Aluminum profile end face milling machine

A face milling machine and aluminum profile technology, which is applied to milling machine equipment, milling machine equipment details, and cutting tools for milling machines, etc., can solve the problems of machine tools without protective devices, clumsy use, and fast wear of the table surface, so as to ensure safety and cleanliness , The design of the device is complete and functional, and the effect of high safety protection factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] refer to Figure 1 to Figure 7 .

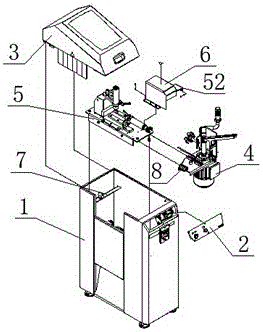

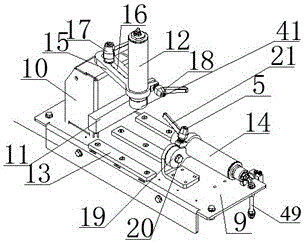

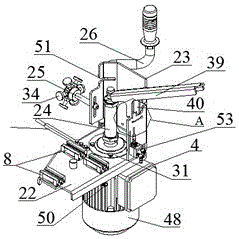

[0039] An aluminum profile end milling machine, comprising a milling machine box 1, a positioning clamping device 5, a tool device 4, a protective cover 6 and a safety cover 3, the inside of the milling machine box 1 is provided with beams 7 on both sides, the positioning The clamping device 5 is installed on the crossbeam 7 by screws, the front of the milling machine box 1 is provided with a control switch 2, the tool device 4 is provided with two rows of parallel sliders 8, and the bottom of the positioning clamping device 5 A guide rail is provided, the slider 8 is adapted to the guide rail, the cutter device 4 moves back and forth through the slider 8, the protective cover 6 is located above the cutter device 4, and the safety cover 3 is installed on the milling machine box 1, it forms a closed whole together wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com