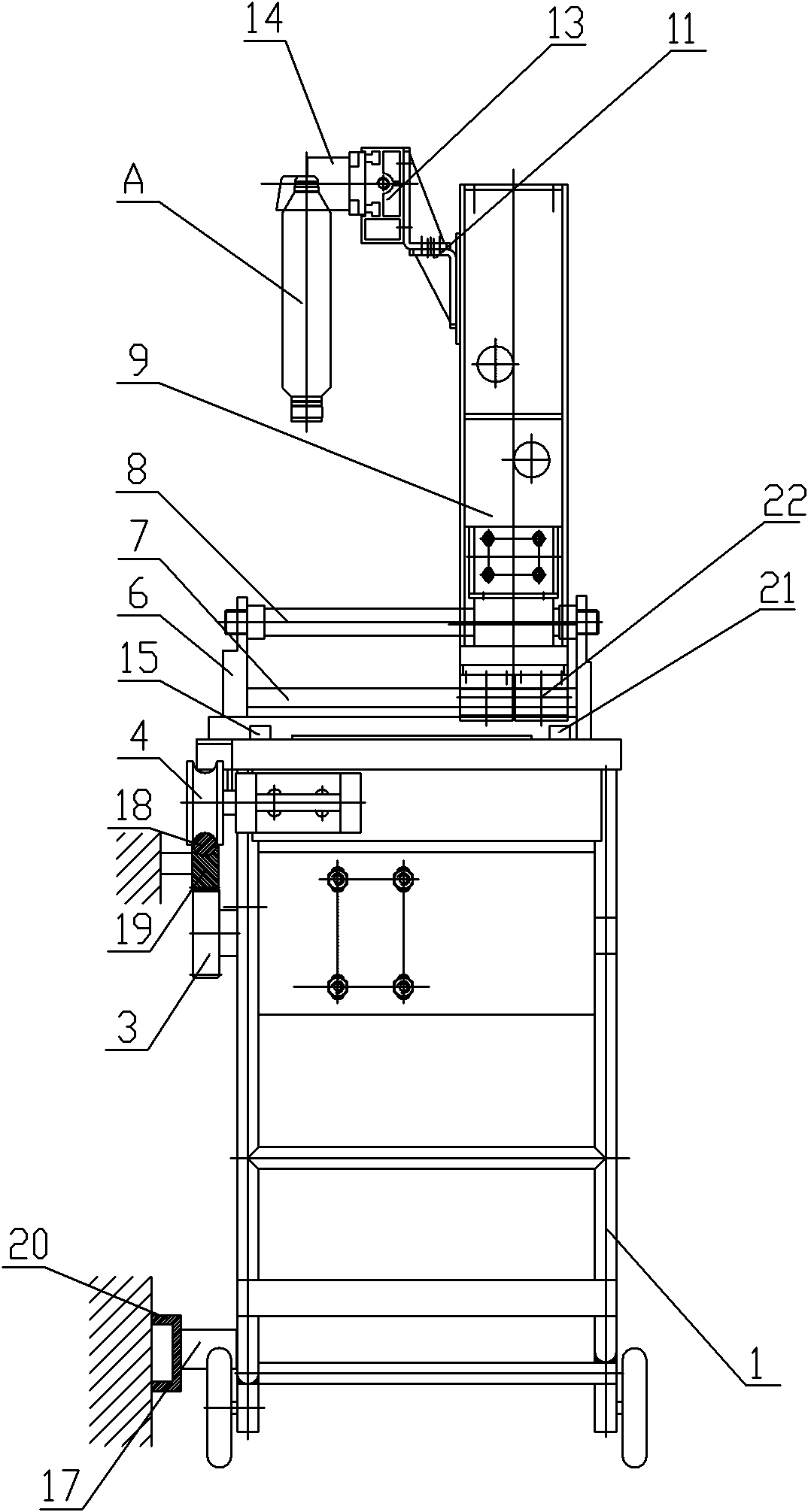

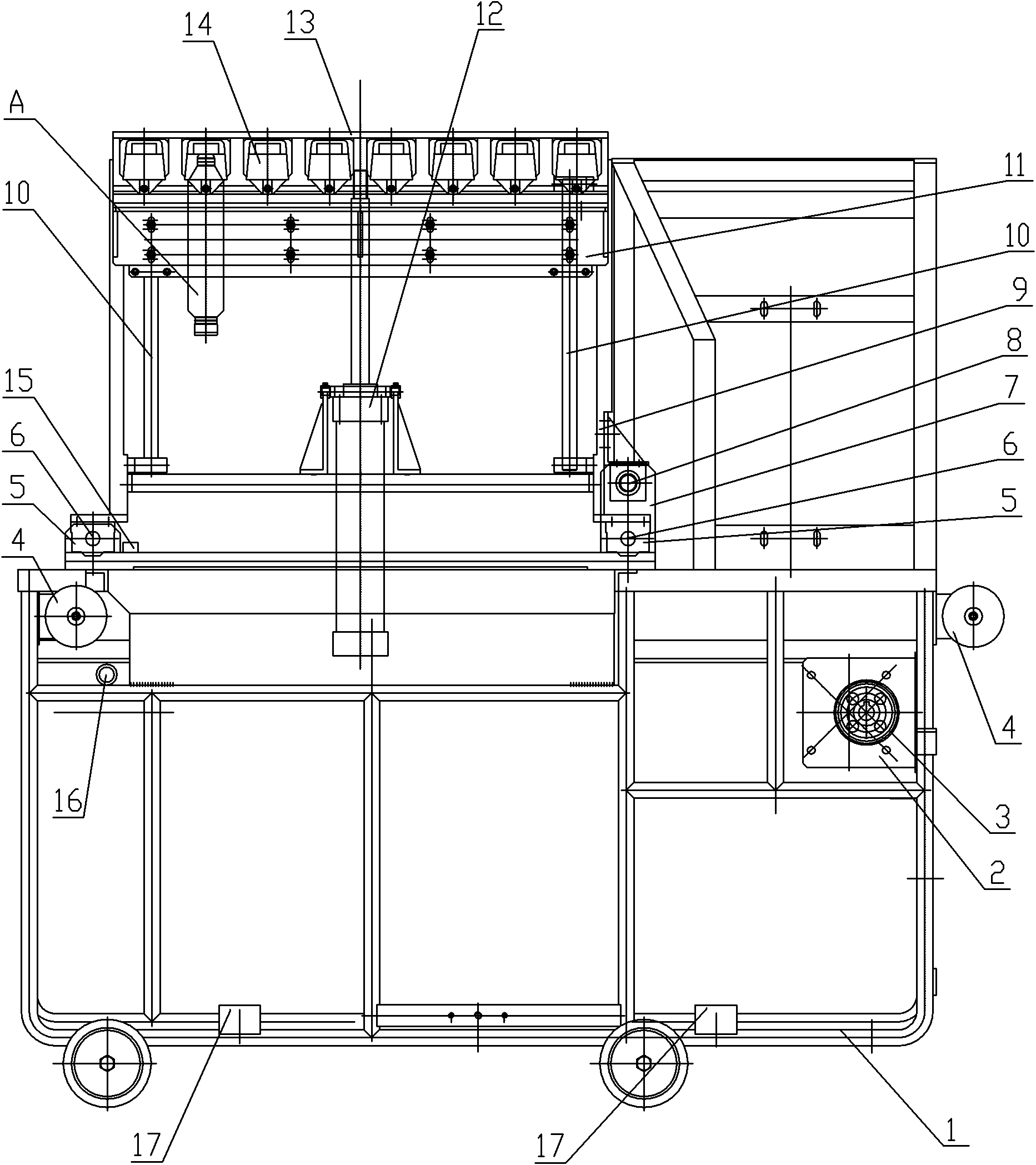

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0021] As shown in the figure: the intermittent automatic extubation device is mainly used on the spinning frame where the spindle and bobbin A are friction-driven, and it is mainly composed of a doffing trolley 1, a walking drive mechanism, an extubation manipulator and a control system; The doffing trolley 1 is placed on the guide rail assembly and can walk along the guide rail assembly. The traveling route of the doffing trolley 1 is parallel to the line connecting the spindle centers of the spinning frame; The driving mechanism is used to drive the doffing trolley 1 to travel intermittently, and the tube pulling manipulator is used to pull out and collect the full bobbins A on the spinning frame; When the doffing trolley 1 is moving, the extubating manipulator stops the extubating action; when the traveling driving mechanism drives the doffing trolley 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com