Loess formation conduit plugging and annulus external fill balance anti-leakage process

A technology of loess layer and conduit, which is applied in the field of oil drilling, can solve the problems of large water loss in the polymer leakage prevention system, unsatisfactory plugging process effect, and difficult secondary sealing, so as to avoid the risk of wellhead operations by personnel, The effect of saving production time and preventing the loss of loess layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

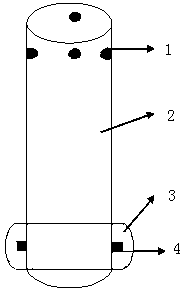

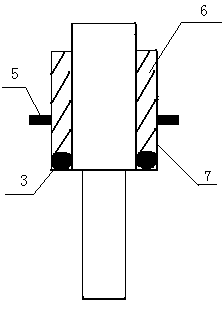

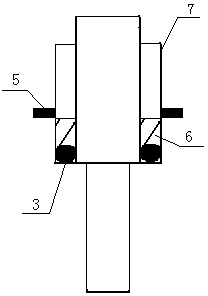

[0038] A loess layer conduit seat plugging, annulus external irrigation balance leak prevention process, including conduit seat plugging, drilling fluid preparation, annulus external grouting plugging slurry, and surface layer drilling. The preparation of the drilling fluid includes: plugging The preparation of mud leakage 6 and the preparation of drilling fluid,

[0039] ① Preparation of plugging slurry

[0040] Isolate the upper water tank connected to the No. 2 pump from other circulation tanks, inject 50 tons of clean water, turn on the agitator, and prepare the plugging slurry with the low-pressure return water of the No. 2 pump. 2.5 tons of bentonite, 5 tons of HD-1 bridge plugging agent, 15 tons of limestone (CaCO 3 ), 15 tons of barite (BaSO 4 ), 0.08 tons of GD-1 high viscoelastic plugging agent, according to the above order of feeding. Mix well and set aside.

[0041] ②Preparation of first drilling fluid (low solid clay slurry)

[0042] Inject 100 tons of clear...

Embodiment 2

[0044]A loess layer conduit seat plugging, annulus external irrigation balance leak prevention process, including conduit seat plugging, drilling fluid preparation, annulus external grouting plugging slurry, and surface layer drilling. The preparation of the drilling fluid includes: plugging The preparation of mud leakage 6 and the preparation of drilling fluid,

[0045] ① Preparation of plugging slurry

[0046] Isolate the upper water tank connected to the No. 2 pump from other circulation tanks, inject 50 tons of clean water, turn on the agitator, and prepare the plugging slurry with the low-pressure return water of the No. 2 pump. 2.5 tons of bentonite, 5 tons of HD-1 bridge plugging agent, 15 tons of limestone (CaCO 3 ), 15 tons of barite (BaSO 4 ), 0.05 tons of GD-1 high viscoelasticity plugging agent, according to the above order of feeding. Mix well and set aside.

[0047] ②Preparation of first drilling fluid (low solid clay slurry)

[0048] Inject 100 tons of ...

Embodiment 3

[0050] A loess layer conduit seat plugging, annulus external irrigation balance leak prevention process, including conduit seat plugging, drilling fluid preparation, annulus external grouting plugging slurry, and surface layer drilling. The preparation of the drilling fluid includes: plugging The preparation of mud leakage 6 and the preparation of drilling fluid,

[0051] ① Preparation of plugging slurry

[0052] Isolate the upper water tank connected to the No. 2 pump from other circulation tanks, inject 50 tons of clean water, turn on the agitator, and prepare the plugging slurry with the low-pressure return water of the No. 2 pump. 2.5 tons of bentonite, 5 tons of HD-1 bridge plugging agent, 15 tons of limestone (CaCO 3 ), 15 tons of barite (BaSO 4 ), 0.1 tons of GD-1 high viscoelasticity plugging agent, according to the above order of feeding. Mix well and set aside.

[0053] ②Preparation of first drilling fluid (low solid clay slurry)

[0054] Inject 100 tons of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com