Grease-proof, heat-resistant expansion type flame-proof rubber

A technology of flame-retardant rubber and oil-resistant rubber, applied in the field of flame-retardant rubber, can solve the problems of loss of heat-resistant and moisture-resistant properties of intumescent flame-retardant rubber, difficulty of gas source expansion, and lack of high-temperature flame resistance, etc. Achieving good heat resistance and stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

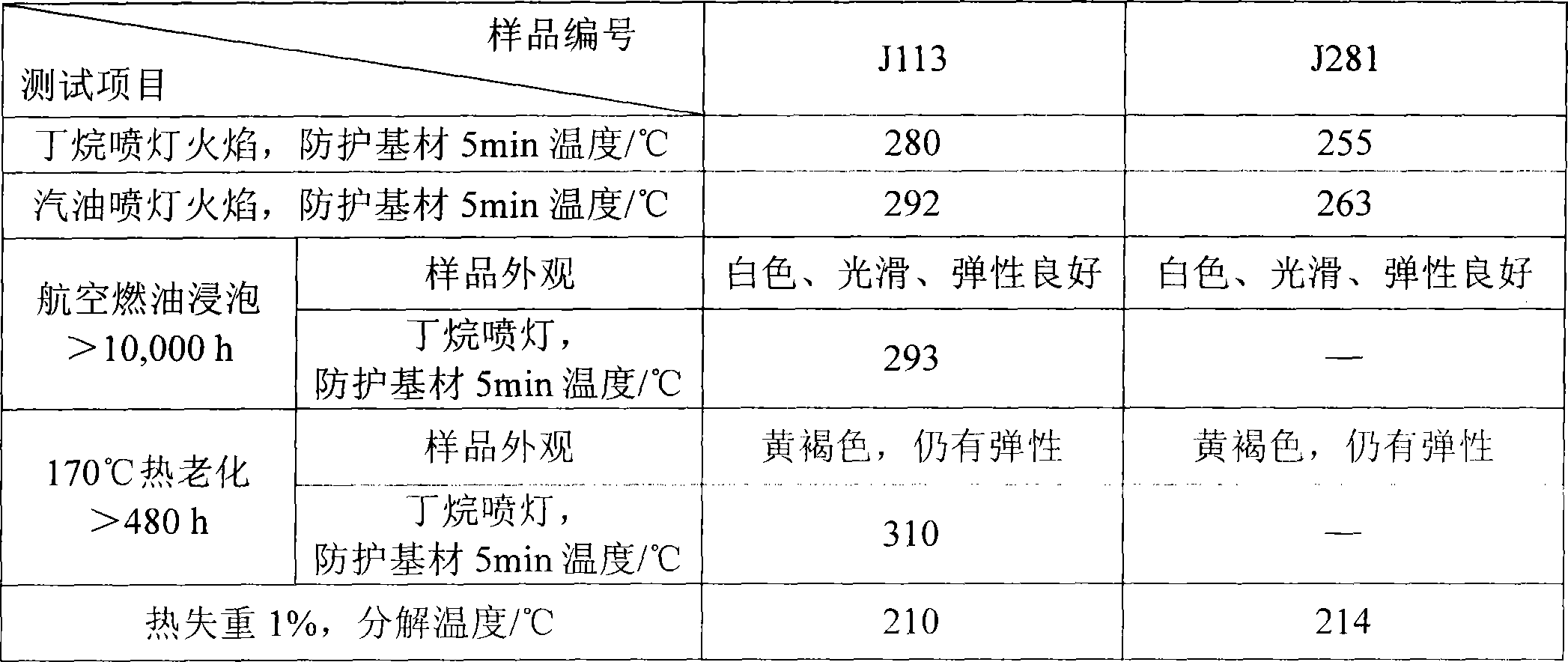

[0034] The embodiment of the intumescent flame-retardant rubber of the present invention is measured by the mass of the matrix resin as 100 parts, and the remaining components are calculated relative to the content of 100 parts of the resin (phr, the number of fillers added per 100 parts of the resin). Table 2 shows the composition content and technical performance indicators of the intumescent flame-retardant rubber formula.

[0035] Table 2 Components and performance indicators of flame retardant rubber examples of the present invention

[0036] Example 1

Example 2

Example 3

Example 4

Oil resistant rubber

100

100

100

100

Resin viscosity modifier / phr

6

8

10

22

Ammonium polyphosphate / phr

80

80

80

80

Melamine / phr

8

8

8

10

Zinc borate / phr

8

8

8

8

Inorganic nanofiller / phr

8

12

14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com