Spiral vibrating type classifying screen

A vibrating sieving and vibrating technology, applied in the direction of sieving, solid separation, grid, etc., can solve the problems that materials cannot be sieved correctly, and the accuracy of screening cannot be guaranteed, so as to reduce the probability of being missed, the collection method is simple, Fine effect of sieving results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

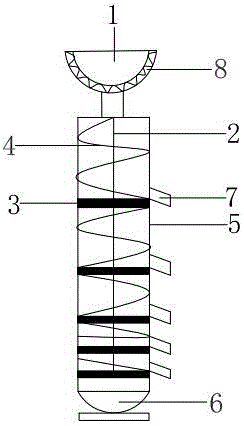

[0031] A spiral vibrating grading screen, comprising a hopper 1, a drive motor and a vibrating screen, the vibrating screen is in a spiral shape and rotates from top to bottom around a central axis 2, and the vibrating screen is divided into multiple parts by a plurality of sieve plates 3. a vibrating sub-sieve 4; each vibrating sub-sieve 4 is externally connected to a corresponding cylinder body 5, and there is no gap between the edge of the vibrating sub-sieve 4 and the cylinder body 5; a cylinder body 5, a sieve plate 3, a vibrating sub-sieve 4 and a vibrating sub-sieve 4 Four of the corresponding central axes 2 form a sieve compartment; the sieve apertures of each sieve compartment are the same size, and the sieve apertures of the sieve compartments decrease successively from top to bottom, and there is a sieve compartment below the bottom sieve compartment A hopper 6; each sieving compartment is connected to a drive motor; the hopper 1 is connected to the uppermost sieving...

Embodiment 2

[0034] A spiral vibrating grading screen, comprising a hopper 1, a drive motor and a vibrating screen, the vibrating screen is in a spiral shape and rotates from top to bottom around a central axis 2, and the vibrating screen is divided into multiple parts by a plurality of sieve plates 3. a vibrating sub-sieve 4; each vibrating sub-sieve 4 is externally connected to a corresponding cylinder body 5, and there is no gap between the edge of the vibrating sub-sieve 4 and the cylinder body 5; a cylinder body 5, a sieve plate 3, a vibrating sub-sieve 4 and a vibrating sub-sieve 4 Four of the corresponding central axes 2 form a sieve compartment; the sieve apertures of each sieve compartment are the same size, and the sieve apertures of the sieve compartments decrease successively from top to bottom, and there is a sieve compartment below the bottom sieve compartment A hopper 6; each sieving compartment is connected to a drive motor; the hopper 1 is connected to the uppermost sieving...

Embodiment 3

[0039] A spiral vibrating grading screen, comprising a hopper 1, a drive motor and a vibrating screen, the vibrating screen is in a spiral shape and rotates from top to bottom around a central axis 2, and the vibrating screen is divided into multiple parts by a plurality of sieve plates 3. a vibrating sub-sieve 4; each vibrating sub-sieve 4 is externally connected to a corresponding cylinder body 5, and there is no gap between the edge of the vibrating sub-sieve 4 and the cylinder body 5; a cylinder body 5, a sieve plate 3, a vibrating sub-sieve 4 and a vibrating sub-sieve 4 Four of the corresponding central axes 2 form a sieve compartment; the sieve apertures of each sieve compartment are the same size, and the sieve apertures of the sieve compartments decrease successively from top to bottom, and there is a sieve compartment below the bottom sieve compartment A hopper 6; each sieving compartment is connected to a drive motor; the hopper 1 is connected to the uppermost sieving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com