Patents

Literature

74results about How to "Fast tool change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

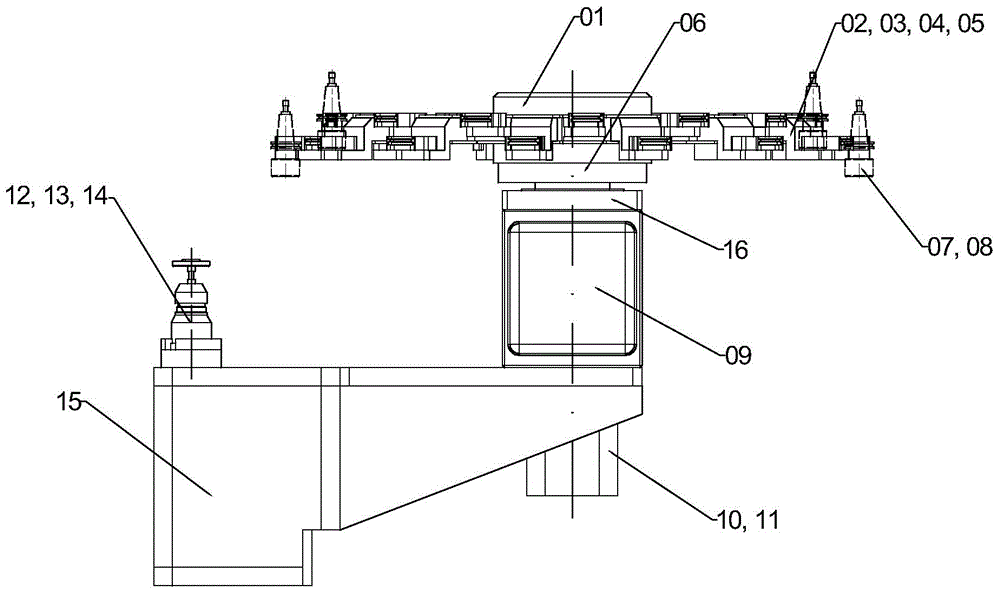

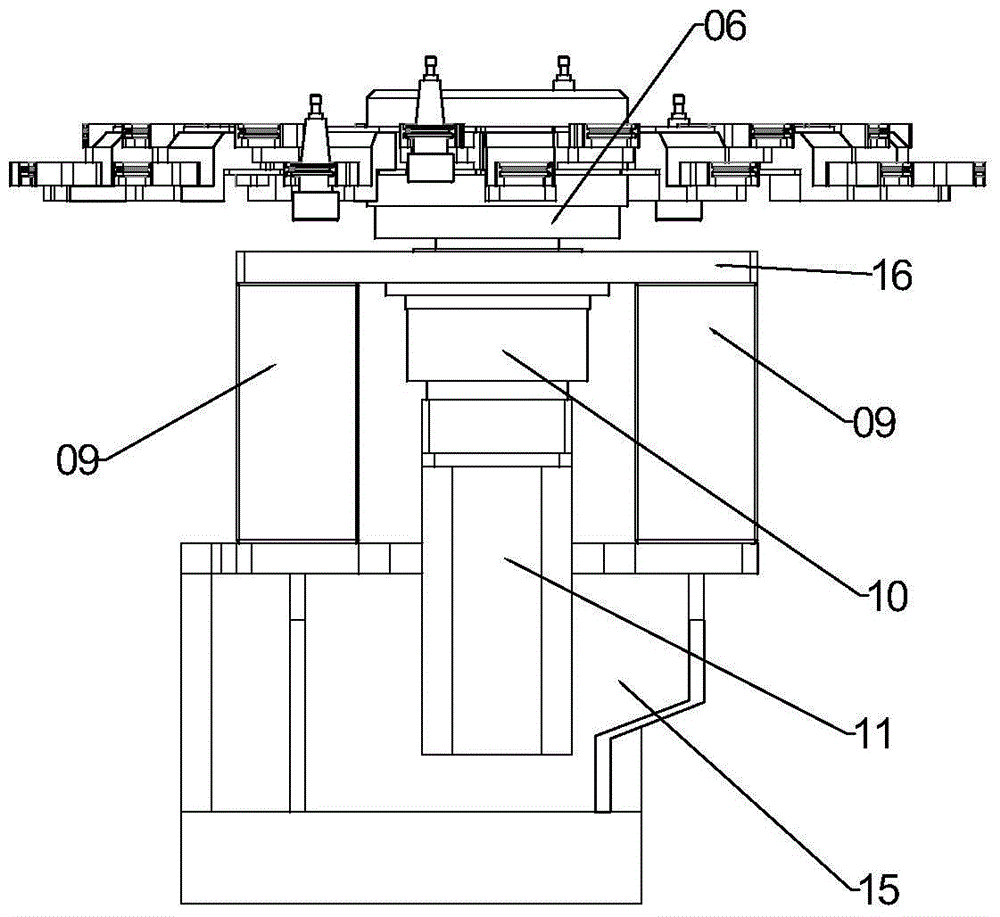

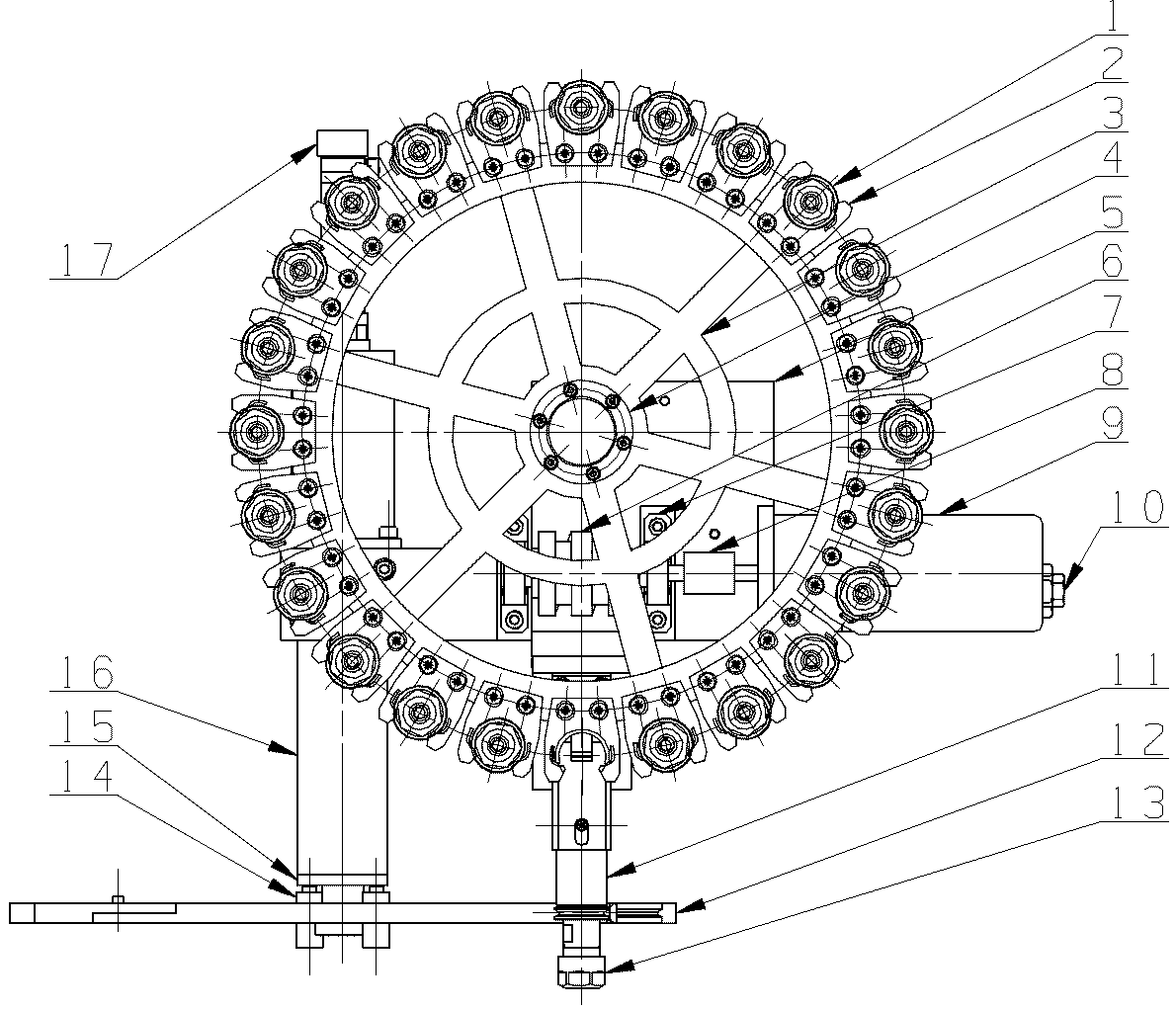

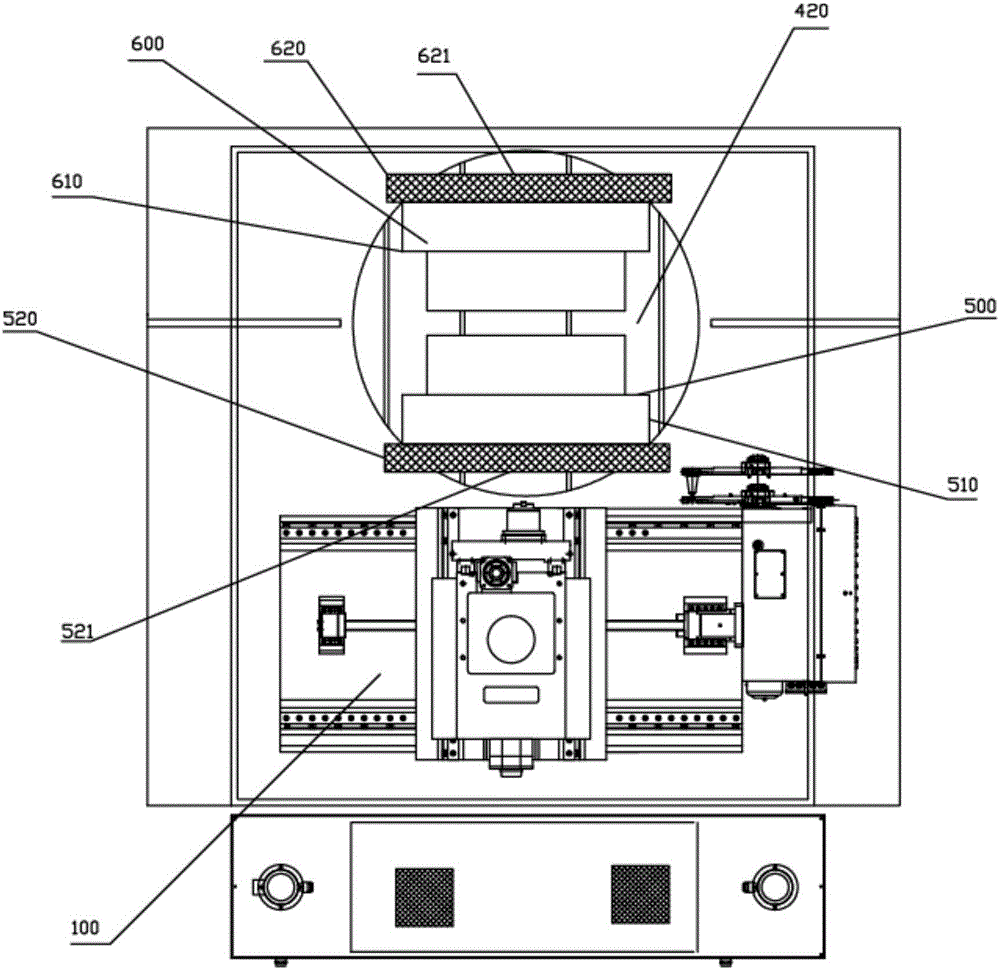

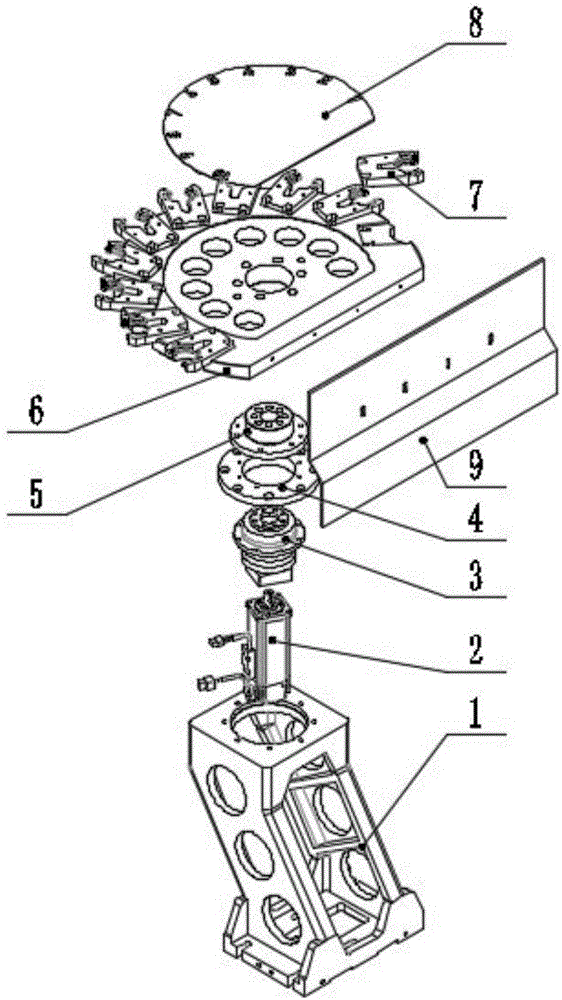

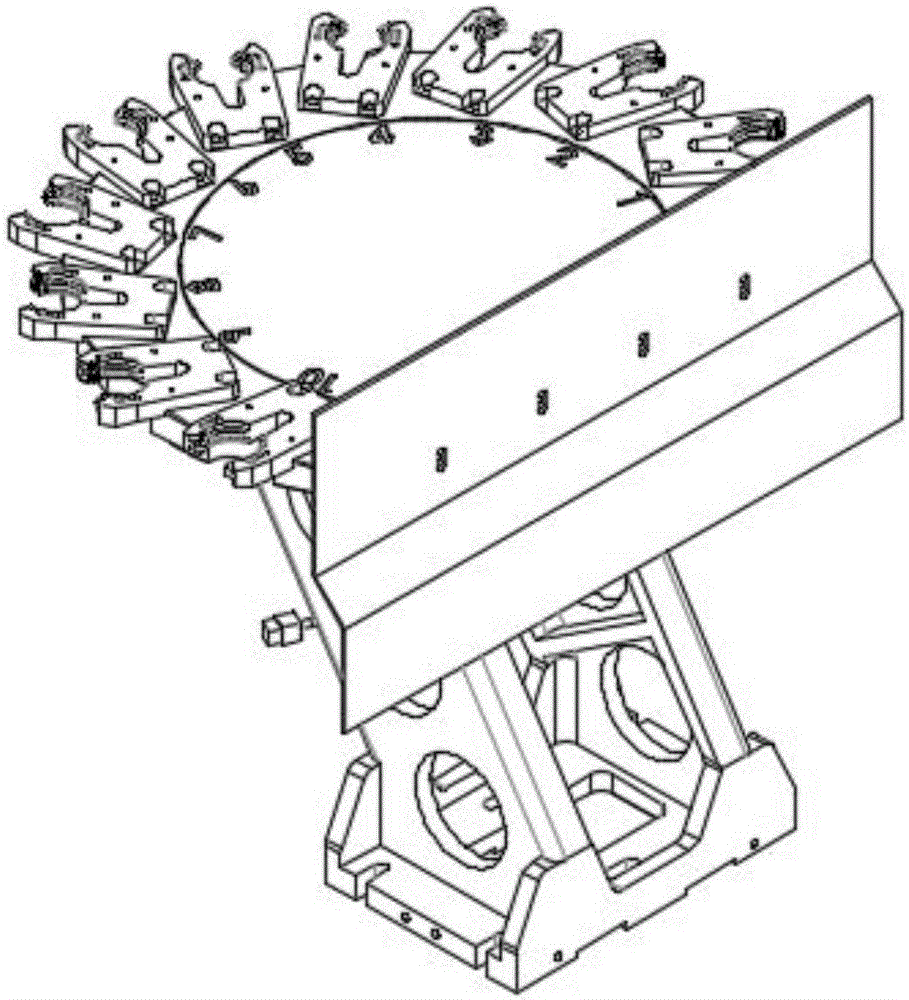

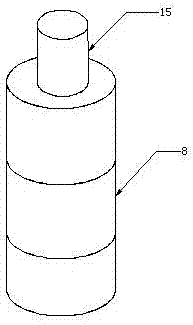

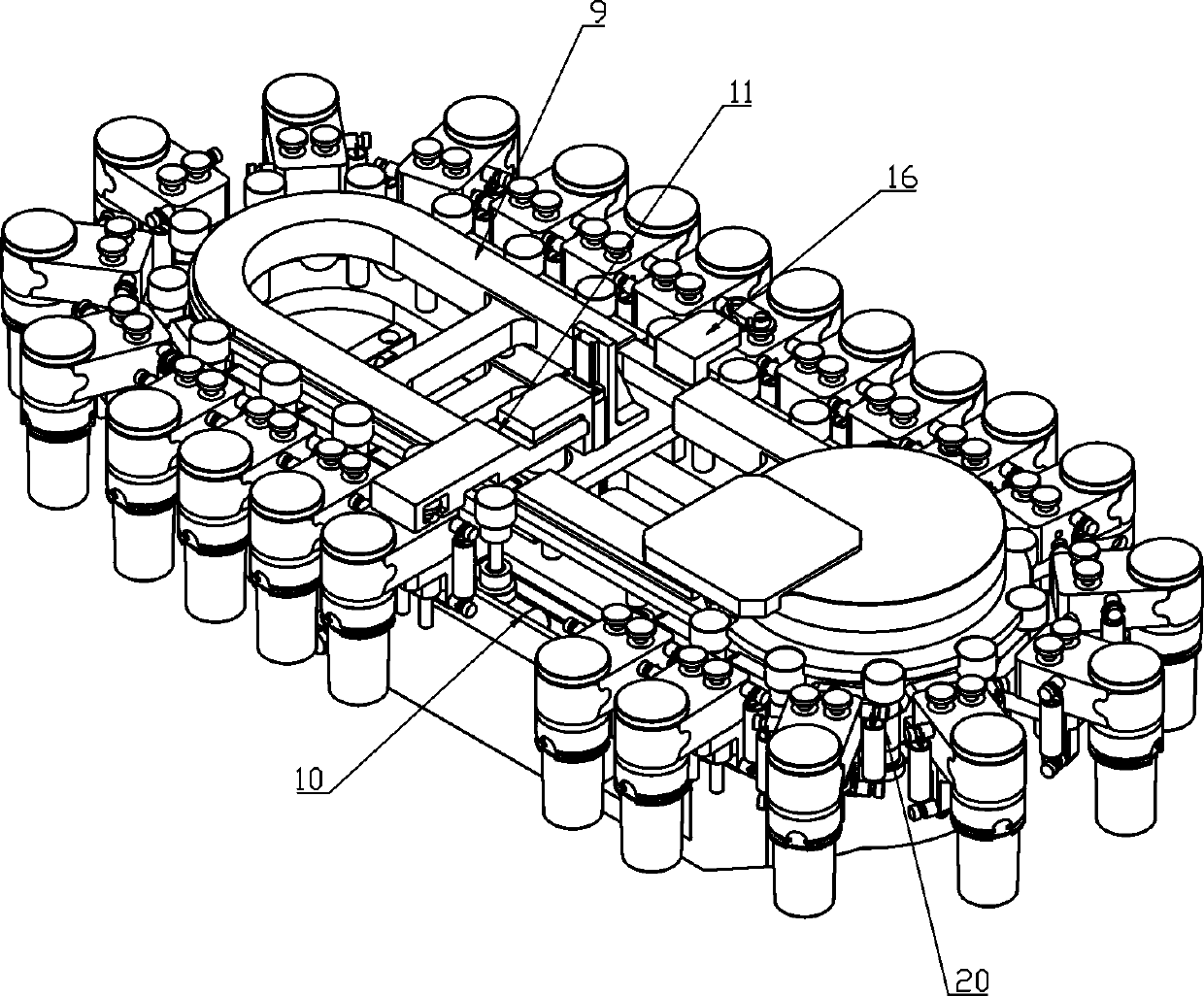

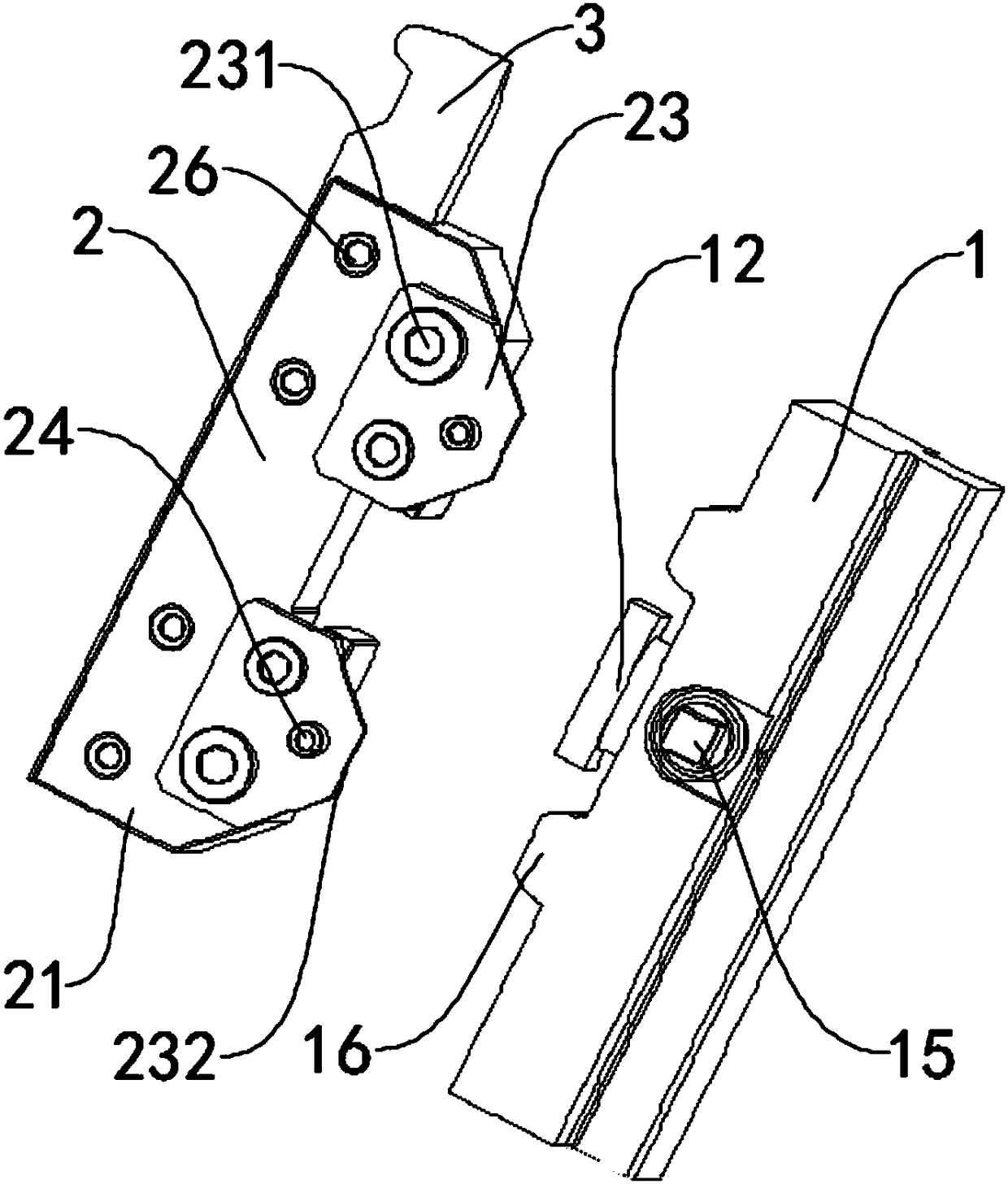

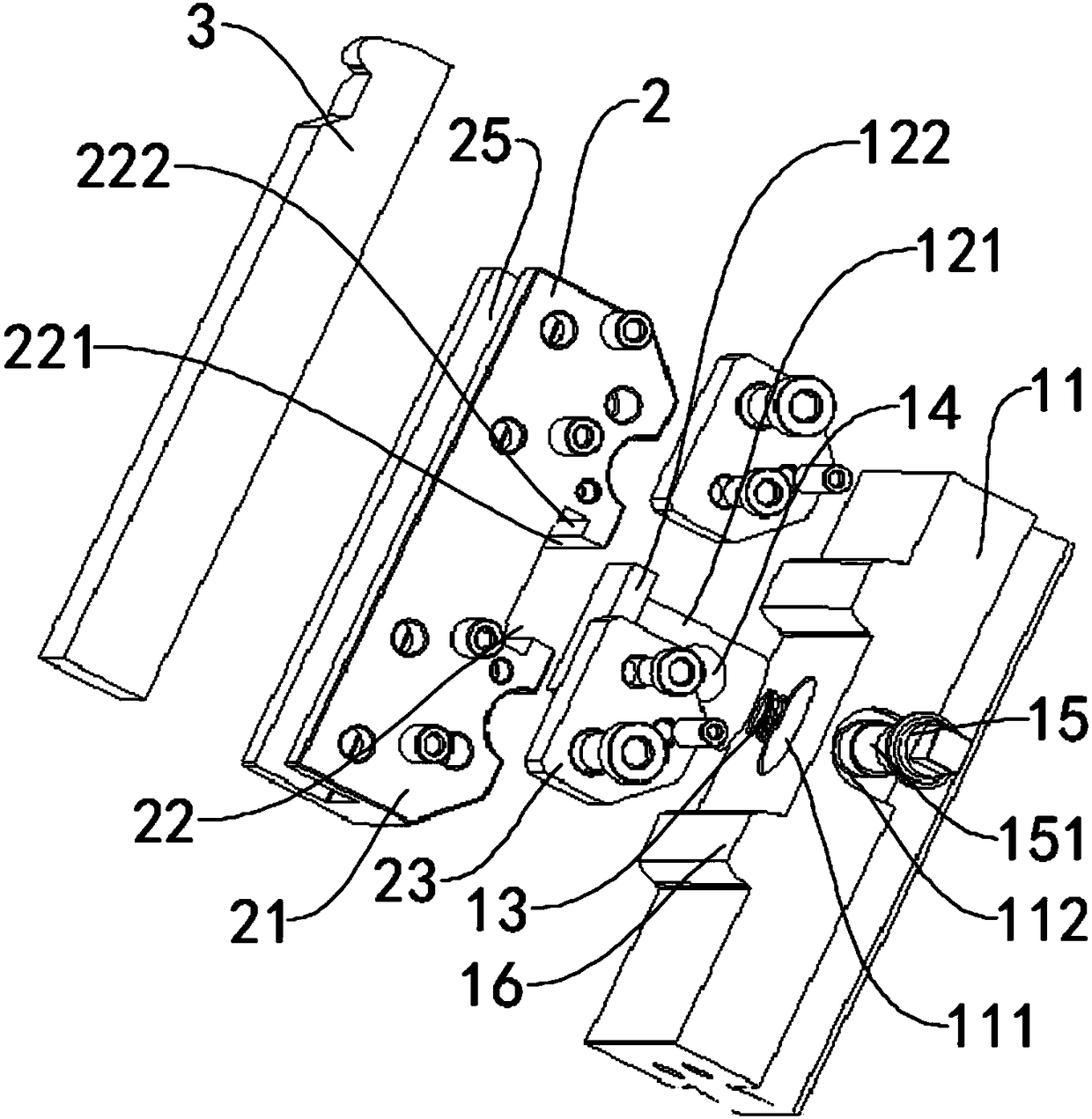

Two-layer disk type tool changer device

ActiveCN104526431ASave money fastFast tool changeAutomatic control devicesTool changing apparatusNumerical controlMachine tool

The invention relates to a two-layer disk type tool changer device matched with a numerical control machine tool. The two-layer disk type tool changer device comprises a tool changer base, a tool changer support, tool sleeve chucks, a tool disk base, tool sleeves and a tool alignment instrument, wherein the tool changer base is connected to and installed on the machine tool, the tool changer support is connected to one end of the tool changer base, the tool disk base is connected to the support through a bolt, the tool alignment instrument is installed at the other end of the tool changer base, the two tool sleeve chucks are installed on the tool disk base and partitioned through a tool disk partition sleeve, the two layers of tool sleeve chucks clamp a tool sleeve base clamp and are fixed through bolts, and a tool disk pressing ring presses the upper portion of the tool sleeve chuck on the upper layer. The two-layer disk type tool changer device is low in overall weight and compact and reasonable in structure and has the advantages of being good in structural rigidity, large in tool installation amount, high in tool storing and changing speed and accuracy, low in operation noise, convenient to install and maintain and the like.

Owner:GREATOO INTELLIGENT EQUIP INC

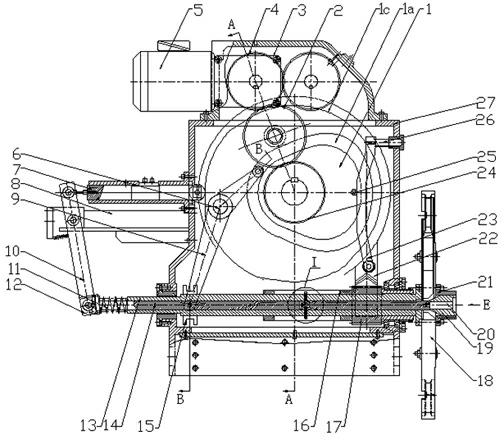

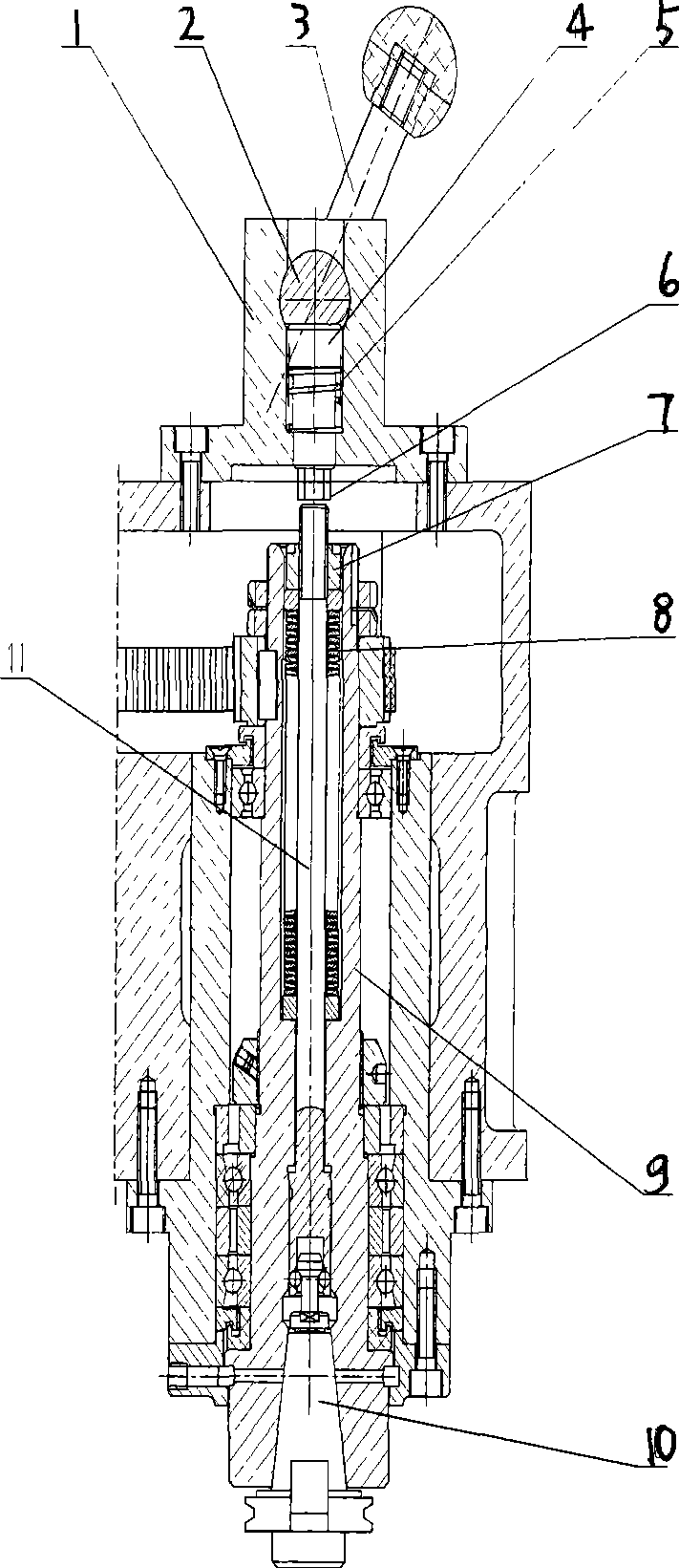

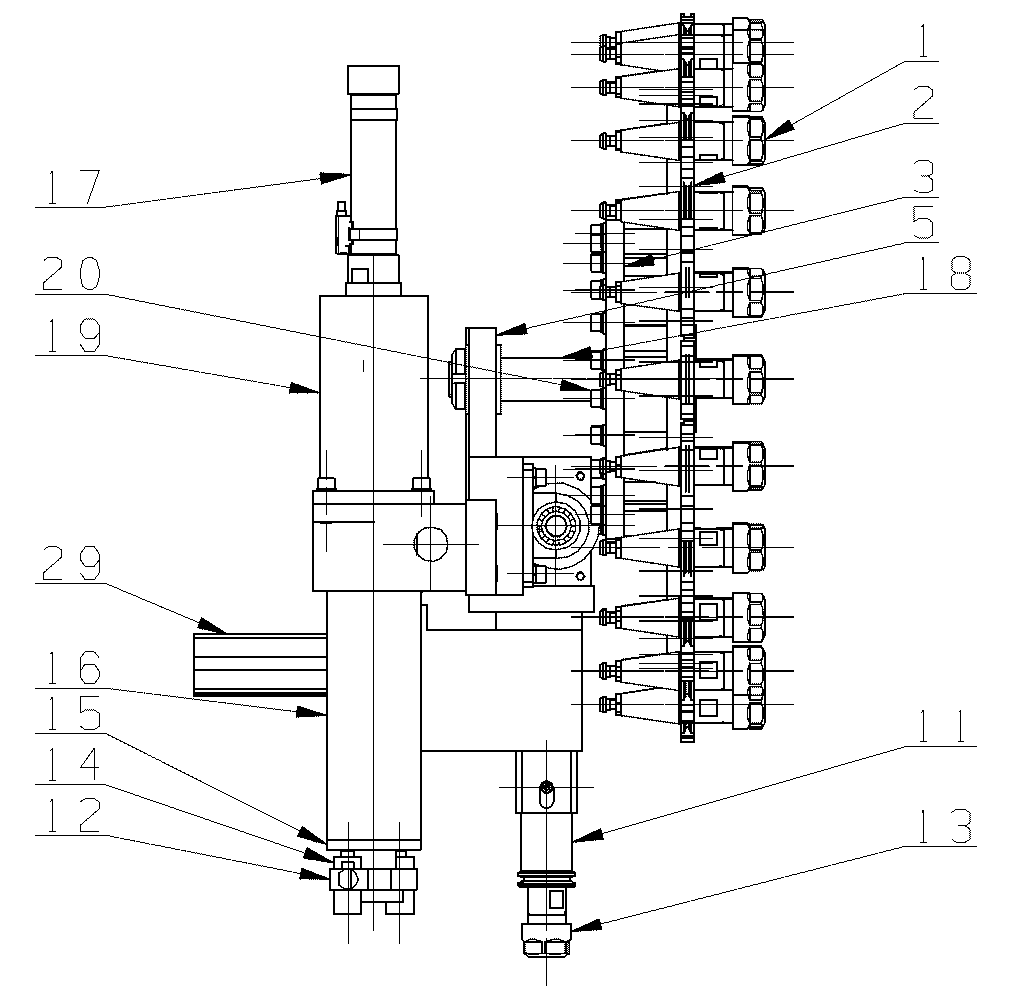

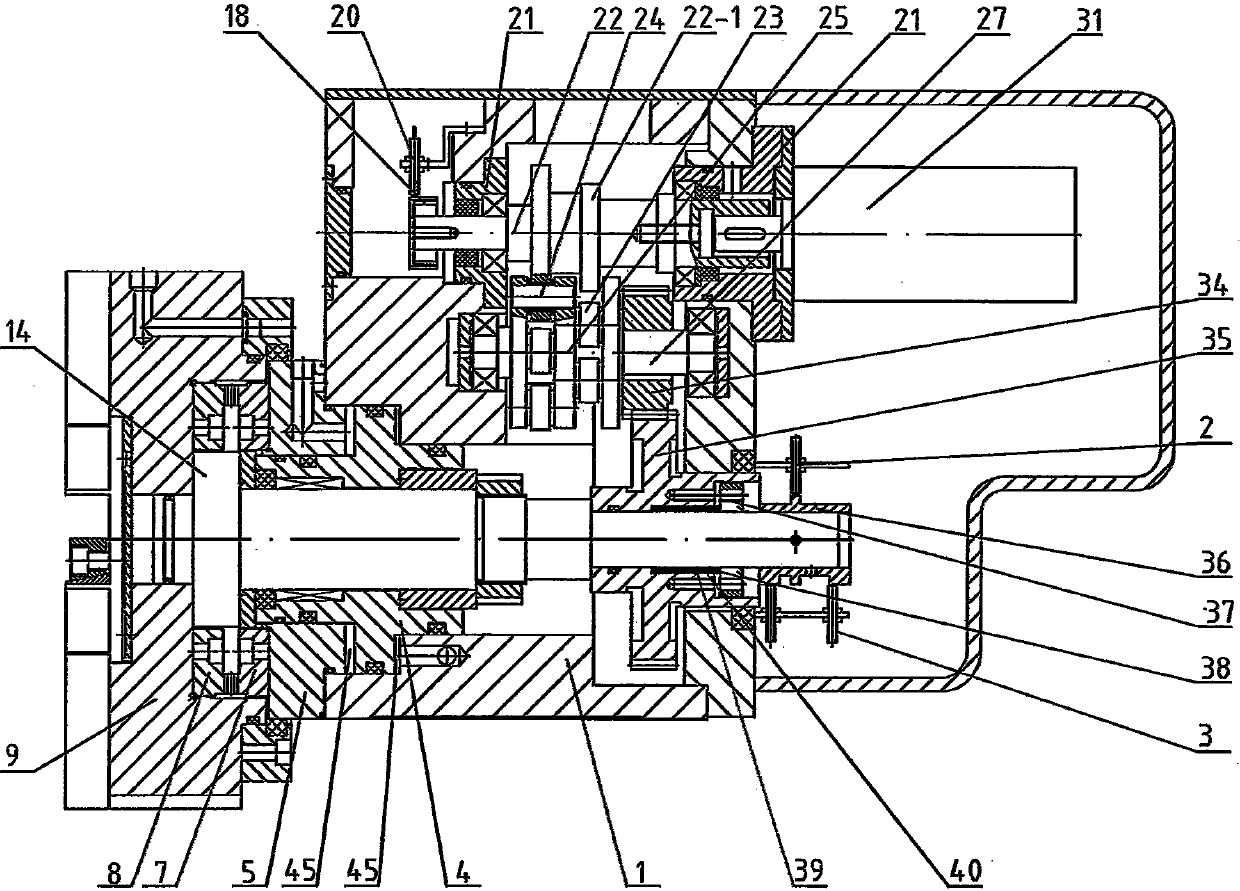

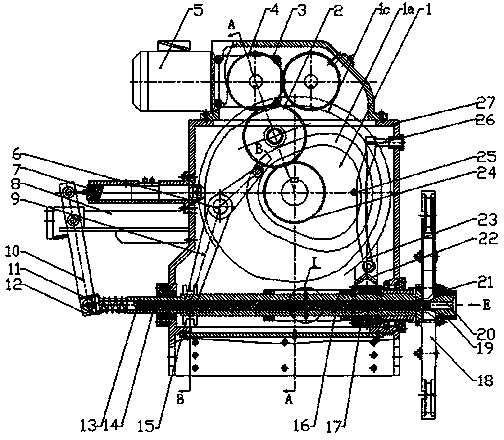

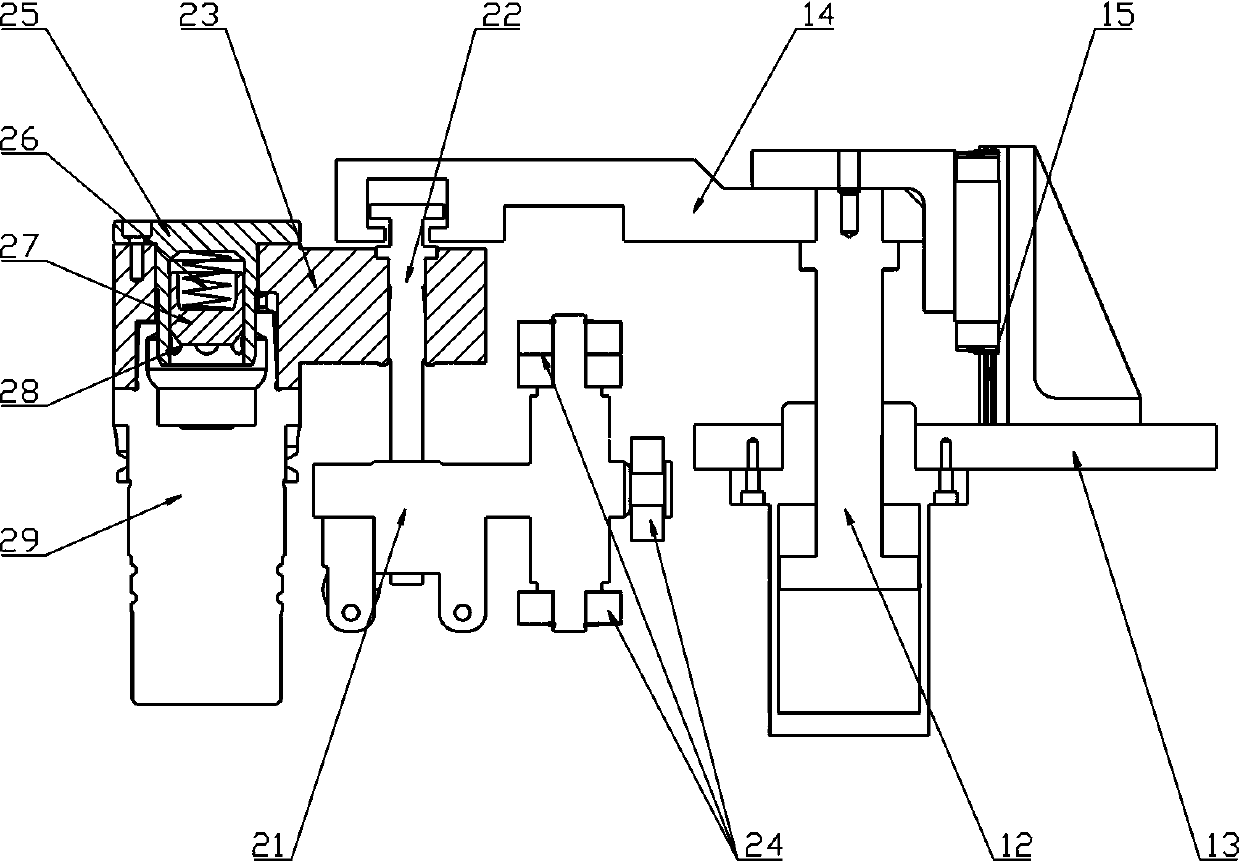

Automatic tool changing device of high-speed machining center

InactiveCN102528508AFast tool changeSimple structurePositioning apparatusMetal-working holdersEngineeringCam

The invention provides an automatic tool changing device of a high-speed machining center, which aims to replace a tool position changing mechanism adopting an arc-surface indexing cam as a main body and has the advantages of simple structure and convenience in manufacture. The automatic tool changing device of the high-speed machining center comprises a box, a tool arm spindle, a tool changing arm, a power transmission mechanism, a tool plugging and unplugging mechanism, a tool position changing mechanism, a tool locking mechanism and a transmission clutch mechanism. The automatic tool changing device is particularly improved by the tool position changing mechanism and the transmission clutch mechanism, the tool position changing mechanism is provided with a rack mechanism meshed with a transmission gear hollowly sleeved on the tool arm spindle, the rack mechanism is in motion association with a composite cam by a position changing oscillating bar, the transmission clutch mechanism is structurally provided with a shaft sleeve hollowly sleeved on the tool arm spindle, one side of the shaft sleeve is fixedly connected with a transmission gear, a T-shaped groove is machined in the middle of a push rod of the tool locking mechanism, a certain angle is formed between the bottom of the T-shaped groove and the axis of the push rod, a T-shaped pin is mounted in the T-shaped groove and is inserted in a positioning hole of the tool arm spindle, and an axial groove matching with a journal of the T-shaped pin is disposed on the shaft sleeve.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

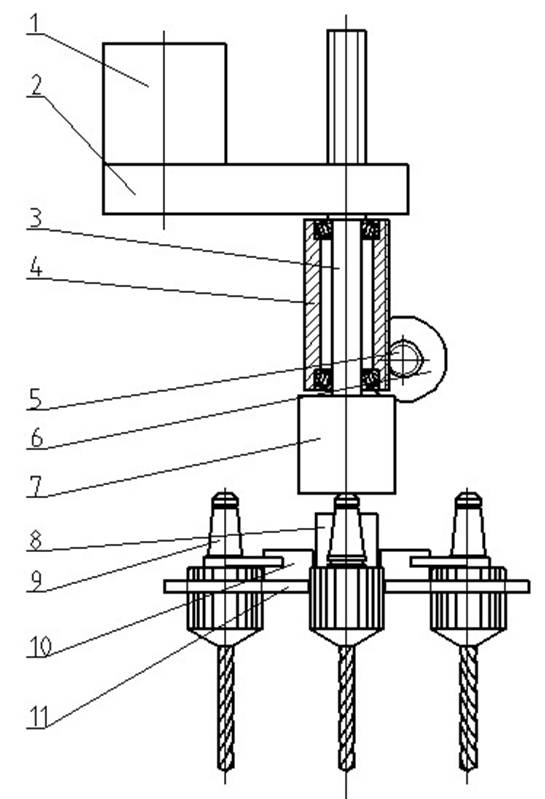

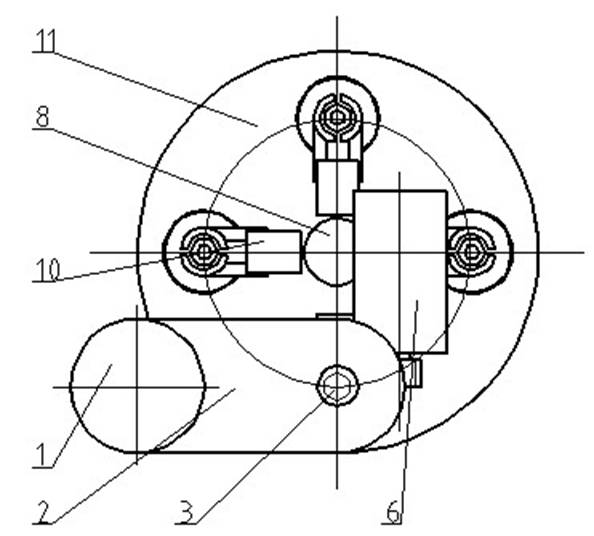

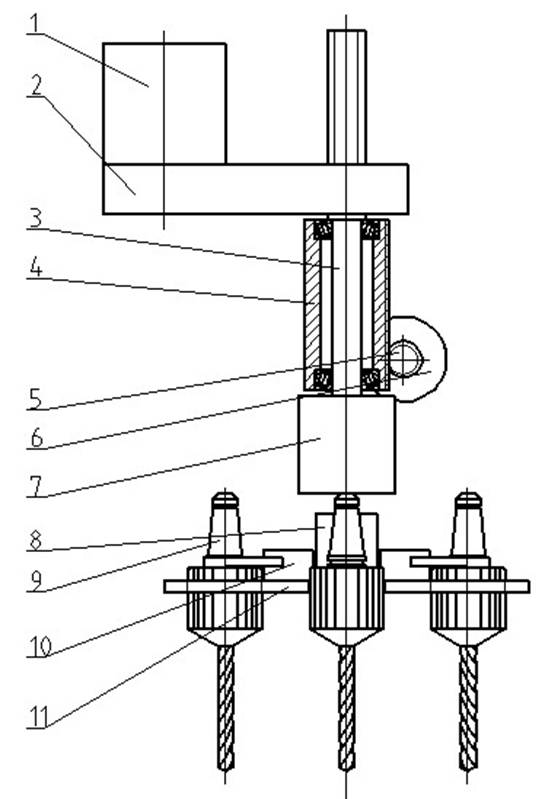

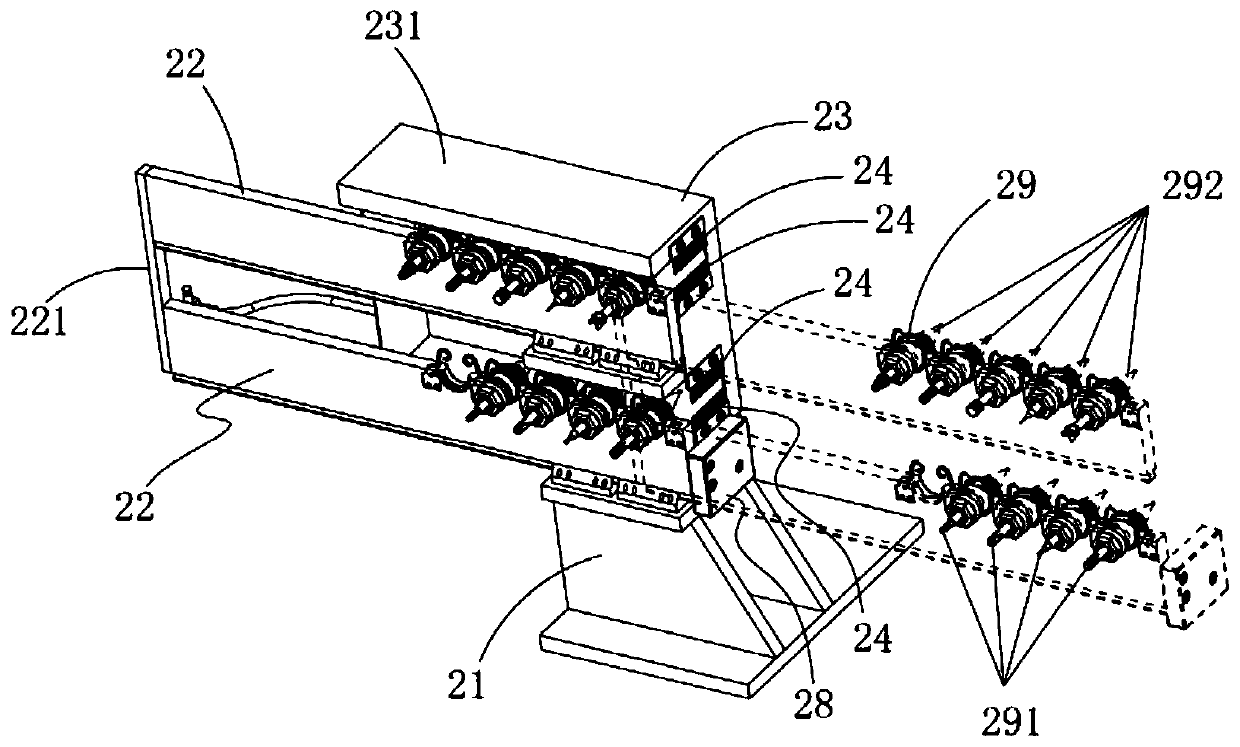

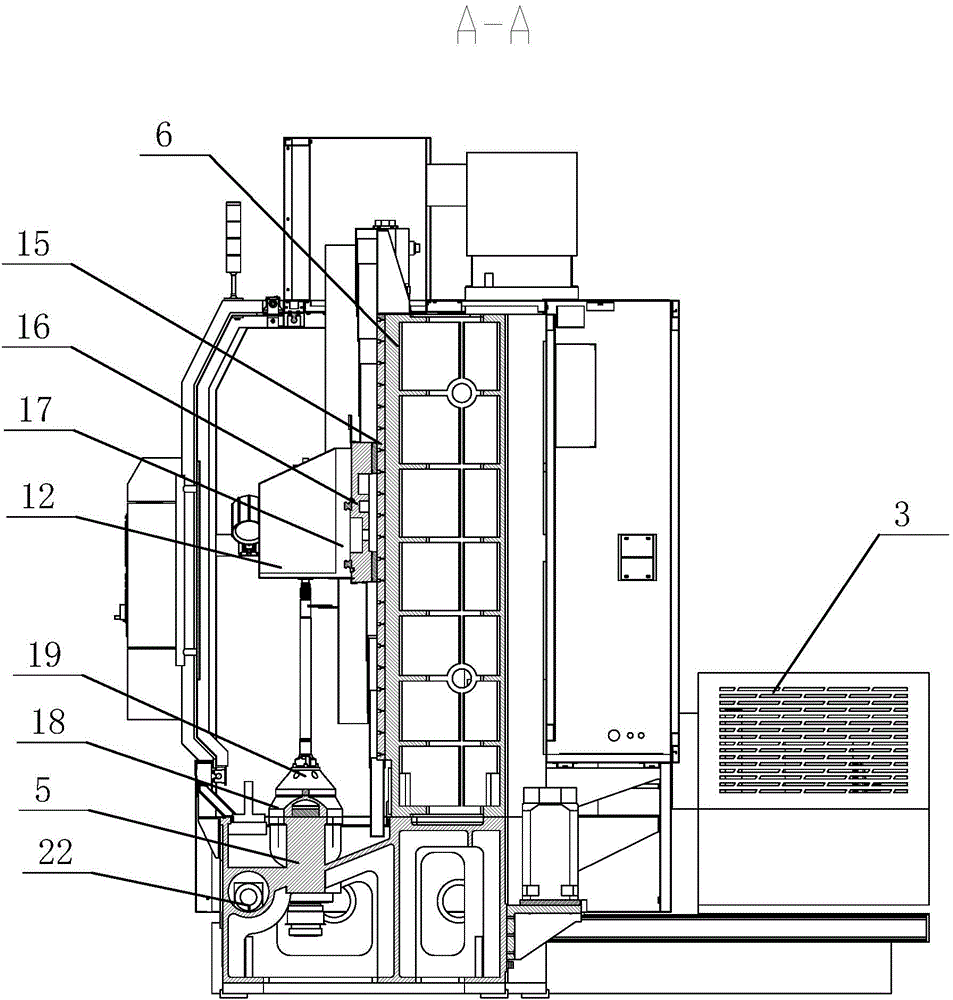

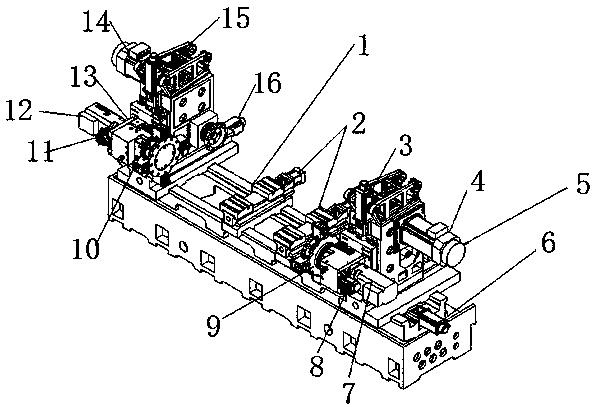

Automatic drill machine and processing technology thereof

InactiveCN102039434ASolve efficiency problemsSolve the time-consuming replacement of toolsBoring/drilling componentsBoring/drilling machinesGear wheelEngineering

The invention discloses an automatic drill machine and a processing technology thereof. A main shaft motor with controllable speed is in connecting transmission with a main shaft by a transmission gear; the upper end part of the main shaft is connected with the output shaft of the transmission gear by a spine; the jacket of the main shaft is fixedly connected with the rack; the main shaft rotates relatively to the jacket of the main shaft by a bearing; an angle elevation motor with controllable speed drives the jacket of the main shaft by a gear rack mechanism and acts on the main shaft by the bearing; and the lower end of the main shaft is provided with a pneumatic automatic clamp which is matched with the conical surface of the chuck of a cutter. Because of the automatic drill machine and the processing technology thereof, the processing process of the drill machine and cutter replacement are completely automated so as to thoroughly solve the problem of low processing efficiency of the existing drill machine and the problem that people take much time to replace the cutter which is difficult to replace. The automatic drill machine and the processing technology thereof have the characteristics of reasonable technology, high degree of automation and high speed of replacing the cutter, and are convenient to manufacture and install.

Owner:星远控股有限公司

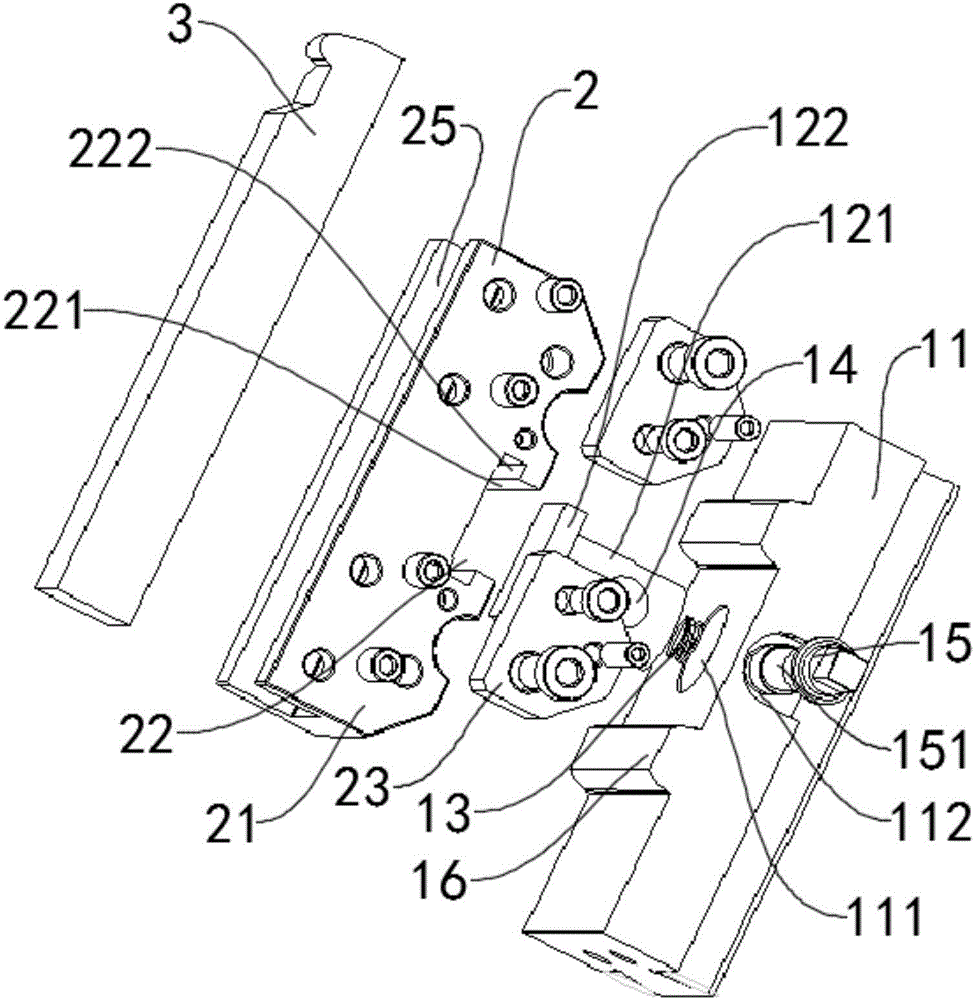

Quick manual too-changing mechanism of numerical-controlled milling machine

InactiveCN101422864AShort moving distanceLocking force to overcomeMilling equipment detailsPositioning apparatusNumerical controlEngineering

The invention relates to a quick manual tool changing mechanism of a numerical control milling machine, which comprises a tool holder. A cam is installed on the holder, a tool-changing handler is connected to the cam, a mandril is arranged on the lower part of the cam, a bolt connected to the end of the mandril around which springs are provided, a spindle is arranged on the lower part of the tool holder, a pull rod which is on the relative position to the spindle is sleeved inside the spindle, disk springs are provided around the upper end of the pull rod, the upper end of the pull rod is connected with the spindle by locknuts, a cutter fixed seat is connected to the end part of the pull rod, and a taper hole at the end of the spindle is led to the cutter fixed seat. The device greatly reduces the manufacturing and using cost, improves tool changing efficiency of manual changing mechanism simultaneously, and reduces working intensity of labors. The mechanism is not only characterized in high efficiency and low working intensity of a pneumatic tool changing mechanism, but also in simple structure and lower cost of the manual tool changing mechanism.

Owner:ANHUI CHIZHOU HOUSEHOLD MACHINE TOOL

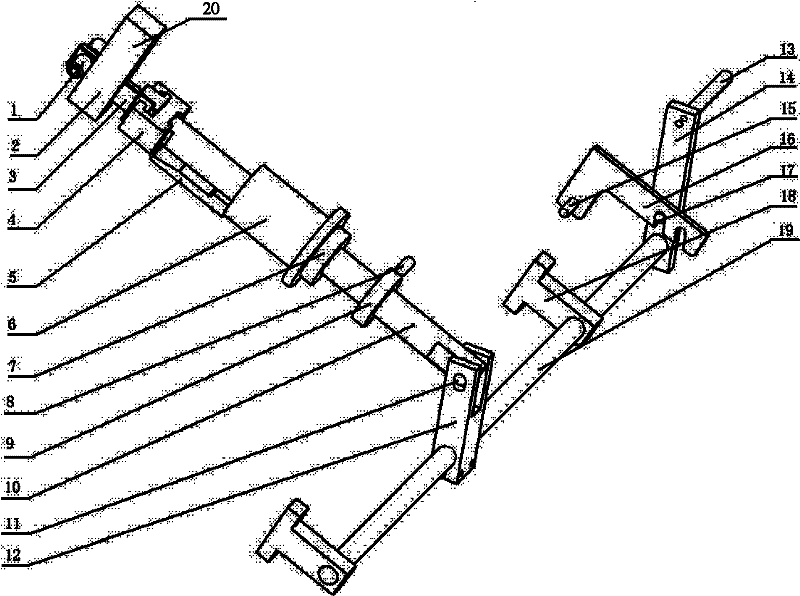

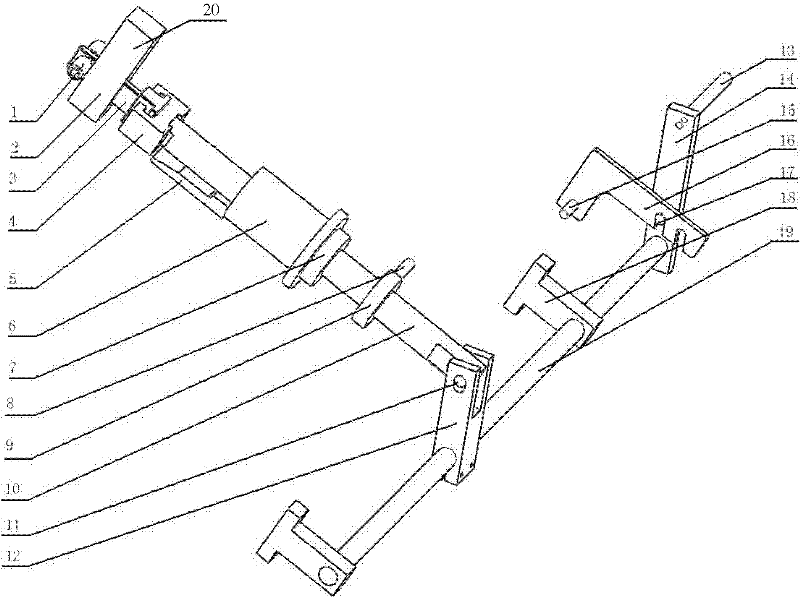

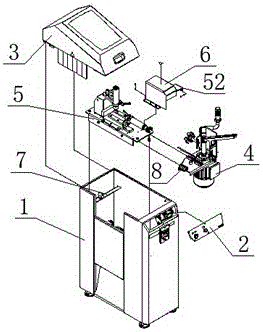

Tool changing device for vertical broaching machine

ActiveCN102328233AAchieve connectionReduce labor intensityPositioning apparatusMetal-working holdersEngineeringMachine tool

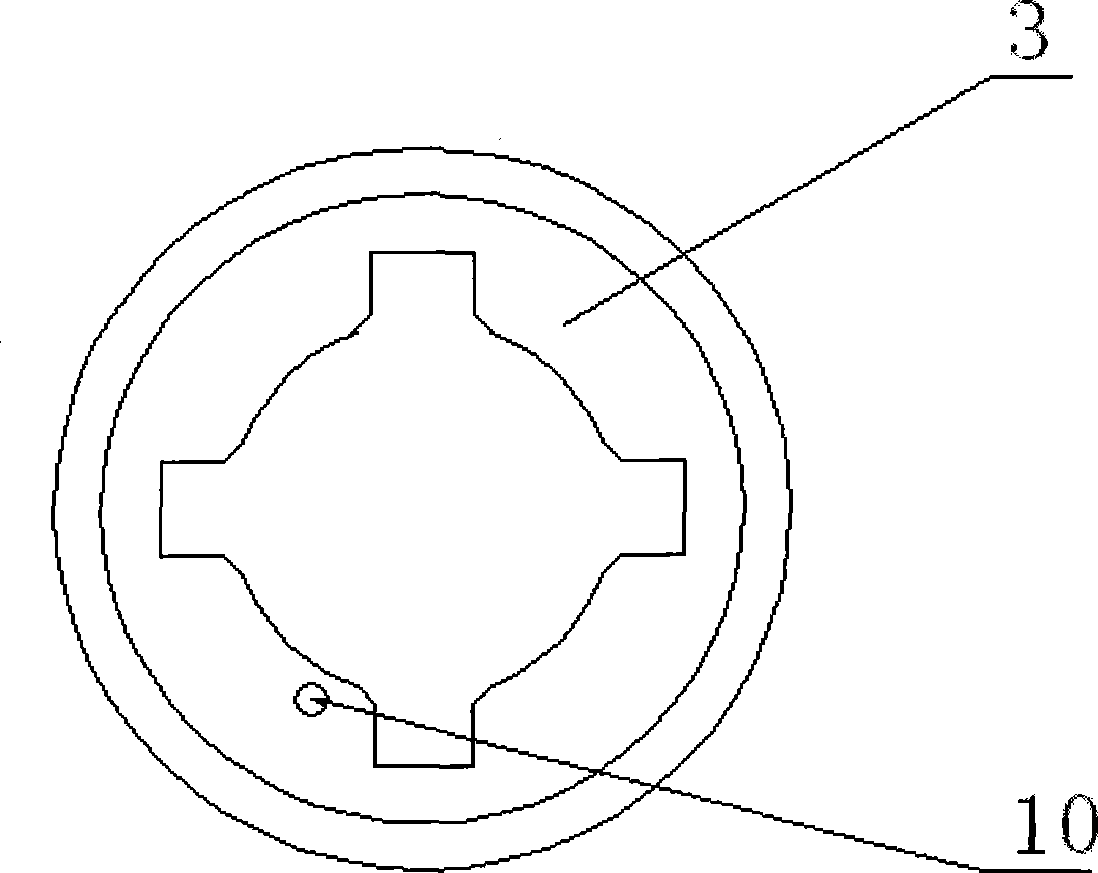

The invention discloses a tool changing device for a vertical broaching machine. The tool changing device comprises a dwang (19), a swing block (12), a guide rod (10) and a sliding block (4), wherein the dwang (19) is rotatably arranged on the vertical broaching machine; one end of the swing block (12) is fixed on the dwang (19); the guide rod (10) can be rotatably arranged on the vertical broaching machine, one end of the guide rod (10) is rotatably connected with the other end of the swing block (12); and the sliding block (4) is arranged on the other end of the guide rod (10) and provided with a sliding chute which can be matched with the end part of a bolt (3) used for installing a broach (20). In the tool changing device for the vertical broaching machine provided by the invention, the tool changing of the vertical broaching machine is performed at the exterior of a machine tool instead of the interior of the machine tool, thereby reducing the labor intensity and operation dangerof an operator, saving time and improving the production efficiency; and the tool changing device is simple in structure, is convenient for regulation, insulation and exchange, is easy to maintain and has extremely low manufacturing cost.

Owner:SHANTUI CONSTR MASCH CO LTD

Quick-replacement fixture

InactiveCN104625817AFast tool changeImprove work efficiencyPositioning apparatusMetal-working holdersEngineeringSteel ball

A quick-replacement fixture comprises a fixture body, a fixture rod, steel balls and a locking sleeve. An installation hole is formed in one end of the fixture body, and two ball sockets are symmetrically arranged on the outer wall of the installation hole of the fixture body. The fixture rod is arranged in the installation hole of the fixture body in a sleeved mode, and locking grooves are formed in the fixture rod. The fixture body is sleeved with the locking sleeve. The inner surface of the locking sleeve is a conical surface at a certain inclination angle, the steel balls are installed in the two ball sockets respectively and clamped in the locking grooves of the fixture rod, and the inner surface of the locking sleeve presses the steel balls. The quick-replacement fixture achieves quick and easy replacement of tools, effectively relieves labor intensity and improves working efficiency.

Owner:成都液力机械有限公司

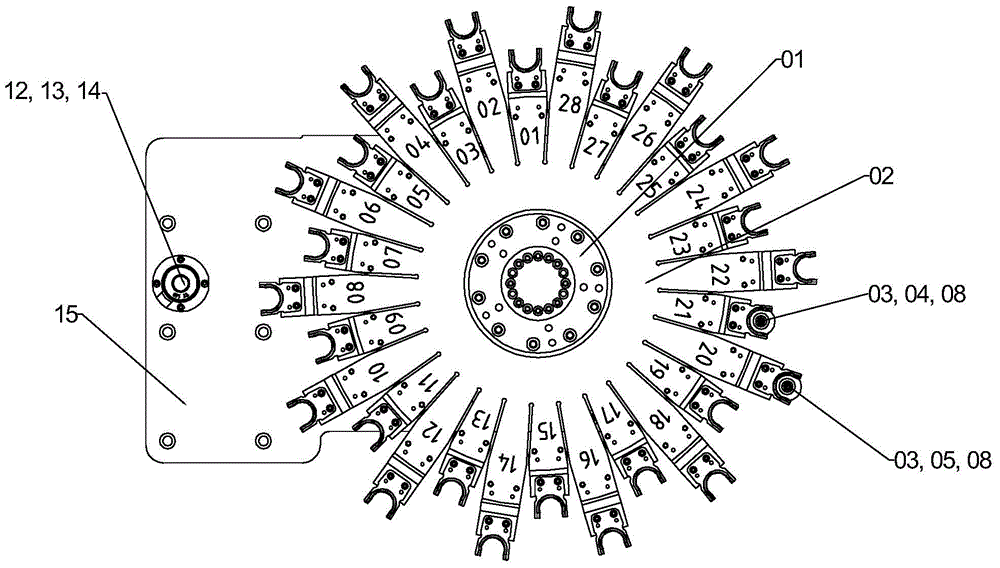

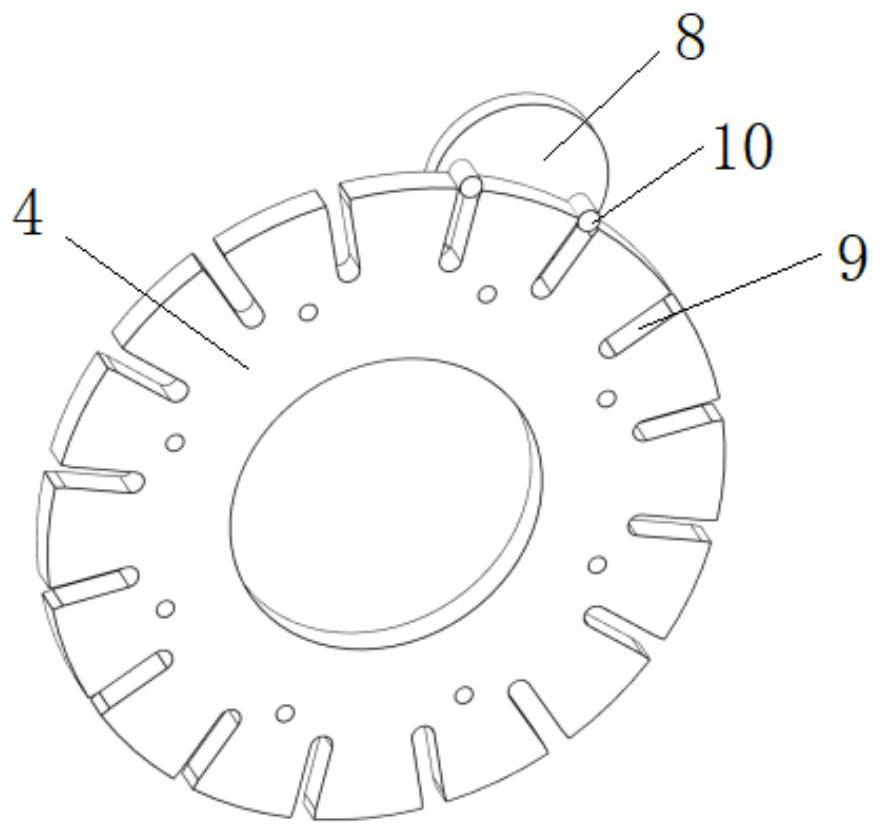

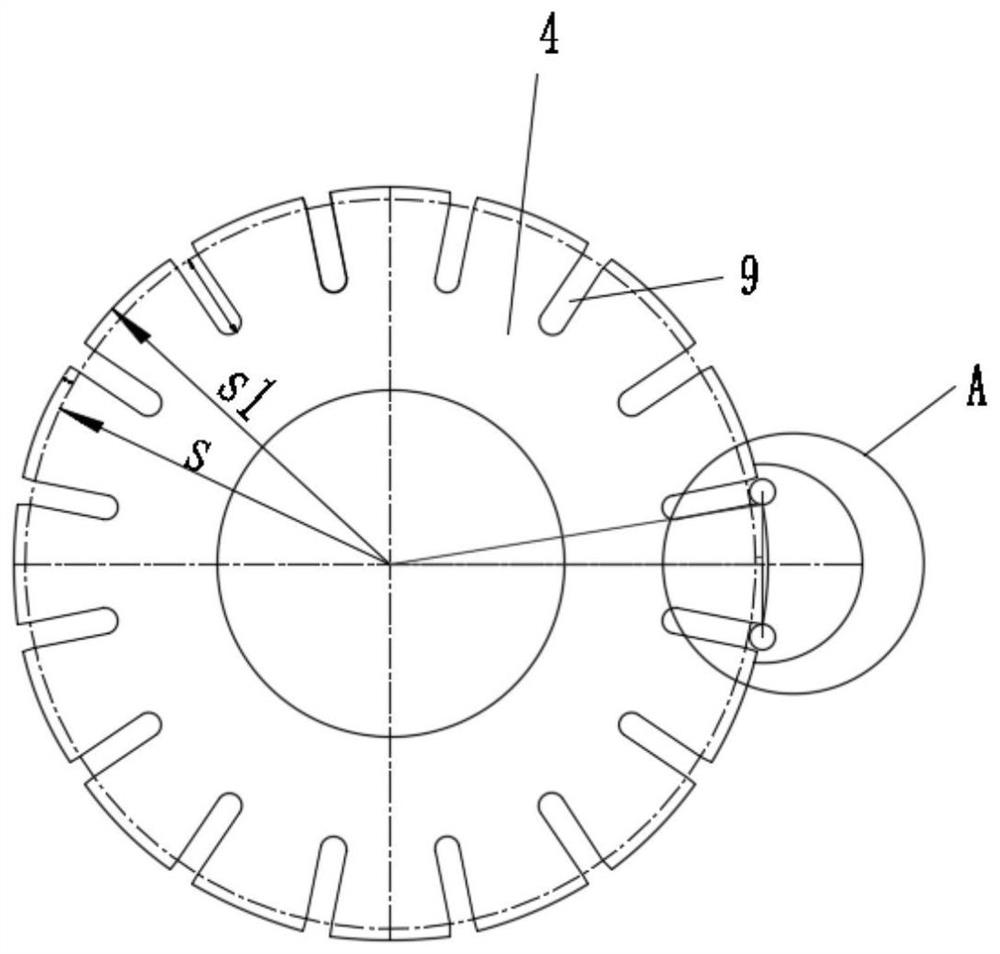

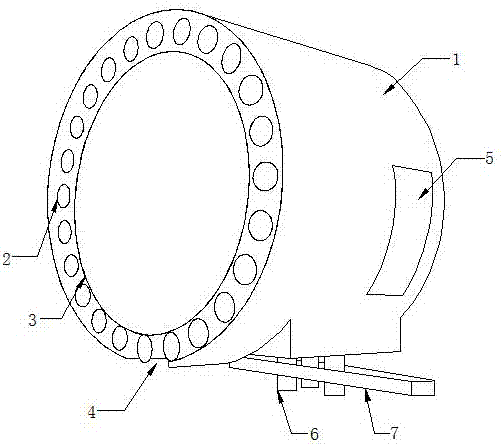

Structure-simplified disc type tool magazine

InactiveCN104385028ASimple structureFast tool changePositioning apparatusMetal-working holdersEngineeringSystem structure

The invention discloses a structure-simplified disc type tool magazine. The structure-simplified disc type tool magazine comprises a disc-shaped tool accommodating device, an automatic tool exchanging device and auxiliary tool exchanging devices, wherein a plurality of elastic tool clamping mechanisms are uniformly distributed on the circumference of the disc-shaped tool accommodating device; the auxiliary tool exchanging devices are arranged below the disc-shaped tool accommodating device and correspond to the positions of the elastic tool clamping mechanisms; the automatic tool exchanging device is arranged on one side of the auxiliary tool exchanging devices; the auxiliary tool exchanging devices are just arranged in the working radius of the tool exchanging device, so that exchanging work can be finished conveniently through the automatic tool exchanging device. The structure-simplified disc type tool magazine driven by a cylinder is adopted, and a group of auxiliary tool exchanging devices are added, so that the problem of interference between a tool shank clamping mechanism and the automatic tool exchanging device is solved. Meanwhile, the steering work of a tool shank is finished, the structure of a tool storing system of the whole tool magazine is simplified greatly, and a high tool exchanging speed is kept simultaneously.

Owner:续宗耀

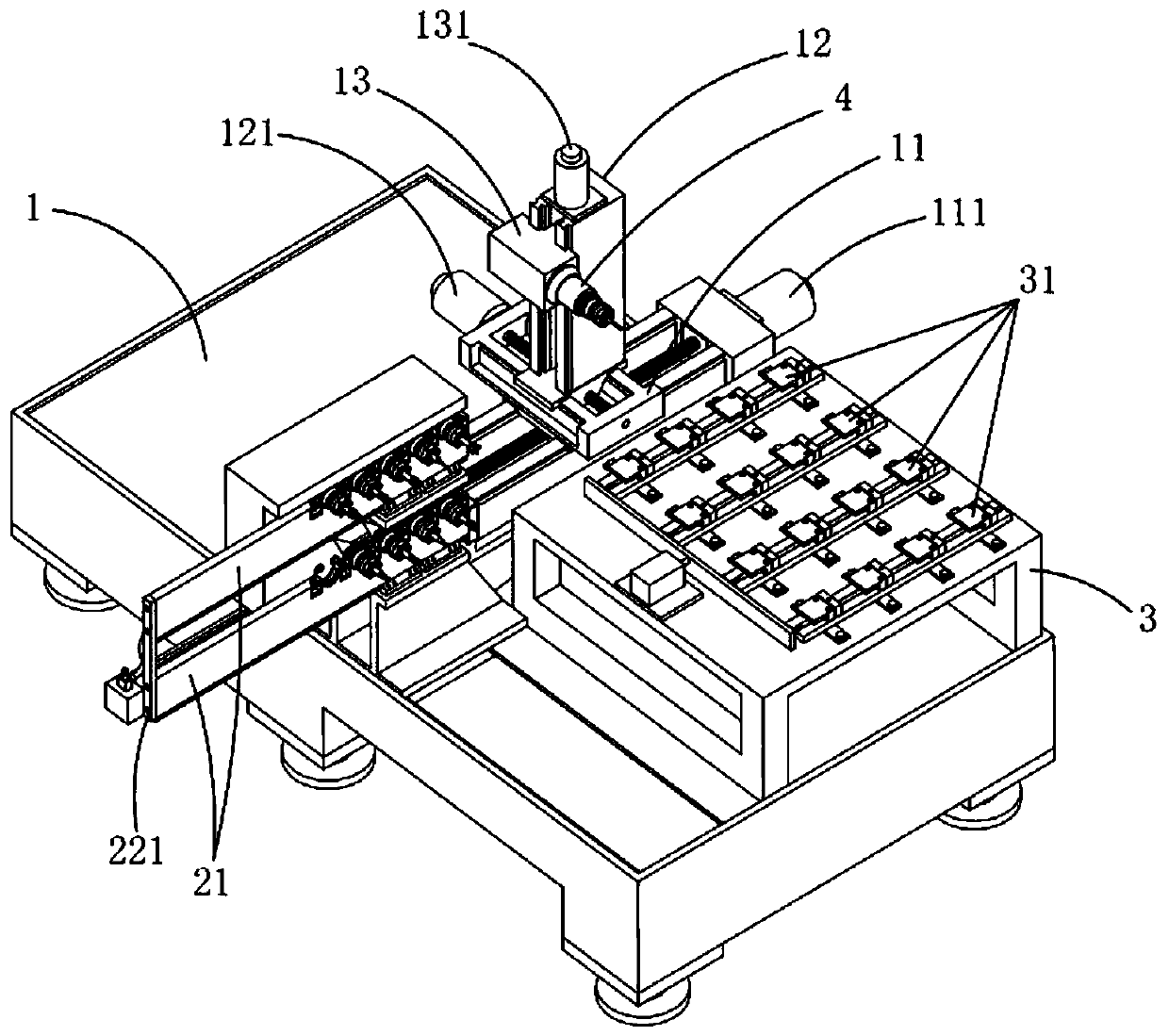

Special numerically-controlled milling machine for machining for television borders

InactiveCN109894654AImprove processing efficiencyImprove machining accuracyMilling machinesMilling equipment detailsMilling cutterEngineering

The invention discloses a special numerically-controlled milling machine for machining for television borders. Milling machine equipment for especially machining the end parts of television borders does not exist at present. The special numerically-controlled milling machine for machining for the television borders is capable of carrying out fully-automatic compound milling machining on parts to be machined, of the end parts of a plurality of border materials simultaneously; a spindle is driven to carry out milling machining and tool changing through a spindle box drive mechanism and a spindledrive mechanism, so that the full automation of the milling machining and the milling tool changing is realized; and the special numerically-controlled milling machine for machining for the television borders is capable of carrying out fully-automatic compound milling machining on the border materials, high in machining efficiency, high in machining accuracy, and stable and reliable in running.

Owner:东莞市广鑫数控设备有限公司

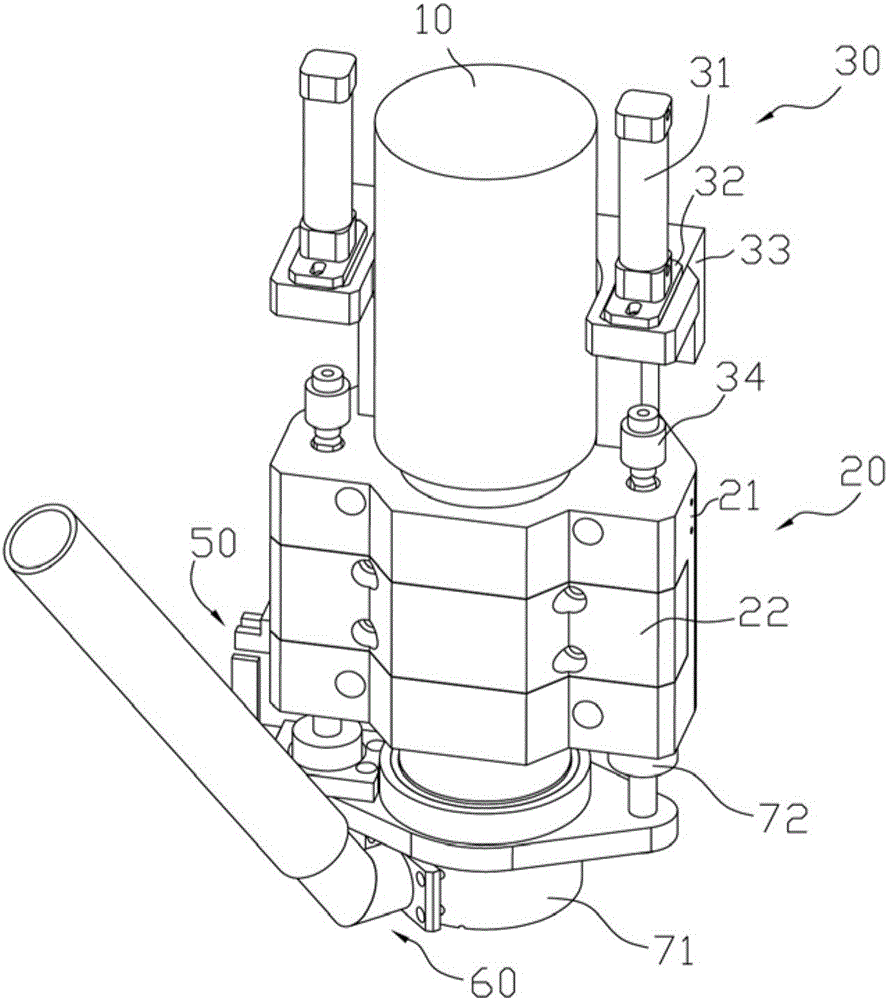

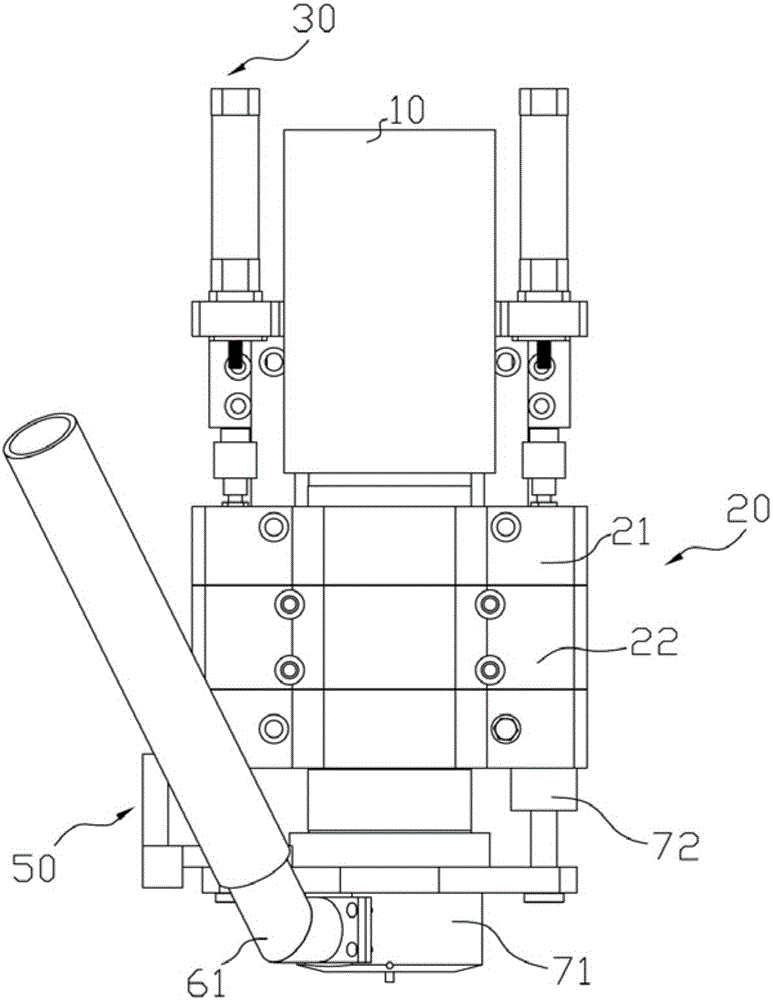

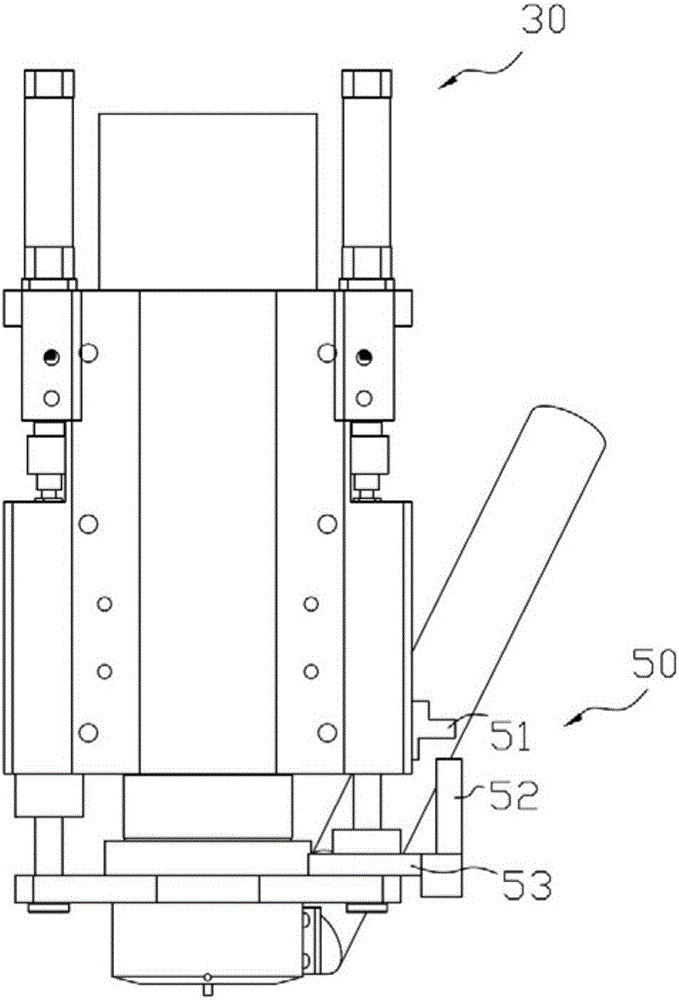

Automatic tool changing spindle device of PCB edge drilling and milling machine

InactiveCN105772750AFast tool changeIncrease productivityLarge fixed membersPositioning apparatusInterference fitEngineering

The invention discloses an automatic tool changing spindle device of a PCB edge drilling and milling machine. The automatic tool changing spindle device comprises a spindle, a clamping block, air cylinder assemblies, guide rod assemblies, an induction assembly, a dust collection assembly and a press foot assembly; the spindle penetrates a central hole of the clamping block to be mounted, and the center line of the spindle coincides with the center line center hole of the clamping block; the two sides of the symmetric face of the clamping block are each provided with one guide rod assembly, and each guide rod assembly comprises a guide rod located in a clamping block guide rod hole and a linear bearing tightly attached to the guide rod; the air cylinder assemblies are arranged over the guide rods, and the press foot assembly is arranged under the guide rods; air cylinder flotation joints of the air cylinder assemblies can be inserted into round holes in the tops of the guide rods to be in interference fit with the guide rods, and the spindle is in interference fit with a press foot table of the press foot assembly; and accordingly, air cylinders can drive the guide rods, the press foot assembly and the spindle to vertically move in the clamping block to achieve automatic tool changing work.

Owner:HUZHOU KEDA CHEM FUEL

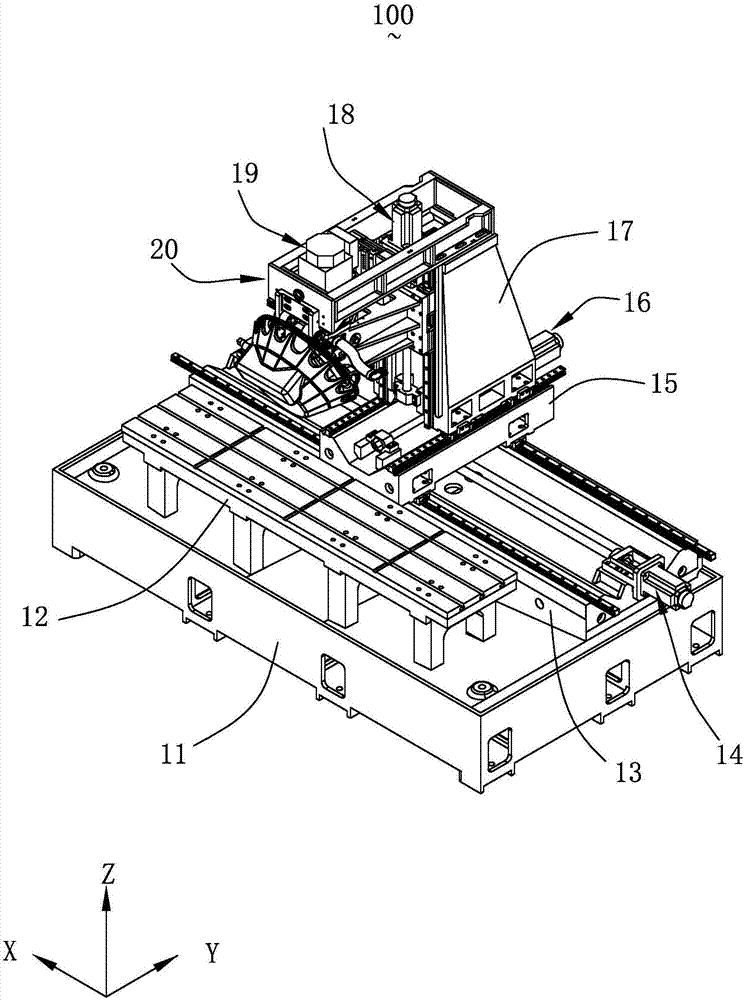

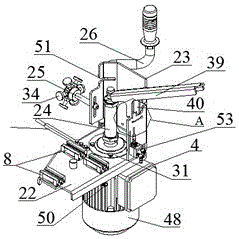

Drilling-milling tapping machine

PendingCN107138967ASmall footprintNot easy to wearLarge fixed membersPositioning apparatusMachineWorkbench

The invention discloses a drilling-milling tapping machine. The drilling-milling tapping machine comprises a base, a workbench fixed to the base, an installation table arranged on the base and located on one side of the workbench, an X-axis driving mechanism arranged on the installation table, a saddle erected on the installation table and driven by the X-axis driving mechanism, a Y-axis driving mechanism arranged on the saddle, a stand column arranged on the saddle and driven by the Y-axis driving mechanism, a Z-axis driving mechanism arranged on one side of the stand column, a main shaft box arranged on one side of the stand column and driven by the Z-axis driving mechanism, a tool changing system fixedly connected with the top of the stand column, and a protective cover arranged on the edge of the base. The main shaft box and the tool changing system are located above the workbench. The drilling-milling tapping machine is constant in load and good in stability.

Owner:中山长准机电有限公司

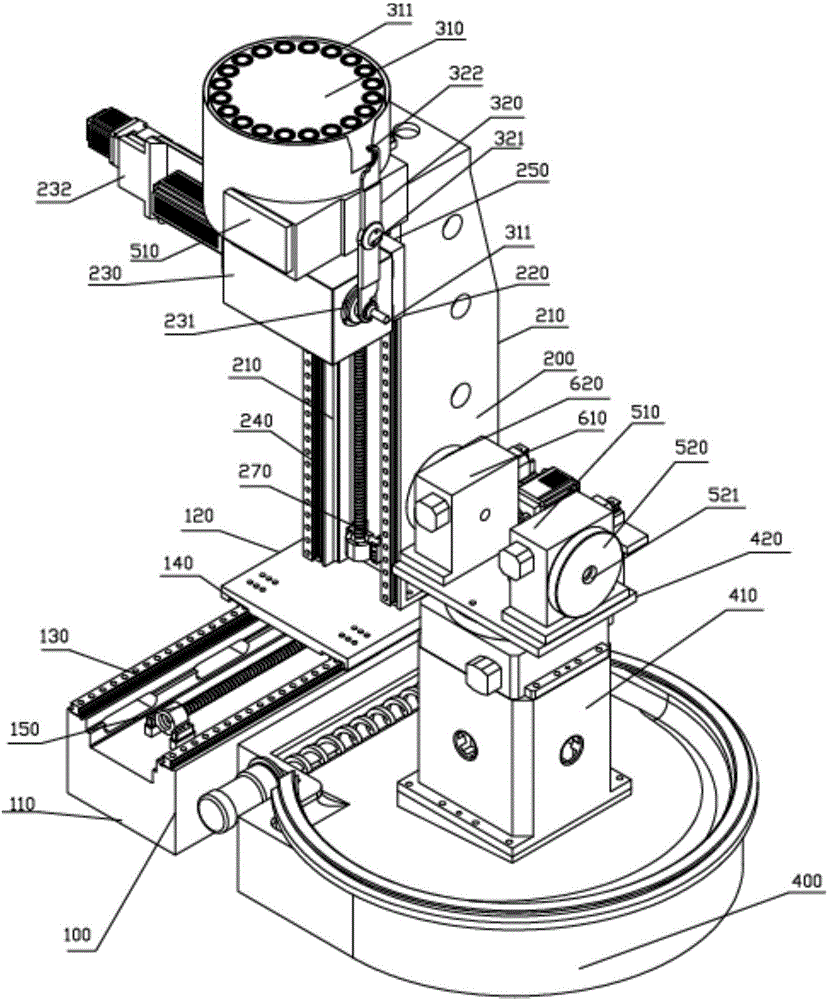

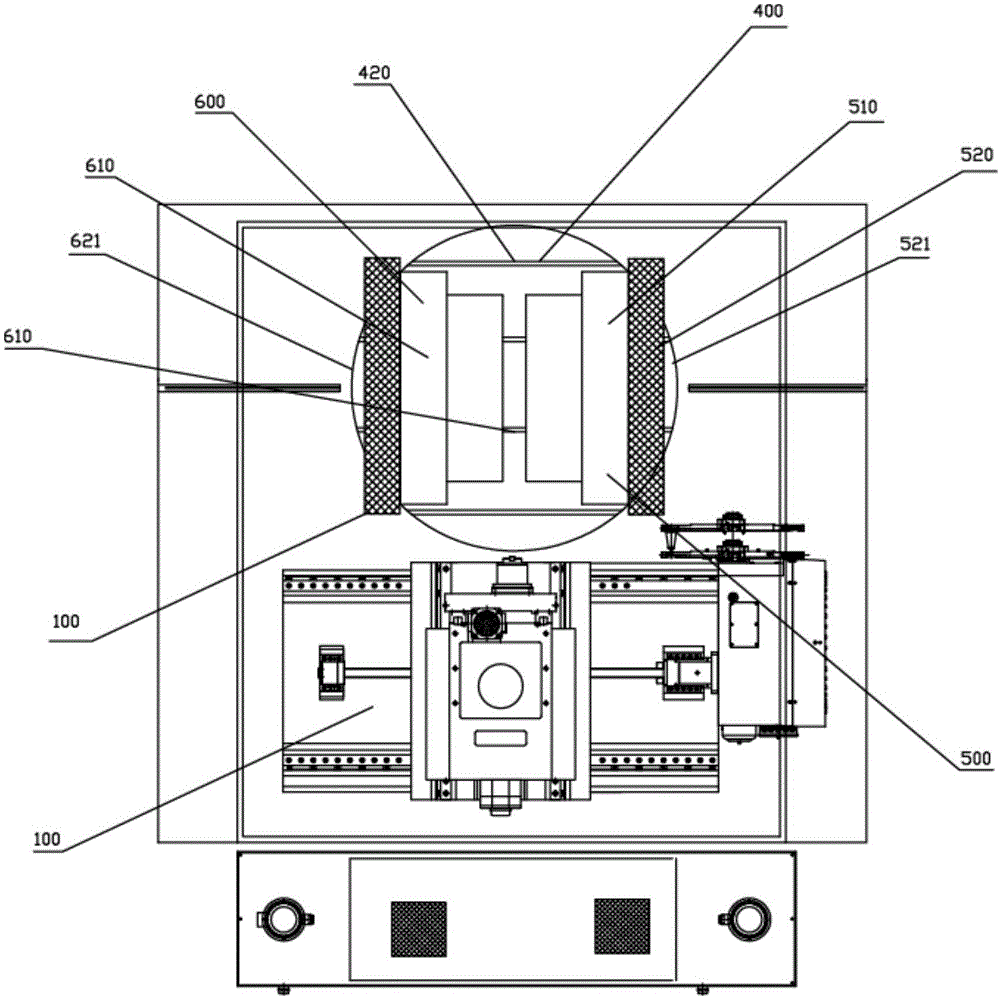

Pentahedron processing machine

ActiveCN106736630AOvercome the disadvantages of processingQuick tool changeFeeding apparatusLarge fixed membersThree-dimensional spaceMachine tool

The invention discloses a pentahedron processing machine which comprises an X-axis platform, a Z-axis platform, a tool magazine device, a first rotating table, a second rotating table and a third rotating table. Three-dimensional space rotation of a work piece is carried out by utilizing the rotating functions of the three rotating tables, and a good operation interface allows the programming difficulty of a pentahedron processing technique to be reduced; a tool changing arm, along with a tool changing library, is adopted for tool management, so that tools can be changed quickly and randomly, and the processing efficiency of a machine tool can be improved; and the three hydraulically driven rotating tables are adopted, the first rotating table is a base table, the second rotating table and the third rotating table that are hydraulically driven are additionally arranged on the upper surface of the first rotating table, the first rotating table allows the work piece to rotate at the Z-axis, the second rotating table and the third rotating table allow the work pieces to rotate at horizontal shafts, through the rotation of the three rotating tables, processing equipment capable of processing the five surfaces of the work pieces is formed, and the work pieces can be exchanged, so that the processing efficiency is higher.

Owner:SHENZHEN HUAYA CNC MASCH CO LTD

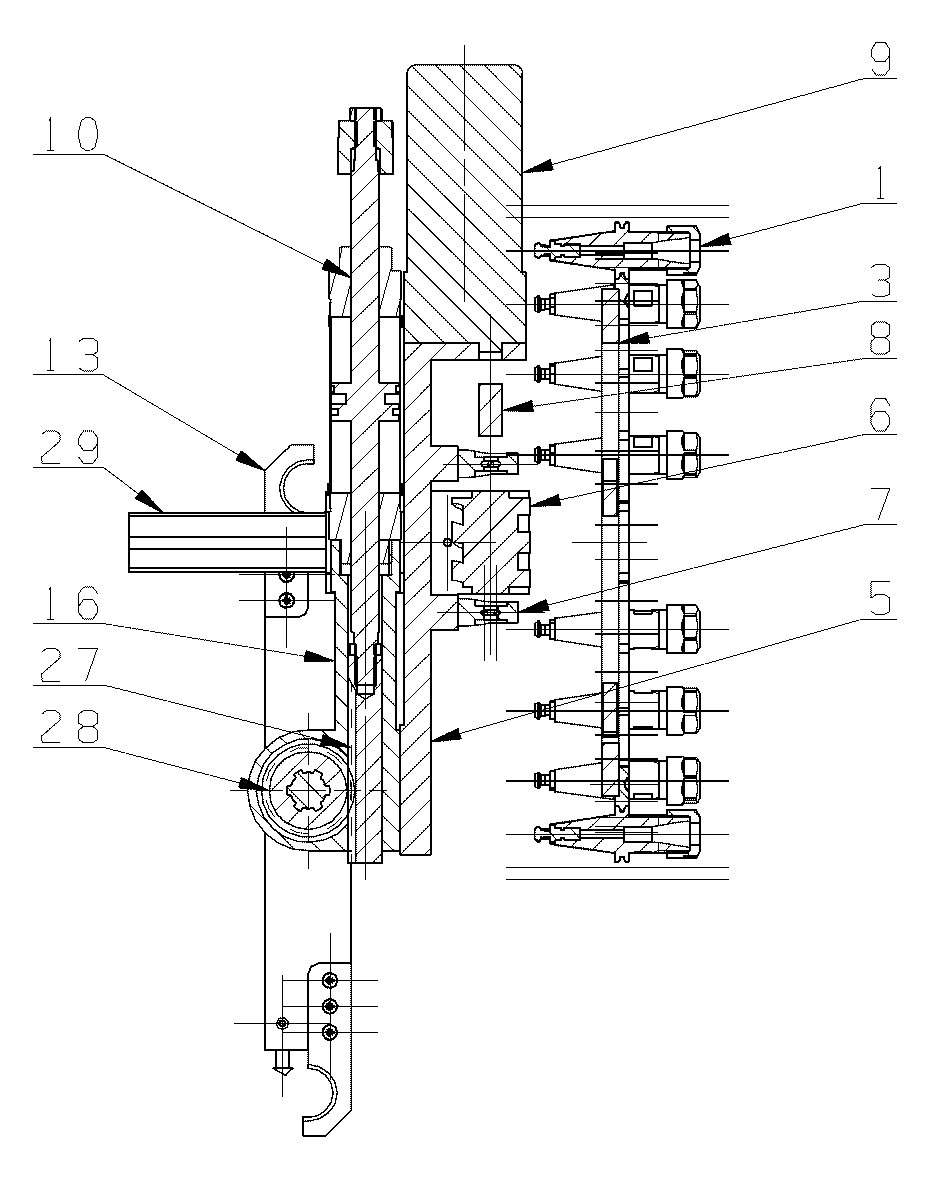

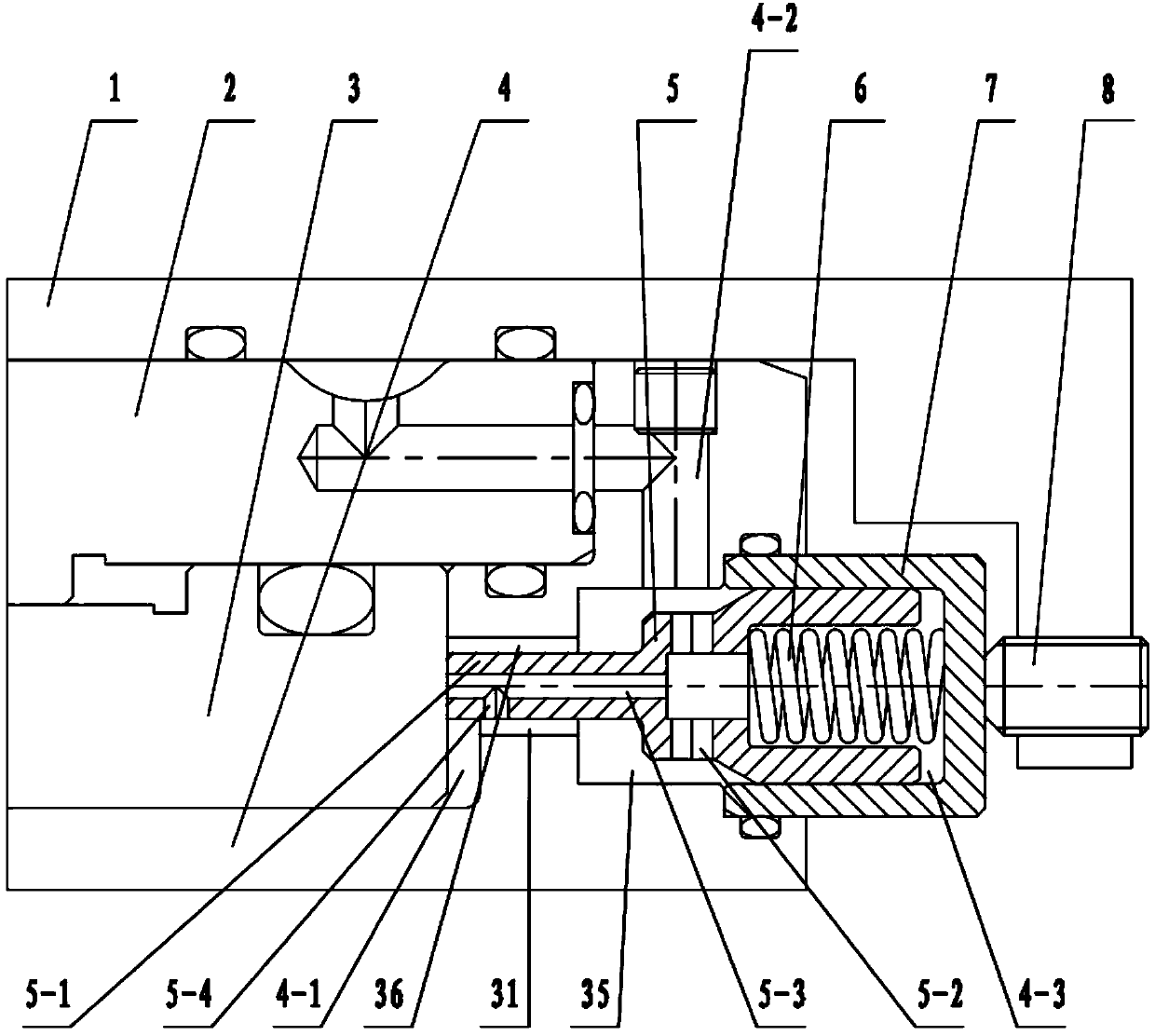

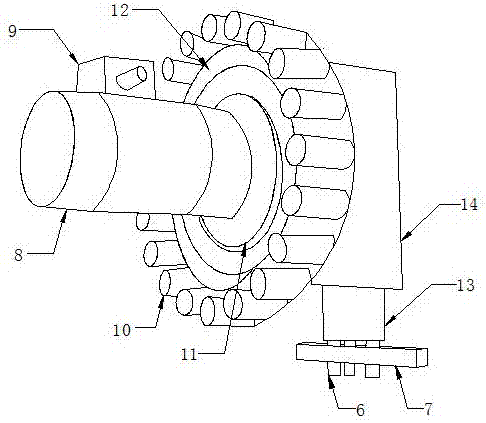

Hydraulic indexing tool rest

ActiveCN103418807AFast tool changeHigh tool change accuracyPrecision positioning equipmentPositioning apparatusPistonCam

The invention discloses a hydraulic indexing tool rest. The hydraulic indexing tool rest comprises a box body, a fixed axle, a cutter, a fixed tooth ring, a movable tooth ring, a tooth disk connecting plate, a piston, a hydraulic motor, a driving gear, a fixed axle gear, a parallel conjugate cam indexing mechanism, a signal sending wheel, a cutter locking sensor, a cutter spacing conversion sensor, a checkout wheel, a cutter sensor and a control system for controlling action of the piston and controlling action of the hydraulic motor, wherein the fixed tooth ring is meshed and matched with the movable tooth ring; the fixed tooth ring is fixedly connected with the tooth disk connecting plate; the movable tooth ring is fixedly connected with the cutter; the driving gear is movably connected with the parallel conjugate cam indexing mechanism; and the hydraulic motor is movably connected with the parallel conjugate cam indexing mechanism so as to drive continuous input motion of the hydraulic motor to be converted into intermittent output motion of the driving gear. According to the hydraulic indexing tool rest, the tool changing speed and tool changing precision can be improved, the cutter is driven to rotate with hydraulic pressure, indexing, loosening and locking actions are smooth, the torque is large and stable, and the hydraulic indexing tool rest is suitable for machine tools for heavy cutting and continuous indexing requirements.

Owner:JIANGSU HONGDA NUMERICAL CONTROL TECH CO LTD

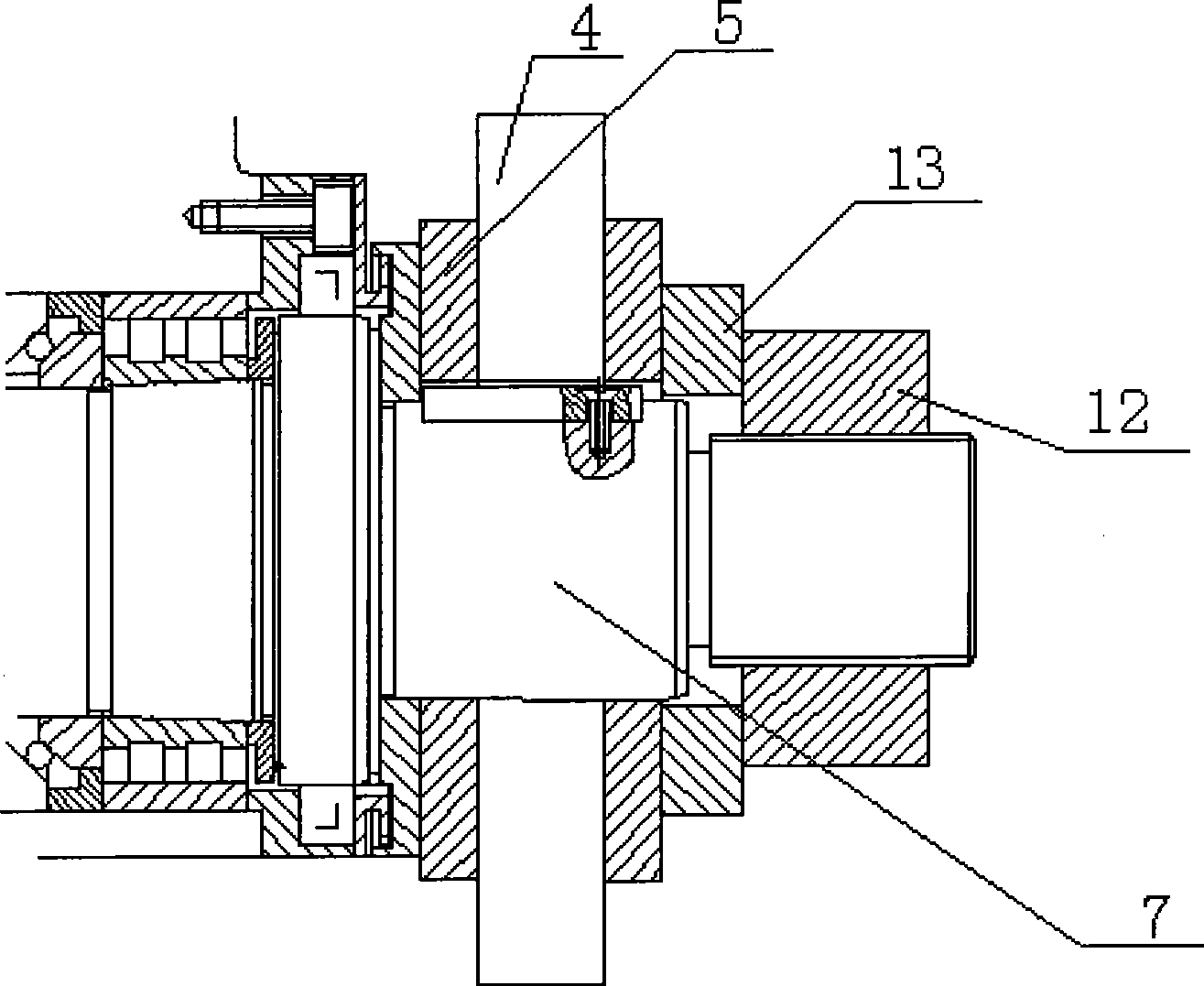

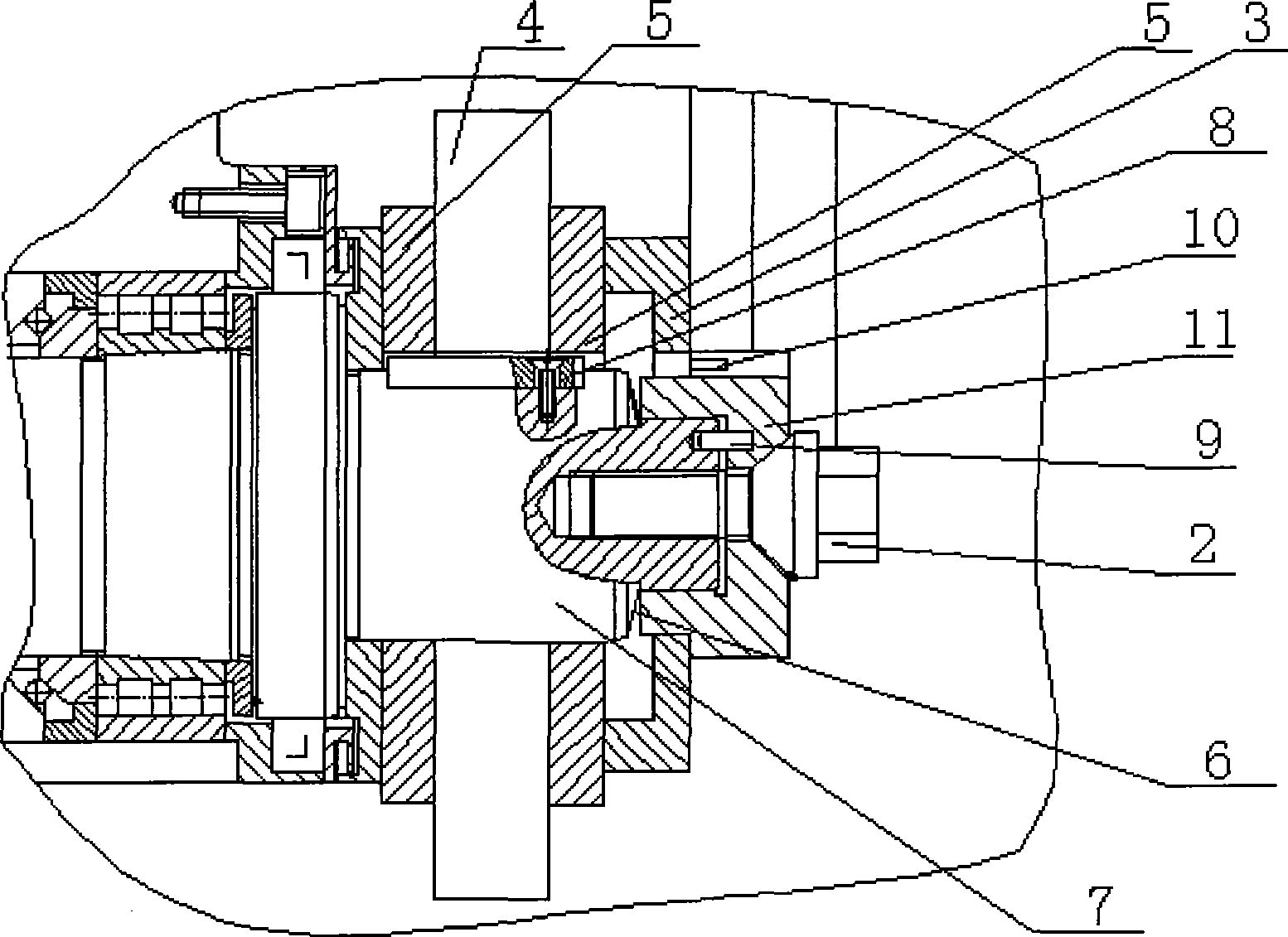

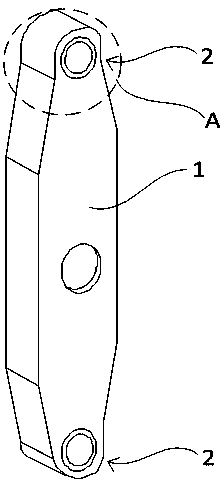

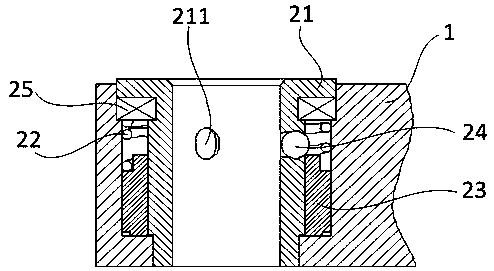

Gear-shaving machine knife quick change mechanism

ActiveCN101474697AEasy to removeFast tool changePositioning apparatusGear-cutting machinesMaximum diameterEngineering

The invention discloses a quick cuter replacing mechanism for a gear tooth shaving machine. A shaving cutter and cutter cushion rings are sheathed on a main shaft, and the cutter cushion rings are positioned on both sides of the shaving cutter. The quick cuter replacing mechanism is characterized in that a spline shaft (11) is sheathed on the outer tip of the main shaft (7) and is tightly fixed by an axial locking screw (12); a spline on the spline shaft (11) is shorter than the spline shaft, and the end of an optical shaft is adjacent to the cutter cushion rings (5); a quick-release cushion ring (3) provided with a spline slot is flexibly sheathed on the spline shaft (11), and spacer pins (10) are arranged on the outer end face of the quick-release cushion ring (3); and the inner diameters of the shaving cutter (4) and the cutter cushion rings (5) are larger than the maximum diameter of the spline shaft (11). The quick cuter replacing mechanism for the gear tooth shaving machine has the advantages of quick cutter replacement, effective looseness prevention, compact structure, convenient operation and high safety and reliability.

Owner:CHONGQING MACHINE TOOL GROUP

Disc type tool magazine for horizontal machining center

InactiveCN105479230AEasy to install manuallyCompact structurePositioning apparatusMetal-working holdersEngineeringMachining

The invention discloses a disc type tool magazine for a horizontal machining center. The disc type tool magazine comprises a disc arranged on a fixing support I, a rotation shaft is arranged at the center of the disc which rotates around the center of the disc through the rotation shaft, a plurality of tool clamps are installed at the edge of the disc, and axes of tool holding portions of the tool clamps are parallel to the surface of the disc. Tools are installed on the tool clamps through the tool holding portions, axes of the tools are parallel to the surface of the disc, and tool noses of the tools point to the circle center of the disc. The fixing support I is installed on one side of the horizontal machining center, and the axis of the disc is parallel to the X axis of the horizontal machining center. By means of the disc type tool magazine, the width of the tool magazine is not limited by the length of the tools and can be further compressed, the structure is simple and compact, and wide application is facilitated.

Owner:SYMGHONG KONGCOMPANY

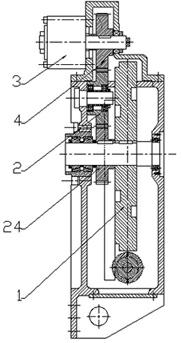

Electromagnetic piston type tool changing device

PendingCN109434535AAvoid wear and tearFast tool changePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides an electromagnetic piston type tool changing device which comprises a tool changing arm for rotating, and a tool changing hand for clamping a tool. The tool changing hand comprises a clamping holder, an elastic piece, a piston, abutted-against pieces and an electromagnet; the clamping holder is arranged on the tool changing arm; multiple assembling holes are formed in the circumferential wall of the clamping holder in a penetrating way; the elastic piece, the piston and the electromagnet are arranged on the clamping holder in a sleeving mode; the position of the electromagnet remains stationary relative to the piston; two ends of the elastic piece are elastically abutted against the electromagnet and the piston; and the multiple abutted-against pieces are movably arranged in the multiple assembling holes in the clamping holder and are abutted against the piston. According to the electromagnetic piston type tool changing device, no impact happens during the tool changing process, and the tool is clamped by multiple independent parallel functional components, so that the safe operation factor is high; and a locking manner is changed, so that the occurrence of the phenomenon of tool falling can be effectively prevented.

Owner:SUZHOU VOCATIONAL UNIV

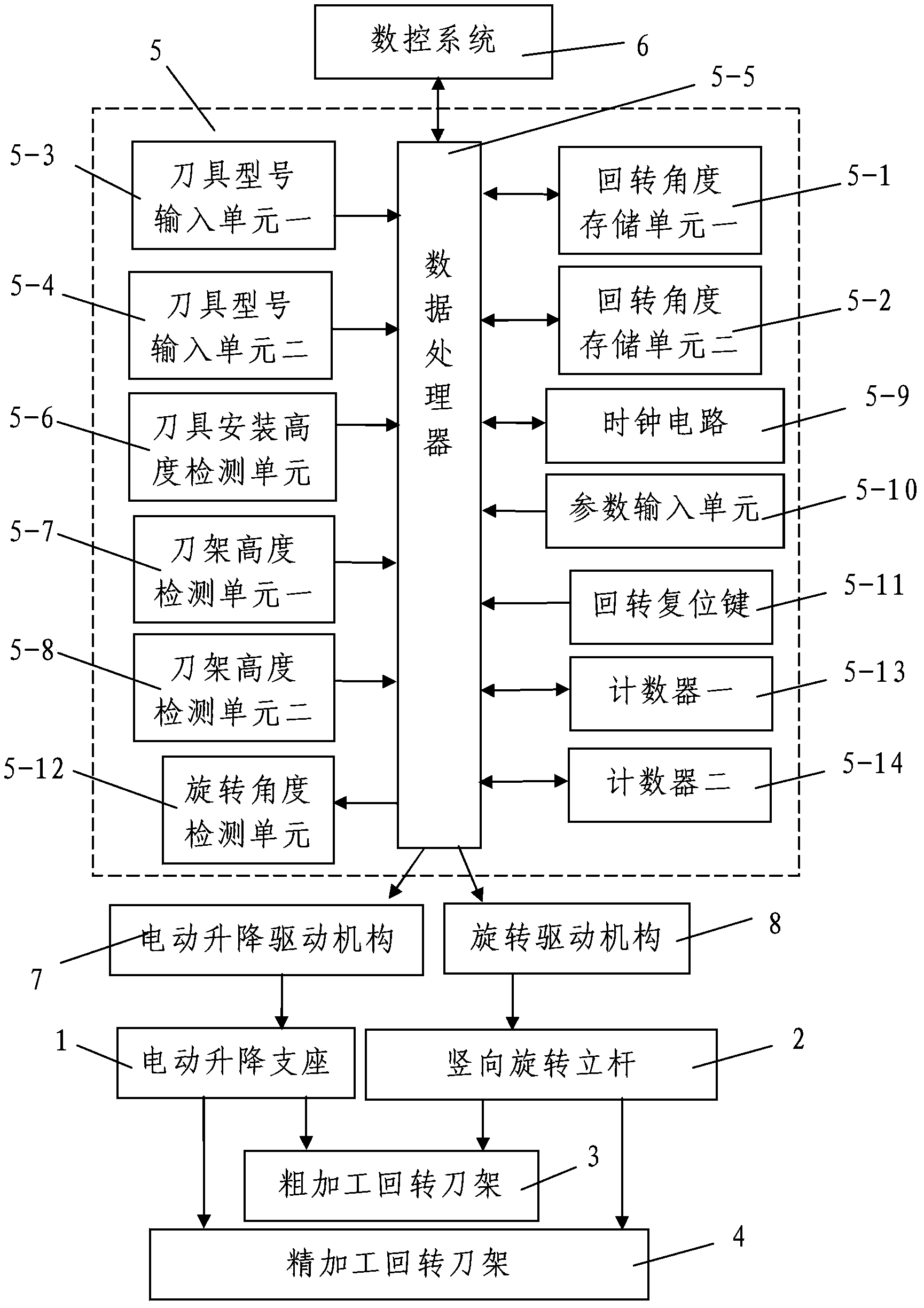

Automatic tool changer of circular cutter holders for CNC machining center

InactiveCN103801963AReasonable designLow costPositioning apparatusMetal-working holdersTurn angleControl system

The invention discloses an automatic tool changer of circular cutter holders for a CNC machining center. The automatic tool changer comprises an automatic tool changing control system, an electric lifting support, an electric lifting driving mechanism, a vertically rotary stand rod, a rotation driving mechanism, the rough machining circular cutter holder and the finish machining circular cutter holder, wherein the rough machining circular cutter holder and the finish machining circular cutter holder are installed on the vertically rotary stand rod. The automatic tool changing control system is connected with a numerical control system of the CNC machining center. The finish machining circular cutter holder is located under the rough machining circular cutter holder. The automatic tool changing control system comprises a data processor, a first turning angle storage unit, a second turning angle storage unit, a first tool model input unit, a second tool model input unit, a tool installation height detection unit, a first tool rest height detection unit and a second tool rest height detection unit. The automatic tool changer is reasonable in design, easy and convenient to operate, high in intelligent degree, good in using effect and capable of changing tools automatically according to rough and finish machining procedures on workpieces by the CNC machining center and meeting the requirement for automatic tool changing of many tools.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

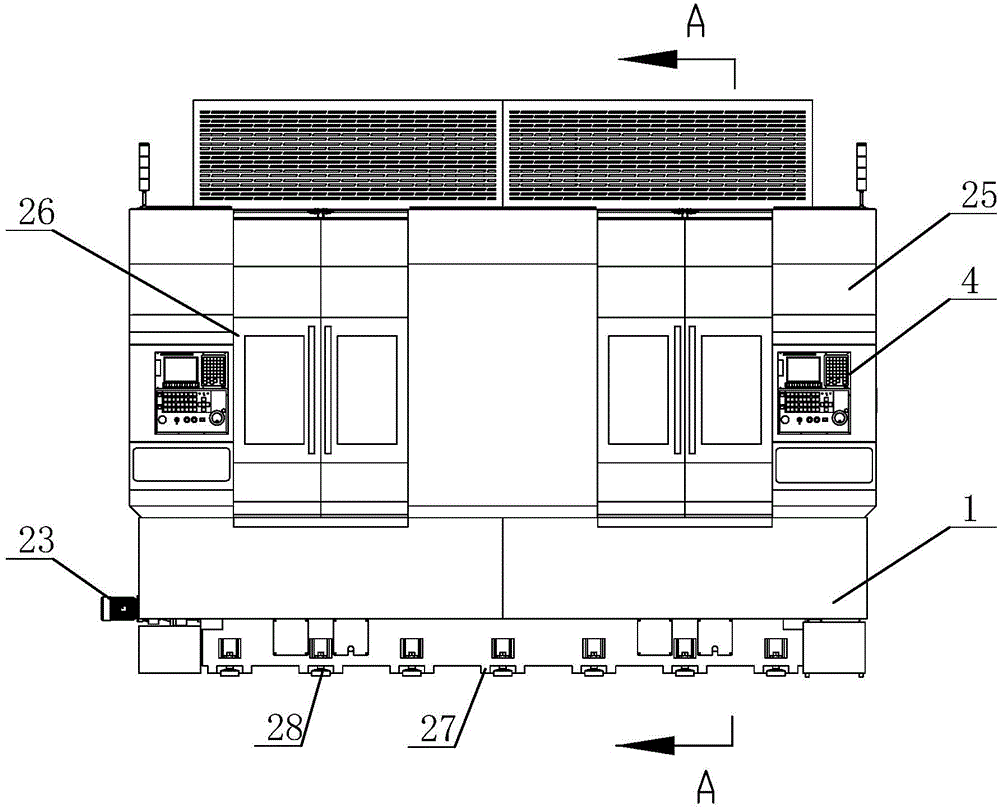

Multi-spindle numerical control vertical type special lathe

ActiveCN104801727AReduce manufacturing costLabor savingCamsAutomatic/semiautomatic turning machinesNumerical controlEngineering

The invention relates to a multi-spindle numerical control vertical type special lathe, which comprises a base, wherein a processing mechanism is arranged on the base and comprises two vertical spindle units, the two spindle units are closely arranged along the transverse direction, a vertical column is arranged at the back side of each spindle unit, a vertical tail seat unit and two feeding units are arranged on each vertical column, and the two feeding units are respectively arranged at the two transverse sides of the corresponding tail seat unit; each tail seat unit comprises a first slide device, a tail seat is arranged on each first slide device, and two vertical tail seat sleeve cylinders are arranged at the lower part of each tail seat, are positioned above spindles, and are correspondingly arranged; each feeding unit comprises a second slide device and a transverse movement device, each transverse movement device is arranged on the corresponding second slide device, a knife holder is arranged on each transverse movement device, each first slide device and each second slide device can be moved on the corresponding vertical column along the vertical direction, and each transverse movement device is moved on the corresponding second slide device along the transverse direction. The multi-spindle numerical control vertical type special lathe has the advantages that multiple different types of camshaft parts can be simultaneously processed, and the production efficiency is high; the whole land occupation area of the equipment is small.

Owner:JINAN FIRST MACHINE TOOL GROUP

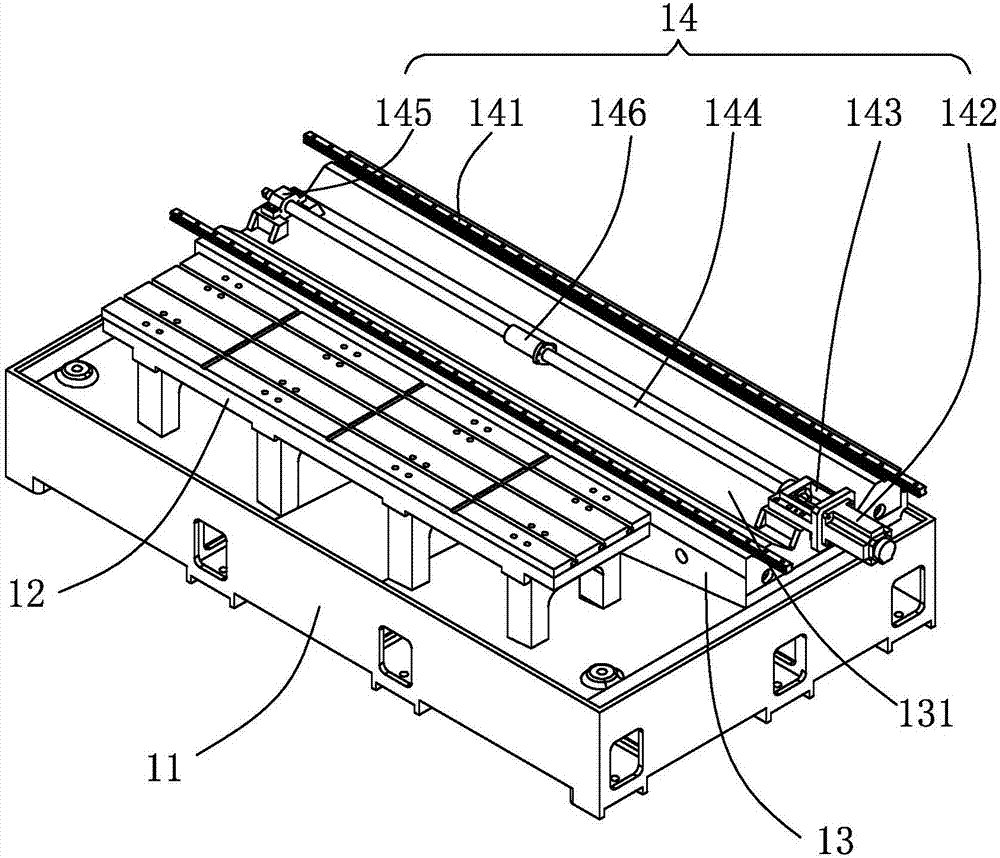

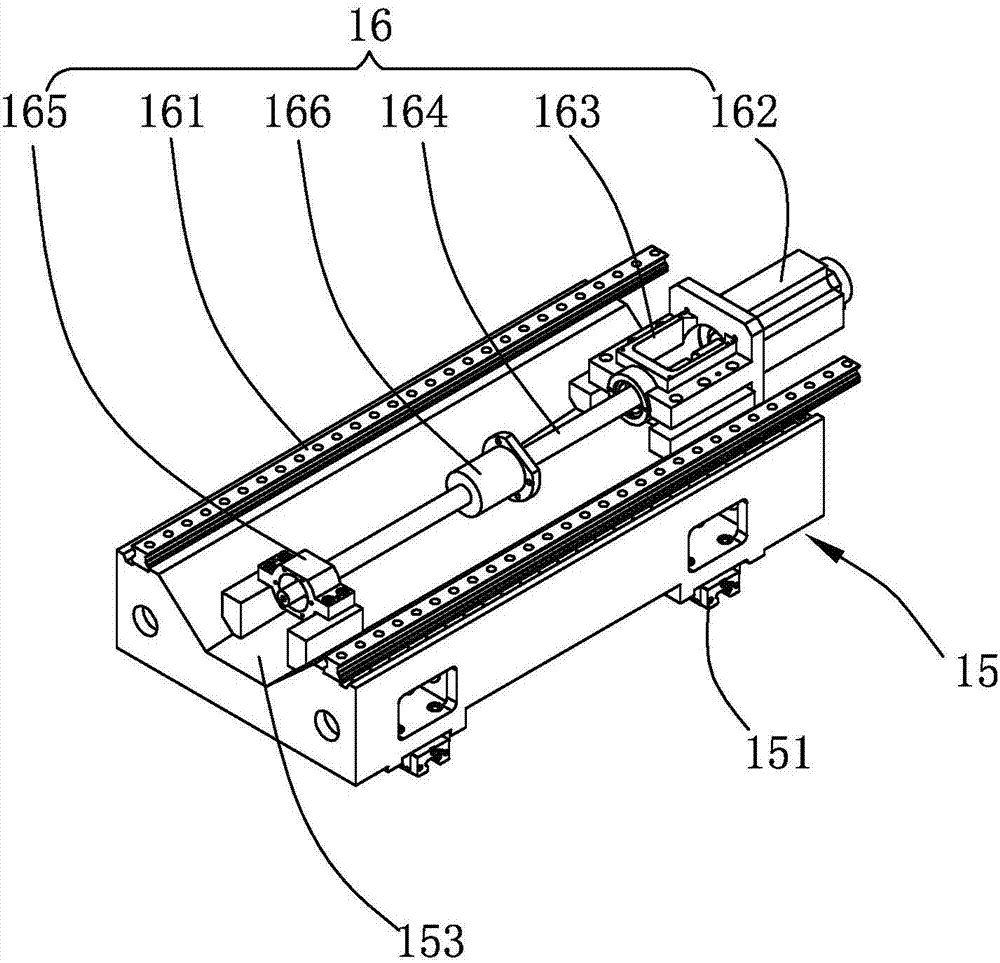

Aluminum profile end face milling machine

ActiveCN105880696AImprove machining accuracyImprove the safety protection factorWork clamping meansWorkpiecesEngineeringAlloy

The invention relates to an aluminum profile end face milling machine which is used for machining of aluminum profiles or PVC or light alloy, and belongs to the field of machining. The aluminum profile end face milling machine comprises a milling machine box, a positioning clamping device, a tool device, a protecting cover and a safety hood, cross beams are arranged on the front side and the right side inside the milling machine box respectively, the positioning clamping device is installed on the cross beams through screws, a control switch is arranged on the front face of the milling machine box, two rows of parallel sliding blocks are arranged on the tool device, a guide rail is arranged at the bottom of the positioning clamping device, the sliding blocks are matched with the guide rail, the tool device moves back and forth through the sliding blocks, the protecting cover is located above the tool device, the safety hood is installed on the milling machine box, and the safety hood and the milling machine box together form a closed whole. The aluminum profile end face milling machine has the advantages of being high in machining precision, high in tool changing speed, convenient to operate, accurate in positioning and high in safety protection coefficient.

Owner:EMMEGI SUZHOU

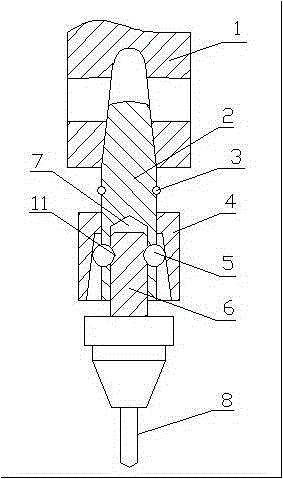

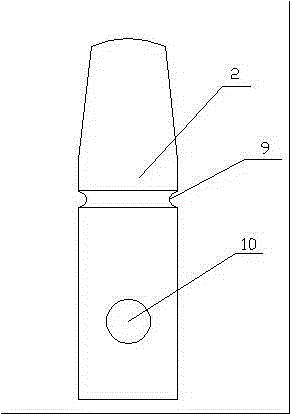

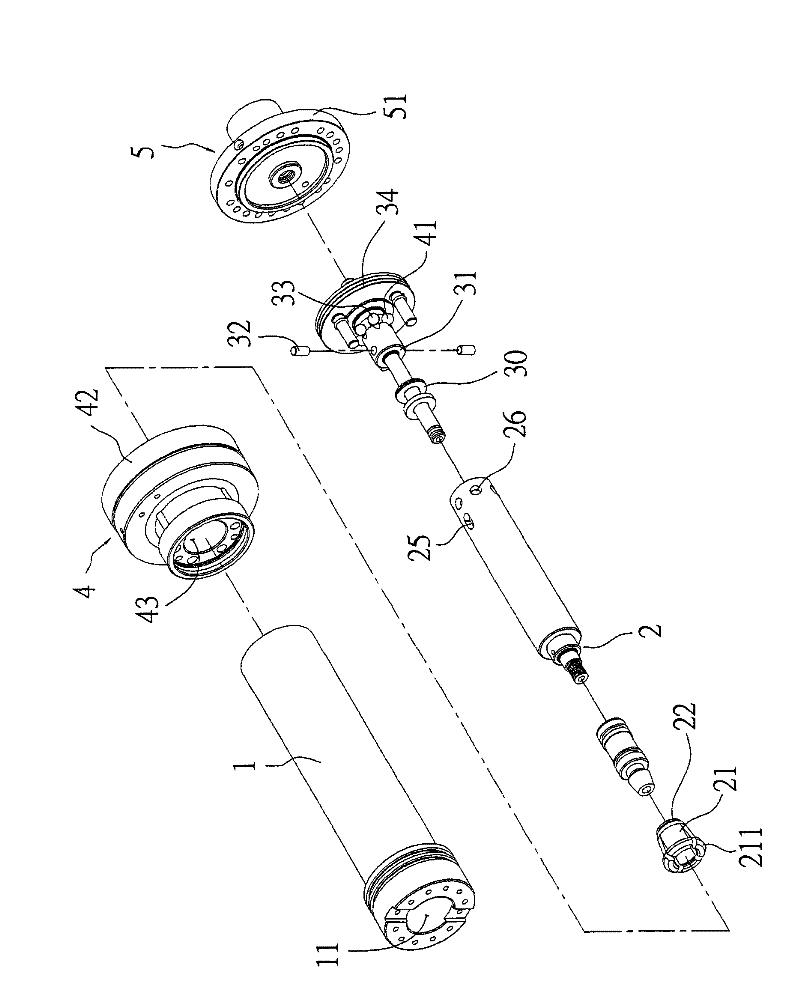

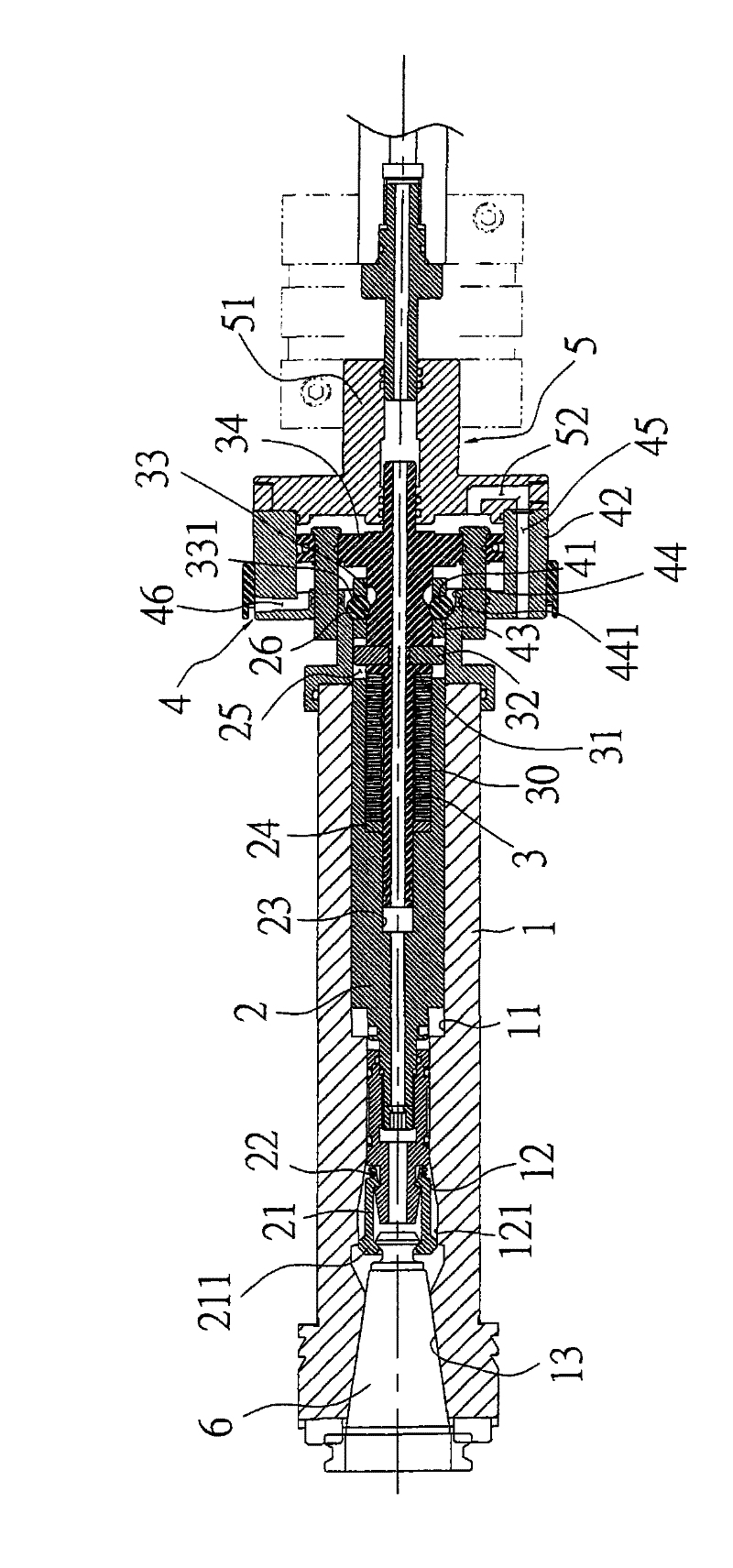

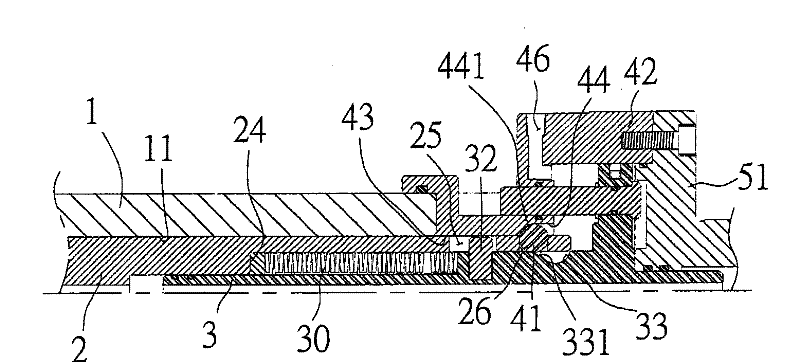

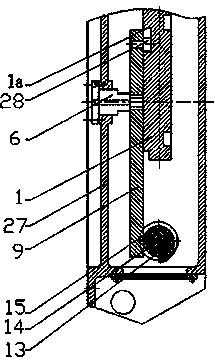

Cutter clamping device

The invention relates to a cutter clamping device. The device is mainly characterized in that a drawbar is arranged in a spindle hole, and a spring set and a push bar are arranged in the draw bar to ensure that the spring set is arranged between the drawbar and the push bar. By using the cutter clamping device of the invention, when the cutter is retracted, the compressed spring set can not directly support and press the spindle hole and damage the bearing covered outside the spindle; and the design of the power intensifier with high amplification factor is utilized to clamp the cutter with the spring set with the least springs and the minimum diameter and the diameter of the spindle is reduced, thus the centrifugal force generated by the rotation of the spindle can be reduced and vibrations can be avoided when the spindle runs so that the condition of inaccurate finished surface can be prevented; and the high-speed actuation of the spindle can be facilitated while the diameter and length of the spindle are reduced.

Owner:FACTORY AUTOMATION TECH CO LTD

Tool magazine of glass machine

InactiveCN106312653AFast tool changePrecise positioningPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a tool magazine of a glass machine. The tool magazine comprises a D-shaped cutter head, wherein 9-11 cutter claws are uniformly arranged on the cutter head, and each cutter claw is loaded with a cutter and is molded by integrating steel and plastic. According to the tool magazine of the glass machine, the weight of the cutter head and the number of the cutter claws are appropriate, cutter replacement is fast, and the operation efficiency is high.

Owner:SHENZHEN CREATE CENTURY MACHINERY

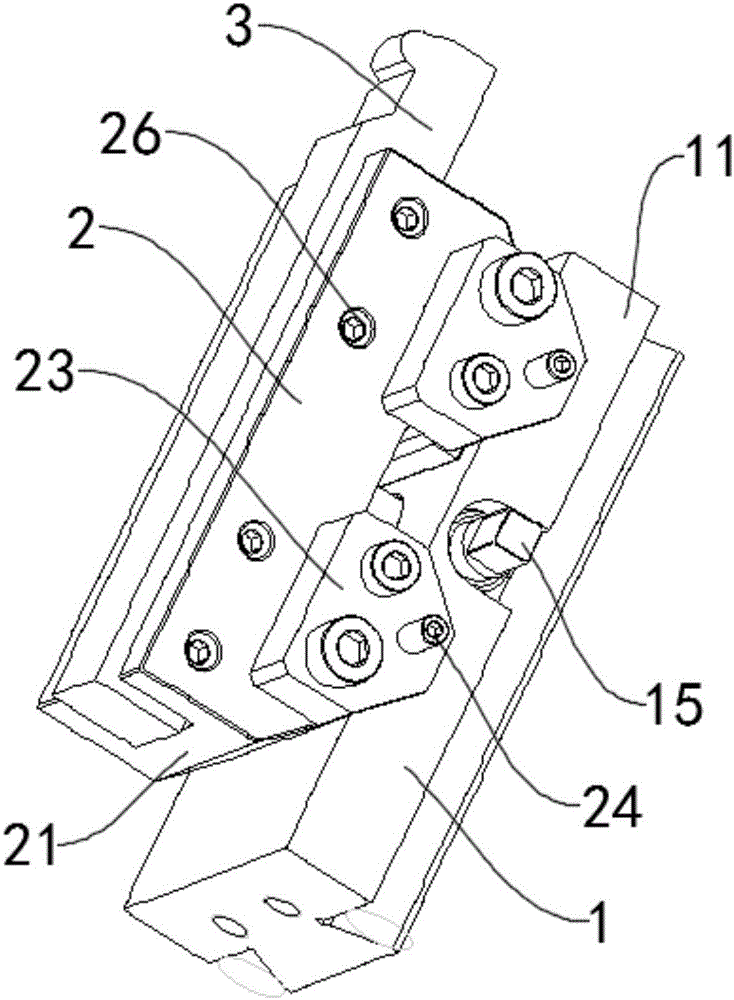

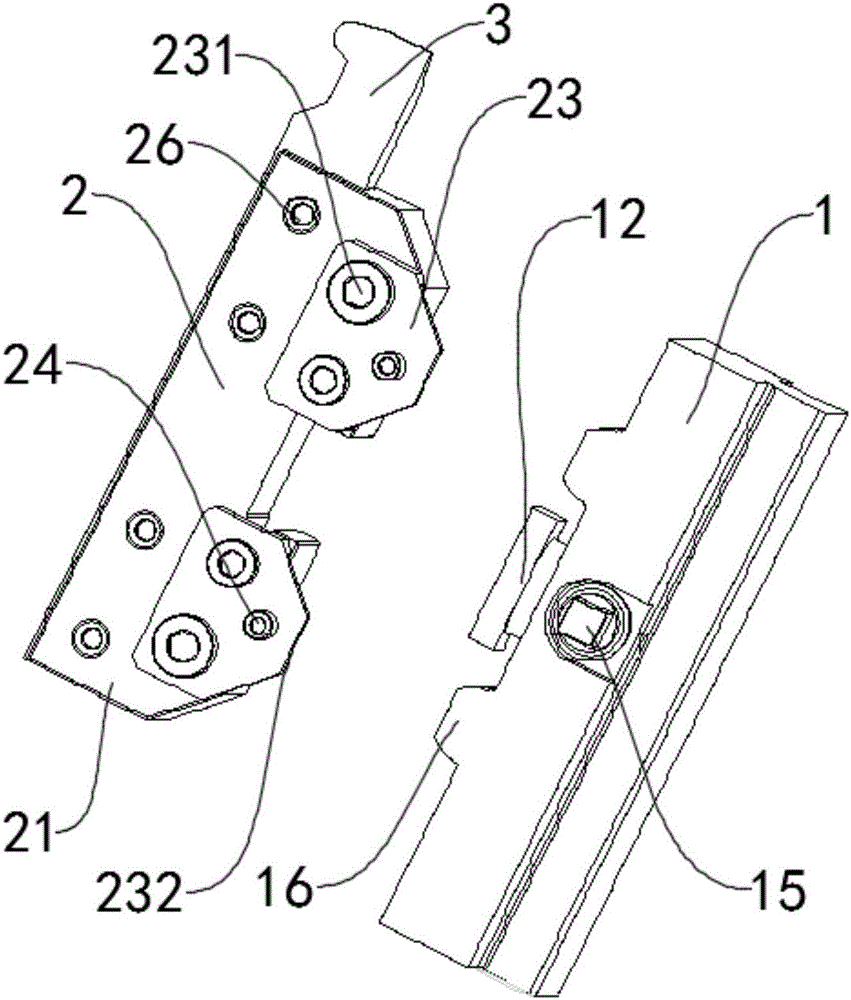

Rapid tool changing device

ActiveCN106181460AFast tool changeIncrease productivityPositioning apparatusMetal-working holdersMechanical engineeringEngineering

A rapid tool changing device comprises a fixed tool apron assembly, a movable tool apron assembly and a blade. The fixed tool apron assembly comprises a fixed tool apron and clamping blocks. The clamping blocks are adjustably fixed to the fixed tool apron. The movable tool apron assembly comprises a movable tool rest and a clamping slot. The clamping slot is fixedly arranged on the movable tool rest. The fixed tool apron assembly and the movable tool apron assembly are fixedly connected in the manner that the clamping blocks and the clamping slot are connected in a clamped manner. The blade is fixed to the movable tool rest. Each clamping block comprises a clamping body and a clamping head. The clamping bodies are fixedly and adjustably fixed into the fixed tool apron. Each clamping head is fixedly arranged at the end, extending out of the fixed tool apron, of the corresponding clamping body. The fixed tool apron is provided with a first installation hole and a second installation hole. The clamping bodies are installed in the first installation hole. A rotatable clamping rod is installed in the second installation hole. According to the rapid tool changing device, tool changing is rapid and convenient, extra fine adjustment is not needed, the tool changing speed is increased, and the production efficiency is improved.

Owner:ZHEJIANG TOMAN ZHIZAO TECH CO LTD

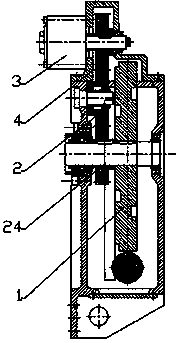

Locking oil cylinder structure with stroke tail end buffered

The invention discloses a locking oil cylinder structure with a stroke tail end buffered. The locking oil cylinder structure comprises an oil cylinder seat, a buffer valve sleeve, a buffer valve element, a piston and a spring, the oil cylinder seat is provided with an oil supply channel and an oil cylinder cavity, the buffer valve sleeve is arranged on the oil cylinder seat, the piston is located in the oil cylinder cavity, the buffer valve element is arranged in the buffer valve sleeve in a sliding and matching mode, the spring is arranged between one end of the buffer valve element and the buffer valve sleeve, the other end of the buffer valve element stretches into the oil cylinder cavity, a large-flow channel and a small-flow buffer channel which are used for supplying oil to the oil cylinder cavity are arranged between the oil supply channel and the oil cylinder cavity, the large-flow channel is arranged between the oil cylinder seat and the buffer valve element, and the small-flow buffer channel is arranged on the buffer valve element. When the piston reaches a certain stroke, the buffer valve element is matched with the oil cylinder seat under the action of the spring to plug the large-flow channel, and oil passes through the small-flow buffer channel from the oil supply channel and flows into the oil cylinder cavity. The locking oil cylinder structure can achieve the quick locking function, and has the buffer function in the later locking period, and therefore tool changing speed can be improved, and meanwhile the impact phenomenon is avoided.

Owner:CHANGZHOU XINSHU MASCH TOOL CNC EQUIP CO LTD

High-stability tool changer rotating indexing mechanism

InactiveCN111975425AFast tool changeReduce shock loadPositioning apparatusMetal-working holdersEngineeringStructural engineering

The invention discloses a high-stability tool changer rotating indexing mechanism. The mechanism comprises a substrate; a pair of slide rails is arranged at the bottom of the substrate; a moving seatis arranged between the slide rails; a rotating indexing disc is arranged at the bottom of the moving seat; a tool changer disc is fixed at the bottom of the rotating indexing disc; an indexing inversion mechanism is arranged on the moving seat and drives the rotating indexing disc to rotate; the indexing inversion mechanism comprises a stirring disc which is arranged at the bottom of the moving seat via a rotating shaft; n concave grooves are equidistantly formed in the rotating indexing disc and n > 8; two symmetrically arranged round pins which are engaged with the concave grooves are arranged on the stirring disc; and transition circular arcs are formed in the outer end parts of the concave grooves, so the concave grooves extend outwardly to form modifying grooves. Through the arrangement that the transition circular arcs are formed in the outer end parts of the concave grooves and that the concave grooves extend outwardly to form modifying grooves, the impact load of engagement between the round pins and the concave grooves is effectively lowered, so abrasion is lowered and durability is improved.

Owner:ZHEJIANG UNIV CITY COLLEGE

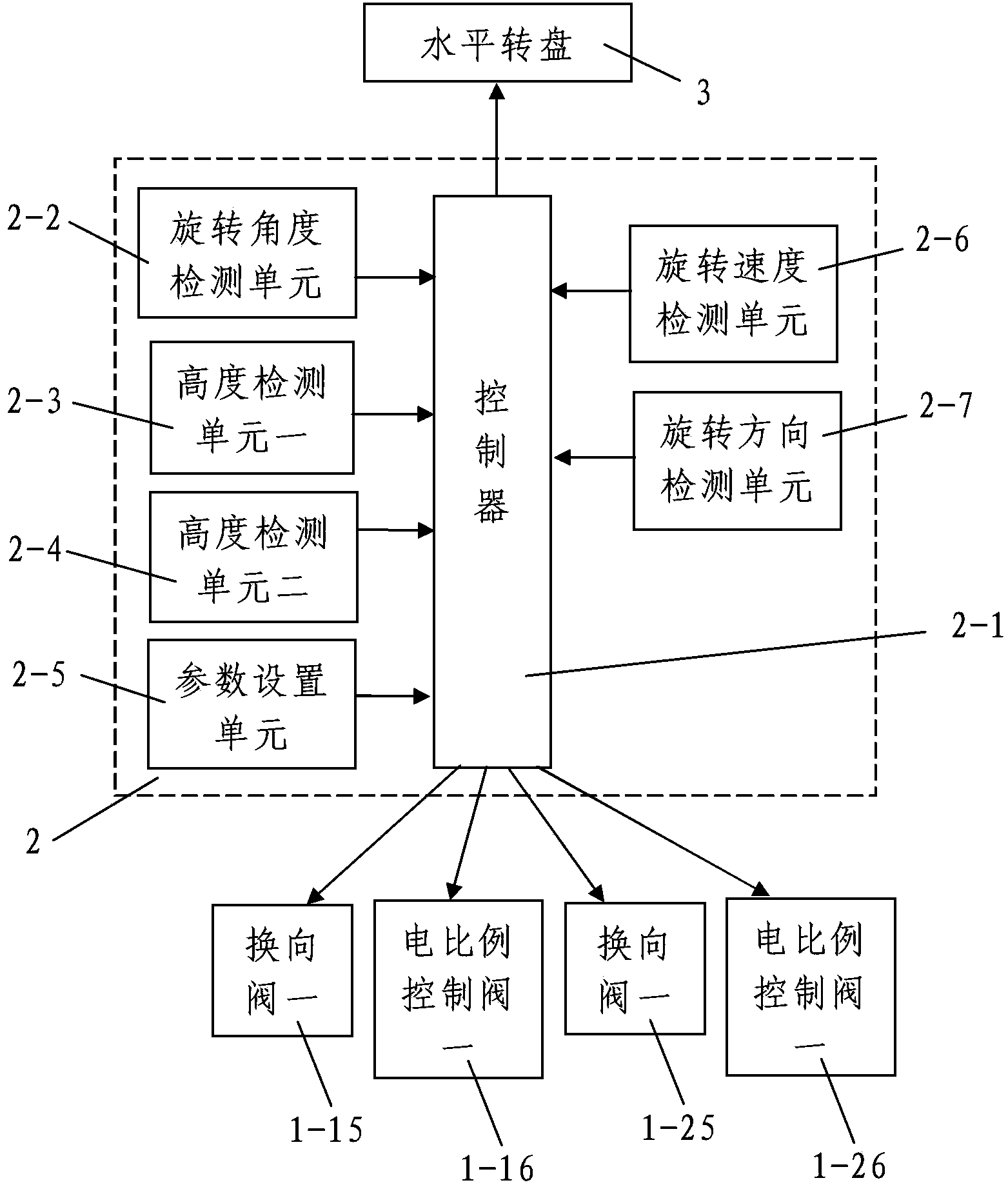

Automatic tool changing motion arm for CNC (Computer Numerical Control) machining center

InactiveCN103801965AReasonable designLow costPositioning apparatusMetal-working holdersHydraulic cylinderNumerical control

The invention discloses an automatic tool changing motion arm for a CNC (computer numerical control) machining center. The motion arm comprises two tool changing arms and an operation control system for automatically controlling the two motion arms, wherein the rear end parts of the two tool changing arms are both arranged on a horizontal rotary table; the two tool changing arms are respectively a motion arm I and a motion arm II; the motion arm I comprises a rear arm I and a front arm I which swings up and down under the driving of a hydraulic cylinder I, and the motion arm II comprises a rear arm II and a front arm II which swings up and down under the driving of a hydraulic cylinder II; the hydraulic cylinder I and the hydraulic cylinder II are respectively connected with a hydraulic oil tank by a hydraulic pipeline I and a hydraulic pipeline II; the hydraulic pipeline I and the hydraulic pipeline II are respectively provided with a reversing valve II and an electric proportional control valve II; the front end of the front arm I is provided with a tool changing structure I for changing a tool, and the front end of the front arm II is provided with a tool changing structure II for changing the tool. The automatic tool changing motion arm is reasonable in design, simple and convenient to operate, high in intelligent degree, good in use effect, flexible in action, fast in tool changing speed and simple to control.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

Automatic tool changing device of high-speed machining center

InactiveCN102528508BFast tool changeSimple structurePositioning apparatusMetal-working holdersEngineeringCam

The invention provides an automatic tool changing device of a high-speed machining center, which aims to replace a tool position changing mechanism adopting an arc-surface indexing cam as a main body and has the advantages of simple structure and convenience in manufacture. The automatic tool changing device of the high-speed machining center comprises a box, a tool arm spindle, a tool changing arm, a power transmission mechanism, a tool plugging and unplugging mechanism, a tool position changing mechanism, a tool locking mechanism and a transmission clutch mechanism. The automatic tool changing device is particularly improved by the tool position changing mechanism and the transmission clutch mechanism, the tool position changing mechanism is provided with a rack mechanism meshed with a transmission gear hollowly sleeved on the tool arm spindle, the rack mechanism is in motion association with a composite cam by a position changing oscillating bar, the transmission clutch mechanism is structurally provided with a shaft sleeve hollowly sleeved on the tool arm spindle, one side of the shaft sleeve is fixedly connected with a transmission gear, a T-shaped groove is machined in the middle of a push rod of the tool locking mechanism, a certain angle is formed between the bottom of the T-shaped groove and the axis of the push rod, a T-shaped pin is mounted in the T-shaped groove and is inserted in a positioning hole of the tool arm spindle, and an axial groove matching with a journal of the T-shaped pin is disposed on the shaft sleeve.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

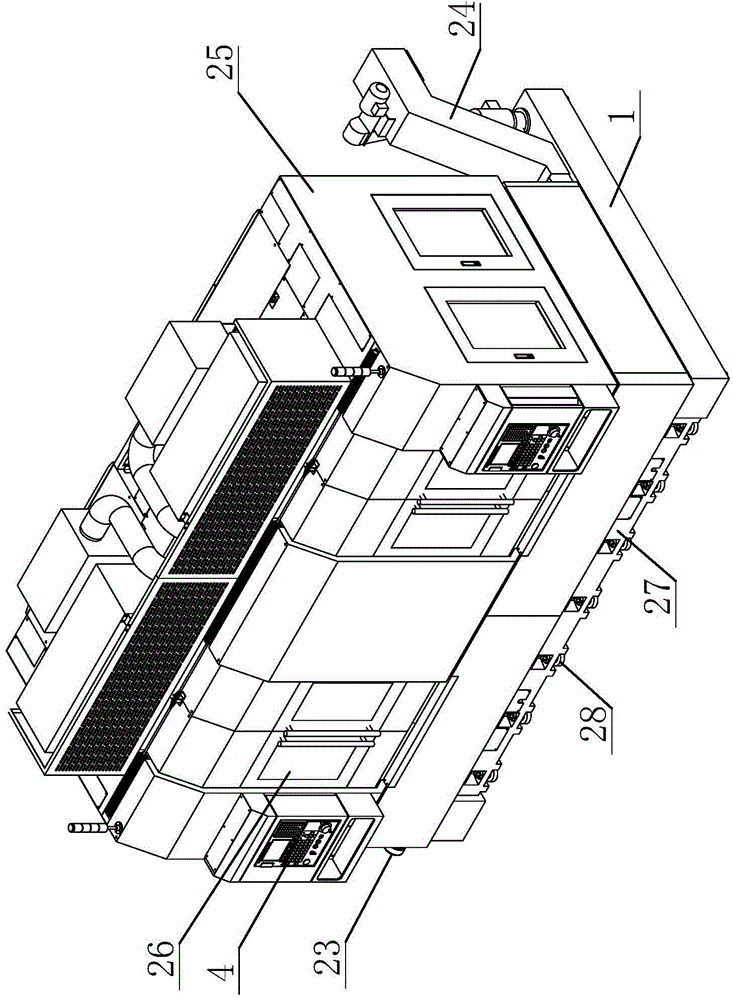

End surface milling and multi-position end surface drilling and tapping compound machine tool

InactiveCN110125692AProcessing advantages are obviousIncrease productivityOther manufacturing equipments/toolsEngineeringPower tool

The invention relates to the technical field of machine tools, in particular to an end surface milling and multi-position end surface drilling and tapping compound machine tool. The end surface milling and multi-position end surface drilling and tapping compound machine tool comprises a machine tool body and a servo control system. A guide rail is arranged on the machine tool body, clamp systems are symmetrically arranged on the guide rail, processing mechanisms are symmetrically arranged at the left and right ends of the guide rail, each processing mechanism comprises a slide, a first feedingmechanism and a second feeding mechanism are separately arranged on the slides, a left power tool turret and a right power tool turret are respectively arranged on the first feeding mechanism and thesecond feeding mechanism, a first powerful milling power motor and a second powerful milling power motor are also respectively mounted on the first feeding mechanism and the second feeding mechanism,and tools are mounted on the first powerful milling power motor and the second powerful milling power motor. According to the structural arrangement of the device, the end surface milling and multi-position end surface drilling and tapping compound machine tool carries out processing at two ends simultaneously, so that the production efficiency of the end surface milling and multi-position end surface drilling and tapping compound machine tool is higher than that of a horizontal processing center or a boring mill. The end surface milling and multi-position end surface drilling and tapping compound machine tool is high in rigidity, has an independent end surface milling system and is suitable for processing with a relatively large dimension and a relatively large chipping allowance.

Owner:SHANDONG YOT MACHINE TOOL MFG

Disc type tool changer

PendingCN107283198ASimple structureFast tool changePositioning apparatusMetal-working holdersPhysicsElectric machinery

The invention discloses a disc type tool changer. The disc type tool changer comprises a motor. A rotary shaft is mounted on one side of the motor. The motor is mounted on a mounting disc. The rotary shaft is connected with a rotary disc. A turning tool mounting shaft is mounted on the rotary disc. A numerical-control device is mounted on one side of the rotary disc, and a shell is mounted outside the rotary disc. A supporting shaft is connected to the bottom of the numerical-control device. A connecting shaft is arranged at the bottom of the supporting shaft. A fixing plate is arranged on the connecting shaft. A heat dissipation opening is formed in the shell, and a tool outlet and a top cover are arranged on one side of the shell. The disc type tool changer is mainly used for a tool storage and changing device during automatic production of a numerical-control lathe, the tool changer is in a disc shape and is simple in structure, and the tool changing speed is high; a gap is formed in the bottom of the shell so that the tool changer can be dismounted and mounted conveniently, a turning tool can be replaced easily, and the tool changer can be maintained easily; the shell is provided with the heat dissipation opening so that the tool changer can be assisted in heat dissipation, and failures are prevented; an infrared position finder is mounted on the motor so that the position of the tool can be measured, and the tool can be assisted in being accurately positioned; and the numerical-control device can automatically receive a signal sent out by the lathe to control the tool changer for tool replacement.

Owner:OKADA SEIKI DANYANG CO LTD

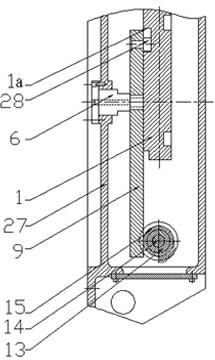

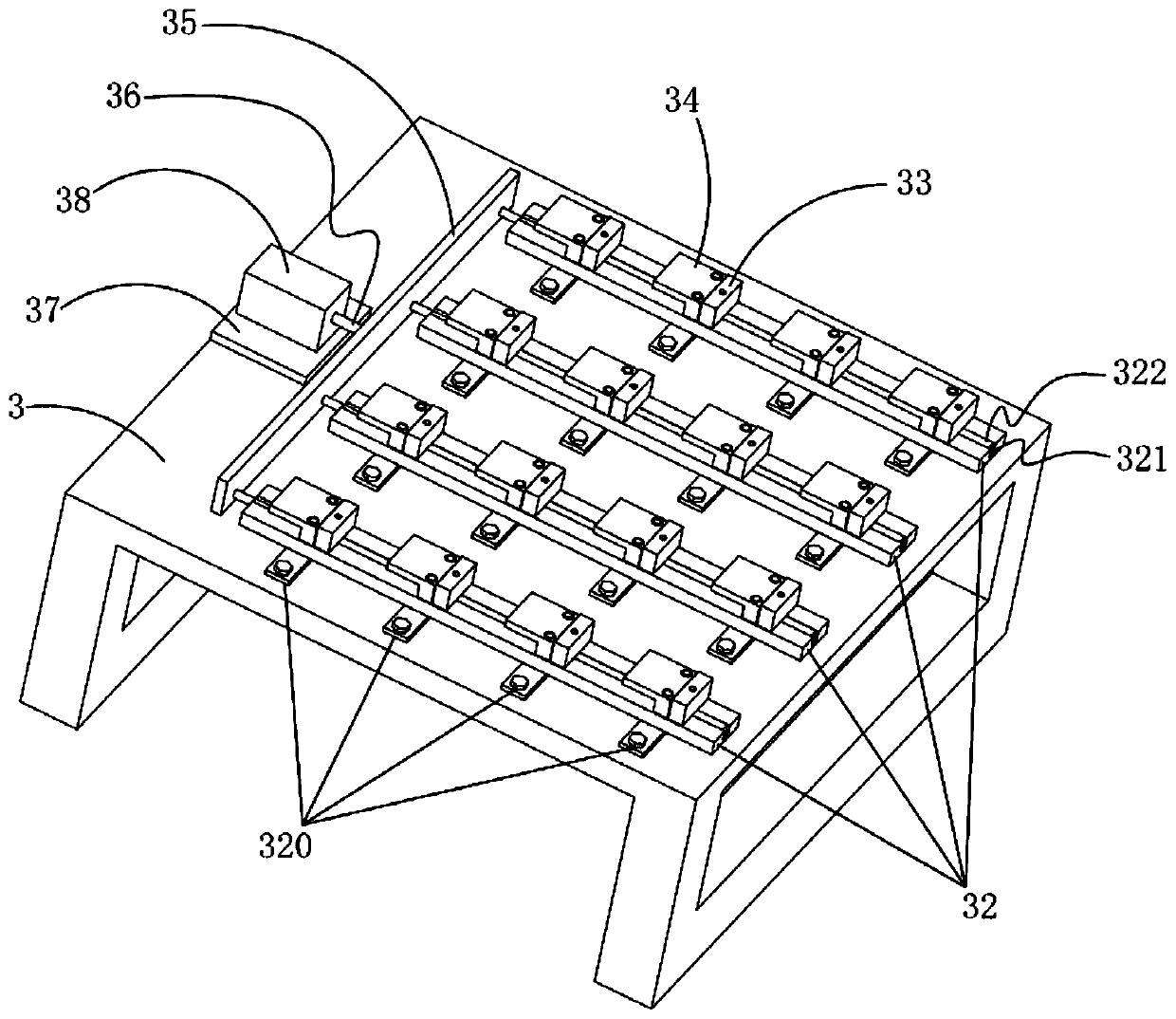

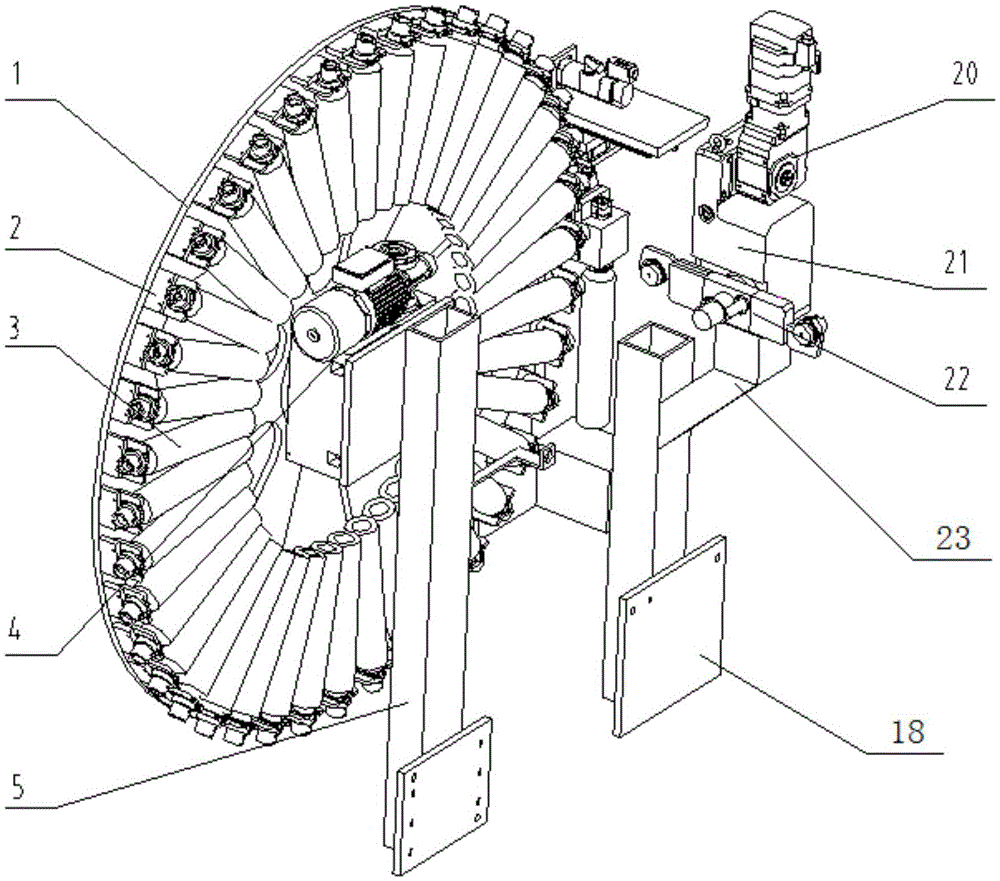

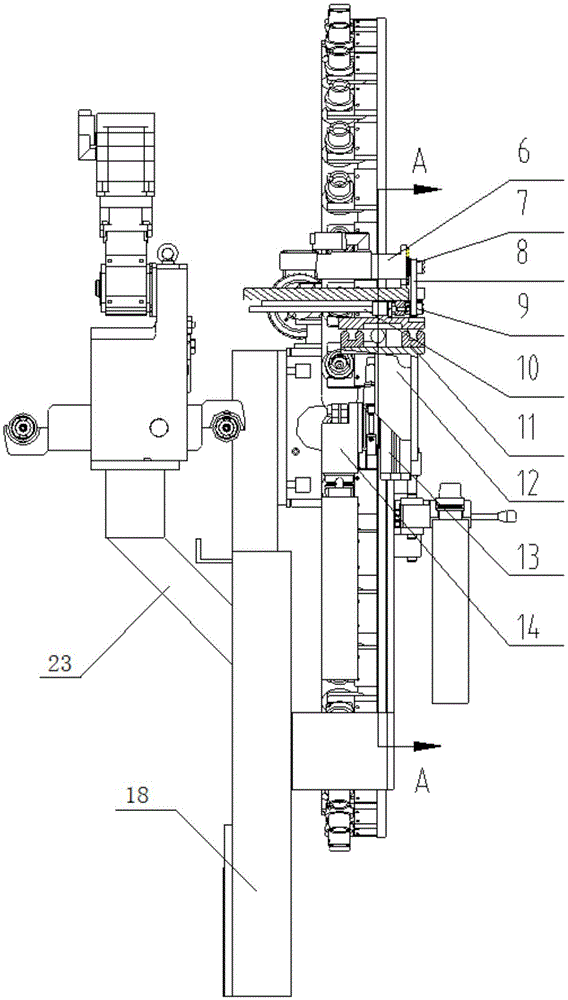

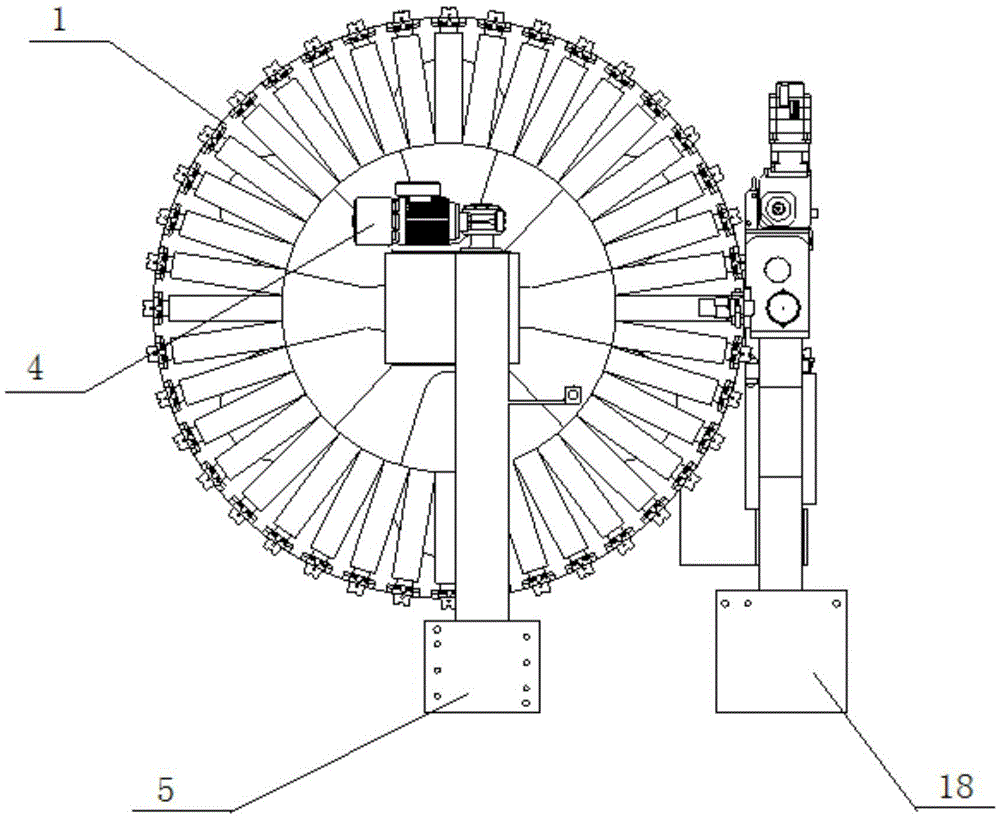

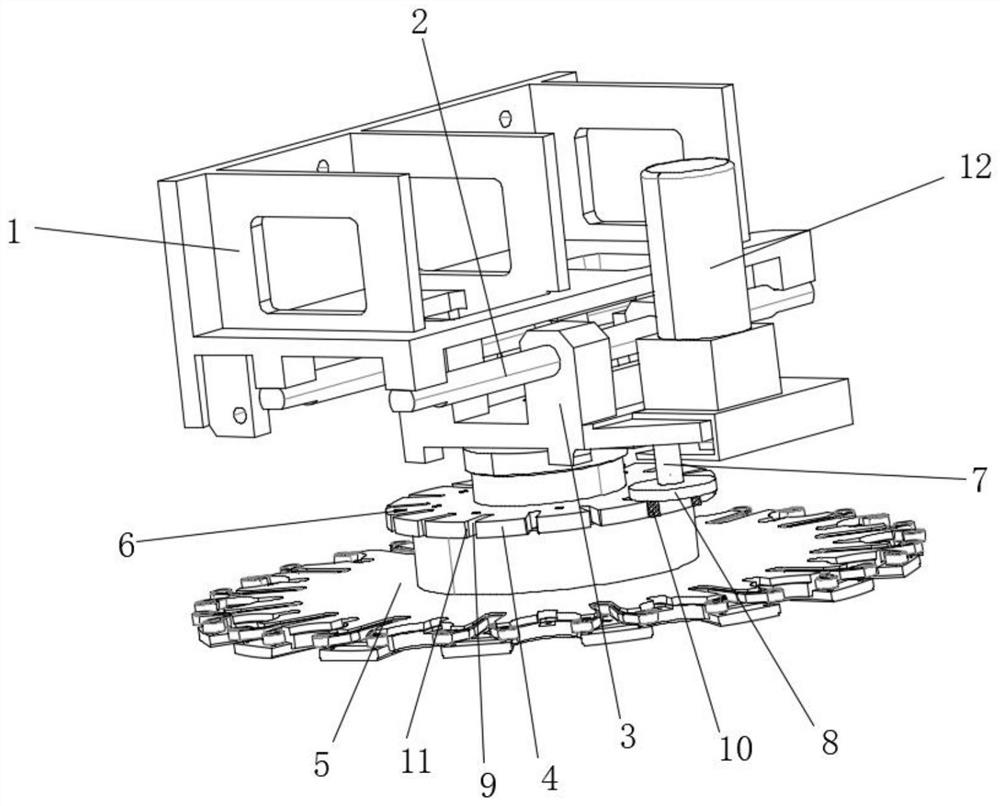

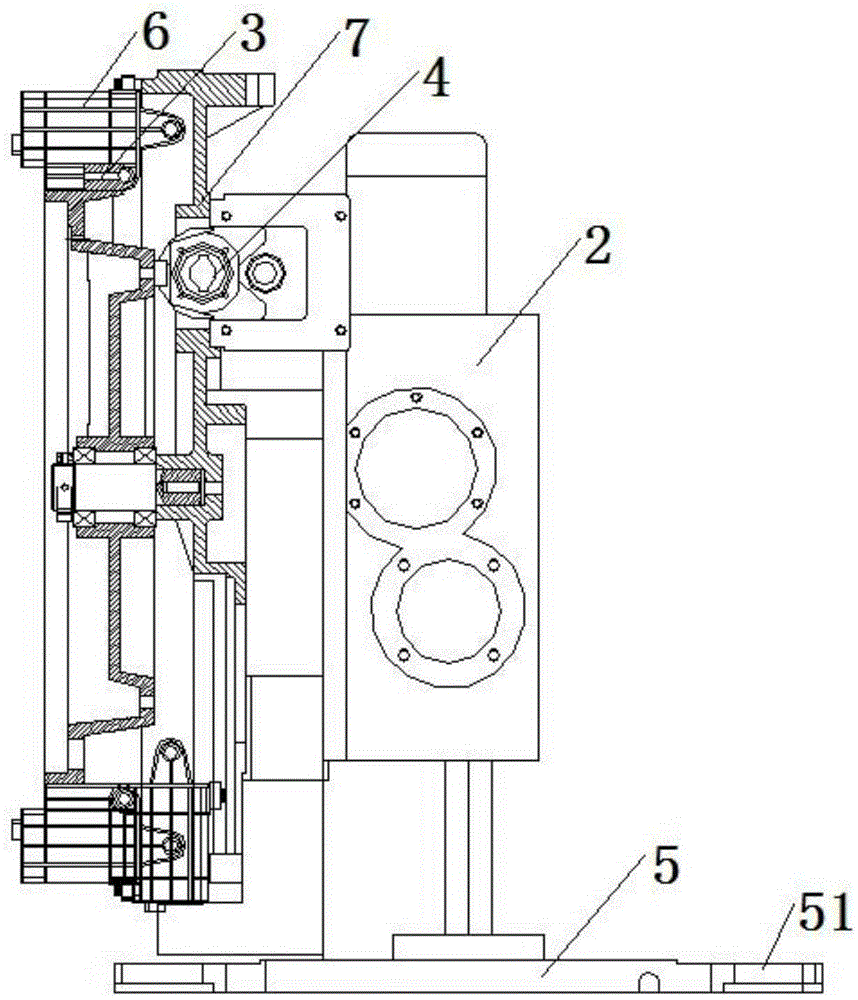

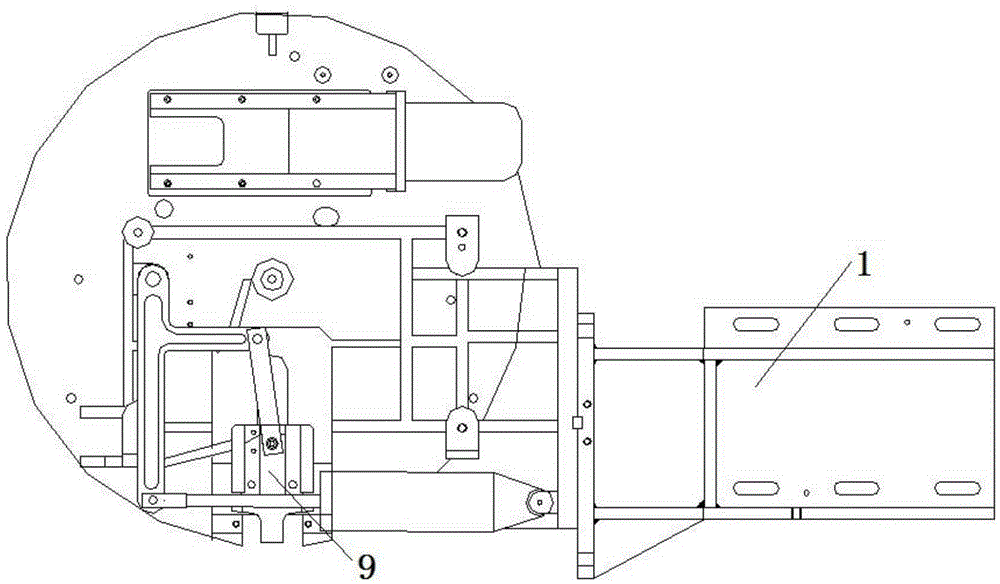

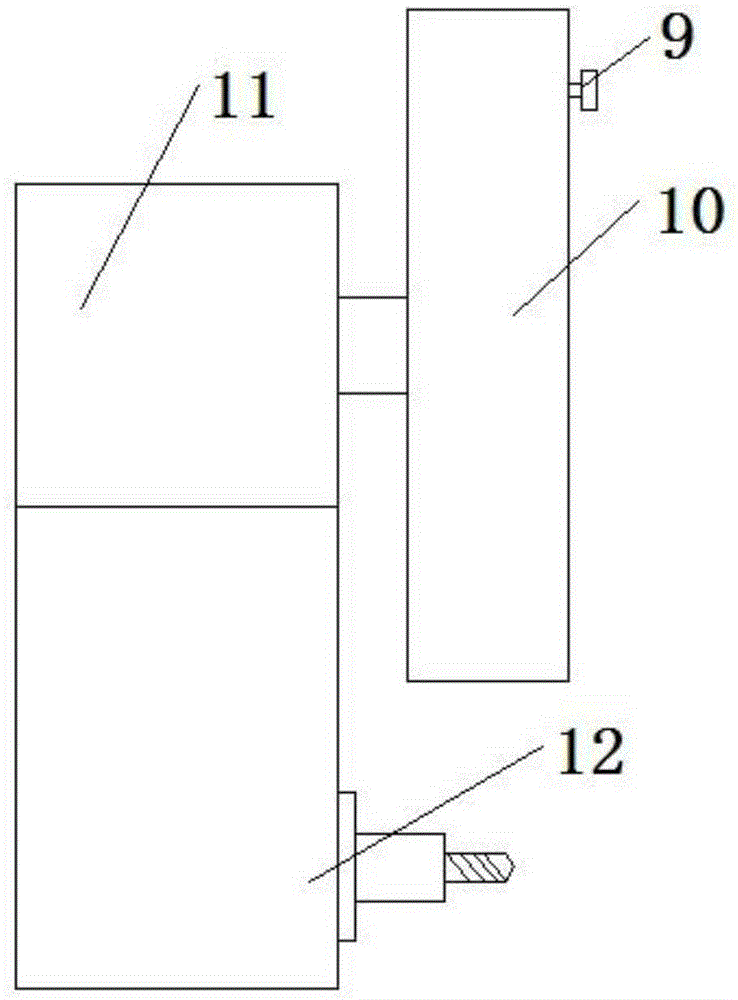

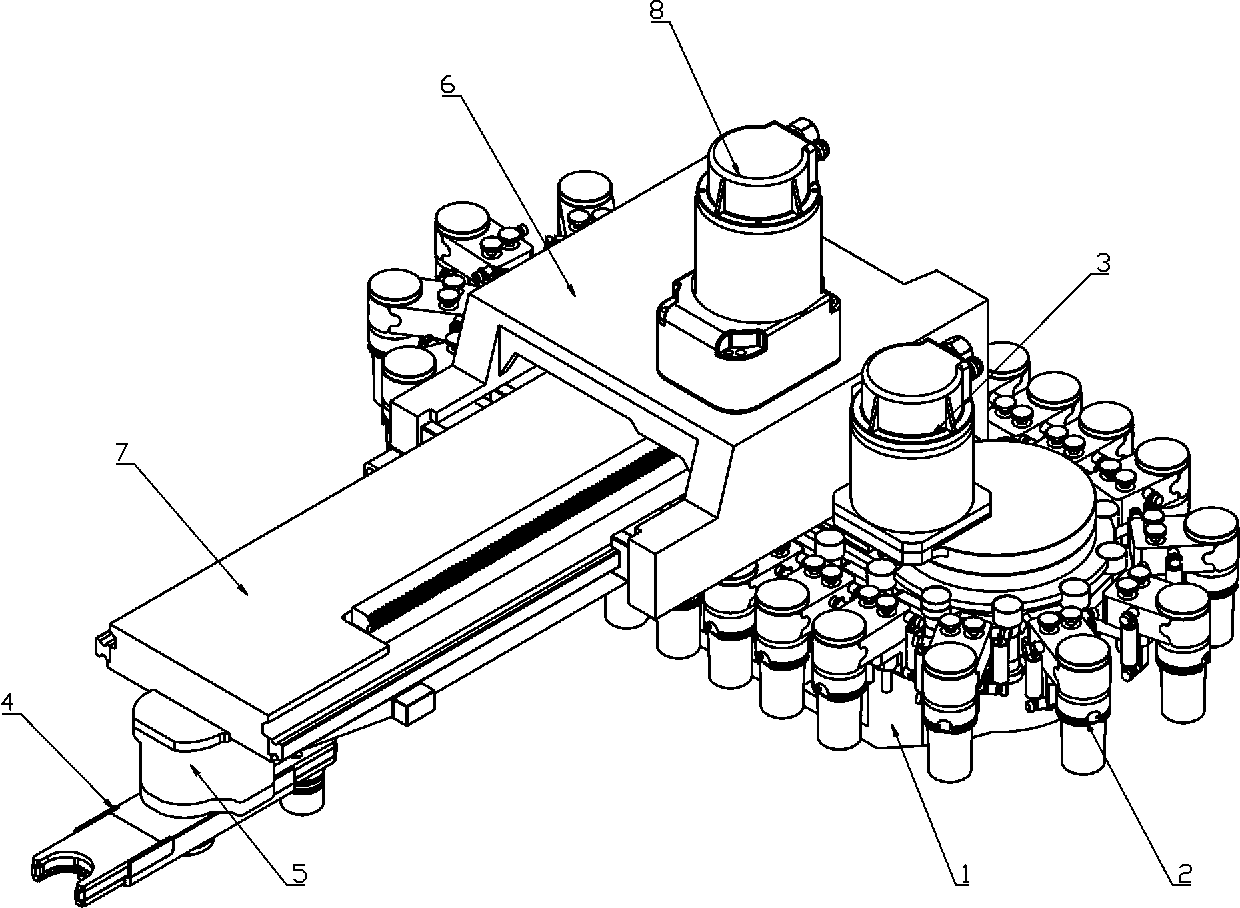

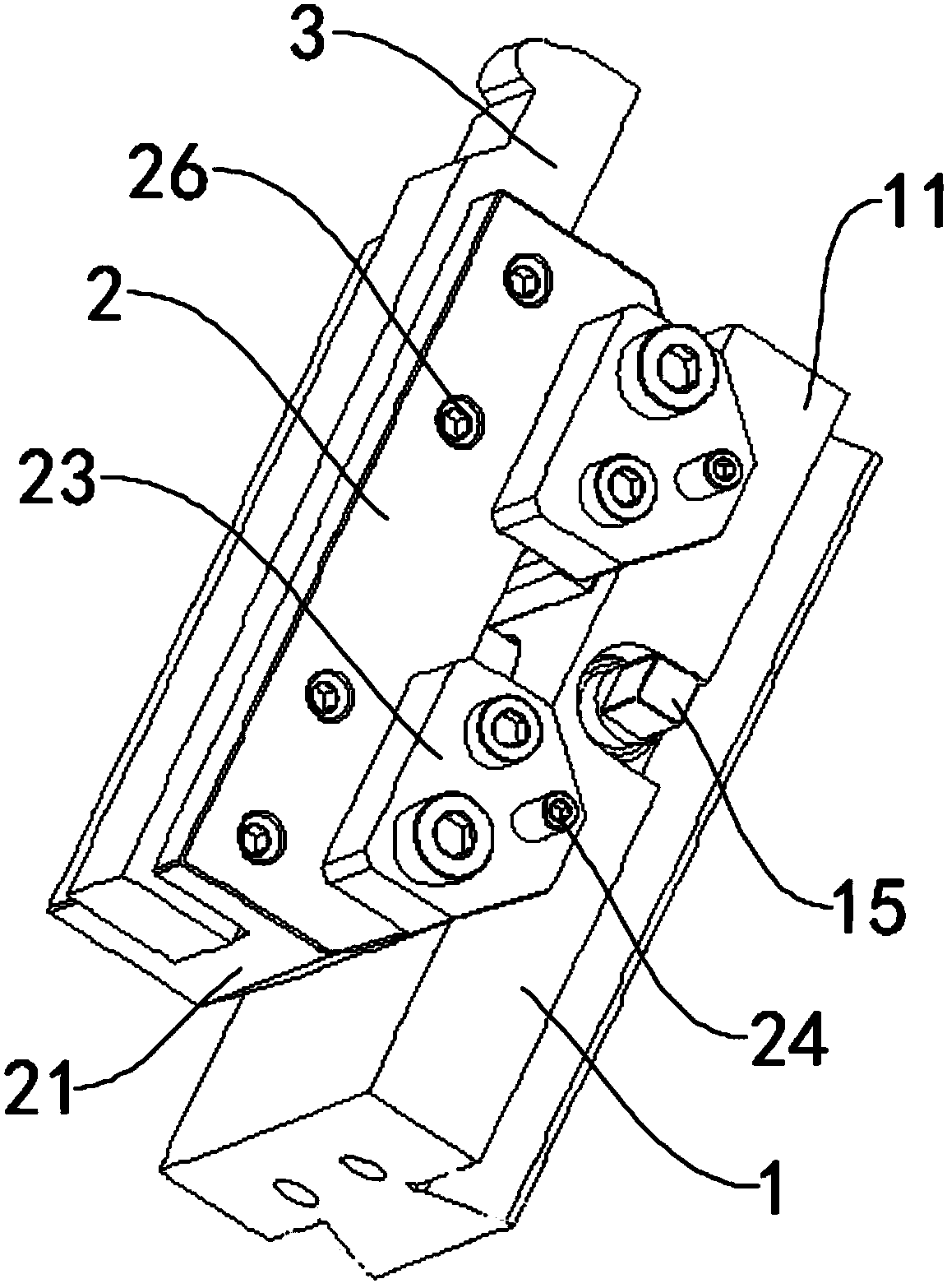

Tool magazine and tool changing method thereof

InactiveCN105397545AFast tool changeNot prone to chaotic knife phenomenonPositioning apparatusMetal-working holdersEngineeringManipulator

The invention provides a tool magazine. The tool magazine comprises a support (1), a manipulator control device (2), a base body (7), a rotating plate (3) and a tool magazine driving device (4), wherein the tool magazine driving device (4) controls the tool location of the rotating plate (3) to be changed. The rotating plate (3) is installed on the base body (7) to form an angle of 90 degrees with a machine tool spindle (8). The manipulator control device (2) is fixedly installed on the base body (7). A manipulator (5) is connected to the output end of the manipulator control device (2) and in a T shape. Tool holders (51) used for clamping a tool are arranged at the two ends of the manipulator (5). The support (1) is installed on the side face of the base body (7) to be used for being connected with a machine tool vertical post. The tool magazine has the beneficial effects that the manipulator is used for changing the tool, so that the tool magazine has the advantages of being high in tool changing speed, stable, reliable and the like, and the disorder phenomenon of the tool is not prone to happening.

Owner:CHUZHOU SHENYU HYDRAULIC TECH CO LTD

Integrated chained tool magazine capable of automatically picking up and replacing tools

PendingCN111590370APrecision high speedImprove accuracyPositioning apparatusMetal-working holdersProduction lineRobot hand

The invention relates to an integrated chain type tool magazine capable of automatically picking up and replacing tools, and aims to provide an integrated chain type tool magazine which is simple in structure, small in occupied space, low in manufacturing cost, high in tool replacing speed and small in tool replacing impact force. The integrated chain type tool magazine can be arranged right behind a machine tool, symmetrical arrangement of the machine tool is realized, machine tool precision loss caused by eccentricity is avoided, and an automatic production line is easy to arrange. The device is composed of a base, a chain mechanism, a chain driving unit, a tool replacing manipulator, a manipulator rotation driving unit, a manipulator moving push-out mechanism and a moving push-out driving unit, wherein the chain mechanism used for containing tools is arranged on the base and can rotate under the action of the chain driving unit; the tool replacing manipulator is installed on the base through the manipulator moving push-out mechanism, on one hand, push-out and returning linear reciprocating movement can be conducted under the action of the moving push-out driving unit, on the other hand, 180-degree rotation can be conducted under the action of the manipulator rotation driving unit, and tool position exchange is achieved.

Owner:北京精雕精密机械制造有限公司

A quick tool change device

ActiveCN106181460BFast tool changeIncrease productivityPositioning apparatusMetal-working holdersEngineeringKnife blades

A rapid tool changing device comprises a fixed tool apron assembly, a movable tool apron assembly and a blade. The fixed tool apron assembly comprises a fixed tool apron and clamping blocks. The clamping blocks are adjustably fixed to the fixed tool apron. The movable tool apron assembly comprises a movable tool rest and a clamping slot. The clamping slot is fixedly arranged on the movable tool rest. The fixed tool apron assembly and the movable tool apron assembly are fixedly connected in the manner that the clamping blocks and the clamping slot are connected in a clamped manner. The blade is fixed to the movable tool rest. Each clamping block comprises a clamping body and a clamping head. The clamping bodies are fixedly and adjustably fixed into the fixed tool apron. Each clamping head is fixedly arranged at the end, extending out of the fixed tool apron, of the corresponding clamping body. The fixed tool apron is provided with a first installation hole and a second installation hole. The clamping bodies are installed in the first installation hole. A rotatable clamping rod is installed in the second installation hole. According to the rapid tool changing device, tool changing is rapid and convenient, extra fine adjustment is not needed, the tool changing speed is increased, and the production efficiency is improved.

Owner:浙江陀曼智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com