CRM Buck PFC convertor with optimal frequency variation range

A technology of frequency change and converter, which is applied in the direction of output power conversion device, irreversible AC power input conversion to DC power output, high-efficiency power electronic conversion, etc., and can solve problems such as complex design of inductors and EMI filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Attached below picture and Specific embodiments further describe the present invention in detail.

[0022] 1 Working principle of CRM Buck PFC converter

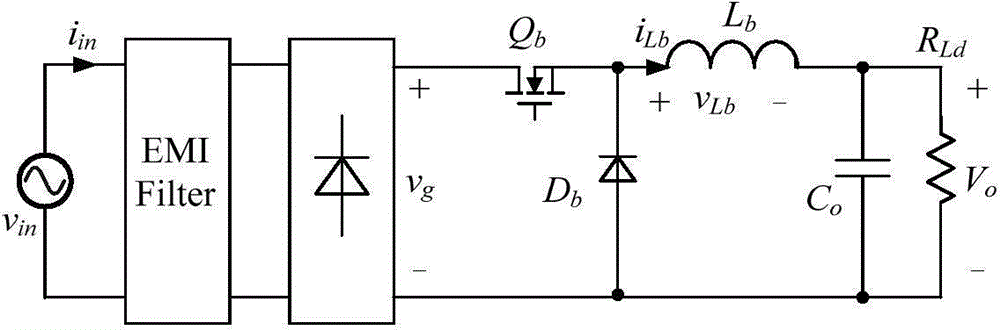

[0023] figure 1 It is the main circuit of the Buck PFC converter.

[0024] For the convenience of analysis, the following assumptions are first made: 1. All devices are ideal components; 2. The output voltage ripple is very small compared with its DC value; 3. The switching frequency is much higher than the input voltage frequency.

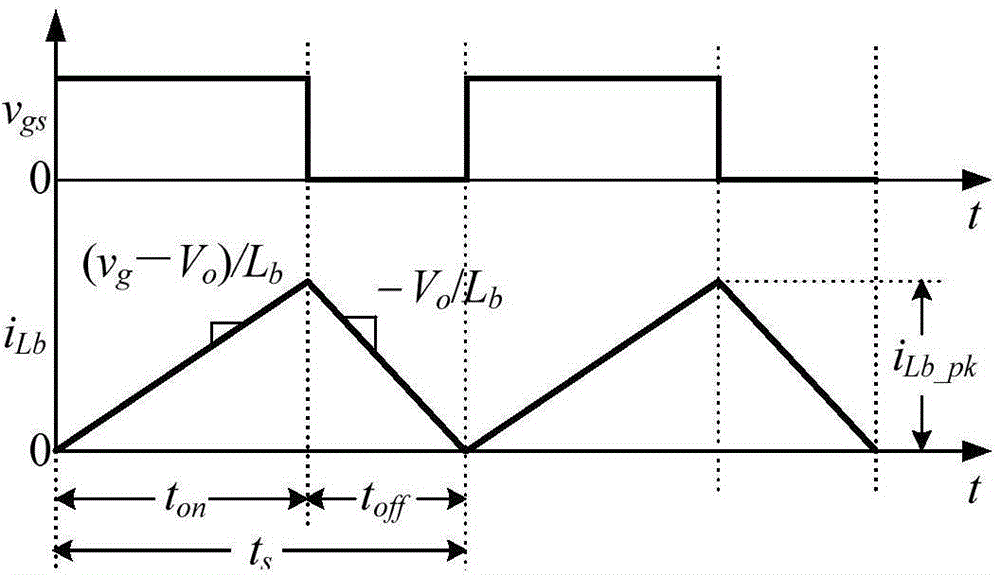

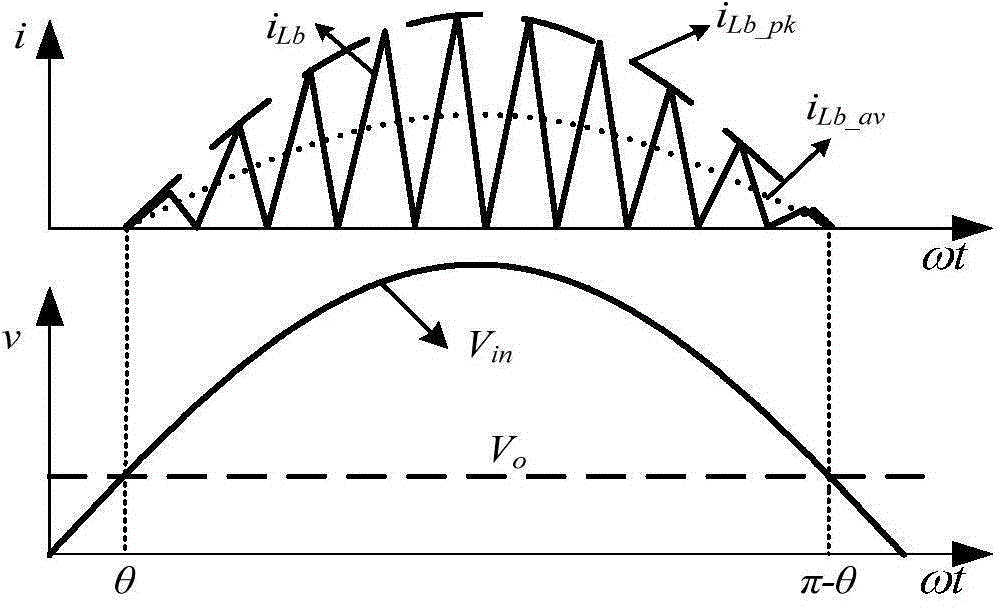

[0025] figure 2 The inductor current waveform in one switching cycle when CRM is given. When Q b When turned on, D b cutoff, the boost inductor L b The voltage across it is v g -V o , its current i Lb Start with zero and start with (v g -V o ) / L b The slope increases linearly. When Q b When shutting down, i Lb by D b freewheeling, at this time L b The voltage across it is v o , i Lb with V o / L b the slope of the drop. Since the Buck converter works in CRM mode,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com