Belt unreeling device

A technology of equipment and tape unwinding machine, applied in welding equipment, metal processing equipment, welding medium, etc., can solve problems such as broken wires, affecting measurement sensitivity, and reducing production efficiency, so as to reduce the frequency of being broken and ensure The effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

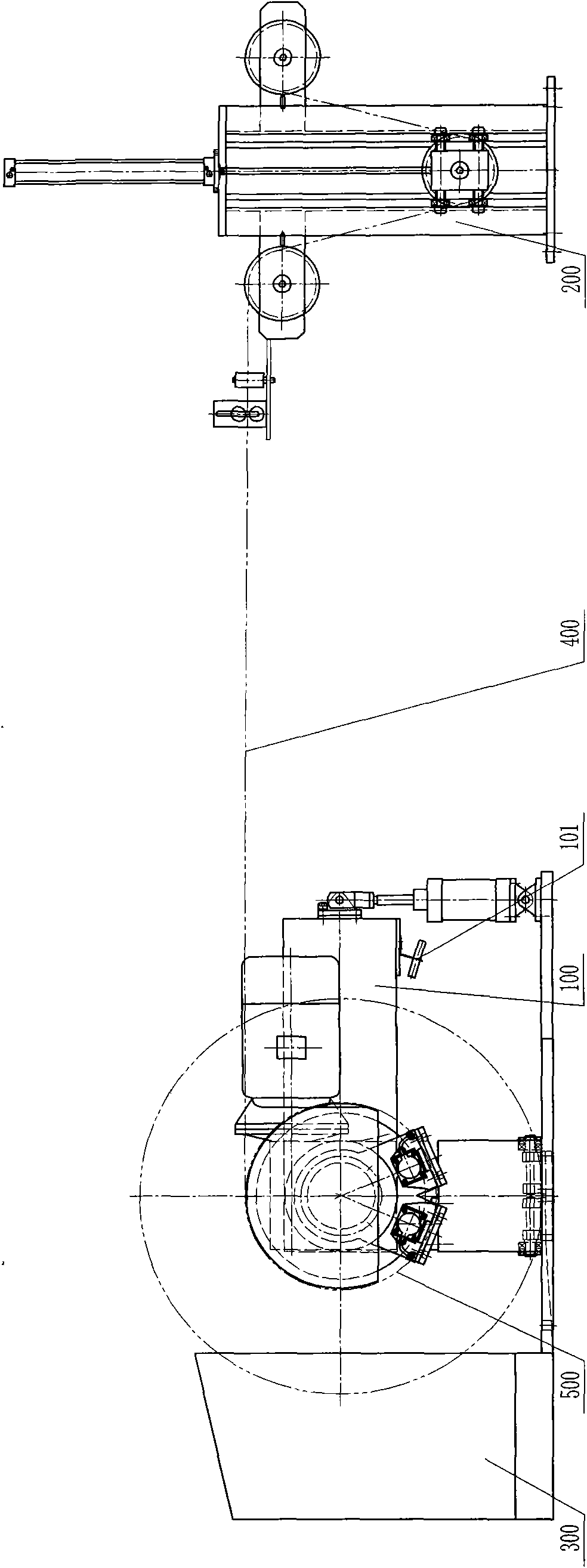

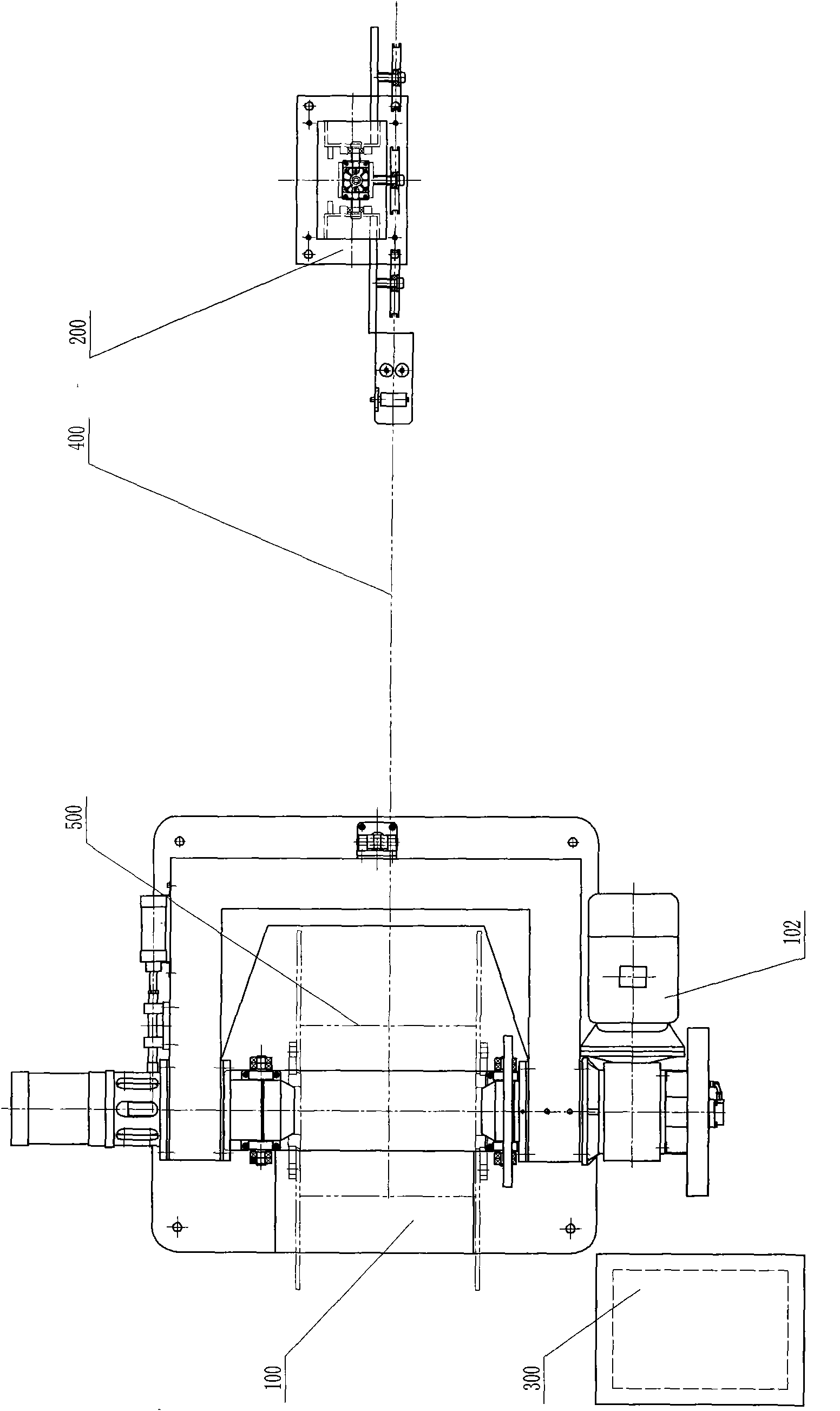

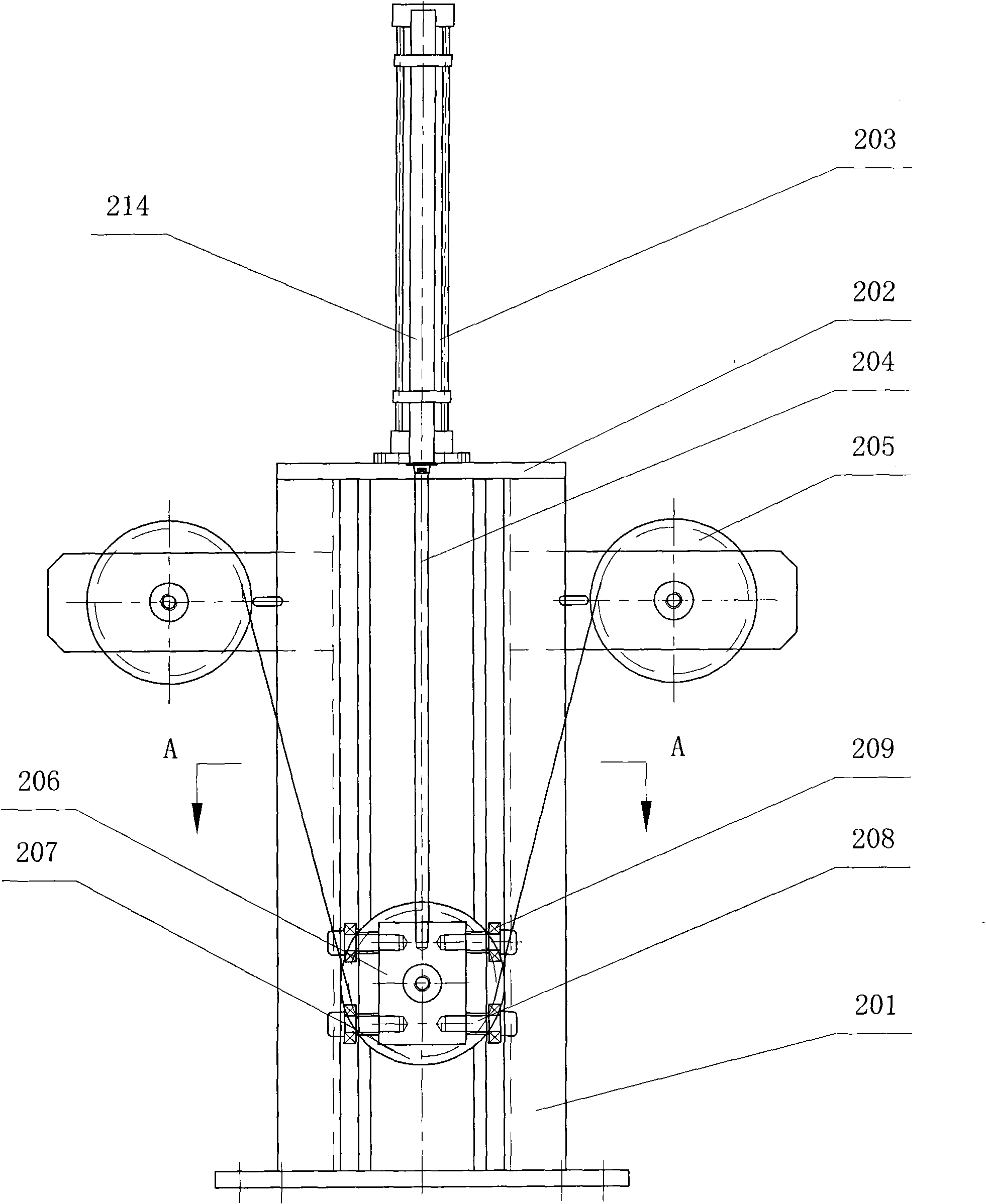

[0027] see Figure 1 ~ Figure 4 , a kind of unwinding equipment of the present invention, comprises unwinding machine 100 and speed difference buffer detection device 200 and their electronic control system 300, unwinding machine 100 is provided with driving motor 102; The distance sensor 101 of the diameter, the distance sensor 101 feeds back the roll diameter signal of the material roll 500 to the electric control system 300, and the electric control system 300 controls the initial speed of the drive motor 102 according to the roll diameter signal and the set speed of the next-level equipment of the unwinding machine The speed difference buffer detection device 200 feeds back the speed difference signal between the tape player 100 and its n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com