Patents

Literature

64results about How to "Heat aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous PU fog face rubbing surface treatment agent for synthetic leather and preparation method thereof

The invention discloses an aqueous PU fog face rubbing surface treatment agent for synthetic leather, comprising the following components by weight percentage: 40-50% of aqueous polyurethane resin, 30-40% of water, 3-6% of matting agent, 1-5% of organic silicon antifoaming agent, 0.5-5% of organic silicon flatting agent and 0.5-5% of aqueous polyurethane thickener. The surface treatment agent provided by the invention takes water as solvent which replaces poisonous solvents such as dimethylformamide and butanone and has the performances of non-combustion, safety, environmental protection and less cost; after being treated by the surface treatment agent provided by the invention in a wiping manner, the prepared leather has good fog face rubbing effect, sharp contrast between colours of a surface layer and a rubbing layer, good visual effect and excellent general effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

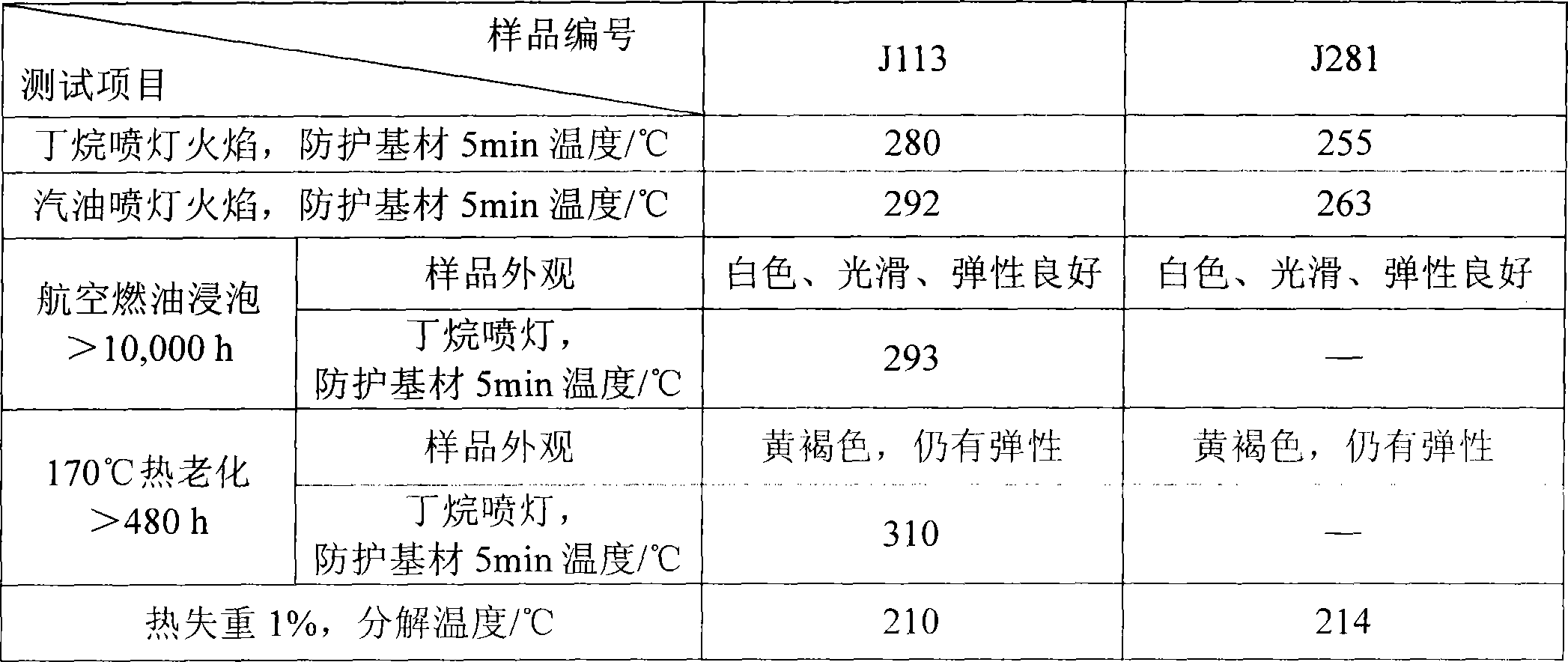

Grease-proof, heat-resistant expansion type flame-proof rubber

This invention discloses an expansion fire-retardant rubber with resistance to oil and heat, particularly being applicable to fire safety protection of conductor bundles in all enclosed spaces, and relates to the technical field of the fire-retardant rubber which is composed by the components with the following portions by weight: 40 to 60 percent of oil-resistant rubber, 5 to 10 percent of resin viscosity regulator, 20 to 40 percent of ammonium polyphosphate, 3 to 10 percent of melamine, 2 to 8 percent of zinc borate, 5 to 20 percent of nano-inorganic and 1 to 5 percent of silica white. The fuel immersion swelling rate of the fire-retardant rubber is zero; when the rubber thickness is less than or equal to 1.0mm, the fire resistance duration is more than or equal to 5 min with the flame temperature of 1200 DEG C and the protected substrate temperature of being less than or equal to 300 DEG C. The fire-retardant rubber of the invention has resistance to heat and ageing, and flexibility and can be used for the fire safety protection of various the conductor bundles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Aqueous PU velvet resin used for synthetic leather

InactiveCN101634109ALow costThe ratio is scientific and reasonableFibre treatmentDimethyl formamideChemistry

The invention discloses an aqueous PU velvet resin used for synthetic leather, which comprises the following raw materials by weight percent: 40-50% of aqueous polyurethane resin, 40-50% of water, 2-5% of low-temperature sheep bar powder, 2-4% of silicon dioxide velvet powder, 1-3% of organic silicone oil smoothing agent, 1-4% of extinction powder, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent and 0.5-2% of aqueous polyurethane thickening agent. The aqueous PU velvet resin used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the advantages of being non-combustible, safe and environment-friendly, saving cost and the like. The aqueous PU velvet resin also has the advantages of good film-forming resistance, firm bonding, coating solvent resistance, cold resistance, hydrolysis resistance and heat-proof aging. Products fabricated by using the resin have the characteristics of plump feel, unique velvet effect, strong real leather quality, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Adhesive tape used for solar cell assembly and preparation method thereof

InactiveCN102816536AGood adhesionGood initial tackFilm/foil adhesivesEster polymer adhesivesAmmonium sulfateEmulsion

The invention relates to a double-sided adhesive tape, and specifically relates to the double-sided adhesive tape used for a solar cell assembly and a preparation method thereof. The double-sided adhesive tape comprises a substrate, an adhesive, a backlining and backlining glue, wherein the adhesive mainly comprises the following components of, by weight, 0.5-1 part of ammonium sulfate, 5-10 parts of methyl methacrylate, 55-65 parts of butyl acrylate, 20-30 parts of hydroxymethyl acrylamide, 1-2 parts of a composite emulsifier, 60-70 parts of a tackifying resin, 0.2-0.8 part of acrylic acid, 1-2 parts of hydroethyl methacrylate, 1-1.5 parts of 2-acrylamide-2-methylpro panesulfonic acid and 1-3 parts of 3-(methacryloxy)propyltrimethoxysilane. The preparation method comprises the steps of firstly pre-preparing a high-strength organosilicone and acrylate co-polymeric emulsion pressure-sensitive adhesive; and then performing operations of double roll reverse coating, drying, compositing, transferring and the like with a B-50 multifunctional coating machine, wherein both the font side and the back side of the backlining of the substrate are already coated by a layer of low-adhesivity backlining glue.

Owner:SUZHOU DATONG ADVANCED MATERIAL

Waterborne PU high smooth wax resin for synthetic leather

The invention discloses a waterborne PU high smooth wax resin for synthetic leather and the resin comprises the following raw materials by weight percent: 30-40% of waterborne silicon-fluorine resin,20-30% of waterborne polyurethane, 10-30% of water, 0.2-0.8% of waterborne wax emulsion, 1-3% of organic silicone oil smoothing agent, 0.5-1% of organic silicone flatting agent, 2-5% of organic silicone defoamer and 0.5-2% of waterborne polyurethane thickener. The waterborne PU high smooth wax resin for synthetic leather provided by the invention uses water as solvent instead of toxic solvents such as dimethyl formamide, butanone and the like and has the advantage of noninflammability, safety, environmental protection, cost-saving and the like. The finished product prepared from the waterbornePU high smooth wax resin for synthetic leather provided by the invention has full hand feeling, high luster and high luminance, extremely smooth waxy feeling, delicate texture and good air permeability; and the prepared synthetic leather has good comprehensive effect in hand feeling, smoothness, water resistance, waxy feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-soluble PU nubuck low-temperature foamex for synthetic leather

InactiveCN101666039ALow costThe ratio is scientific and reasonableFibre treatmentSolventWater soluble

The invention discloses water-soluble PU nubuck low-temperature foamex for synthetic leather, prepared by the following raw materials in percentage by weight: 30-40 percent of water-soluble polyurethane, 40-50 percent of water, 2-10 percent of low-temperature nubuck foam powder, 2-5 percent of organosilicon levelling agent, 2-5 percent of organosilicon antifoaming agent and 0.5-2 percent of water-soluble polyurethane thickener. The mixture ratio of each component of the water-soluble PU nubuck low-temperature foamex for synthetic leather is scientific and reasonable, and the components mutually coordinate and jointly act. The nubuck low-temperature foamex has the advantages of good film reforming property and firm adhesion, and coating is resistant to solvent, cold, hydrolysis and thermalageing. The original effect of the leather surface of a finished product prepared from the water-soluble PU nubuck low-temperature foamex can not be influenced; after the leather surface is treated bythe foamex, low-temperature foaming is carried out to produce nubuck leather, and therefore, the effect of the leather surface is unique; moreover, the synthetic leather has exquisite texture, good air permeability and excellent resultant effect of hand feeling, water proofing, adhesion and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU high solid resin combination for synthetic leather

The invention discloses a water-based PU high solid resin combination for synthetic leather, which comprises the following materials by weight percent: 25 to 35 percent of water-based polyurethane resin, 45 to 55 percent of water, 10 to 20 percent of modified organic silicon polymer, 0.5 to 1.5 percent of organic silicon flatting agent, 1 to 3 percent of organic silicon foam killer and 1.5 to 4.5 percent of water-based polyurethane thickening agent. The water-based PU ironing finishing agent has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the high solid resin combination has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the high solid resin combination, has the advantages that the original effect of the leather surface is not affected, raised patterns on the leather surface are sufficient in contrast to the leather sole after the leather surface is treated and modified, and the leather surface has unique high solid effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU brush surface conditioning agent for synthetic leather

InactiveCN101705623AExcellent crosslink hardnessGood recoatabilityFibre treatmentWater basedSilicon dioxide

The invention discloses a water-based PU brush surface conditioning agent for synthetic leather, which comprises the following materials by weight percent: 10 to 20 percent of water-based stoving varnish resin, 1 to 6 percent of water-based polyurethane, 60 to 70 percent of water, 5 to 13 percent of silicon dioxide matting agent, 0.5 to 2 percent of organic silicon flatting agent, 1 to 5 percent of organic silicon foam killer and 2 to 6 percent of water-based modified polyethylene wax emulsion. In the water-based PU brush surface conditioning agent for synthetic leather, water is taken as solvent to replace noxious solvents, such as dimethyl formamide and butanone, so that the water-based PU brush surface conditioning agent has the performances of non-inflammation, safety, environmental protection and cost saving, and resin has the advantages of good film reforming property, firm bonding, solvent resistance, cold resistance, hydrolysis resistance and thermosenescence resistance of coating, and the finished product made of the surface conditioning agent has unique brush effect, strong dermis effect, water resistance and good air permeability.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU matte surface finishing agent for synthetic leather

The invention discloses a water-based PU matte surface finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 45 to 55 parts of water, 4 to 10 parts of modified organic silicon polymer, 0.5 to 1.5 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 3 to 5 parts of modified organic silicon matting agent. For the water-based PU matte surface finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Hydraulic PU crazy horse resin for synthetic leather

The invention discloses a hydraulic PU crazy horse resin for synthetic leather; the hydraulic PU crazy horse resin is constituted by the following raw materials by weight percentage: 35-45 percent of waterborne polyurethane, 30-40 percent of water, 5-8 percent of silicon dioxide color changing powder, 1-3 percent of silicone oil slip agents, 1-4 percent of extinction powder, 0.5-1 percent of organic silicon flatting agent, 2-5 percent of silicone defoaming agents, 0.5-2 percent of waterborne polyurethane thickeners and 2-5 percent of villus. The hydraulic PU crazy horse resin for synthetic leather takes water as solvent, toxic solvents such as dimethyl fomamide and butanone are replaced, therefore, the hydraulic PU crazy horse resin has non-inflammable, safe, environmental-protection, cost-saving performances, and the crazy horse resin has the advantages of good film forming property, firm adhesion, solvent-proof, cold-resistance, hydrolyzation-resistance and heat-proof ageing coating. The finished products manufactured by the crazy horse resin has the advantages of full handle, good crazy horse color-changing effect, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water PU cracking resin for synthesizing leather

The invention discloses water PU cracking resin for synthesizing leather, which comprises following materials in percentage by weight: 60-70 percent of water polyurethane resin, 20-35 percent of water, 0.3-2 percent of organic silicon flatting agent and 0.5-4 percent of water polyurethane thickener. The water PU cracking resin for synthesizing leather uses water as solvent to replace dimethyl formamide and butanone and other toxic solvents, thereby achieving the non-inflammable, safe, environmental-protection and cost-saving performance. In addition, the cracking resin has the advantages of good film forming, firm bonding, solvent-resist, cold resist, hydrolysis-resist and heat aging-resist performances, and the like. Finished products made by using the cracking resin have the advantages of excellent cracking effect, better real leather quality, fine and smooth texture, good air permeability, and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

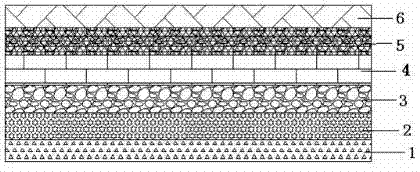

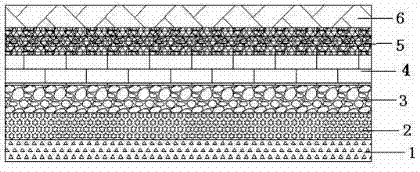

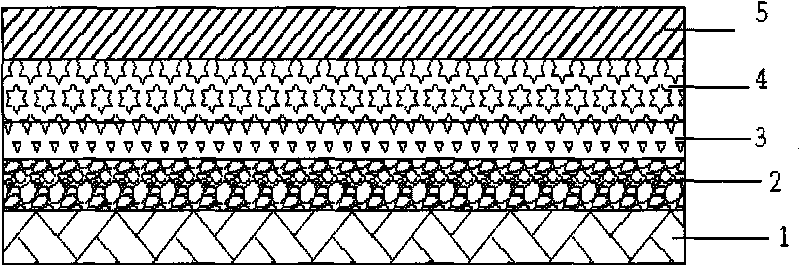

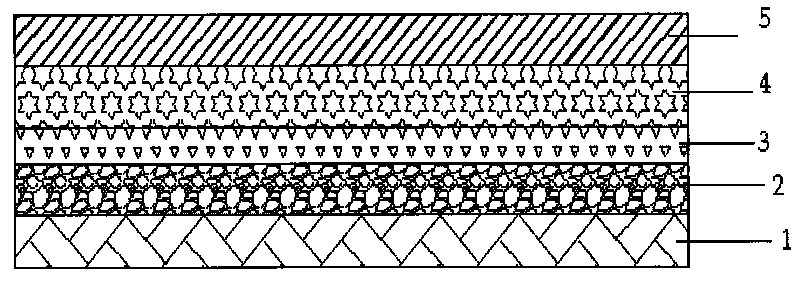

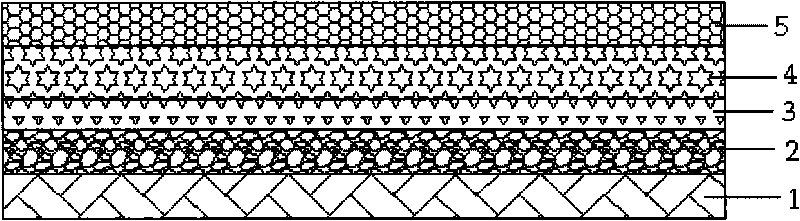

Crystal-like synthetic leather having contraction pattern

InactiveCN102407637AWith high glossStrong sense of transparencySynthetic resin layered productsSpecial ornamental structuresPolymer sciencePolyurethane adhesive

The invention discloses crystal-like synthetic leather having a contraction pattern. The synthetic leather comprises a base cloth layer (1), a modified polyurethane foaming layer (2) coated on the base cloth layer (1), a polyurethane adhesive layer (3) coated on the modified polyurethane foaming layer (2), an aqueous polyurethane resin layer (4) coated on the polyurethane adhesive layer (3), an acrylic resin layer (5) coated on the aqueous polyurethane resin layer (4) and a crystal-like resin (6) coated on the acrylic resin layer (5). Contracted lines of the synthetic leather provided in the invention can generate different patterns according to difference of lines of release paper, producing a unique visual effect; the obtained synthetic leather has the effects of high brightness and high light, a strong sense of transparency and crystal and the advantages of smoothness, a strong leather feel and the like.

Owner:WUJIANG SANHUI TEXTILE

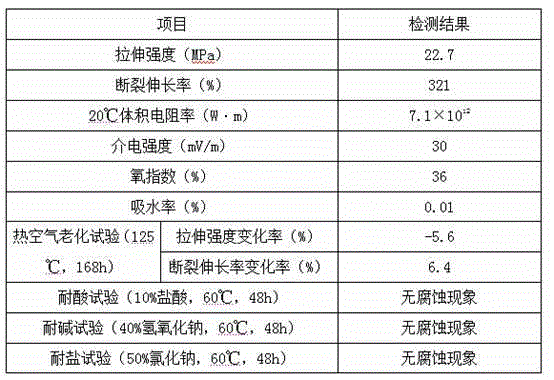

Waterproof chemical-corrosion-resistant heat tracing cable sheath material and preparation method thereof

InactiveCN104479191AGood chemical resistanceImprove waterproof performancePlastic/resin/waxes insulatorsInsulated cablesPolyethylene glycolMaterials science

The invention discloses a waterproof chemical-corrosion-resistant heat tracing cable sheath material and a preparation method thereof, the waterproof chemical-corrosion-resistant heat tracing cable sheath material comprises the following raw materials by weight: 38-56 parts of high density polyethylene, 22-34 parts of polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol ester, 18-26 parts of polypropylene random copolymer, 15-20 parts of wollastonite powder, 10-15 parts of alum powder, 3-7 parts of calcium phosphate tribasic, 4-8 parts of zinc hydroxystannate, 2-3 parts of polymethyl triethoxy silane, 16-22 parts of basalt fiber powder, 1.5-2.5 parts of barium naphthenate, 3-4 parts of calcium rosinate, 10-15 parts of dioctyl terephthalate, 5-10 parts of strontium hydroxide, 3-5 parts of N-hydroxymethyl stearamide, 8-12 parts of tricresyl phosphate, 10-15 parts of calcium borate, 1-2 parts of 4-chloro-N-(stearamide methyl) pyridine, and 2.5-4.5 parts of additives. The cable sheath material has good chemical corrosion resistance, strong waterproofness, also has high mechanical strength, good flexibility, heat aging resistance, excellent mechanical damage resistance and other characteristics, long service life, low cost, no environmental pollution, and wide application prospect.

Owner:ANHUI ANNENG CABLE

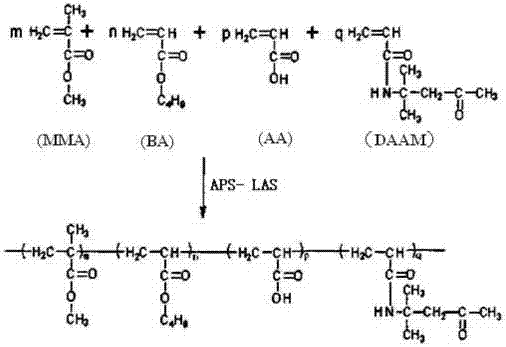

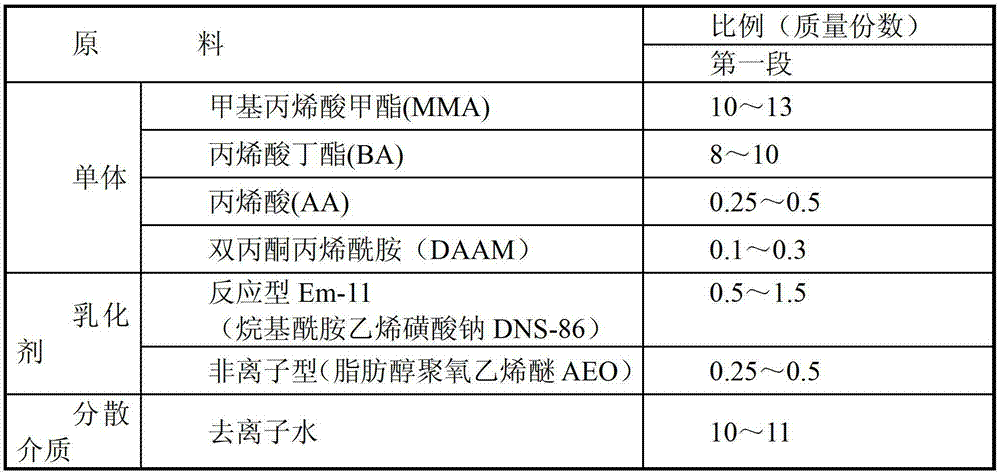

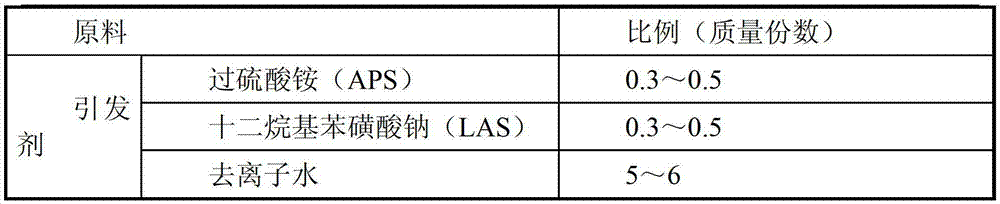

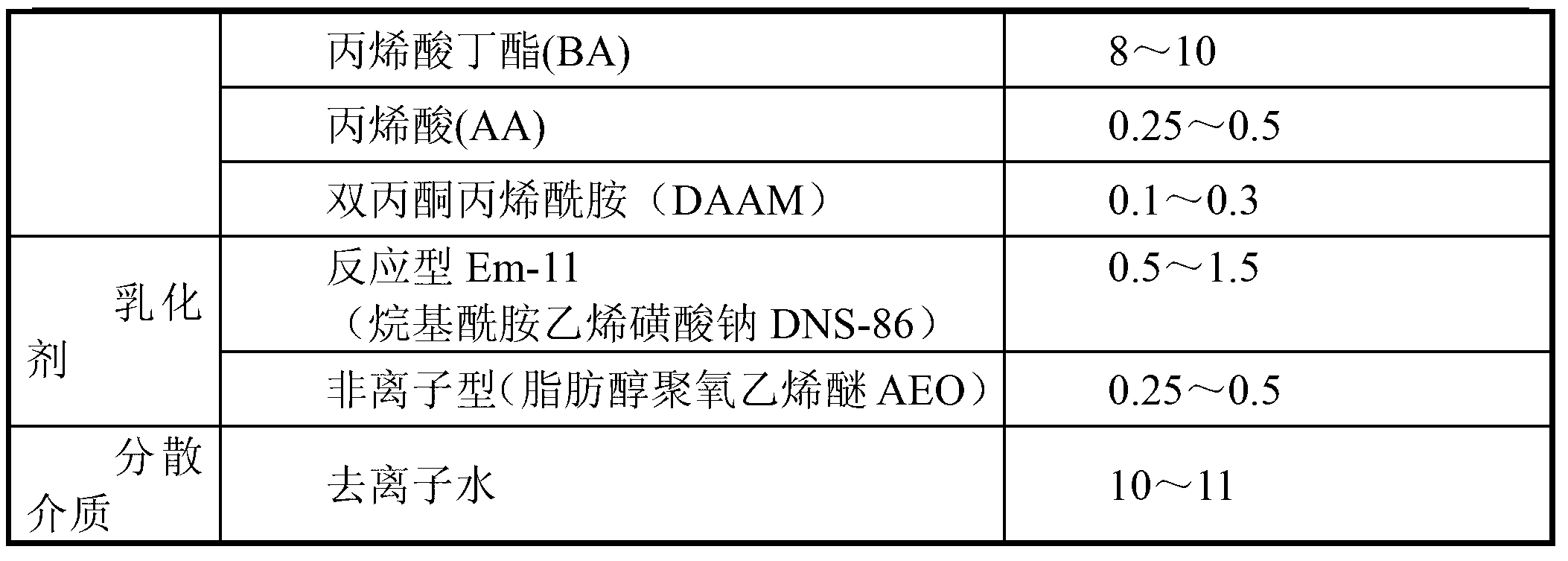

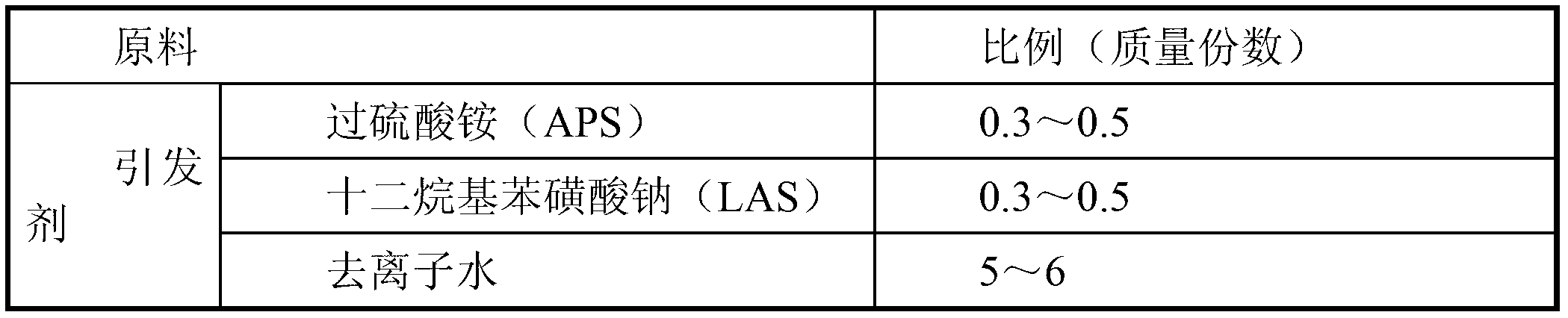

Water-based polyacrylate emulsion

The invention discloses a water-based polyacrylate emulsion, which is prepared from a preliminary emulsion, a seed emulsion, a secondary emulsion, 10% adipic dihydrazide aqueous solution and ammonia water, wherein the preliminary emulsion is prepared from methyl methacrylate, butyl acrylate, acrylic acid, diacetone-acryloamide, sodium alkyl amide vinyl sulfonate, fatty alcohol-polyoxyethylene ether and de-ionized water; the secondary emulsion is composed of monomers and an emulsifier, and the monomers include methyl methacrylate, butyl acrylate, acrylic acid and diacetone-acryloamide; and the emulsifier is prepared from fatty alcohol-polyoxyethylene ether and de-ionized water. The water-based polyacrylate emulsion is characterized in that diacetone-acryloamide (DAAM) is introduced into the system and simultaneously, adipic dihydrazide (ADH) is introduced to modify the branch chain so that the cross-linking sites in a system can be increased through introduction of diacetone-acryloamide (DAAM) and adipic dihydrazide (ADH) to modify a branch chain, so that the self-cross-linking performance of water-based PA can be improved and medium-temperature self-cross-linked base slurry is formed; and the roasting temperature can be appropriately reduced by 10-30 DEG C so that energy source can be saved.

Owner:长兴三伟热熔胶有限公司

Aqueous PU color changing treating agent used for synthetic leather

InactiveCN101634110ALow costThe ratio is scientific and reasonableFibre treatmentEnvironmental chemistryColor changes

The invention discloses an aqueous PU color changing treating agent used for synthetic leather, which comprises the following raw materials by weight percent: 30-40% of aqueous polyurethane resin, 10-15% of emulsifying agent, 1-3% of amino silicone oil, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon antifoaming agent, 0.5-2% of aqueous polyurethane thickening agent and 40-60% of water. The aqueous PU color treating agent used for synthetic leather of the invention takes water as solvent to replace toxic solvent, such as dimethyl fomamide, butanone and the like and has the performance of being non-combustible, safe, environment-friendly and saving cost. The aqueous PU color treating agent also has the advantages of no influence on the original effect of leather surfaces, good hand feel, fine and smooth texture, good air permeability and the like, especially when being used in treating sheep bar leather. The synthetic leather manufactured by the color changing treating agent in the invention has fine comprehensive effects, such as hand feel, smoothness, water proof, waxy feel and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

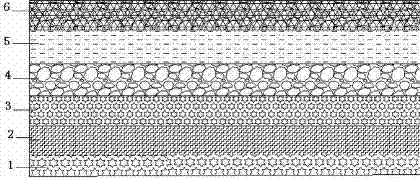

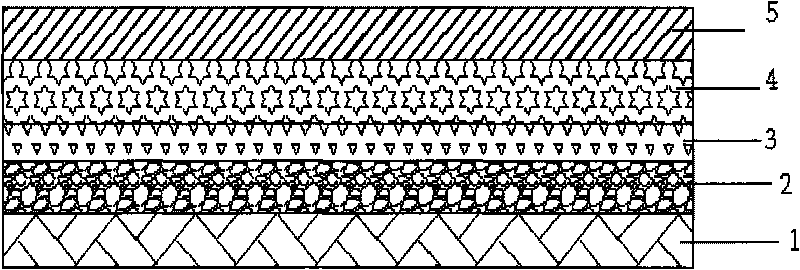

Synthetic leather with crazy horse contracted patterns

InactiveCN101694066ARealistic leather effectUnique visual effectsTextiles and paperPolyurethane adhesiveChemistry

The invention discloses synthetic leather with crazy horse contracted patterns, which comprises a substrate cloth layer (1), a polyurethane foaming layer (2) coated on the substrate close layer (1), a polyurethane adhesive layer (3) coated on the polyurethane foaming layer (2), crazy horse resin (4) coated on the polyurethane adhesive layer (3), modified polyurethane resin (5) coated on the crazy horse resin (4) and acrylic modified resin (6) coated on the modified polyurethane resin (5). In the synthetic leather, the crazy horse resin coated on the polyurethane adhesive layer can grow naps after performing posterior water massage treatment, has special nap feeling and is high in corium effect when adding with color-changing effect. In addition, the acrylic modified resin coated on the modified polyurethane resin can generate different patterns when combining and using contracted texture according to texture of release paper due to difference of polarities of the acrylic modified resin and the modified polyurethane resin, and then the synthetic leather has unique visual effect and strong visual aesthetics.

Owner:JIANGSU BAOZE POLYMER MATERIAL

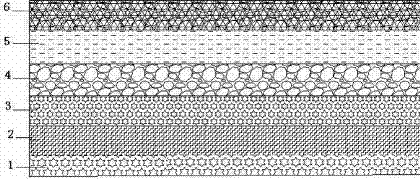

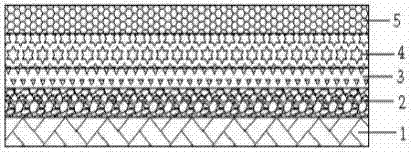

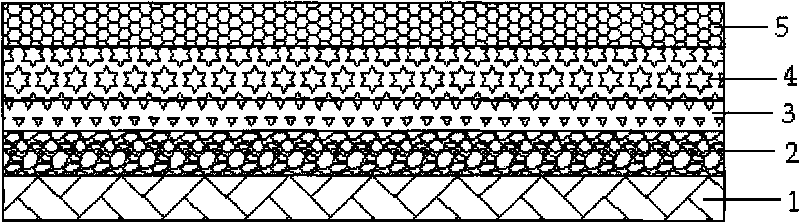

Synthetic leather with crystal-feel crazy horse contracted patterns

InactiveCN102409548ARealistic leather effectUnique visual effectsSynthetic resin layered productsSpecial ornamental structuresPolymer chemistryPolymer science

The invention discloses synthetic leather with crystal-feel crazy horse contracted patterns. The synthetic leather comprises a base cloth layer (1), a modified polyurethane foaming layer (2) coated on the base cloth layer (1), a polyurethane bonding layer (3) coated on the modified polyurethane foaming layer (2), a modified polyurethane resin layer (4) coated on the polyurethane bonding layer (3), a crystal-feel resin layer (5) coated on the modified polyurethane resin layer (4) and a crazy horse resin layer (6) coated on the crystal-feel resin layer (5). The synthetic leather provided by the invention has a highlight effect and strong transparent and crystal feeling; the crazy horse resin layer has a special crazy horse discoloring effect; and particularly after the posterior water kneading treatment, fluff is grown on the crazy horse resin layer so that the synthetic leather has special fluffy feeling and a vivid real-leather effect.

Owner:WUJIANG SANHUI TEXTILE

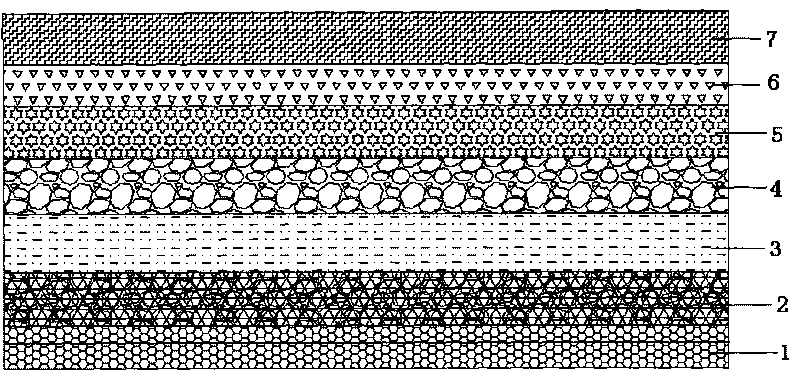

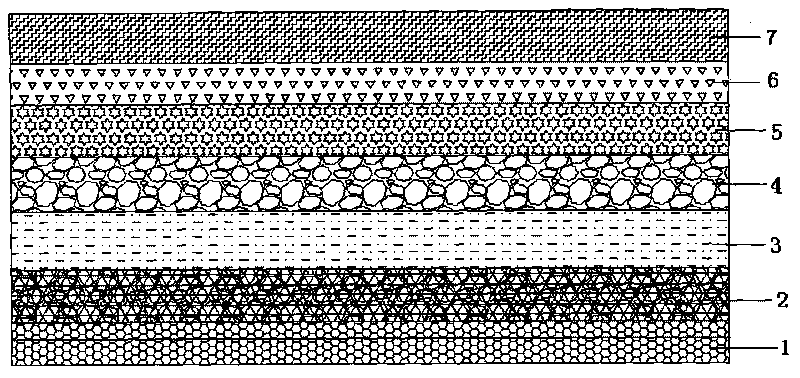

Contracted pattern synthetic leather with patent leather feeling

InactiveCN101694067AUnique visual effectsWith high glossSynthetic resin layered productsTextiles and paperPolyurethane adhesiveAcrylic resin

The invention discloses contracted pattern synthetic leather with patent leather feeling, which comprises a substrate cloth layer (1), a polyurethane foaming layer (2) coated on the substrate cloth layer (1), a polyurethane adhesive layer (3) coated on the polyurethane foaming layer (2), acrylic resin (4) coated on the polyurethane adhesive layer (3), modified polyurethane resin (5) coated on the acrylic resin (4), crystal feeling resin (6) coated on the modified polyurethane resin (5) and high-strength polished resin (7) coated on the crystal feeling resin (6). Contracted texture of the acrylic resin layer and the modified polyurethane resin layer can generate different patterns according to texture of release paper due to difference of polarities of the acrylic resin and the modified polyurethane resin layer, the crystal feeling resin and the high-strength polished resin can be used integrally, and then the synthetic leather not only has characteristics of high gloss and high brightness, but also has the advantages of smoothness, scrapping resistance, napped feeling, strong corium feeling and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Water-based PU matte surface color fixing finishing agent for synthetic leather

The invention discloses a water-based PU matte surface color fixing finishing agent for synthetic leather, which comprises the following materials in parts by weight: 30 to 40 parts of water-based polyurethane resin, 50 to 60 parts of water, 3 to 6 parts of modified organic silicon polymer, 1 to 2 parts of organic silicon flatting agent, 1 to 2 parts of organic silicon foam killer, 1 to 2 parts of water-based polyurethane thickening agent, and 2 to 3 parts of modified organic silicon matting agent. For the water-based PU matte surface color fixing finishing agent, the mixture ratio of the components is scientific and reasonable, and the components are coordinated with each other and act together. The matte surface color fixing finishing agent has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating. The finished product made of the synthetic leather, the surface of which is treated by the matte surface finishing agent, has the advantages that the original effect of the leather surface is not affected, particularly the combined application of the modified organic silicon matting agent and the polyurethane resin ensures that the treated leather surface has unique matte surface color fixing effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

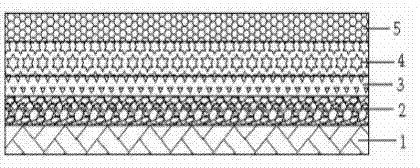

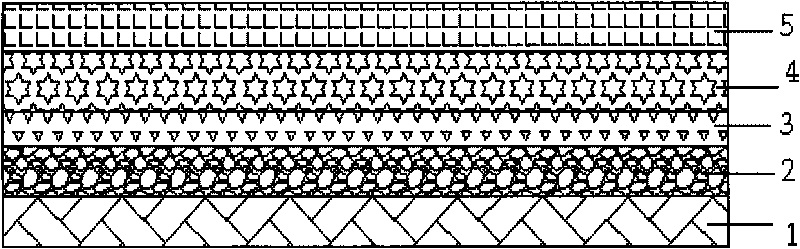

Synthetic leather with cracking patterns

InactiveCN102409550ASpecial shiny surface cracking effectPlay a role in synergistically promotingSynthetic resin layered productsTextiles and paperPolymer sciencePolymer chemistry

The invention discloses synthetic leather with cracking patterns. The synthetic leather comprises a base cloth layer (1), a polyurethane foaming layer (2) coated on the base cloth layer (1), a polyurethane bonding layer (3) coated on the polyurethane foaming layer (2), a water-borne polyurethane resin layer (4) coated on the polyurethane bonding layer (3) and a polyurethane cracking resin layer (5) coated on the water-borne polyurethane resin layer (4). In the synthetic leather provided by the invention, the polyurethane cracking resin layer (5) coated on the water-borne polyurethane resin layer (4) has a special bright surface cracking effect, and the two layers are combined to realize a synergic promotion effect; and different patterns can be contracted according to different lines of release paper, and strong cracking contraction visual aesthetic feeling is obtained.

Owner:WUJIANG SANHUI TEXTILE

Water-based PU bright surface brush clear varnish for synthetic leather

The invention discloses a water-based PU bright surface brush clear varnish for synthetic leather, which comprises the following materials in parts by weight: 35 to 45 parts of water-based polyurethane resin, 50 to 65 parts of water, 0.5 to 1 part of organic silicon flatting agent, and 2 to 5 parts of organic silicon foam killer. The water-based PU bright surface brush clear varnish has the advantages that the mixture ratio of the component is scientific and reasonable, and the components are coordinated with each other and act together; the bright surface brush clear varnish has the advantages of good film reforming property, firm bonding, solvent resistance, hydrolysis resistance and thermosenescence resistance of coating; the finished product made of the synthetic leather, the surface of which is treated by the bright surface brush clear varnish, has the advantages that the original effect of the leather surface is not affected, the treated leather surface has unique slippery effect, and the synthetic leather has good comprehensive effects of good air permeability, good hand feel, water resistance, cohesiveness and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Method for producing automobile valve cover or oil pan by using fiber reinforced modified polypropylene composite material

The invention relates to a method for producing an automobile valve cover or oil pan by using a fiber reinforced modified polypropylene composite material. The method comprises the steps of: producing a fiber reinforced modified polypropylene block by using an extruder, pressing and machining, or also comprises the steps of producing a roughly-produced valve cover or oil pan by using an injection molding machine and machining. The valve cover provided by the invention has the advantages of high temperature and corrosion resistance, high strength, heat ageing resistance and the like, and is low in noise compared with a metal valve cover. The method provided by the invention is simple and easy to operate, is little in investment, and has good economic benefits and good market prospects.

Owner:北京国材汽车复合材料有限公司

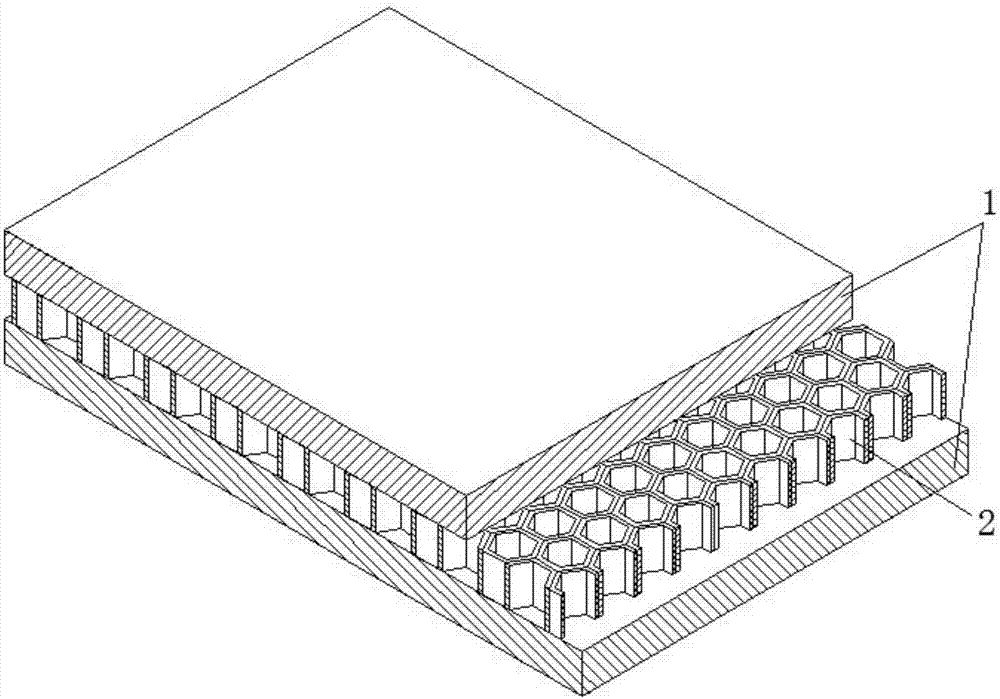

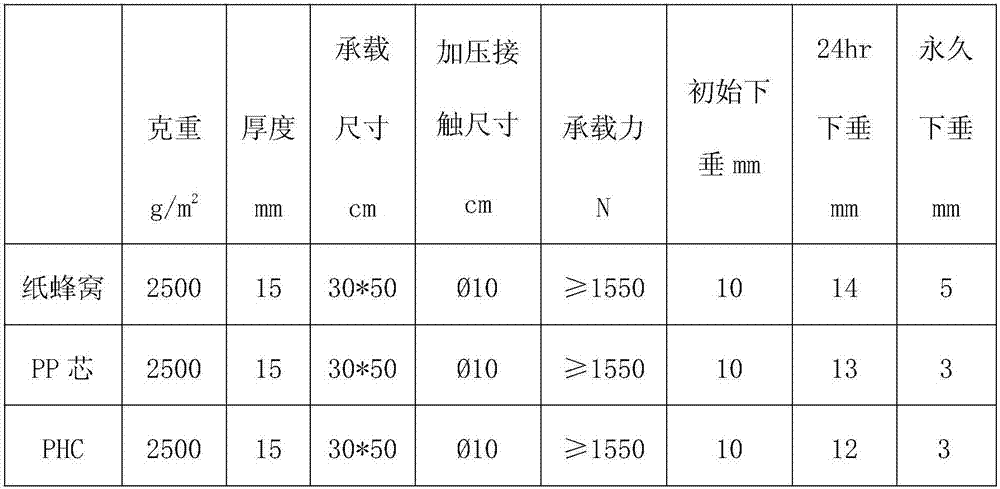

Polypropylene honeycomb-core glass fiber polypropylene composite plate and manufacture method thereof

InactiveCN107150464AHeat agingWith permanent moisture resistanceSynthetic resin layered productsLaminationEnvironmental resistancePolypropylene composites

The invention discloses a polypropylene honeycomb core glass fiber polypropylene composite board. The composite board is composed of a polypropylene glass fiber layer, a polypropylene honeycomb core and a polypropylene glass fiber layer laminated sequentially from bottom to top. The constituent materials of the composite board are in parts by weight, including 29.5 parts of polypropylene fibers, 35 parts of glass fibers, 0.5 parts of carbon black, and 35 parts of polypropylene honeycomb cores; the raw materials of the polypropylene honeycomb cores are in parts by weight, wherein 90 parts of polypropylene, 10 parts of low melting point polypropylene. The invention has the characteristics of heat aging resistance, permanent moisture resistance, mildew resistance and no peculiar smell, no deformation, no peculiar smell and no mildew after long-term use, low odor, low volatility and low VOC, the inner and outer materials are the same, the core layer and the The skin has good adhesion, high load-bearing strength, and high peeling strength. Leftovers and scrap products can be recycled directly, saving resources and meeting environmental protection requirements.

Owner:合肥杰迈特汽车新材料有限公司

Organic silicon pouring sealant for LEDs and preparation method for organic silicon pouring sealant

InactiveCN105086923ASimple to useAutomatic defoamingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkVacuum pumping

The invention relates to an organic silicon pouring sealant for LEDs. The organic silicon pouring sealant for LEDs is characterized by comprising the following components (in parts by weight): 90-100 parts of low-viscosity 107 glue, 1-5 parts of hydroxyl end-capping silicone oil, 2-5 parts of methyl silicone oil, 1-5 parts of methyl fluorosilicone oil , 5-10 parts of a cross-linking agent, 1-5 parts of a cross-linking agent and 1-5 parts of a catalyst. The preparation method comprises: adding the low-viscosity 107 glue, the hydroxyl end-capping silicone oil, the methyl silicone oil and the methyl fluorosilicone oil into a stirrer in formula to be stirred for 30 minutes at a high speed, and carrying out vacuum pumping to remove air bubbles to obtain a mixture II; taking the mixture I as base glue; adding the cross-linking agent, the coupling agent and the catalyst according to the formula to be uniformly mixed to obtain a mixture II, and taking the mixture II as an auxiliary gent; and uniformly mixing the base glue with the auxiliary agent in a ratio of the base glue to the auxiliary agent being 10:1, thereby obtaining the organic silicon pouring sealant for LEDs. The organic silicon pouring sealant disclosed by the invention is excellent in bonding force, high in transparency, good in bubble discharge, quick in deep-layer curing and free of yellowing. The organic silicon pouring sealant can be used for protecting the LEDs from invasion of the external environment for a long time.

Owner:SUZHOU DATONG ADVANCED MATERIAL

Synthetic leather with contracted patterns

InactiveCN101694065ASpecial shiny surface cracking effectPlay a role in synergistically promotingTextiles and paperPolyurethane adhesiveChemistry

The invention discloses synthetic leather with contracted patterns, which comprises a substrate cloth layer, a polyurethane foaming layer (2) coated on the substrate close layer (1), a polyurethane adhesive layer (3) coated on the polyurethane foaming layer (2), polyurethane cracking resin (4) coated on the polyurethane adhesive layer (3) and modified polyurethane (5) coated on the polyurethane cracking resin (4). In the synthetic leather, the polyurethane cracking resin coated on the polyurethane adhesive layer has special polished cracking effect, the modified polyurethane is coated on the cracking resin, the modified polyurethane and the cracking resin are combined to play a synergistic function and can generate fine contraction effect with unique patterns, and the cracking resin and the modified polyurethane can be contracted to form different patterns according to different texture of release paper, thereby having strong visual aesthetics.

Owner:JIANGSU BAOZE POLYMER MATERIAL

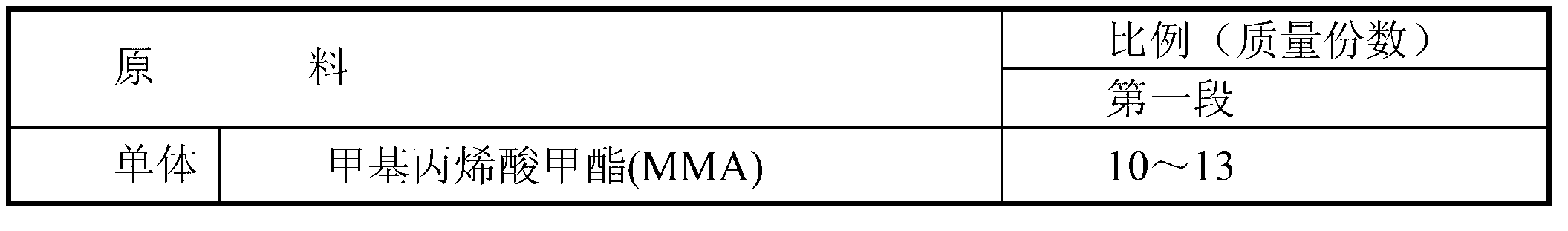

Self-cross-linking type waterborne polyacrylate powder-free base slurry for clothing fusible interlining

The present invention discloses a self-cross-linking type waterborne polyacrylate powder-free base slurry for a clothing fusible interlining. The self-cross-linking type waterborne polyacrylate powder-free base slurry is prepared from a waterborne polyacrylate emulsion, a waterborne acrylic acid thickener, an additive, deionized water and ammonia water, wherein the waterborne polyacrylate emulsion is prepared from a pre-emulsion, a seed emulsion, a secondary emulsion, a 10% adipic dihydrazide aqueous solution and ammonia water. According to the present invention, diacetone acrylamide (DAAM) is introduced into the system, and the adipic dihydrazide (ADH) modified branch chain is introduced, such that the cross-linking sites in the system can be increased so as to improve a self-cross-linking performance of the aqueous PA and form the medium temperature self-cross-linking type base slurry; and the baking temperature can be appropriately reduced by 10-30 DEG C so as to save energy sources.

Owner:长兴三伟热熔胶有限公司

Hydraulic PU pressing color-changing resin for synthetic leather

The invention discloses a hydraulic PU pressing color-changing resin for synthetic leather; the hydraulic PU pressing color-changing resin is constituted by the following raw materials by weight percentage: 35-45 percent of waterborne polyurethane, 25-35 percent of water, 5-15 percent of silicon dioxide color changing powder, 5-10 percent of extinction powder, 0.3-1 percent of organic silicon flatting agents, 1-3 percent of silicone defoaming agents, and 0.5-2 percent of waterborne polyurethane thickeners. The hydraulic PU pressing color-changing resin for synthetic leather takes water as solvent, toxic solvents such as dimethyl fomamide and butanone are replaced, therefore, the hydraulic PU pressing color-changing resin has non-inflammable, safe, environmental-protection, cost-saving performances, and the pressing color-changingresin has the advantages of good film forming property, firm adhesion, solvent-proof, cold-resistance, hydrolyzation-resistance and heat-proof ageing coating. The finished products manufactured by the pressing color-changing resin has the advantages of full handle, good pressing double-color effect, fine and smooth texture, good air permeability and the like.

Owner:JIANGSU BAOZE POLYMER MATERIAL

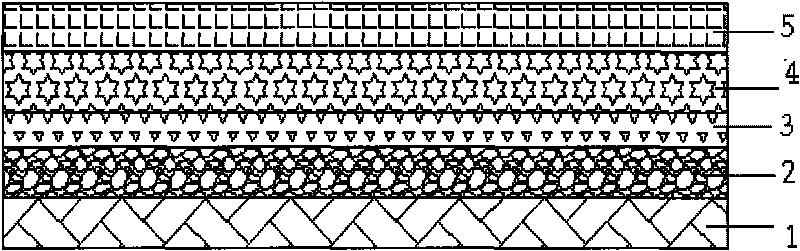

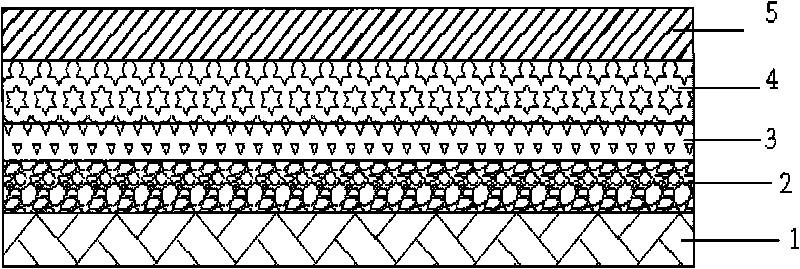

Aquosity foaming synthetic leather with knurling shrunken patterns

InactiveCN101725055AGood coverageSoft touchSynthetic resin layered productsTextiles and paperChemistryKnurling

The invention discloses an aquosity foaming synthetic leather with knurling shrunken patterns, comprising a base fabric layer (1), a polyurethane foaming layer (2) coated on the base fabric layer (1), an aquosity polyurethane bonding layer (3) coated on the polyurethane foaming layer (2), an aquosity foaming resin layer (4) coated on the aquosity polyurethane bonding layer (3) and a modified polyurethane resin layer (5) coated on the aquosity foaming resin layer (4). In the synthetic leather provided, the aquosity foaming resin layer has strong concave-convex three-dimensional sense after rear-segment foaming treatment at a high temperature of 170 DEG C; the combination of the foaming layer, the shrinkage layer and the knurling processing have unique three-dimensional sense effect; besides, the modified polyurethane can shrink to form different patterns according to different release paper patterns as a result of the polarity difference between the modified polyurethane resin coated on the aquosity foaming resin layer and the aquosity foaming resin layer combined for use, thereby the invention has favorable shrinkage effect, unique patterns and strong visual aesthetics.

Owner:JIANGSU BAOZE POLYMER MATERIAL

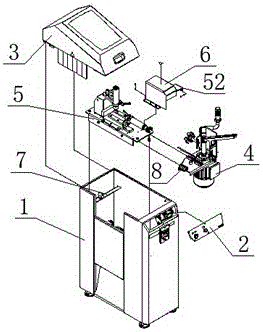

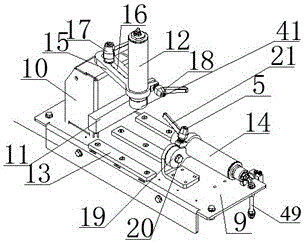

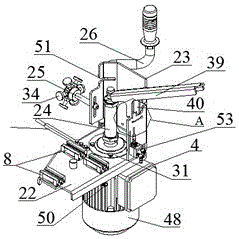

Aluminum profile end face milling machine

ActiveCN105880696AImprove machining accuracyImprove the safety protection factorWork clamping meansWorkpiecesEngineeringAlloy

The invention relates to an aluminum profile end face milling machine which is used for machining of aluminum profiles or PVC or light alloy, and belongs to the field of machining. The aluminum profile end face milling machine comprises a milling machine box, a positioning clamping device, a tool device, a protecting cover and a safety hood, cross beams are arranged on the front side and the right side inside the milling machine box respectively, the positioning clamping device is installed on the cross beams through screws, a control switch is arranged on the front face of the milling machine box, two rows of parallel sliding blocks are arranged on the tool device, a guide rail is arranged at the bottom of the positioning clamping device, the sliding blocks are matched with the guide rail, the tool device moves back and forth through the sliding blocks, the protecting cover is located above the tool device, the safety hood is installed on the milling machine box, and the safety hood and the milling machine box together form a closed whole. The aluminum profile end face milling machine has the advantages of being high in machining precision, high in tool changing speed, convenient to operate, accurate in positioning and high in safety protection coefficient.

Owner:EMMEGI SUZHOU

Ultraviolet curing coating for coating plastic surface and preparation method thereof

InactiveCN103525288AImprove adhesionImprove insulation performancePolyurea/polyurethane coatingsPolyvinyl alcoholPliability

An ultraviolet curing coating for coating a plastic surface is prepared from the following materials of 50-55 parts of aromaticurethane acrylate, 2-3 parts of isopropyl alcohol, 4-5 parts of photoinitiator 184, 1-2 parts of nanosilicon dioxide, 9-12 parts of tripropylene glycol diacrylate, 1-2 parts of zirconium oxide, 1-2 parts of titanium dioxide, 2-4 parts of butyl acrylate, 1-2 parts of fatty acid polyglycol ester, 1-2 parts of glycidolbutyl ether, 3-4 parts of triethylene glycol, 1-2 parts of polyvinyl alcohol, 1-2 parts of titanatecoupling reagent TMC-TTS, and 5-6 parts of dispersing auxiliaryaccording to parts by weight. Due to the use of the aromaticurethane acrylate, the coating provided by the invention has the excellent high-wearing feature, excellent anchoring strength, excellent flexibility, excellent high peel strength and excellent low temperature resistance property as well as the remarkable optical property and weather resistance of the polyacrylate, and has high cohesiveness on plastics and the like; due to the use of the nano silicon carbide and titanium dioxide, the coating has an excellent shielding effect and fulfills the purposes of ultraviolet aging resistance and thermal aging resistance, the heat insulation property of the coating is added at the same time, and the coating provided by the invention is applicable to the coating of a plastic product.

Owner:安徽蓝柯复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com