A punching and conveying device for aluminum plates

A conveying device and aluminum plate technology, applied in the field of mechanical conveying devices, can solve the problems of slow manual operation and increased punching production costs, and achieve the effects of convenient assembly and disassembly, improved versatility, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

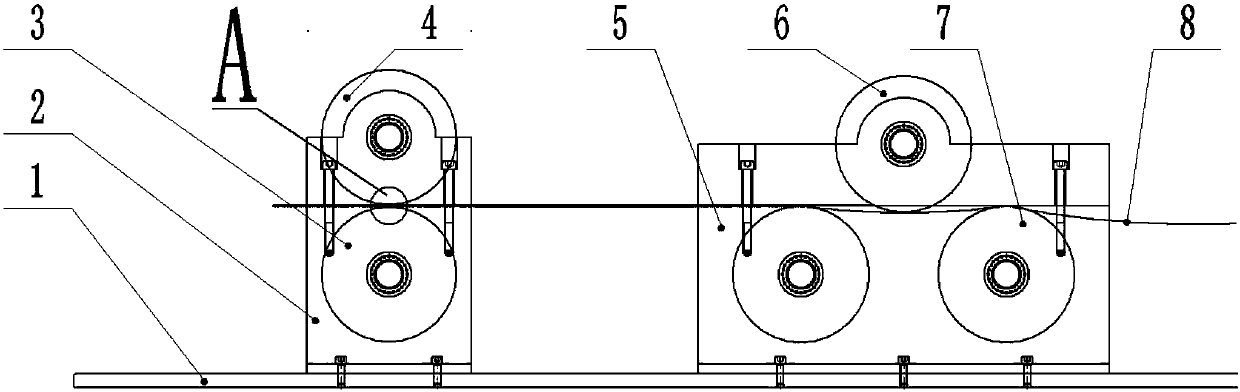

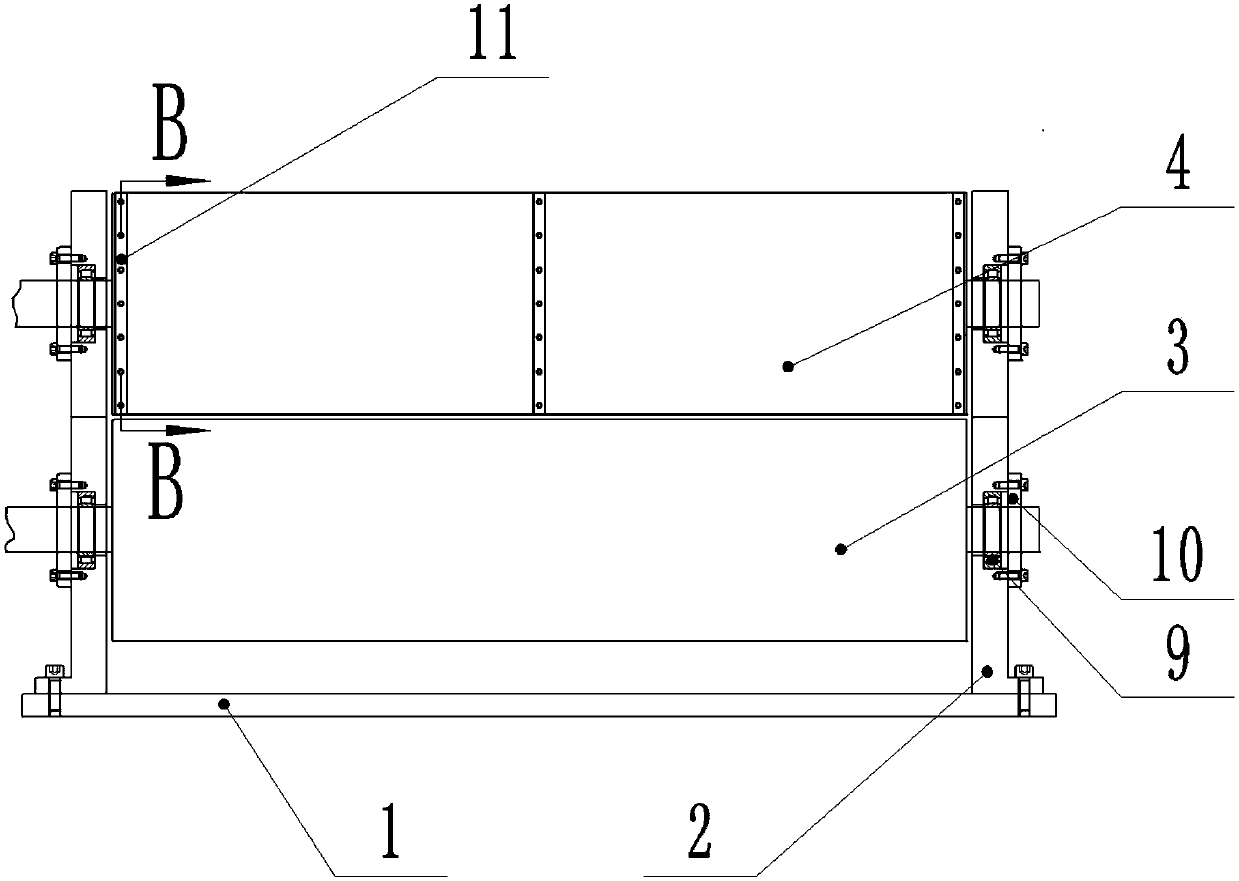

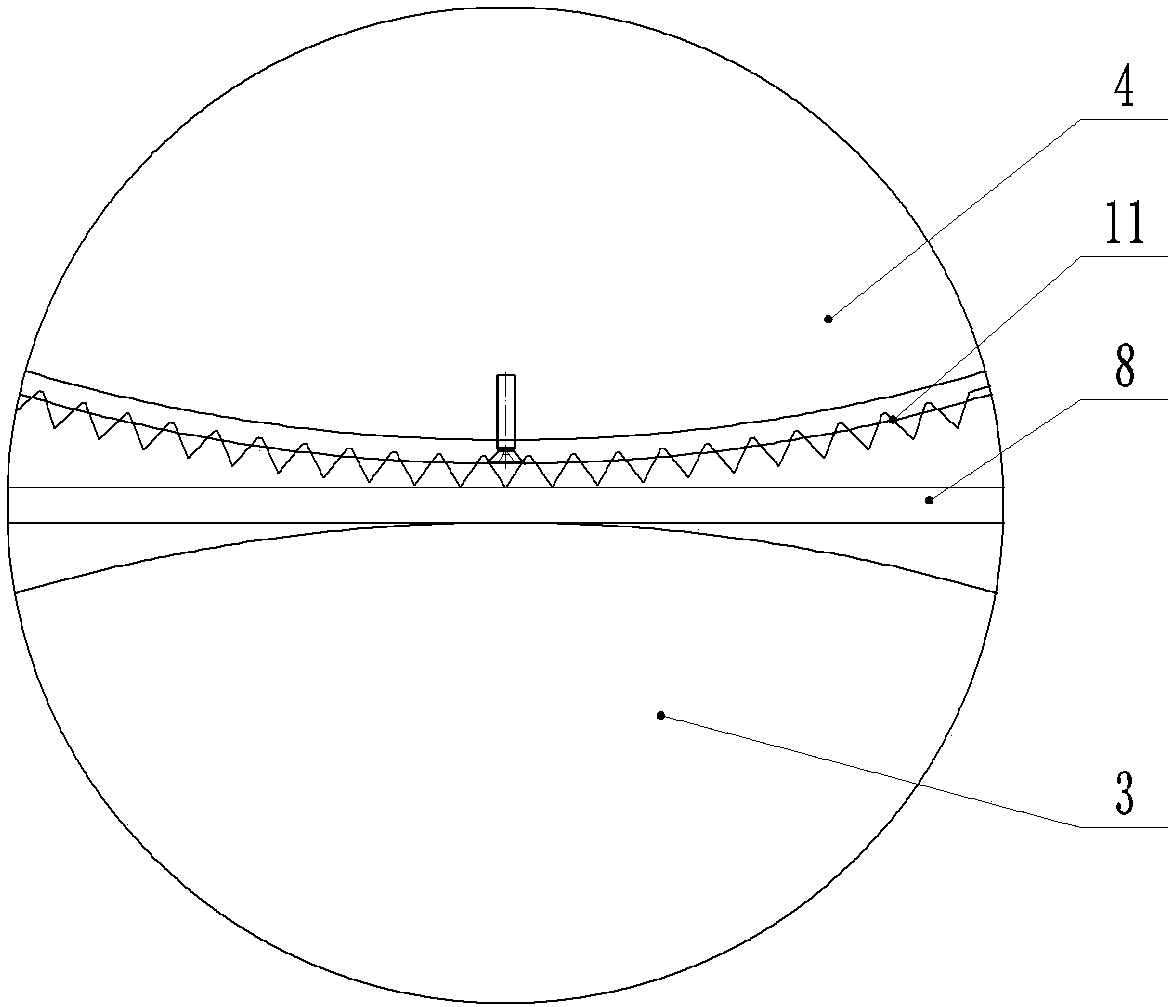

[0028] like Figure 1-2 As shown, a punching and conveying device for aluminum plates described in the embodiment of the present invention includes: two left vertical boards 2 and two right vertical boards 5 are installed on the workbench 1 through bolts, and the left vertical board 2 is divided into upper and lower two Parts are connected by bolts, and gaskets are added in the middle. The right vertical plate 5 is divided into upper and lower parts, which are connected by bolts, and gaskets are added in the middle. When the thickness of the punched aluminum plate changes, the thickness of the gaskets can be changed. The lower conveying roller 3 and the upper conveying roller 4 are installed on the 2 left vertical plates through the bearing 9 and the flange 10. The outer surface of the lower conveying roller 3 is smooth, and the conveying positioning mechanism 11 is installed on the upper conveying roller 4. 2 right vertical plates The upper forming drum 6 and the lower formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com