Quick manual too-changing mechanism of numerical-controlled milling machine

A tool changing mechanism and CNC milling machine technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of high labor intensity, low tool change efficiency, inconvenient use, etc., and reduce labor intensity. Manufacturing cost and use cost, the effect of easy tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

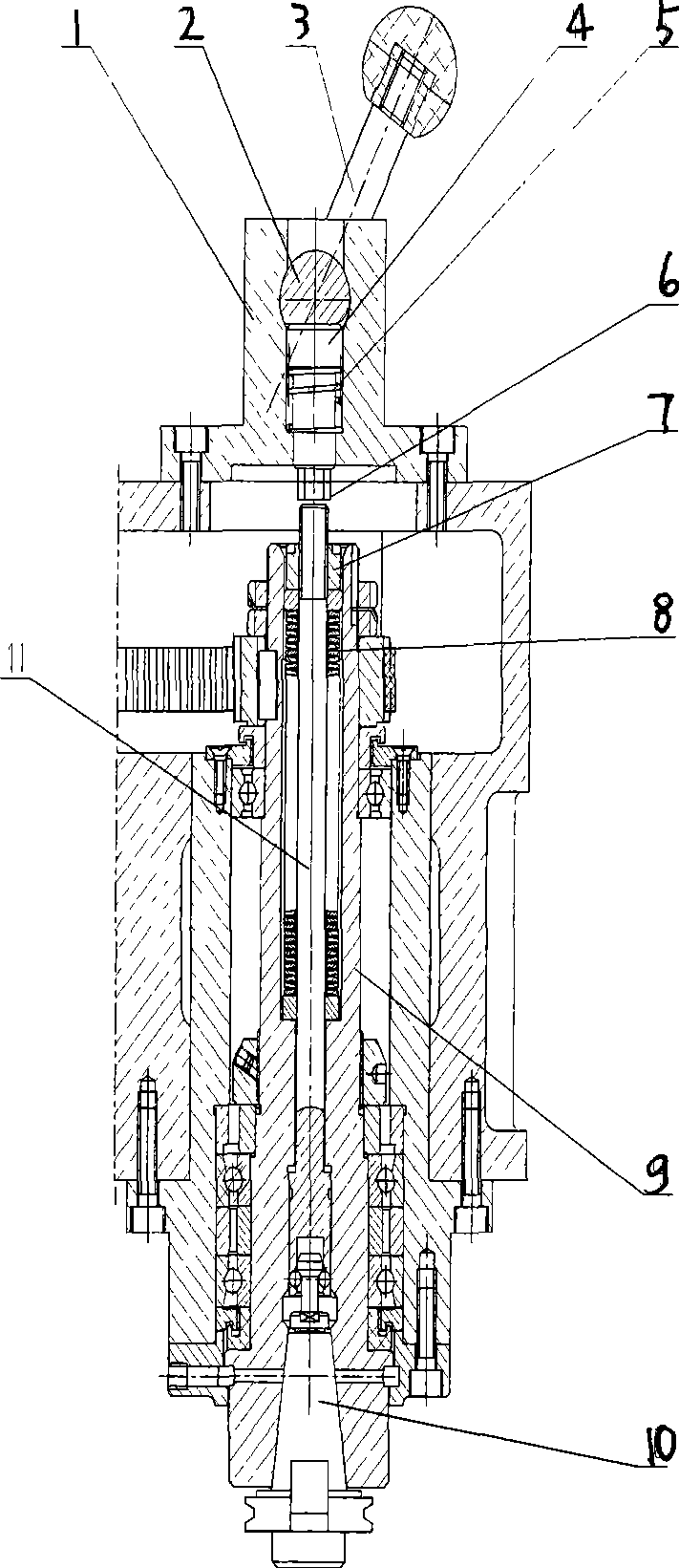

[0011] A rapid manual tool change mechanism for a CNC milling machine, comprising a tool changer seat 1, an opening at the lower end of the tool changer seat 1, a ring platform on the inner wall of the opening, and a slide-fit ejector rod 4 inside the opening, the ejector rod 4 There is a rotatable cam 2 on the top, and the cam 2 is fixedly connected with a tool change handle 3. The upper end of the ejector rod 4 has a ring edge, and the outer cover of the ejector rod is equipped with a first spring 5, and the upper end of the first spring 5 is pressed against the ejector rod 4. On the ring edge of the upper end, the lower end of the first spring 5 is pushed against the ring platform in the opening; there is a main shaft 9 under the tool changer seat 1, and there is a stepped hole in the main shaft 9, and a pull rod 11 is located under the ejector rod 4 in the stepped hole , the lower part of the pull rod 11 is slidingly matched with the step hole, the upper end of the pull rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com