Tunable dispersion compensator designing and making method

A technology of dispersion compensator and design method, which is applied in the directions of eliminating distortion/dispersion, coupling of optical waveguides, electromagnetic wave transmission systems, etc., can solve the problems of large sampling period variation range, difficult fabrication, and incomplete realization of equivalent conversion, etc. Achieve the effect of improving performance, simplifying the production process, and avoiding chirp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

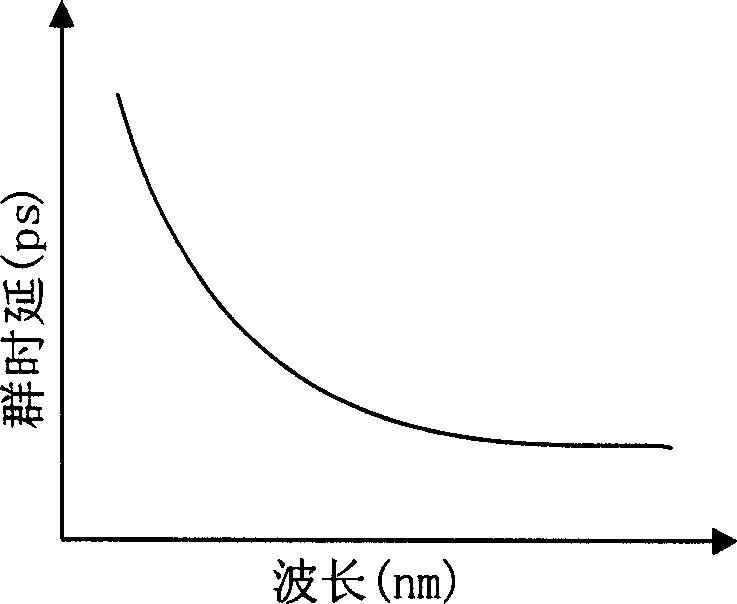

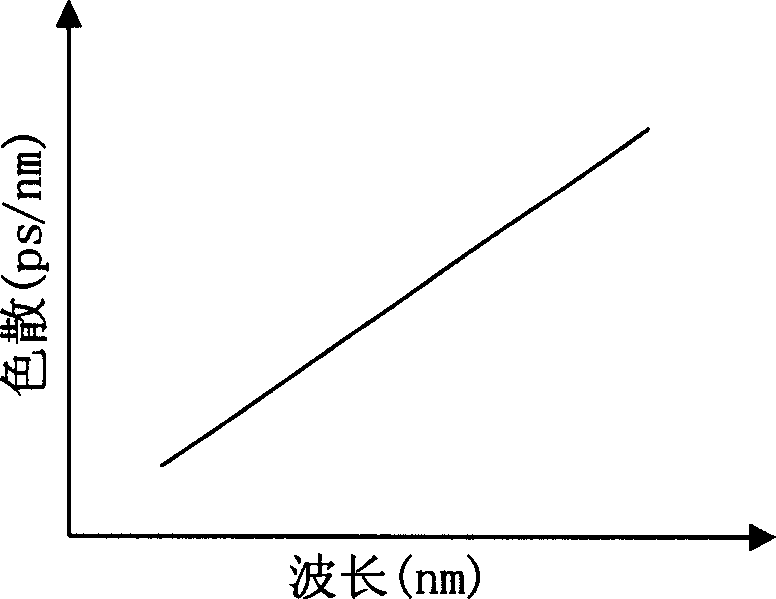

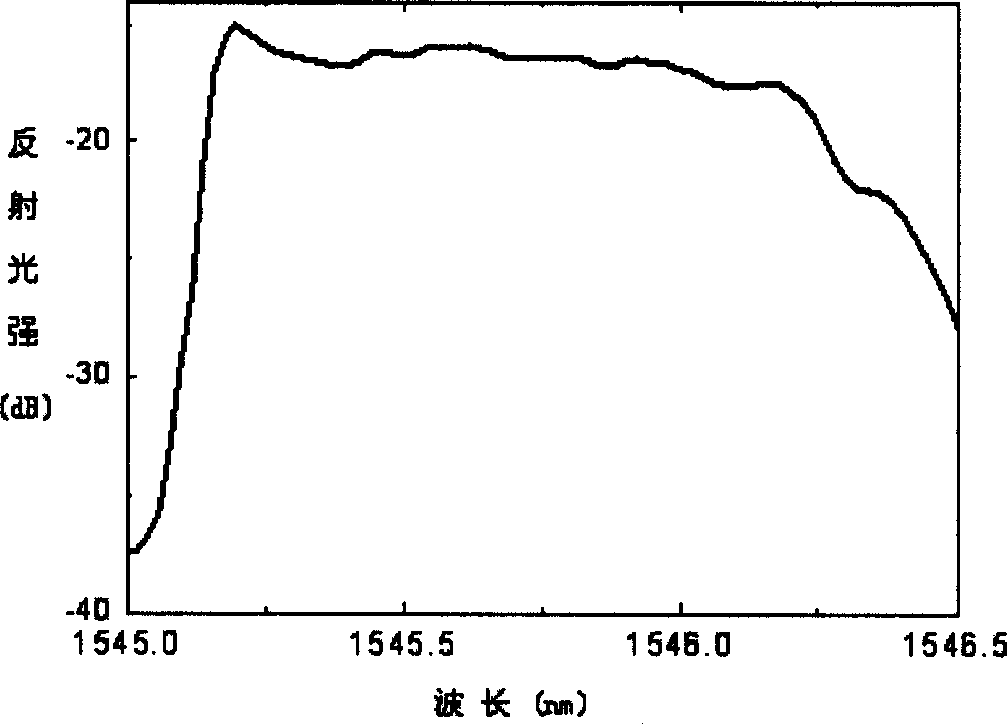

[0059] The manufacturing method of the tunable dispersion compensator of the present invention is divided into two parts: one is the design of the apodized sampling fiber grating of the quadratic delay curve, and the other is the manufacture of the tunable dispersion compensator. Concrete implementation example is described in detail as follows in conjunction with accompanying drawing:

[0060] 1. Design of fiber grating used in tunable dispersion compensator

[0061] The equivalent chirp of the tunable dispersion grating required by the design is: Λ -1 =Λ -1,0 (1+cz 1 / 2 ), take Λ -1,0 =1545.7nm, c=3×10 -4 (mm) -1 / 2 .

[0062] For formula (4), take Z 0 = 0.28 mm. Get a=0.037(mm) from formula 2 -1 / 2 . The chirp coefficient c' of the linear chirp template is 0.048nm / mm, thus obtaining b=0.0024(mm) -1 , using Hamming apodization κ ( z ) = 1 + H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com