Elasticity tension automatic compensator for contact net

An elastic tension and automatic compensation technology, applied in the direction of overhead lines, etc., can solve the problems of hydraulic automatic compensator easy to produce leakage, small compensation amount of elastic tension compensator, small compensation amount of butterfly spring compensator, etc., to adapt to the environment. Wide temperature difference range, high tension compensation accuracy and stable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

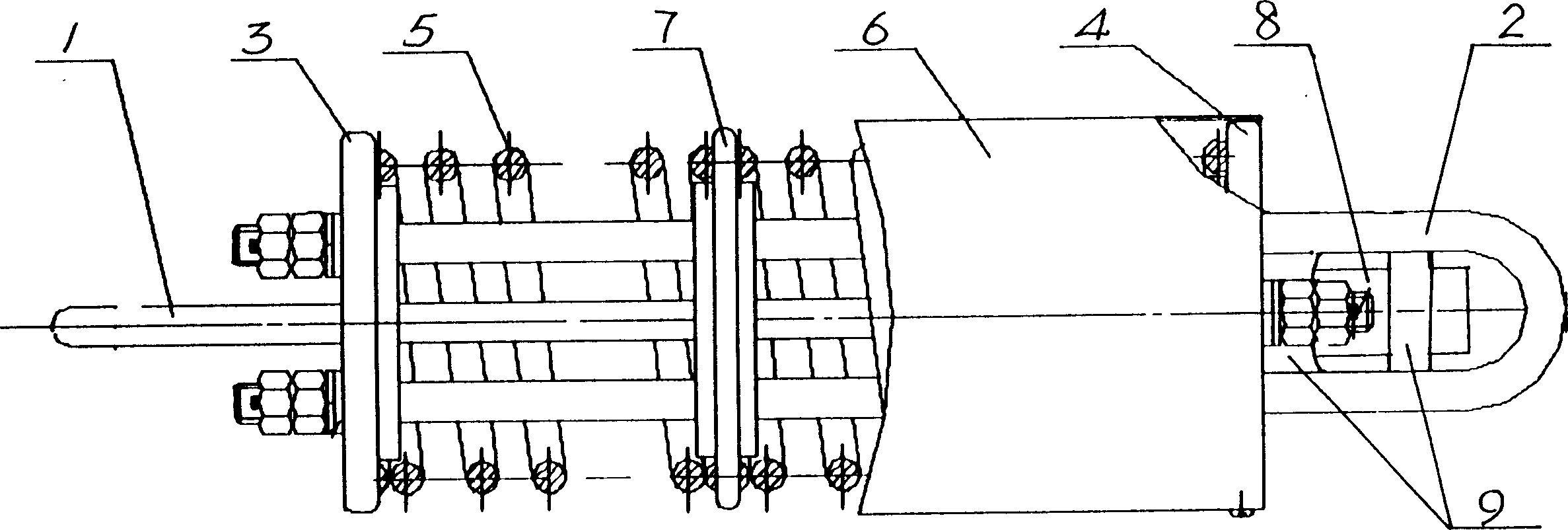

[0012] like figure 1 The catenary elastic tension automatic compensator shown includes a left pull hook 1, a right pull hook 2, a left outer support pad 3, and a right outer support pad 4. In order to prevent the pull hook from deforming when the compensator is stressed, the free expansion and contraction of the spring 5 is affected. , a support block 9 is arranged at the bend of the left outer support pad 3 and the right outer support pad 4, the left pull hook 1 passes through the left outer support pad 3 and is fixedly connected with the right outer support pad 4, and the right pull hook 2 passes through the right outer support pad 4 is fixedly connected with the left outer support pad 3, the left hook 1 and the right hook 2 are installed perpendicular to each other, and at least two springs are set on the left hook 1 and the right hook 2 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com