Patents

Literature

55results about How to "Speed match" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-corrosion and anti-explosion full-automatic multihead filling packaging line

ActiveCN105502259ASatisfy anti-corrosionFulfil requirementsSynchronising machinesControl systemEngineering

The invention discloses an anti-corrosion and anti-explosion full-automatic multihead filling packaging line. The anti-corrosion and anti-explosion full-automatic multihead filling packaging line comprises a filling machine capable of conducting filling on bottles, a control system which is provided with a touch screen and adopts a PLC, a stopper sealing machine capable of installing a stopper in each bottle, a stopper installing detection photoelectric sensor, a stopper installing bottle blocking baffle, a stopper installing pneumatic mechanism, an outer cover installing machine capable of installing an outer cover on each bottle, an outer cover installing detection photoelectric sensor, an outer cover installing bottle blocking baffle, an outer cover installing pneumatic mechanism, a cover screwing machine capable of screwing the outer covers, a labeling machine, a labeling detection photoelectric sensor, an automatic inkjet printing machine and an inkjet printing detection photoelectric sensor. A transport mechanism runs through the whole anti-corrosion and anti-explosion full-automatic multihead filling packaging line and is responsible for transport of the bottles.

Owner:ZHUHAI YUZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

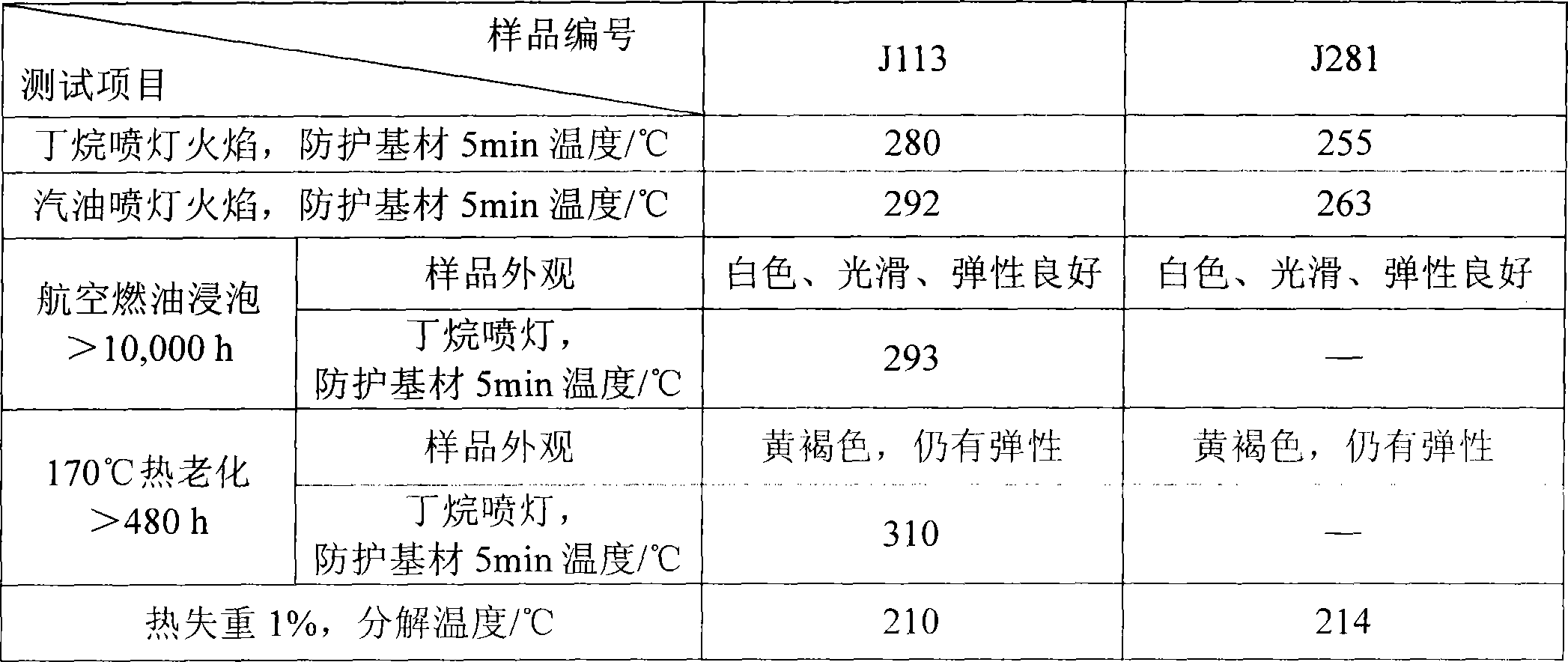

Grease-proof, heat-resistant expansion type flame-proof rubber

This invention discloses an expansion fire-retardant rubber with resistance to oil and heat, particularly being applicable to fire safety protection of conductor bundles in all enclosed spaces, and relates to the technical field of the fire-retardant rubber which is composed by the components with the following portions by weight: 40 to 60 percent of oil-resistant rubber, 5 to 10 percent of resin viscosity regulator, 20 to 40 percent of ammonium polyphosphate, 3 to 10 percent of melamine, 2 to 8 percent of zinc borate, 5 to 20 percent of nano-inorganic and 1 to 5 percent of silica white. The fuel immersion swelling rate of the fire-retardant rubber is zero; when the rubber thickness is less than or equal to 1.0mm, the fire resistance duration is more than or equal to 5 min with the flame temperature of 1200 DEG C and the protected substrate temperature of being less than or equal to 300 DEG C. The fire-retardant rubber of the invention has resistance to heat and ageing, and flexibility and can be used for the fire safety protection of various the conductor bundles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

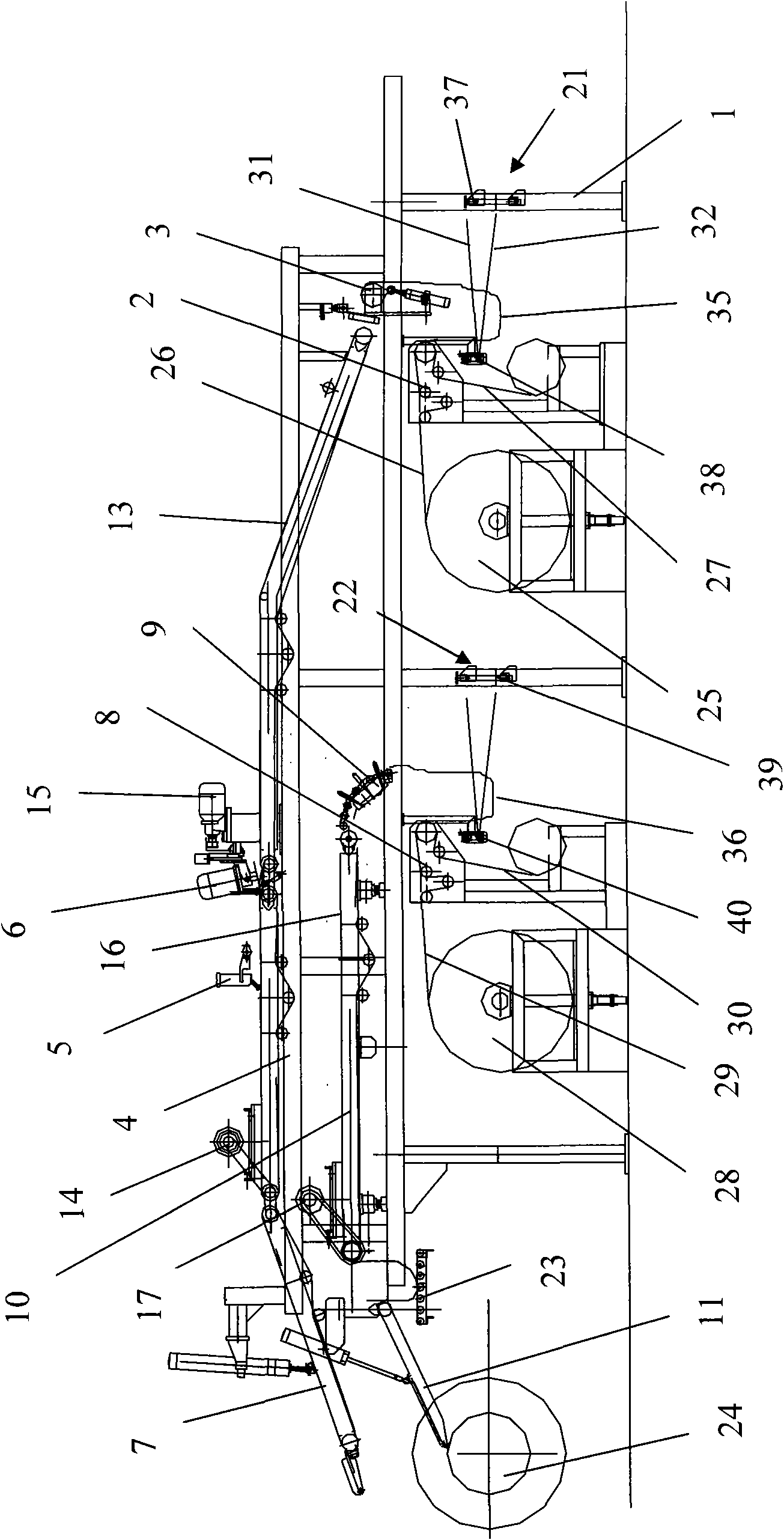

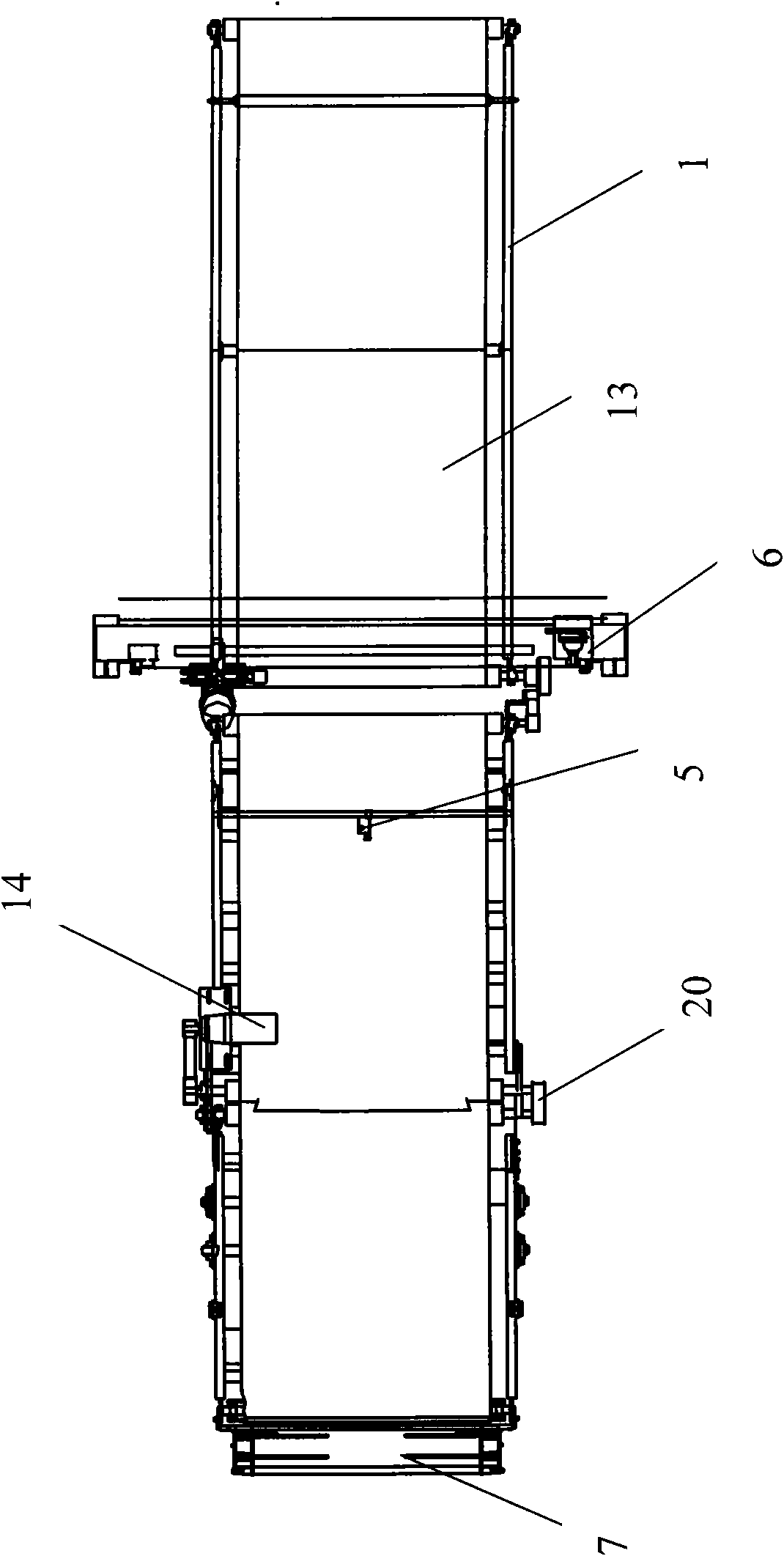

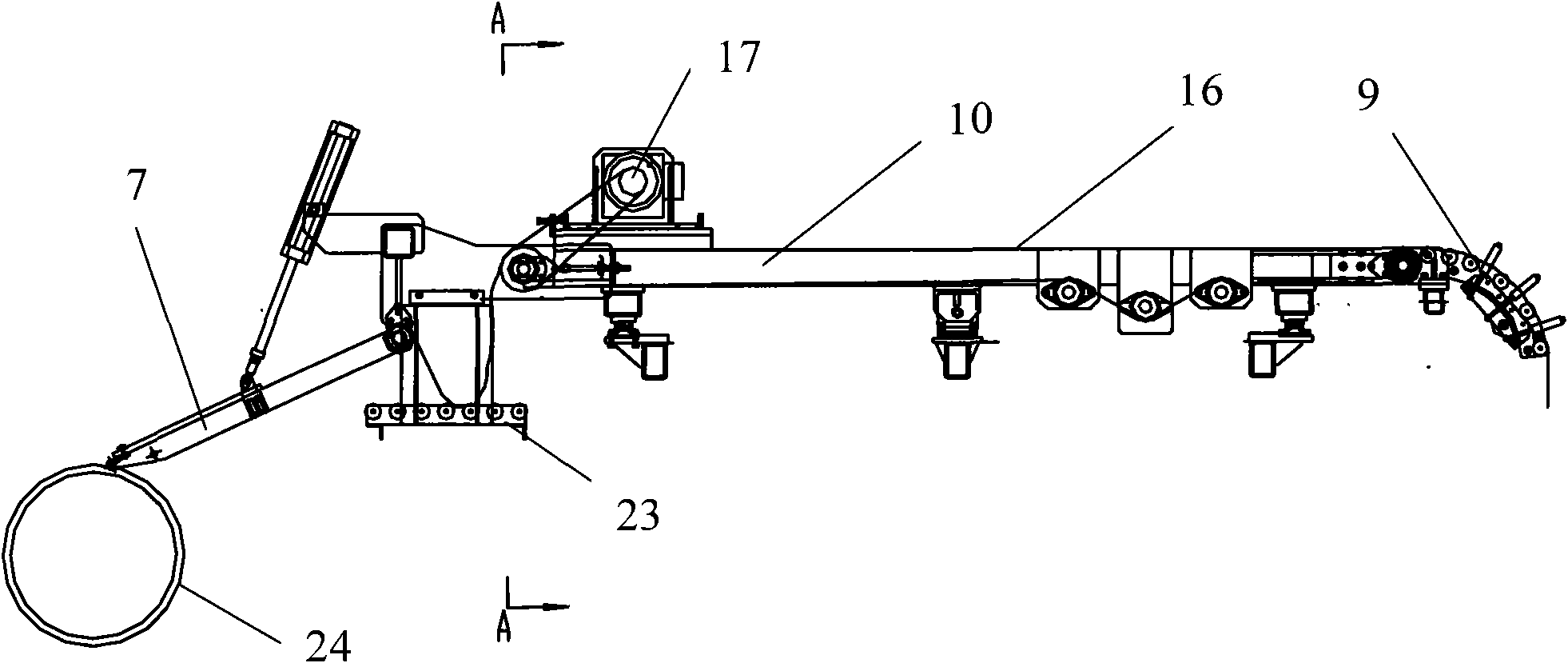

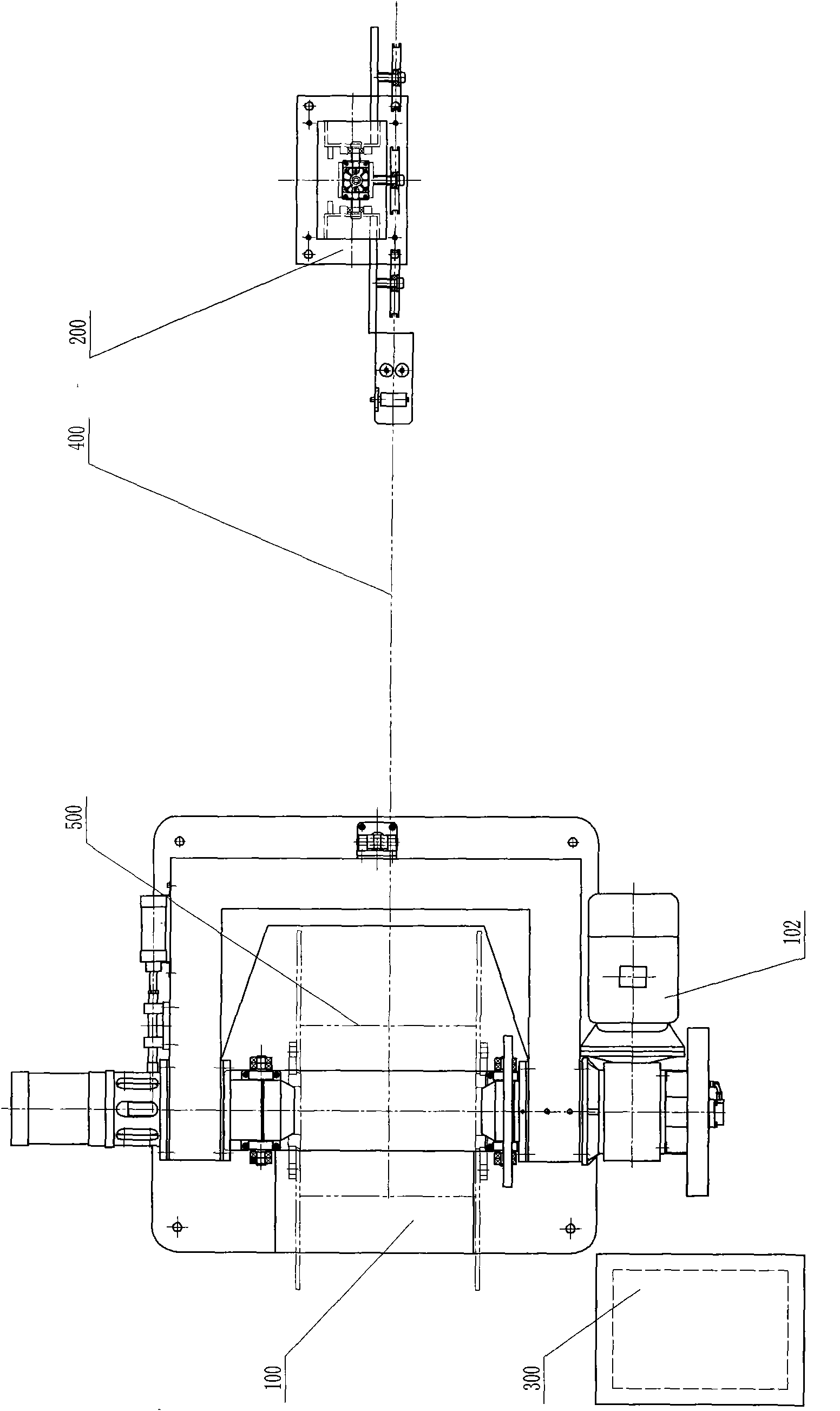

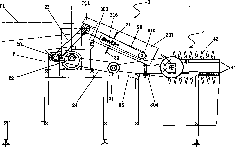

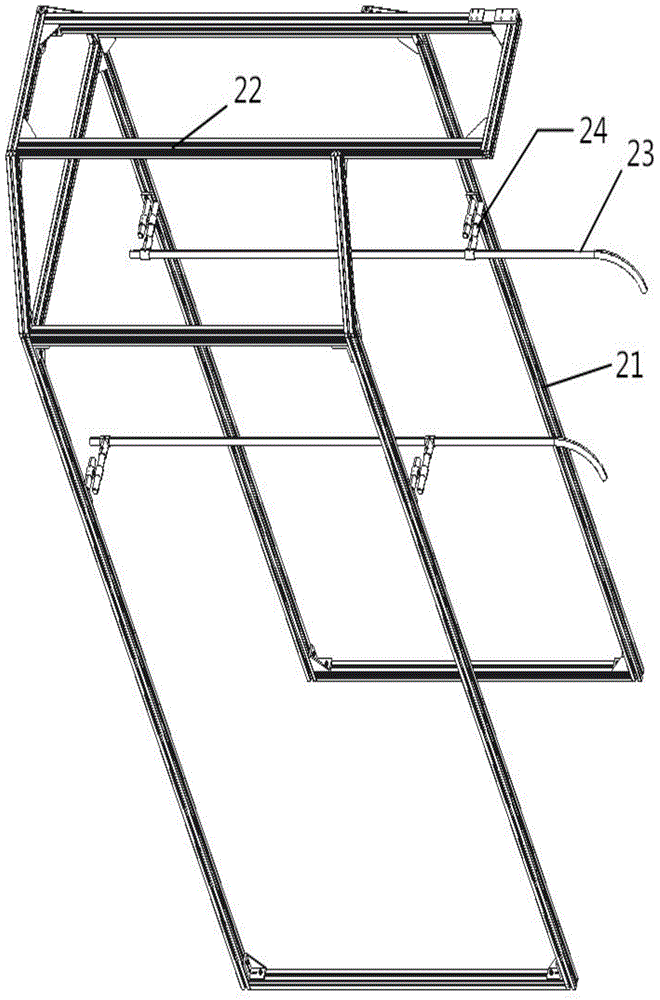

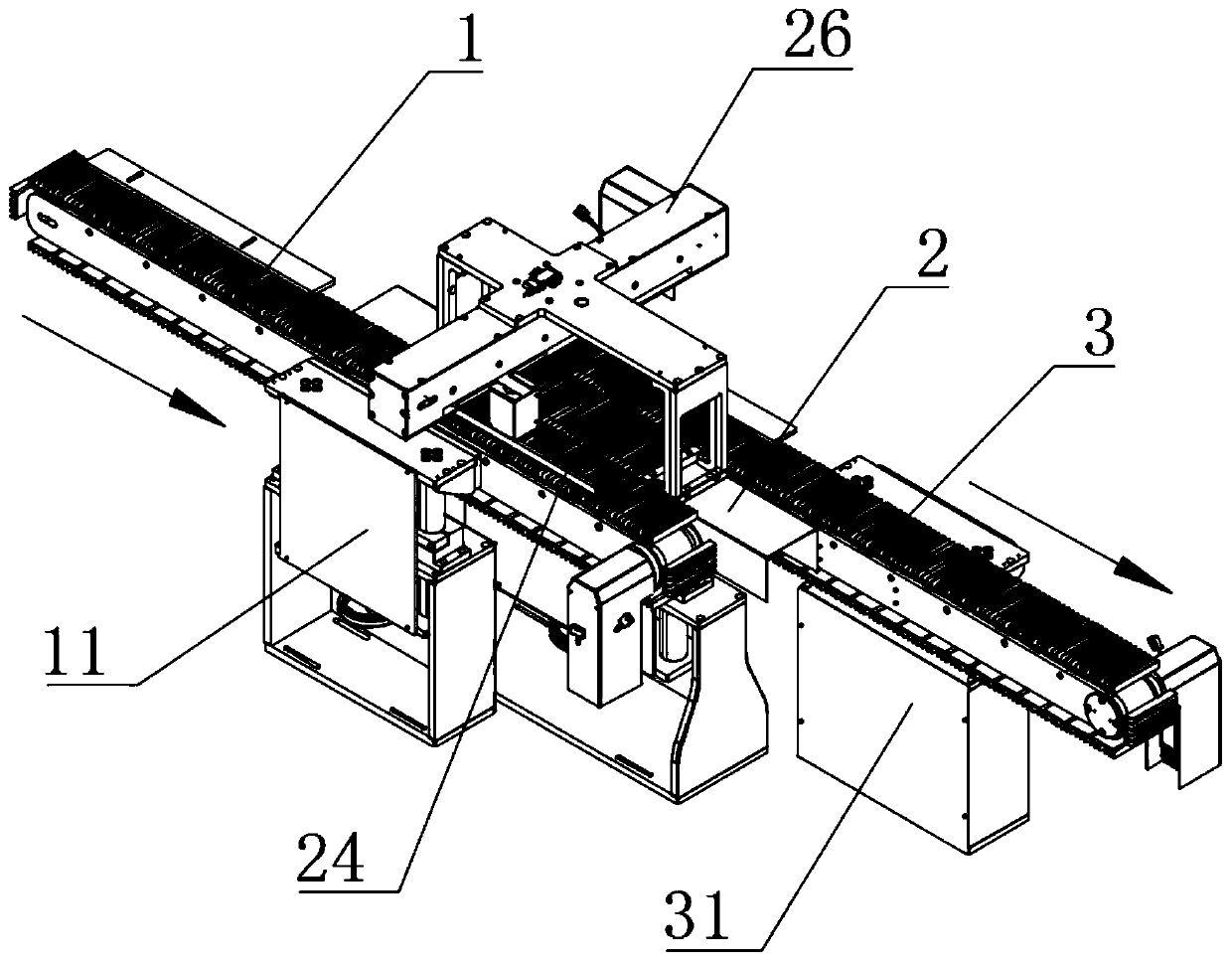

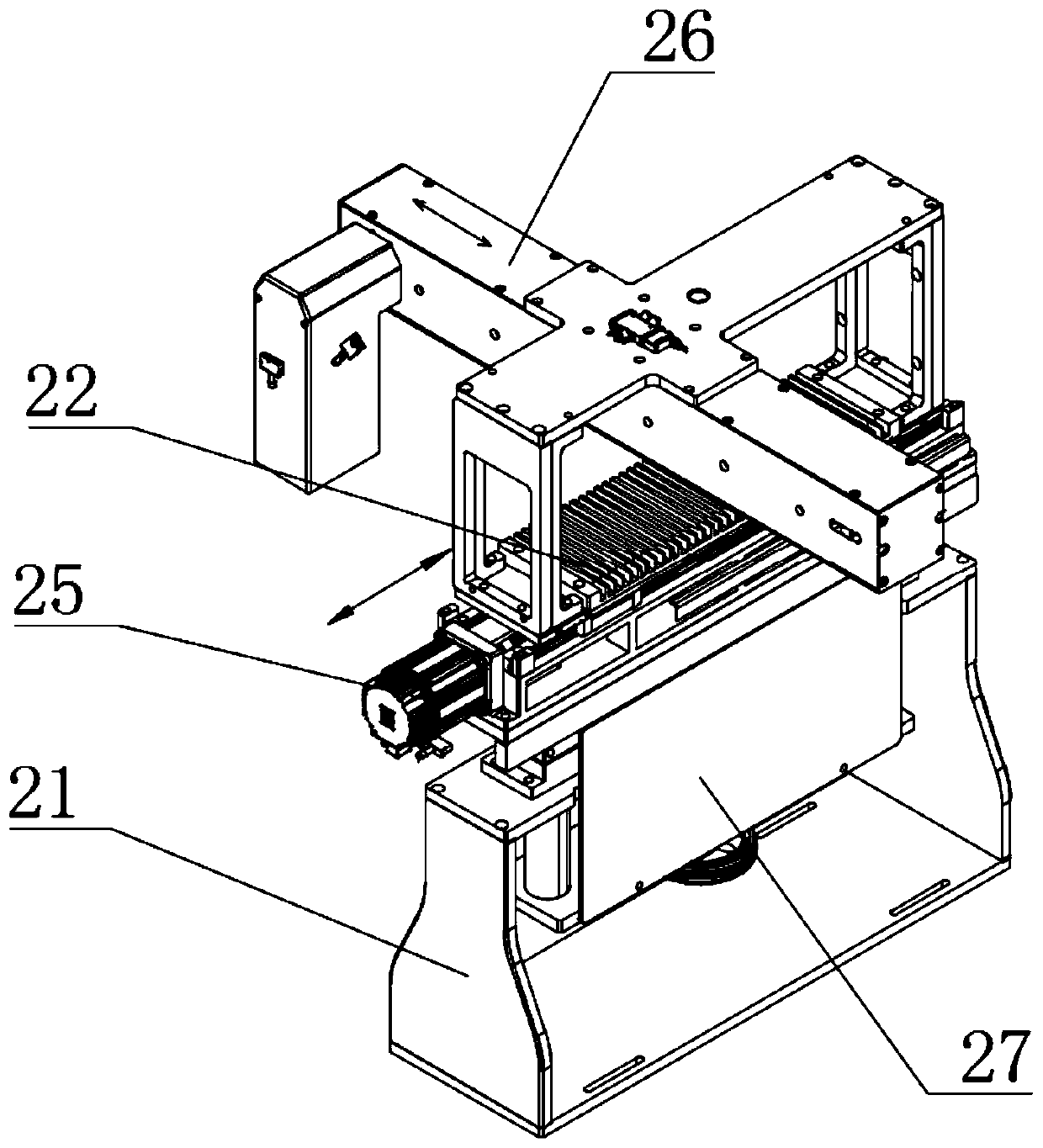

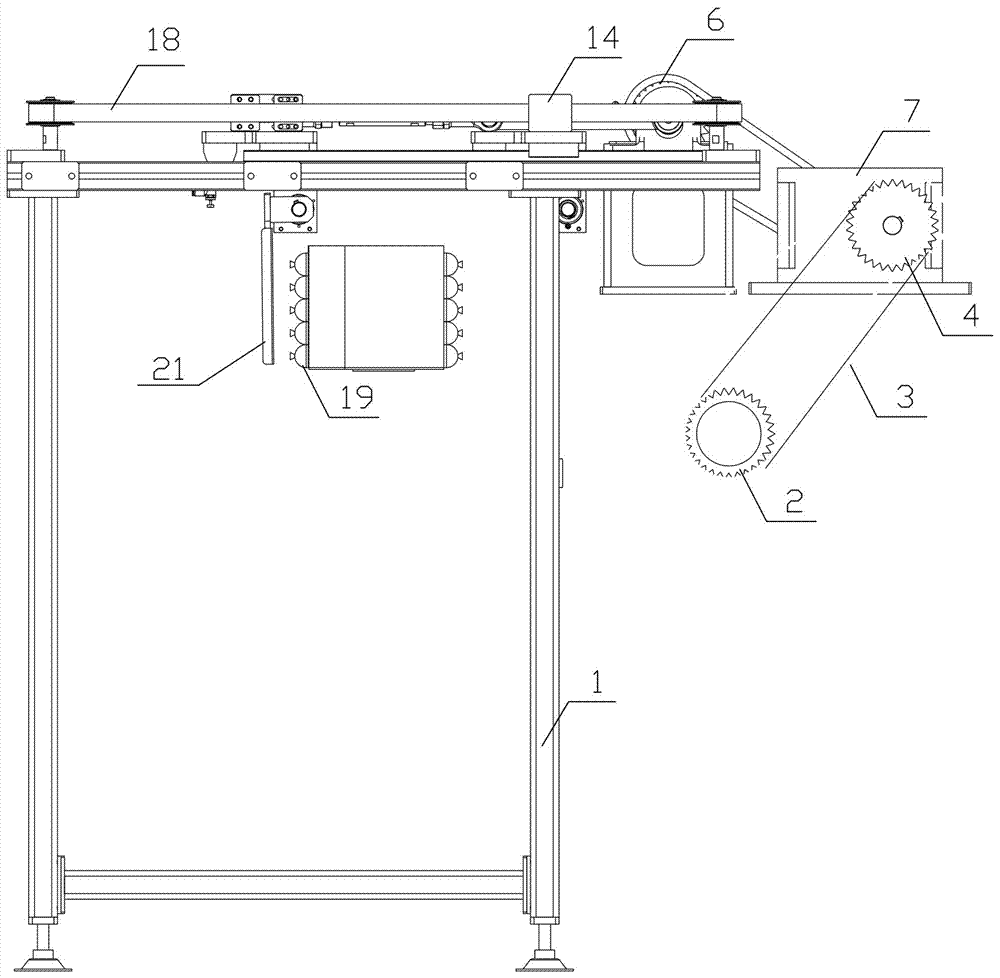

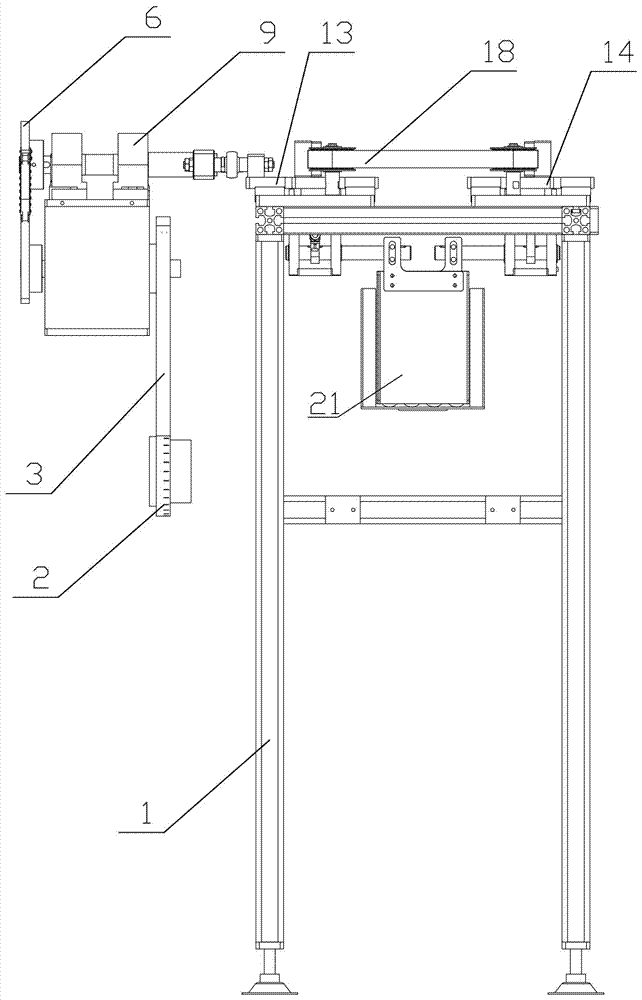

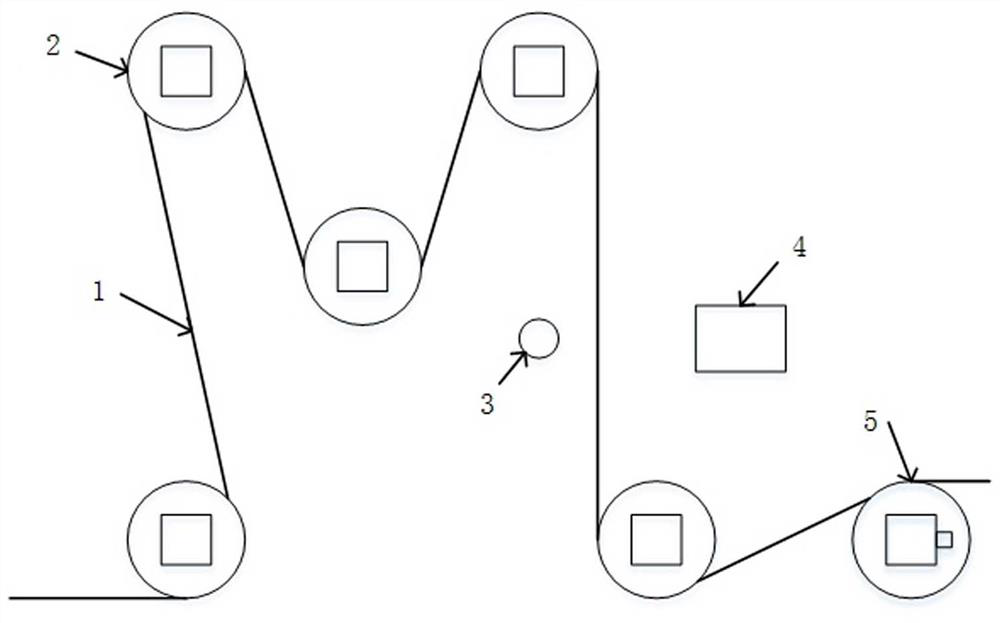

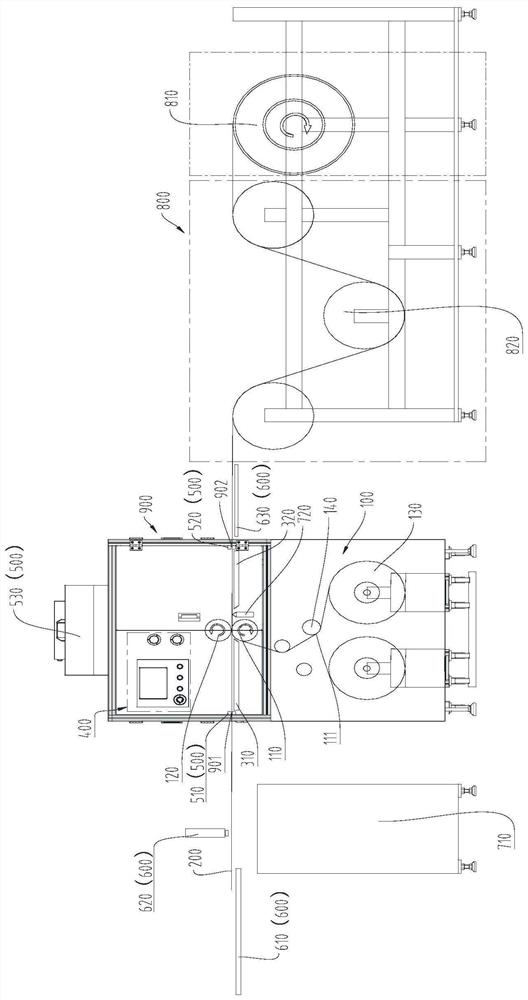

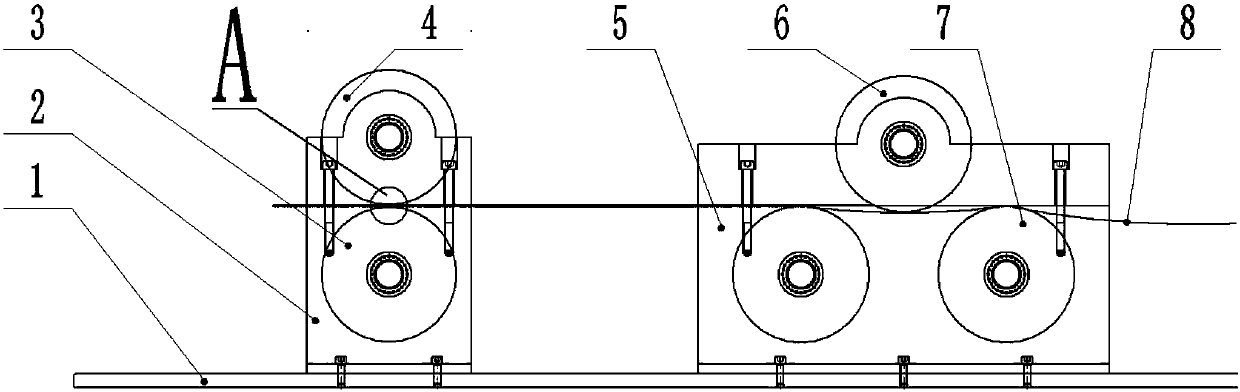

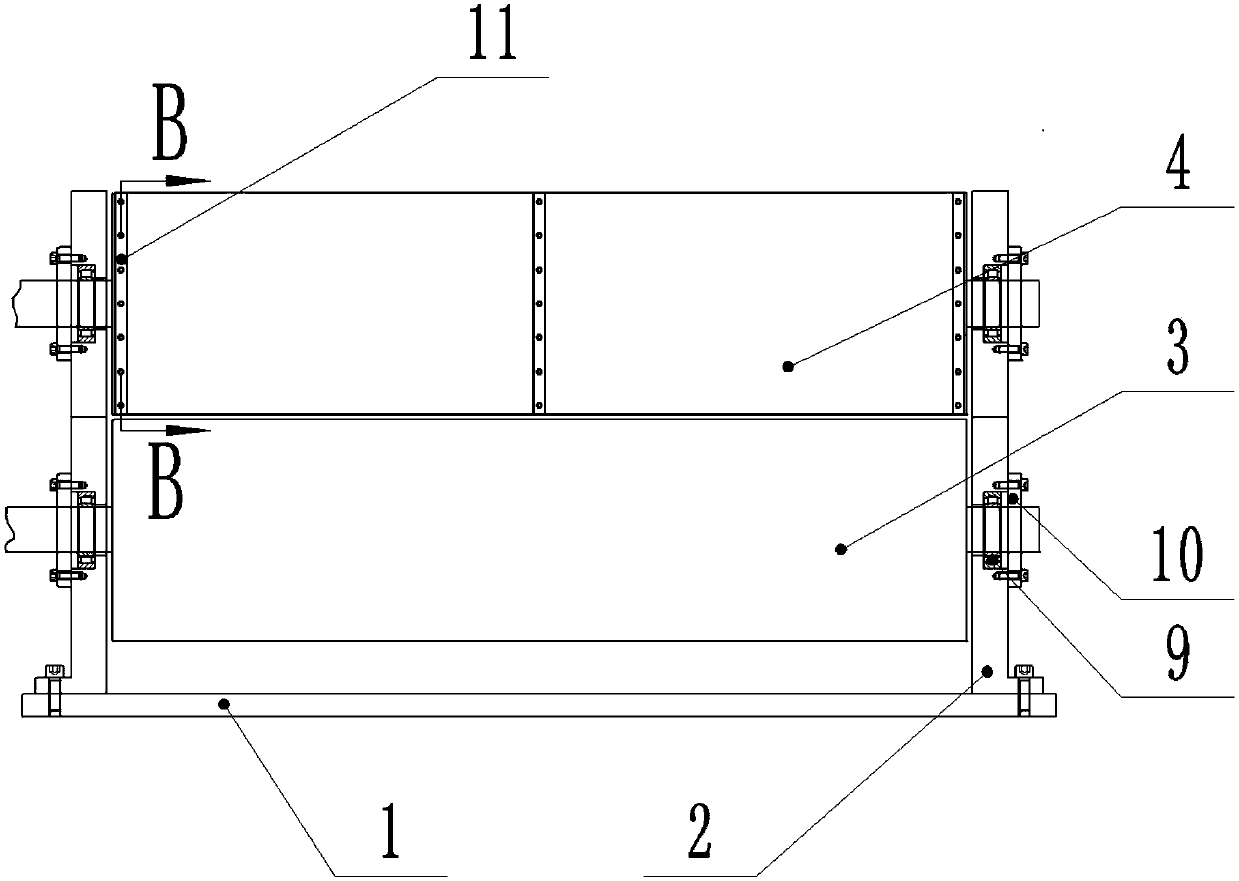

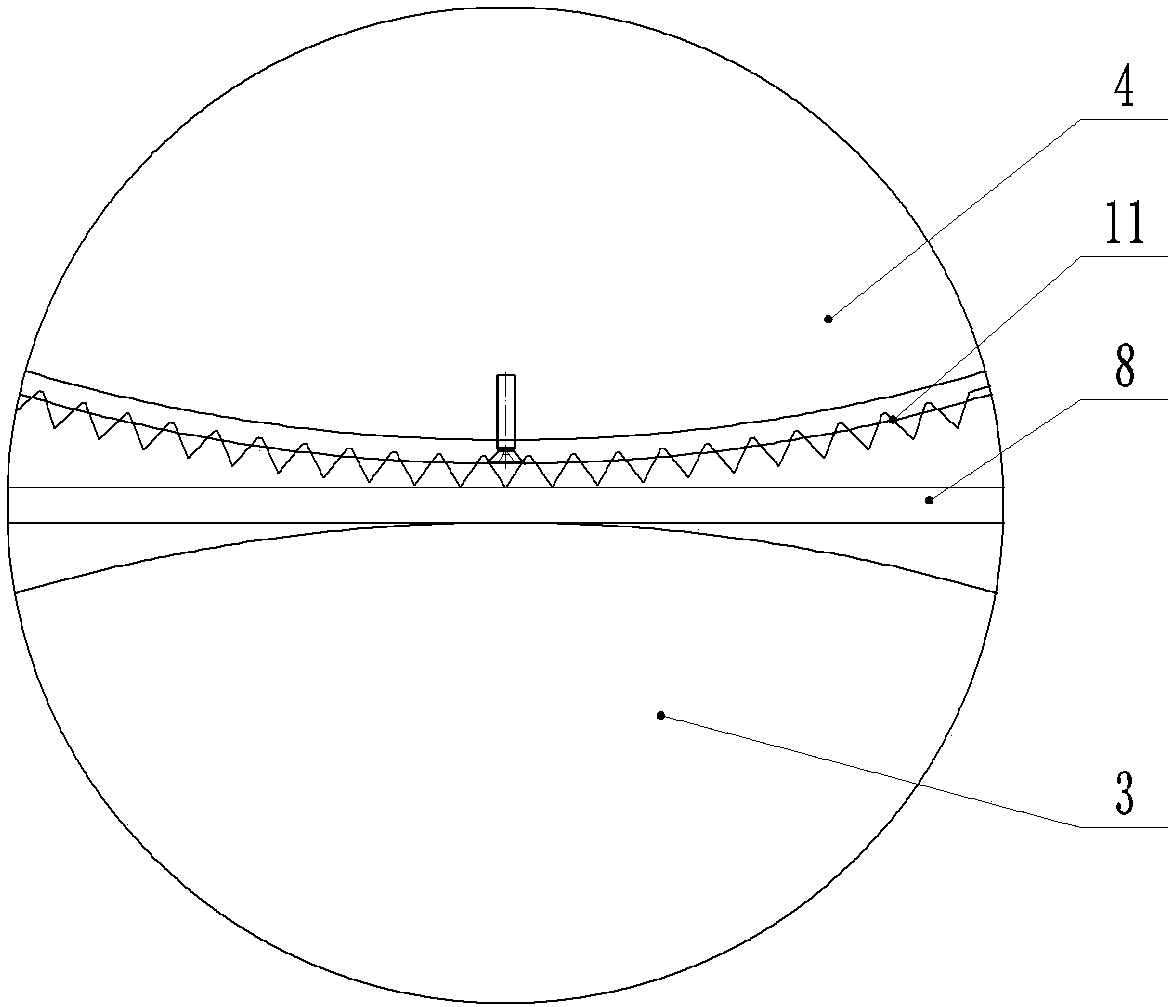

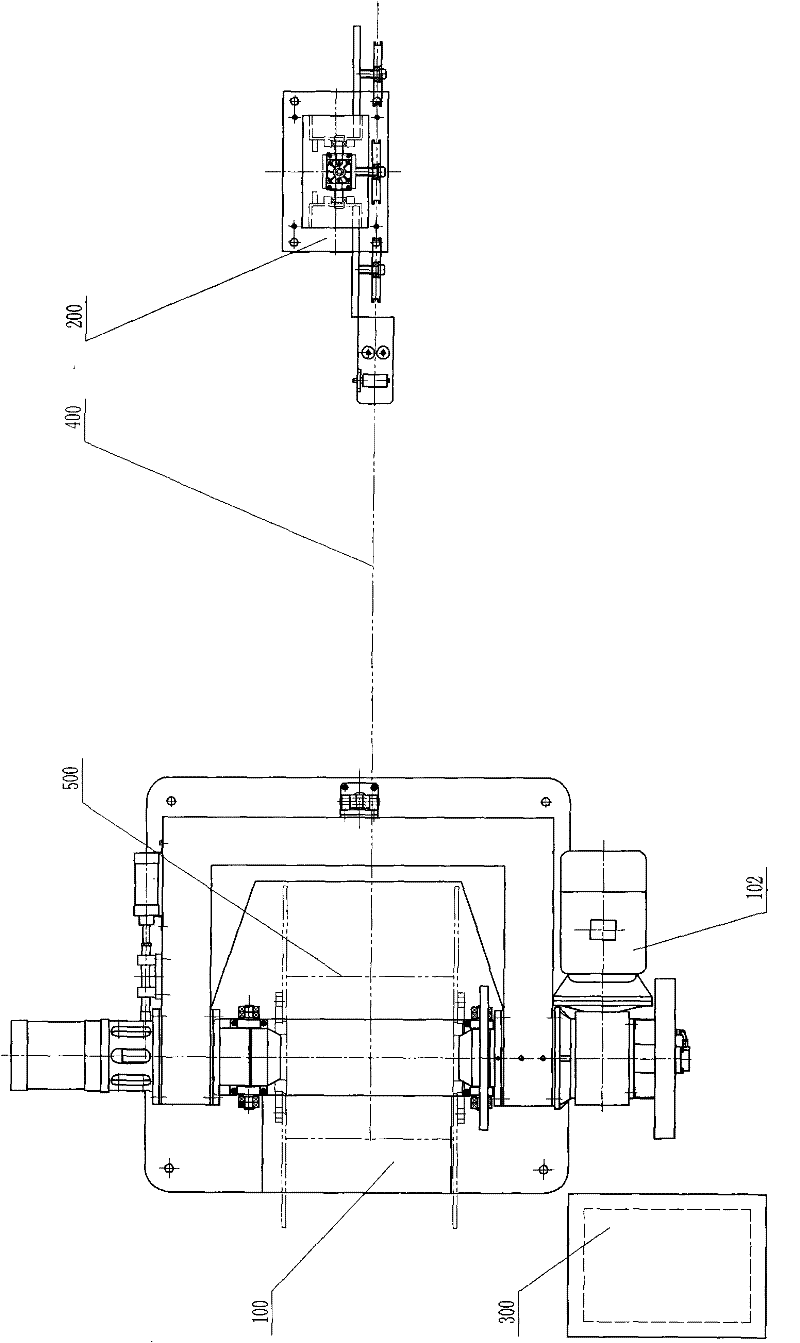

Joint feeding device of inner liner layer and cord fabric layer in radial ply tire building machine

The invention relates to a joint feeding device of an inner liner layer and a cord fabric layer in a radial ply tire building machine, comprising a stander, inner liner layer unwinding equipment, an inner liner layer correcting device, an inner liner layer feeding rack, length measurement sensor, a disk cut-off knife, an inner liner layer swing frame, cord fabric layer unwinding equipment, a cord fabric layer unwinding frame, a cord fabric layer feeding rack, a cord fabric layer swing frame and a multiposition cylinder. The joint feeding device of the inner liner layer and the cord fabric layer in the radial ply tire building machine utilizes the multiposition cylinder to move the cord fabric layer feeding rack towards left and right to realize staggered joint of the cord fabric layer; as a device used for moving the cord fabric layer feeding rack is simpler that a device used for moving a joint drum in the prior art, the whole device has simple structure and low power consumption. In addition, the device is also provided with a locating system, so that the positioning accuracy can be guaranteed, and the moving range can be adjusted at will.

Owner:TIANJIN SAIXIANG TECH

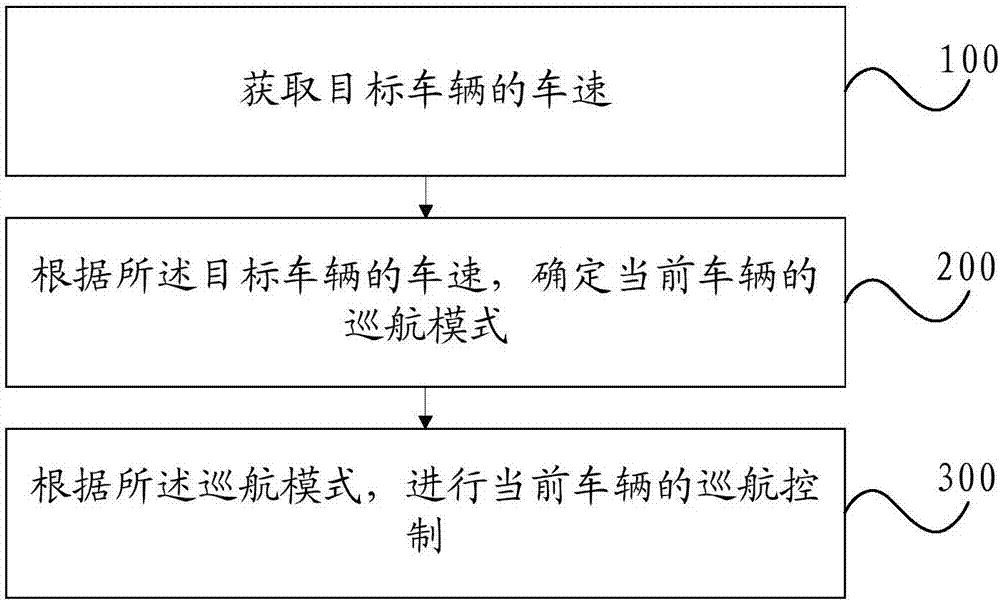

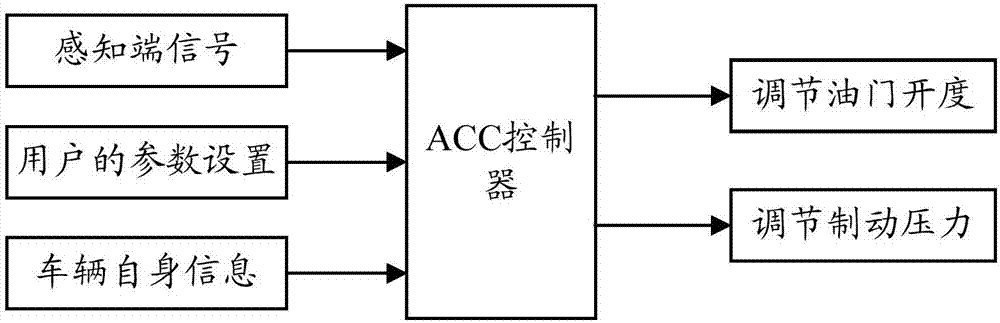

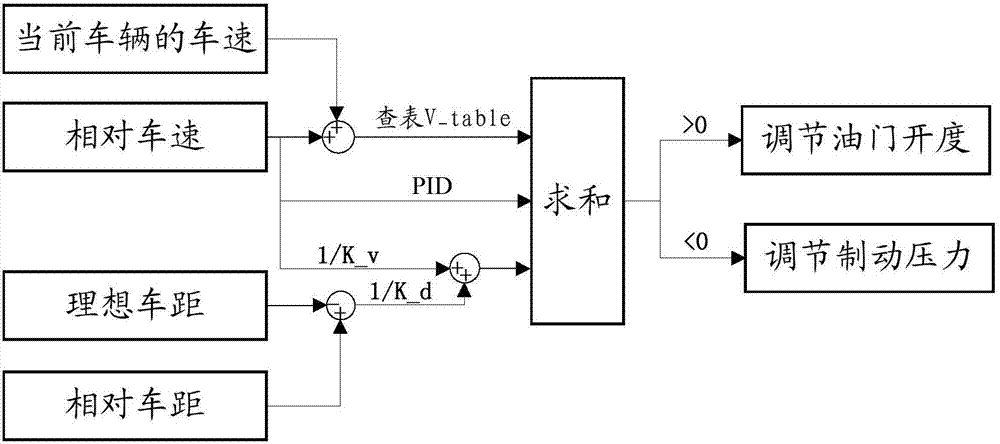

Vehicle cruise control method and device, and automobile

ActiveCN107128307AEnsure driving safetySpeed matchExternal condition output parametersDriving safetyOccurrence probability

The invention provides a vehicle cruise control method, a vehicle cruise control device, and an automobile, and relates to the technical field of automatic driving. The vehicle cruise control method comprises the steps of operating to acquire the speed of a target vehicle; determining a cruise mode of the current vehicle according to the speed of the target vehicle; and performing cruise control on the current vehicle according to the cruise mode. According to the method and the device provided by the invention, cruise control is performed on the current vehicle according to the speed of the target vehicle, matching between the current vehicle and the speed of the target vehicle is ensured, and thus the speed of the current vehicle can be adjusted according to a current traffic condition, driving safety of an automatically driving vehicle is ensured, and occurrence probability of a traffic accident is reduced.

Owner:成都前锋电子股份有限公司

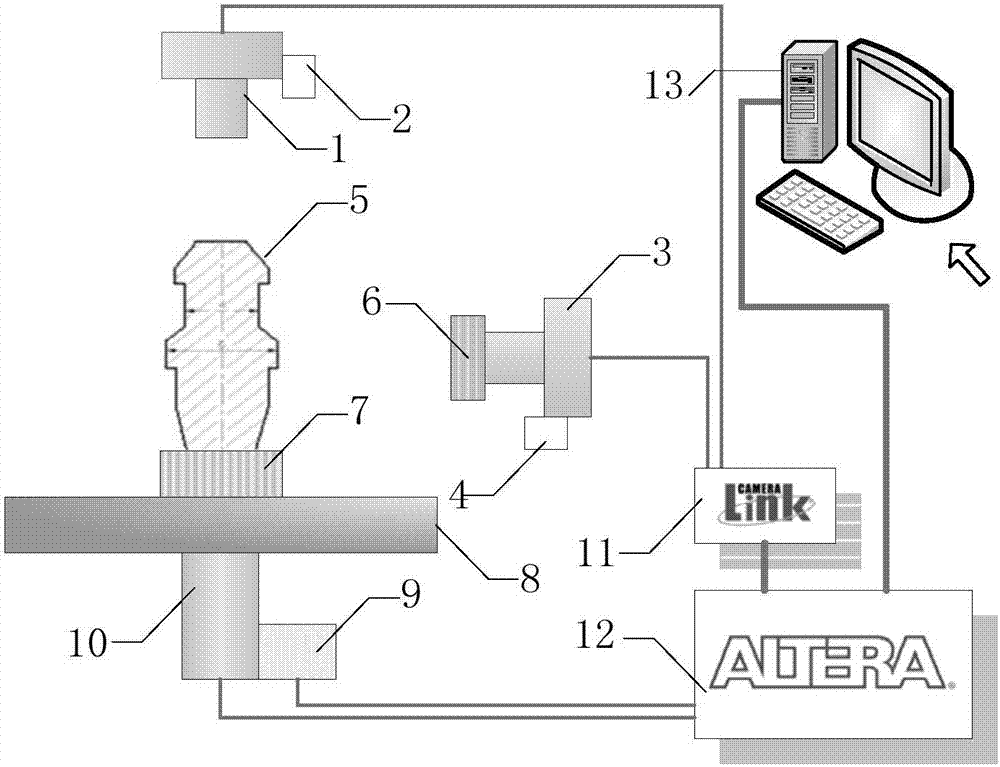

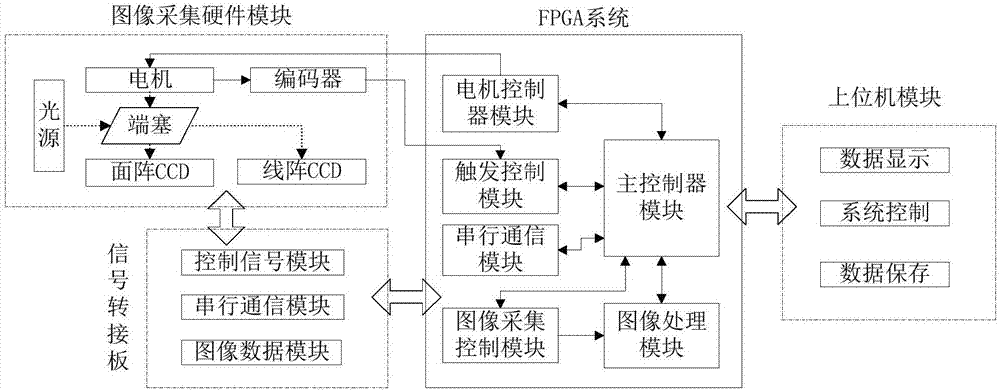

FPGA-based end plug defect detection device and method

PendingCN107966454AQuality assuranceEliminate missing detectionOptically investigating flaws/contaminationComputer hardwareImaging processing

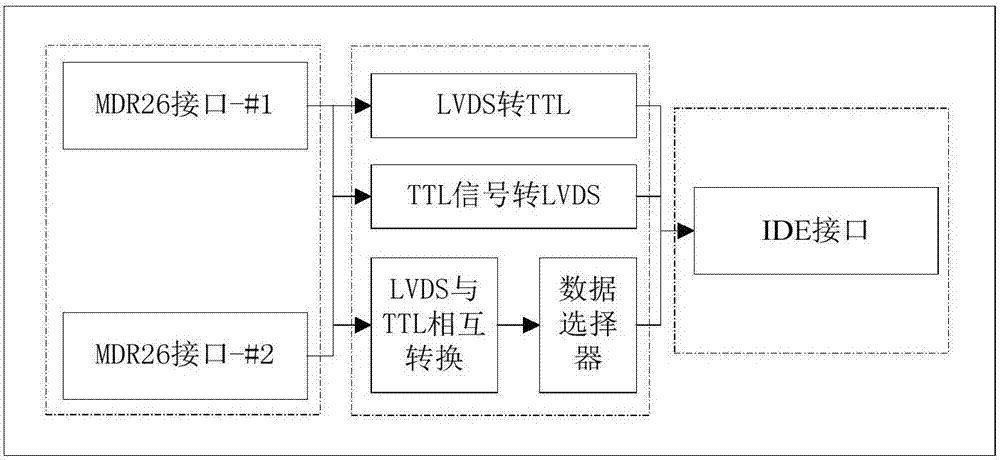

The invention discloses an FPGA-based end plug defect detection device. The device comprises an image collecting module, a signal transfer module, an FPGA master control module and an upper computer,wherein the image collecting module is used for collecting the lateral surface image and upper surface image data of an end plug and using a signal transfer plate as the transmission conversion mediumto convert the LVDS type image data into TTL type data and transmit the TTL type data to the FPGA master control module; the FPGA master control module is mainly used for processing the end plug image data, detecting end plug defects and transmitting the result to the upper computer for display. The device has the advantages that machine vison and the FPGA-based image processing technology are applied to end plug surface defect detection, and the instantaneity and precision of end plug detection are guaranteed effectively.

Owner:SHAANXI UNIV OF SCI & TECH

Method and device for playing monitoring video

InactiveCN105554516AEasy to viewSpeed matchClosed circuit television systemsSelective content distributionComputer graphics (images)Video image

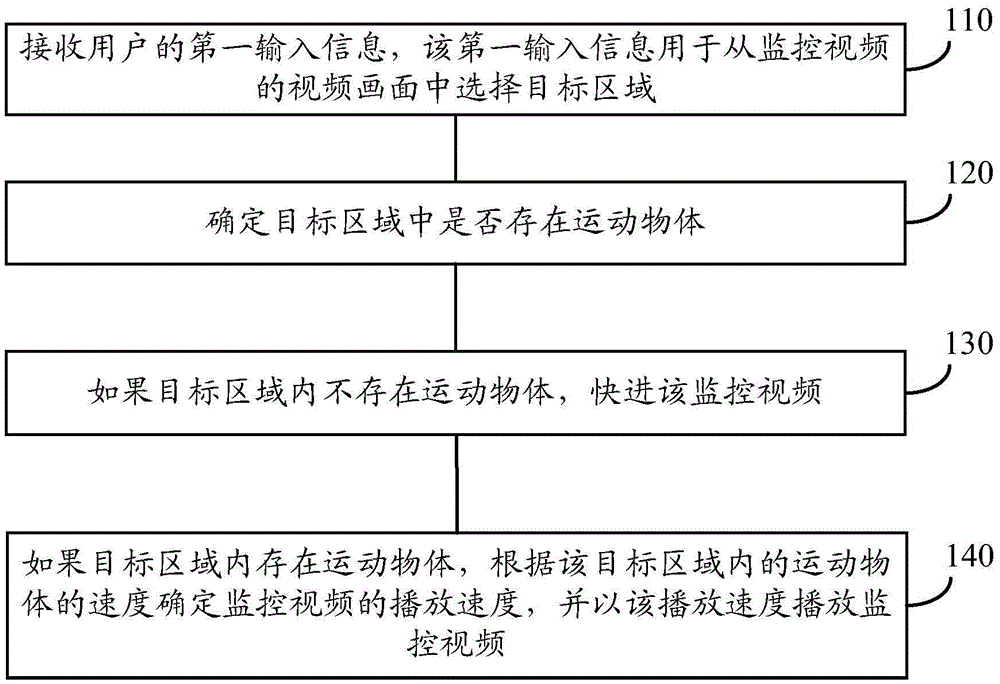

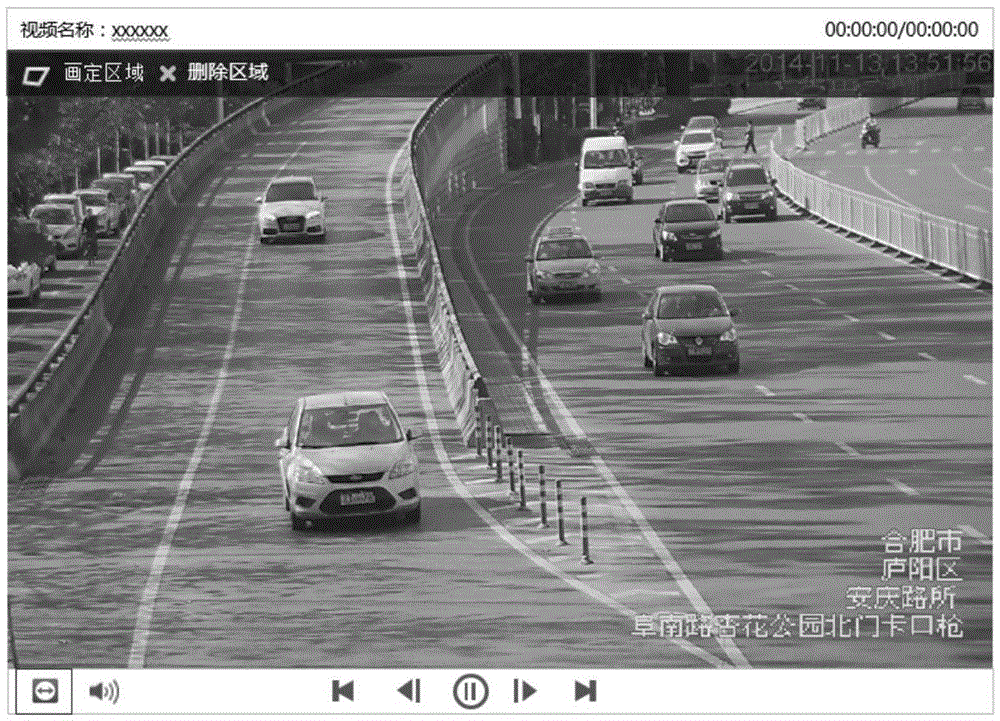

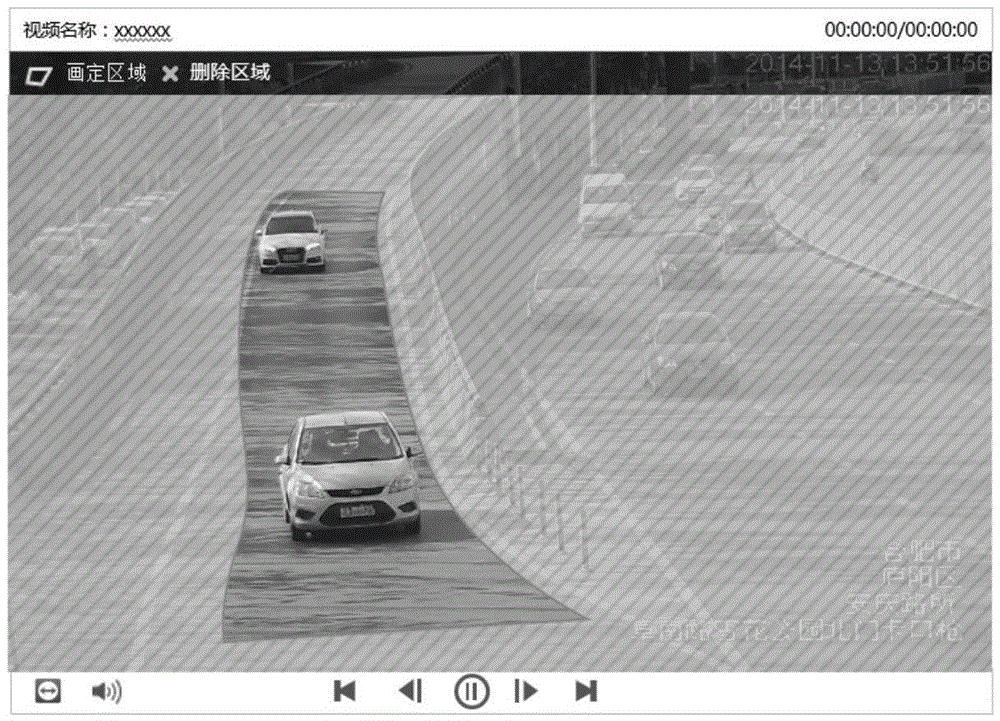

Embodiments of the invention provide a method and a device for playing a monitoring video. The method comprises the following steps: receiving first input information of a user, wherein the first input information is used for selecting a target area from a video image of the monitoring video; determining whether a moving object exists in the target area; if no moving object exists in the target area, fast forwarding the monitoring video; and if the moving object exists in the target area, determining a play speed of the monitoring video according to the speed of the moving object in the target area, and playing the monitoring video at the play speed. In the method and the device provided by the embodiments of the invention, the target area is selected according to the input information of the user, the video image of the input information focused by the user can be located quickly, the play speed of the monitoring video is determined according to the speed of the object in the target area, the play speed of the monitoring video can be matched with the speed of the object, and the check effect of the monitoring video is improved.

Owner:HUAWEI TECH CO LTD

Belt unreeling device

InactiveCN101850485ASpeed matchPrecisely control startup speedWelding/cutting media/materialsSoldering mediaPull forceEngineering

The invention discloses a belt unreeling device which comprises a belt unreeling machine, an electric control system and a speed difference buffer detector, wherein the belt unreeling machine is provided with a drive motor; the speed difference buffer detector feeds a speed difference signal between the belt unreeling machine and the next stage device back to the electric control system, and the electric control system adjusts the rotation speed of the drive motor according to the speed difference signal; the belt unreeling machine is provided with a distance sensor for measuring the diameter of the material reel; the range sensor feeds a reel diameter signal of the material reel back to the electric control system; and the electric control system controls the initial rotation speed of the drive motor according to the reel diameter signal and the preset speed of the next stage device of the belt unreeling machine. The invention can realize speed matching between the current device and the next device, ensures stable relative running speed and stable tensile force on the steel belt, reduces the frequency of the steel belt being fractured by tension, enhances the production efficiency and ensures the product quality.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

Method and device for rotationally hanging, tracking and positioning manipulator on paint line

InactiveCN101618798AMove at the same speedSpeed matchLiquid surface applicatorsConveyorsManipulatorPower unit

The invention relates to a method for tracking and positioning cargoes conveyed on a conveyer, and the tracking and positioning processes start at a first moving position of the conveyer and end at a second moving position of the conveyer; a tracking and positioning device is used in the tracking and positioning processes, and comprises a clamping unit, a connecting unit, a power unit, a detecting unit and a control unit. Because the tracking and positioning device moves forwards by depending on the power of the conveyer in the tracking and positioning processes, the tracking and positioning device can keep the consistent moving speed with the conveyer, thereby the speed of the tracking and positioning device can be well matched with the transporting speed of the manipulator, and the whole production line is in a highly effective operating process.

Owner:SUZHOU LIUSH MACHINERY EQUIP

Plate turning mechanism for tableware cleaning equipment

InactiveCN101822524AAvoid disorderSpeed matchTableware washing/rinsing machine detailsEngineeringMechanical engineering

Owner:俞明 +1

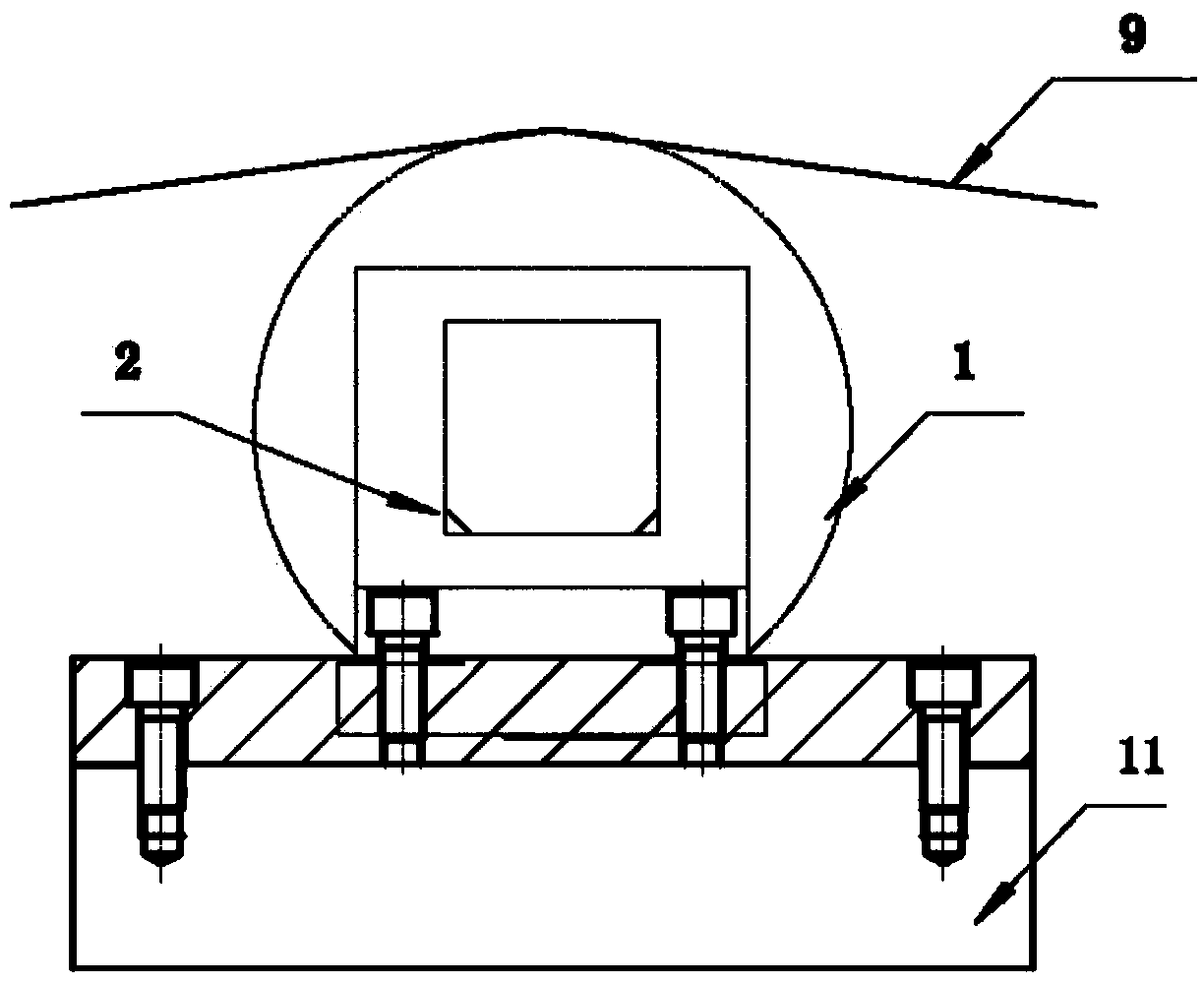

Tension test device and tension test method for tension rollers

ActiveCN103722026ALow priceSpeed matchMeasuring devicesMetal rolling arrangementsPressure sensorTensometer

The invention provides a tension test device and a tension test method for tension rollers, solving problems of high price and failure in repairing of tensiometers in the prior art. The tension test device for the tension rollers comprises a bearing block for bearing one tension roller, the bearing block is connected with a guide block that is connected with a servo hydraulic cylinder, and a pressure sensor is arranged at a lower cavity oil port of the servo hydraulic cylinder. Since the servo hydraulic cylinder is connected with the bearing block that is used for bearing the tension roller and the pressure sensor is arranged at the lower cavity oil port of the servo hydraulic cylinder, pressure applied to the tension roller is transmitted to the pressure sensor through the servo hydraulic cylinder and is detected by the pressure sensor and then compared with the set pressure value through the servo hydraulic cylinder, extension of the hydraulic cylinder is adjusted to adjust position of belts, and further, speed matching between racks is achieved under control. In addition, the servo hydraulic cylinder and the pressure sensor are low in manufacturing cost and are reusable and can be maintained even when damaged.

Owner:HENAN WANDA ALUMINUM

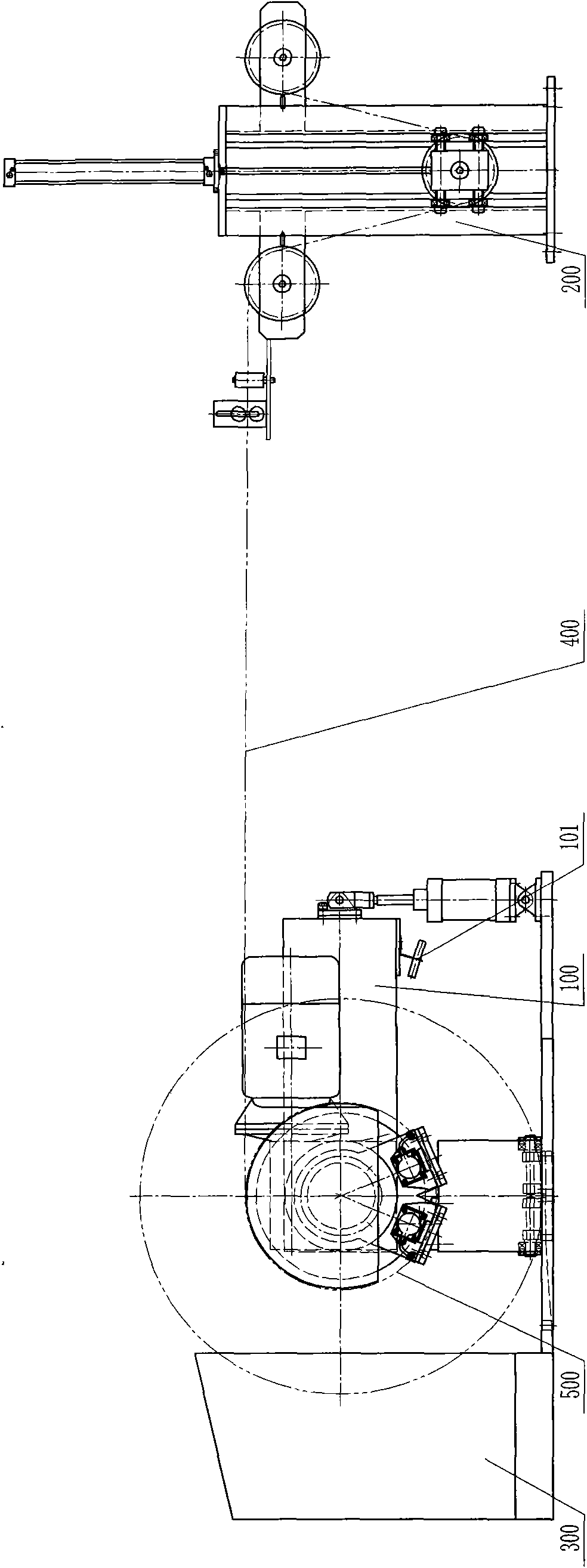

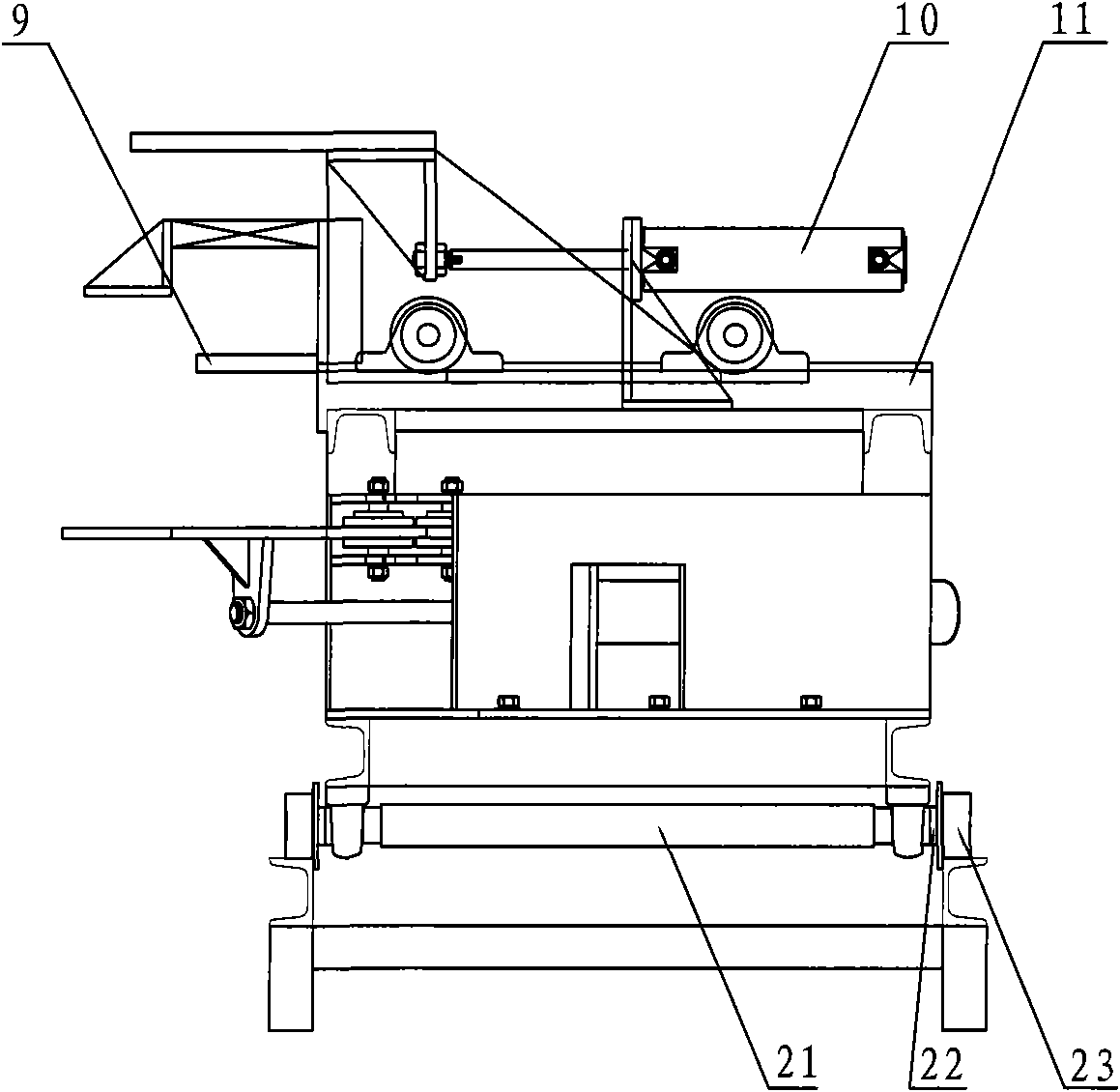

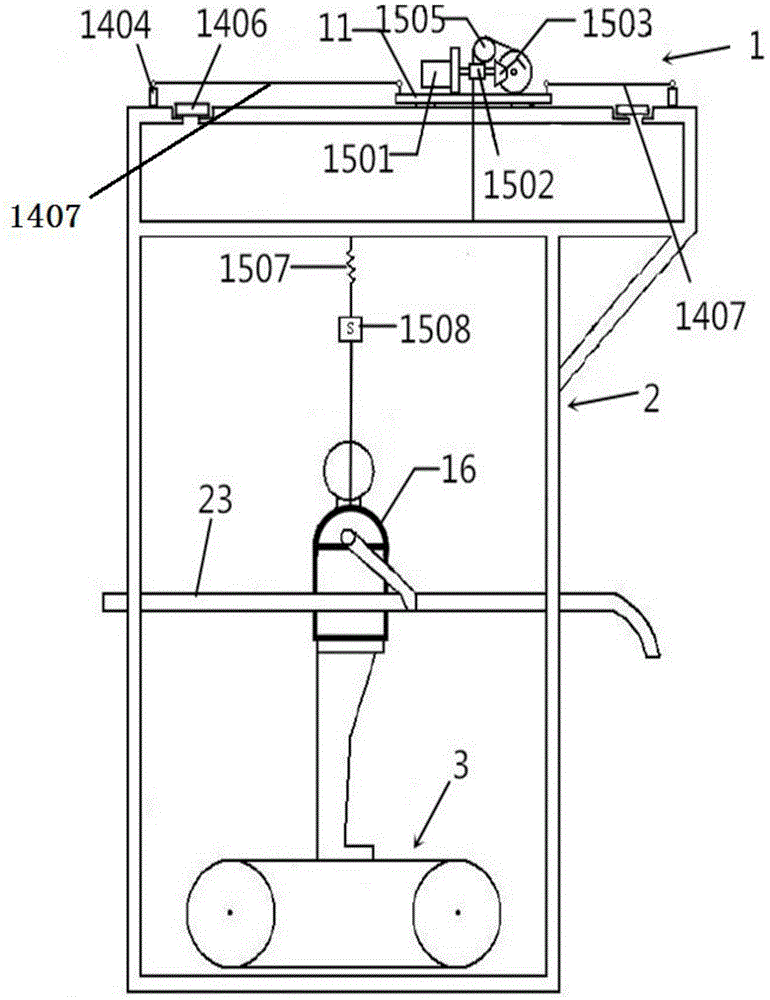

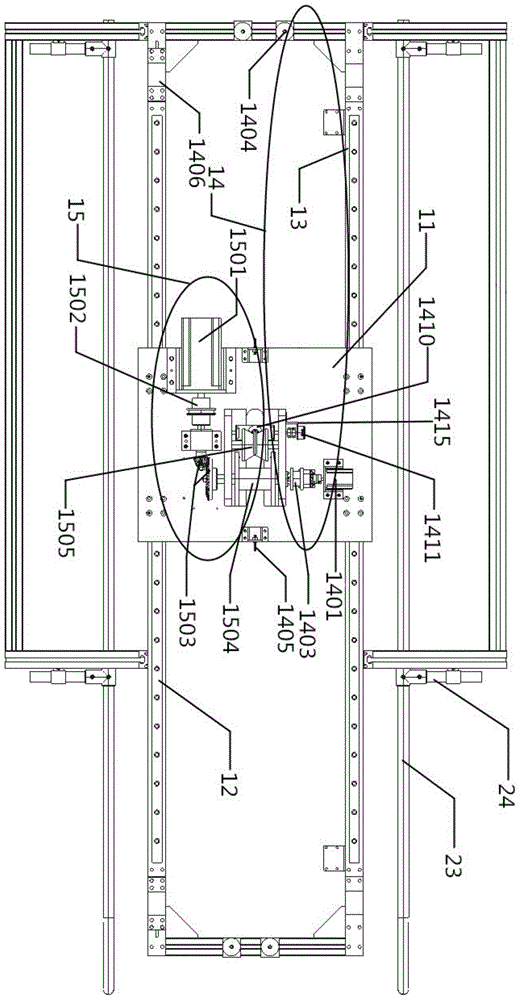

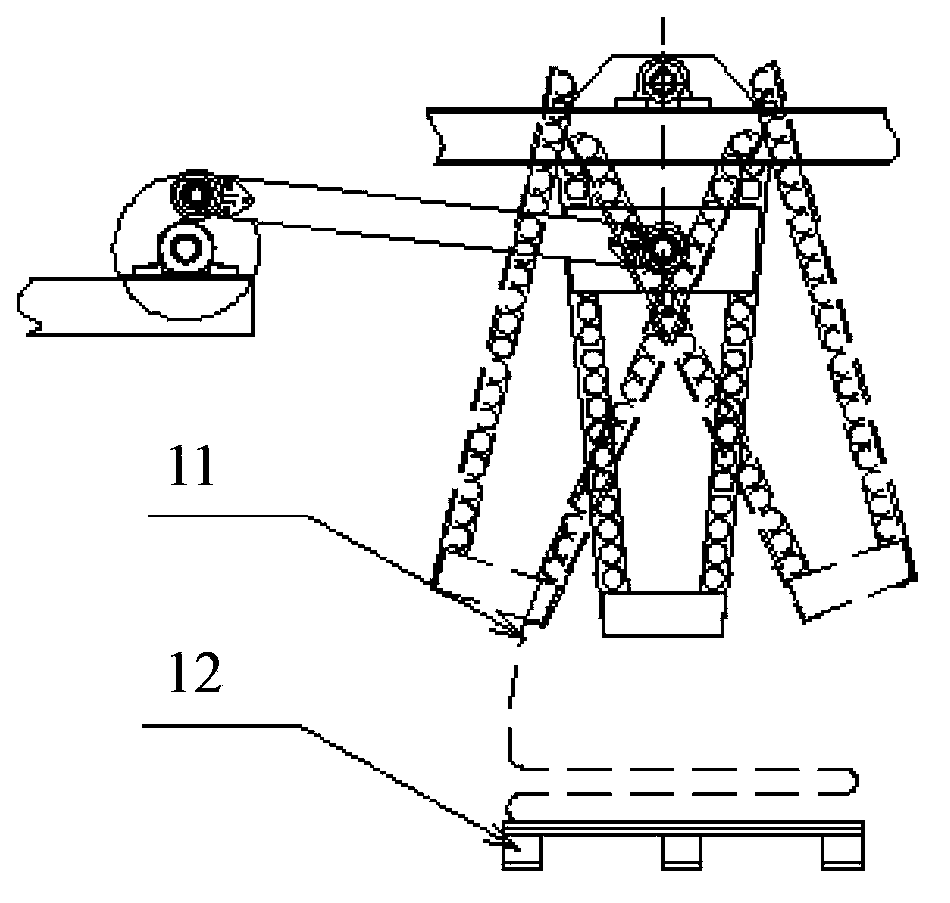

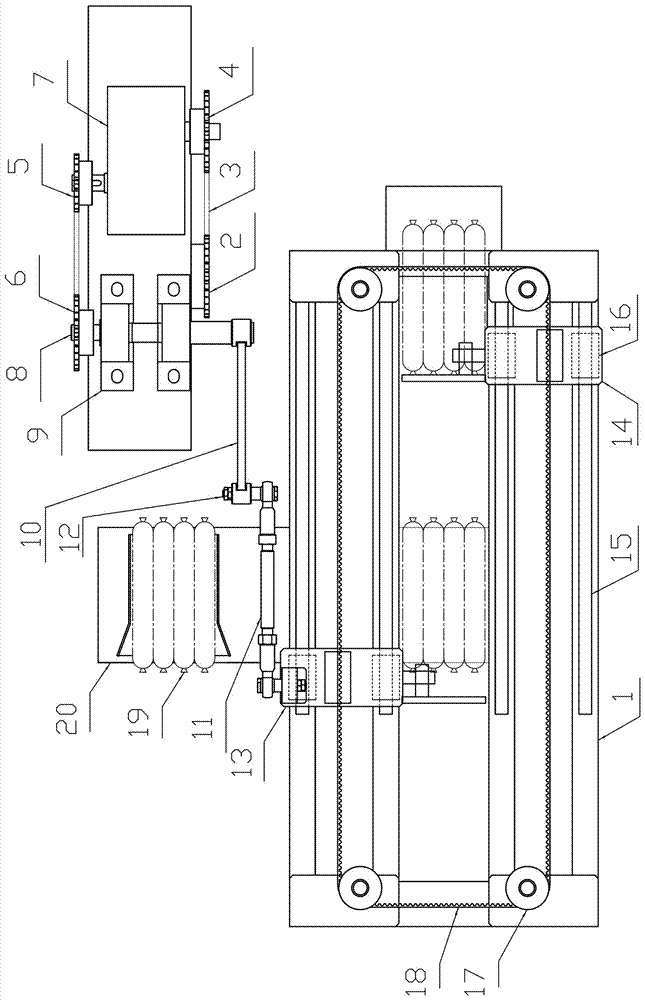

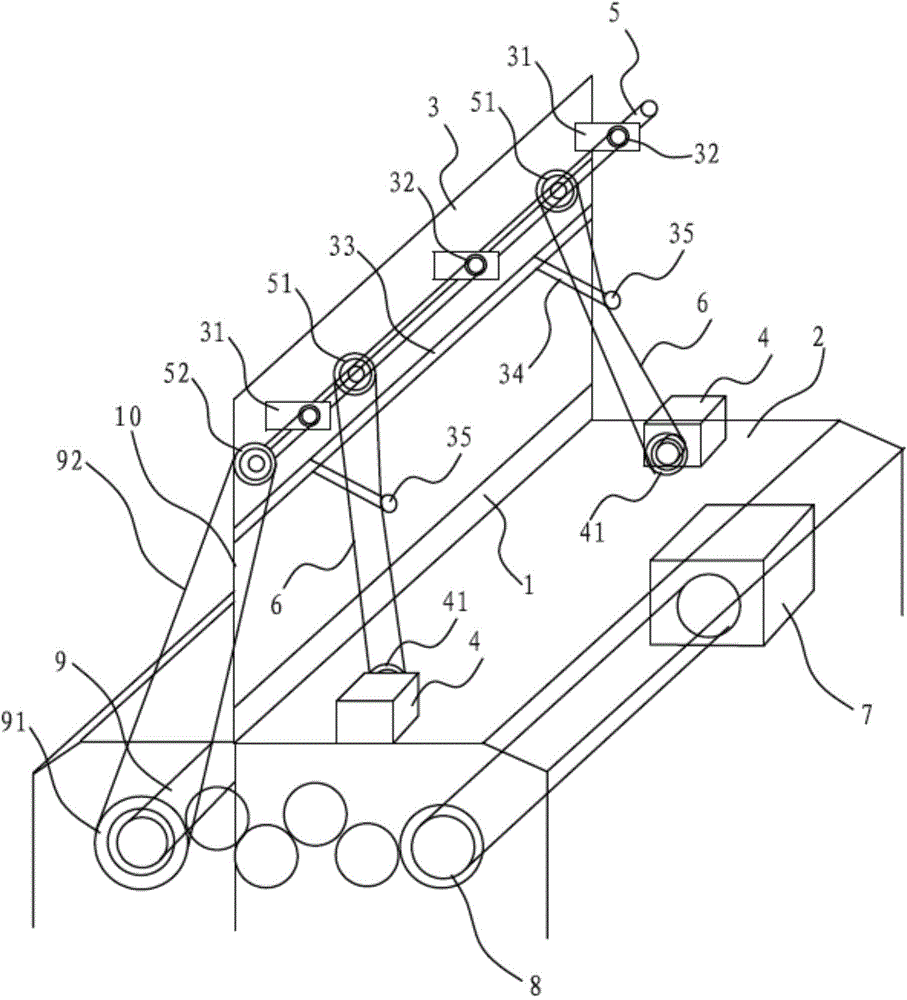

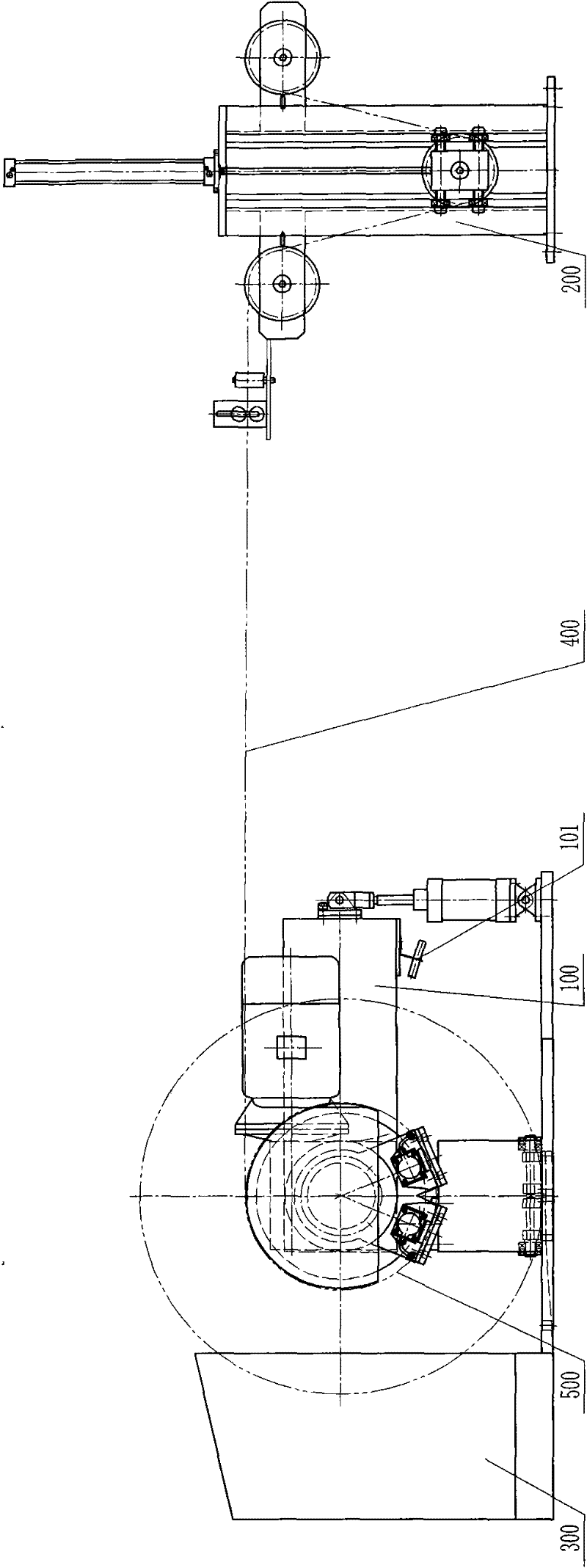

Weight losing system for lower limb patient rehabilitation training

InactiveCN105169627AHighlight substantiveSignificant progressMovement coordination devicesCardiovascular exercising devicesConstant forceDrive motor

A weight losing system for lower limb patient rehabilitation training comprises a system support device, a treadmill training platform device and a control device. The system support device is fixed to the two sides of the treadmill training platform device and comprises vertical supports, a weight losing platform support, a guardrail and adjusting supporting frames, the guardrail is installed on the inner side of the corresponding vertical support through the corresponding adjusting supporting frame, and the weight losing platform support is connected with the upper portions of the vertical supports and is rectangular. The treadmill training platform device comprises a training platform and a drive motor controlled through the control device. The system is characterized in that the system further comprises a follow-up weight losing platform device fixed to the upper portion of the weight losing platform support; the control device is used for controlling movements of the follow-up weight losing platform device and the treadmill training platform device; the control device is provided with a constant-force weight losing control program and a speed control program for the treadmill training platform device and the follow-up weight losing platform device.

Owner:HEBEI UNIV OF TECH

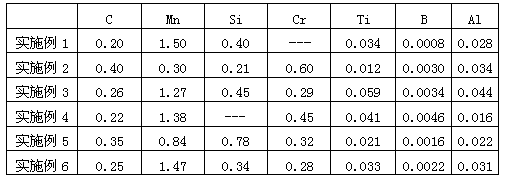

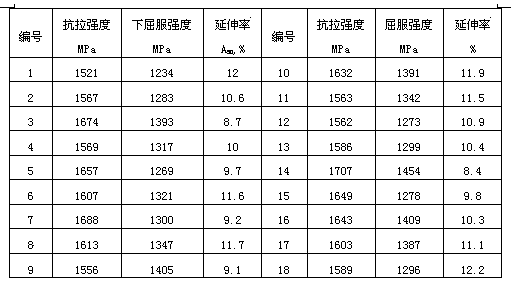

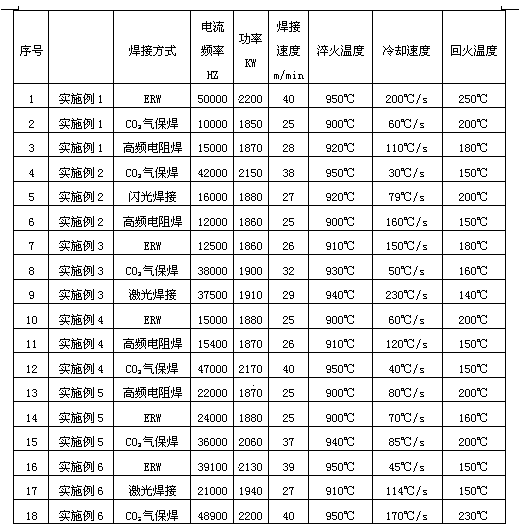

Steel pipe with ultrahigh strength and continuous production method of steel pipe

InactiveCN103938098AReduce manufacturing costAvoid transshipmentFurnace typesHeat treatment furnacesSteel tubeHeat treated

The invention discloses a steel pipe with ultrahigh strength and a continuous production method of the steel pipe. The continuous production method is suitable for producing steel pipes with ultrahigh strength, pipe diameters of 20-51mm and wall thickness of 1.5-2.5mm. The steel pipe is prepared from the following components by mass percent: 0.20-0.40% of C, 0.30-1.50% of Mn, not more than 0.80% of Si, not more than 0.60% of Cr, 0.01-0.06% of Ti, 0.0008-0.0050% of B, 0.015-0.050% of Al and the balance of Fe and inevitable impurities. After adopting the above raw materials, the steel pipe can be produced by adopting a common welded pipe mill and online continuous heat treatment. The obtained welded steel pipe has ultrahigh strength and avoids the process scheme that a high strength steel plate is used as the raw material and the pipe is prepared by welding the high strength steel plate by adopting laser after roll forming of the high strength steel plate, thus greatly reducing the production cost. The mechanical properties of the obtained steel pipe with ultrahigh strength are as follows: the tensile strength is not less than 1500MPa, the yield strength is not less than 1200MPa and the elongation is not less than 6%. In the method, a heat treatment production line is installed behind a welding production line and the welding speed is matched with the heat treatment speed by adjusting the heat treatment speed, so that continuous production can be achieved, the production operability can be effectively improved and the production time and operation strength can be saved.

Owner:HEBEI IRON AND STEEL

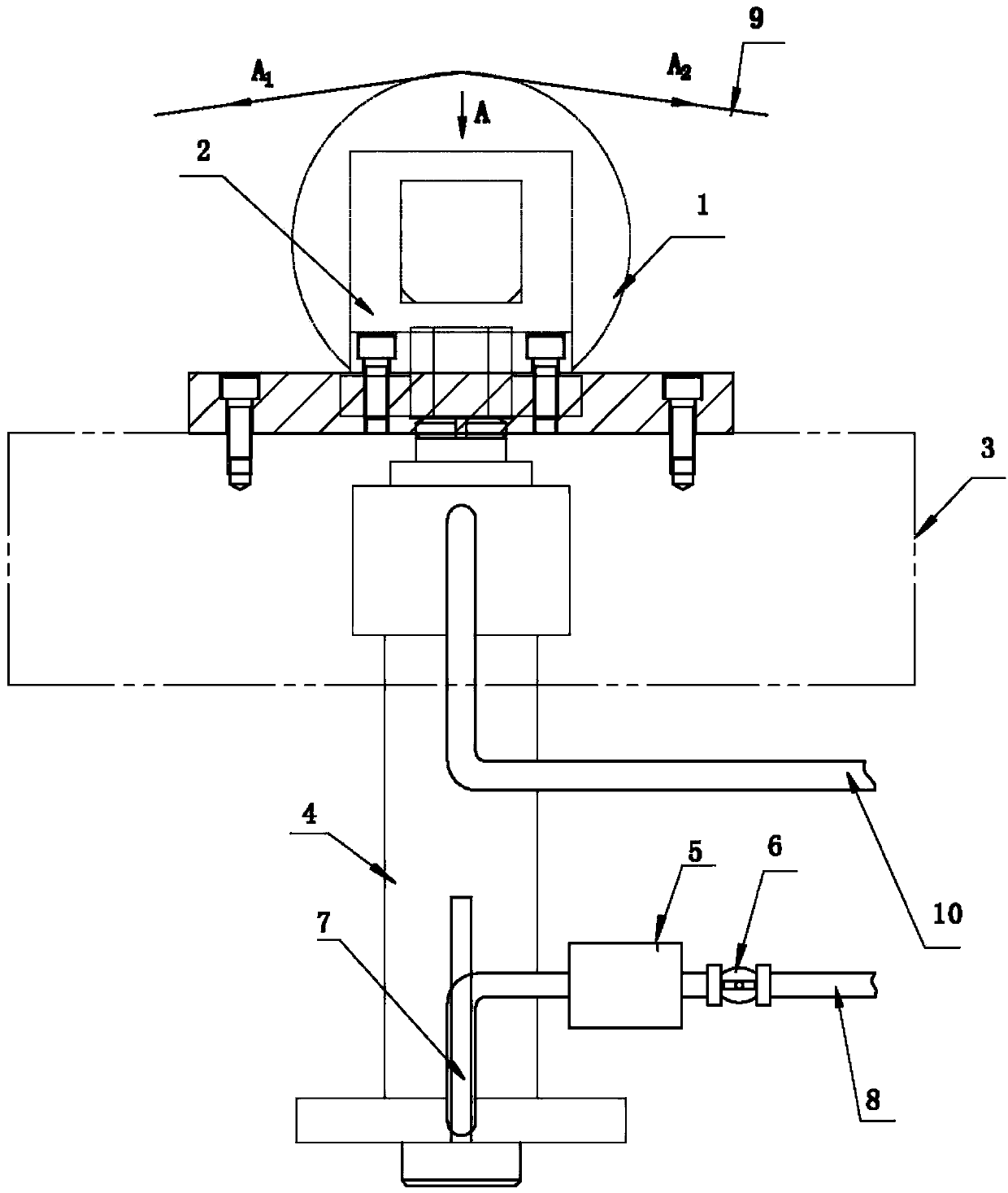

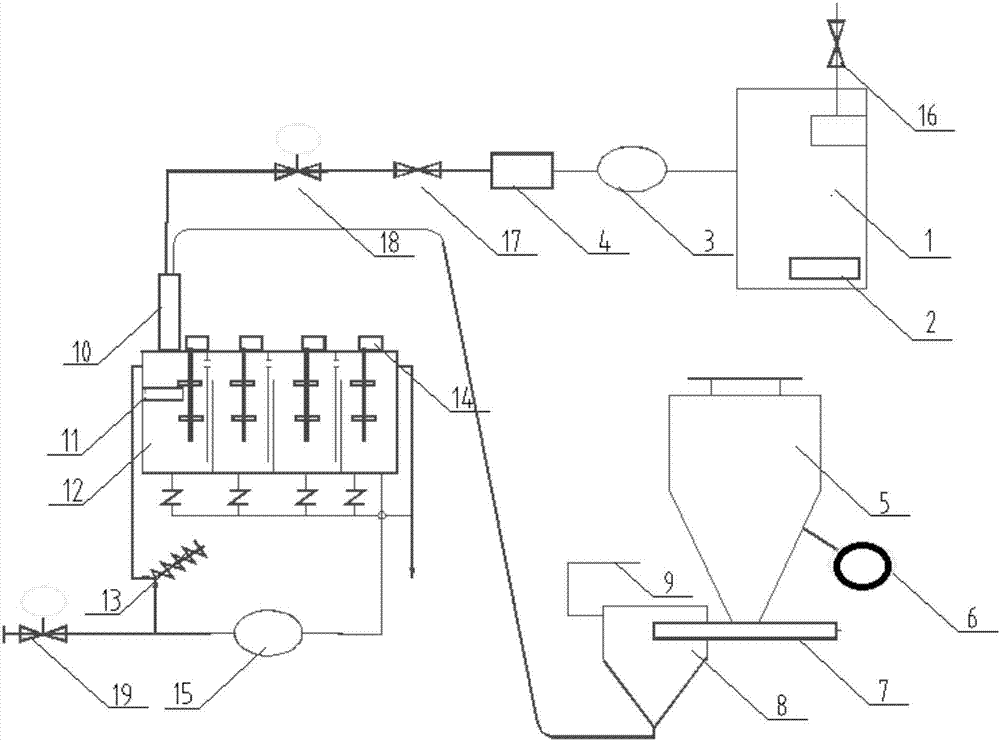

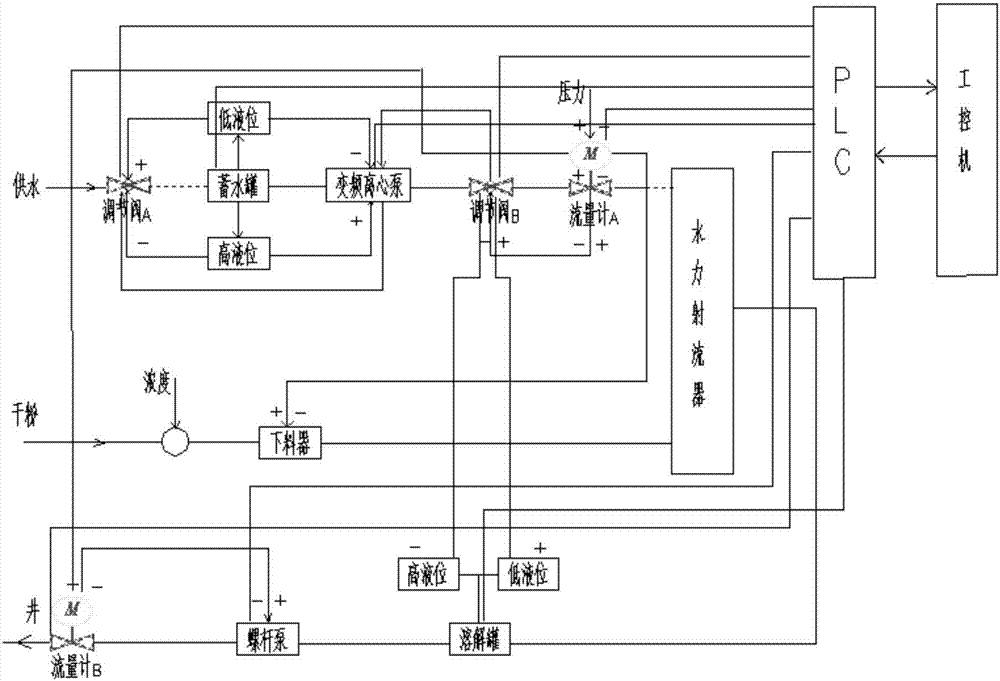

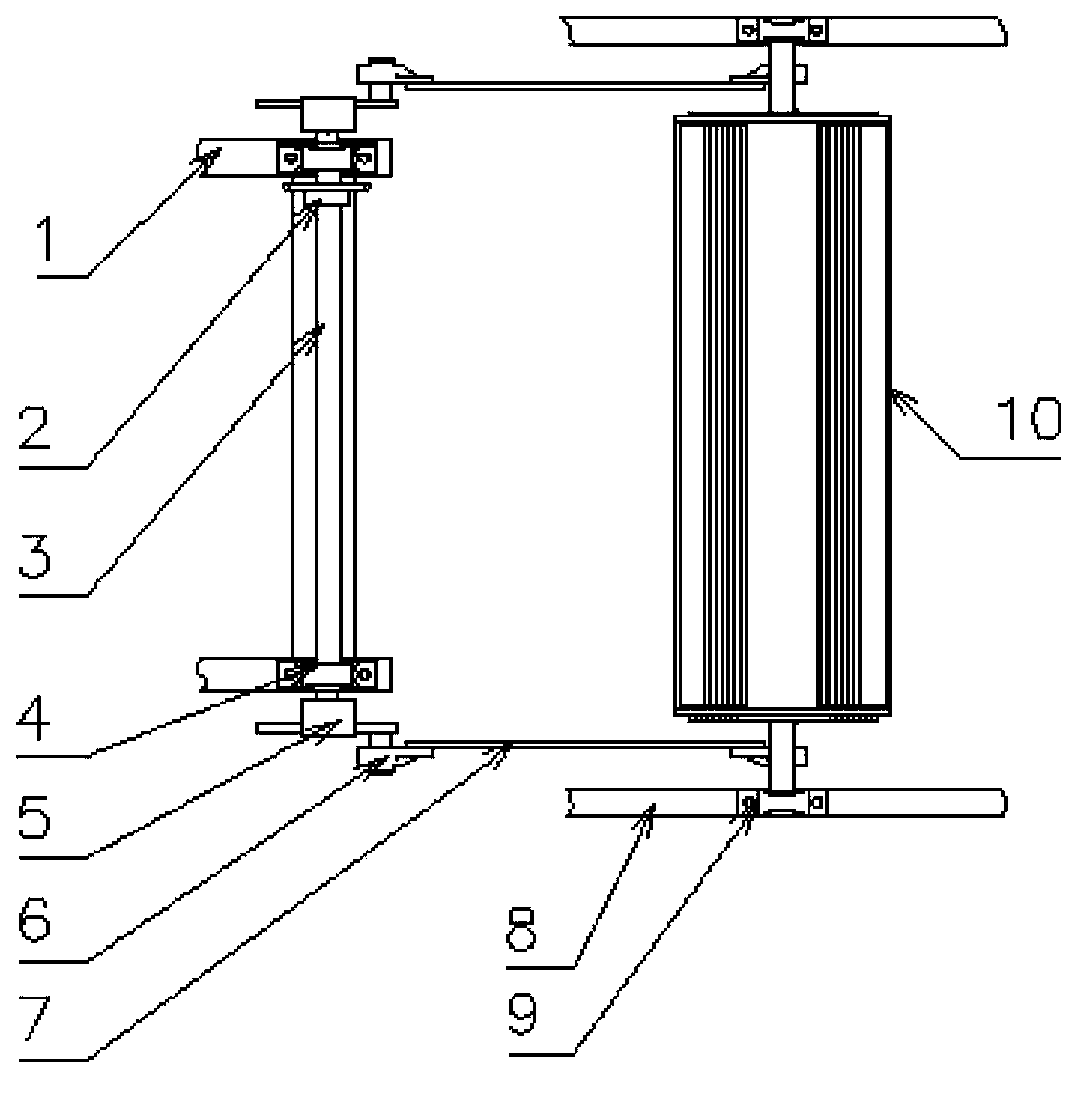

Novel on-line continuous preparation profile control oil displacement device

InactiveCN107060706AImprove working condition adaptabilityReduce selection costsJet pumpsFluid removalCentrifugal pumpAutomatic control

The invention discloses a novel on-line continuous preparation profile control oil displacement device which comprises an incoming water decompression system, a disperse dissolution system and an automatic control system. The incoming water decompression system comprises a high-pressure end and a low-pressure end; the high-pressure end is connected with a water storage tank through a high-pressure water supply pipeline provided with an adjusting valve A; a water level indicator is arranged at the bottom of the water storage tank; the low-pressure end is composed of a centrifugal pump, a filter, an adjusting valve B and a flowmeter A which are sequentially connected through water supply pipelines; the disperse dissolution system comprises a hopper, an unloader, an airtight funnel, a powder air pipeline, a hydraulic jet device and a dissolution tank; and the automatic control system is composed of a programming module, a DCS system, an adjusting valve, frequency conversion equipment and a flowmeter. According to the novel on-line continuous preparation profile control oil displacement device, higher working condition adaptability, control stability and using safety are achieved, on-line preparation of a high concentration polymer solution is achieved, meanwhile, preparation processes for multiple aspects can be achieved, a wider system selective space is achieved accordingly, and the purpose of reducing system selective cost is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

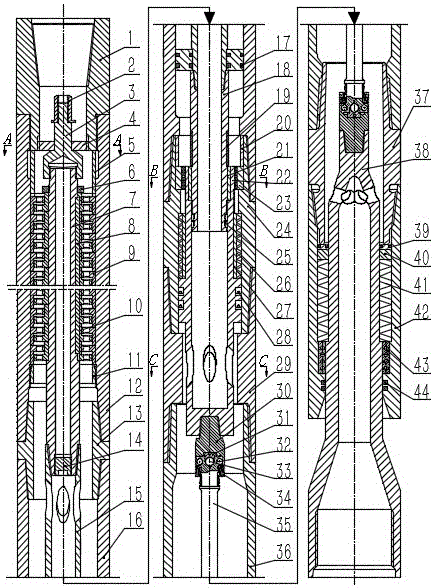

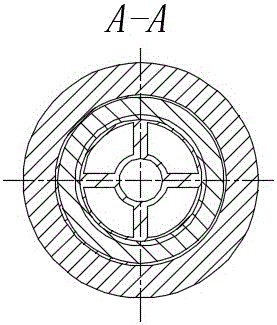

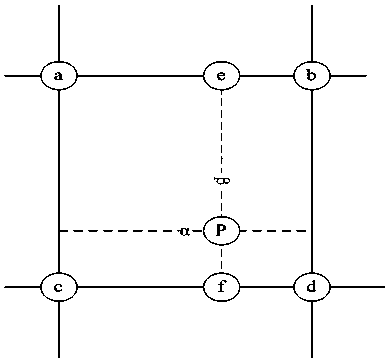

Speed reduction tool for achieving large transmission ratio through harmonic gear

ActiveCN106594226AReduce speedLower requirementFluid gearingsGearing detailsInterference fitHarmonic

The invention relates to a speed reduction tool for achieving the large transmission ratio through a harmonic gear, and belongs to the field of petroleum drilling. The speed reduction tool is installed to the upper portion of a drill bit through threaded connection and comprises a turbine assembly, a harmonic gear assembly, a universal shaft assembly and a damping assembly. The harmonic gear assembly is composed of an oval harmonic producer used as power input, a flexible gear used as power output and a rigid gear fixed to a shell. An input shaft is in interference fit with the harmonic producer, and the flexible gear is subjected to controllable elastic deformation through the harmonic producer to be in an oval shape also. According to the speed reduction tool for achieving the large transmission ratio through the harmonic gear, the tooth number of the rigid gear is slightly larger than that of the flexible gear in harmonic gear transmission, the formula of the transmission ratio is shown in the description, ZR is the tooth number of the flexible gear, ZG is the tooth number of the rigid gear, meanwhile, the engaged tooth number is large, the characteristics of the large transmission ratio can be achieved, the rotating speed of a turbine drill is effectively reduced, the torque is greatly increased, and the drilling efficiency of the turbine drill is improved.

Owner:重庆桐雨石科技有限公司

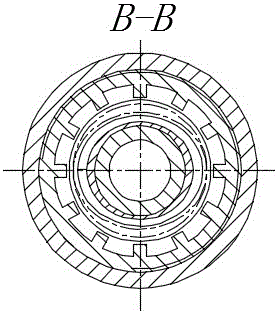

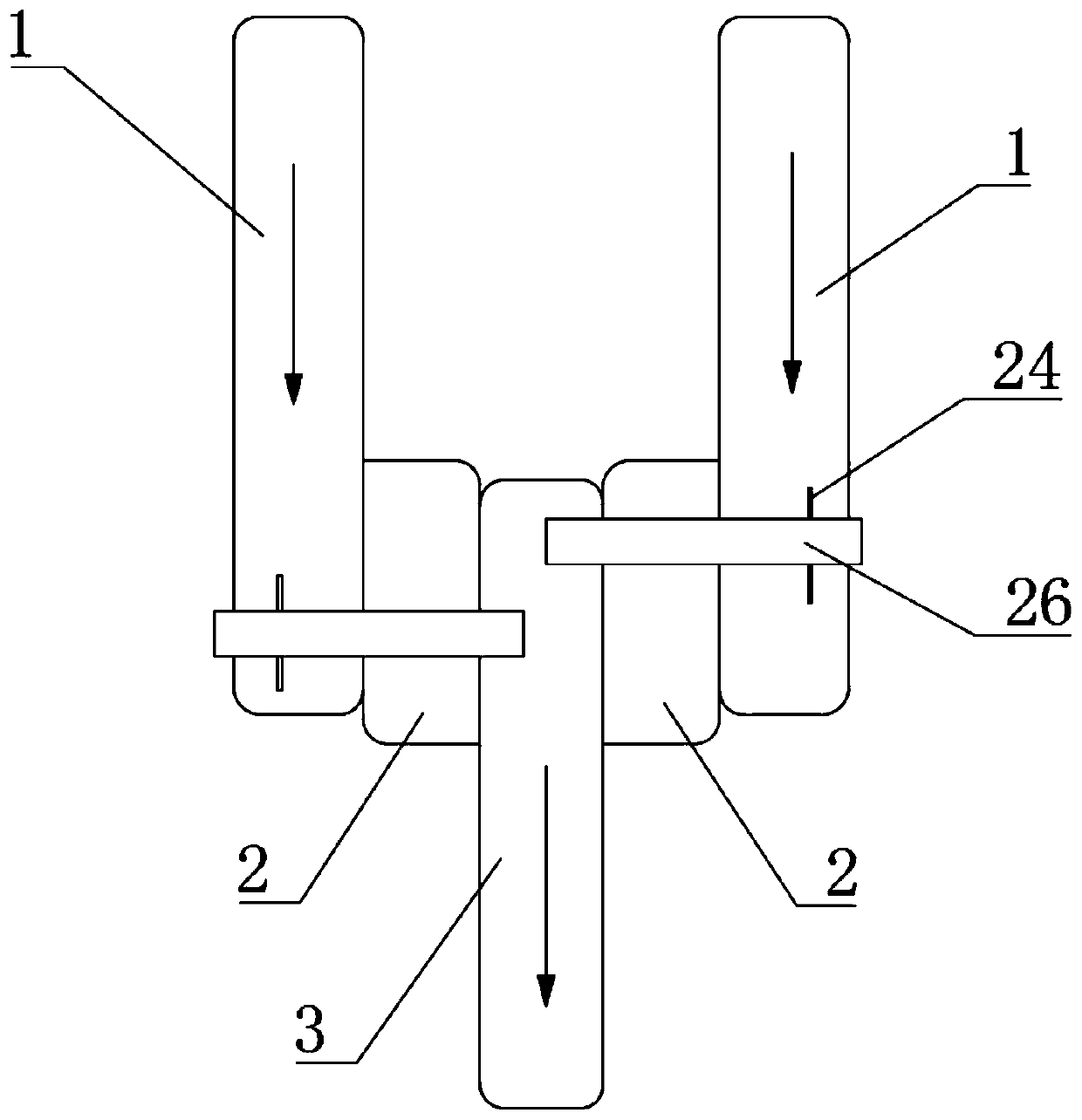

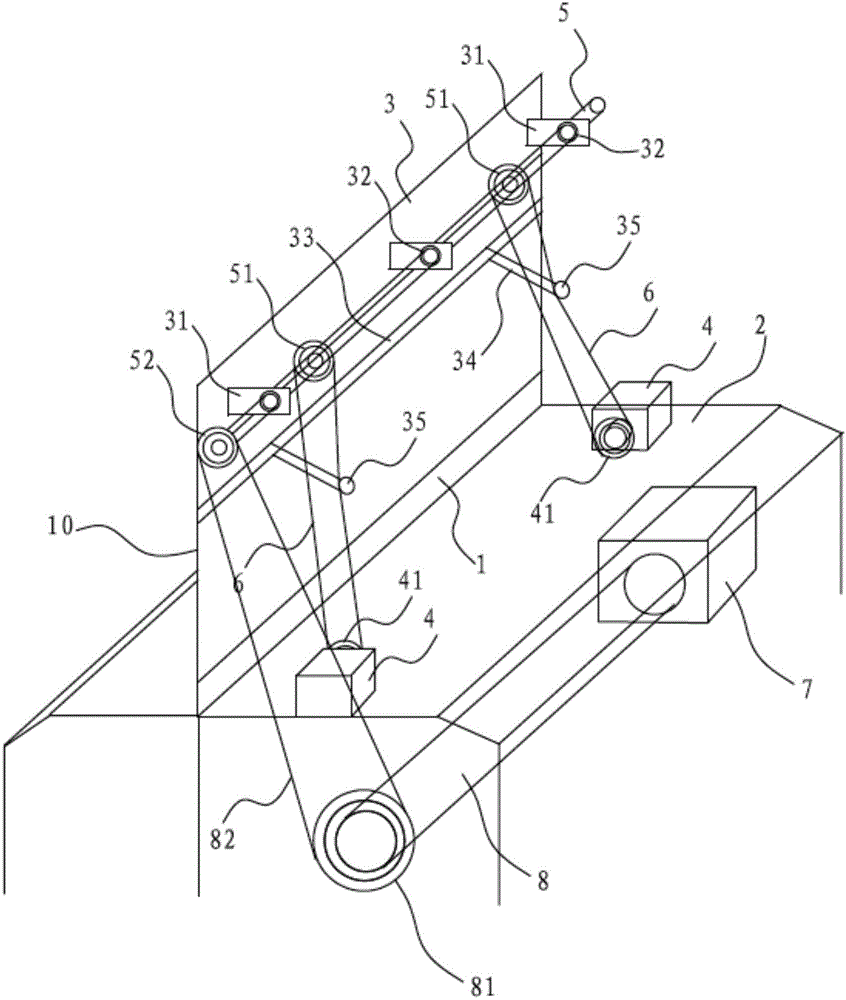

Follow-up combining and conveying device for strip packages

PendingCN110980235ARealize quantitative follow-up material shiftingSpeed matchConveyor partsReciprocating motionControl engineering

A follow-up combining and conveying device for strip packages comprises feeding servo conveying belts, a discharging servo conveying belt and follow-up combining mechanisms, wherein the feeding servoconveying belts are connected with the discharging servo conveying belt through the follow-up combining mechanisms; each follow-up combining mechanism comprises a support frame, a transition sliding groove platform, a longitudinal linear reciprocating drive assembly, a stirring mechanism and a transverse linear reciprocating drive assembly, the longitudinal linear reciprocating drive assembly is connected with the transition sliding groove platform to drive the transition sliding groove platform to reciprocate linearly and longitudinally, and the transverse linear reciprocating drive assemblyis connected with the stirring mechanism to drive the stirring mechanism to reciprocate transversely and linearly above the feeding servo conveying belt, the transition sliding groove platform and thedischarging servo conveying belt to stir materials. By the structural design of the follow-up combining mechanisms, the speeds of the strip packages and a stirring plate can be adjusted, strip packages can be transited onto the discharging servo conveying belt smoothly while the material states have no relative changes, and meanwhile, combination of multiple feeding conveying belts and quantitative follow-up stirring can be realized.

Owner:GUANGZHOU PHARMA INTELLIGENT EQUIP CO LTD

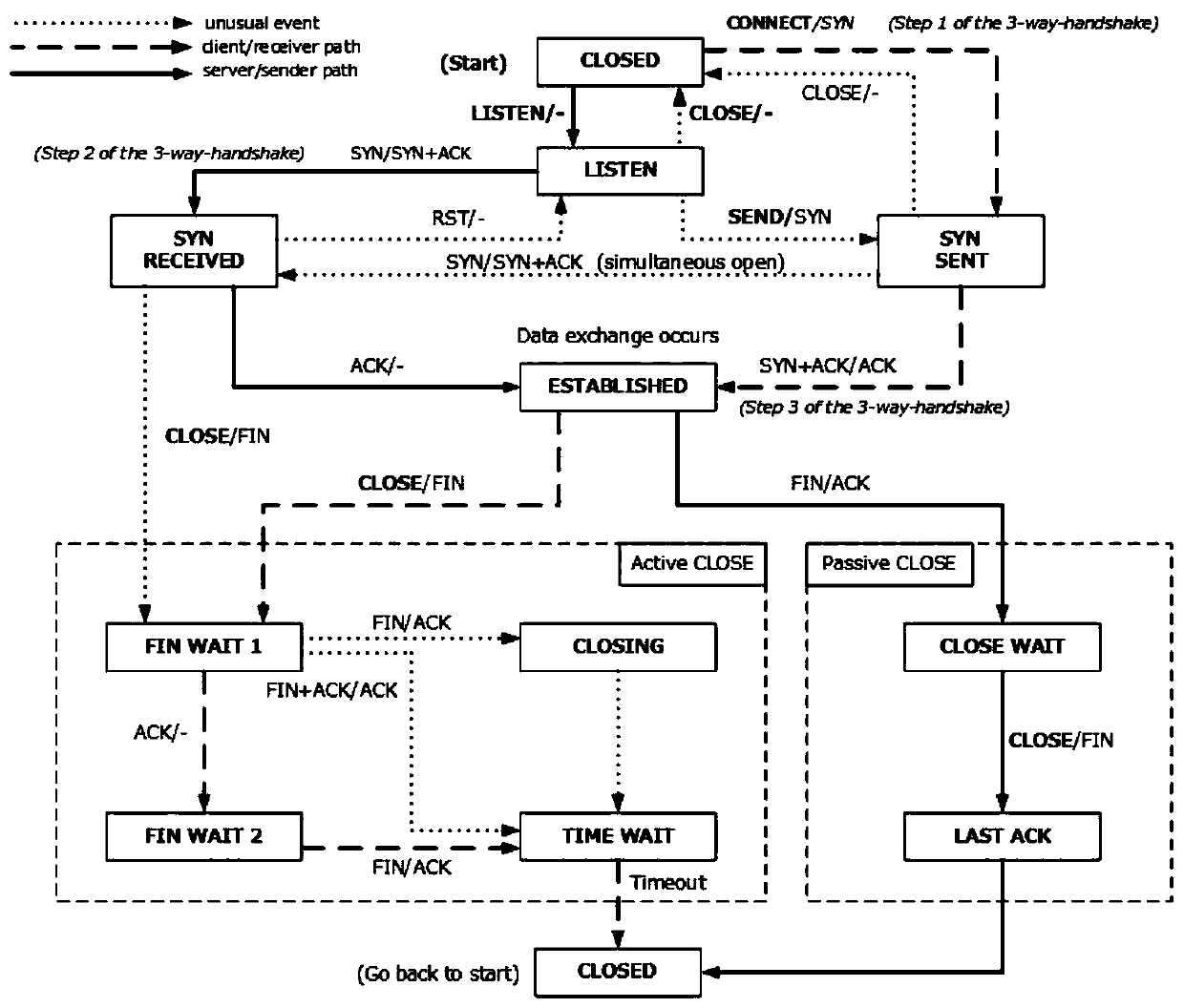

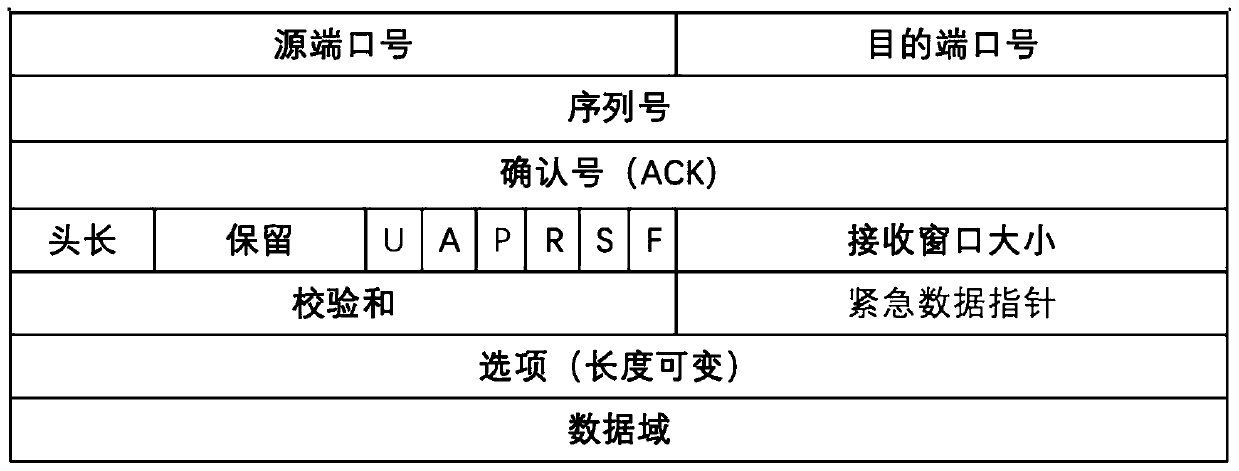

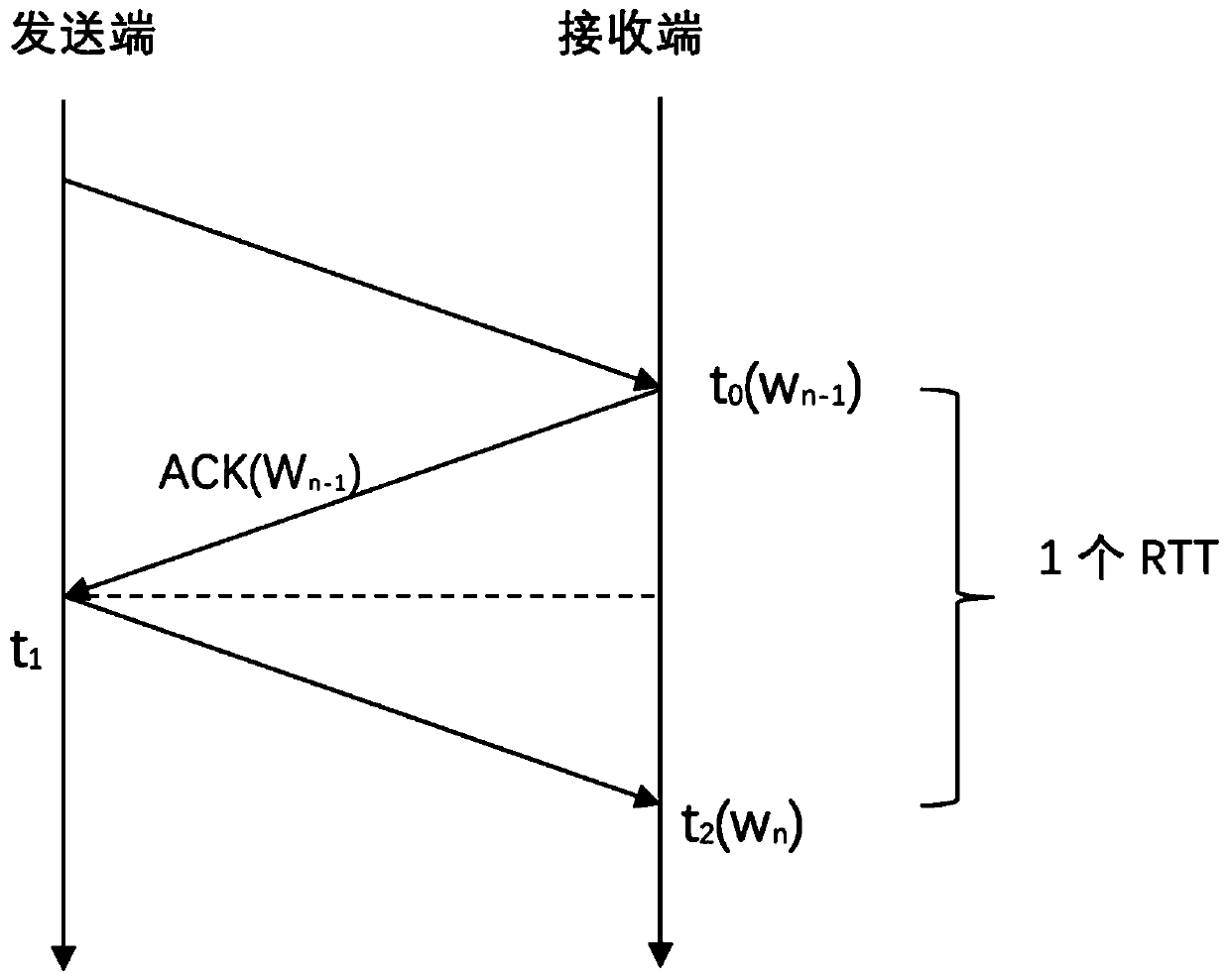

Flow control method based on window prediction

ActiveCN110535781AImprove communication efficiencyGood matchData switching networksData bufferReal-time computing

The invention discloses a flow control method based on window prediction, which comprises the following steps: 1) in the stage of establishing TCP (Transmission Control Protocol) connection, a sendingend and a receiving end negotiate the window size, and meanwhile, the receiving end reserves a data buffer area; 2) the sending end sends a data byte stream conforming to the window size according tothe negotiation result, and waits for confirmation of the receiving end; 3) the sending end substitutes the size of the remaining receiving window in the confirmation information which is just returned and the size of the remaining receiving window predicted last time into a formula (4); 4) the size of the residual receiving window predicted this time is calculated through a formula (4), and thesending rate of the sending end is adjusted according to the size of the residual receiving window, so that the deviation between the return value of the size of the receiving window adopted by the sending end and the actually matched numerical value is reduced; and 5) the step 3) is repeated until the communication is finished, and the connection is closed to realize the flow control of the sizeof the receiving window. The TCP communication efficiency is improved, and the reasonable utilization of resources is ensured.

Owner:XI AN JIAOTONG UNIV

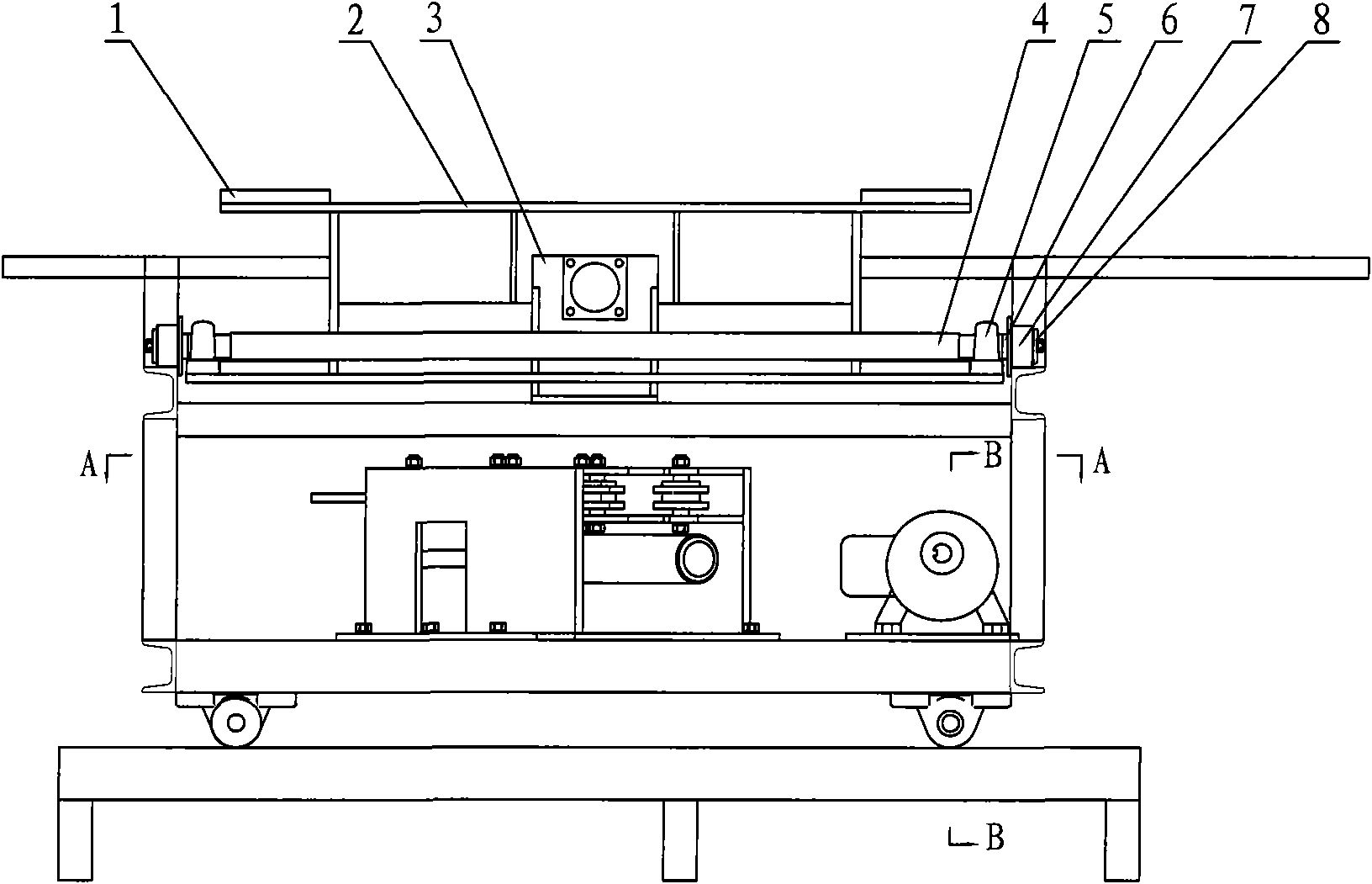

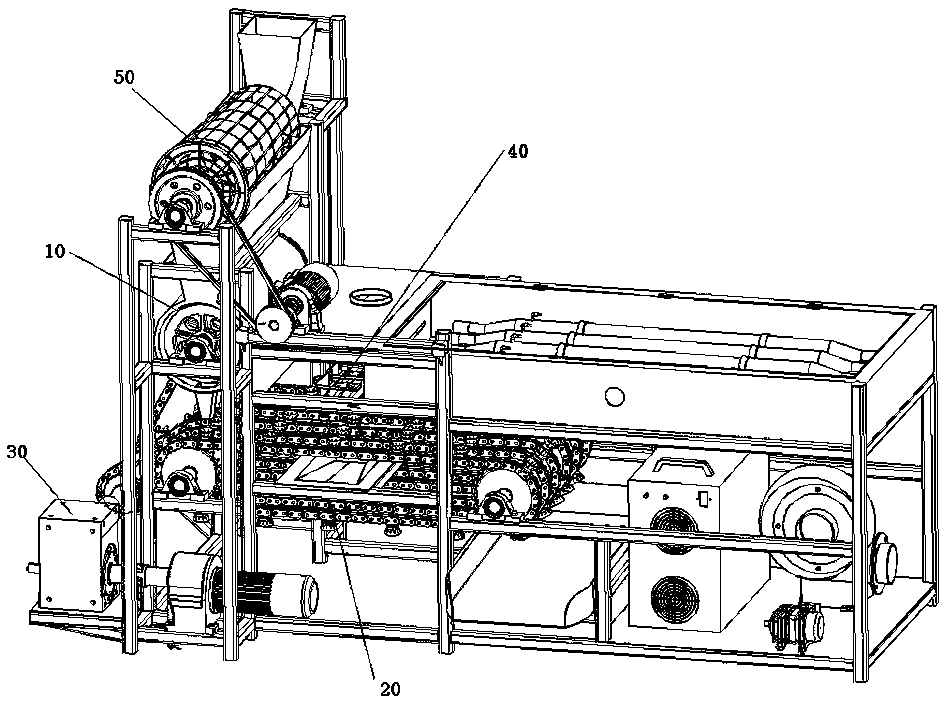

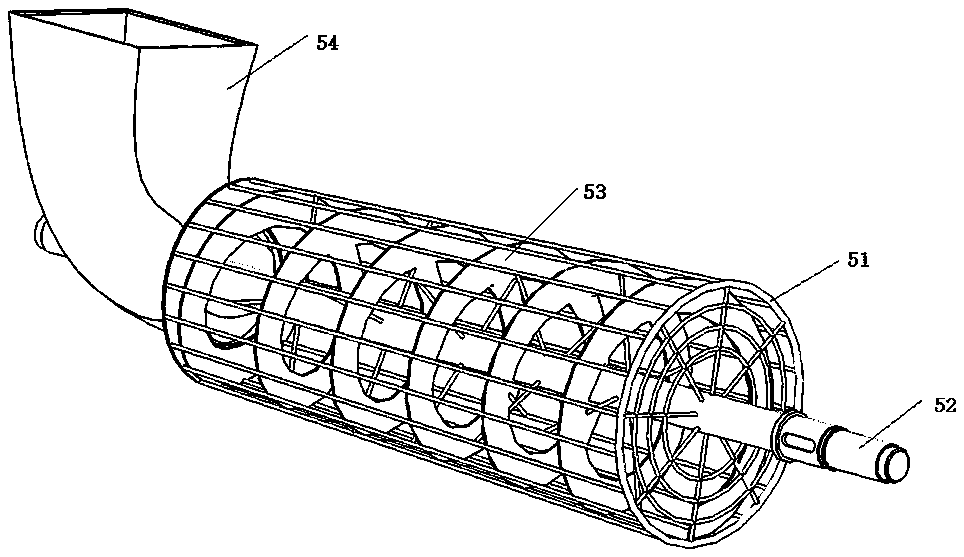

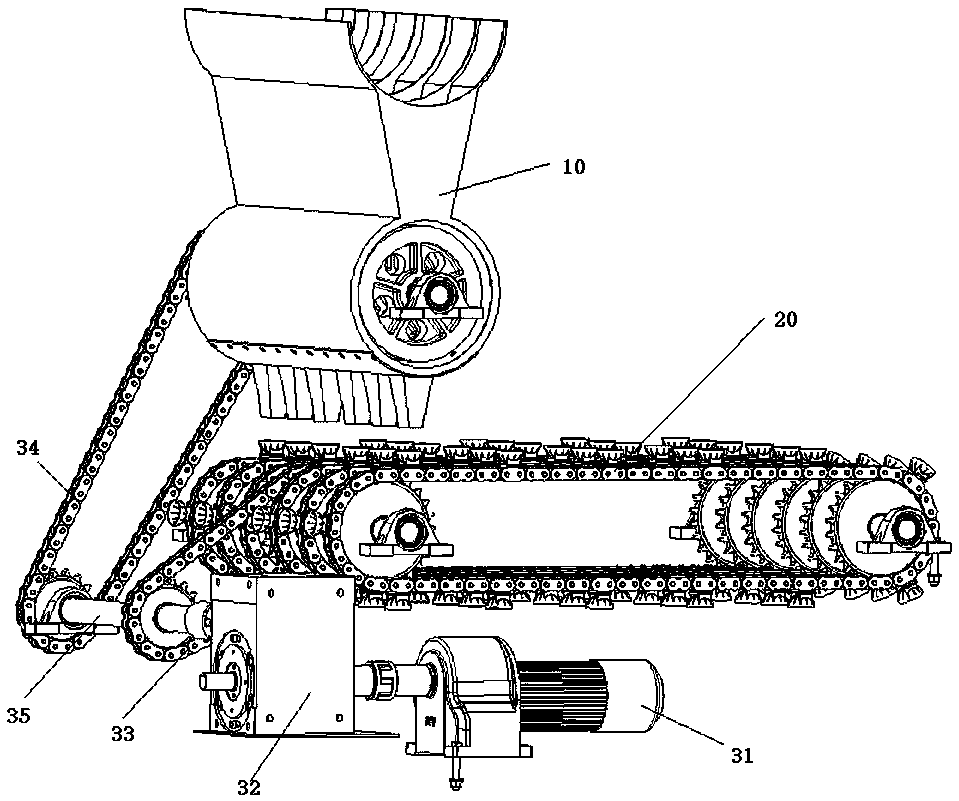

Rubber stacking mechanism for tire automatic production line

The invention relates to a rubber stacking mechanism for a tire automatic production line. The mechanism comprises a main shaft device and a stacking device, wherein the main shaft device comprises a framework a, a chain wheel, a main shaft, a bearing seat a and a driving disc; the bearing seat a is arranged on the framework a; the main shaft is arranged on the bearing seat a; the chain wheel is connected with the main shaft and the driving disc; the stacking device comprises a framework b, a bearing seat b and a stacking opening; the bearing seat b is arranged on the framework b; the stacking opening is formed in the bearing seat b; the driving disc is connected with the bearing seat b through a crank rocker mechanism. Compared with the prior art, the mechanism has the advantages that the efficiency is high, space is saved, manual work is replaced by machinery, the requirement of automatic production is met, stacked rubber saves storage space, and the like.

Owner:SHANGHAI JIAZHENG MACHINERY

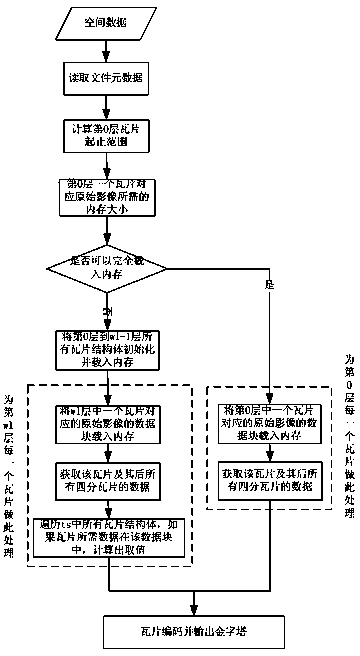

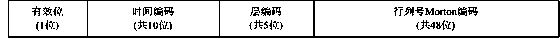

Method for quickly constructing raster database facing to Virtual Earth

InactiveCN102509022BImprove build efficiencyEliminate bottlenecksSpecial data processing applicationsComputer hardwareSensing data

The invention relates to a method for quickly constructing a raster database facing to Virtual Earth. The method comprises the step of: beginning to construct a pyramid from an intermediate layer (a minimum memory requirement layer) if original remote sensing image data corresponding to a tile of a zero layer cannot be completely loaded to a memory once. Therefore, limit of the conventional construction layer by layer is broken through, people are only necessary to scan an original data file once, therefore, the number of I / O (Input / Output) operations is reduced, and the bottleneck problem of reading data when mass data is processed is eliminated. According to the method disclosed by the invention, a tile processing thread and a tile calculating thread are also designed. As the two threads are enabled to operate simultaneously, system resources are fully utilized; a plurality of tile calculating threads are arranged according to different hardware conditions so that the speeds of reading data and writing data by a program are matched, the synchronism of read-write operations is realized, the waiting time of the read-write operations is saved, the efficiency of pyramid construction is improved, and the method is particularly suitable for processing of extra large remote sensing data files.

Owner:WUHAN UNIV

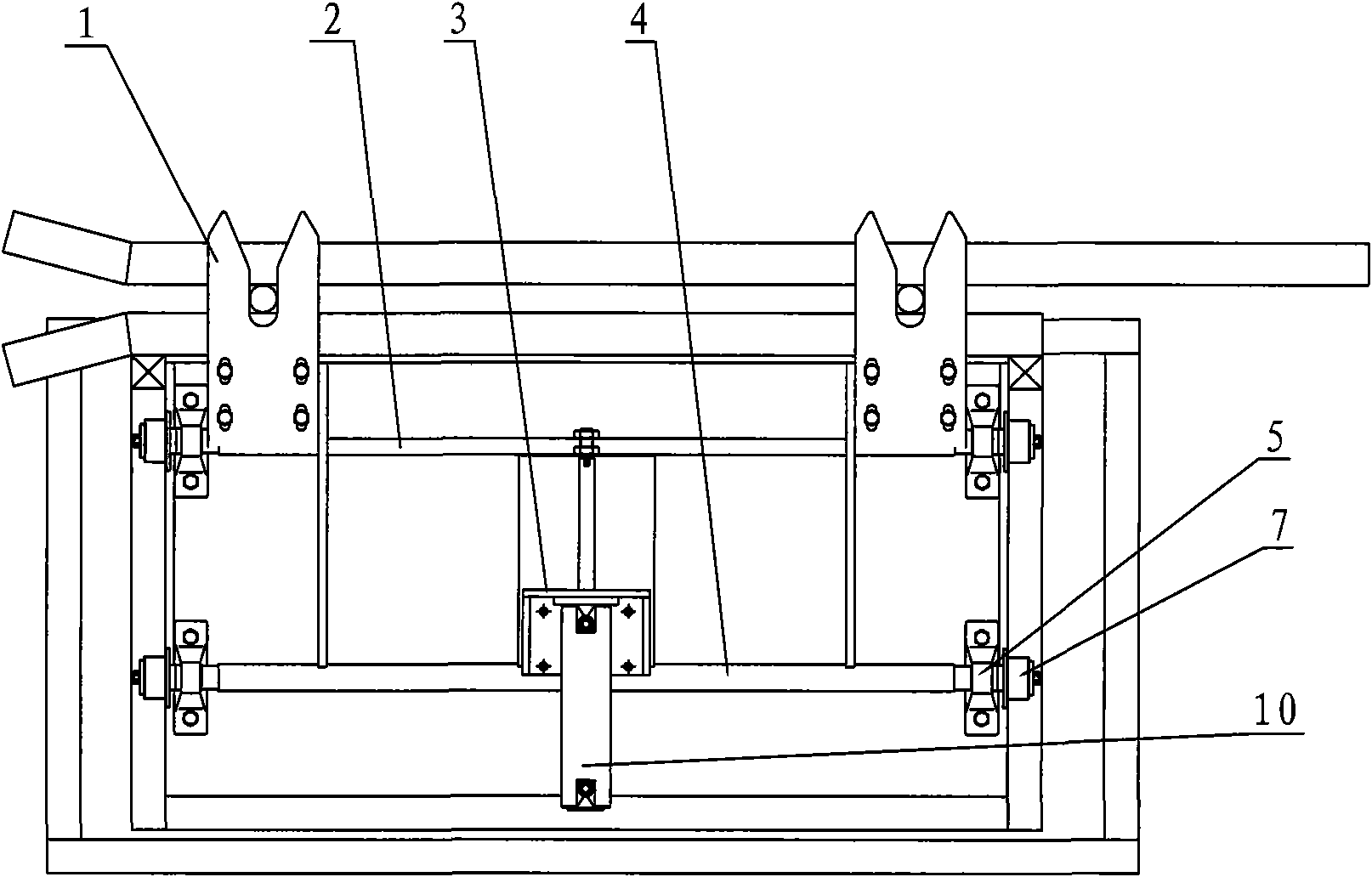

Feeding device for bar-shaped cartridges

PendingCN107512577ASolve the problem of long waiting timeSolve the problem of inertia rushing outConveyor partsEngineeringControl theory

The invention discloses a feeding device for bar-shaped cartridges. The feeding device for the bar-shaped cartridges comprises a frame-shaped rack, a synchronous belt assembly, a crank-sliding block mechanism, two groups of pushing mechanisms used for pushing the bar-shaped cartridges and a transmission mechanism which is driven by continuous rotation power of the next procedure and can convert the continuous rotation power into intermittent rotation power to be output; the synchronous belt assembly is arranged on the frame-shaped rack, the pushing mechanisms are arranged on the synchronous belt assembly in an opposite and staggered manner, the output end of the transmission mechanism is connected with one pushing mechanism through the crank-sliding block mechanism and drives the pushing mechanism to do straight back-and-forth motion with the speed decreasing progressively, the synchronous belt assembly drives the other pushing mechanism to synchronously do straight back-and-forth motion with the speed decreasing progressively, and the motion directions of the two pushing mechanisms are parallel and opposite. The feeding device has the advantages of being simple in structure, high in feeding efficiency, easy to control, safe and reliable in conveying and the like.

Owner:HUNAN KENON AUTOMATIC EQUIP

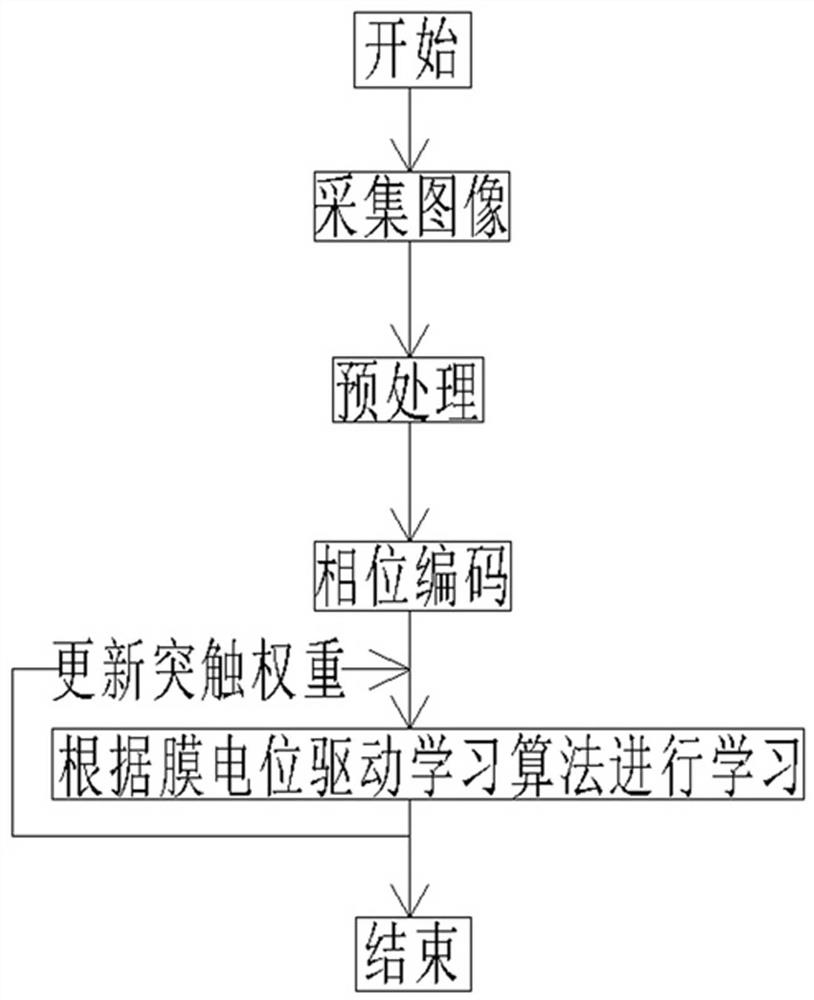

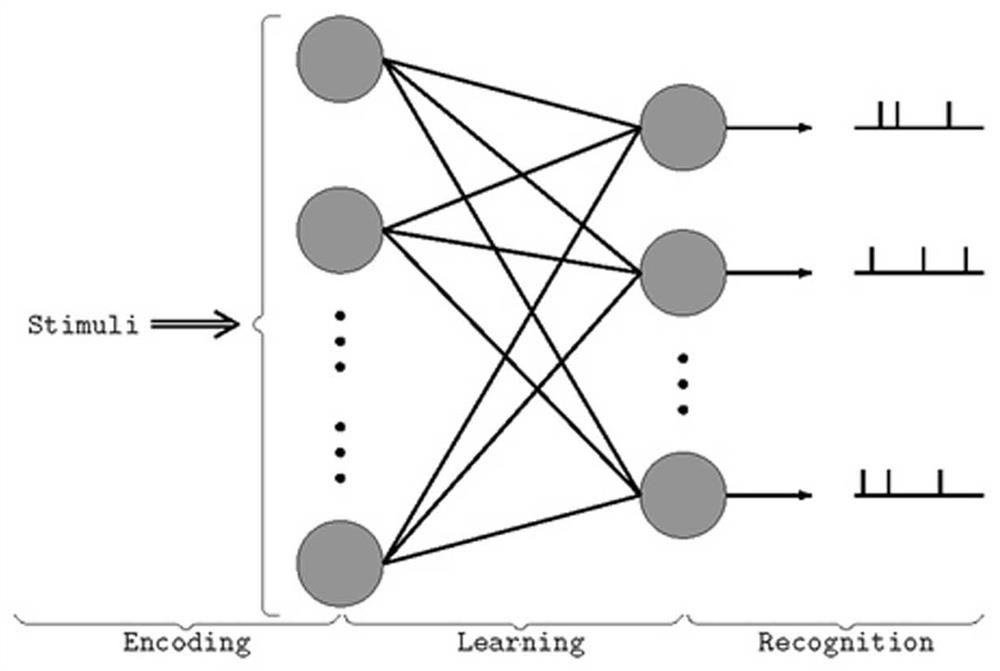

Identification method of drying agent packaging bag identification model of spiking neural P system

PendingCN111723726AReduce the effects of noiseAvoid interferenceCharacter and pattern recognitionNeural architecturesPattern recognitionEngineering

The invention discloses an identification method for a drying agent packaging bag identification model of a spiking neural P system, and the method comprises the following steps: (1) employing a camera to shoot an image of each drying agent packaging bag on a drying agent strip driven and conveyed by a motor, and obtaining a color drying agent packaging bag image corresponding to each drying agentpackaging bag; (2) converting the color drying agent packaging bag image obtained in the step (1) into a drying agent packaging bag grey-scale map, converting the grey-scale map of the drying agent packaging bag into a binary image of the drying agent packaging bag, encoding the binary image of the drying agent packaging bag into a pulse sequence, then sending the pulse sequence to a drying agentpackaging bag identification model based on a spiking neural membrane system, and performing online image classification by using a membrane potential driven learning algorithm based on the spiking neural membrane system so as to identify whether drying agent packaging bags are intact, empty, half-packaged, clamped and the like. The method can quickly and accurately identify whether the drying agent packaging bag is intact, empty, half-packaged, clamped and the like.

Owner:SUZHOU UNIV

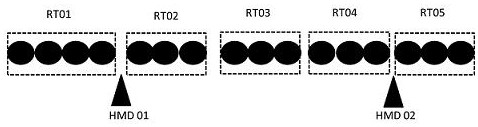

Heating furnace discharging roller way control system

PendingCN113357921ARealize communicationSpeed matchCharge manipulationControl devices for furnacesControl systemElectric machine

The invention discloses a heating furnace discharging roller way control system which comprises a heating furnace control system and a rolling line control system and further comprises a discharging roller way control system for controlling a heating furnace discharging roller way. The furnace discharging roller way control system is in communication connection with the heating furnace control system and the rolling line control system respectively. The speed of the heating furnace discharging roller way is matched with the speed of a heating furnace cantilever roller way and the speed in front of a first rolling mill, the heating furnace discharging roller way is driven by 16 motors, and the heating furnace discharging roller way is divided into five sections including the RT01 section, the RT02 section, the RT03 section, the RT04 section and the RT05 section. A first hot metal detector HMD01 is arranged between roller way bodies of the RT01 section and the RT02 section, and a second hot metal detector HMD02 is arranged between the RT04 section and the RT05 section. According to the heating furnace discharging roller way control system, fine control over the furnace discharging roller way is achieved, the yield is improved, and the friction problem caused by speed mismatching between the roller way and a steel billet is solved.

Owner:SHANDONG LAIGANG YONGFENG STEEL & IRON

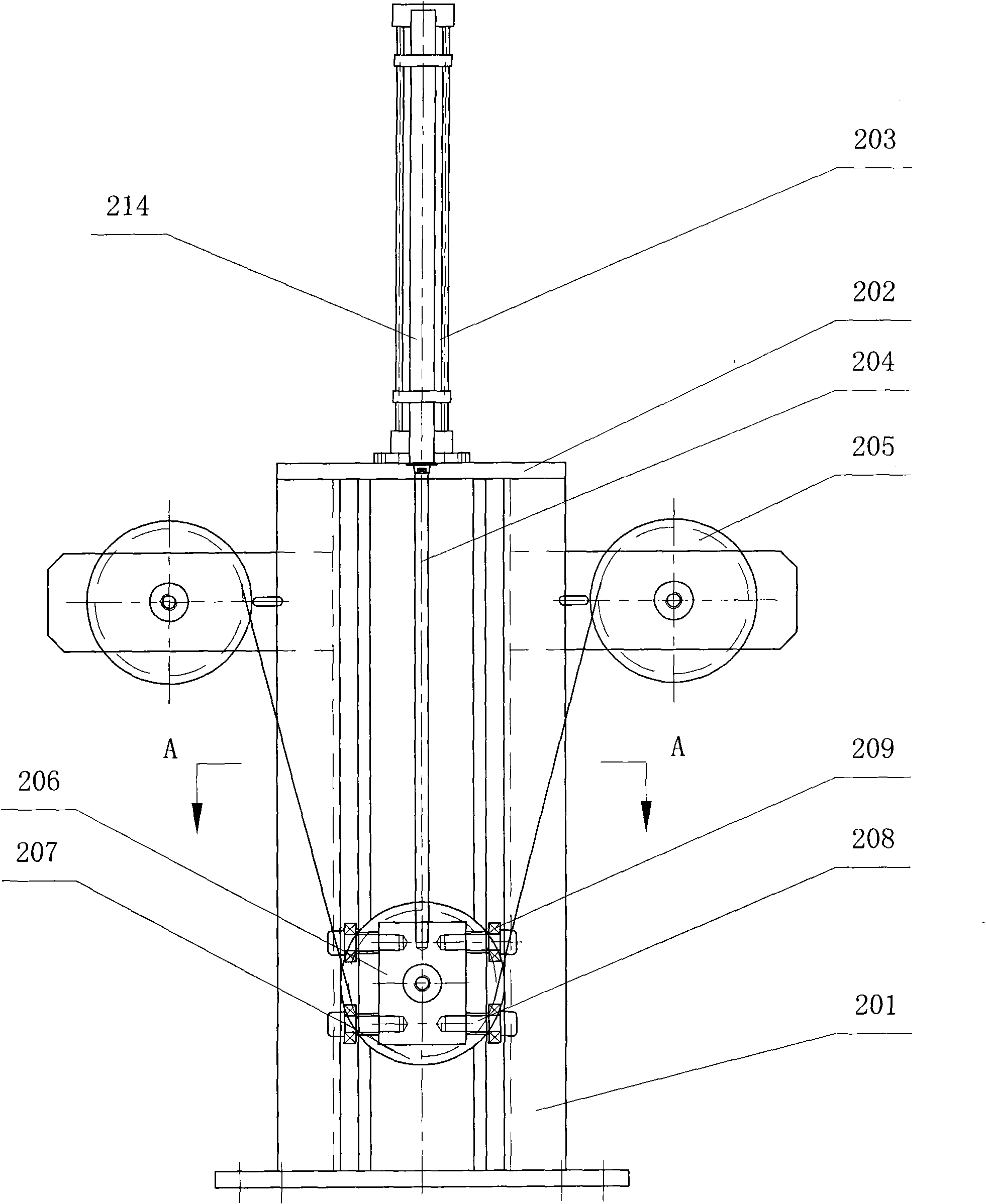

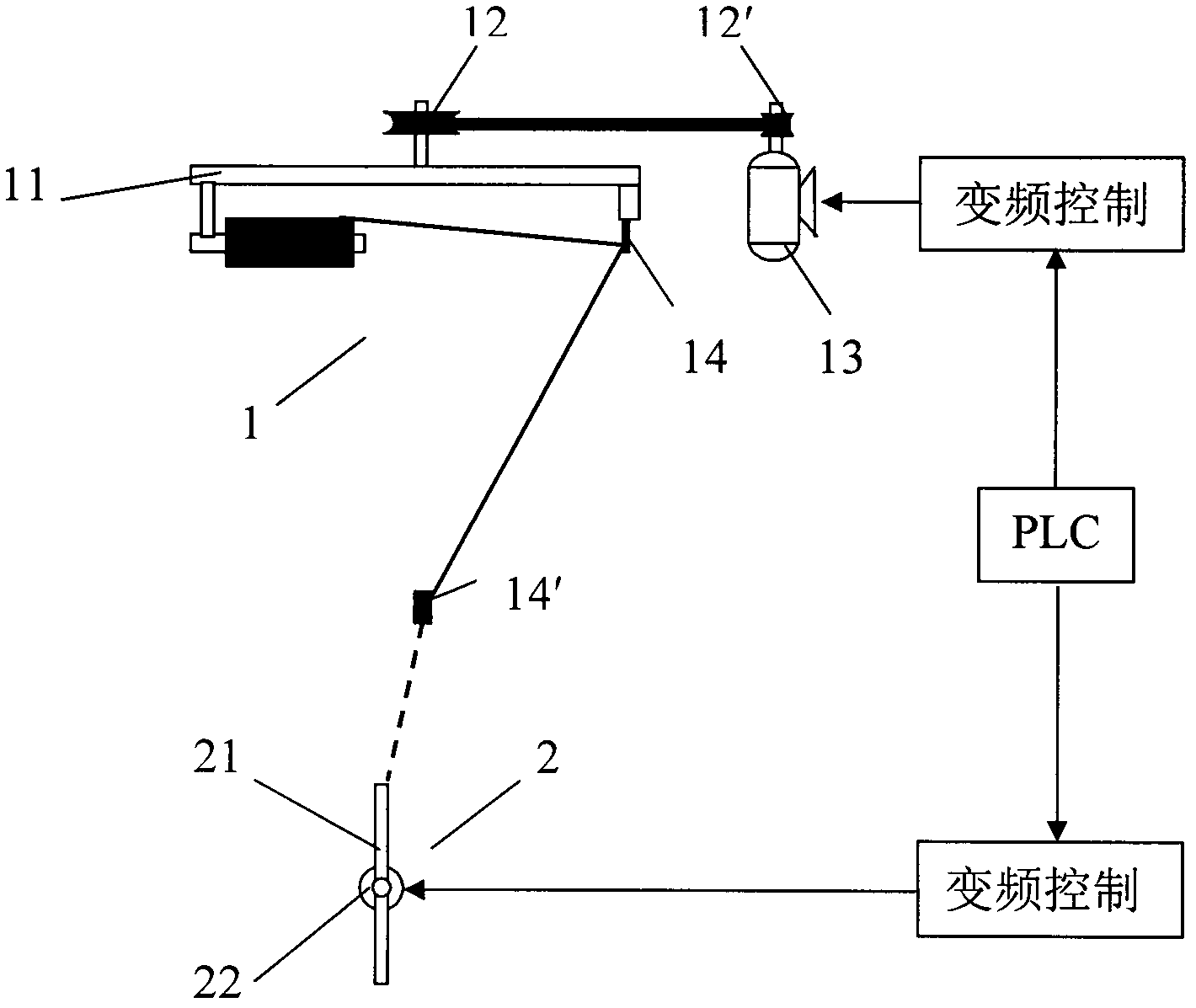

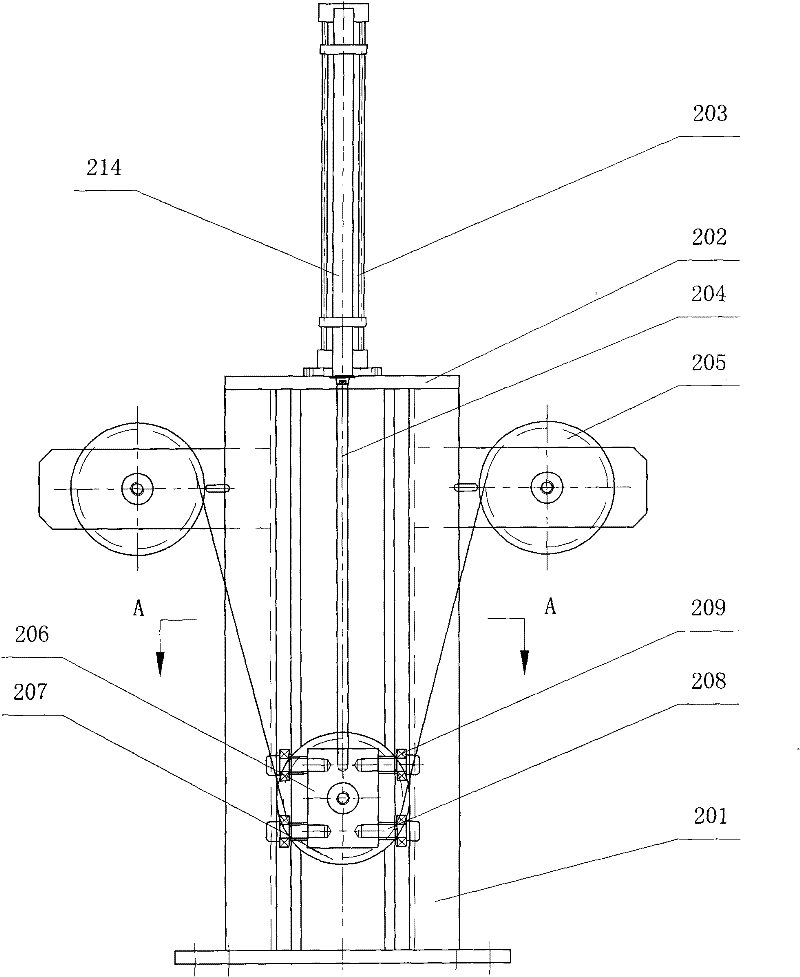

Twisting device for preparing hollow fiber membrane

InactiveCN102580552ASpeed matchEasy to stretchSemi-permeable membranesProgrammable logic controllerMicrofiltration membrane

The invention relates to a twisting device for preparing a hollow fiber membrane by drawing and hole forming. The device comprises an untwisting system for untwisting strands, a reeled silk twisting system and a PLC (Programmable Logic Controller). The device is characterized in that the untwisting system is composed of a rotary rack, a variable-frequency and variable-speed motor and a filament guide hook; the reeled silk twisting system is composed of a rectangular twisting frame and a variable-frequency and variable-speed motor; and the two variable-frequency and variable-speed motors of the untwisting system and the twisting system are connected with the PLC respectively. The device is capable of preparing the reeled silk without twist and is beneficial to the preparation of high-quality hollow fiber microfiltration membrane.

Owner:TIANJIN POLYTECHNIC UNIV

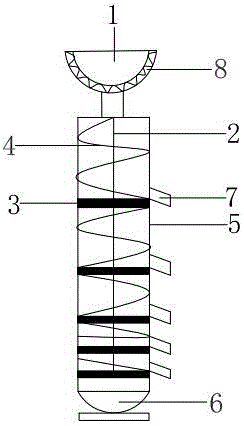

Spiral vibrating type classifying screen

InactiveCN106269473AReduce the chance of missingFine screening resultSievingScreeningDrive motorEngineering

The invention discloses a spiral vibrating type classifying screen. The spiral vibrating type classifying screen comprises a feeding hopper, a driving motor and a vibrating screen, and the vibrating screen is divided by a plurality of screen plates into a plurality of sub vibrating screens; a corresponding barrel is connected to the exterior of each sub vibrating screen, and one barrel, one screen plate, one sub vibrating screen and a corresponding center shaft form one screening compartment; and the hole diameters of screen holes of each screening compartments are the same, and the hole diameters of screen holes of the screening compartments are sequentially reduced from top to bottom. By means of the spiral vibrating type classifying screen, the spiral sub vibrating screens and the screen plates are adopted, screen holes are formed in the sub vibrating screens and the screen plates, and the sub vibrating screens and the screen plates are combined. The spiral sub vibrating screens conduct screening while conducting transporting, and screened materials are screened for the first time. When conveyed to the screen plates, the materials are screened for the second time, and the screened materials enter the next screening compartment. The sub vibrating screens and the screen plates both vibrate under the effects of the driving motor, double guarantees are achieved, the rate of leakage of wee materials is decreased, and the screening result is more exquisite.

Owner:CHENGDU DAHONGLI MACHINERY

Water-jet loom with edge-locking devices

The invention discloses a water-jet loom with edge-locking devices. The water-jet loom comprises a loom body. The loom body comprises a nose, a breast beam and a top beam. The breast beam is disposed in the middle of the loom body. The top beam is disposed on the top of the loom body. Two ends of the breast beam are provided with two edge-locking devices, respectively. A fishnet is discharged from the nose and is edge-locked by the edge-locking devices during looming. Production of the fishnet by the water-jet loom is high in efficiency, production benefit can be effectively improved, no flying floc occurs from the water-jet loom, and no influence is caused to the operating smoothness; the edge-locking devices disposed on the breast beam of the water-jet loom are applicable to edge-locking of the produced fishnet, and thus the quality and strength of fishnet cloth is improved.

Owner:SUZHOU JIUQIANG TEXTILE

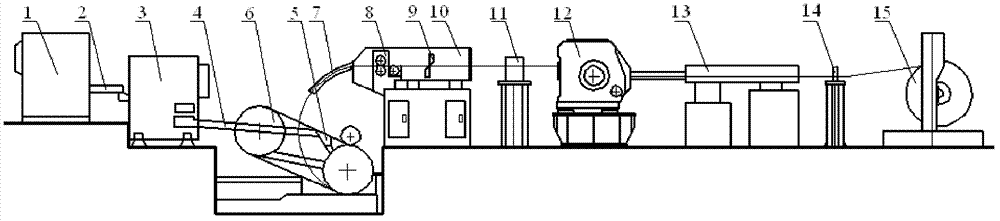

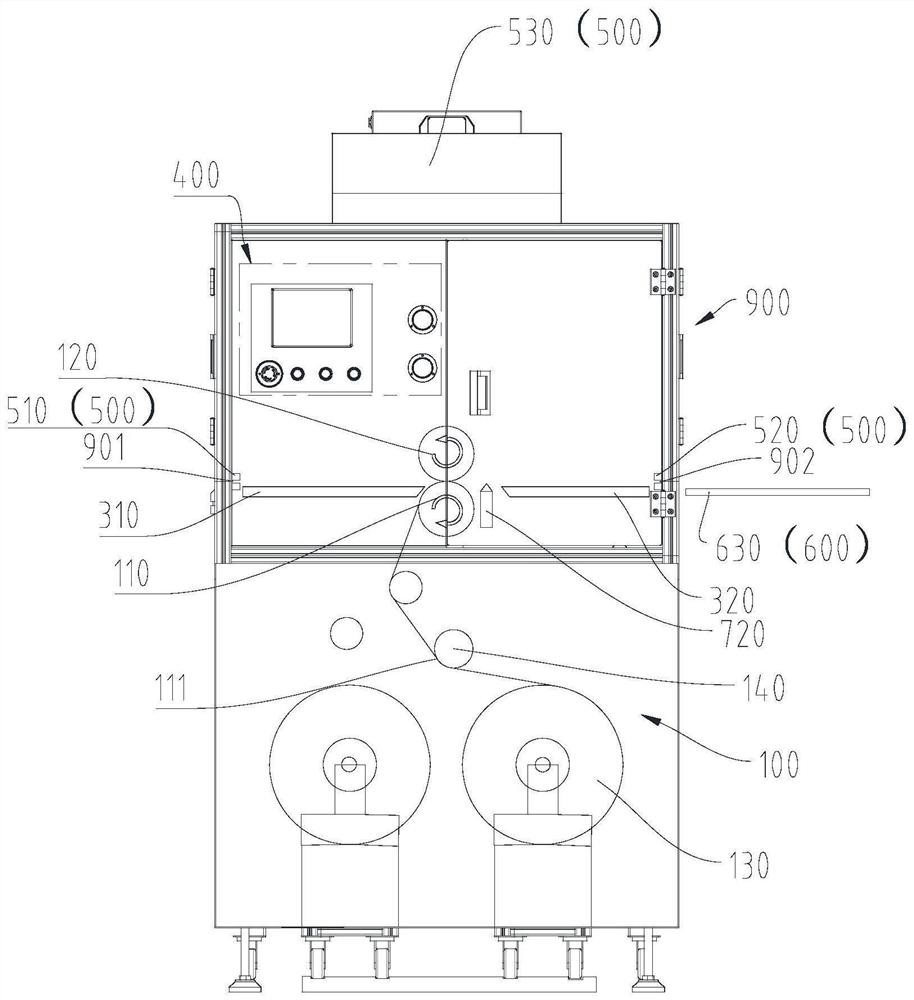

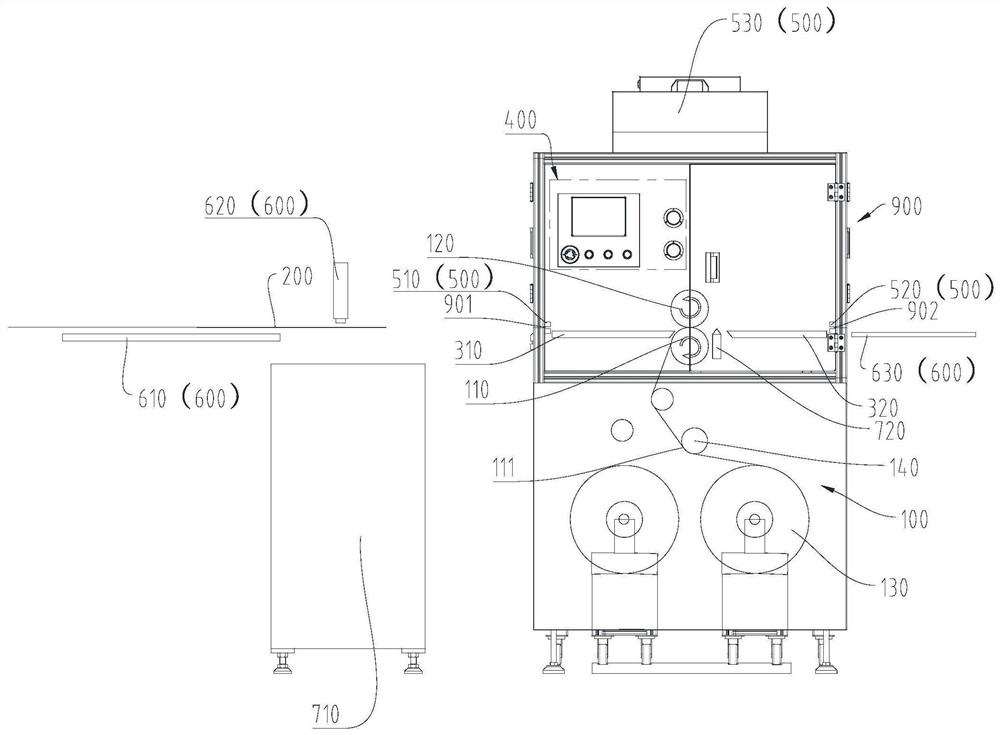

Continuous casting and continuous extrusion device and production method for metal

InactiveCN102303057BOmit coolingShorten the production cycleExtrusion control devicesThermal insulationAlloy

The invention discloses a continuous casting and continuous extrusion device and a production method for a metal, wherein the device comprises a melting furnace, a maintaining furnace, a continuous casting machine, a continuous extruding machine, an anti-oxidation thermal insulation device and a loop device. In the production method, molten metal is poured into a molten metal pond of the continuous casting machine, and the molten metal is cooled and solidified in a compulsive water-cooling crystallizer; a dragger pulls out a casting blank from the crystallizer with certain speed; and the casting blank pulled out is conveyed into the continuous extrusion machine set after passing through the anti-oxidation thermal insulation device. In the method, since the cast metal with afterheat can becontinuously extruded in a direct way, at this moment, the metal has higher plasticity and lower resistance to deformation, greater deformation can be realized with less energy, and energy can be saved; and the device and the method provided by the invention are particularly suitable for the metal and alloy thereof which need to be preheated before continuous extrusion, so that types of alloys processed by continuous extrusion are increased. With the device and the method, multiple work procedures are combined, short flow is implemented, production cycle can be shortened by more than 50%, andproduction efficiency is improved.

Owner:DALIAN JIAOTONG UNIVERSITY

Glass substrate packaging device and method

InactiveCN112550807AAvoid scratchesAvoid defects such as pollutionShock-sensitive articlesComposite materialSi substrate

Owner:福州东旭光电科技有限公司 +2

A punching and conveying device for aluminum plates

ActiveCN105798189BStable outputOutput speed matchingMetal-working feeding devicesPositioning devicesPunchingFlange

A conveying device for aluminum plate punching is provided. Two left vertical plates and two right vertical plates are mounted on a worktable by means of bolts. A lower conveying cylinder and an upper conveying cylinder are mounted on the two left vertical plates by means of bearings and flanges. An upper shaping cylinder and lower shaping cylinders are mounted on the two right vertical plates by means of bearings and flanges. A conveying positioning mechanism is fixed on a circumferential surface of the upper conveying cylinder. During aluminum plate punching, an aluminum plate coil is allowed to pass between the upper shaping cylinder and the lower shaping cylinders and reach between the upper conveying cylinder and the lower conveying cylinder; the upper conveying cylinder and the lower conveying cylinder are enabled to rotate under double action of single power; meanwhile, teeth of a positioning ring mounted on the upper conveying cylinder produce certain occlusion to the aluminum plate to prevent the aluminum plate from displacement. A plurality of motion combinations are adopted, such that the coiled aluminum plate is shaped at the upper shaping cylinder and the lower shaping cylinders to become straight; and finally, the aluminum plate can be accurately conveyed to a punching position. The conveying device is novel in design and reasonable in structure, and capable of ensuring the accuracy of aluminum plate punching and increasing the utilization rate of the aluminum plate.

Owner:宁波宁蒸铝业有限公司

Belt unreeling device

InactiveCN101850485BSpeed matchPrecisely control startup speedWelding/cutting media/materialsSoldering mediaPull forceElectric machinery

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

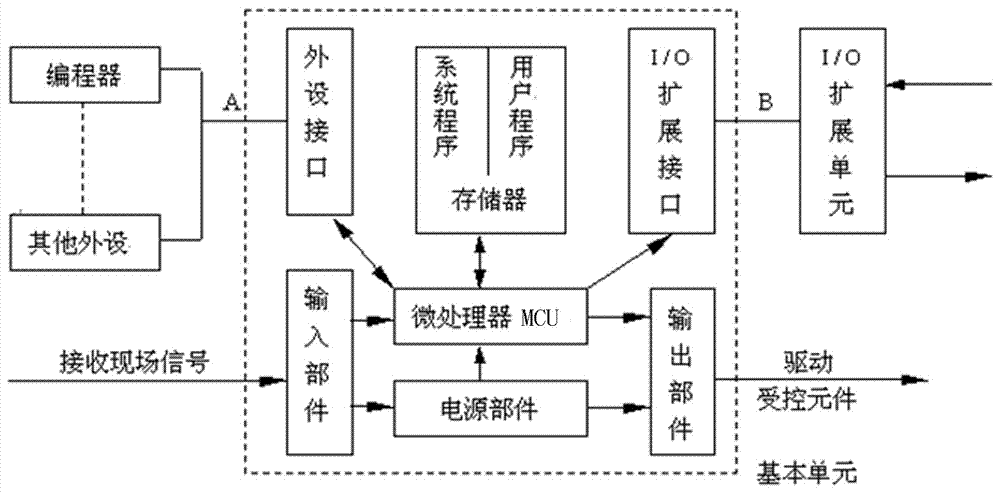

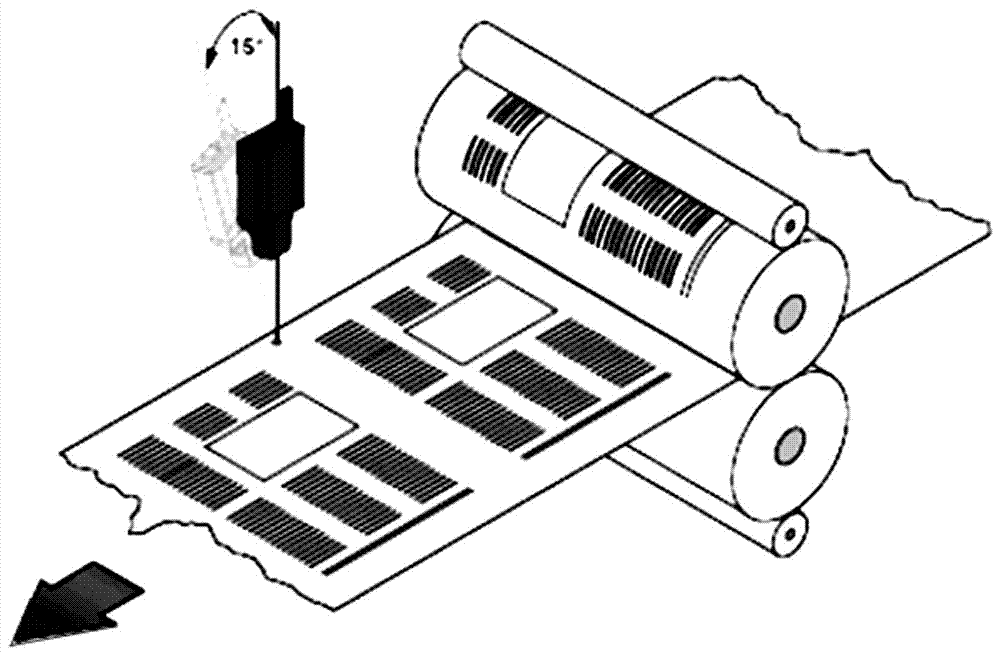

High-speed and high-precision die cutting machine control system based on four-axis motion controller

The invention discloses a high-speed and high-precision die cutting machine control system based on a four-axis motion controller. The system includes a basic unit, a programmer, and an I / O extension unit. The basic unit is equipped with a microprocessor MCU, a memory, an input part, an output part, and the like. The output part is connected with a controlled element and used for driving the controlled element. The controlled element includes a servo motor or a stepper motor. The basic unit has four adjustable pulse outputs, and can drive the four-axis servo motor or stepper motor. The highest frequency of each pulse output can be up to 5MHz, and the repeatability precision is + / -0.1Hz. The number of pulses is between -2,147,483,647 and +2,147,483,648. The system can control gold-stamping printing and die-cutting indentation to make the speeds thereof match each other. The system is mainly applied to a high-speed gold-stamping die cutting machine, which is a special device for printing, packaging industry cartons, paper boxes, trademarks and other products.

Owner:浙江奇赛其科技有限责任公司

Walnut laser opening forming machine based on chain transmission

The invention discloses a walnut laser opening forming machine based on chain transmission, and relates to the field of walnut deep processing equipment. The walnut laser opening forming machine comprises a drawing-in device, a feeding device, a laser opening forming device and a classifying device, wherein the classifying device comprises a bar grating roller and spiral blades; the bar grating roller can perform effective dimension classifying on walnuts; the drawing-in device comprises a feeding bin, a drawing-in cylinder, a roller shaft and rollers; walnut grooves on the circumferential surfaces of the rollers can be utilized to orderly transport classified walnuts to a positioning pipe below the feeding bin; the feeding device comprises a feeding chain and a plurality of walnut supporting grooves; the walnut supporting grooves are fixed to the outer side of the feeding chain at an equal spacing to take the walnuts; and the laser opening forming device is used for forming openings in the walnuts on the walnut supporting grooves. According to the walnut laser opening forming machine based on chain transmission disclosed by the invention, high quality opening forming is guaranteedthrough a manner of laser opening drawing; the classifying device, the drawing-in device and the feeding device are integrally arranged, so that the walnut laser opening forming machine integrates walnut screening, material drawing-in and material feeding, and opening forming; and the walnut laser opening forming machine has the advantages of being excellent in opening forming pretreatment quality, high in efficiency, easy to control and the like.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com