Patents

Literature

97results about How to "Good speed control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

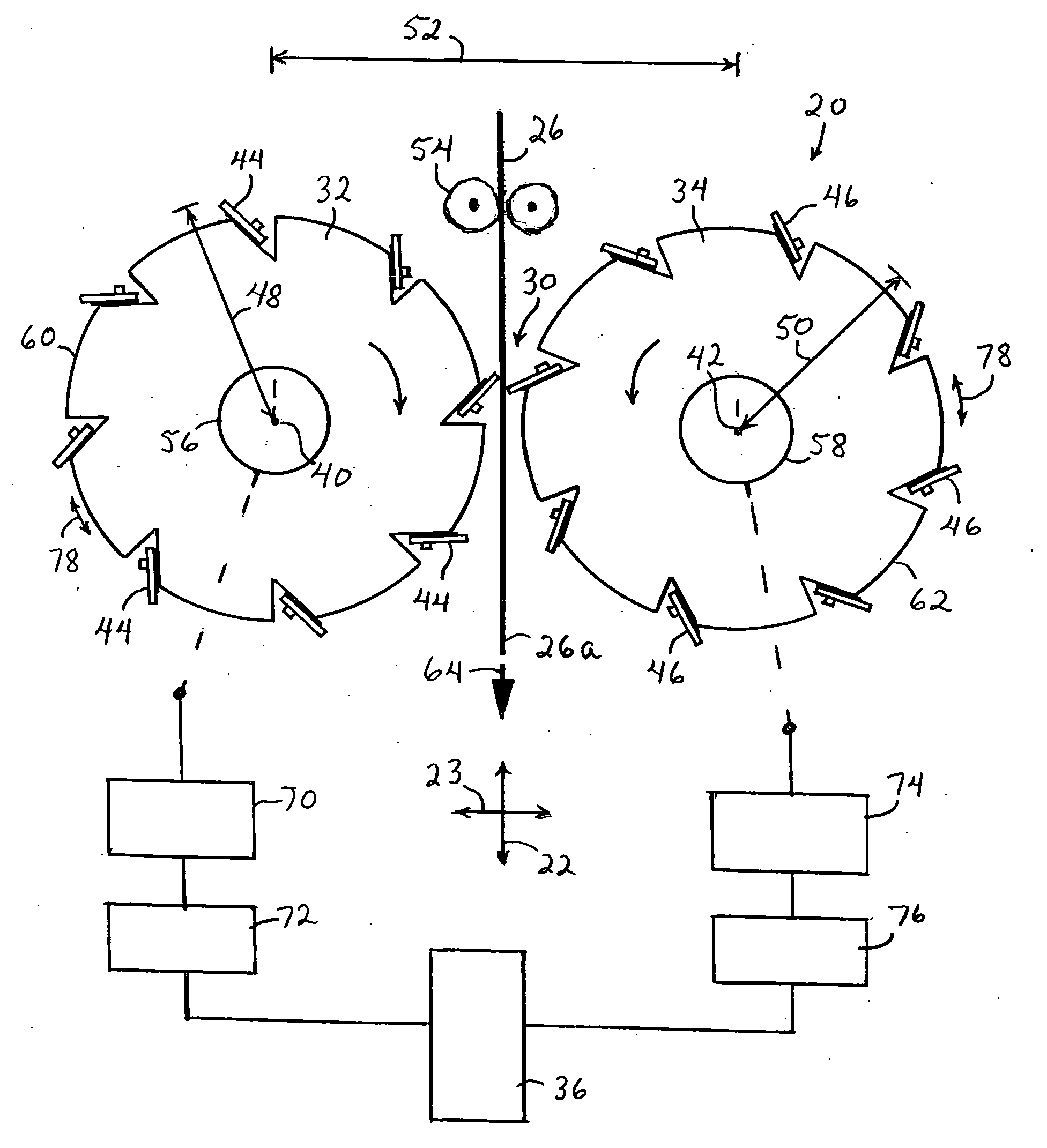

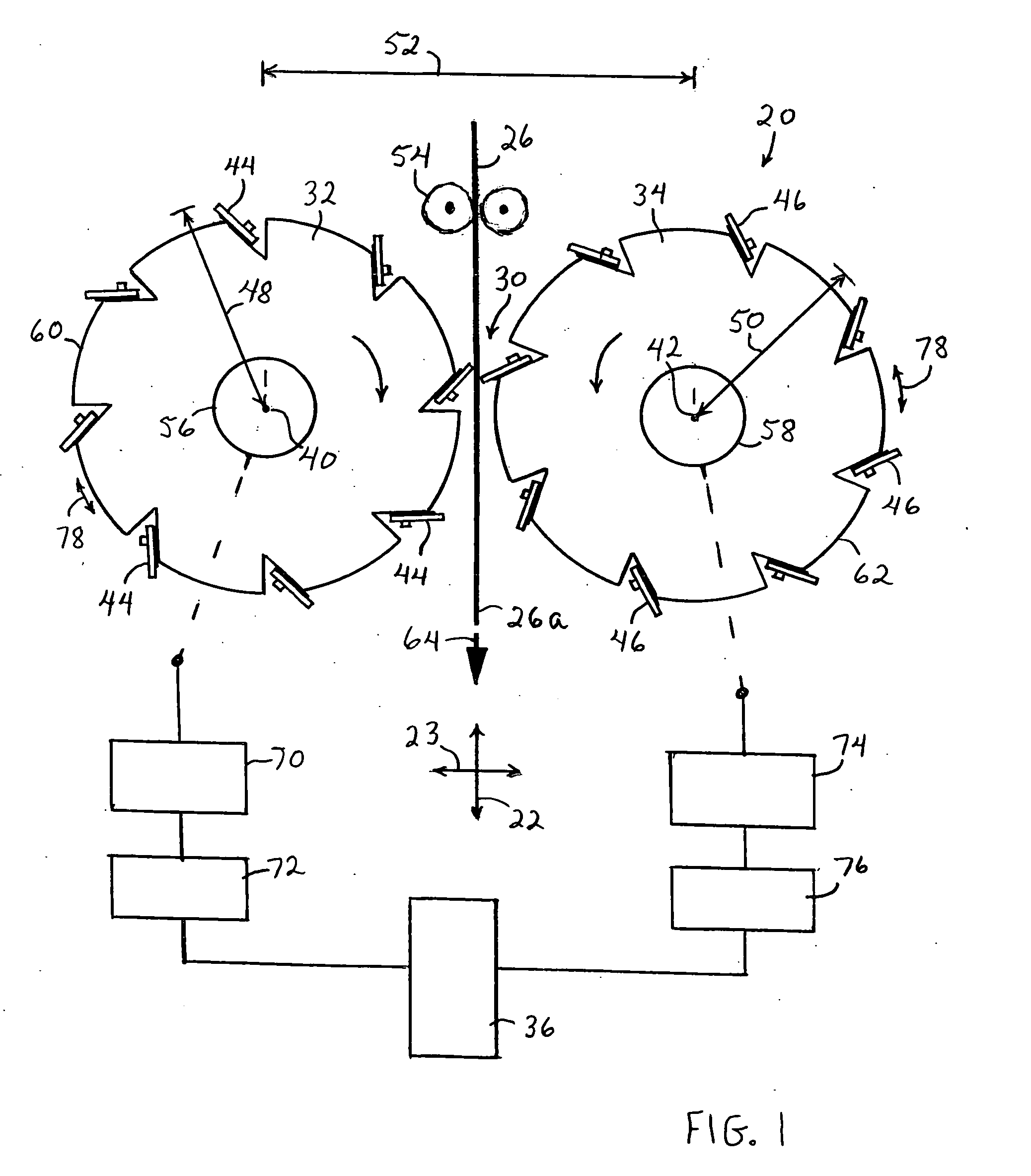

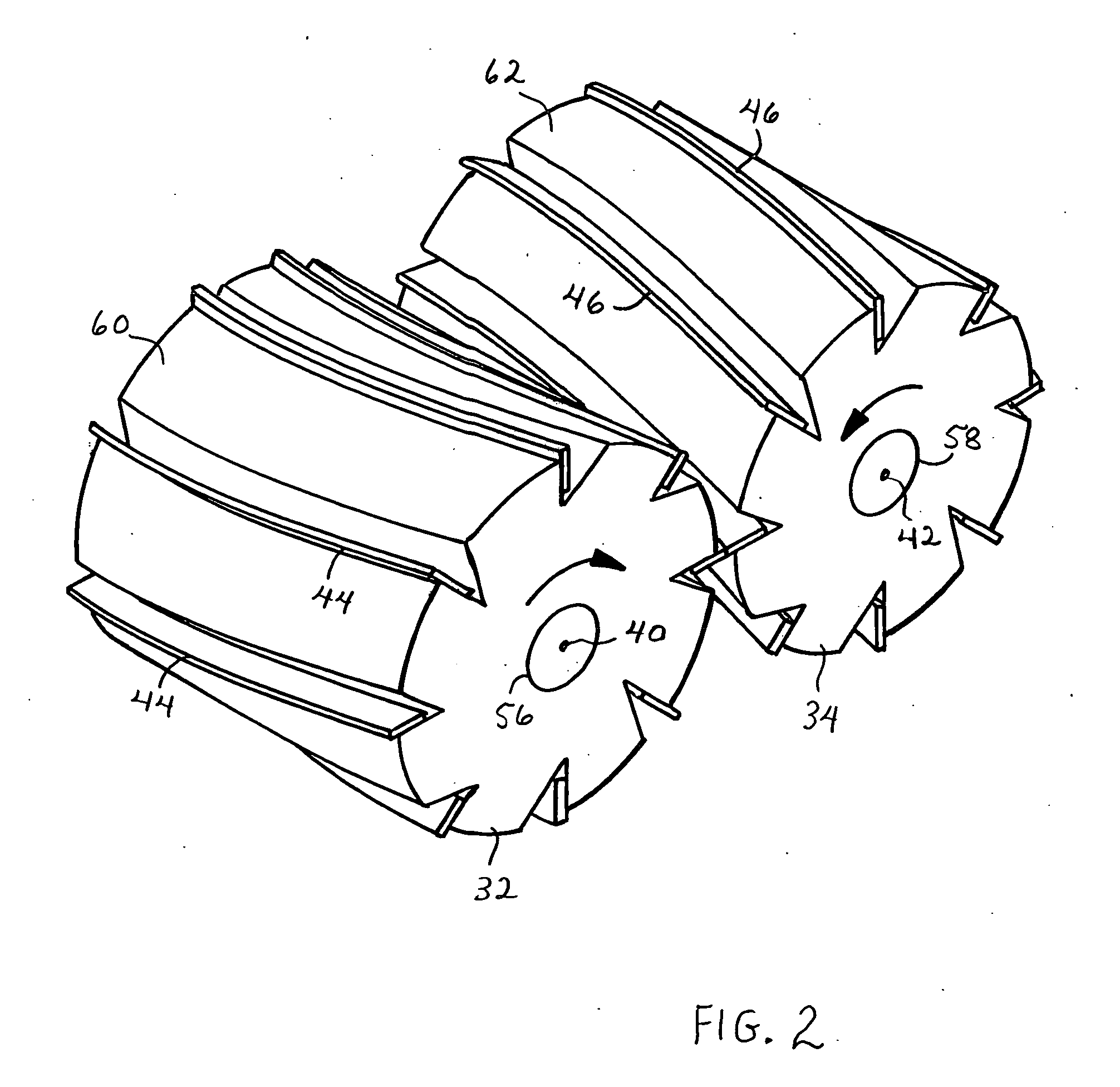

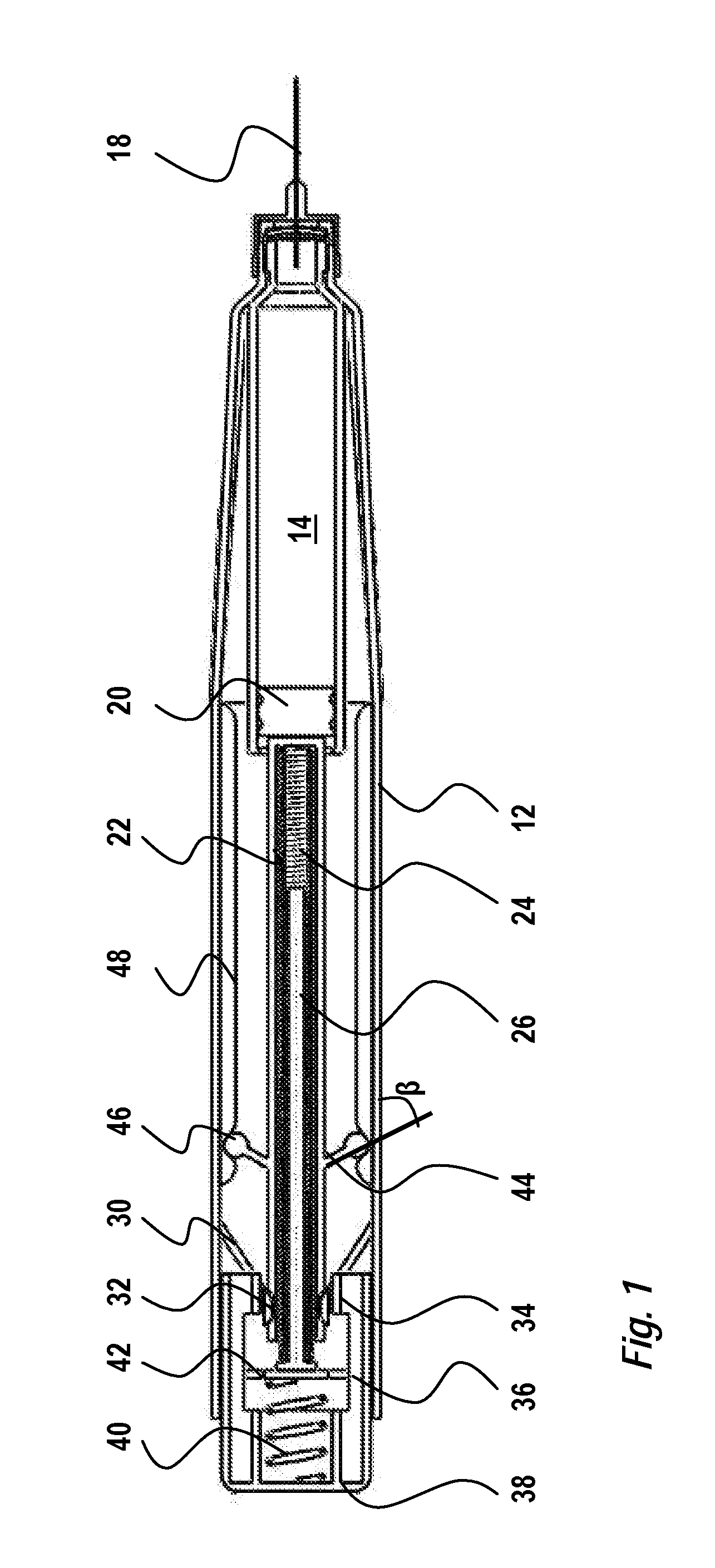

Dual roll, variable sheet-length, perforation system

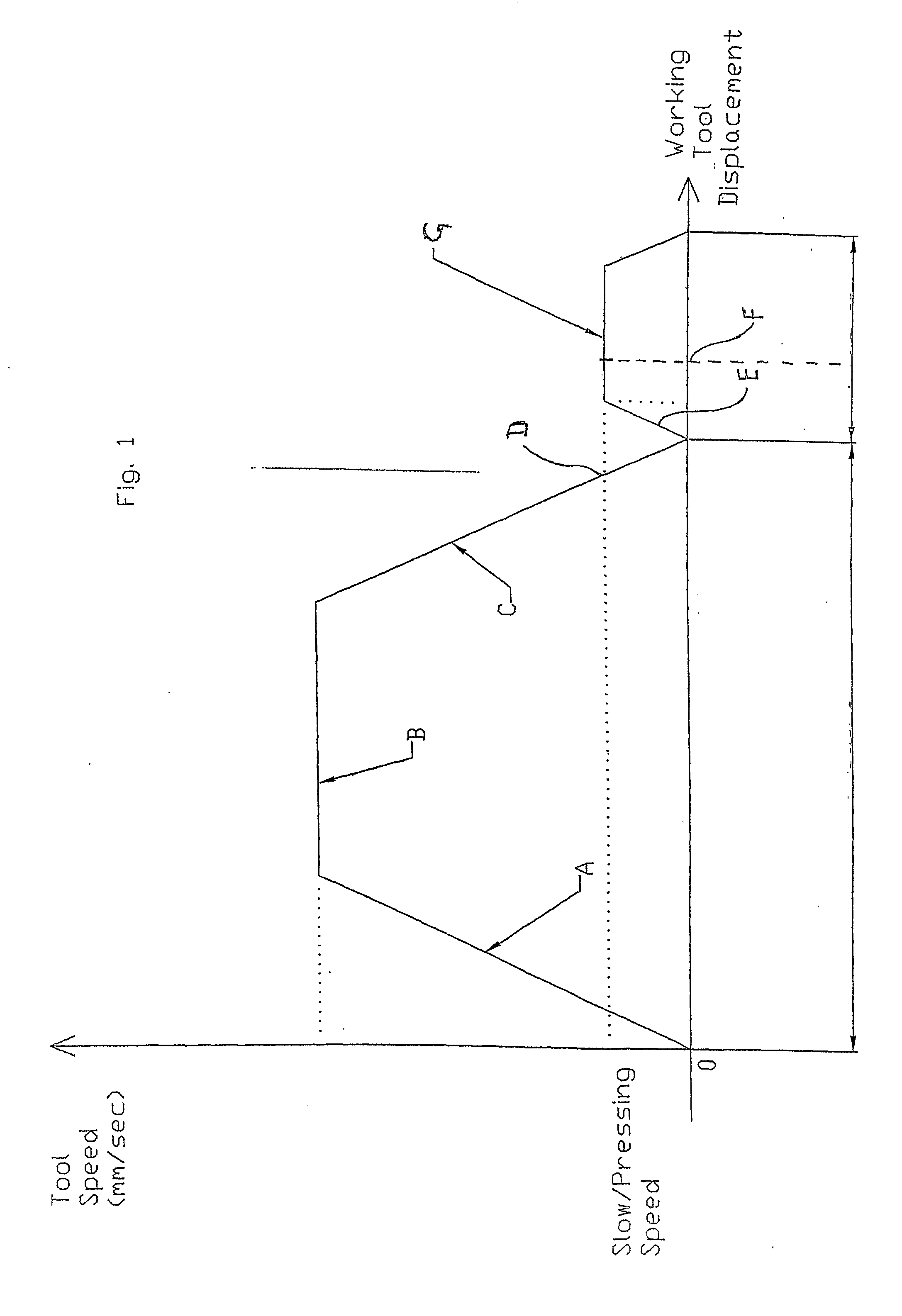

InactiveUS20080028902A1Good speed controlReliable and more consistent bonding, perforating or other cutting operationStock shearing machinesMetal working apparatusMaterial PerforationMechanical engineering

A method and apparatus (20) for intermittently cutting a moving target web (26) includes rotating a knife roll (32) having at least one knife member (44) to provide an operative knife-member speed, and rotating an anvil roll (34) having at least one anvil member (46) to provide an operative anvil-member speed. The knife roll and anvil roll have been positioned to provide an operative nip region (30) therebetween, and a substantially continuous target web (26) has been moved at a selected web speed through the nip region. A rotational positioning of the knife member has been coordinated with a rotational positioning of its cooperating anvil member to provide an operative, cutting engagement between the knife member and its cooperating anvil member, thereby cutting the moving web at cut locations which are intermittently spaced along a machine-direction (22) of the target web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

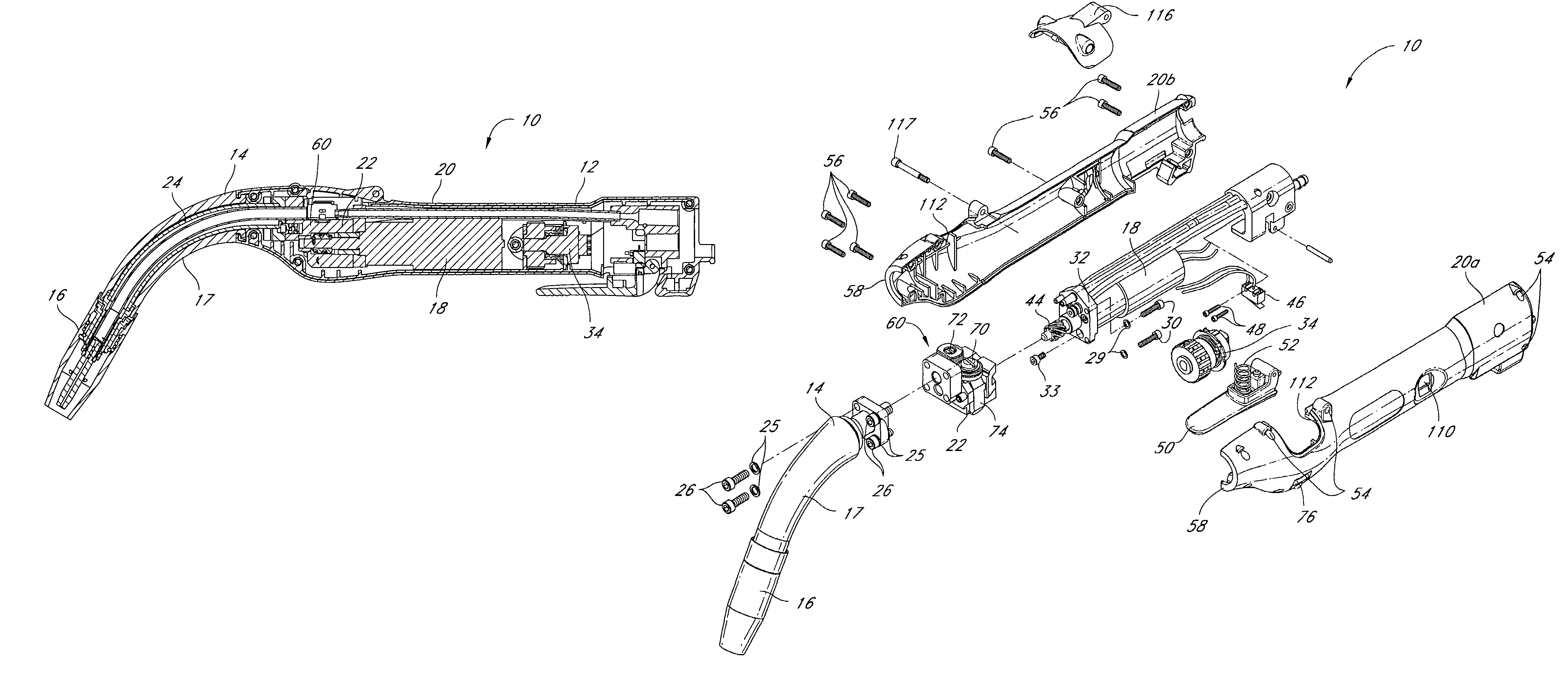

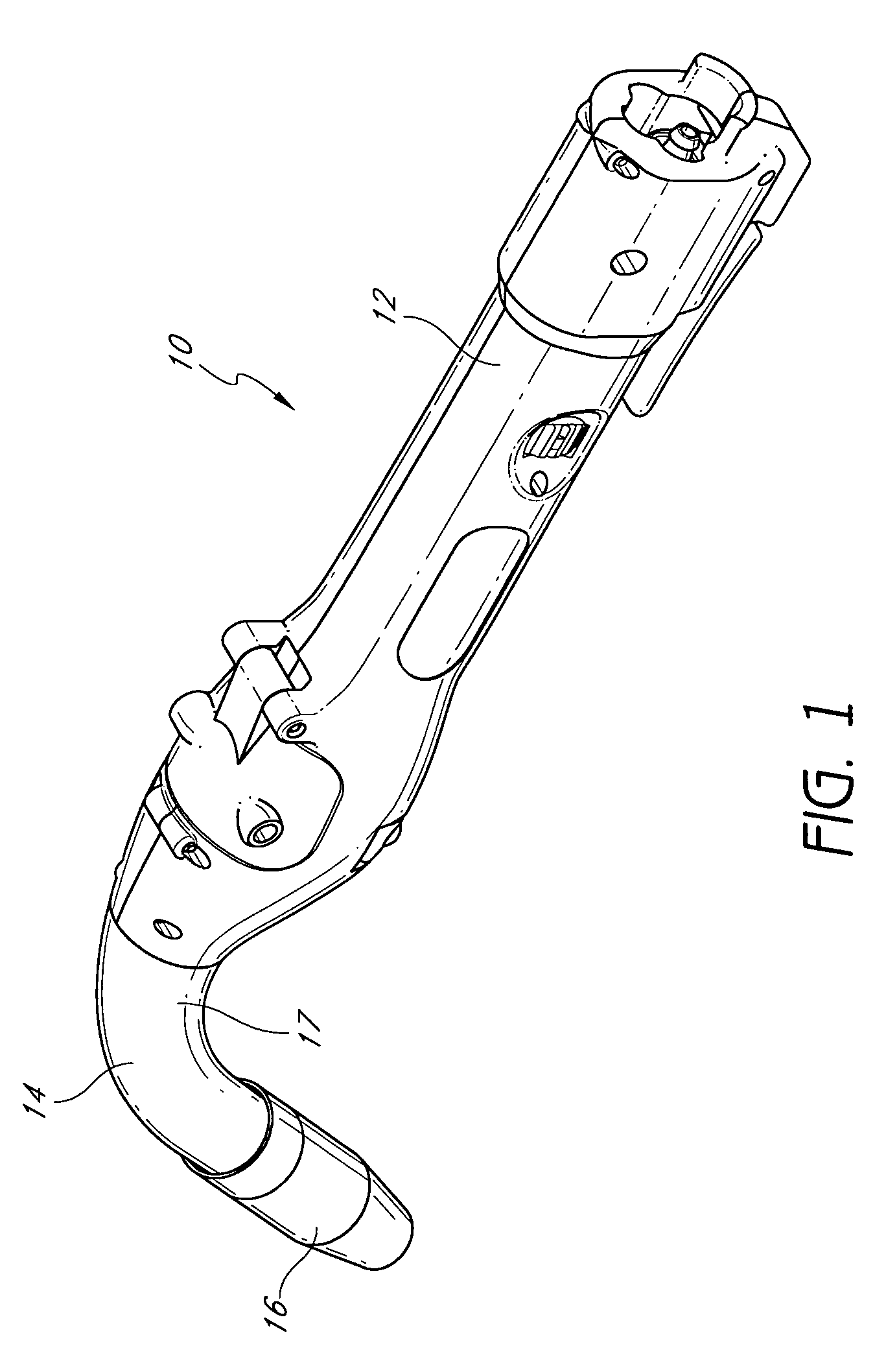

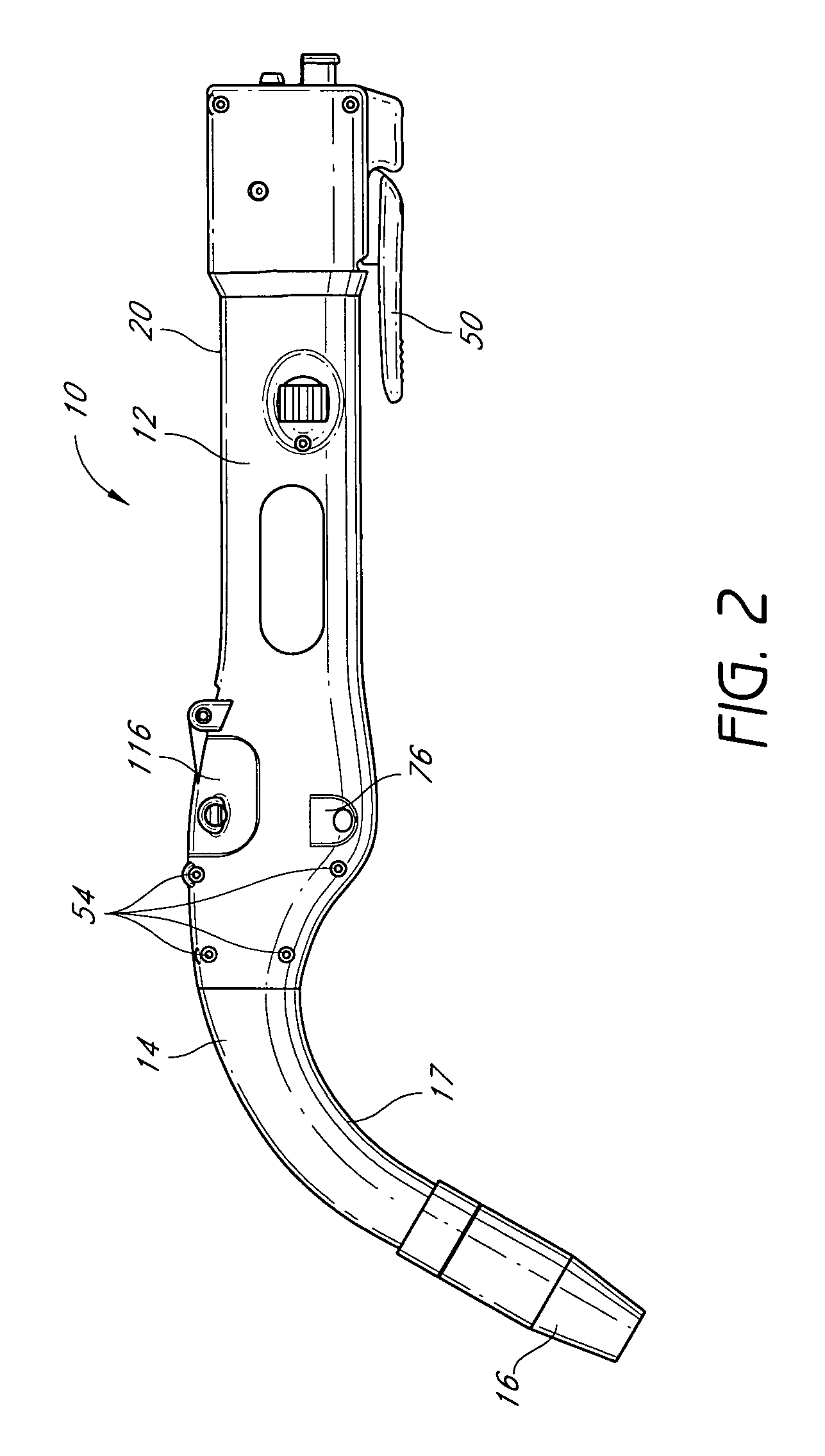

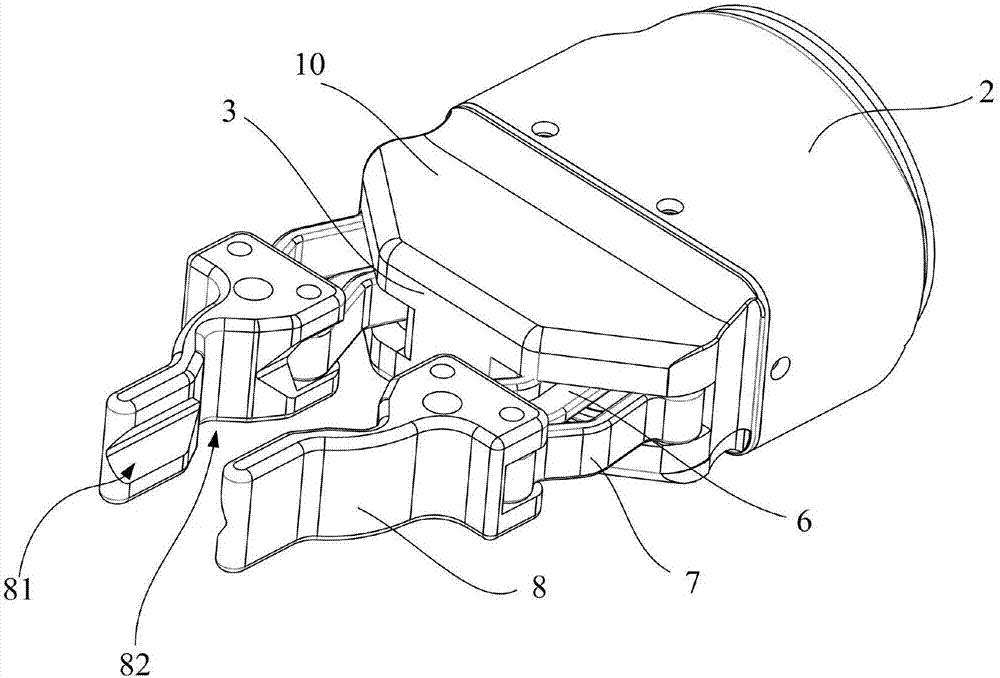

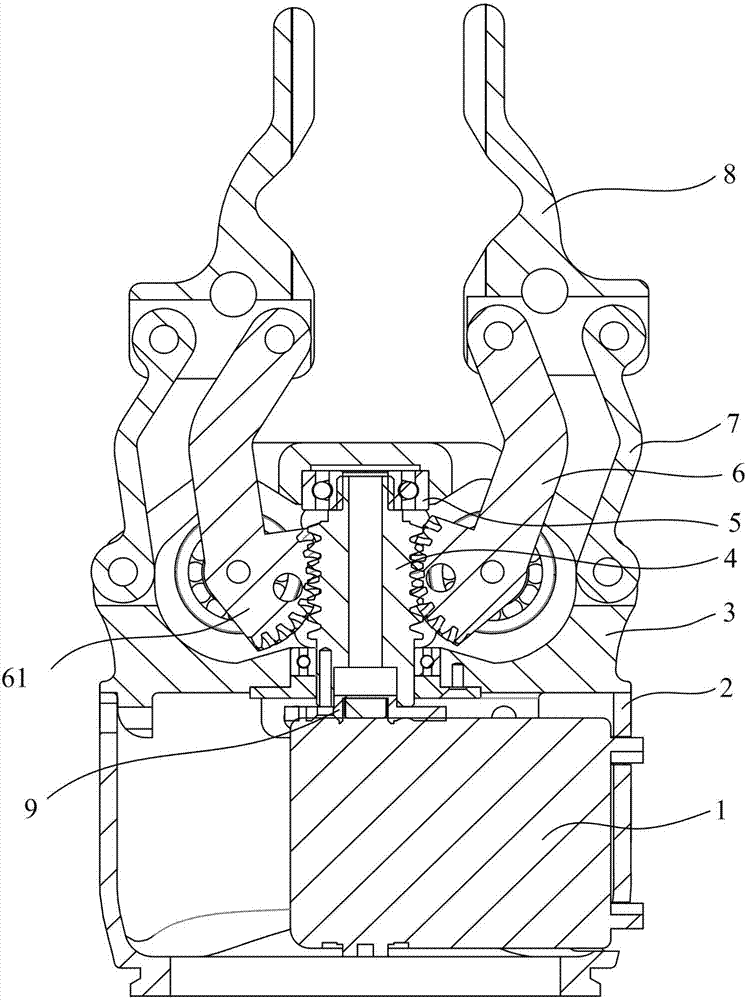

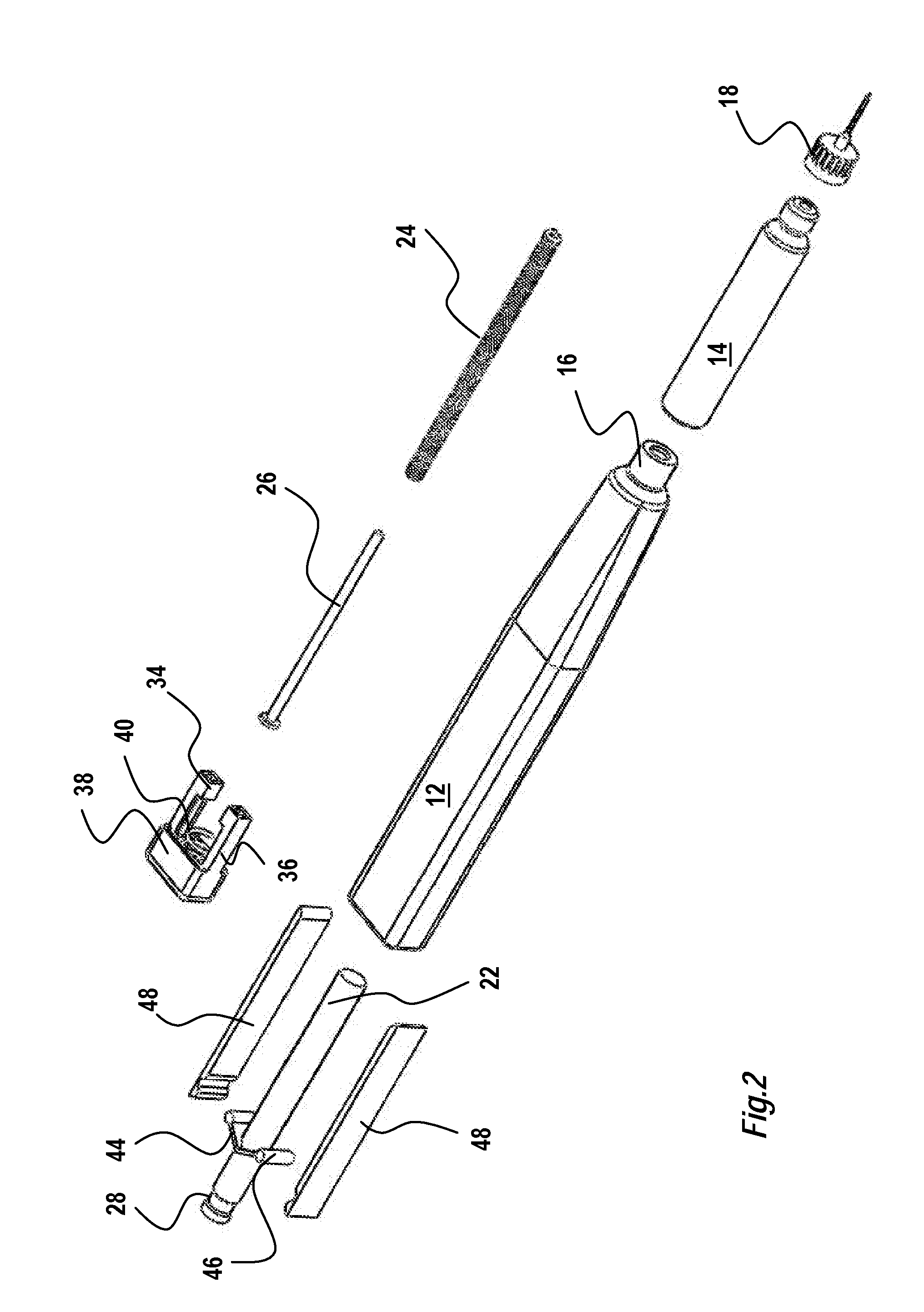

Welding gun

ActiveUS7244909B2Good speed controlPrevent unintentional adjustmentSoldering apparatusElectrode supporting devicesMotor driveTorch

Several aspects of an in-line welding gun are disclosed. In one aspect, the welding gun has a variable profile insulating boot disposed over the torch barrel of the gun. The variable profile insulating boot may include a molded material having varying thickness to provide the desired insulating properties. In another aspect of the welding gun, a speed control mechanism for the motor driving the wire feed assembly is positioned in a recess in the housing such that it reduces the risk of being unintentionally adjusted during operation of the welding gun. In another aspect of the welding gun, the wire feed mechanism features a feeder roller and an idler roller that may be separated without opening the housing of the welding gun. To separate the rollers, the user may depress a portion on the exterior of the housing to press on a pivotable lever on which the idler roller is disposed.

Owner:M K PRODS

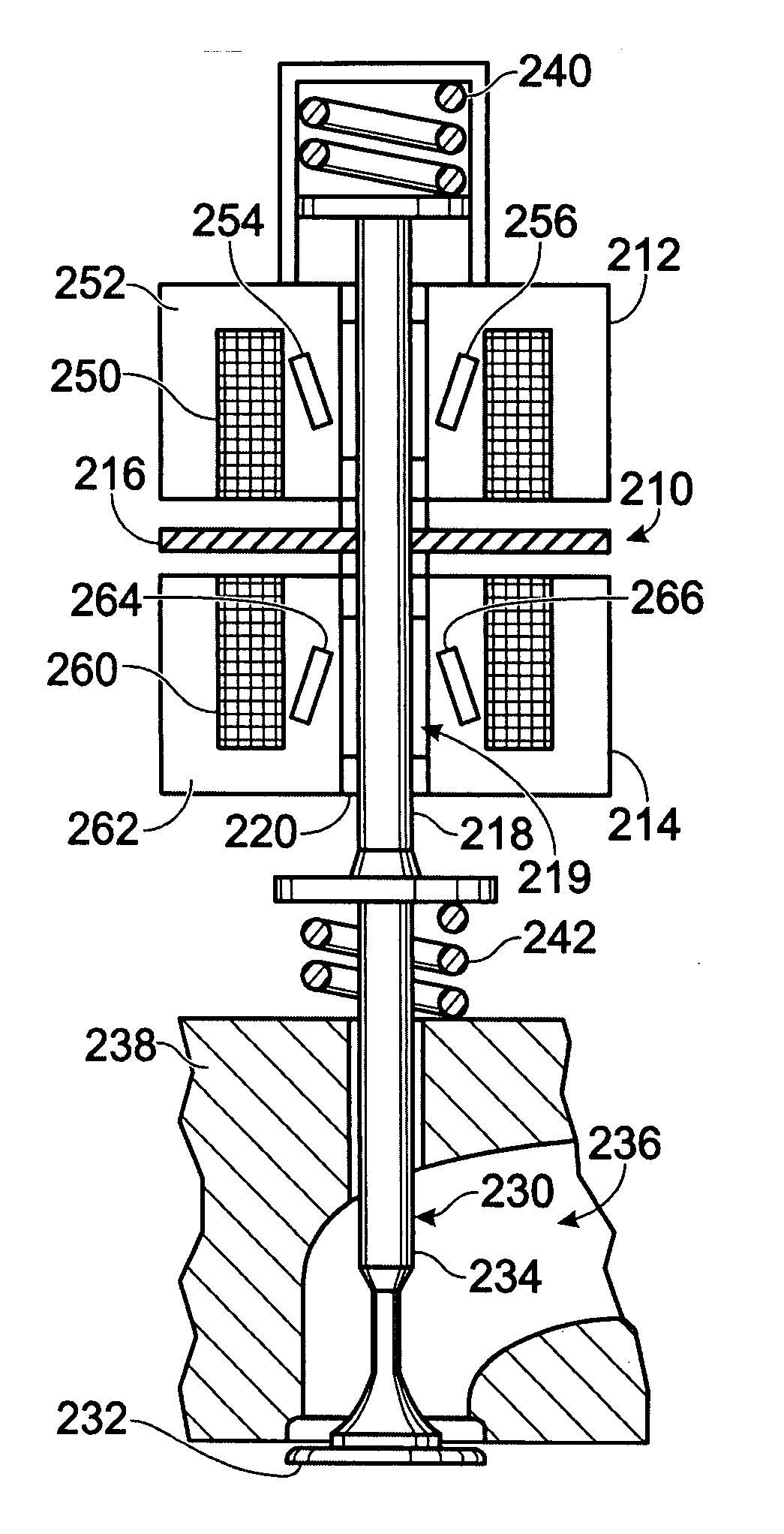

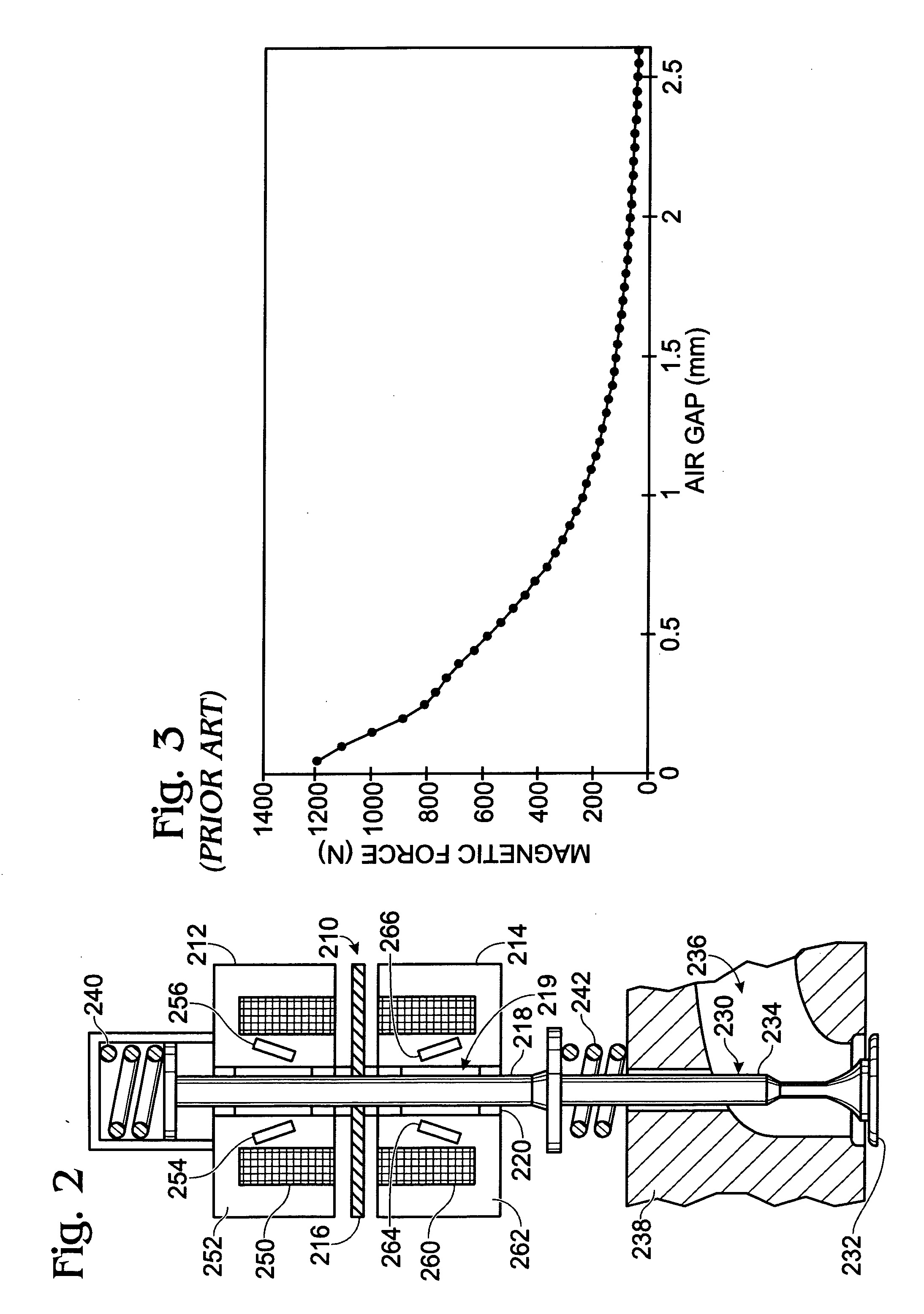

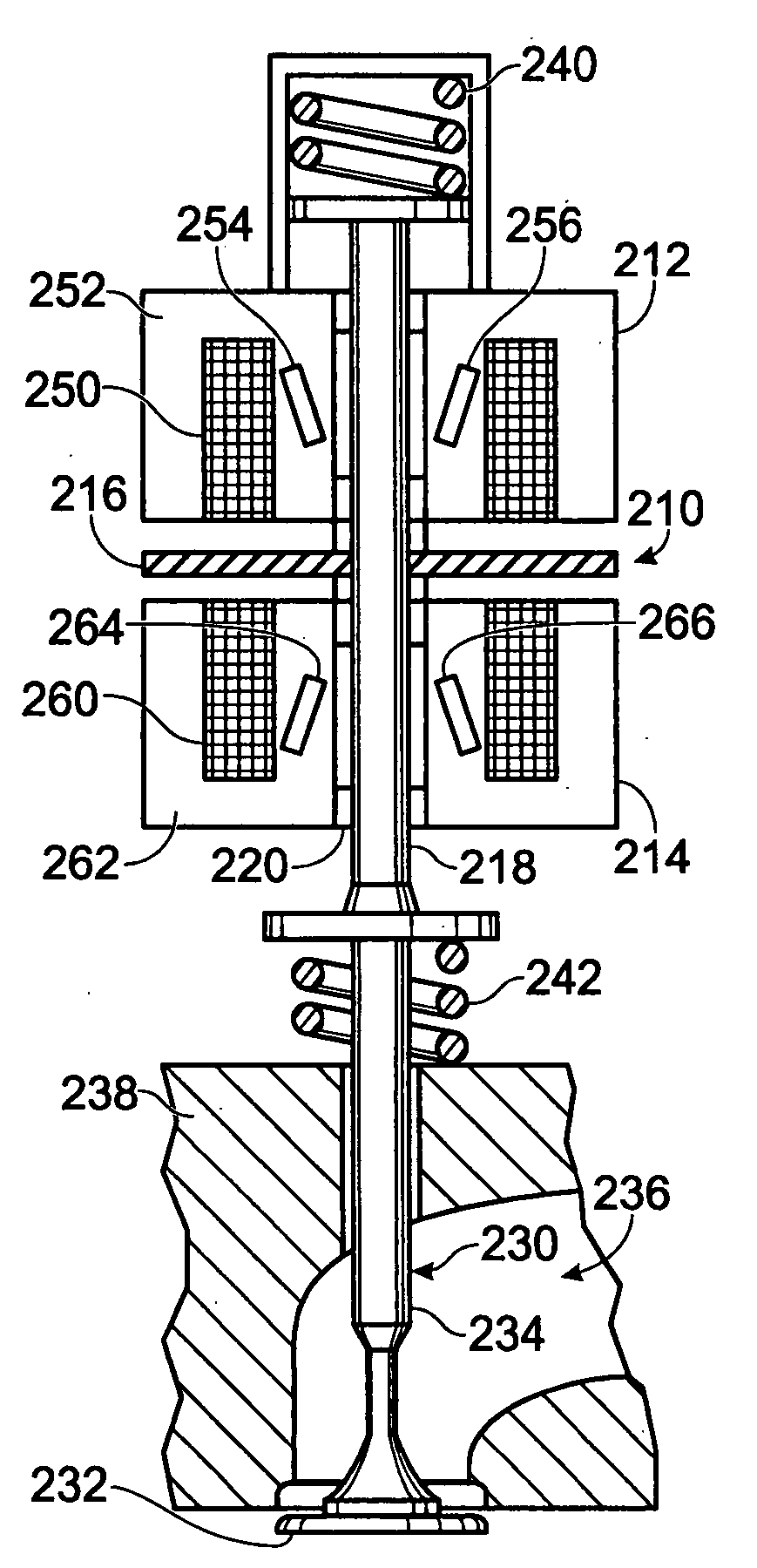

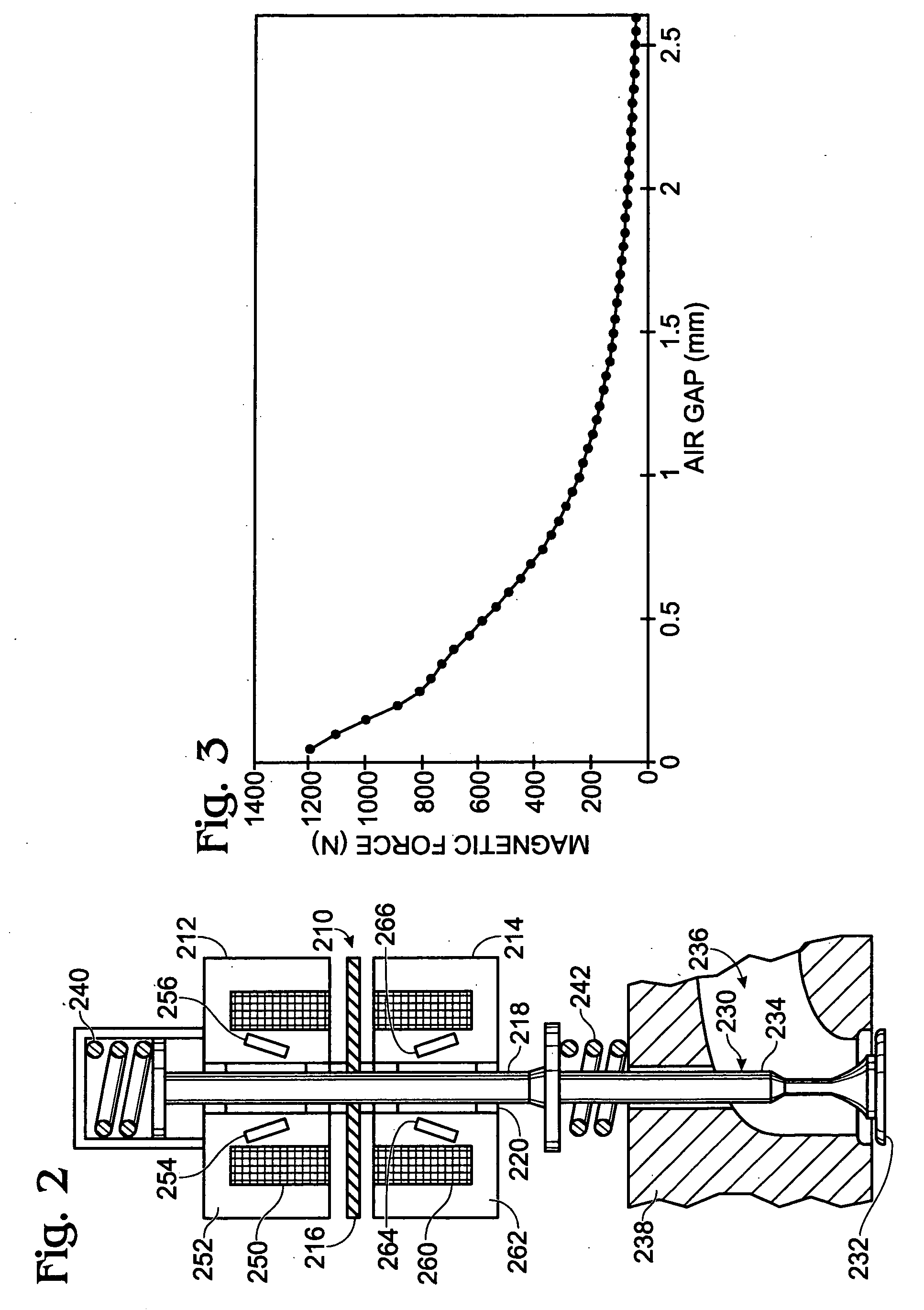

Enhanced permanent magnet electromagnetic actuator for an electronic valve actuation system of an engine

InactiveUS20050211200A1Increase the areaIncrease flux densityWindings insulation shape/form/constructionMachines/enginesValve actuatorForce generation

A valve actuator for an internal combustion engine is described having a core having a wound coil located therein, said core further having at least one permanent magnet located at least partially inside or outside said coil and positioned at an angle relative to a direction of movement of an armature. Further, various recesses, indentations, chamfers, bevels, and / or depressions may be included to affect flux leakage, and / or force generation.

Owner:FORD GLOBAL TECH LLC

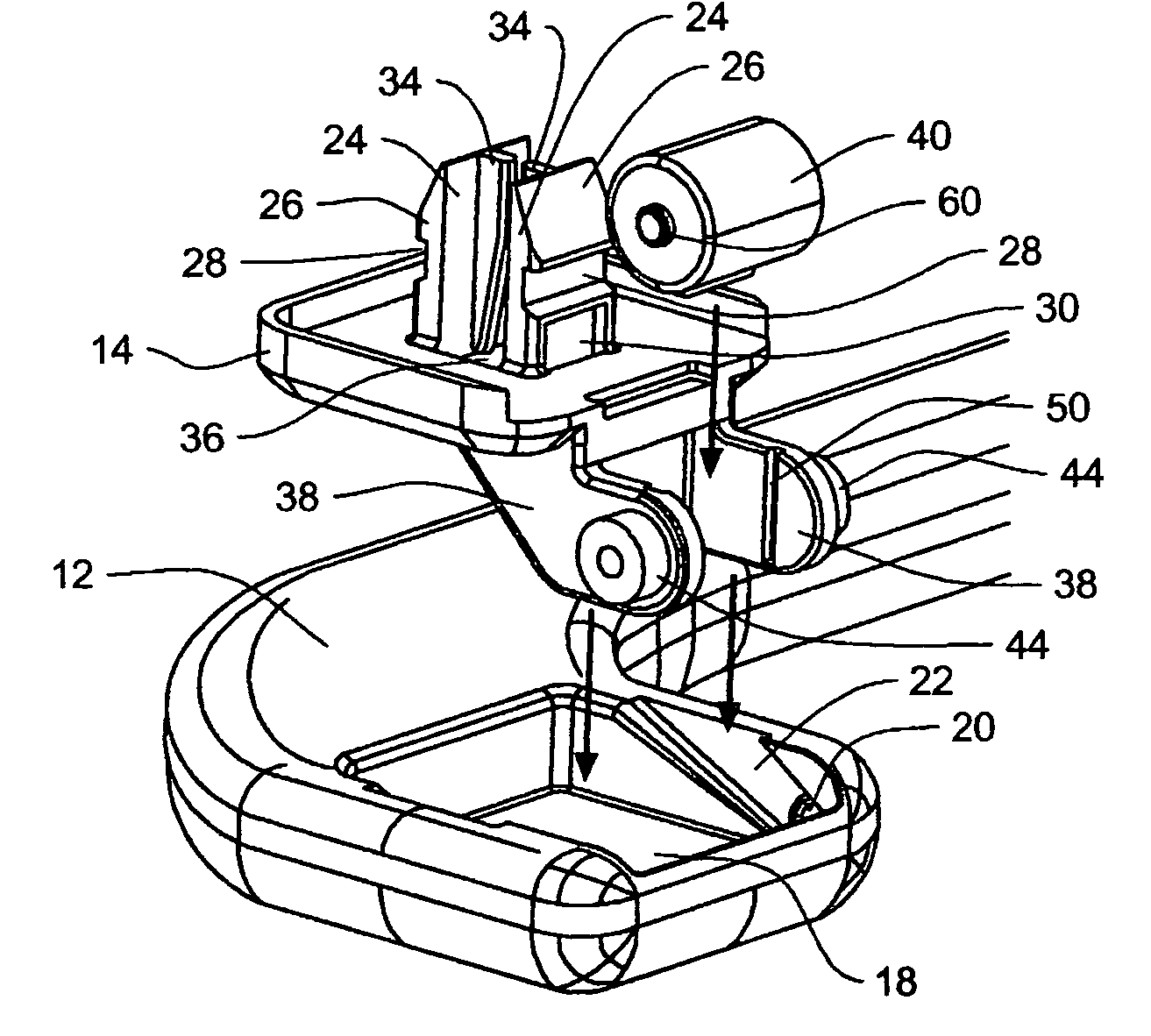

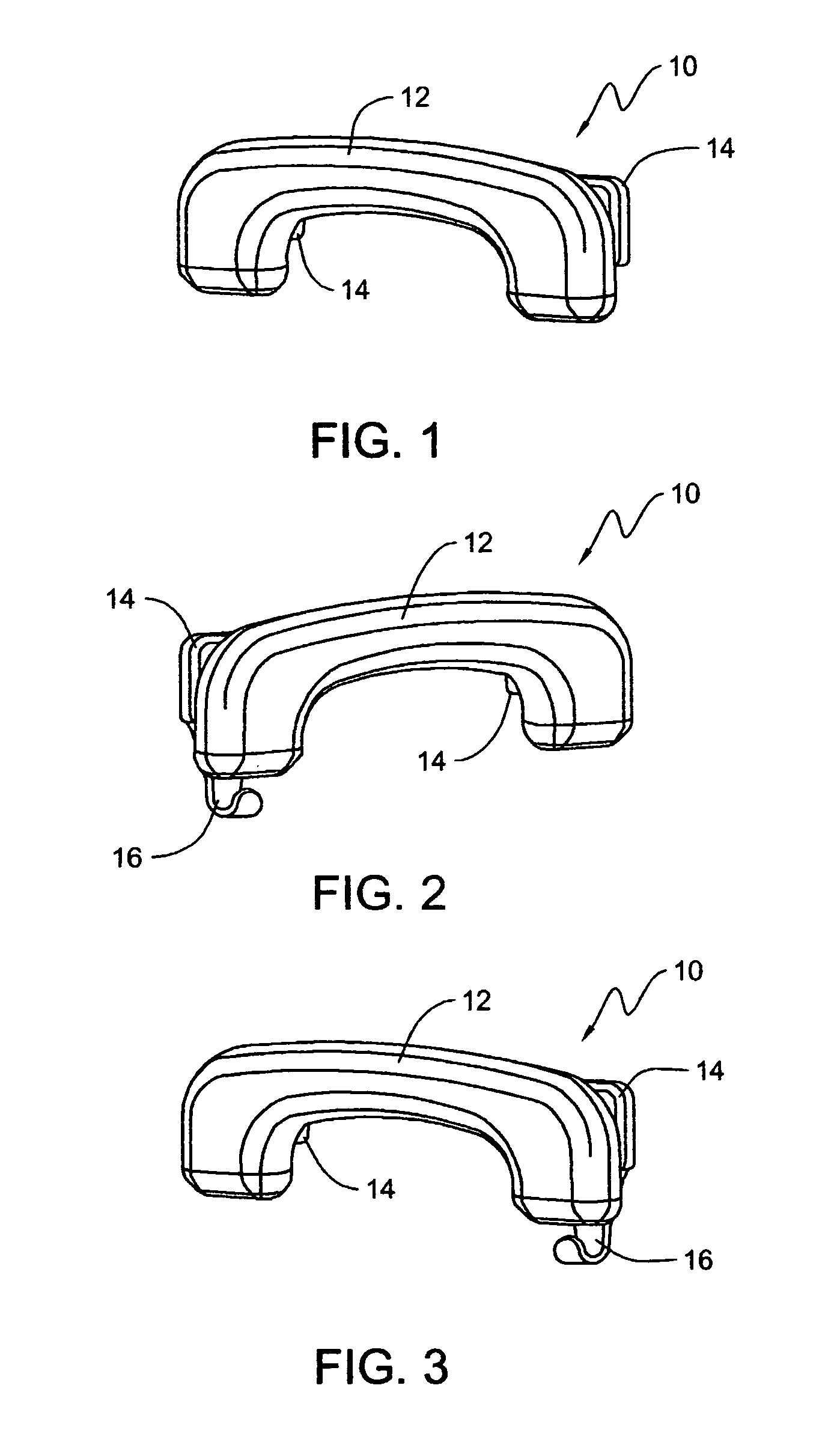

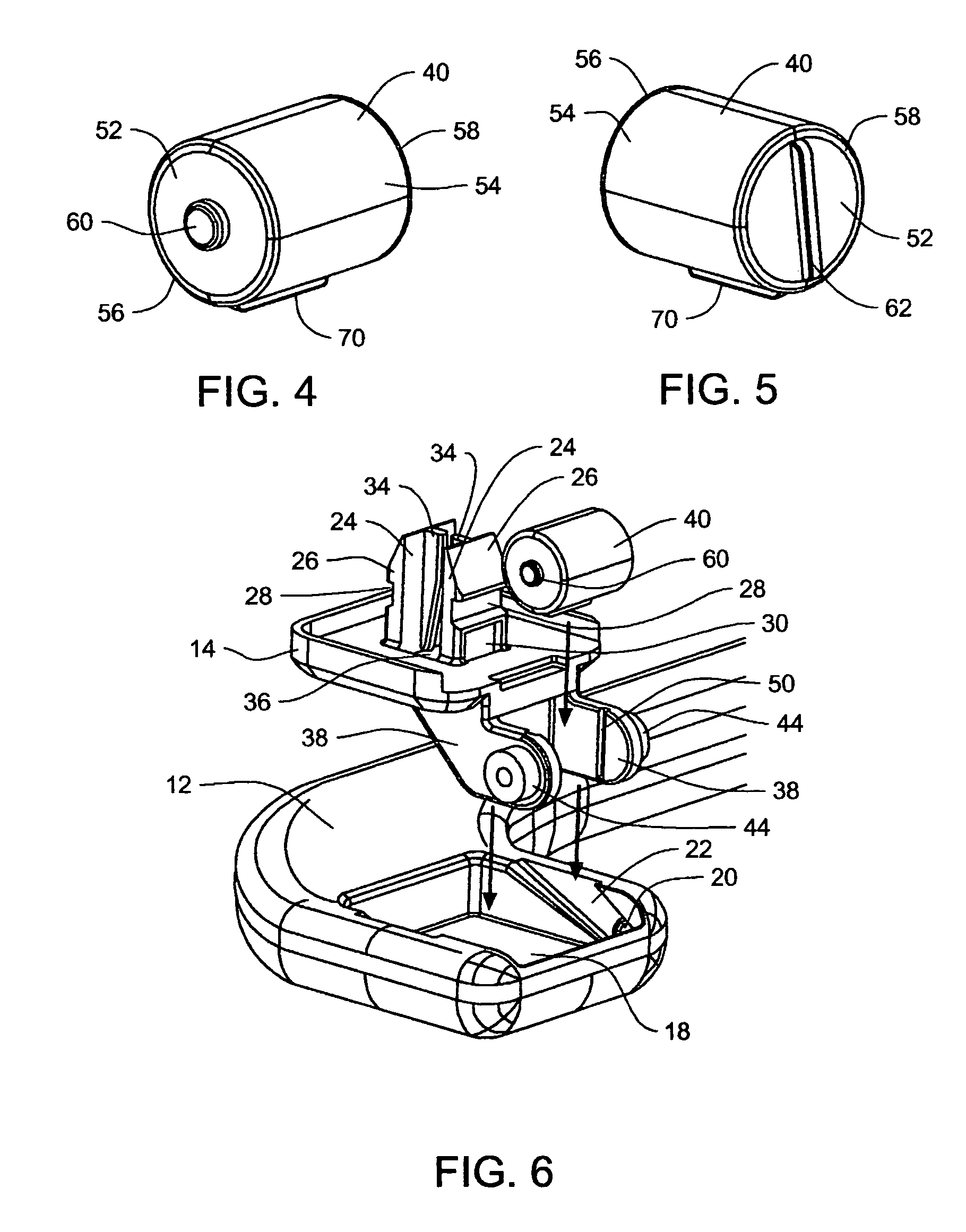

Pin-less damper assembly for an assist grip handle

ActiveUS7103939B2Good speed controlLess complexTravelling carriersVehicle arrangementsSnubberShock absorber

An assist grip handle assembly that may be snap-fit to the interior of a vehicle or other structure includes a damper assembly provided with the handle assembly that does not require the use of a pivot pin. The damper assembly of the invention easily snap-fits into the assist grip handle assembly and provides improved speed control of the rotational movement of the assist grip handle. With the present invention, no special tools are required to assemble the assist grip handle assembly as the components may be snap-fit together resulting in a less complex and cumbersome assembly.

Owner:ILLINOIS TOOL WORKS INC

Radial flux permanent magnet AC motor/generator

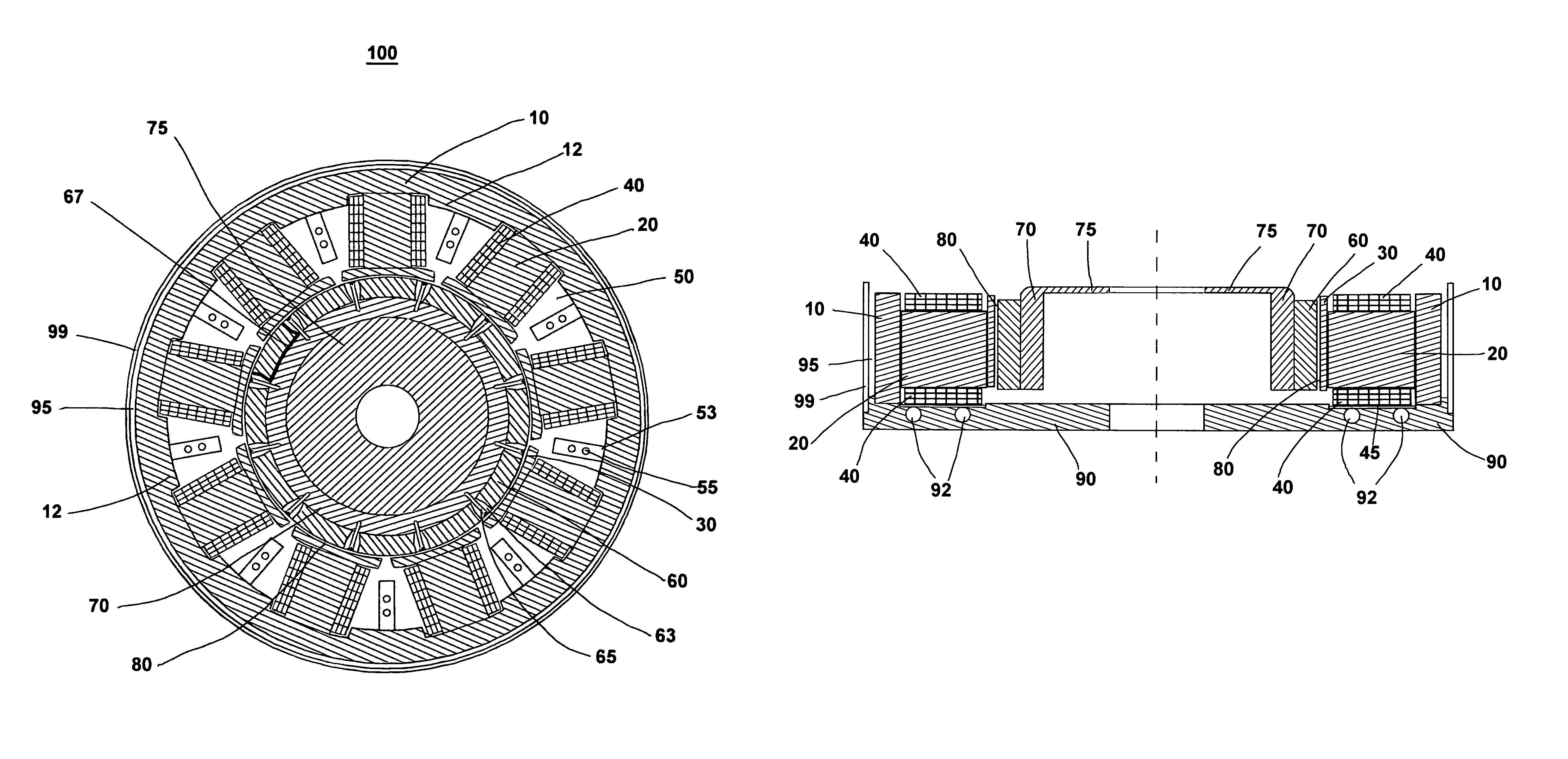

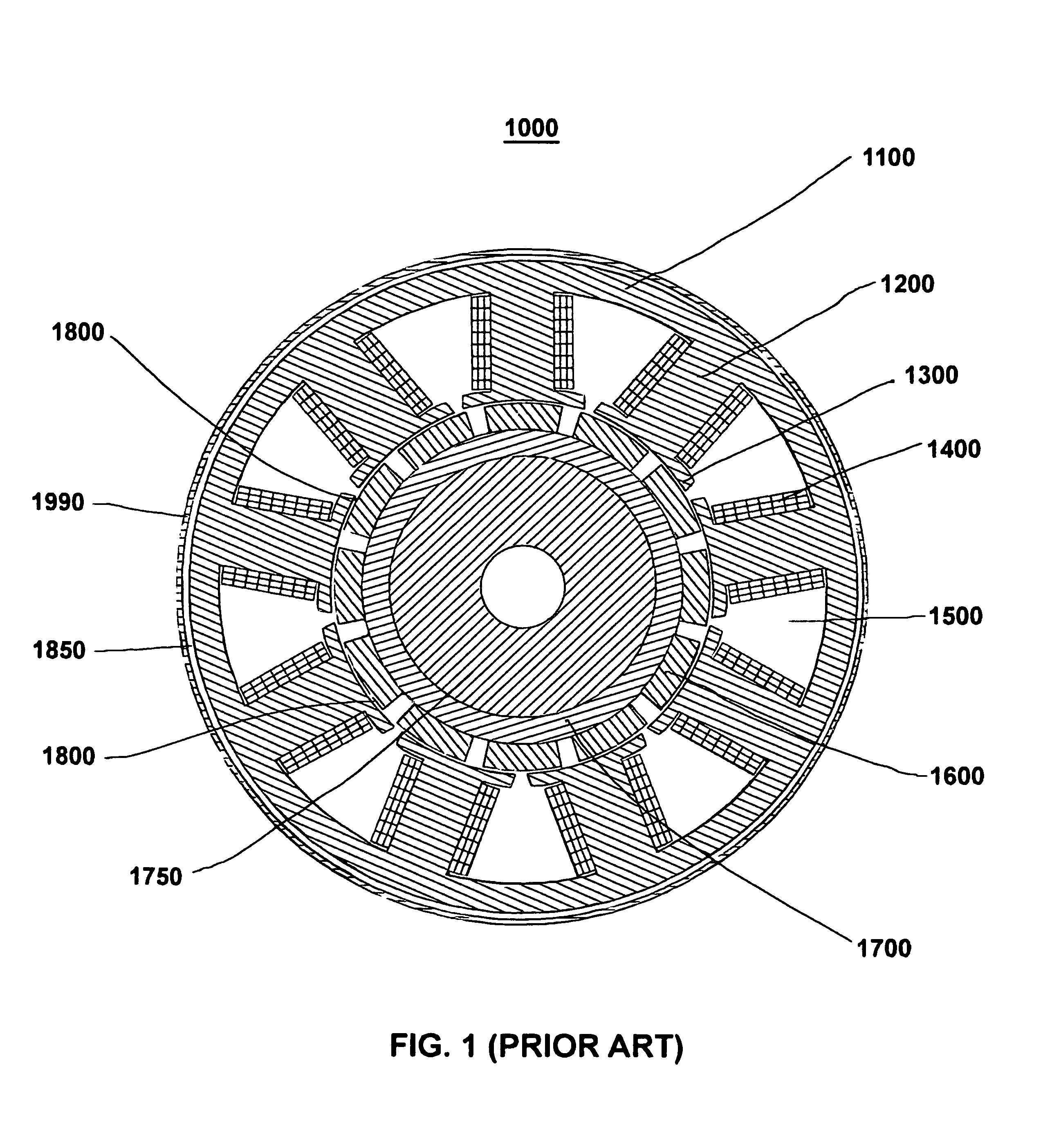

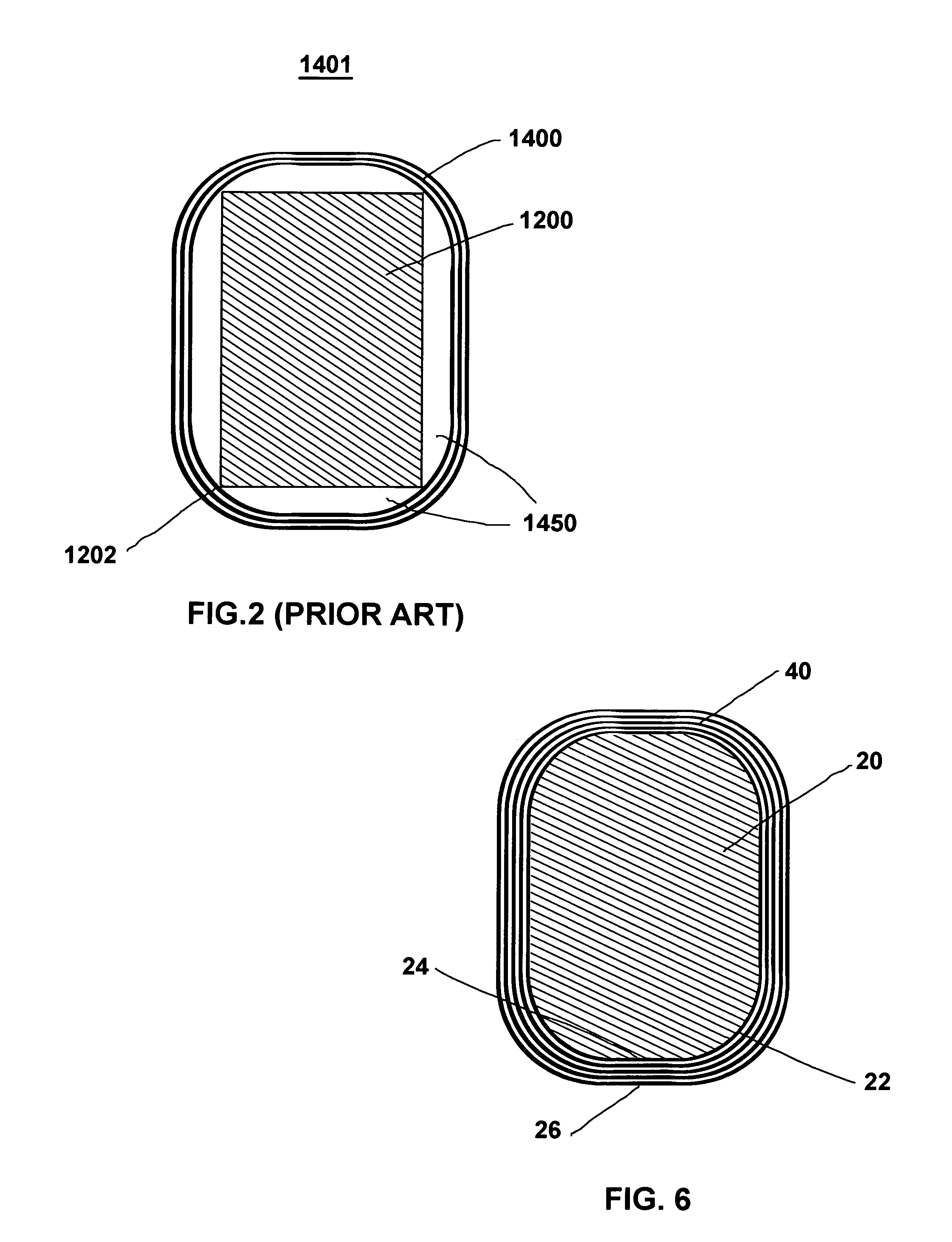

InactiveUS8310126B1Heavy weightLow powerMagnetic circuit rotating partsMagnetic circuit stationary partsRing patternConductor Coil

A radial flux permanent magnet AC motor / generator employs a flat circular stator plate having a plurality of separately-formed electromagnets mounted in a ring pattern on a top surface thereof. A circular flux ring fabricated of powdered metal is mounted to the stator plate outside the ring of electromagnets. A plurality of permanent magnets are mounted in a ring pattern on the outer cylindrical surface of a steel rotor. The stator plate and rotor are axially and diametrically aligned such that the ring of permanent magnets rotates in close proximity to and inside the ring of electromagnets. The electromagnets utilize powder metal cores shaped to have rounded corners and flat sides that permit the use of heavier gauge windings and eliminate the air gaps that exist between the core and windings of prior art electromagnets.

Owner:PATENT LICENSORS

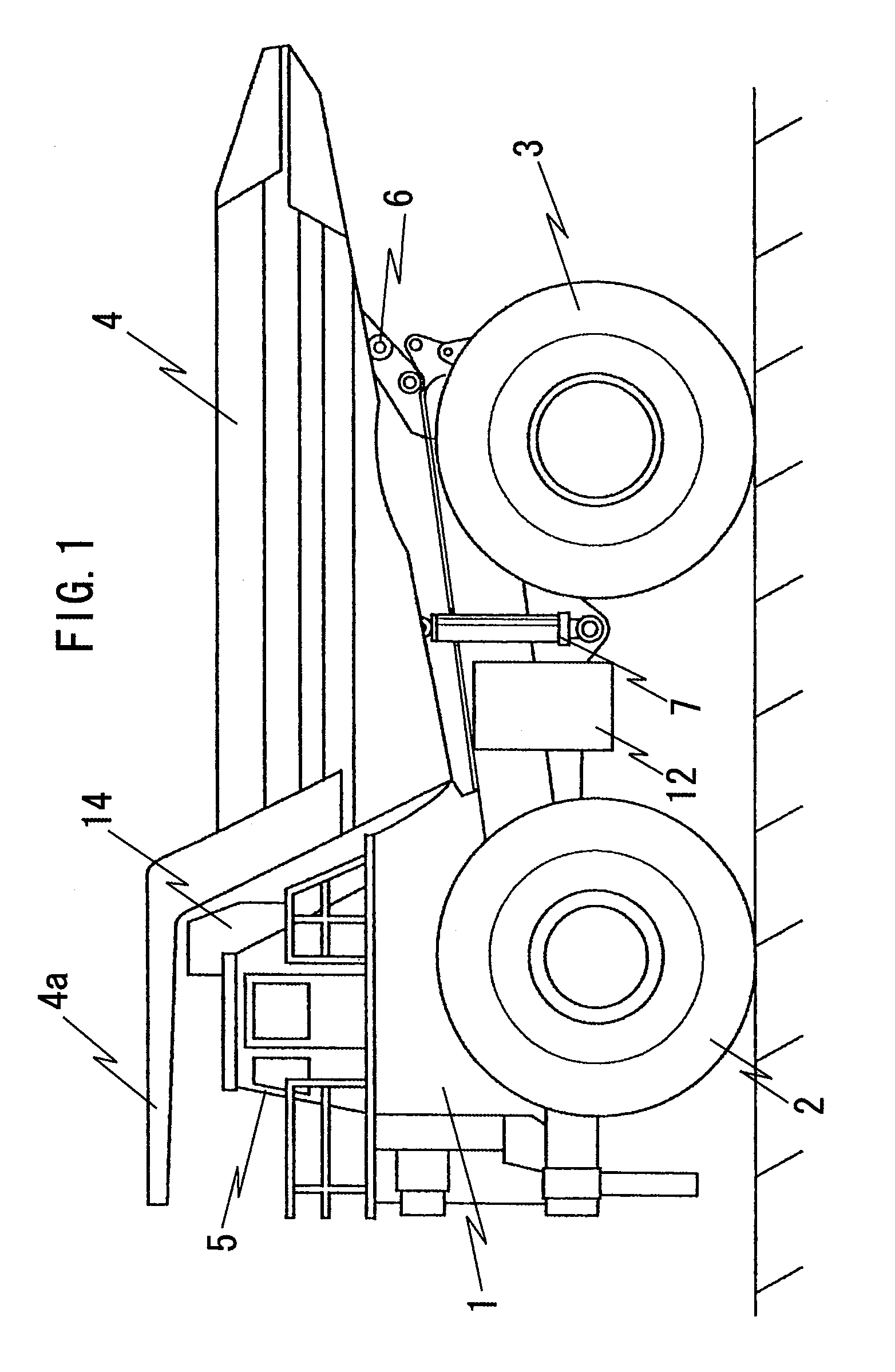

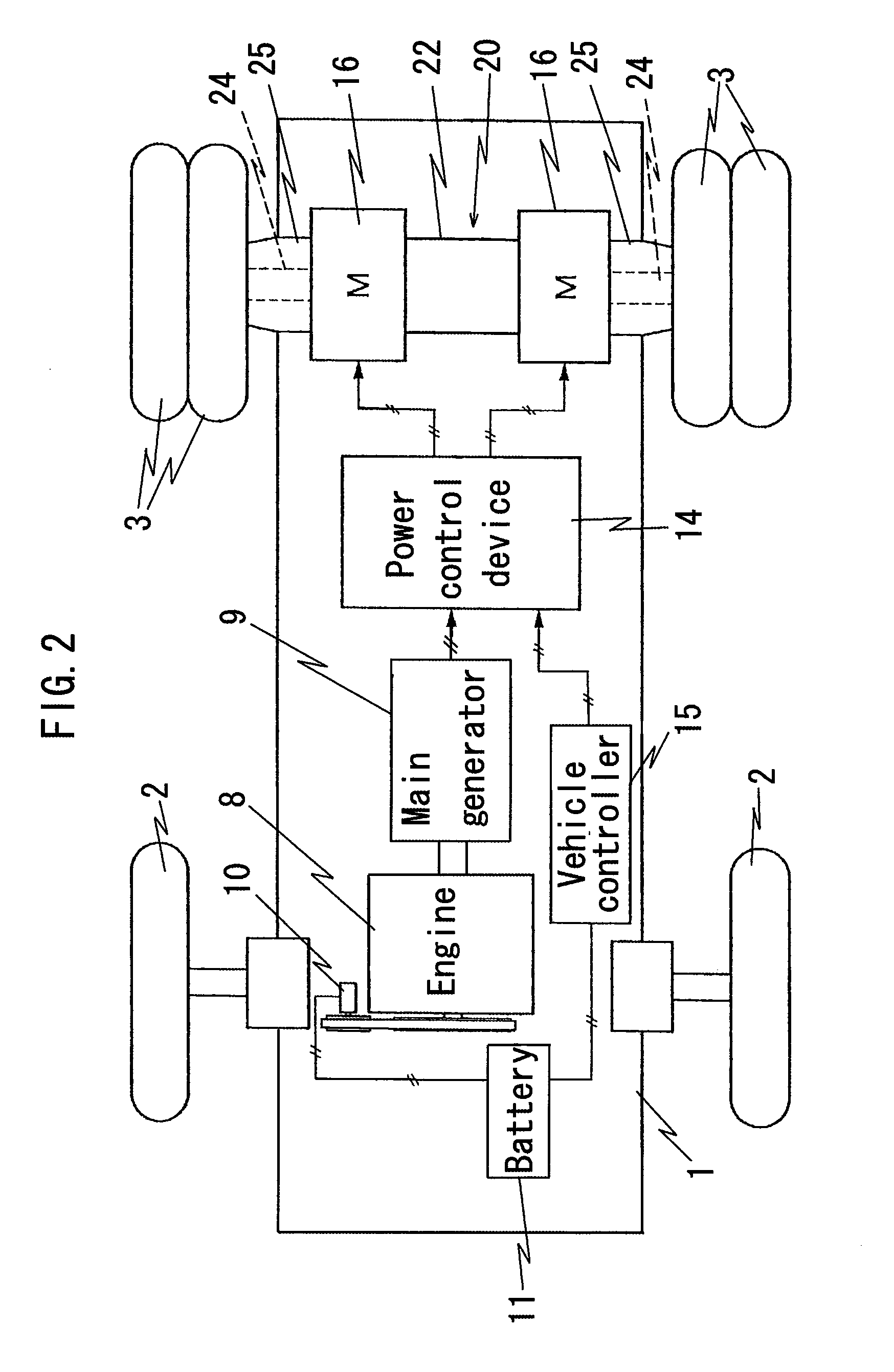

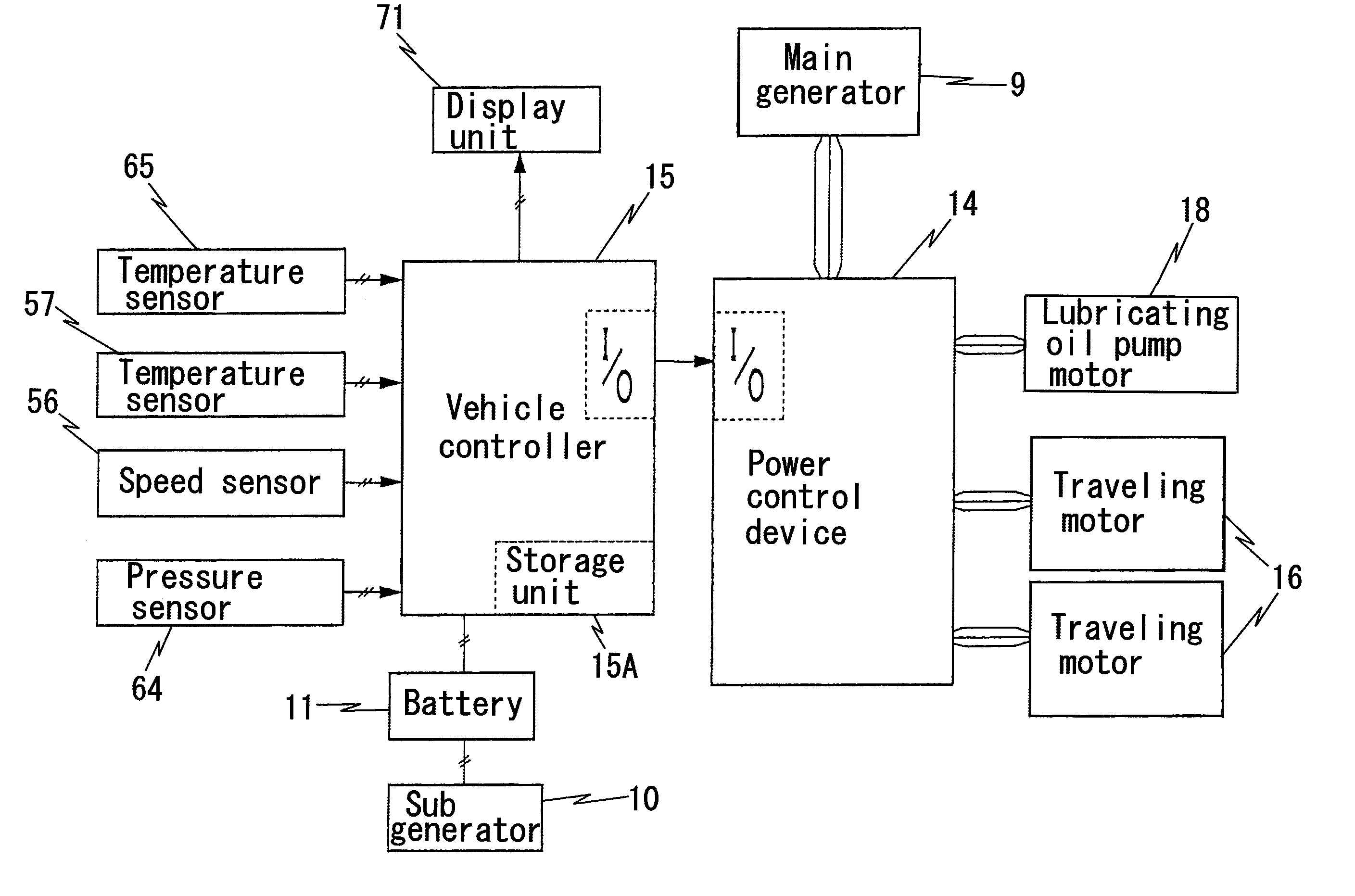

Lubricating oil cooling device for traveling speed reduction gear

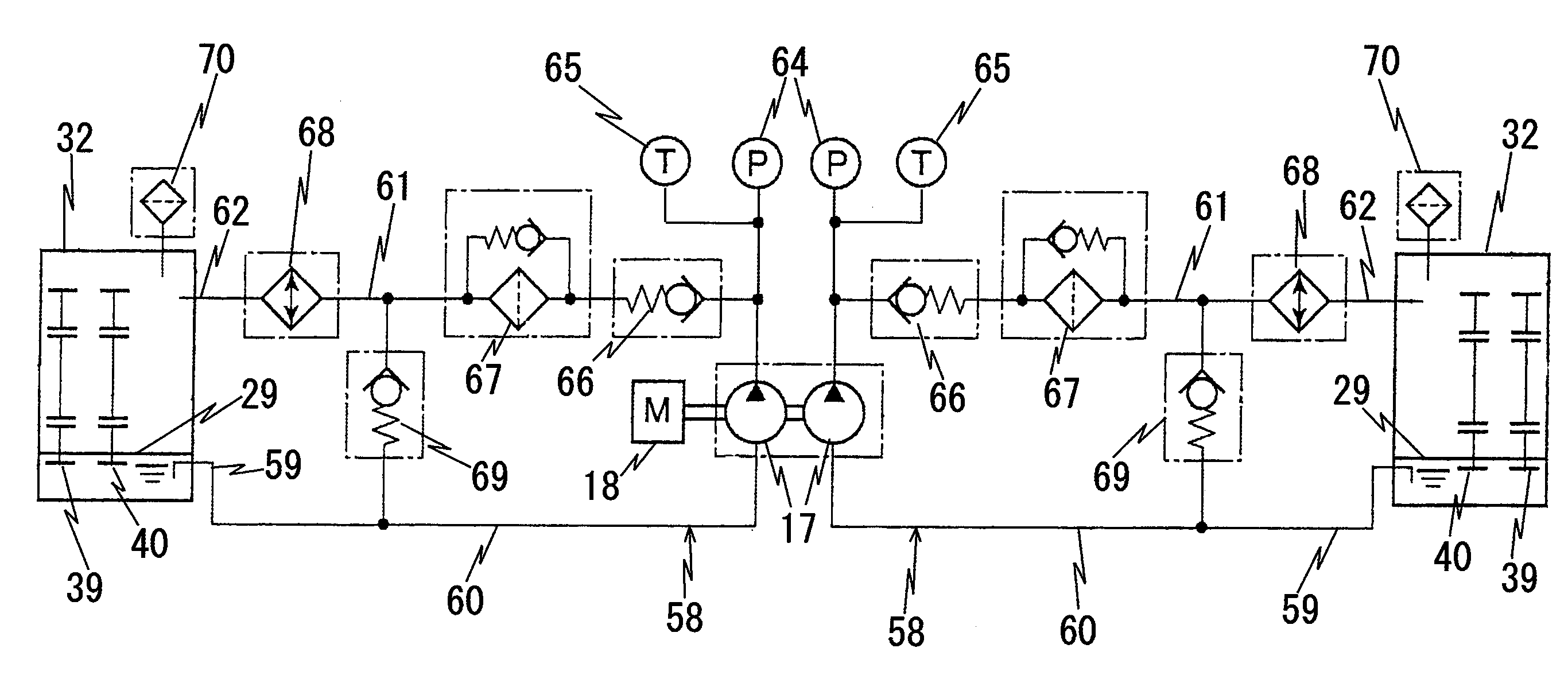

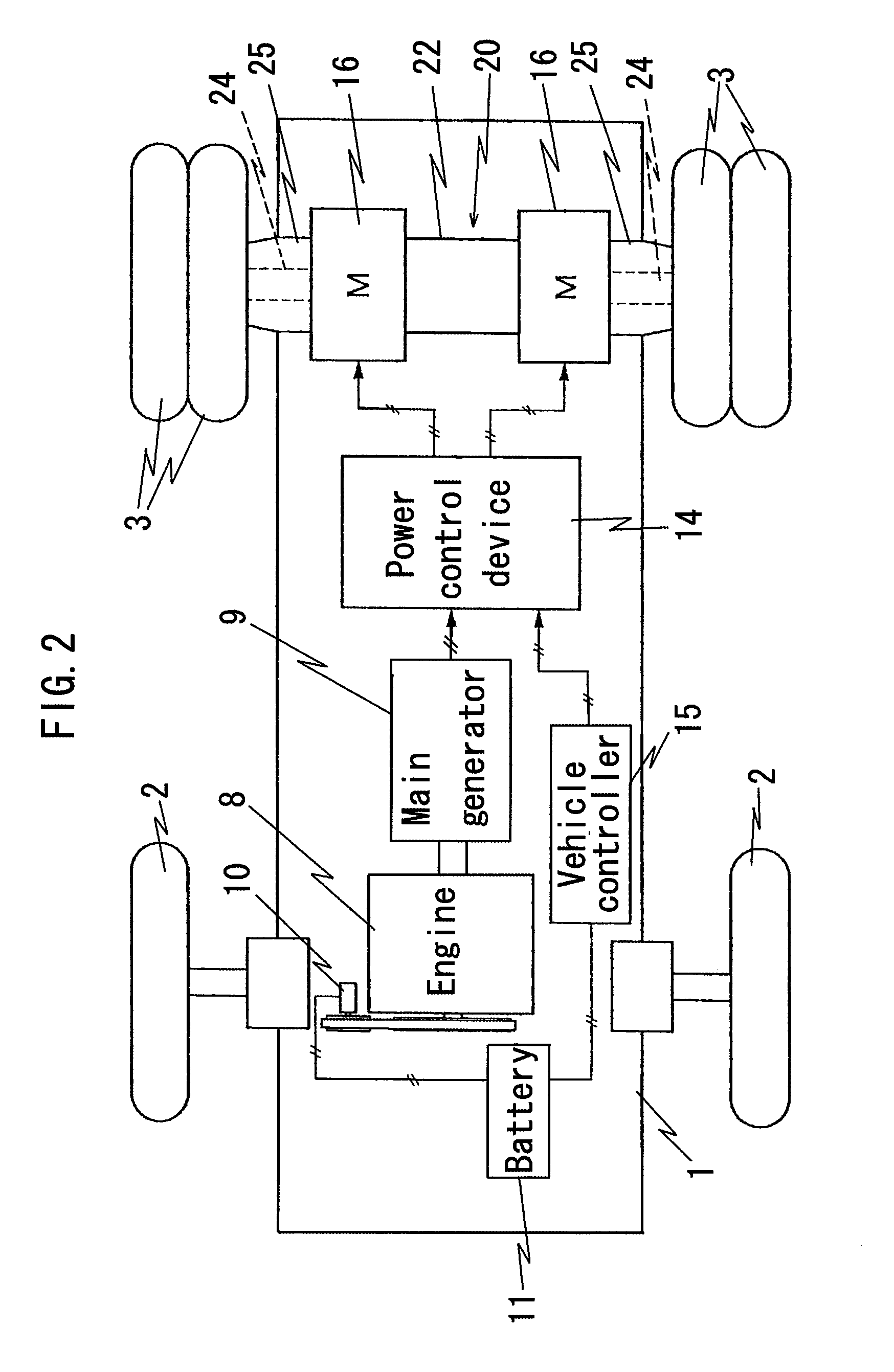

ActiveUS20100187043A1Small motorReduce the temperatureGearboxesAnalogue computers for trafficTemperature controlLow speed

The present invention provides a traveling speed reduction gear lubricating oil cooling device that enables optimal temperature control for lubricating oil delivered via a lubricating oil pump that can be started up with a relatively small motor without running the risk of damage to an oil cooler in a cold work environment even when a temperature sensor that detects the temperature of the lubricating oil is installed outside a wheel mounting sleeve. During a startup operation, provided that the detected temperature at a traveling motor is higher than the reference temperature, the lubricating oil pump is driven at a speed in a lower speed range relative to the normal operation speed range. In addition, during the startup operation, the rotation speed of the drive motor for the lubricating oil pump is increased in correspondence to a rise in the temperature detected by a lubricating oil temperature detection sensor.

Owner:NIHON KENKI CO LTD

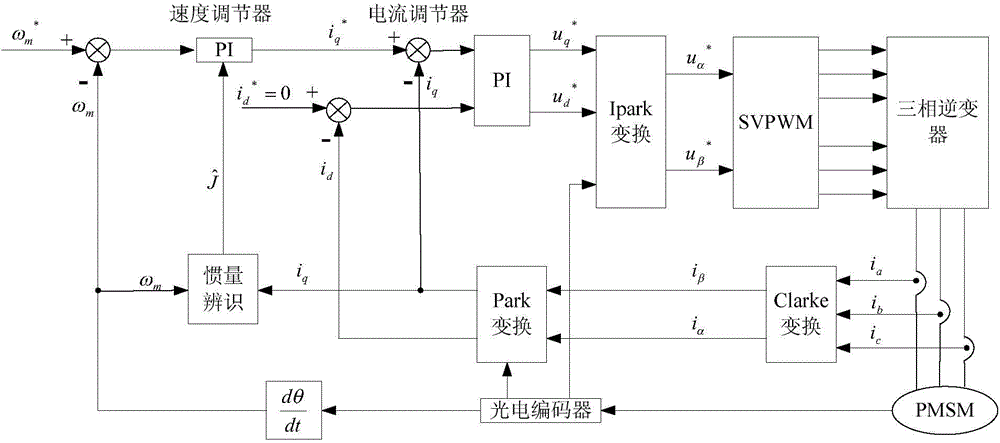

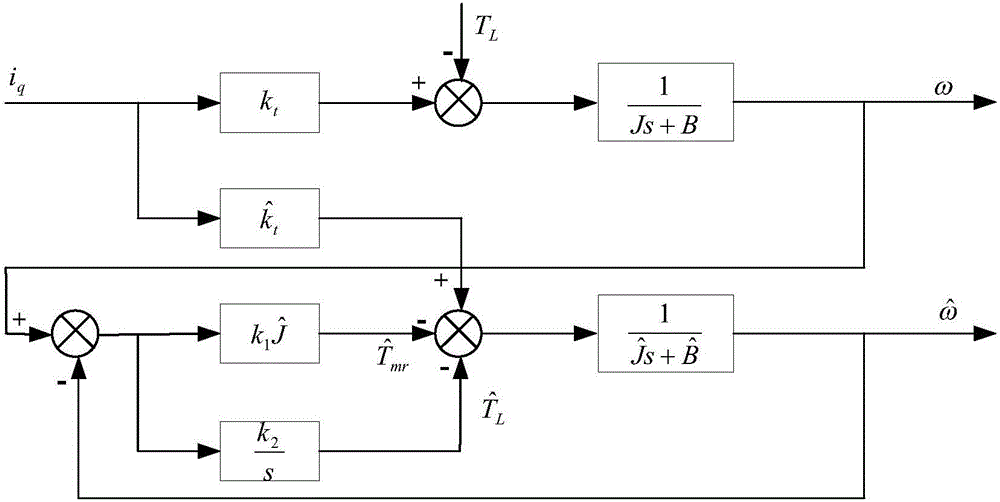

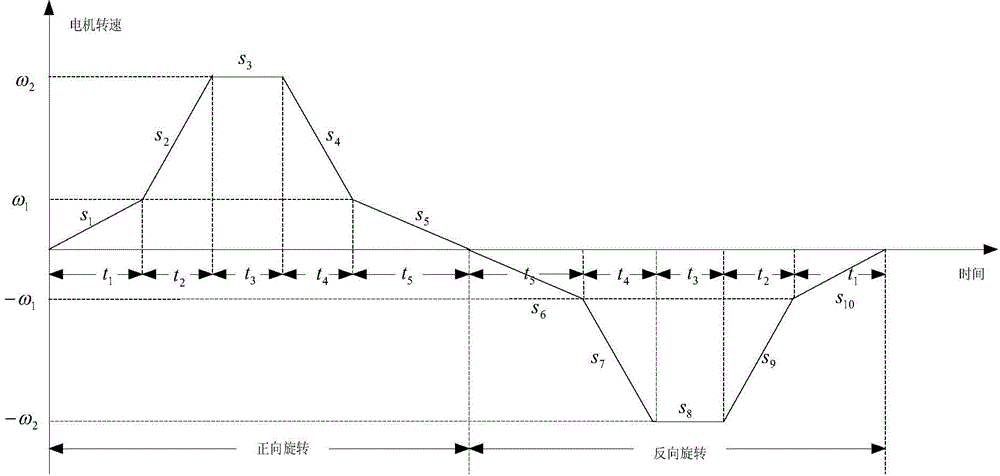

AC servo system rotation inertia identification method

ActiveCN104639003AEasy to implementImprove real-time performanceElectronic commutation motor controlVector control systemsRotor inertiaMoment of inertia

The invention provides an AC servo system load torque and rotation inertia identification method and aims to achieve the fine dynamic and static characteristics of highly accurate control of a servo system according to the effect on the system performance by the permanent magnet synchronous AC servo system load rotation inertia and load torque. The method adopting the load inertia and motor rotor inertia as an entire inertia, allowing a servo system to perform regular forward and reverse speed increasing and decreasing movement, adopting a load disturbance torque state observer to observe the load disturbance torque changes of the motor, acquiring a model disturbance torque, adopting the integration identification algorithm, and identifying the system rotation inertia through mathematical derivation.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

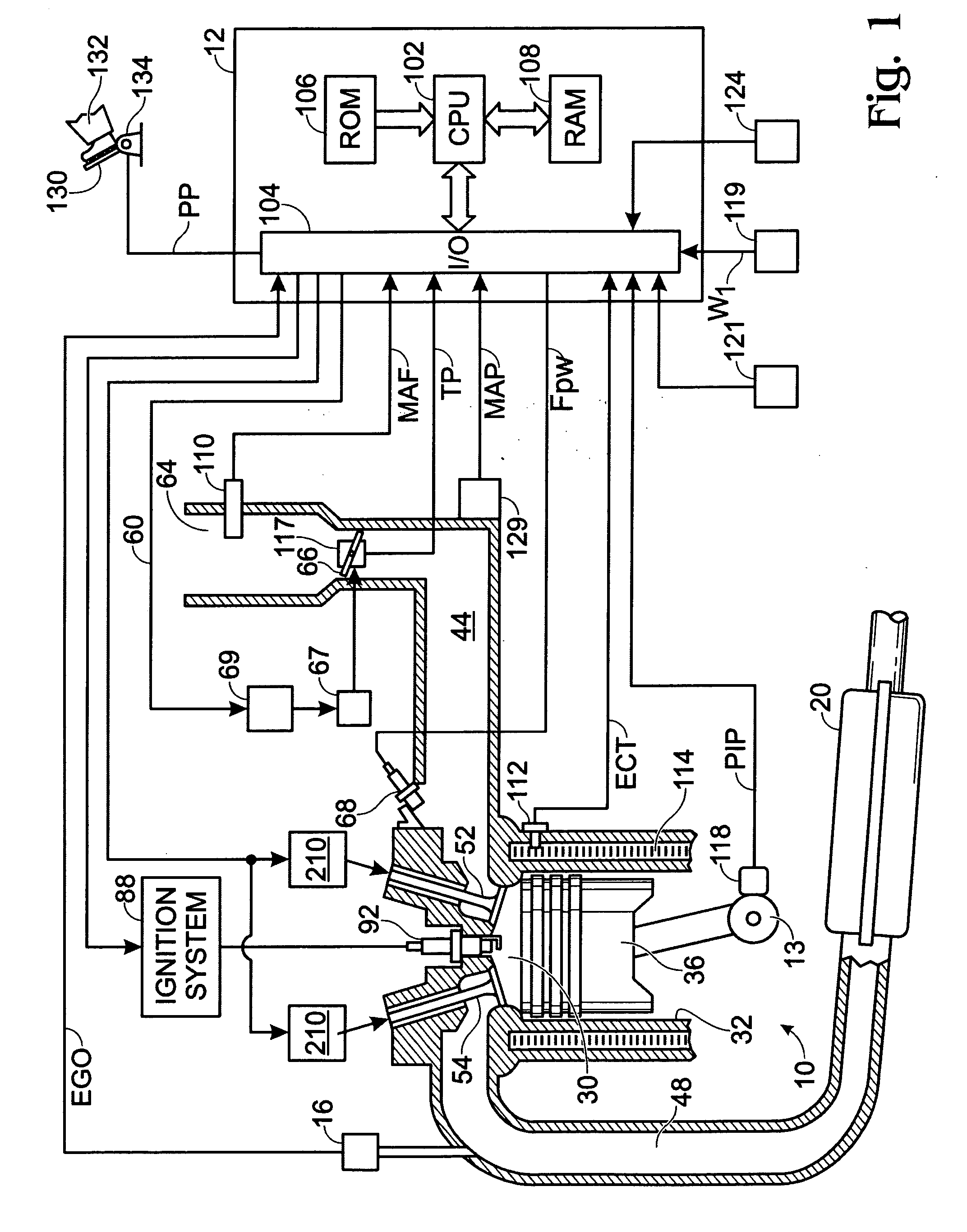

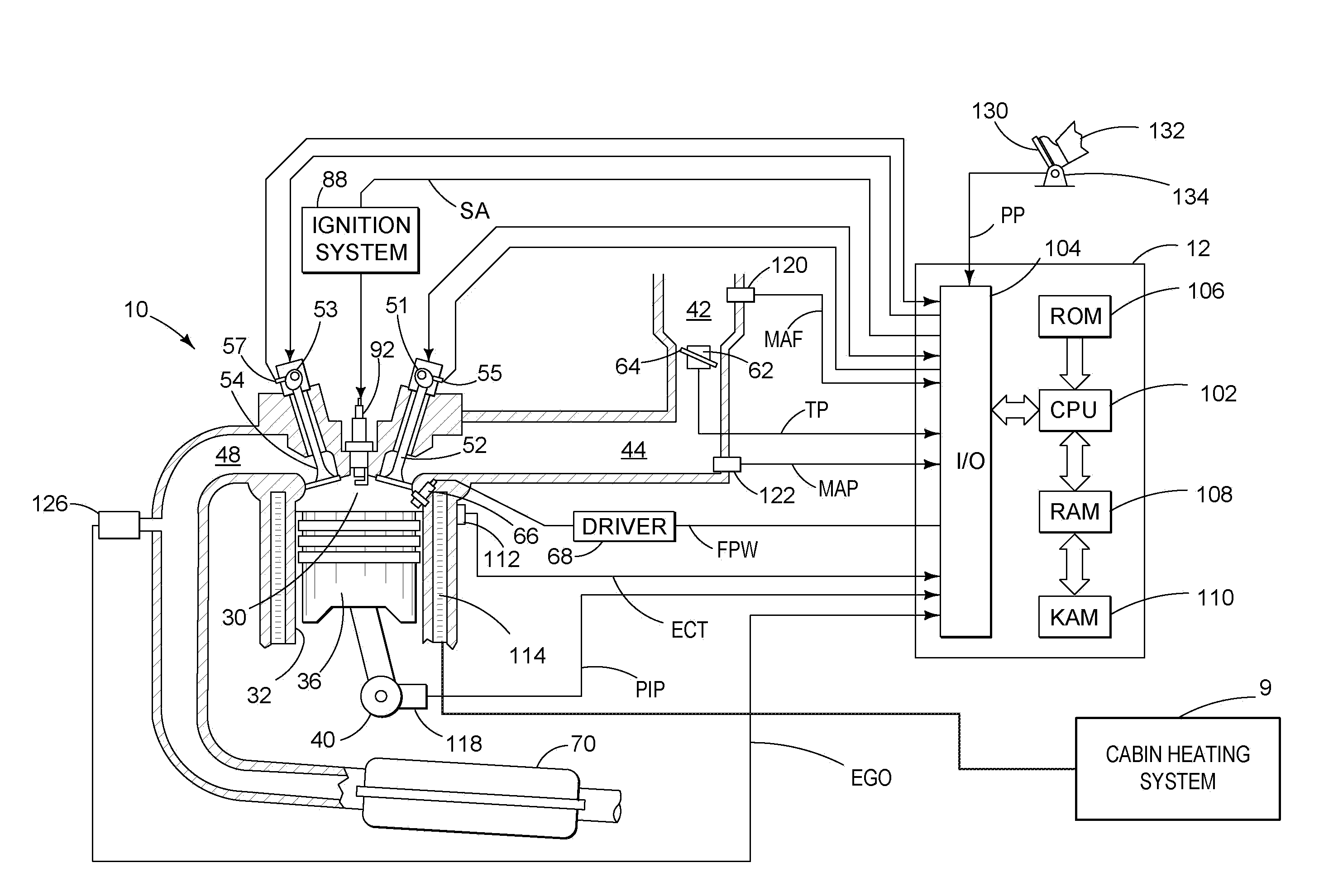

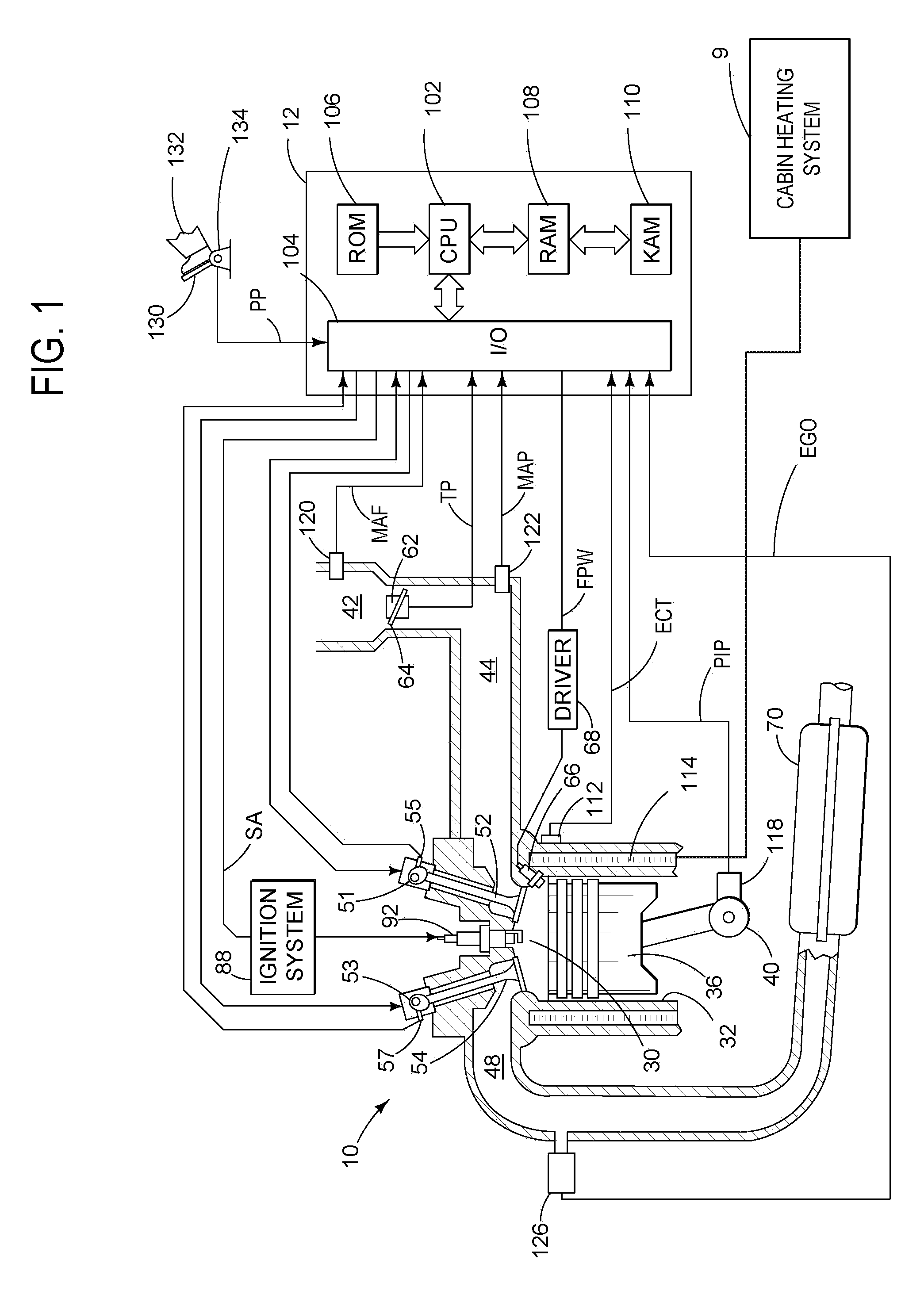

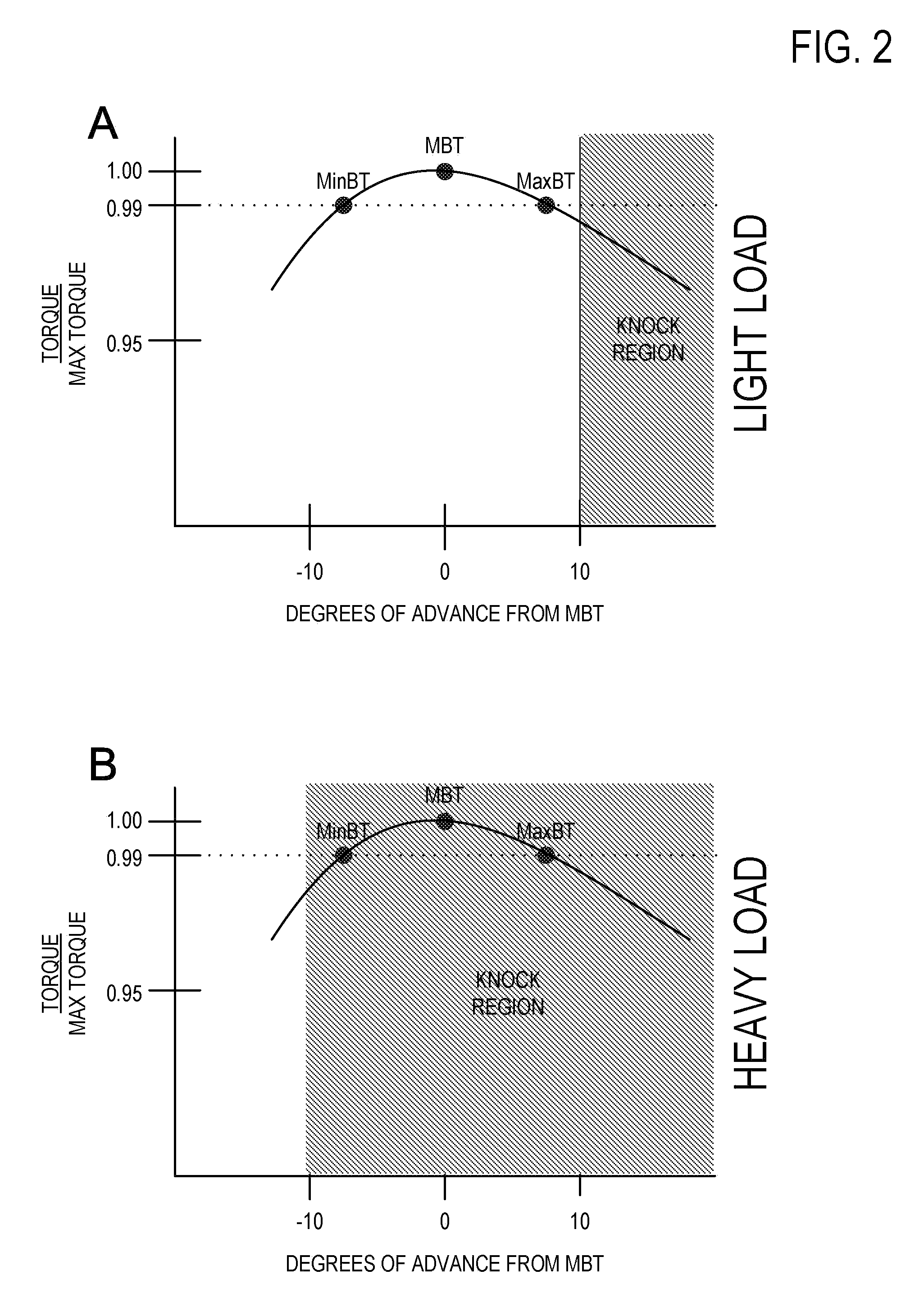

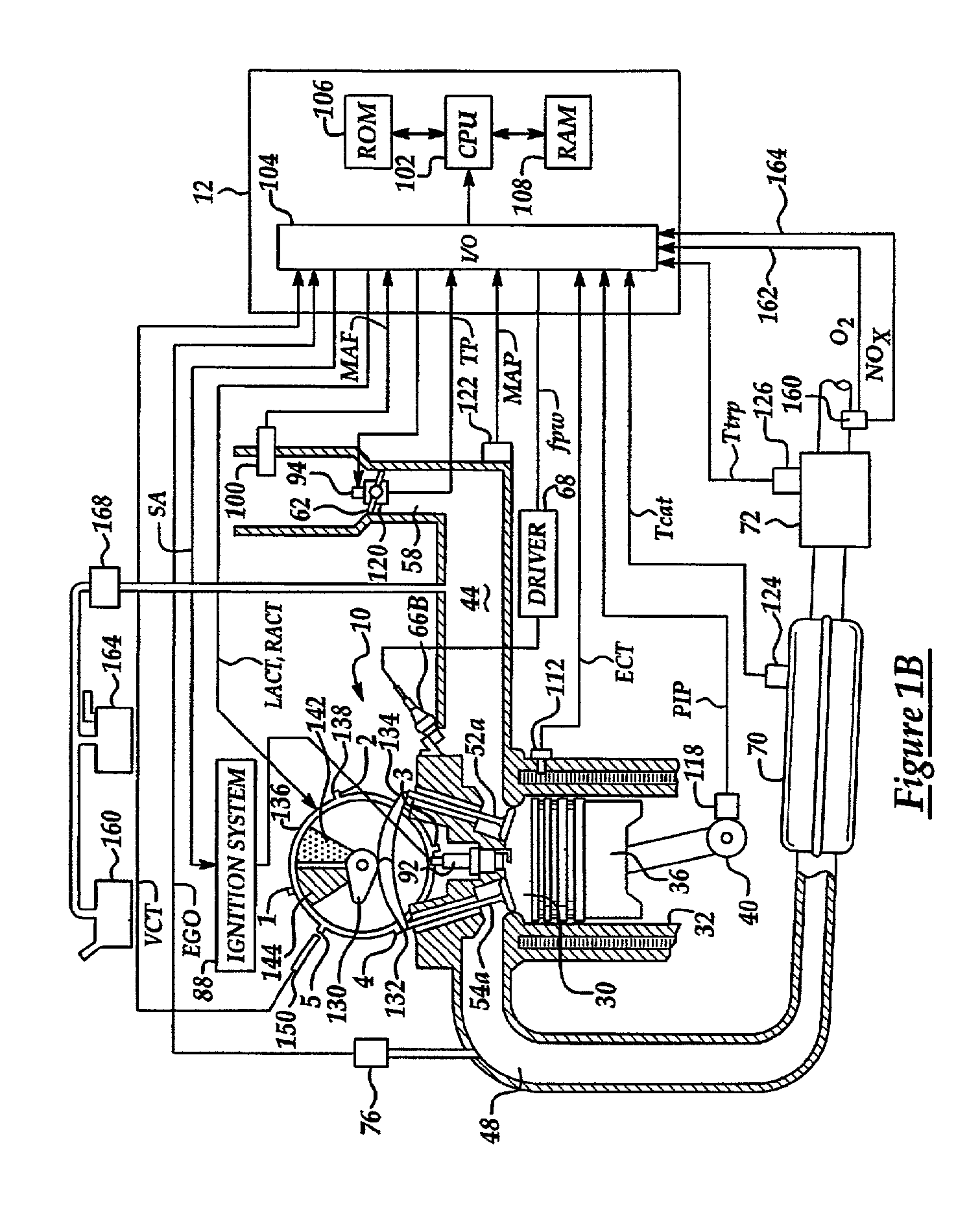

Engine and exhaust heating

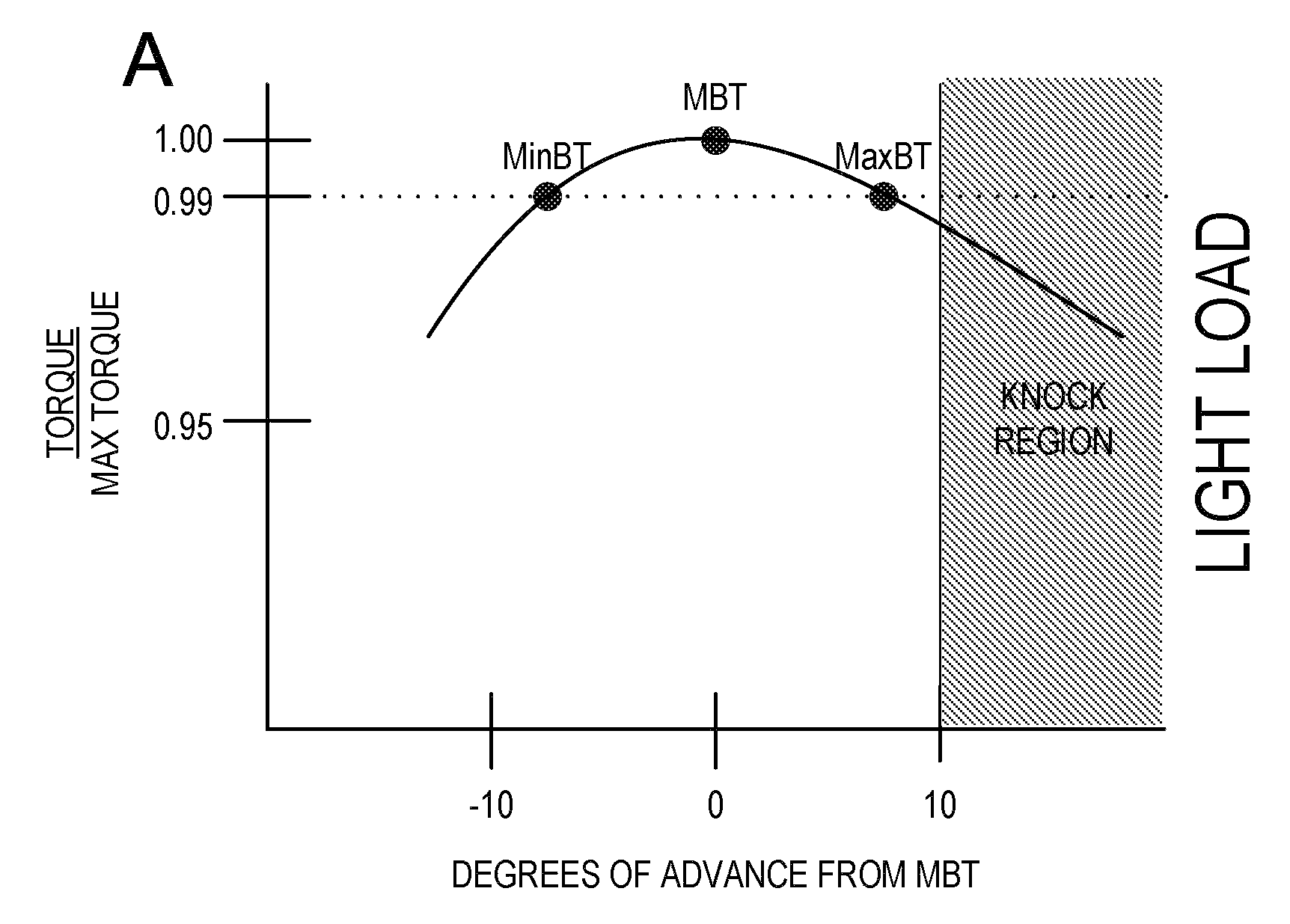

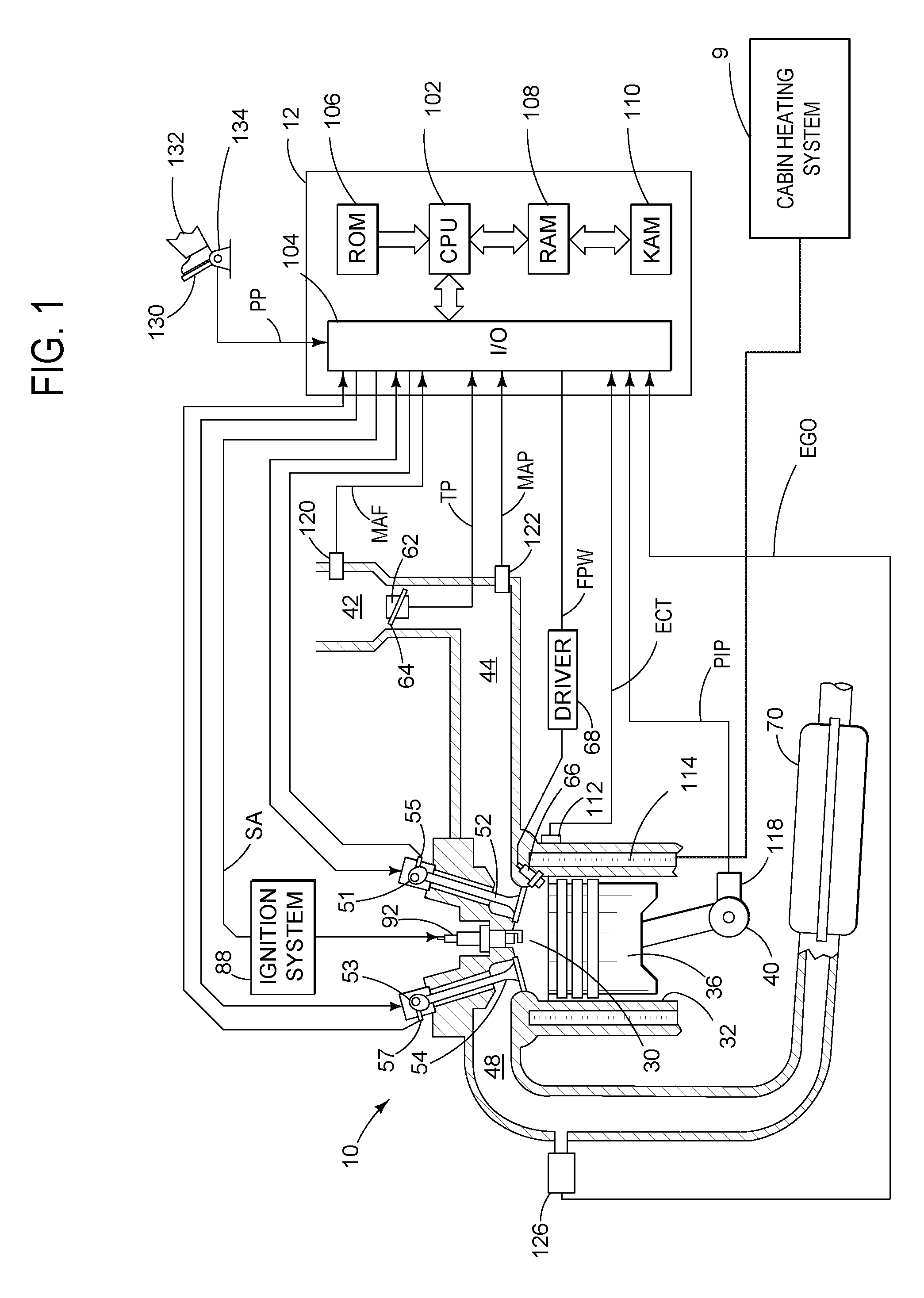

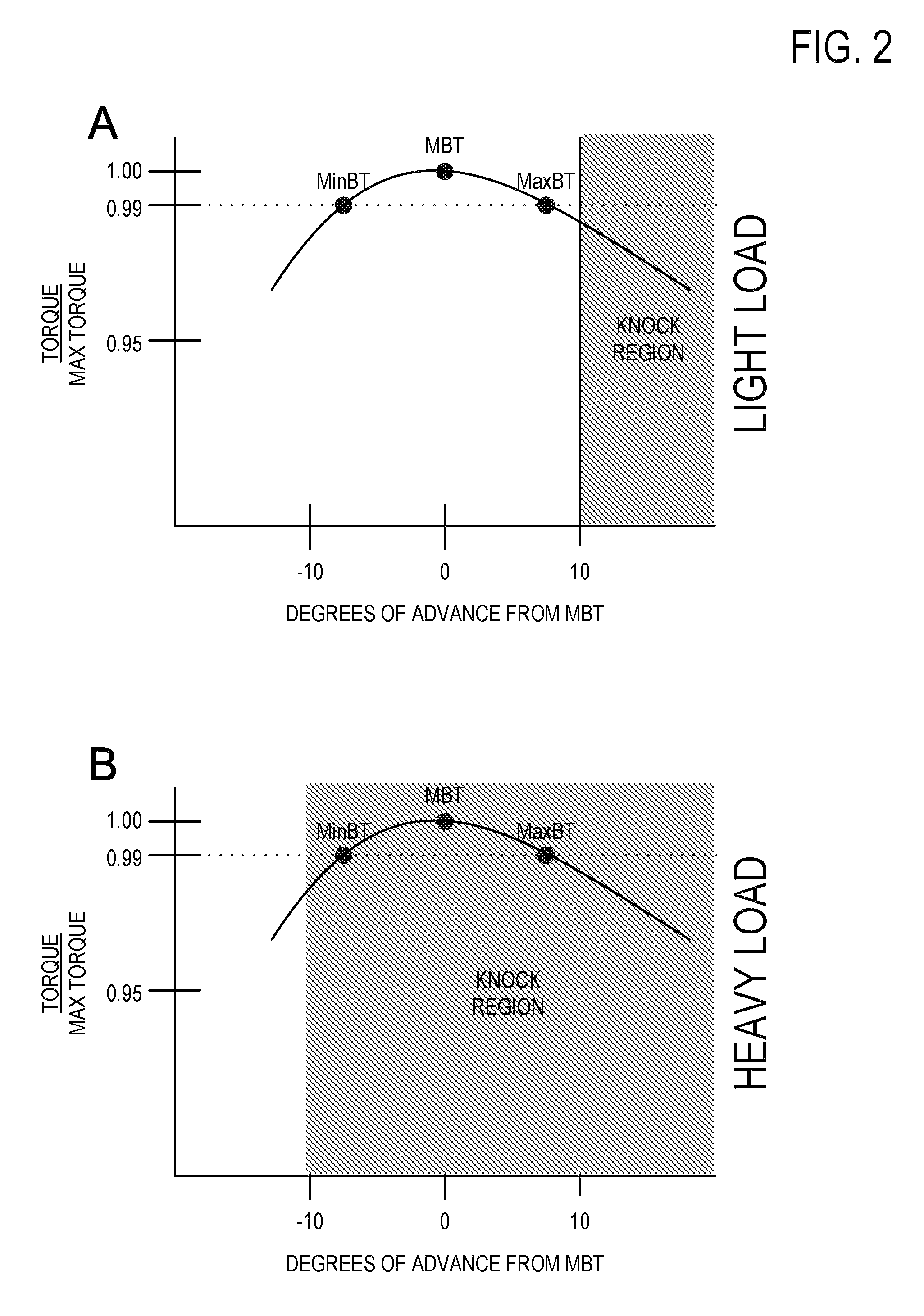

ActiveUS20100108031A1Reduce emissionReduce lubricant viscosityAnalogue computers for vehiclesInternal combustion piston enginesControl theory

Owner:FORD GLOBAL TECH LLC

Permanent magnet electromagnetic actuator for an electronic valve actuation system of an engine

InactiveUS20050211199A1Increase spacingActuator height is not requiredWindings insulation shape/form/constructionMachines/enginesValve actuatorEngineering

A valve actuator for an internal combustion engine is described having a core having a wound coil located therein, said core further having at least one permanent magnet located at least partially inside said coil and positioned at an angle relative to a direction of movement of an armature.

Owner:FORD GLOBAL TECH LLC

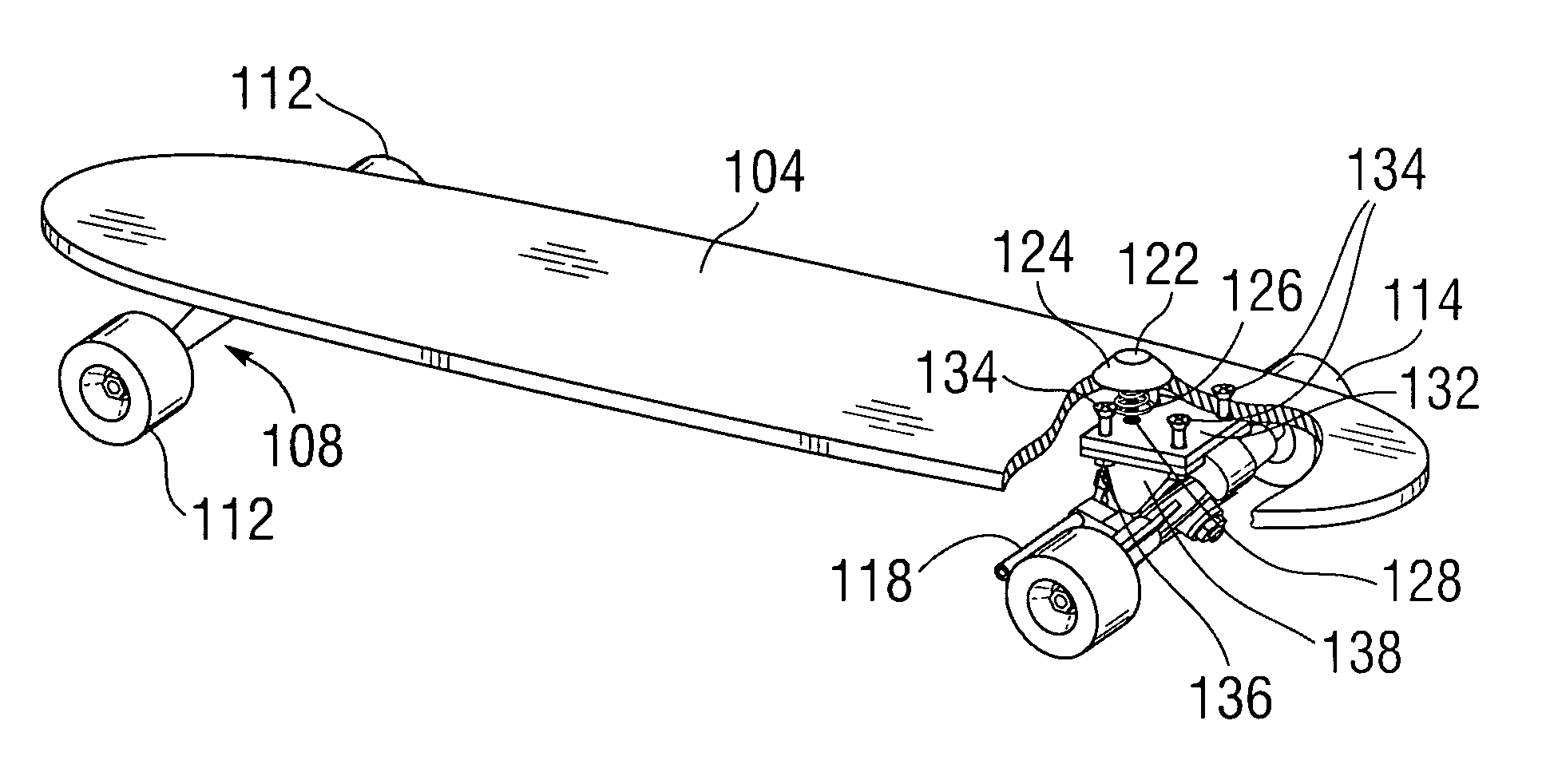

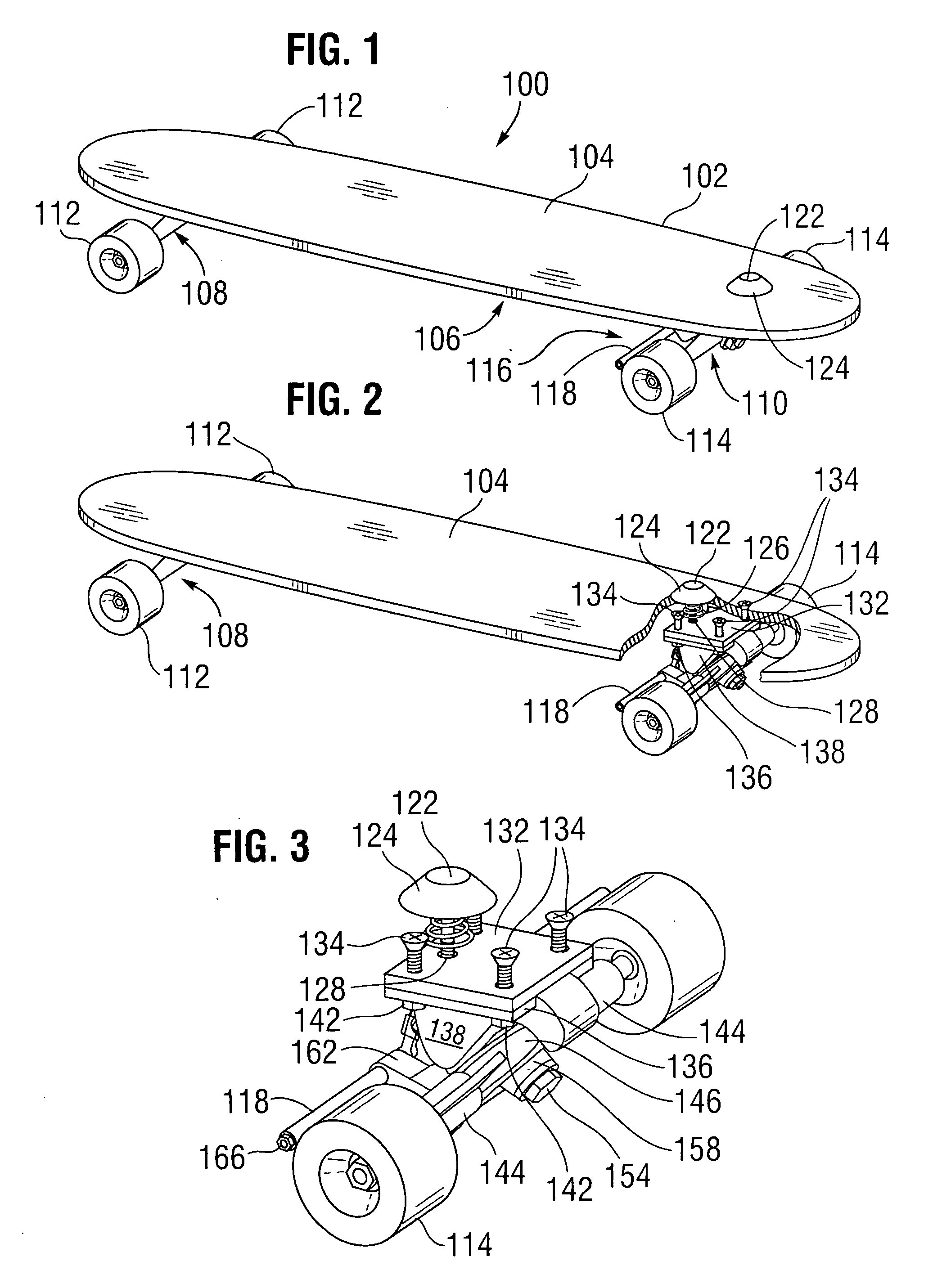

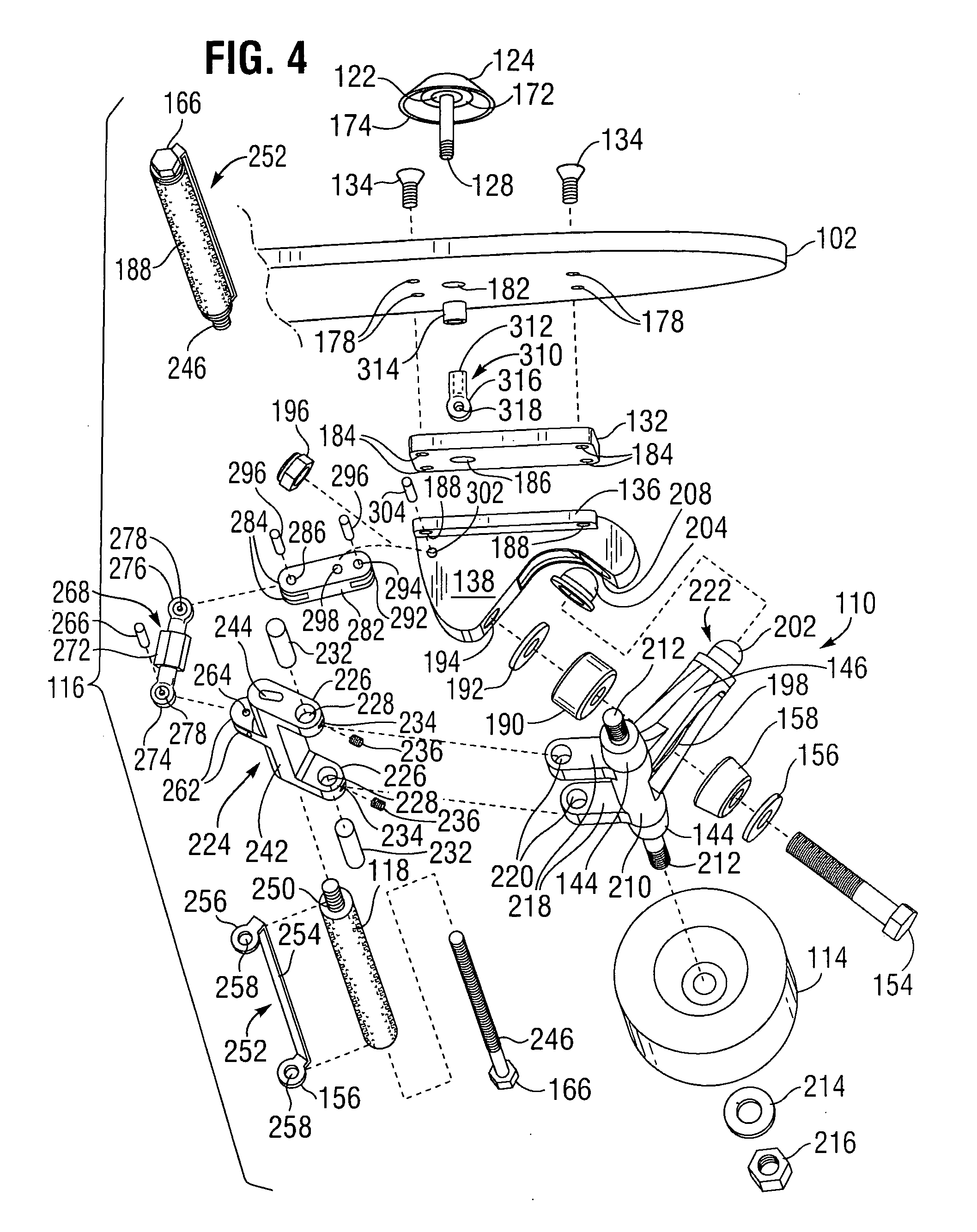

Speed control system

InactiveUS20100314851A1Easy to controlProcess controlBraking element arrangementsRider propulsionSpeed control systemControl system

Skateboard speed control is achieved by improved application of a mechanism to provide even force to the wheels by a simplified speed control system. The speed control system is durable, compact, simple, uses minimal components, is ergonomic, and has speed control pads that move in sync while simultaneously tolerating variations in wheel orientation and position while a rider is maneuvering the skateboard.

Owner:PALMER JAMES STEWART +1

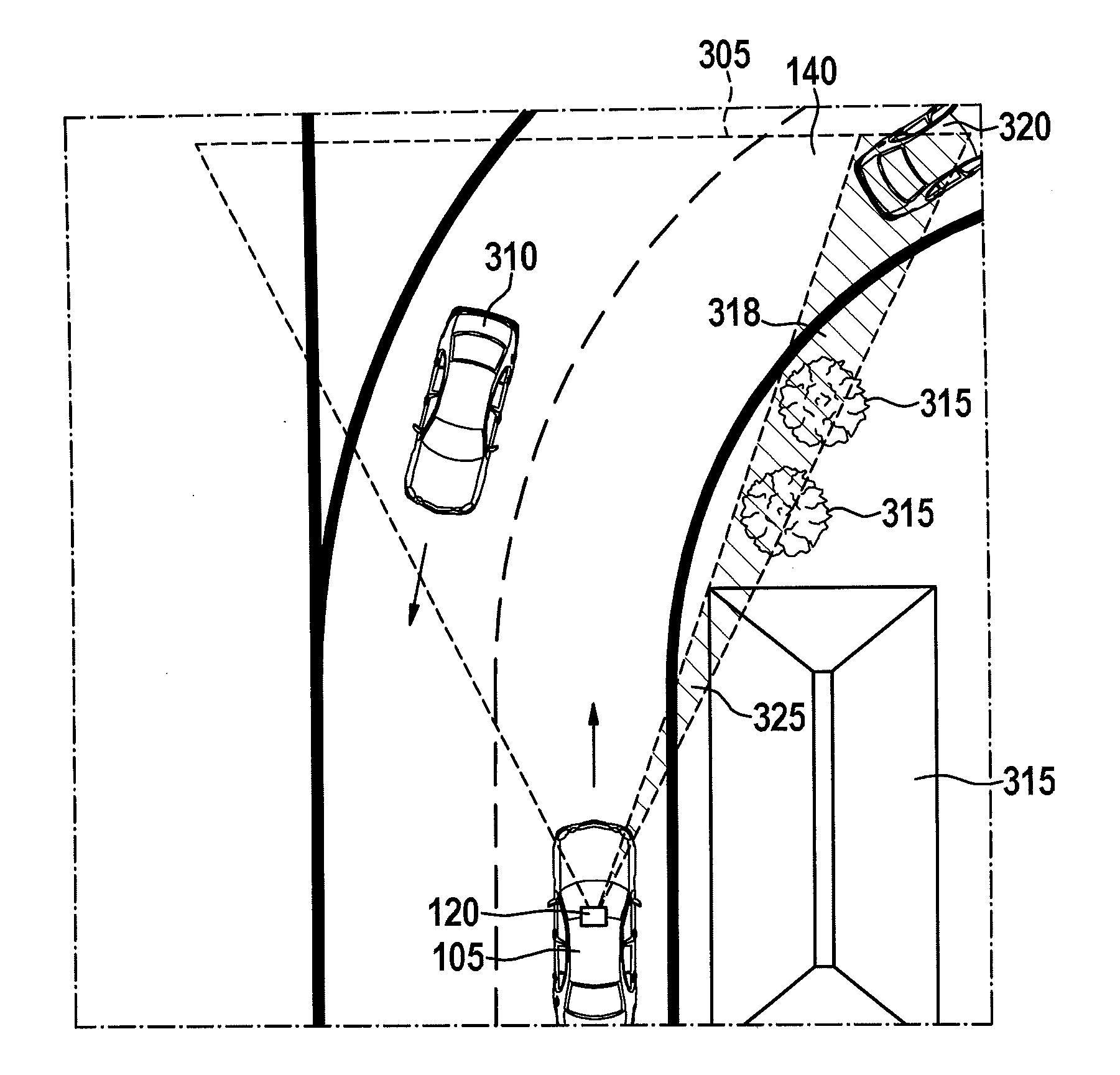

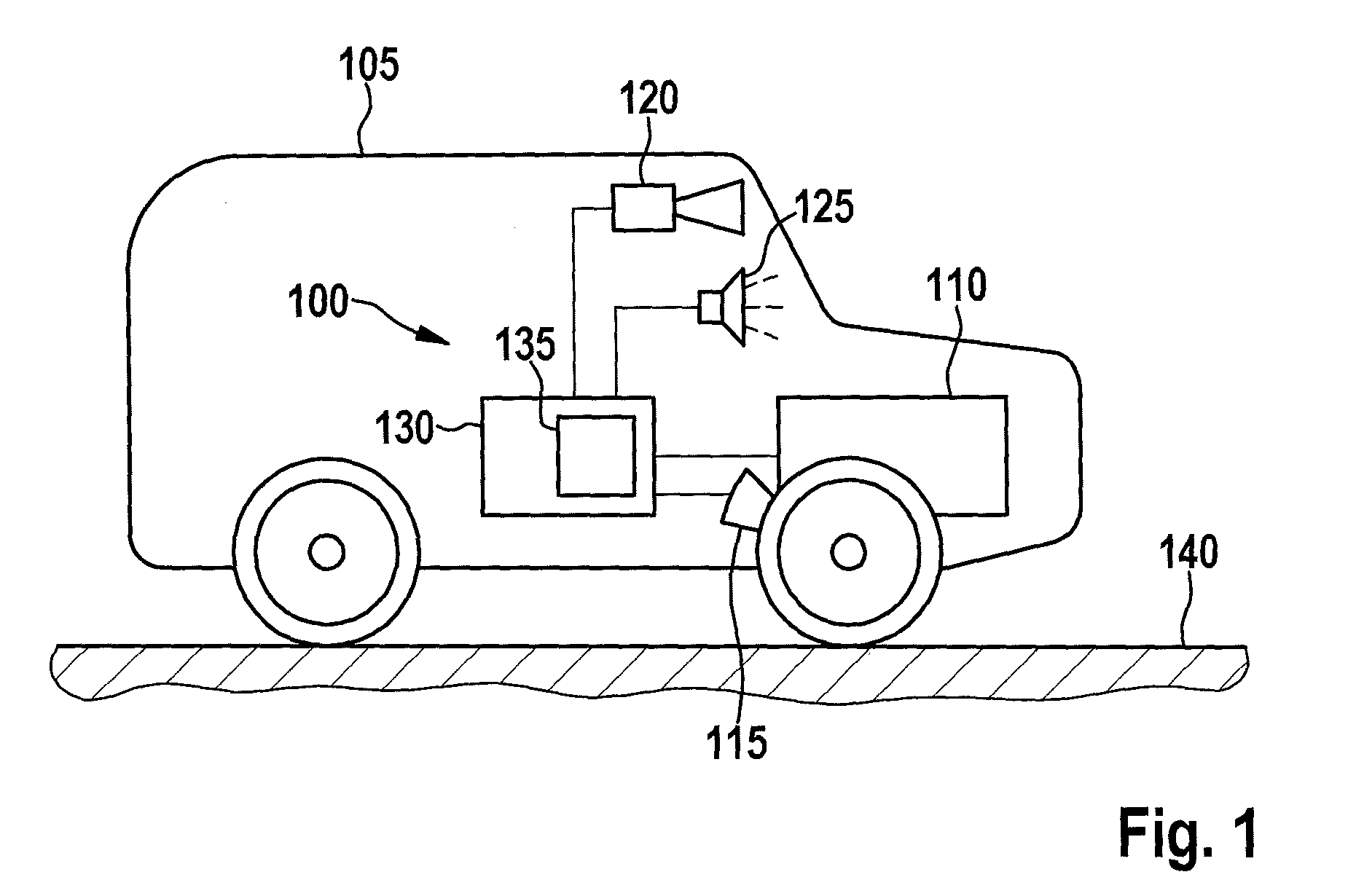

Speed assistant for a motor vehicle

ActiveUS20150066329A1Safer driving behavior resultGood speed controlRoad vehicles traffic controlDigital data processing detailsMobile vehicleOn board

A method for controlling a motor vehicle includes steps of controlling a longitudinal speed of the motor vehicle to a predetermined value and scanning an upcoming driving route with the aid of a sensor on board the motor vehicle. One end of a section of the driving route which is visible with the aid of the sensor is determined. Assuming that there is an obstacle on the driving route beyond the visible section, it is determined that a deceleration which would be required to maintain a predetermined minimum distance from the assumed obstacle exceeds a predetermined threshold value, and a signal is output to a driver of the motor vehicle.

Owner:ROBERT BOSCH GMBH

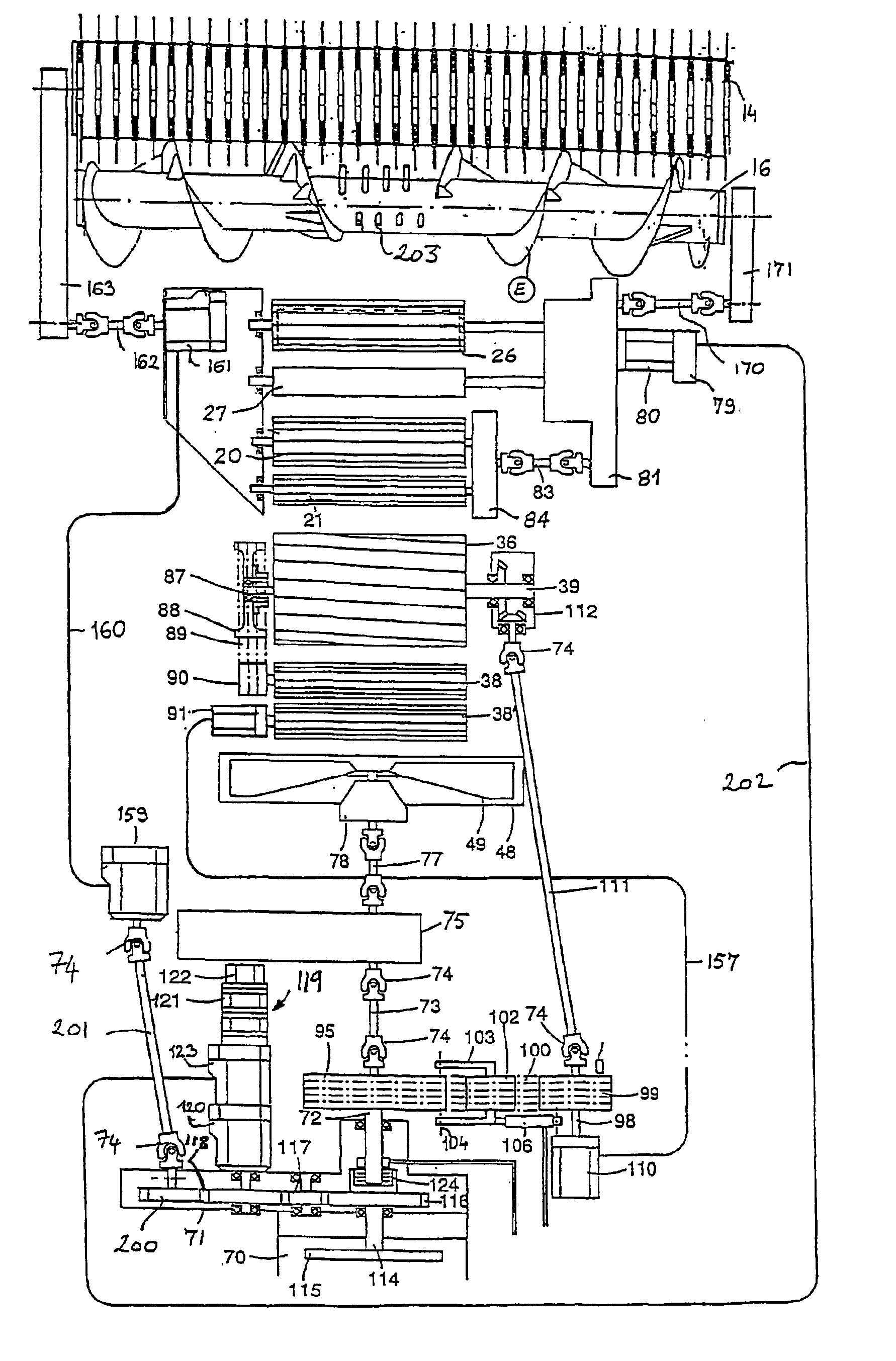

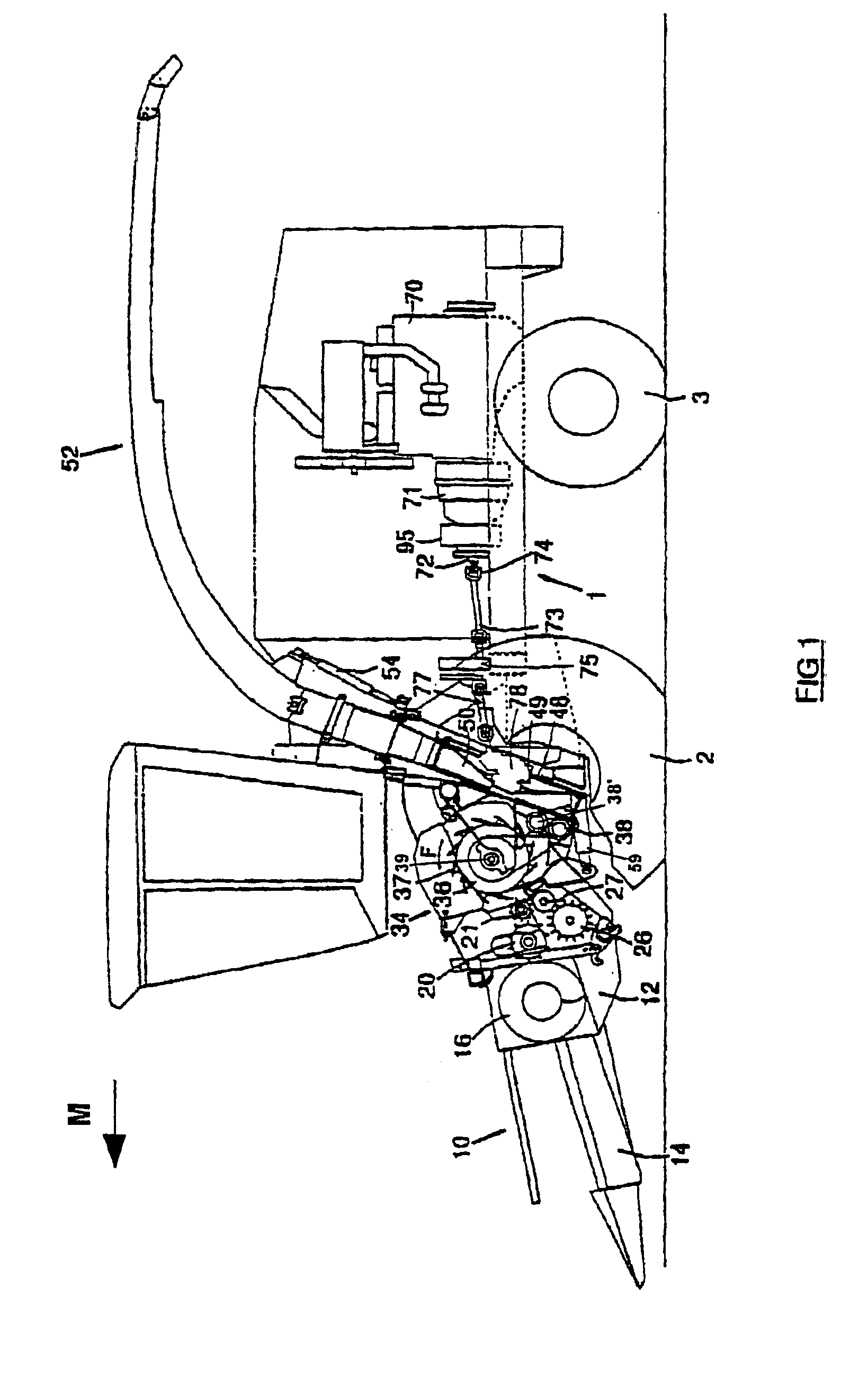

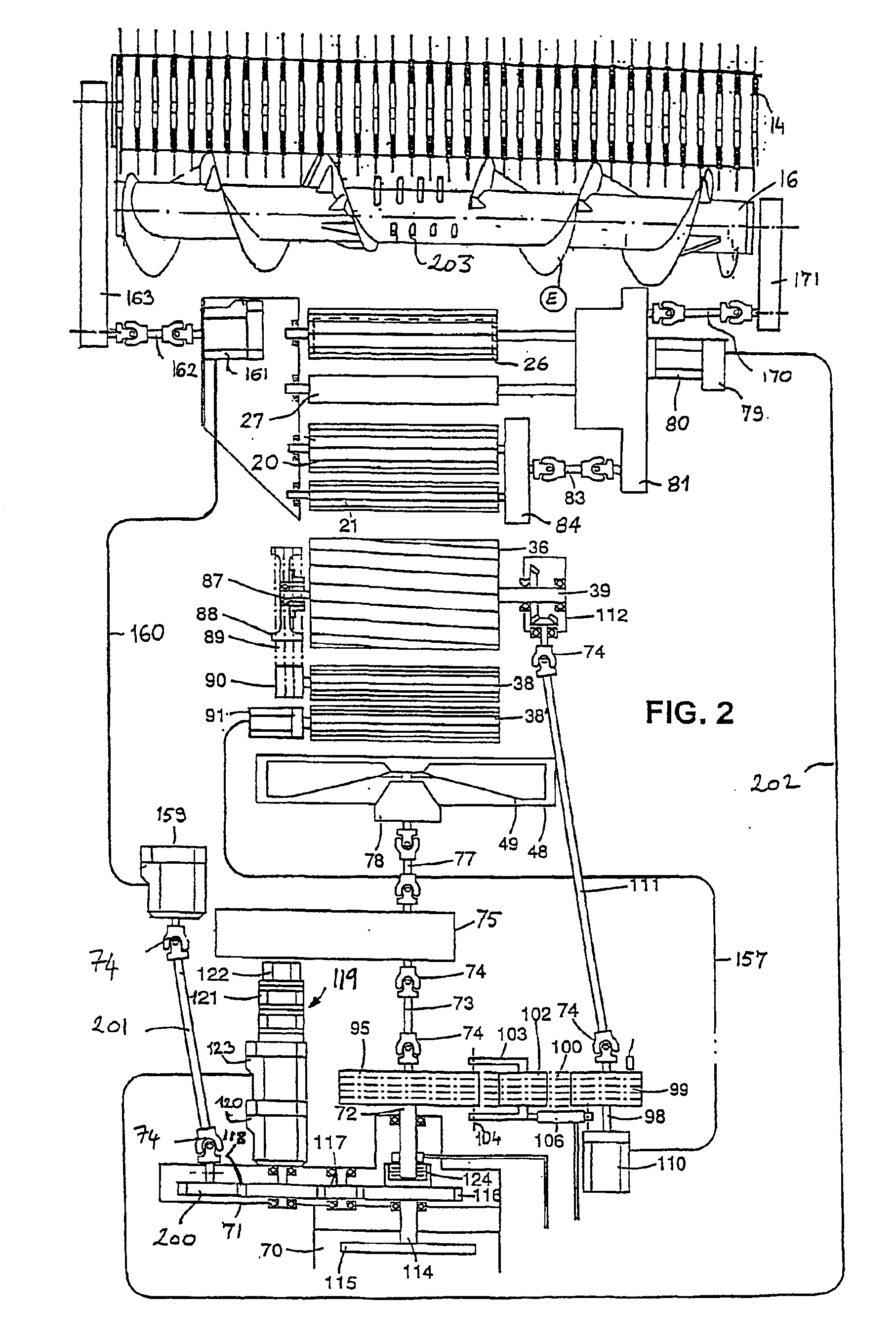

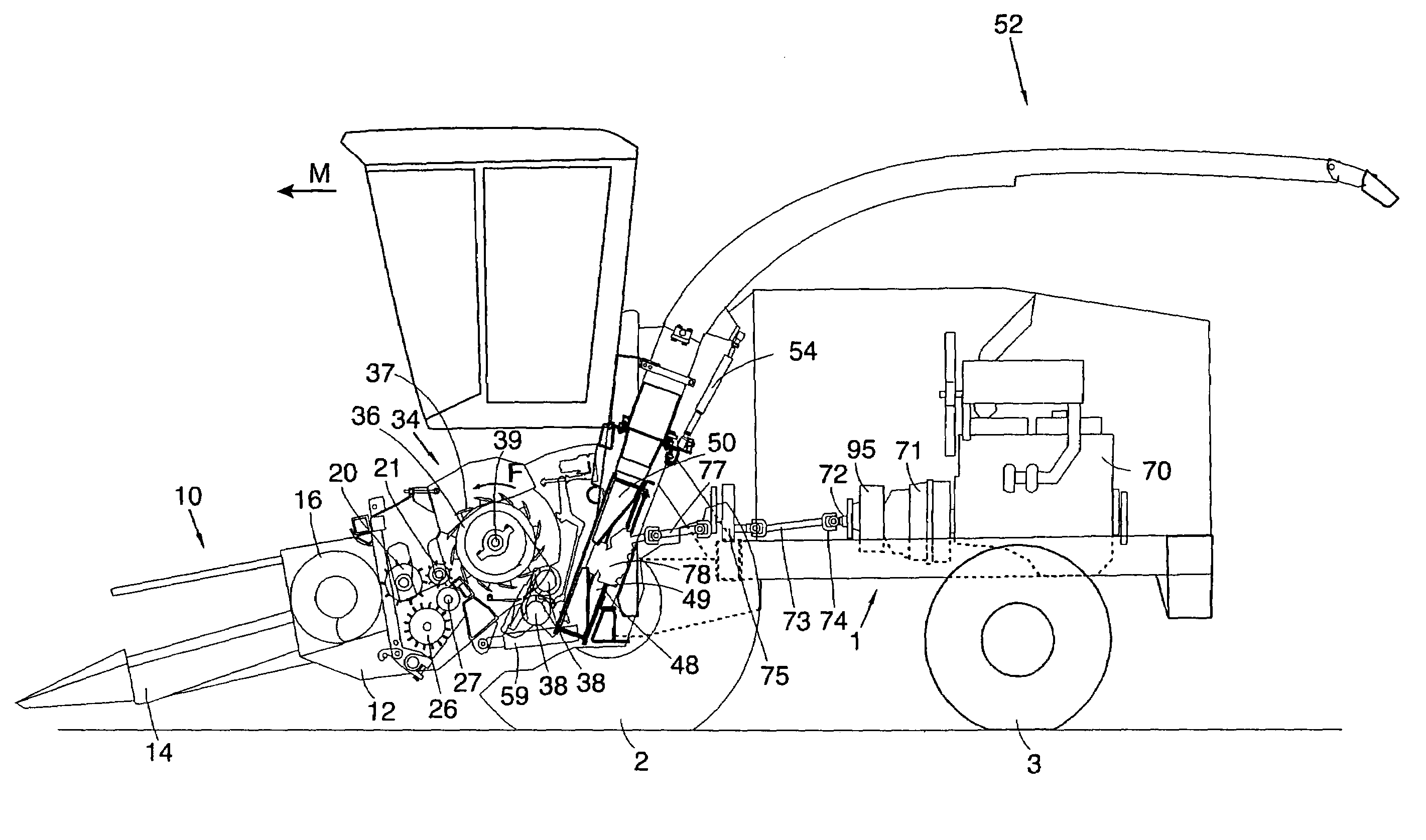

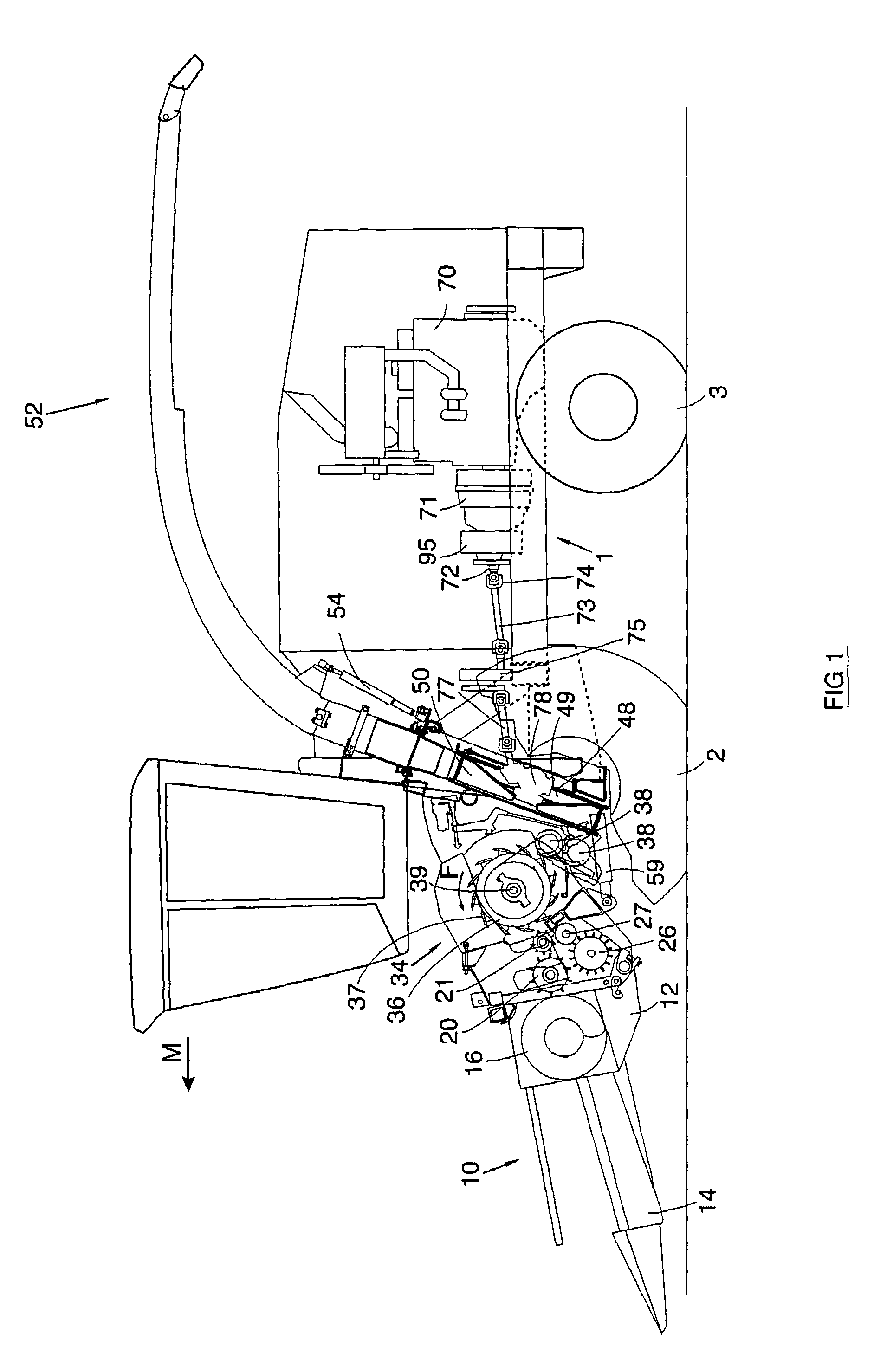

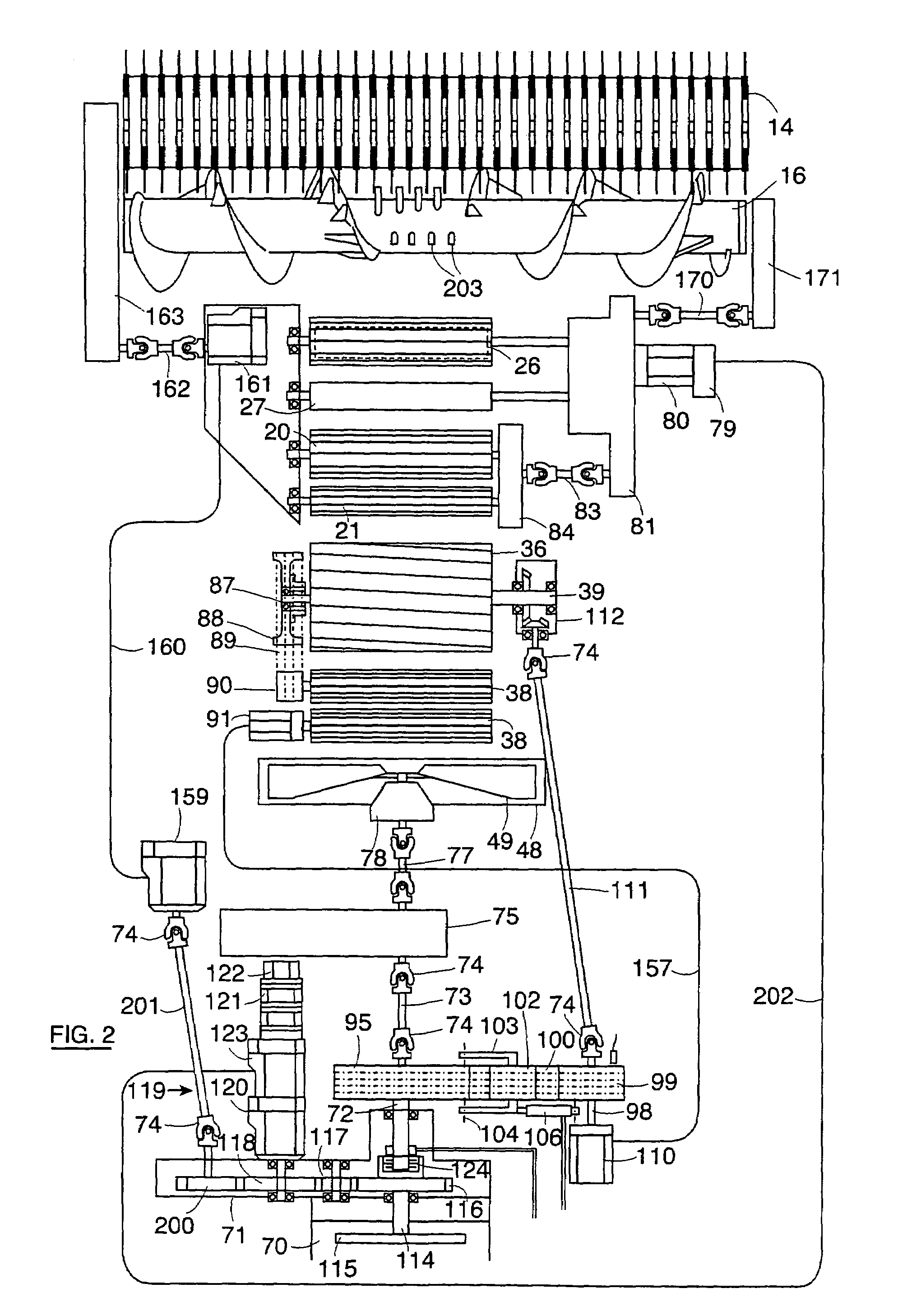

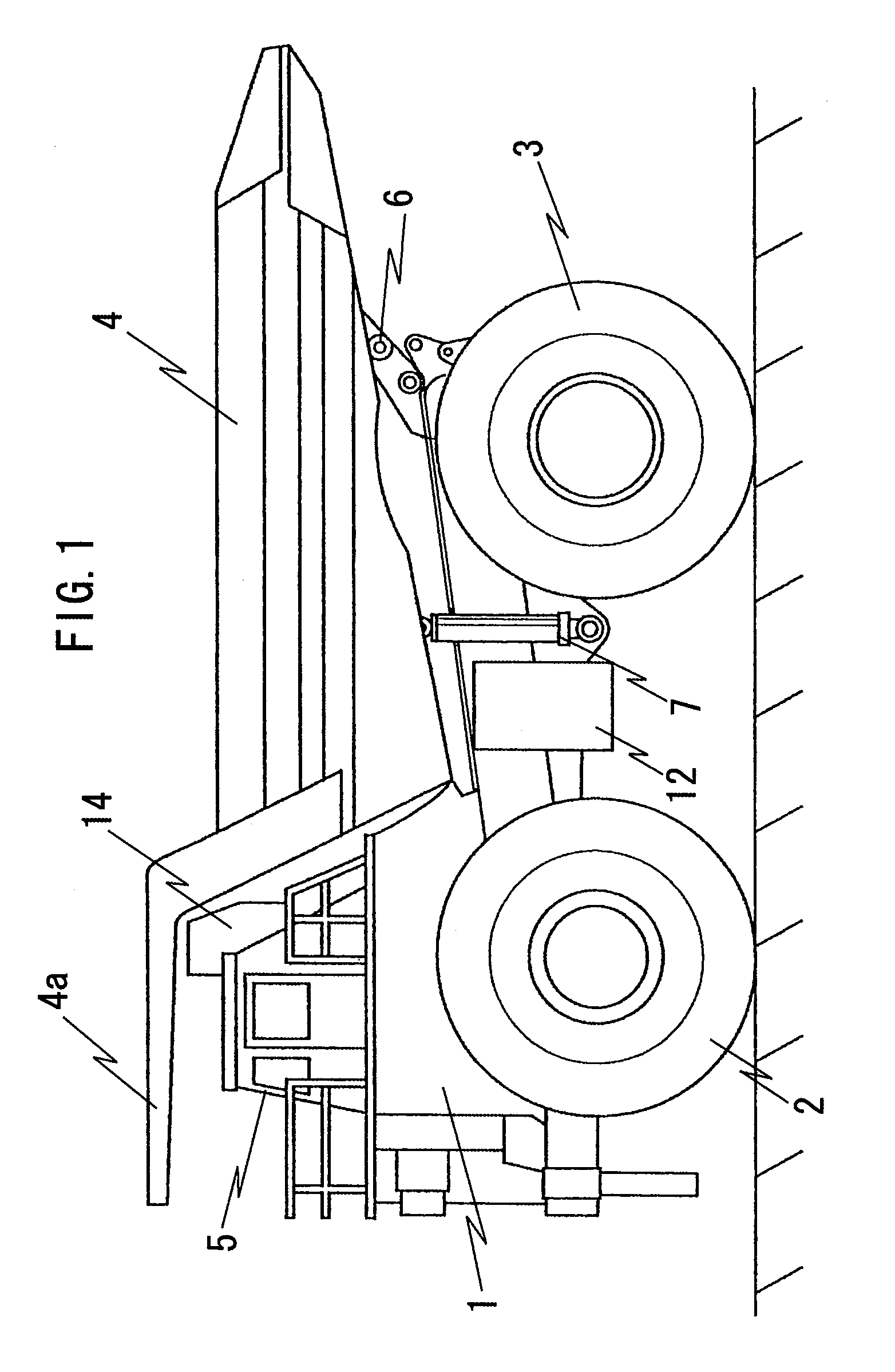

Agricultural harvesting machines and front attachments therefor

InactiveUS6895734B2Good effectGood harvesting effectMowersCuttersRate independentMechanical engineering

An agricultural harvesting machine is includes a first gathering element (14) adapted to be driven by a first drive mechanism (161) so as to gather crop and to feed the crop in a direction substantially opposite to a direction of motion of the harvesting machine. A second gathering element (16) is adapted to receive the crop from the first gathering element (14) and is further adapted to be driven so as to transfer the crop in a direction substantially transverse to the direction of motion. Intake elements (20, 21, 26, 27) are adapted to receive the crop from the second gathering element (16). The second gathering element (16) and intake elements (20, 21, 26, 27) are adapted to be driven at related rates. The first gathering element (14) is driveable at a rate independent from a driven rate of the second gathering element (16) and the intake elements (20, 21, 26, 27).

Owner:BLUE LEAF I P INC +1

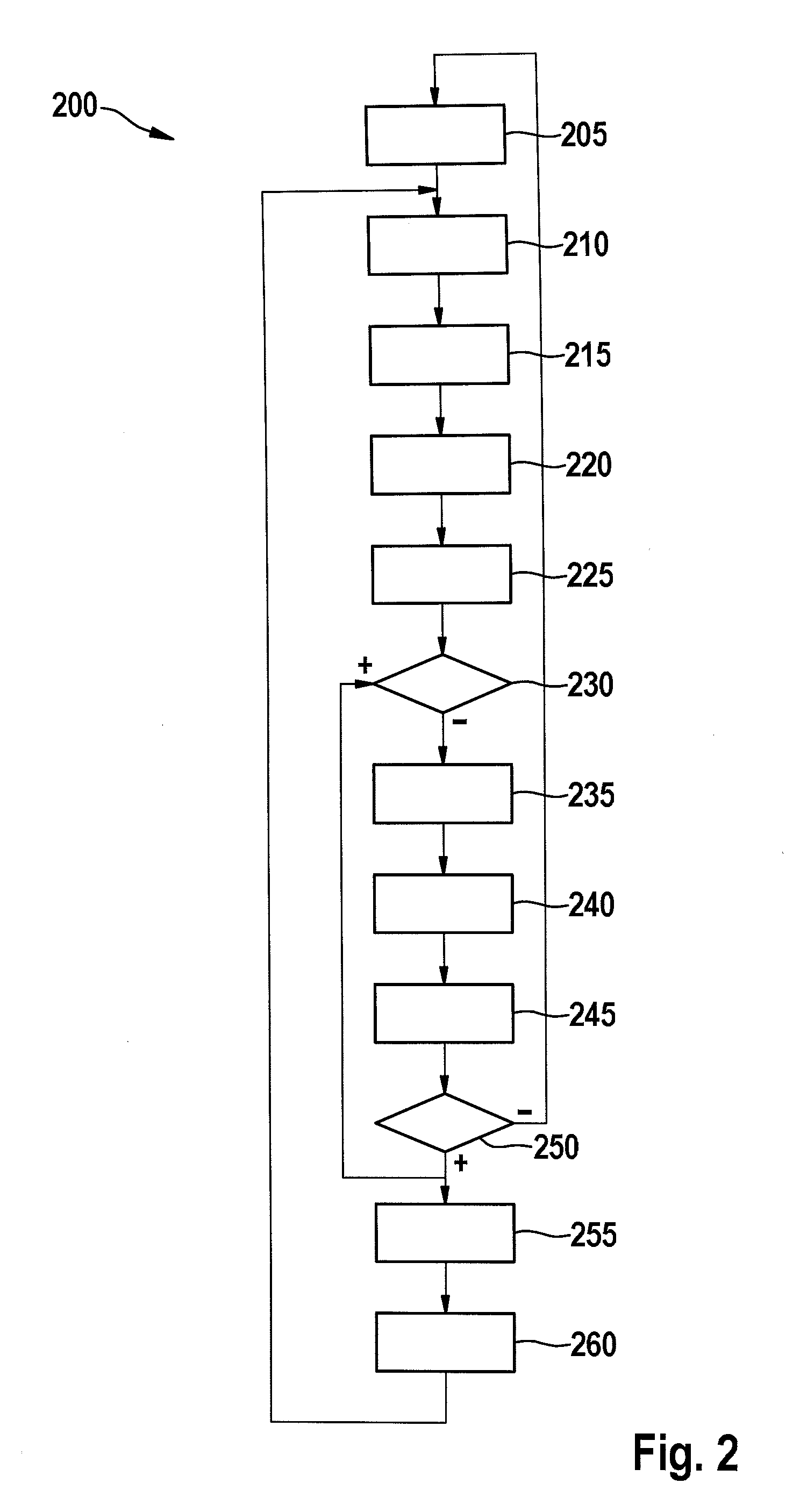

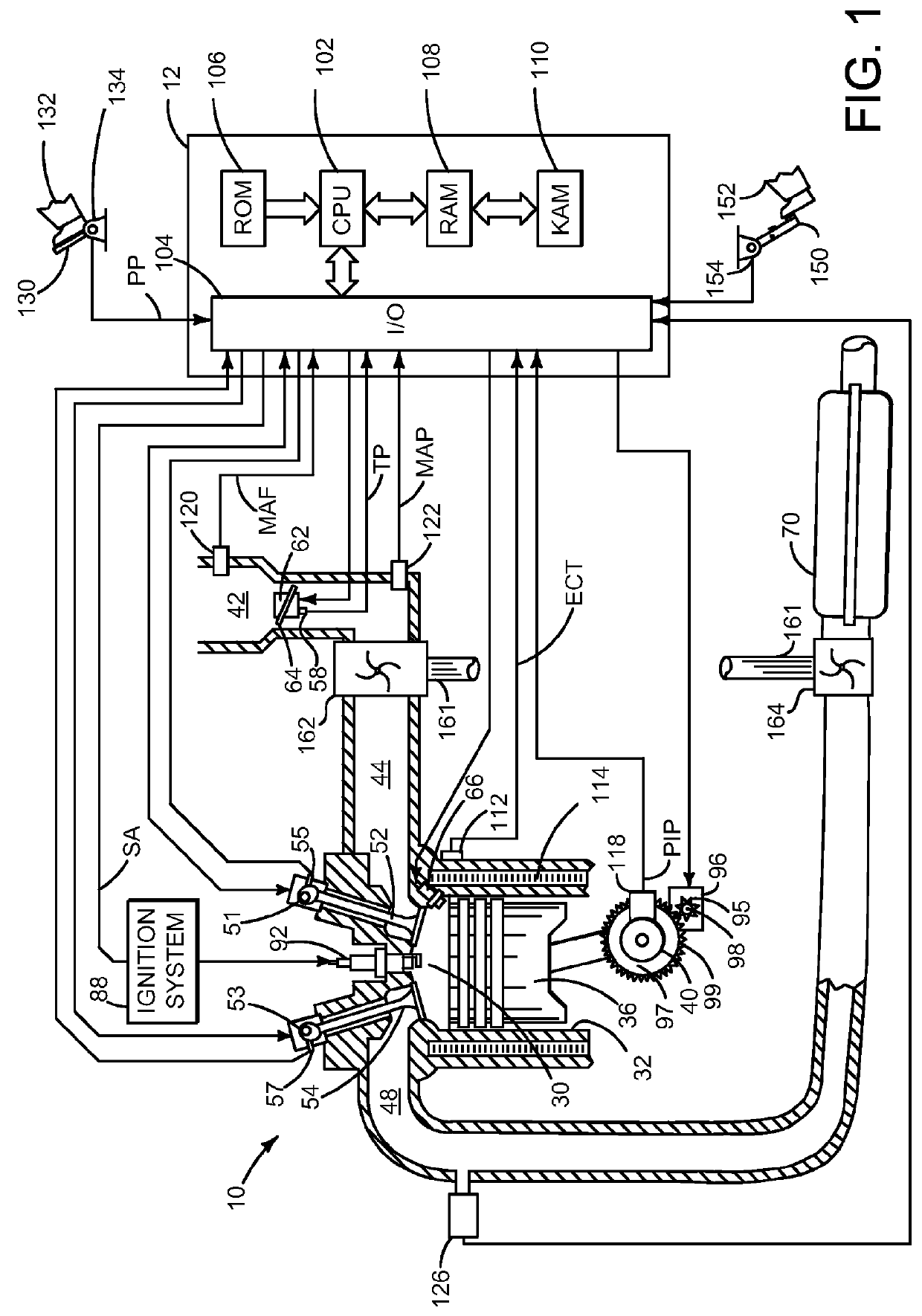

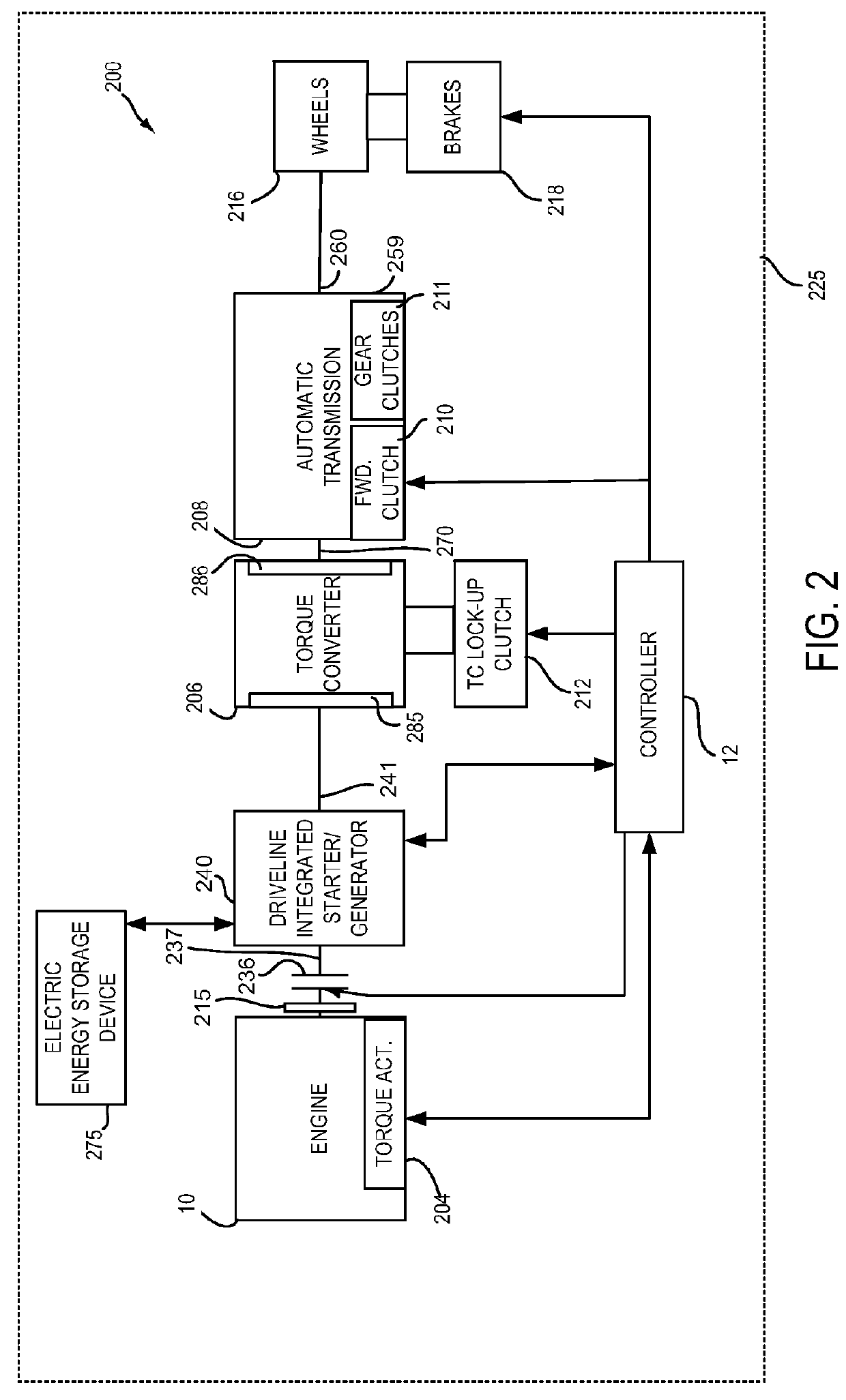

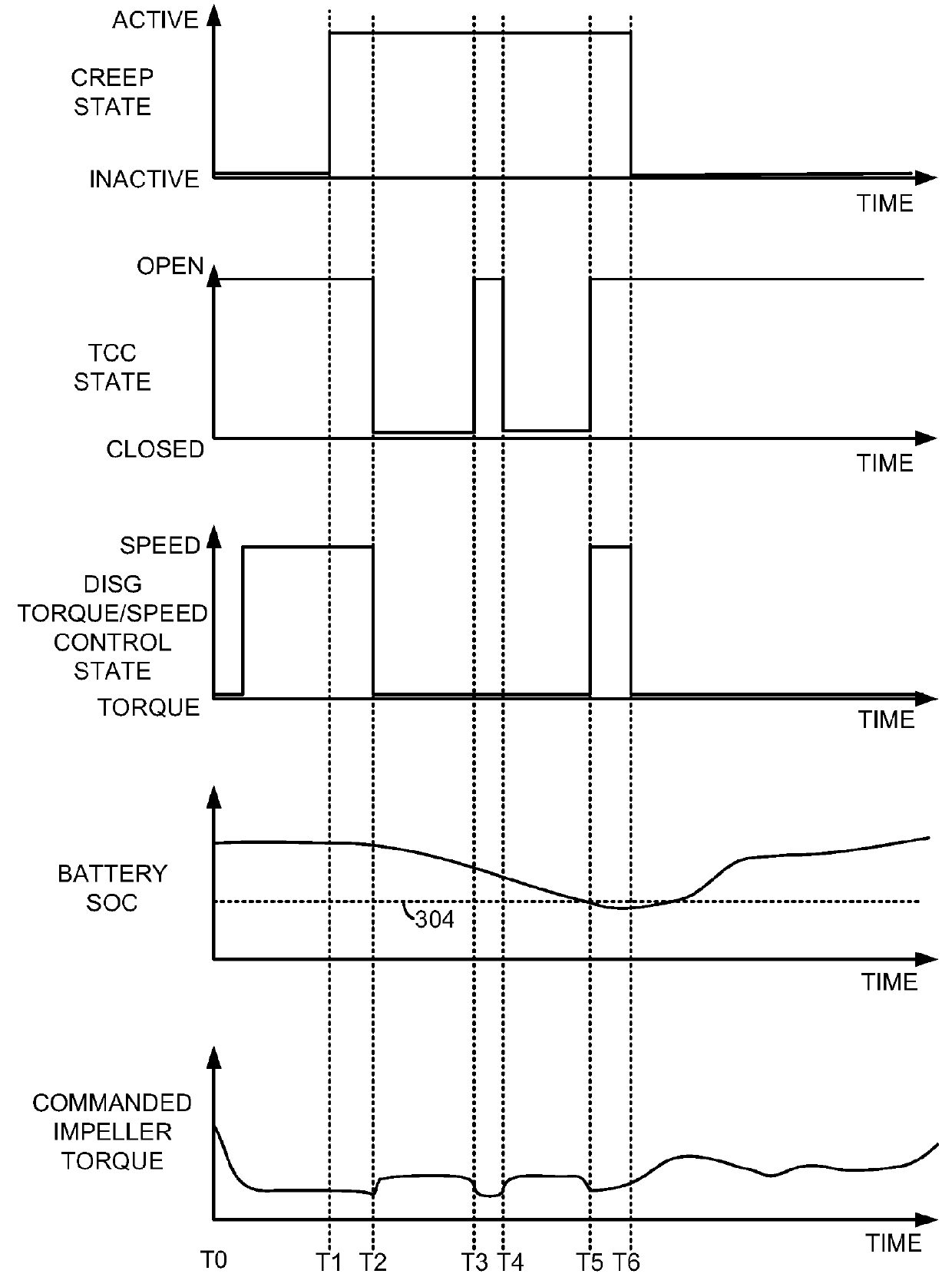

Methods and system for transitioning between control modes while creeping

ActiveUS20160031431A1Guaranteed uptimeEasy transitionHybrid vehiclesGearing controlElectric machineControl mode

Systems and methods for transitioning a torque source between speed control and torque control modes during a vehicle creep mode are disclosed. In one example, torque of an electric machine is adjusted in response to a torque converter model. The torque converter model provides for a locked or unlocked torque converter clutch.

Owner:FORD GLOBAL TECH LLC

Imaging and safety system and method for an industrial machine

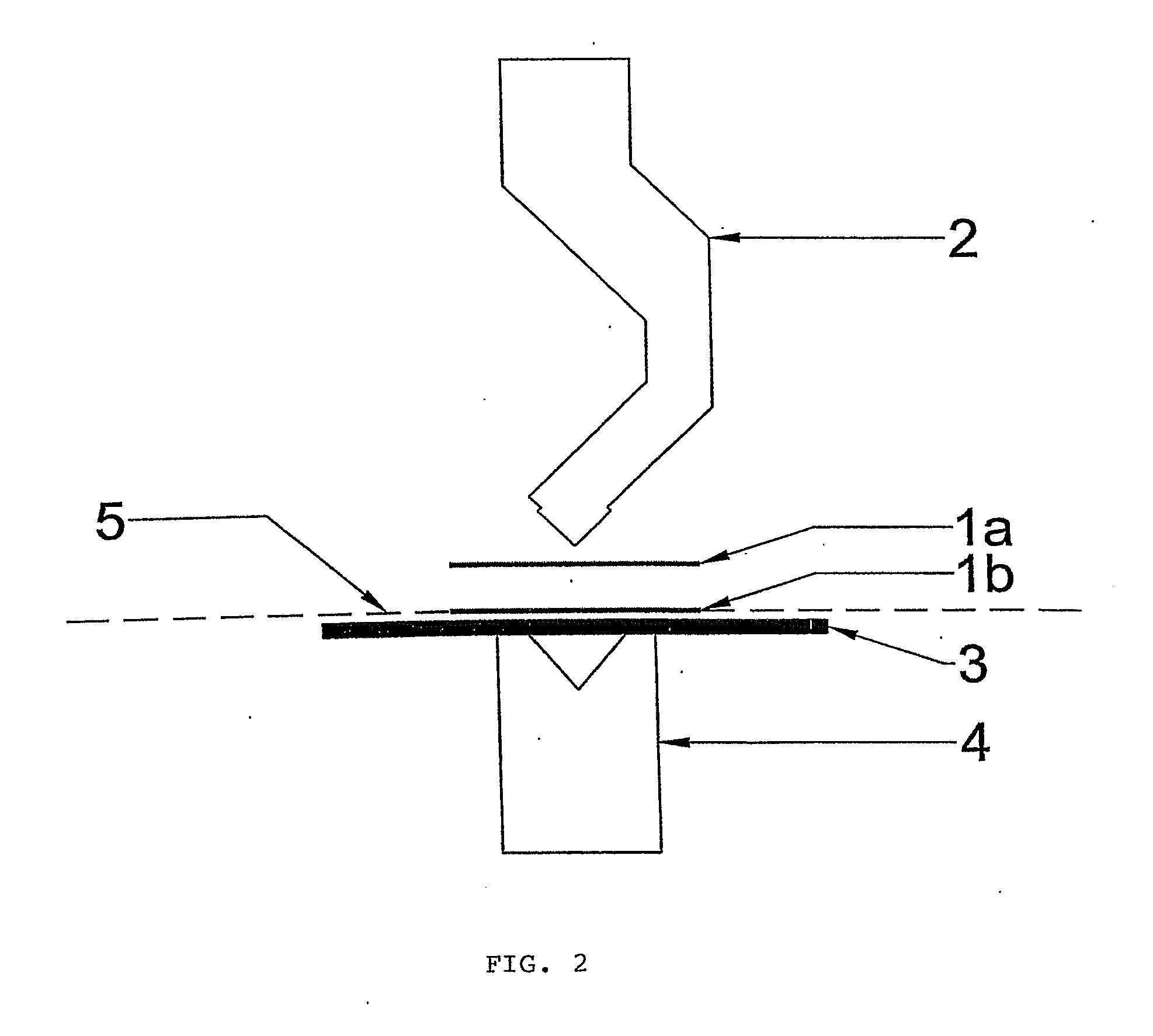

ActiveUS20100220184A1Halt operationGood speed controlShaping safety devicesMaterial analysis by optical meansImaging processingTip position

An imaging system (40), safety system (58) or combined imaging and safety system (FIG. 1) for an industrial machine (20), including a light transmitter (26) and a corresponding receiver (28). In an imaging application, image data relating to a machine tool (22) and / or work piece (32) is derived from said at least one receiver and processed by an image processing means to determine information regarding said tool and / or tool position and / or extent of work carried out on said work piece. A screen (34, 46), such as a shadow screen, can be used to form an image of a profile of the tool tip and end of the workpiece. Took tip position and extent of work on the workpiece can be derived from the image, e.g., via a camera viewing an image formed on the screen. Multiple cameras may be used. A safety system application (FIGS. 10a to 10d) for halting the machine or tool when a light beam is interrupted can include a broad or block beam (62) and can provide progressive muting of beam interruption detection by progressively muting detection. Progressive muting can be achieved by systematically disregarding or muting signals from rows of receiver array elements as the beam passes through a mute point (66) ahead of the tool tip (60).

Owner:LAZER SAFE PTY LTD

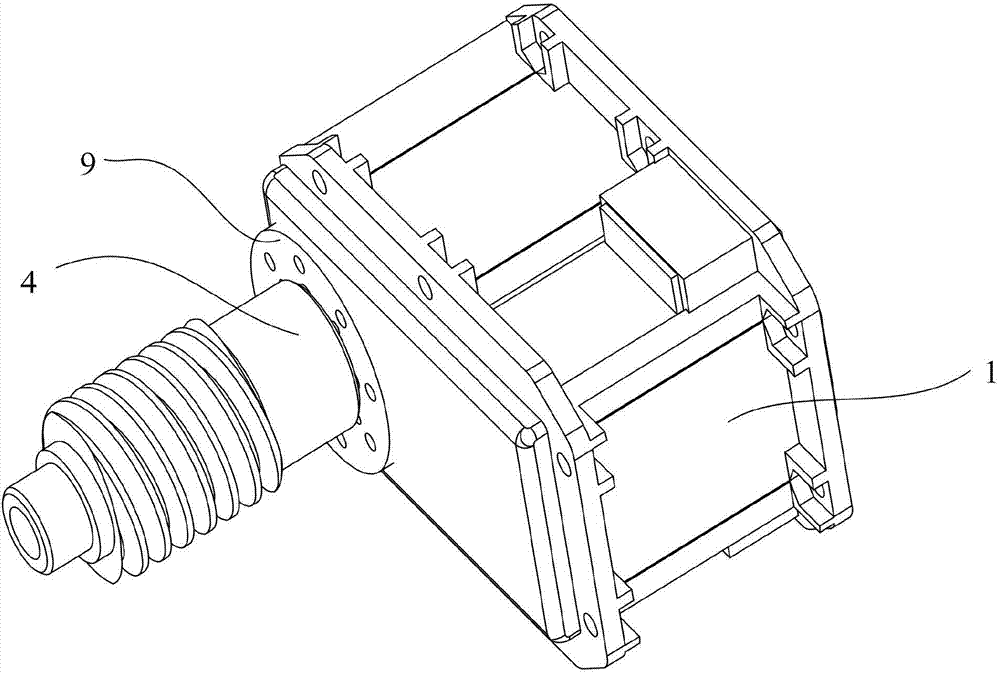

Robot end clamping module driven by steering engine

The invention discloses a robot end clamping module driven by a steering engine. The end clamping module comprises the drive steering engine capable of outputting power outwards. The power output end of the drive steering engine is connected with a steering engine output disc. The other end of the steering engine output disc is connected with one end of a worm arranged in an upper base and drives the worm to rotate forwards or backwards. A pair of drive clamping arms is further hinged into the upper base in a bilateral symmetry mode. The worm is in engaged transmission connection with the drive clamping arms, so that the drive clamping arms swing around the hinge center of the upper base. The clamping ends of the drive clamping arms can be reunited or separated. Compared with the prior art, the robot end clamping module driven by the steering engine has the advantages of being simple in structure, small in size, compact, flexible to operate and the like; control under conditions of various torque, speeds and positions can be achieved by controlling the steering engine motion mode; and a lower base is of a replaceable structure, and can cooperate with ends of different robots for operation quite conveniently, so that a work procedure needing to prevent workpieces from being damaged during clamping is efficiently completed.

Owner:GUANGDONG UNIV OF TECH

Agricultural harvesting machines and front attachments therefor

InactiveUS7219487B2Good effectGood harvesting effectAgricultural machinesLoadersEngineeringRate independent

An agricultural harvesting machine includes a first gathering element adapted to be driven by a first drive mechanism so as to gather crop and feed the crop in a direction substantially opposite to a direction of motion of the harvesting machine. A second gathering element is adapted to receive the crop from the first gathering element and is further adapted to be driven so as to transfer the crop in a direction substantially transverse to the direction of motion. Intake elements are adapted to receive the crop from the second gathering element. The second gathering element and intake elements are adapted to be driven at related rates. The first gathering element is driveable at a rate independent from a driven rate of the second gathering element and the intake elements.

Owner:BLUE LEAF I P INC

Engine and exhaust heating

InactiveUS7950368B2Improve efficiencyImprove performanceAnalogue computers for vehiclesInternal combustion piston enginesControl theoryEngineering

Owner:FORD GLOBAL TECH LLC

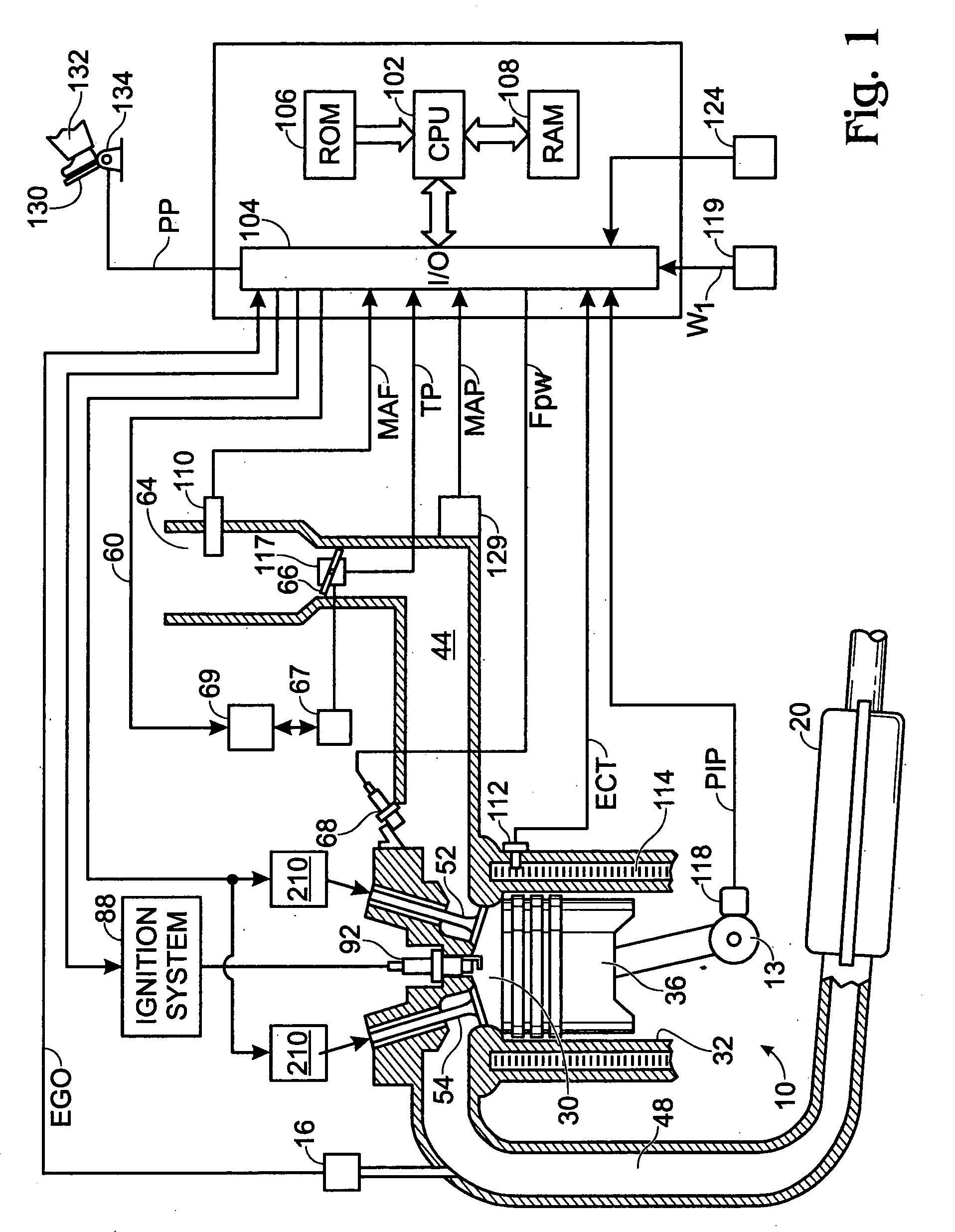

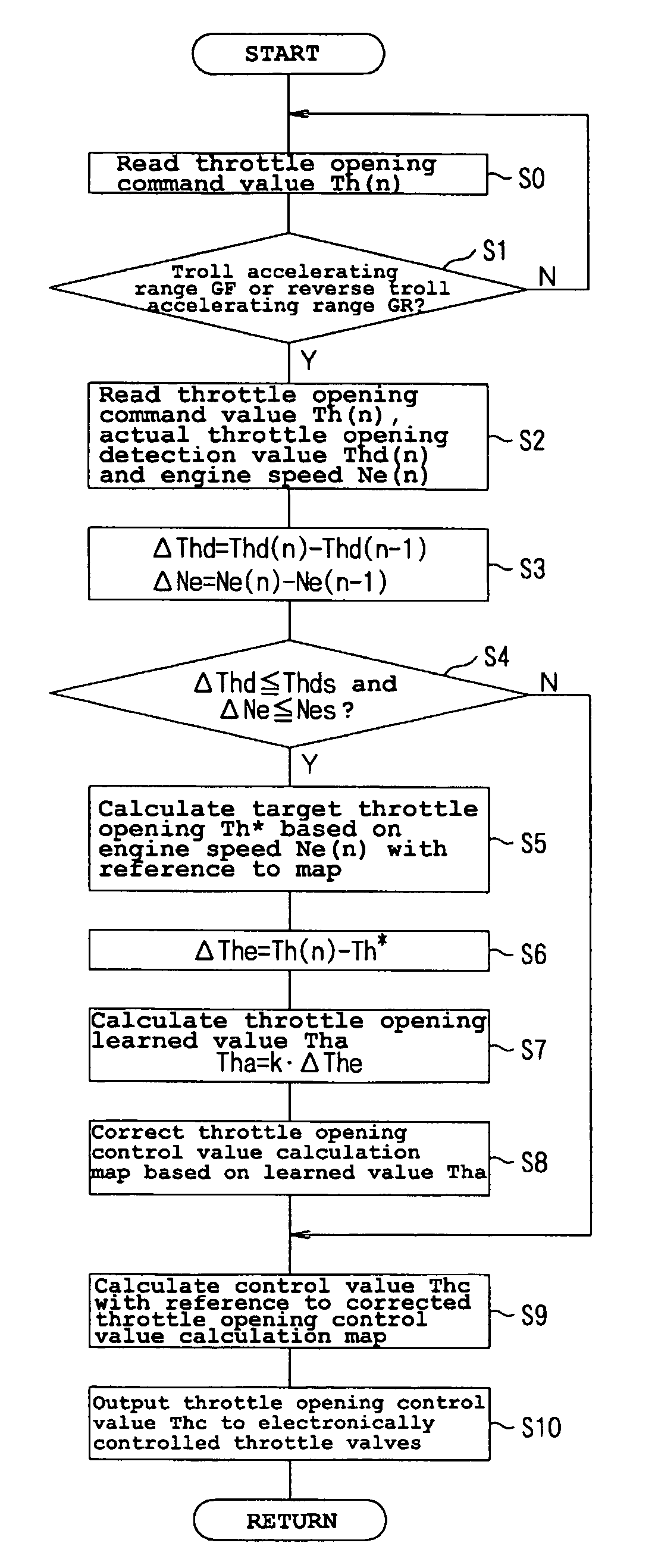

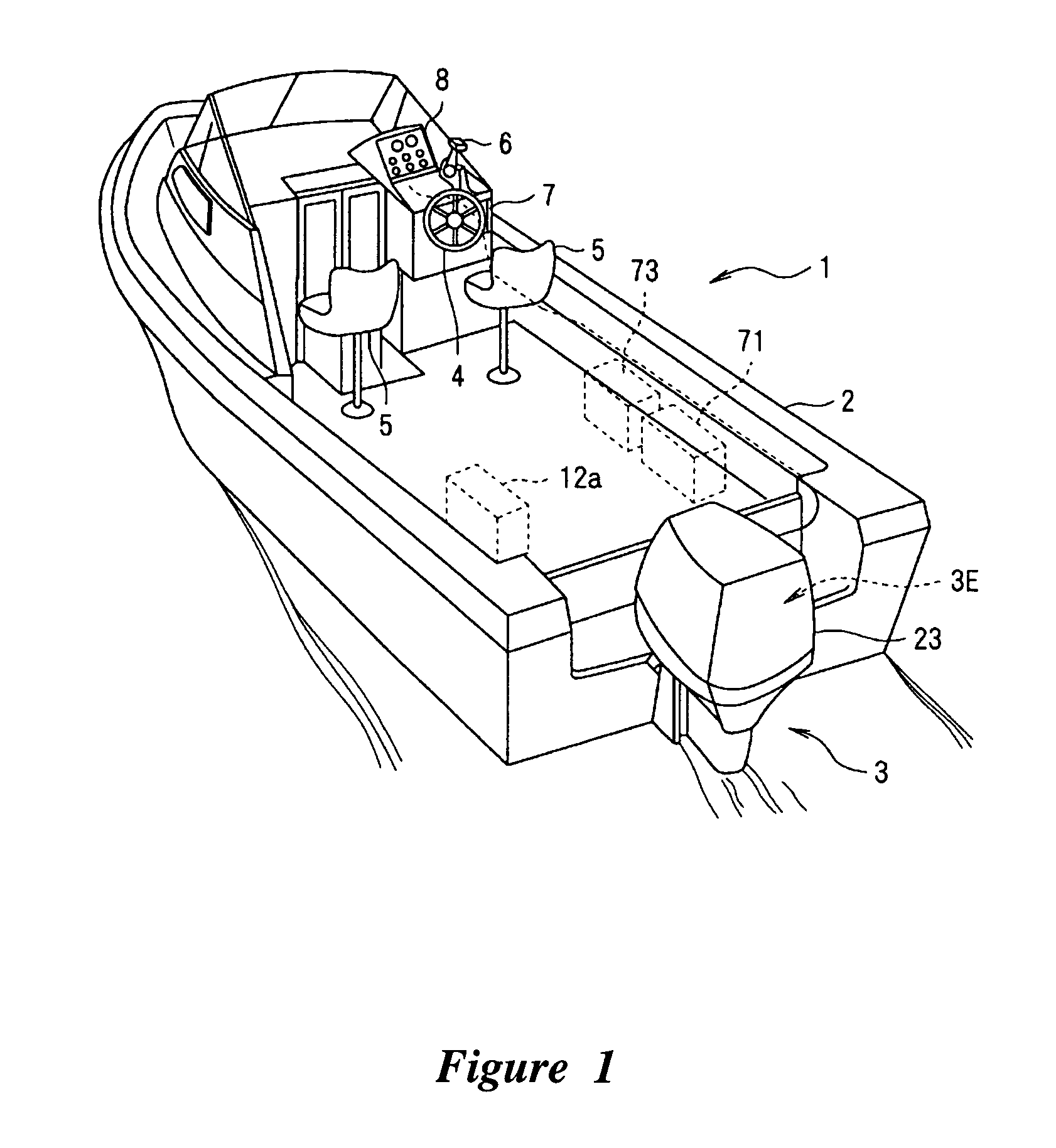

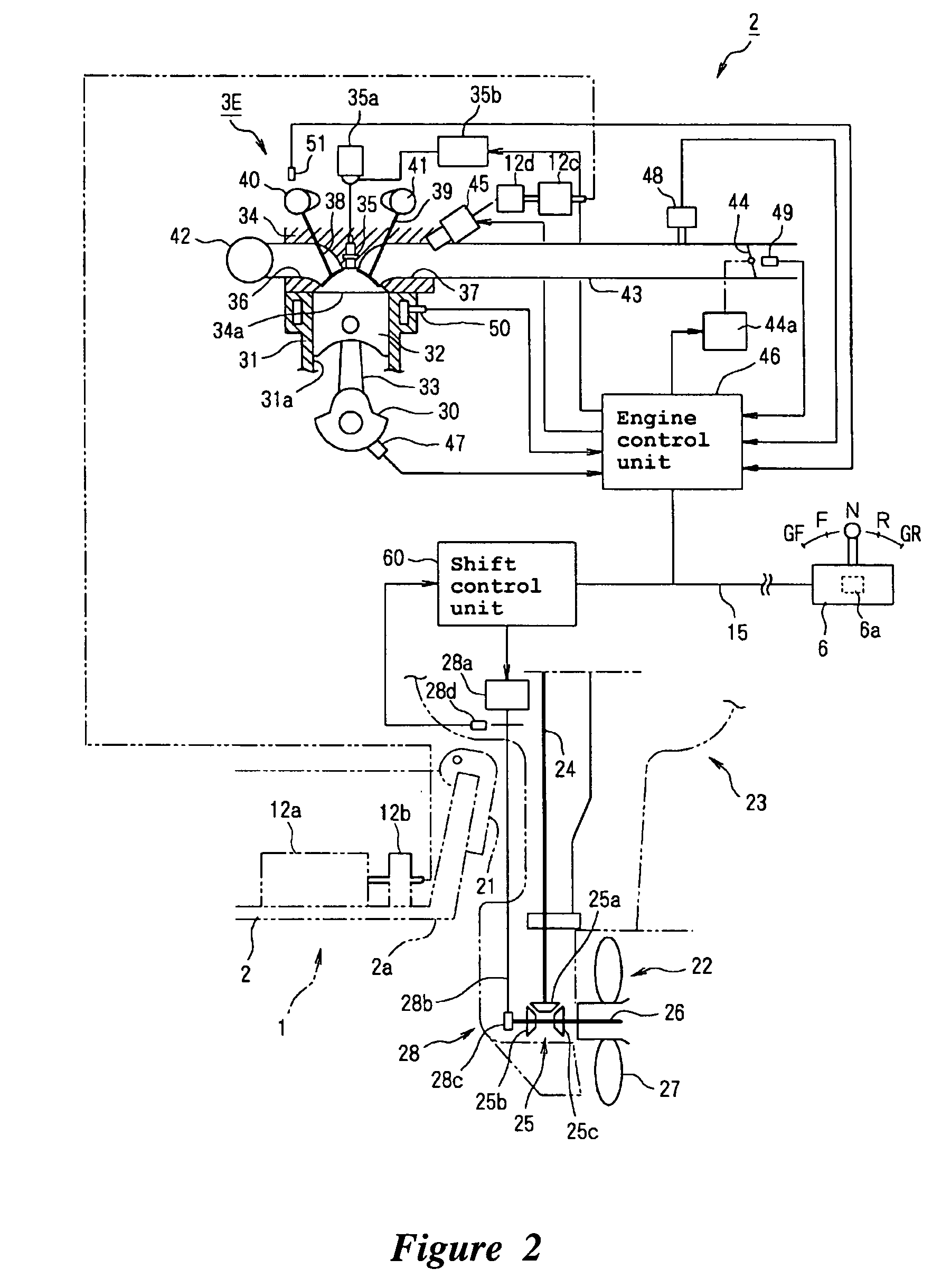

Control device for engine of boat

ActiveUS7021283B2Good speed controlElectrical controlPropulsion power plantsThrottle controlValue set

A throttle opening command value setting device for setting a throttle opening command value, a throttle control device for controlling a throttle valve of an engine based on a throttle opening command value set by the throttle opening command value setting means, and an engine speed detecting device for detecting the engine speed of the engine are provided. The throttle control device learns and controls the throttle opening based on the deviation of the throttle opening command value set by the throttle opening command value setting device from a target throttle opening corresponding to the engine speed detected by the engine speed detecting device.

Owner:YAMAHA MARINE KK

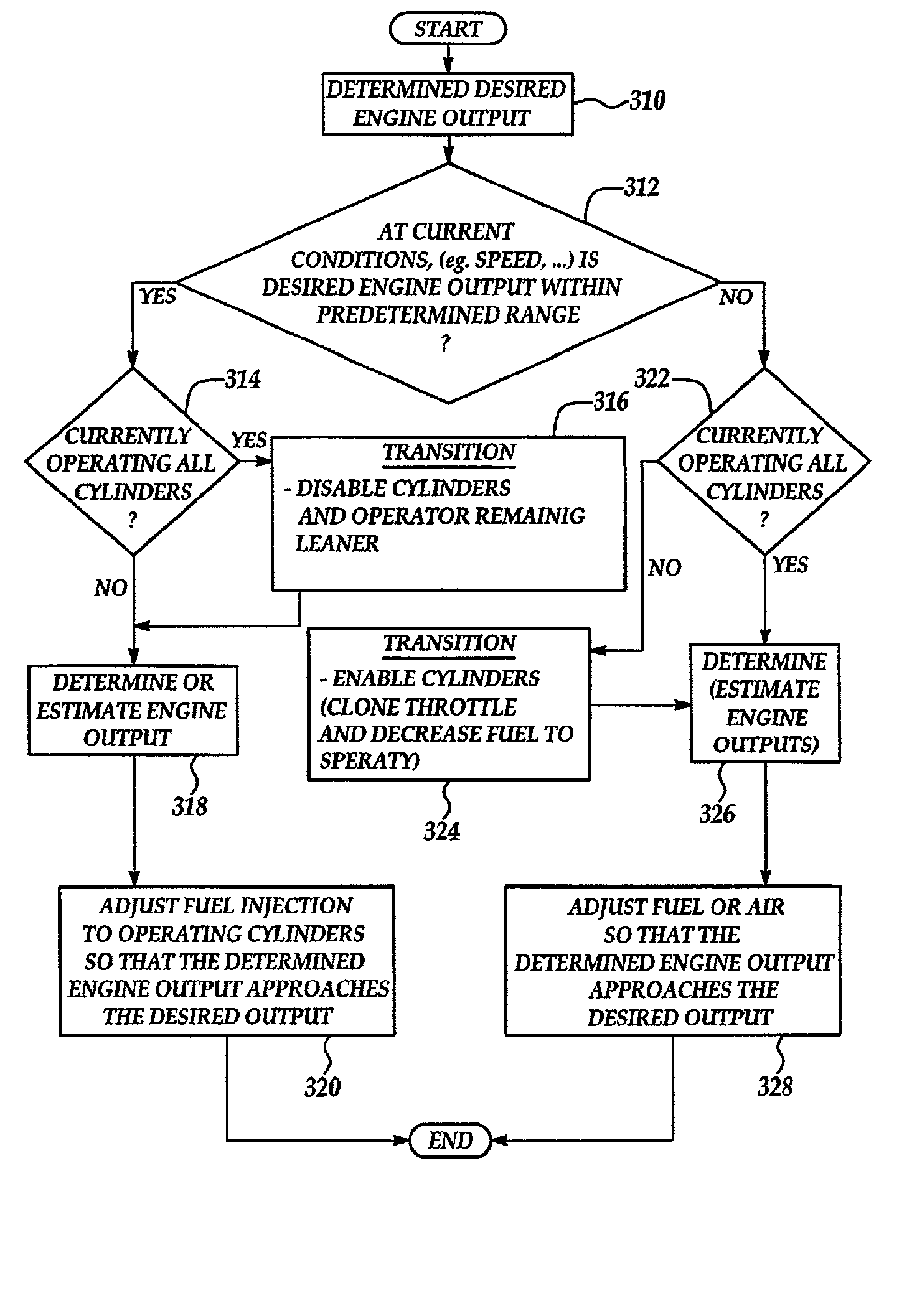

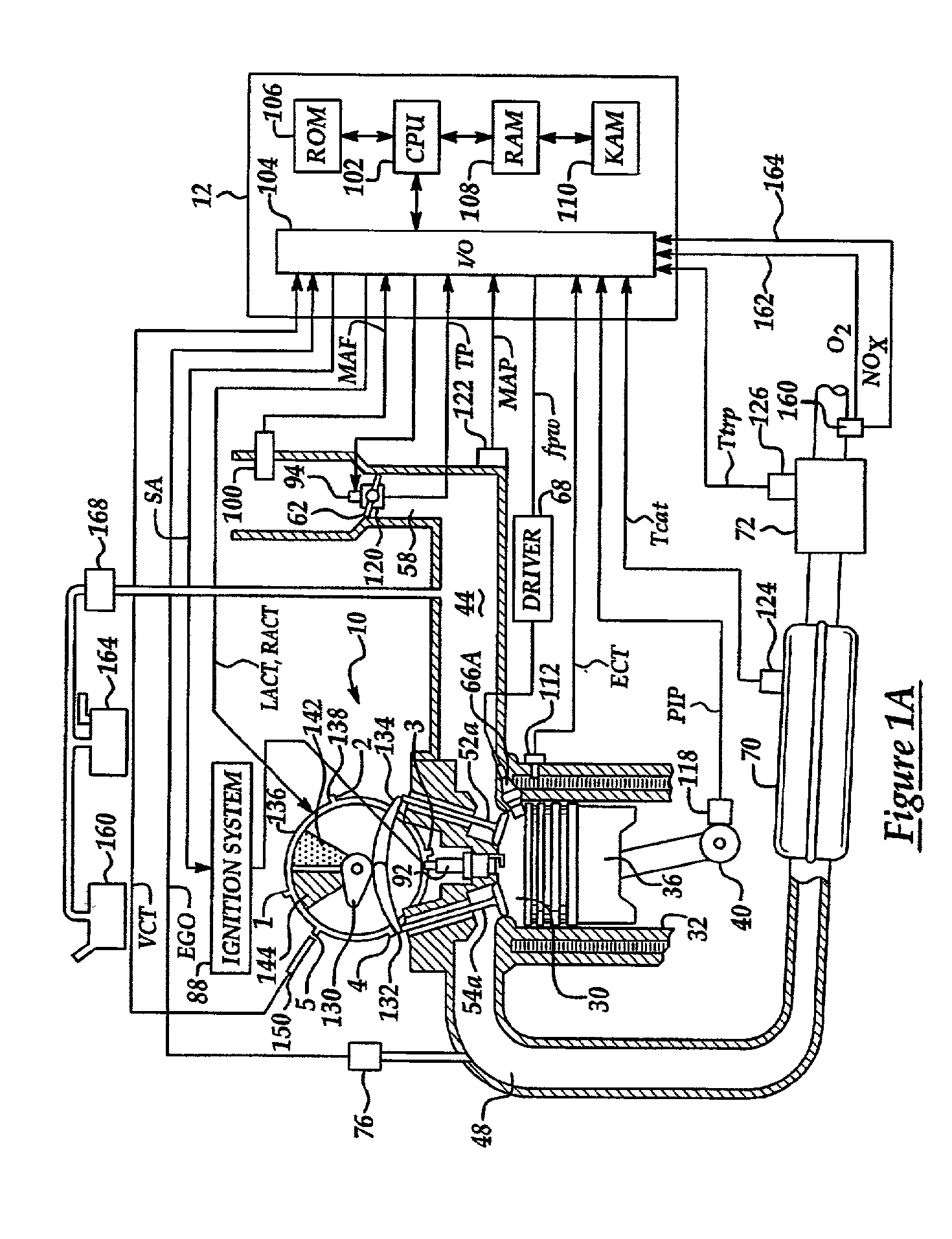

Idle speed control for lean burn engine with variable-displacement-like characteristic

InactiveUS20030221666A1Minimized degraded combustionEasy to operateElectrical controlIdling devicesAdaptive learningIdle speed control

A method is disclosed for controlling operation of a engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air-fuel mixture and a second group of cylinders pumping air only (i.e. without fuel injection.) In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: auto speed control, sensor diagnostics, air-fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, and default operation. In addition, the engine control method also disables the split air / lean operating mode under preselected operating conditions.

Owner:FORD GLOBAL TECH LLC

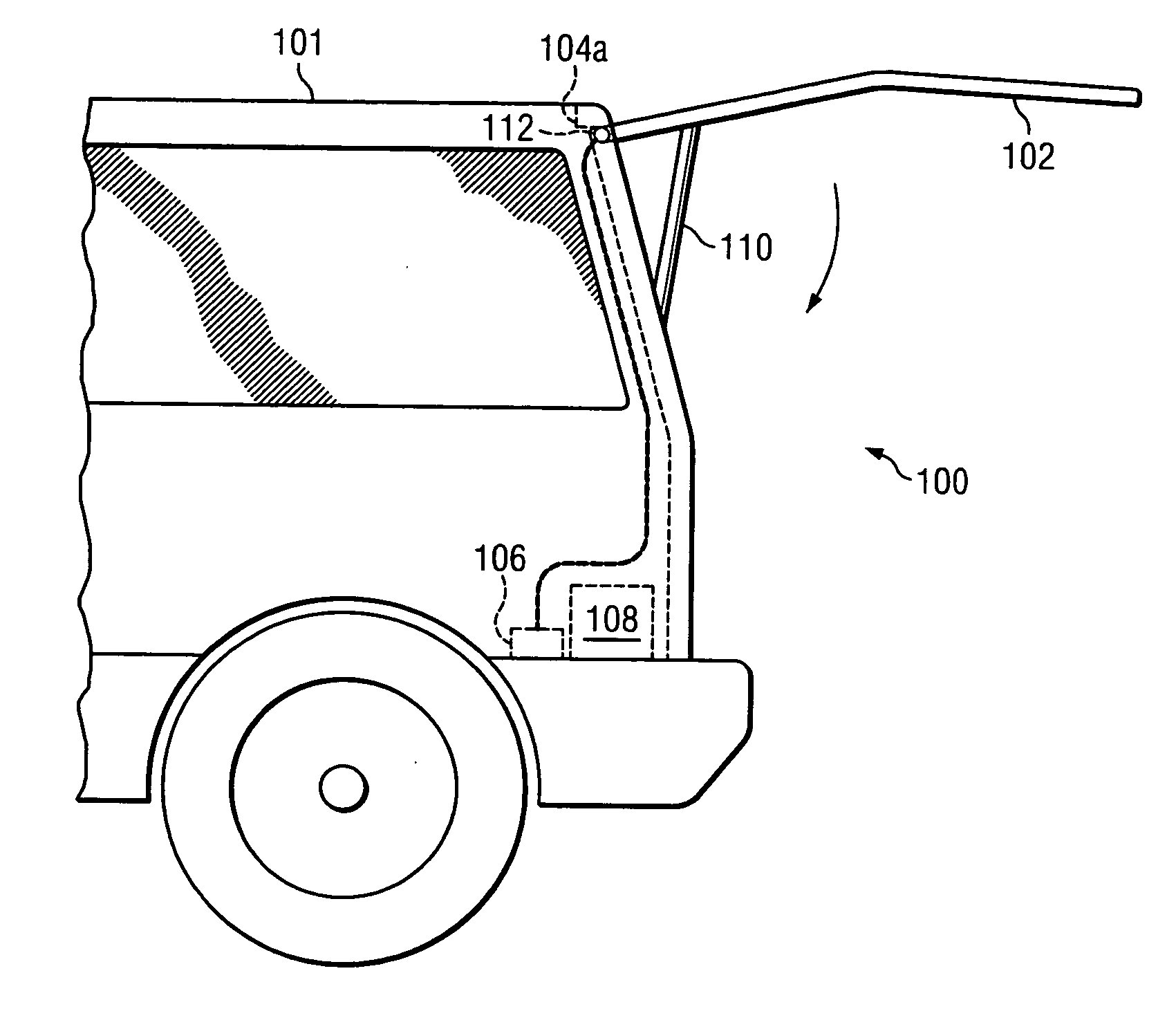

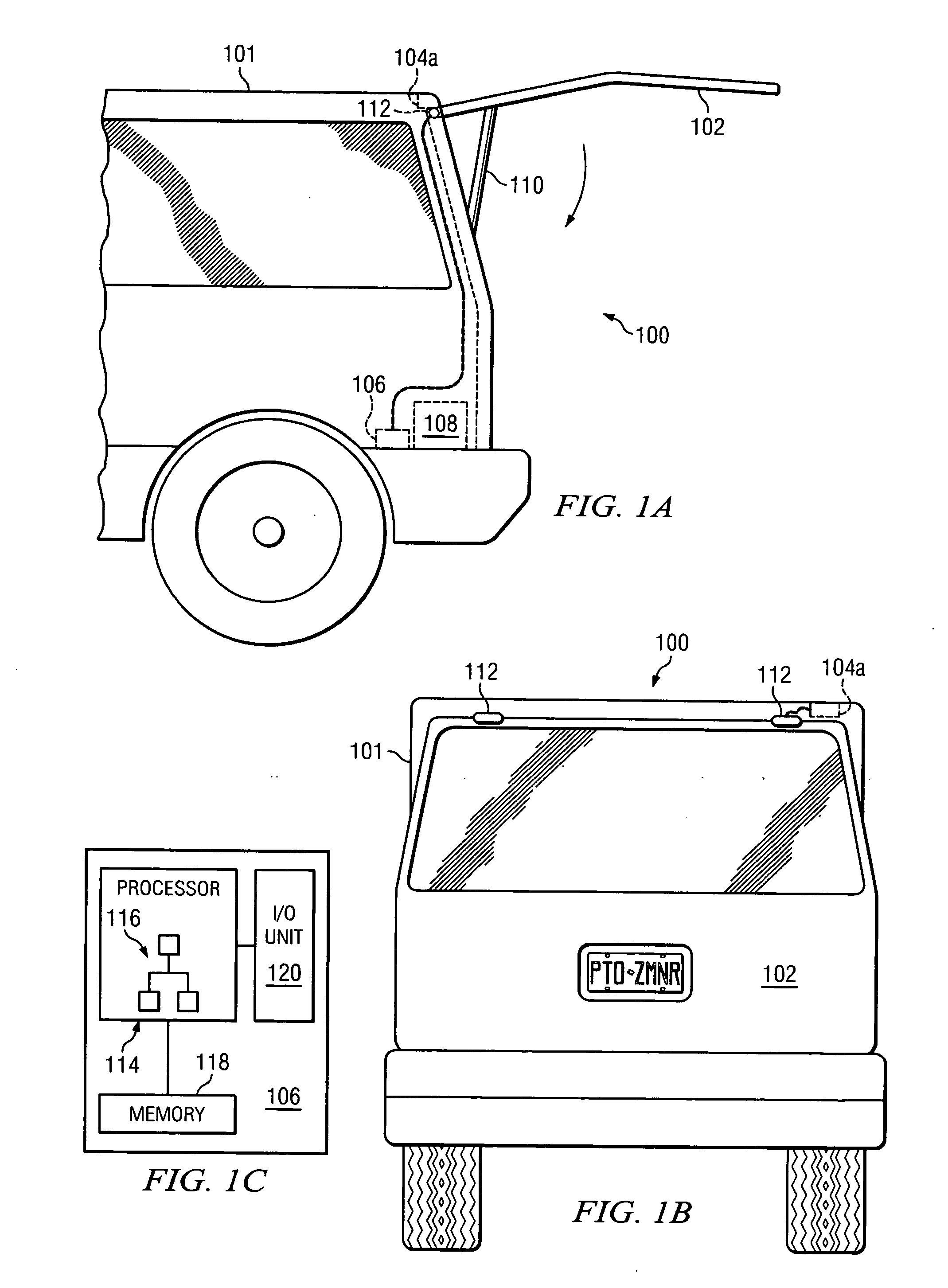

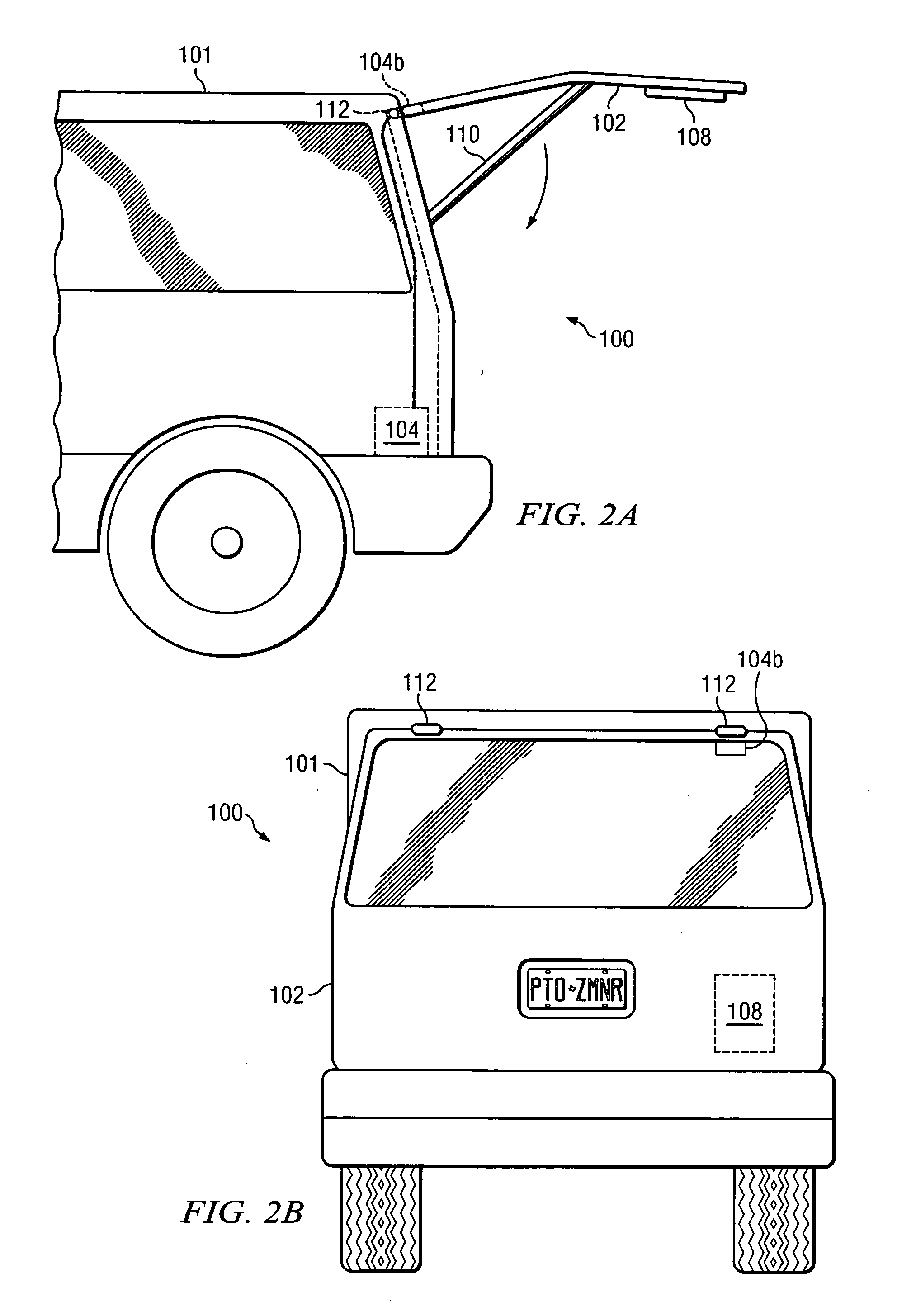

System and method for controlling velocity and detecting obstructions of a vehicle lift gate

ActiveUS20080007191A1Good speed controlDC motor speed/torque controlEmergency protective circuit arrangementsControl theoryPulse-width modulation

A system and method for controlling a rotational closure system, such as a lift gate, of a vehicle may include sensing an angle of the rotational closure system, generating a drive signal, driving a drive mechanism with the drive signal to output a mechanical force for moving the rotational closure system, generating an angle signal having a digital pulsewidth modulation form with a duty cycle based on the angle of the rotational closure system, feeding back the angle signal, and, in response to the feedback angle signal, altering the drive signal while the drive mechanism is moving the rotational closure system between open and closed positions. In one embodiment, the angle signal is generated from a location disposed on the rotational closure system. A controller mounted to the rotational closure system may include an angle sensor and be configured to receive and process the angle signal to drive the drive mechanism.

Owner:FLEXTRONICS AUTOMOTIVE

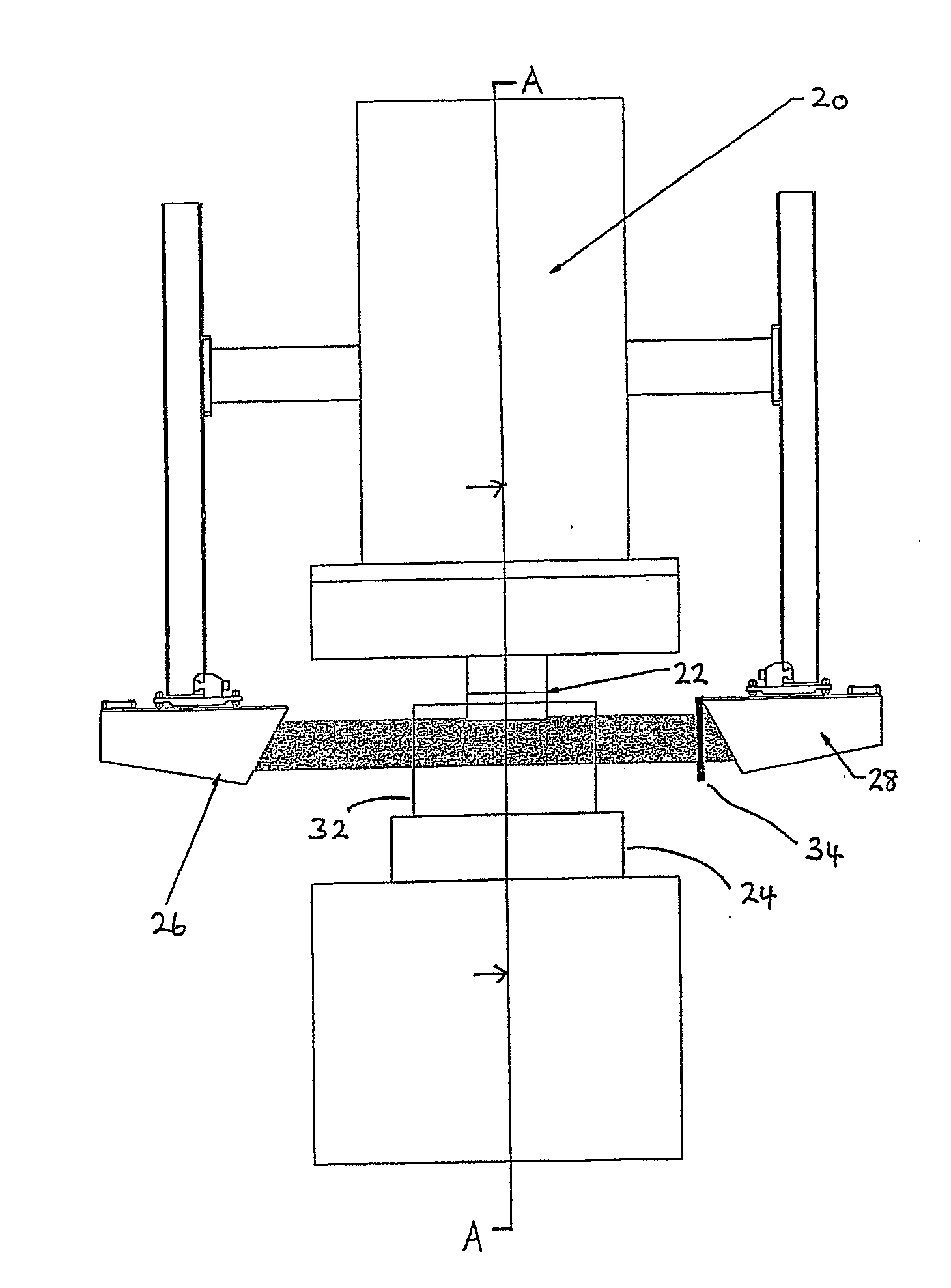

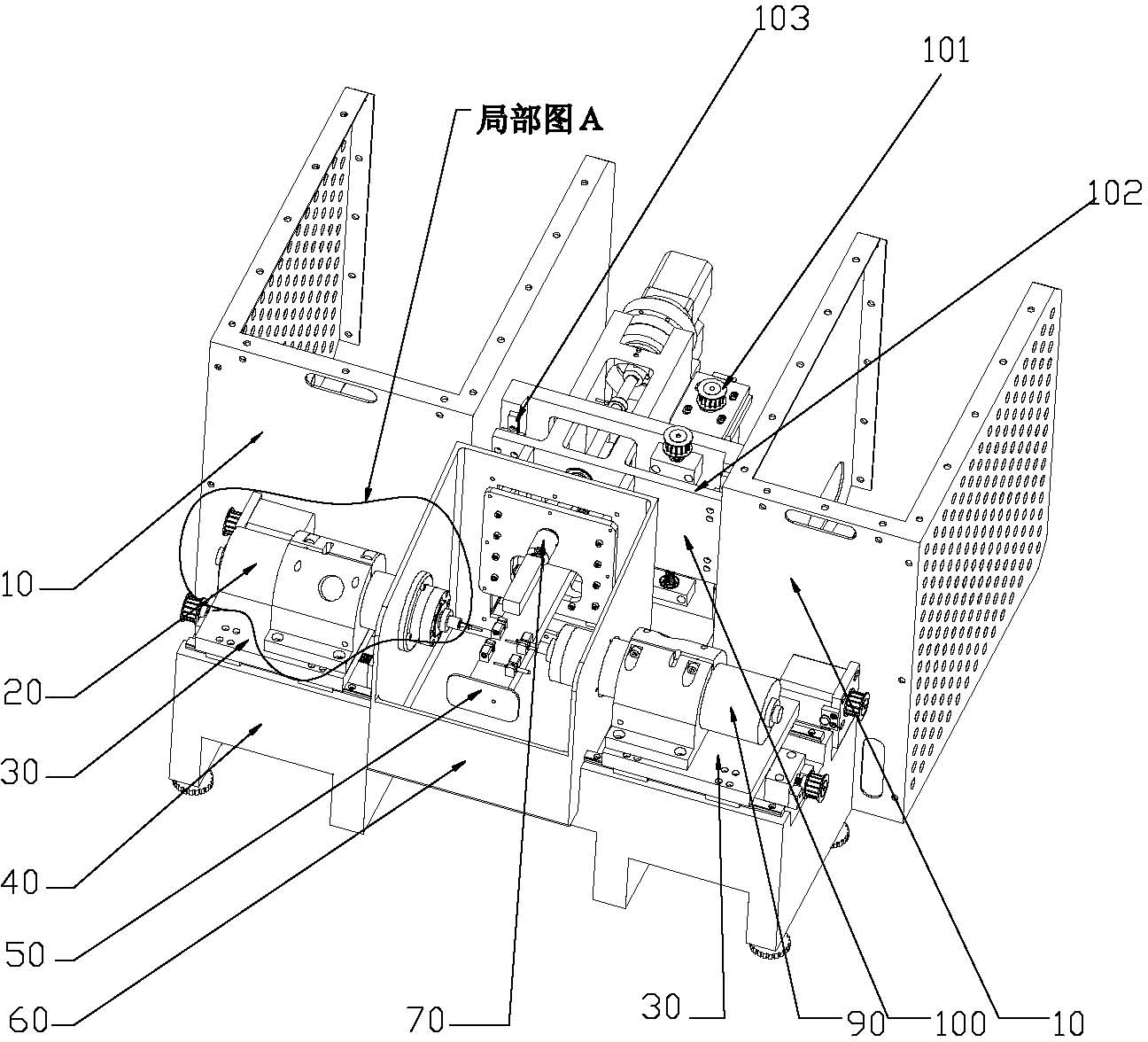

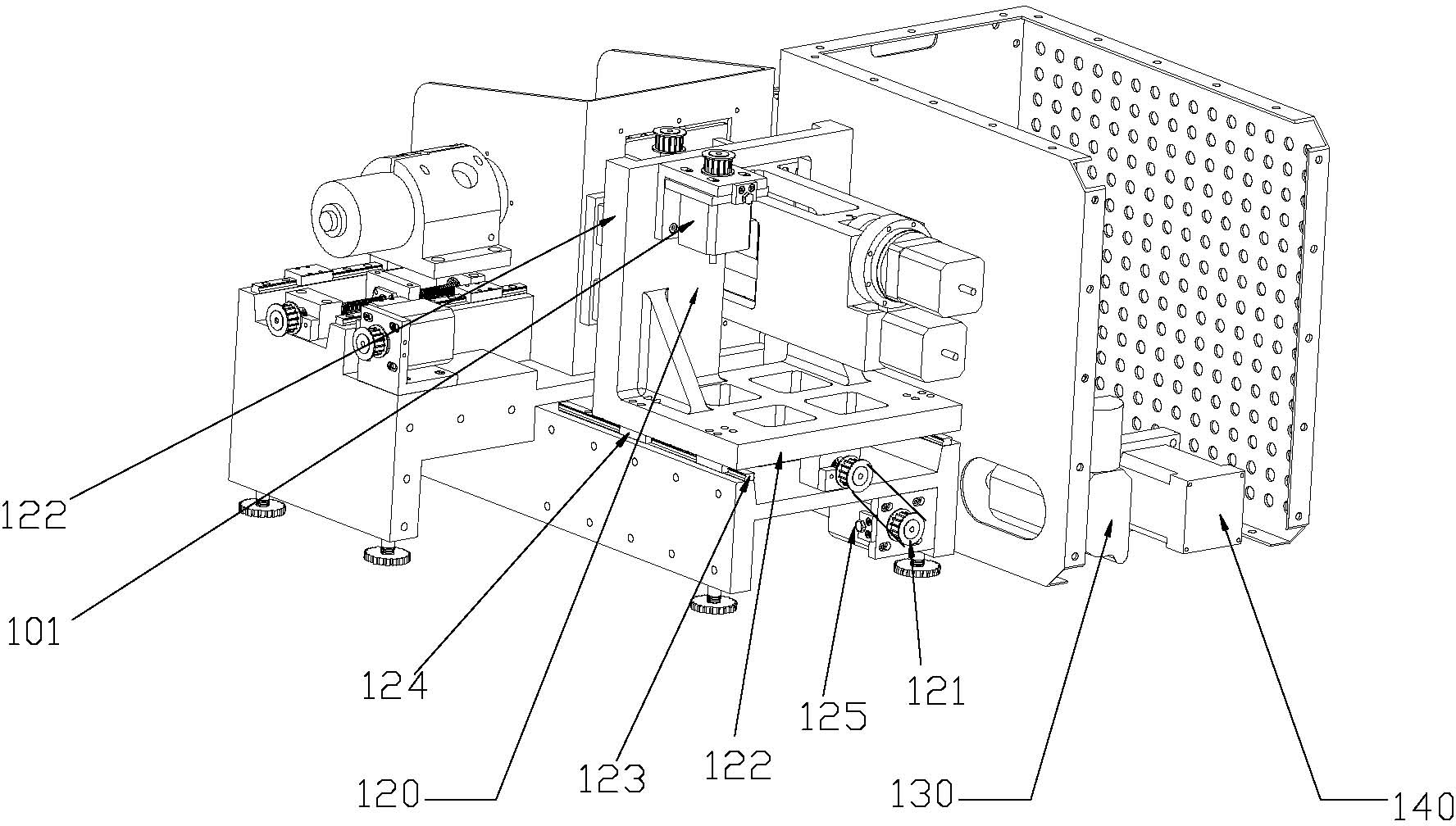

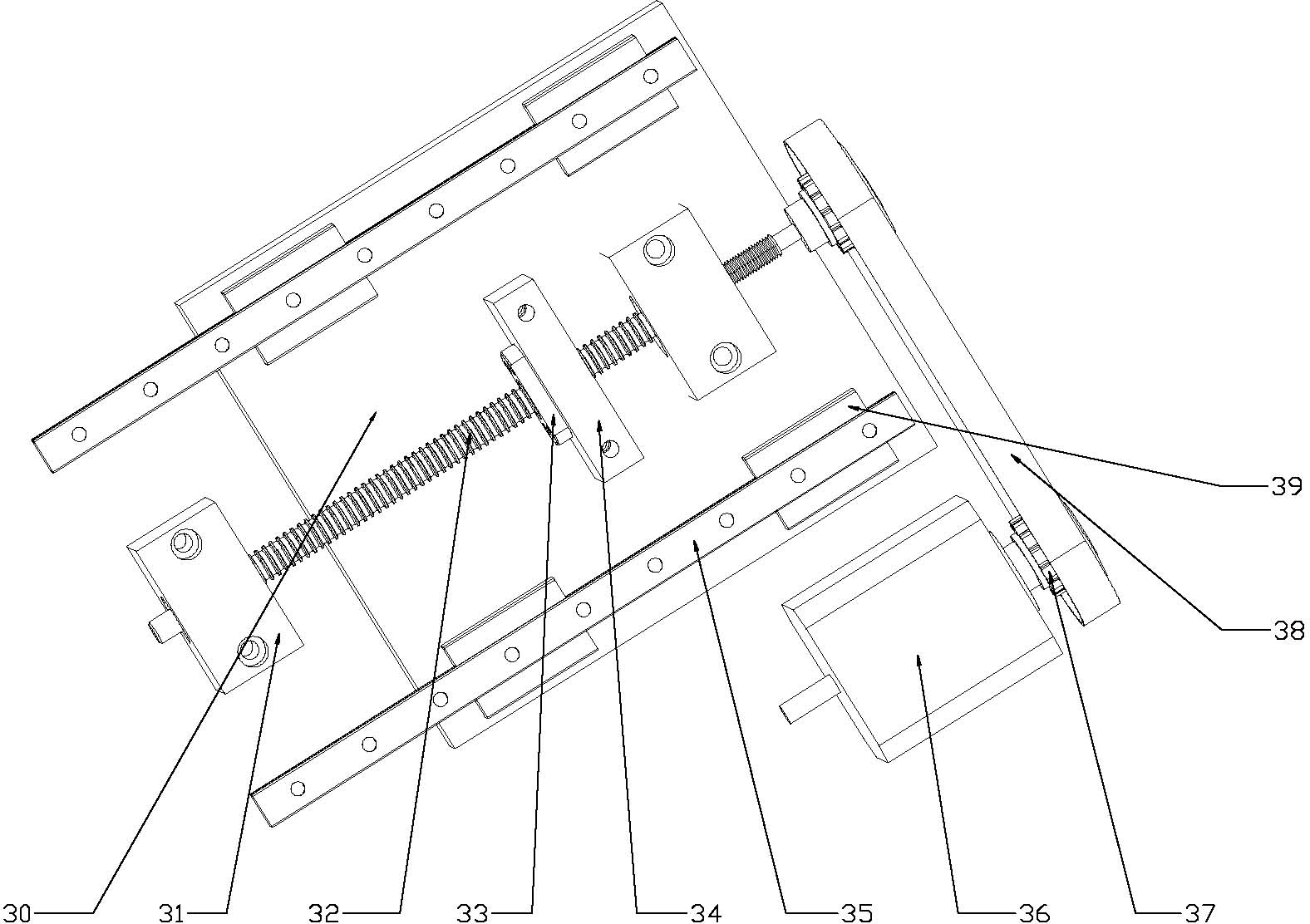

Micro double-spindle false tooth repair machine

ActiveCN102525677ASimplified volumeGuaranteed machining accuracyArtificial teethEngineeringMachining

The invention discloses a micro double-spindle false tooth repair machine. The false tooth repair machine comprises a base (40) and a first electric spindle system (20), a second electric spindle system (90), electric cabinets (10) and a workpiece rotating mechanism (70) which are arranged on the base (40). The false tooth repair machine is characterized in that: the first electric spindle system (20) and the second electric spindle system (90) are arranged coaxially, and cutters arranged on the first electric spindle system (20) and the second electric spindle system (90) and a workpiece arranged on the workpiece rotating mechanism (70) extend into a machining space (60) and are arranged vertically in a horizontal plane; the first electric spindle system (20) and the second electric spindle system (90) are arranged on respective X-axial feeding mechanisms (30); the workpiece rotating mechanism (70) is arranged on a Y-axis feeding mechanism (100), the Y-axis feeding mechanism (100) is arranged on a Z-axis feeding mechanism (120), and the Z-axis feeding mechanism (120) is arranged on the base (40); and a tool magazine system (50) is also arranged on the Y-axis feeding mechanism (100). The false tooth repair machine has the advantages of simple structure, small volume, high machining precision and convenience in operation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

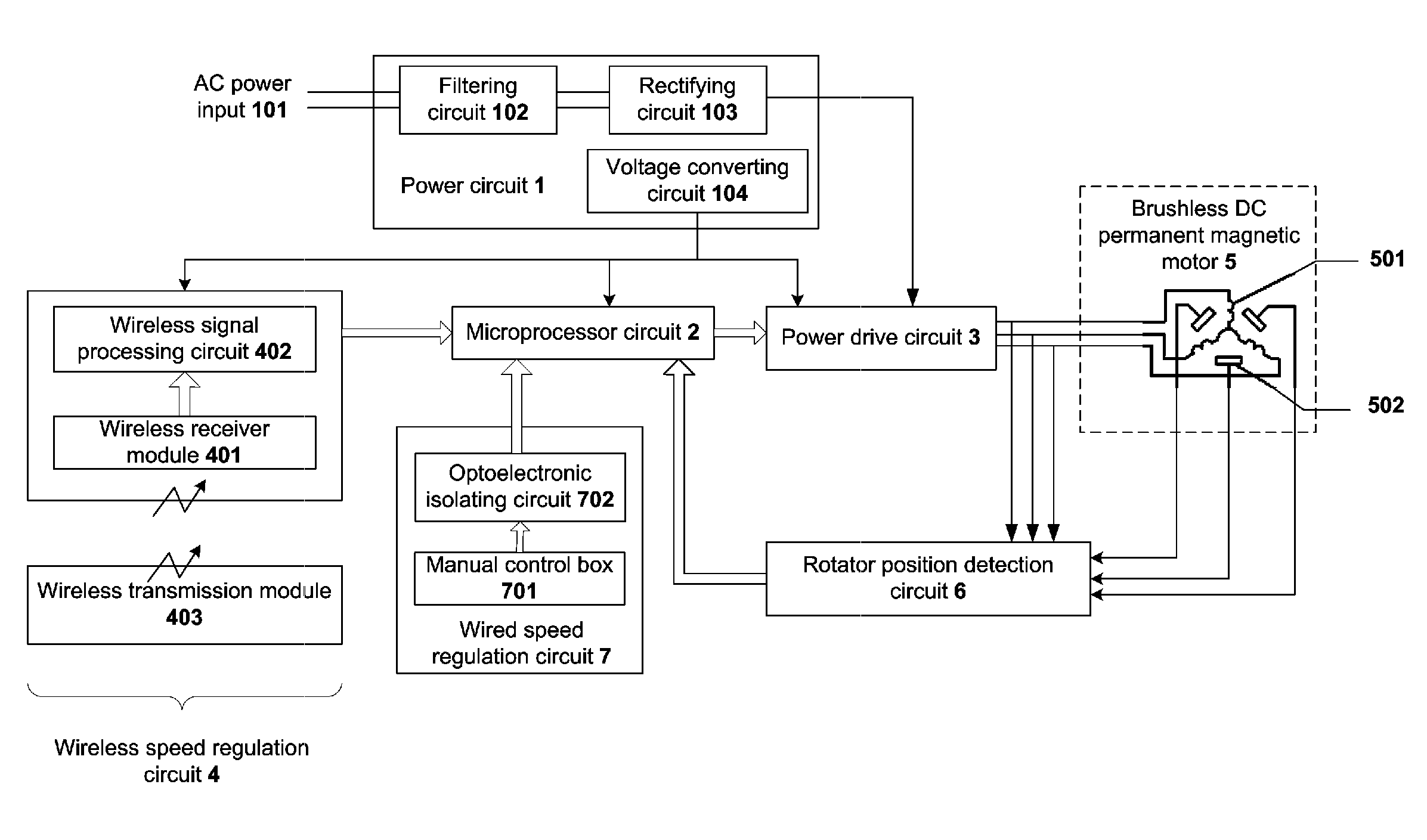

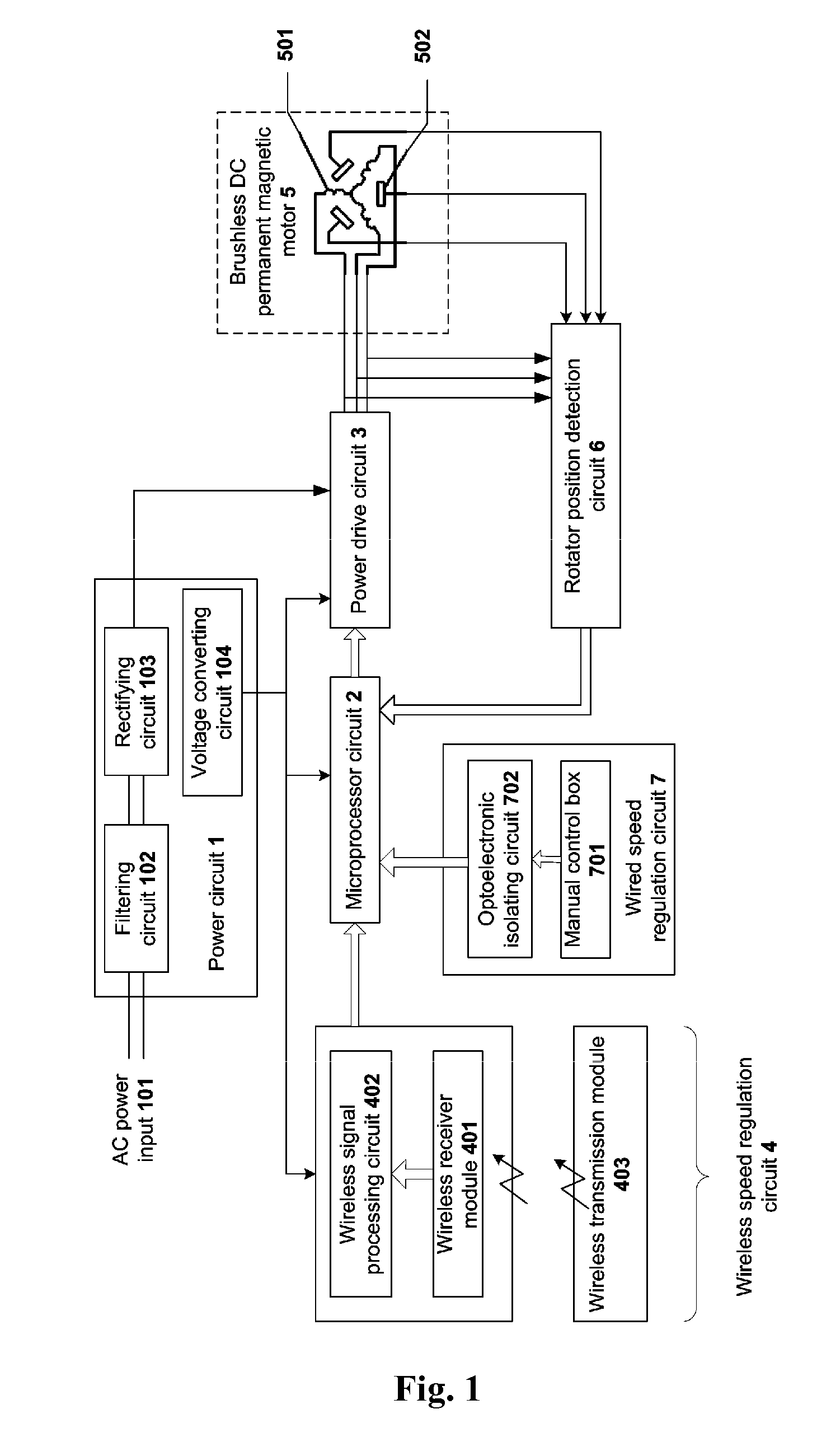

Speed control system for a ceiling fan motor

ActiveUS20080037962A1Easy speed regulationReduce energy consumptionMotor/generator/converter stoppersSynchronous motors startersCeiling fanLow noise

The invention teaches a speed control system for a brushless DC motor for a ceiling fan, comprising a power circuit 1, a microprocessor circuit 2, a power drive circuit 3, a speed regulation circuit, and a brushless DC permanent magnetic motor 5, wherein the input terminal of the power circuit 1 is connected to the output terminal 101 of an AC power source, the output terminal of the power circuit 1 serves to power the various circuits, the output terminal of the microprocessor circuit 2 is connected to the input terminal of the power drive circuit 3, the output terminal of the power drive circuit 3 is connected to the coil windings 501 of the brushless DC permanent magnetic motor, and the output terminal of the speed regulation circuit is connected to the input terminal of the microprocessor circuit 2. The speed control system of the invention provides the advantages of low energy consumption, low noise during the operation of the motor, and a stable operation at low speeds.

Owner:ZHONGSHAN BROAD OCEAN

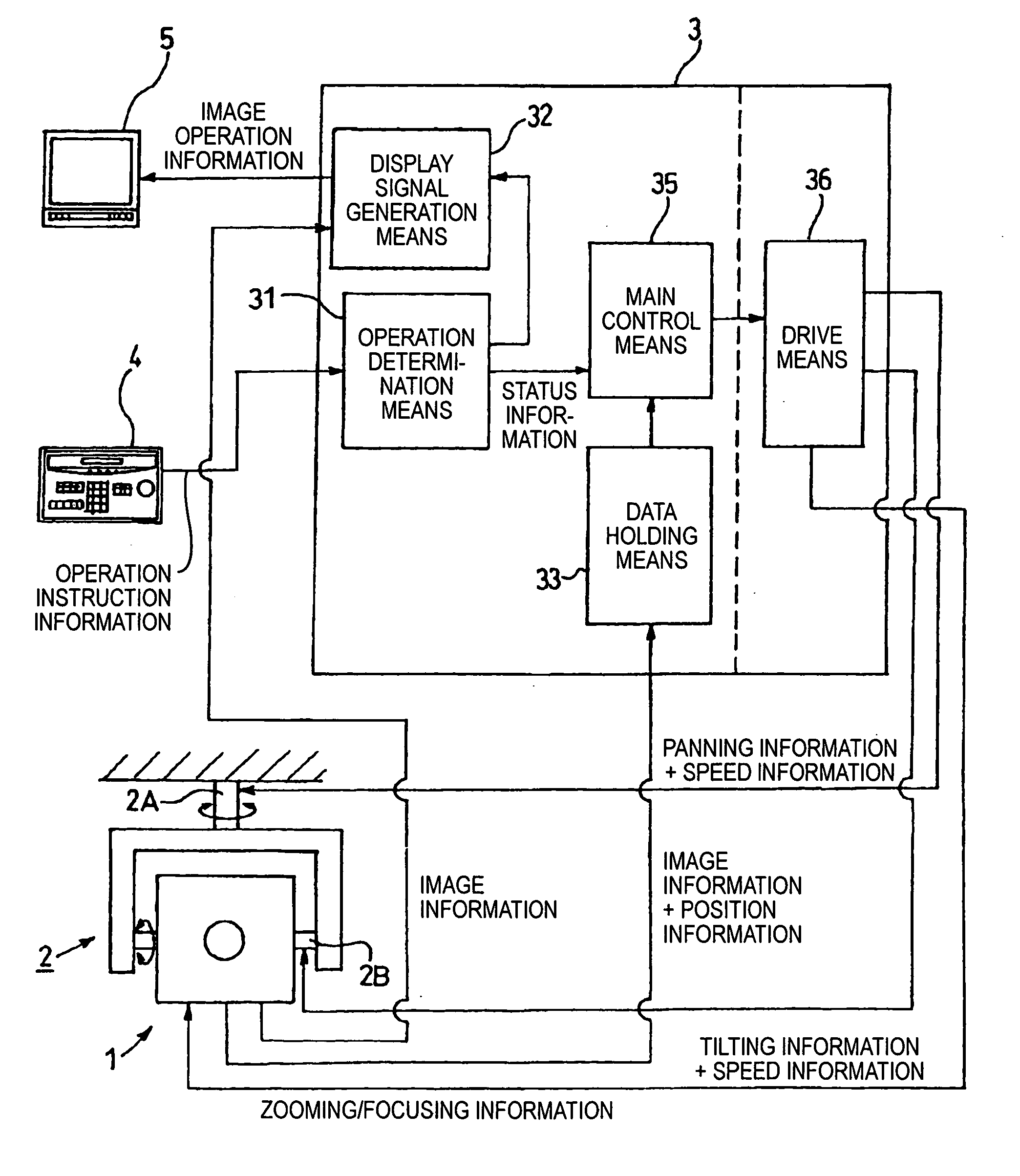

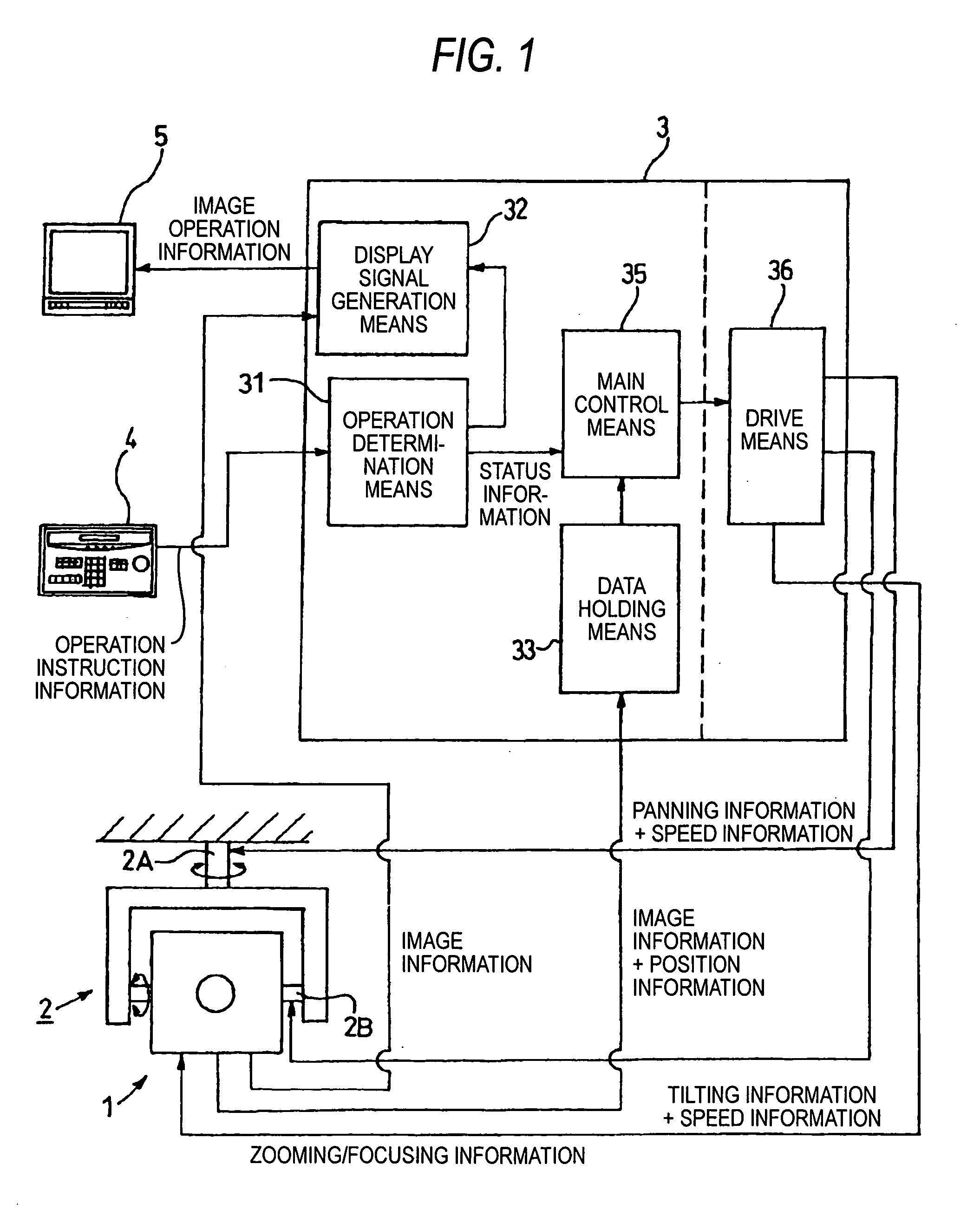

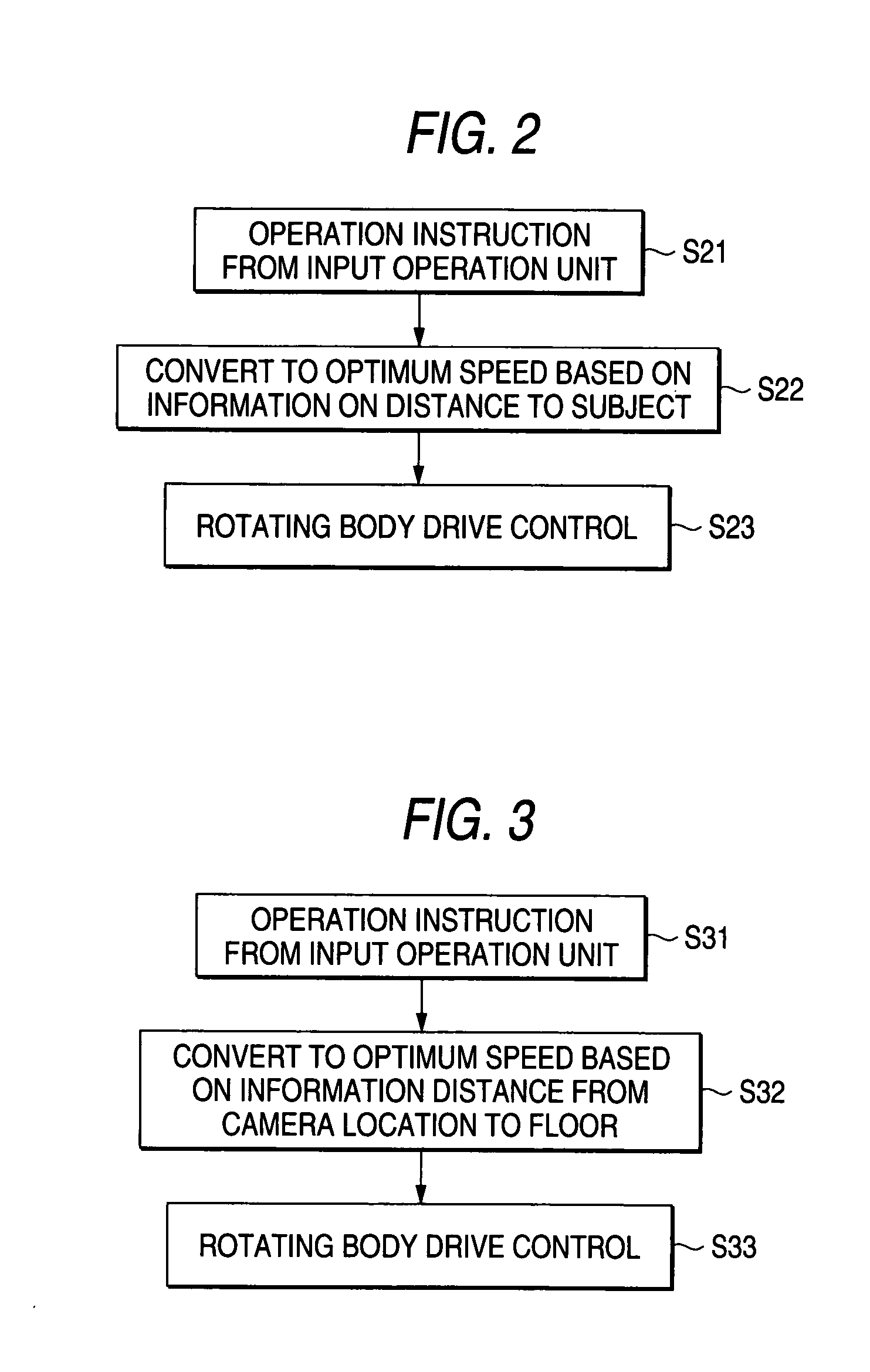

Camera apparatus, a camera system, and a method for controlling the camera system

InactiveUS20040114037A1Easy to trackGood speed controlTelevision system detailsPrintersControl unitVideo camera

Providing camera apparatus and a camera system capable of performing optimum speed control by themselves and even facilitate tracking of a subject by way of a plurality of cameras while using a same controller, even in case the location of the camera or the distance between the camera and the subject has changed, and a method for controlling the camera system The camera apparatus includes: a camera for photographing a subject; a rotating body for rotating the camera in order to track the subject; and a controller for controlling the motion of the rotating body and the operation of the camera; characterized in that the controller includes: an operation determination unit for analyzing and determining the input operation instruction information on the rotating body and the camera; a data holding unit for holding the status information on the photographing operation of the camera; a main control unit for calculating an optimum speed to track the subject based on the information output from the operation determination unit and the data holding unit and outputting the speed to the rotating body; and a drive unit for driving the rotating body.

Owner:PANASONIC CORP

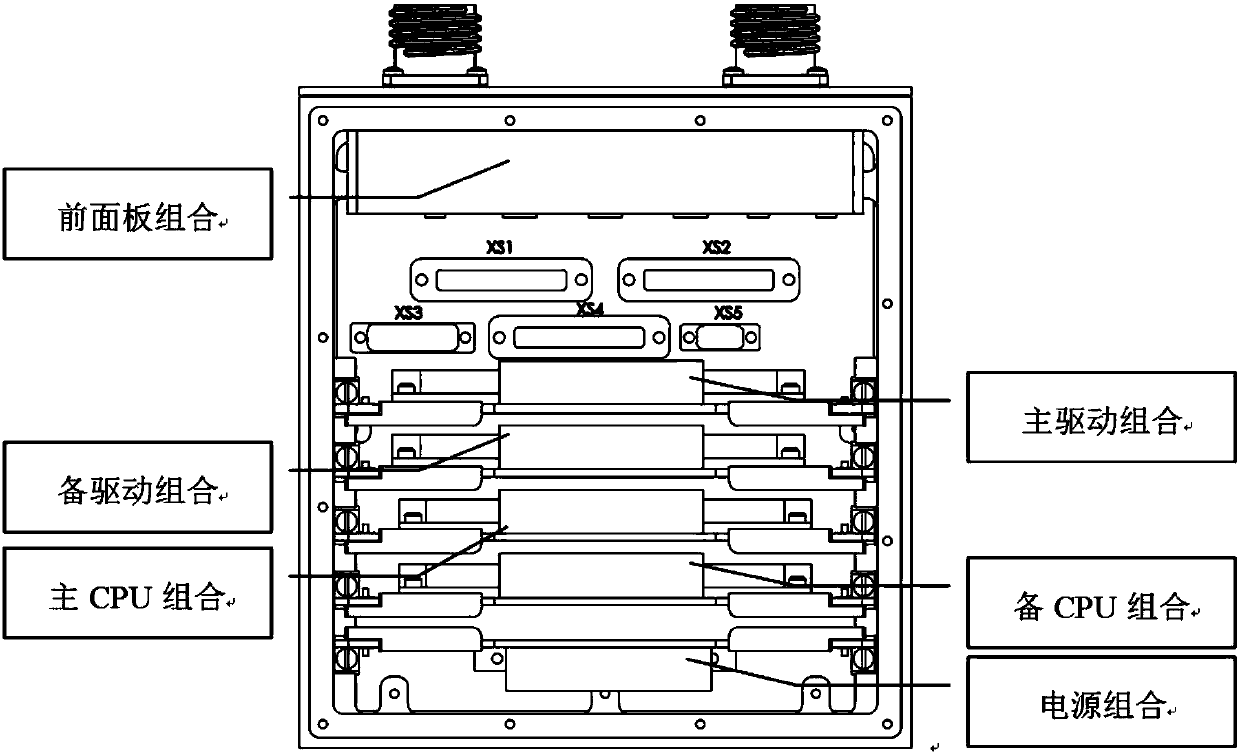

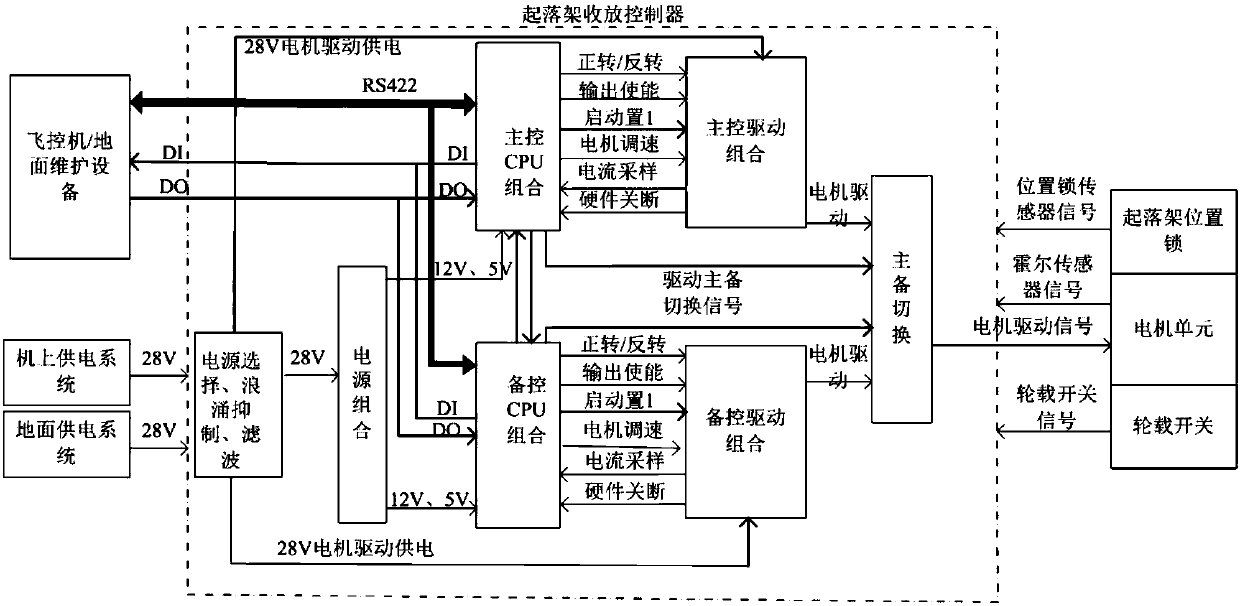

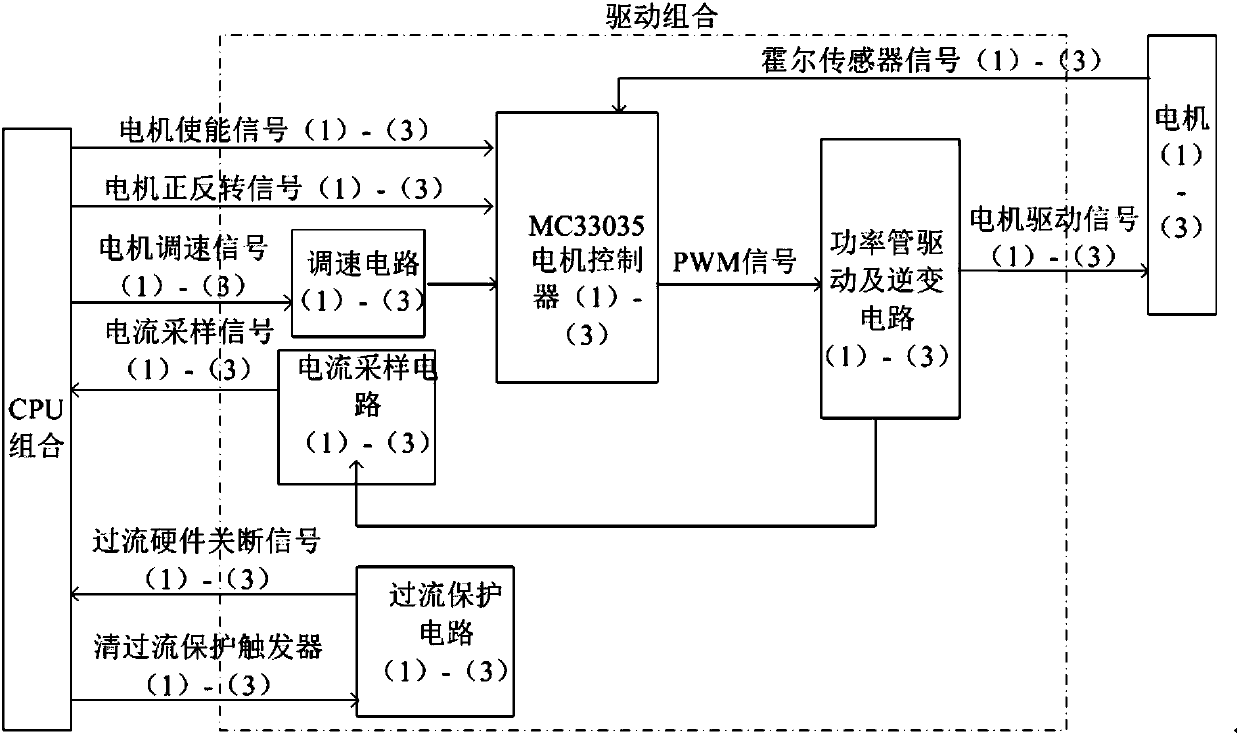

Multi-redundancy landing gear electric retraction controller

PendingCN109823522AReduce weightReduce volumeSafety arrangmentsUndercarriagesMotor driveSignal lines

The invention discloses a multi-redundancy landing gear electric retraction controller, and aims to provide a controller with light weight, small size, good reliability and strong environmental adaptability. According to the technical scheme, a main control CPU combination module is connected with a standby control CPU combination module and is correspondingly connected with a main control drivingcombination module and a standby control driving combination module through forward rotation and reverse rotation, output enabling, start setting 1, motor speed regulation, current sampling and hardware cut-off control lines respectively; the main control CPU combination module and the standby control CUP combination module are connected with a switching module and a standby switching module through driving main and standby control switching signal lines and a motor driving control line; the main and standby switching modules are connected with a landing gear motor unit through the motor driving signal line; the main control CPU combination module receives a landing gear retraction command, controls logic processing and sends a motor control command; the main control driving combinationmodule and the standby control driving combination module receive motor control commands of the main control CPU combination module and standby control CPU combination module and a motor Hall sensor signal.

Owner:CHENGDU KAITIAN ELECTRONICS

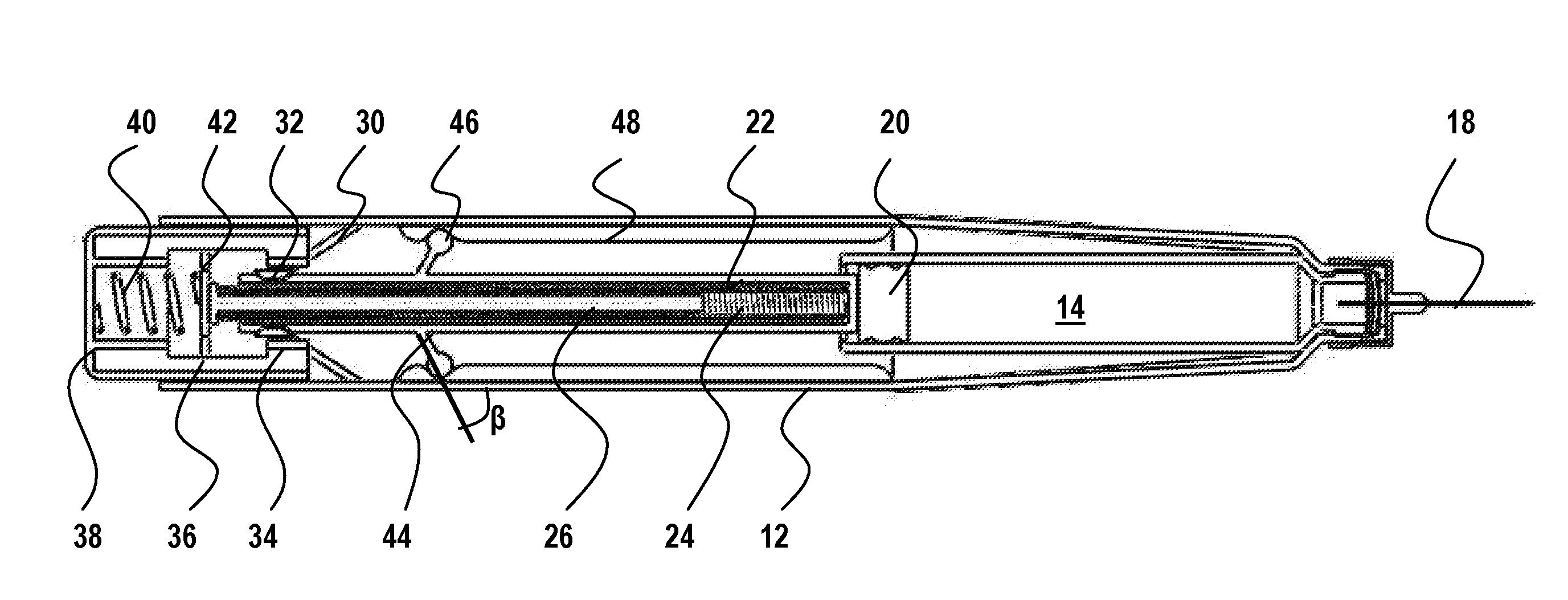

Medicament Delivery Device

ActiveUS20110288492A1Good speed controlFew partsAutomatic syringesIntravenous devicesBiomedical engineeringDrug delivery

Owner:SHL MEDICAL AG

Lubricating oil cooling device for traveling speed reduction gear

ActiveUS8145384B2Small motorReduce the temperatureGearboxesAnalogue computers for trafficTemperature controlLow speed

The present invention provides a traveling speed reduction gear lubricating oil cooling device that enables optimal temperature control for lubricating oil delivered via a lubricating oil pump that can be started up with a relatively small motor without running the risk of damage to an oil cooler in a cold work environment even when a temperature sensor that detects the temperature of the lubricating oil is installed outside a wheel mounting sleeve. During a startup operation, provided that the detected temperature at a traveling motor is higher than the reference temperature, the lubricating oil pump is driven at a speed in a lower speed range relative to the normal operation speed range. In addition, during the startup operation, the rotation speed of the drive motor for the lubricating oil pump is increased in correspondence to a rise in the temperature detected by a lubricating oil temperature detection sensor.

Owner:NIHON KENKI CO LTD

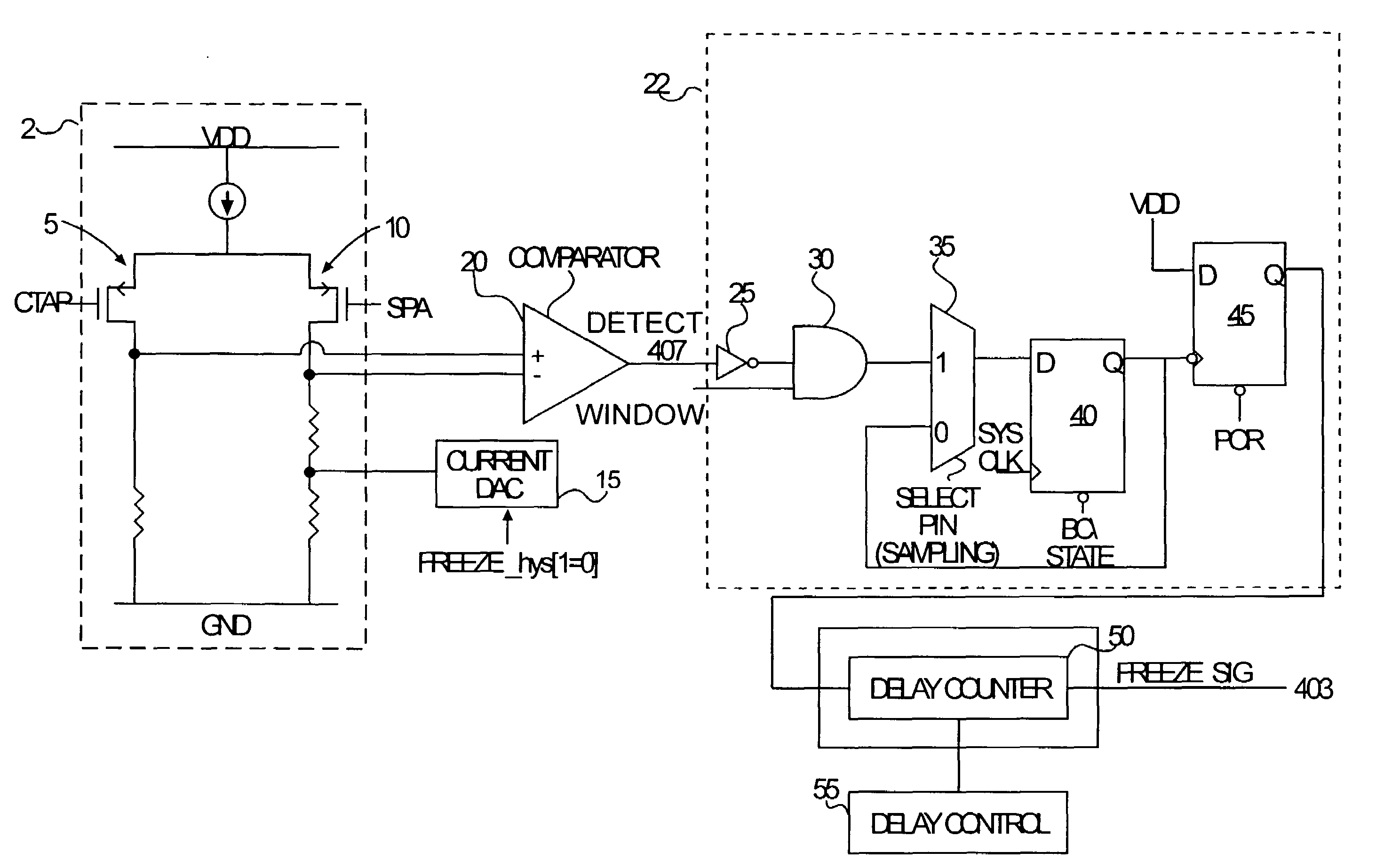

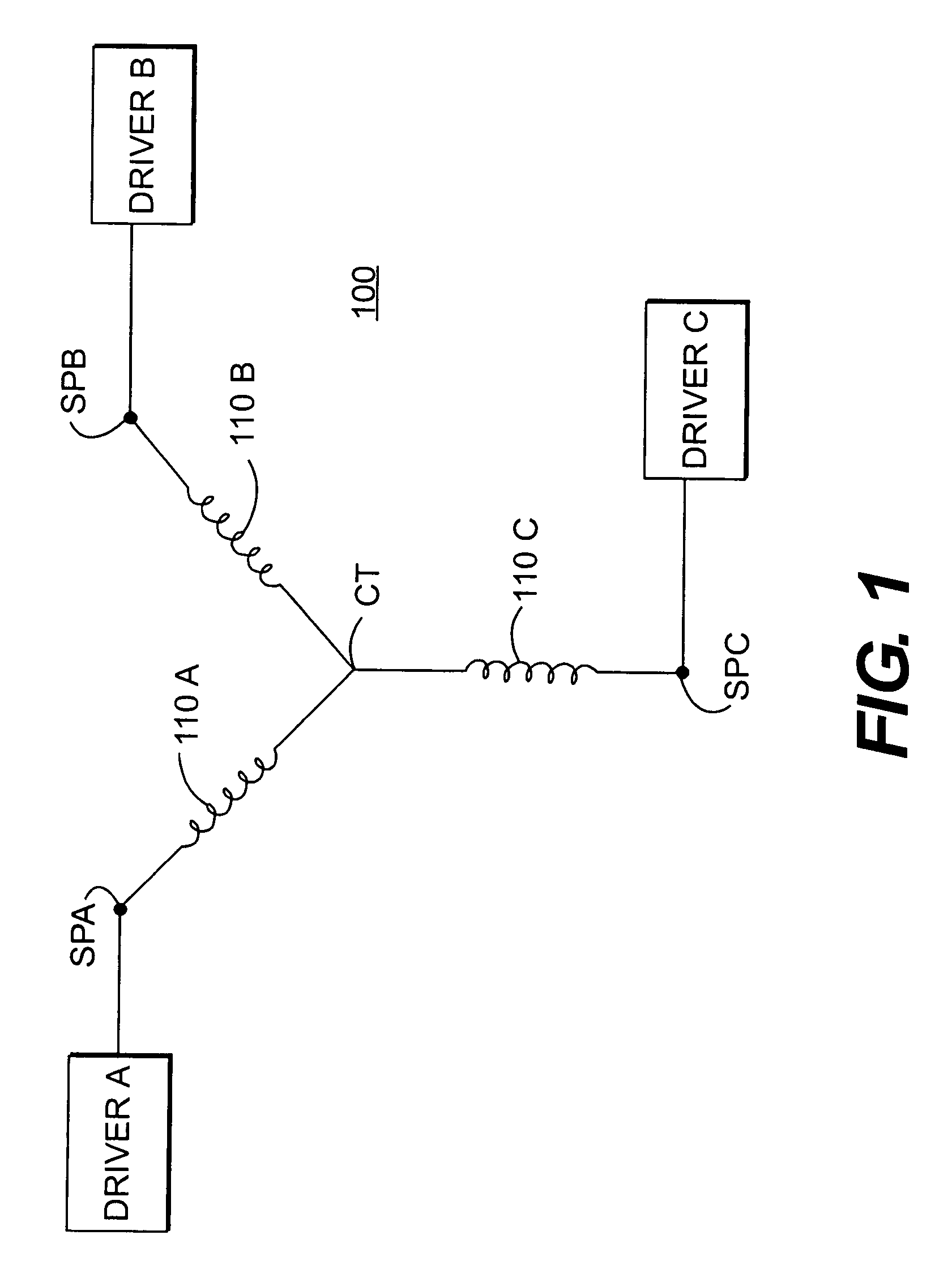

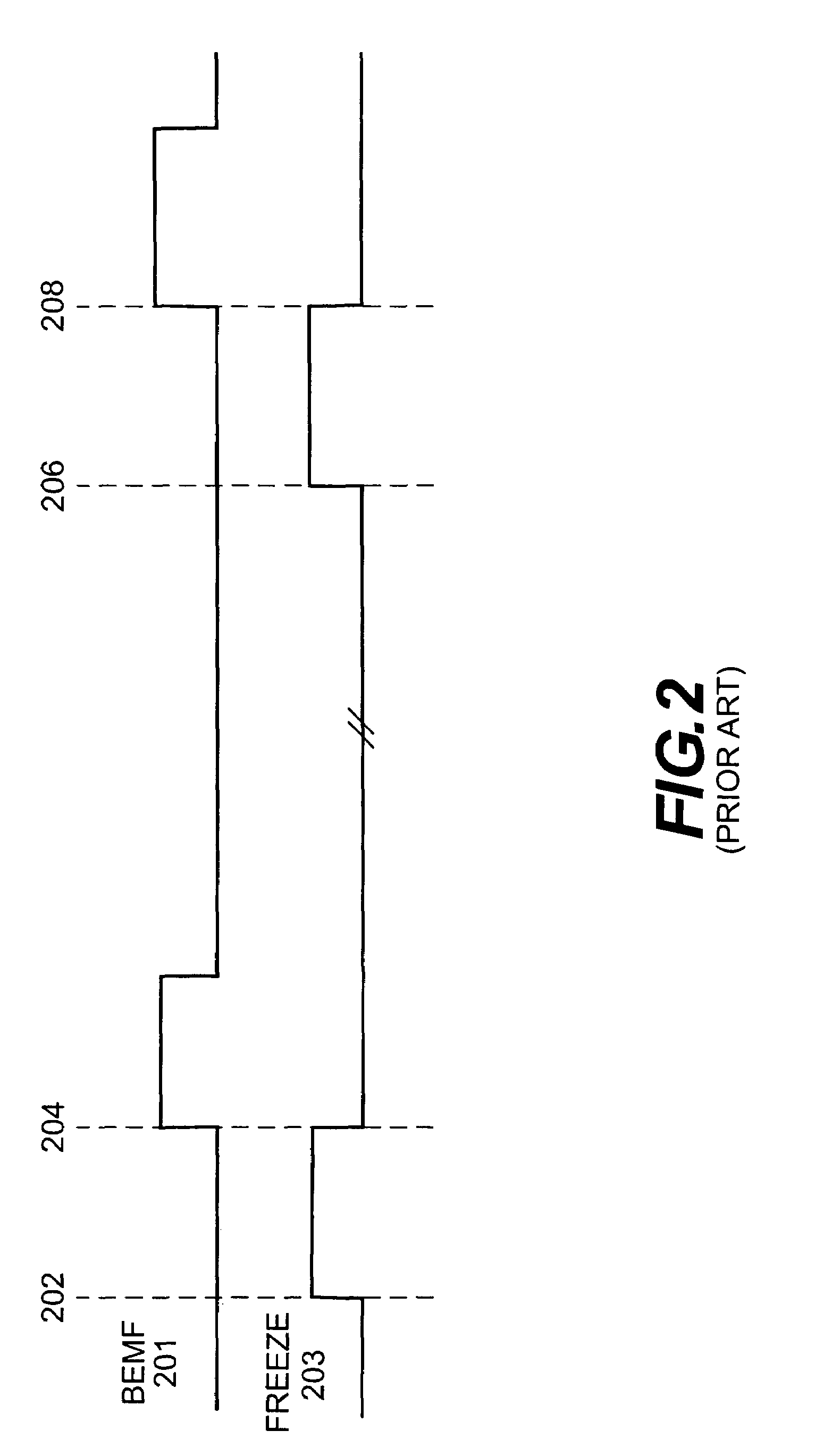

System and method for detecting back electromotive force with automatic pole calibration

InactiveUS7385364B1Accurate detectionAmount of timeElectronic commutation motor controlAC motor controlDrive motorThree-phase

A system and method for determining the rotational speed of a motor, such as a three-phase disk drive motor, detects back electromotive force voltage generated during operation of the motor with an automatic pole calibration to minimize or eliminating variations in the wave of a freeze signal. A phase voltage at a winding is compared against a center tap (CT) voltage. Once the phase voltage falls to a specified voltage level, a detect signal is generated. A predetermined time after the detect signal is generated, a freeze signal is generated for freezing at least the circuit associated with the winding.

Owner:MARVELL ASIA PTE LTD

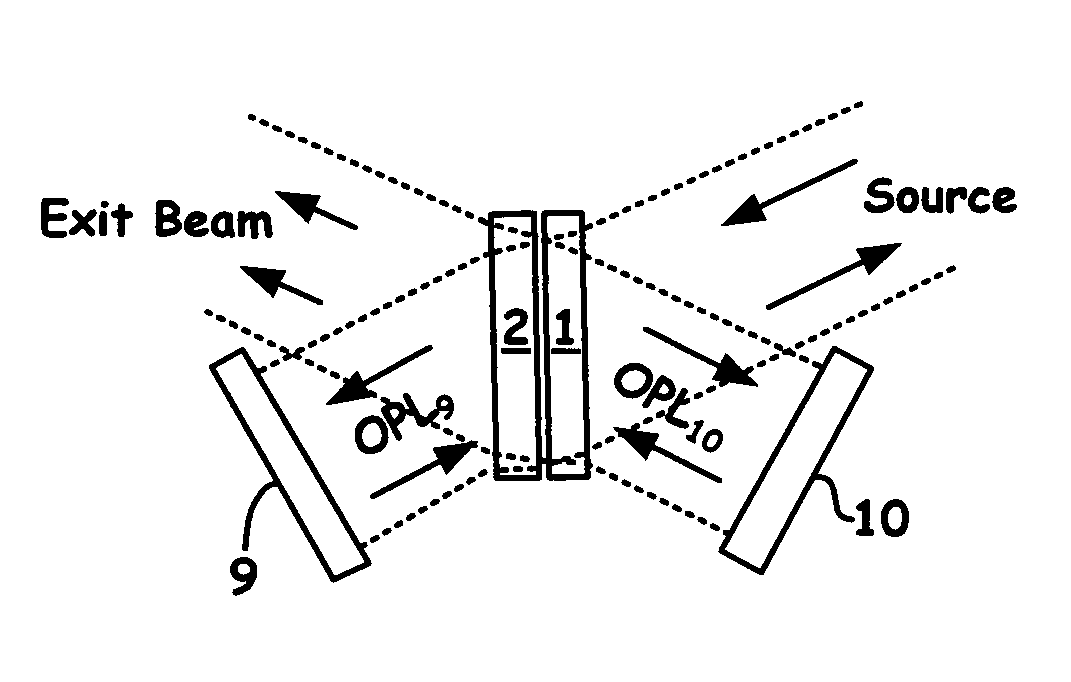

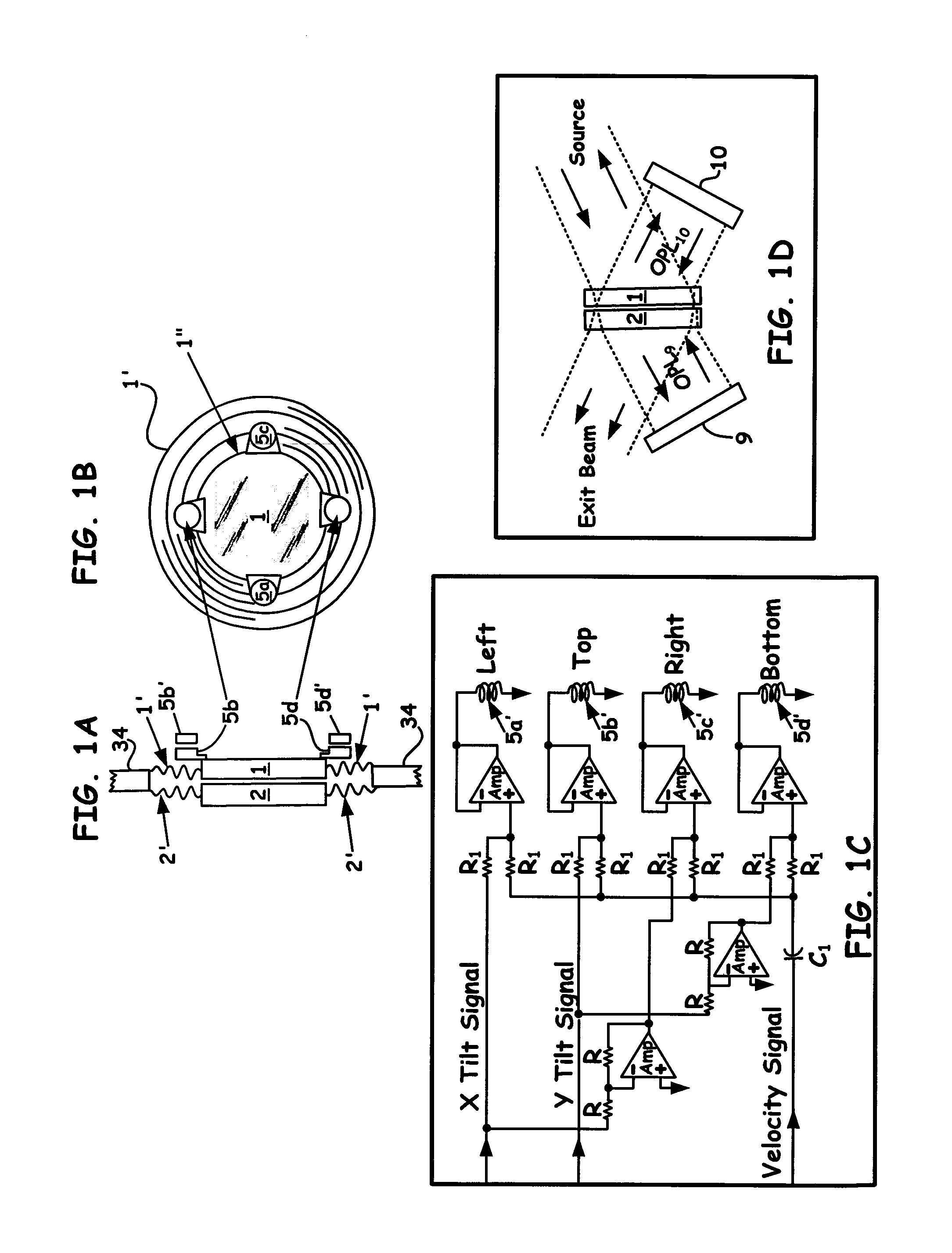

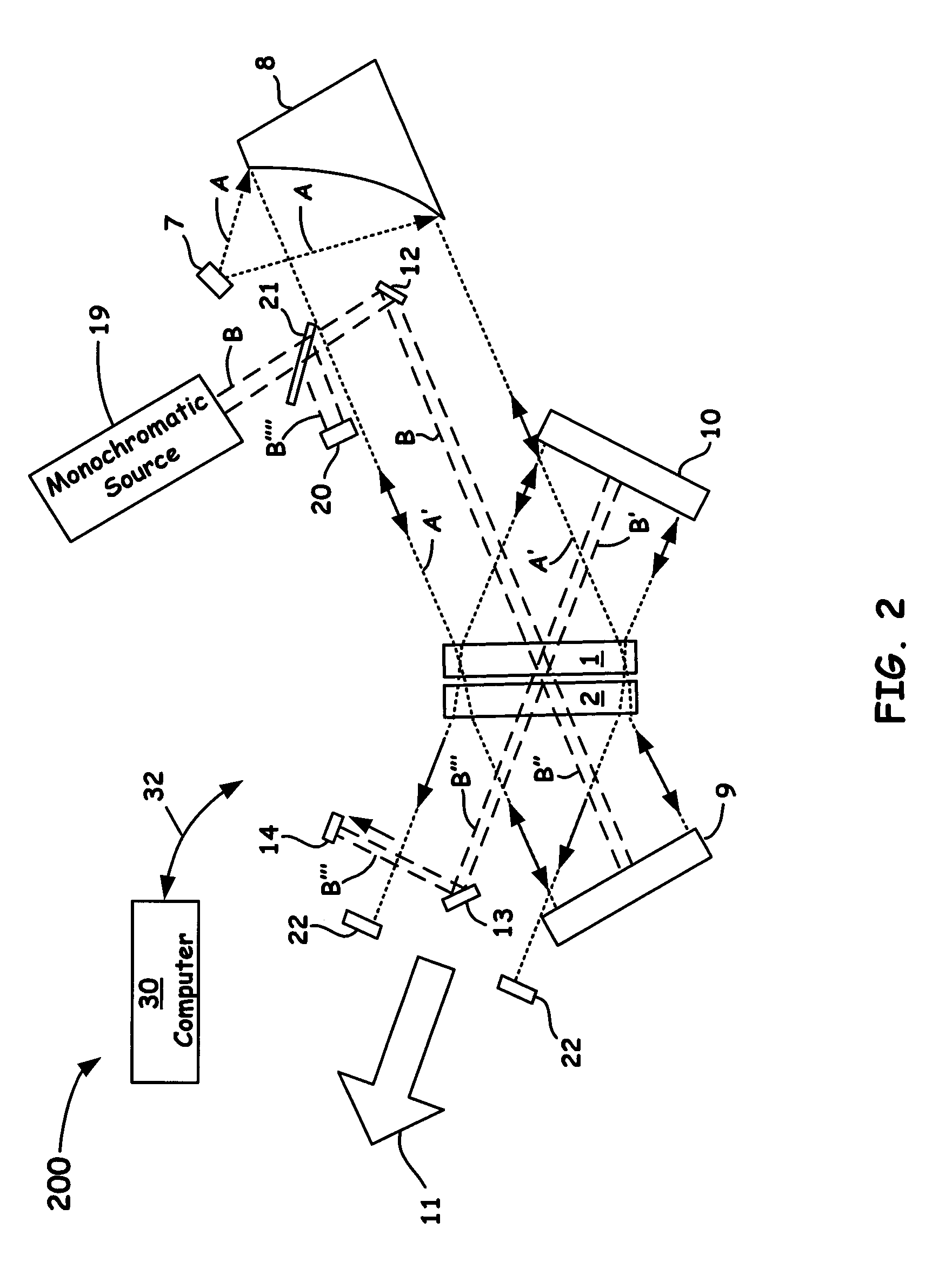

Interferometer Velocity Control of Beamsplitter and Moving Mirrors

ActiveUS20120120405A1Good speed controlFast response timeRadiation pyrometryInterferometric spectrometryLow noiseHigh rate

A novel means of provided velocity control of an interferometer wherein one of the moving components includes the beamsplitter element is introduced herein. Using a moving beamsplitter and coupled flexure mounting allows improved velocity control because the low mass of the beamsplitter enables the systems disclosed herein to respond faster than conventional mirror velocity controlled interferometer instruments with a resultant lower velocity error so as to provide a more stable and lower noise spectra from the analytical instrument. The control of the velocity of the beamsplitter and if desired, one or both of the configured mirrors, reduces the time wasted changing velocity at the ends of each scan. The result is an increase in data collection available in any given experiment time frame. Such desirable arrangements of the present invention thus allow scans to be collected at higher rates, which beneficially increase the ability to monitor rapidly changing systems.

Owner:THERMO ELECTRONICS SCI INSTR LLC

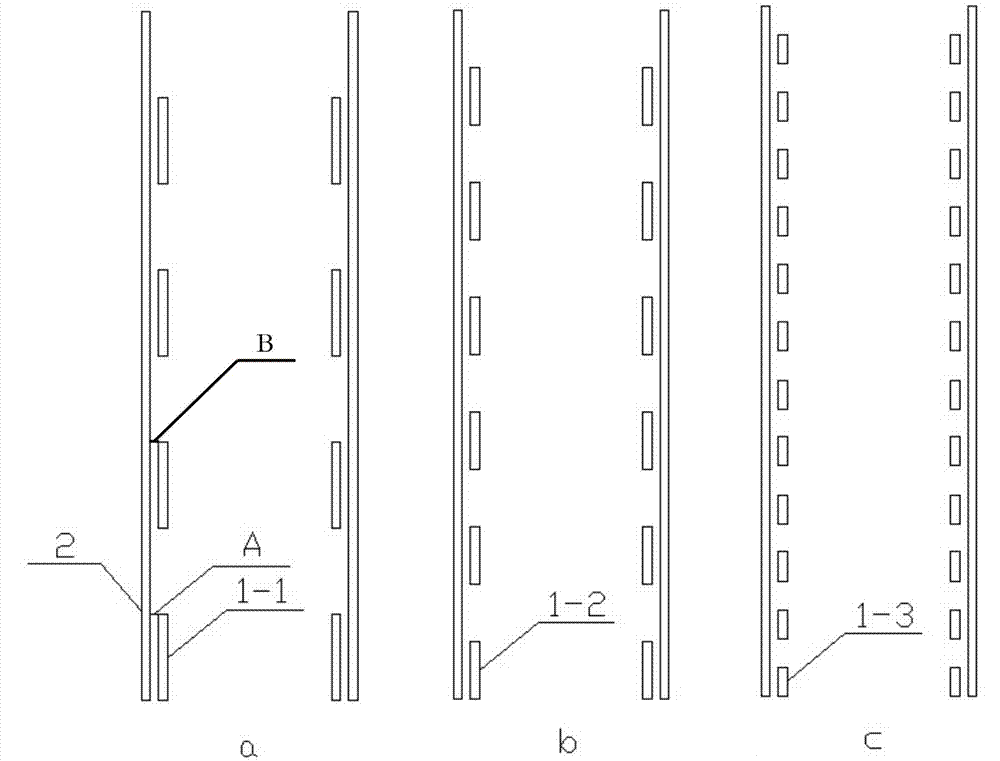

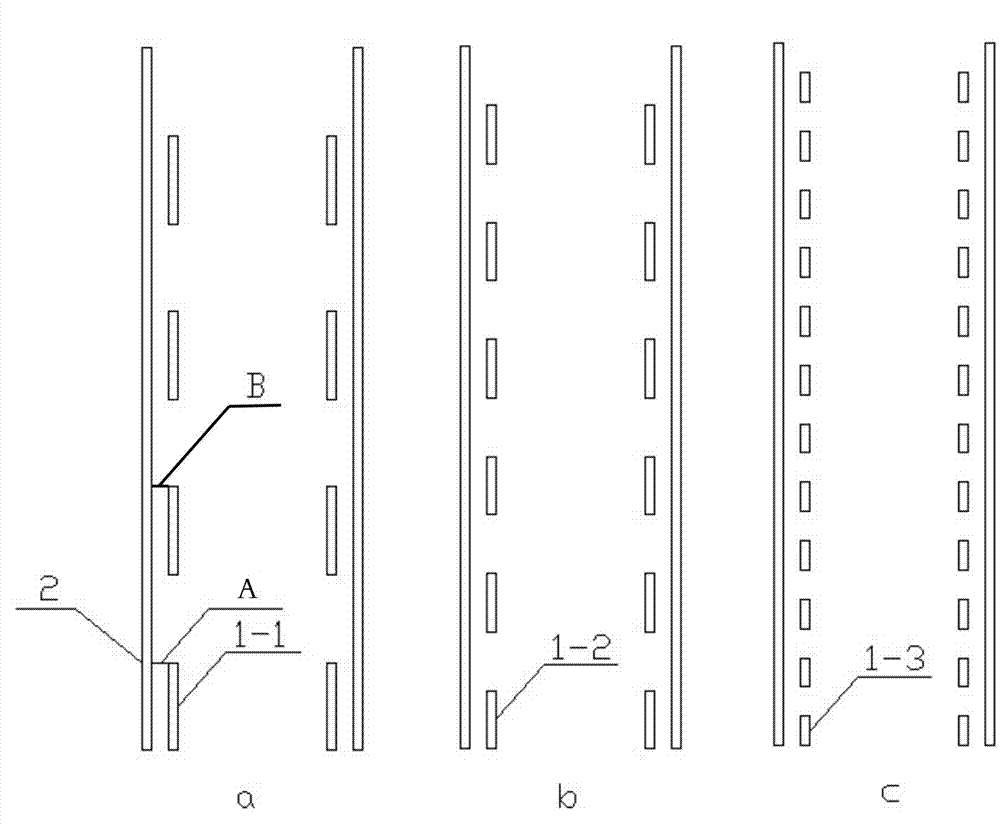

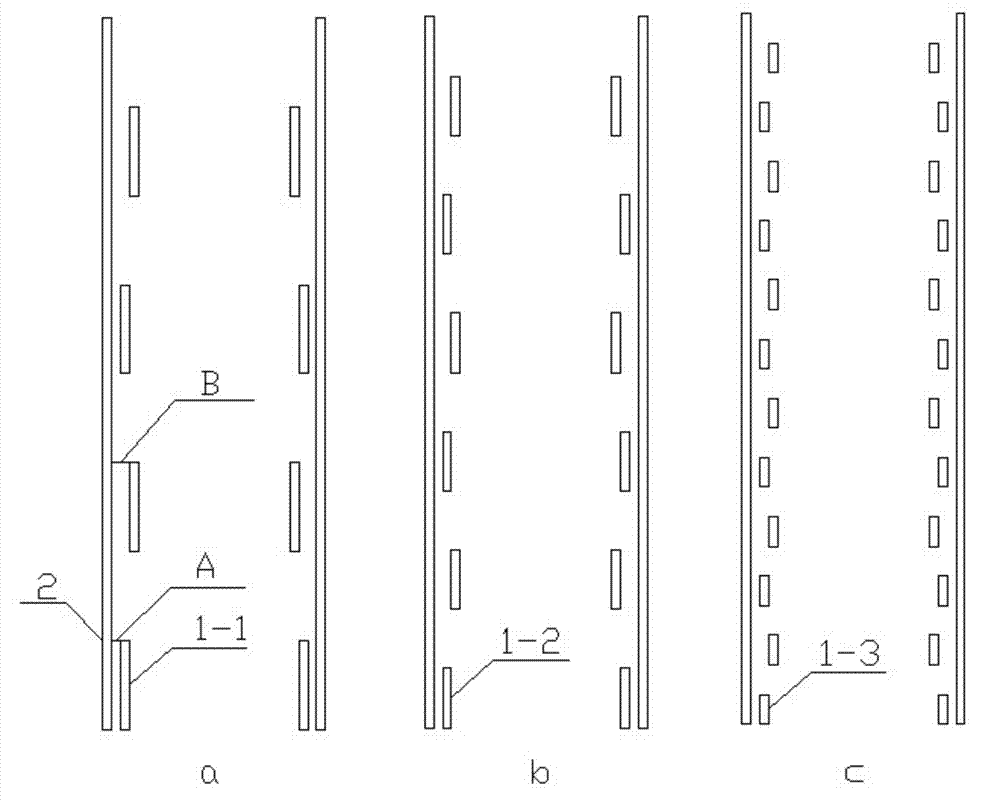

Method for setting double-row road surface speed control edge lines for controlling vehicle speed

InactiveCN102787568AIncrease perceived speedImprove subjective risk awarenessTraffic signalsRoad signsWater basedDriver/operator

The invention provides a method for setting double-row road surface speed control edge lines for controlling the vehicle speed. The method comprises the following steps that 1) the inner side of a lane cutting line is provided with speed control edge wires, and materials adopt hot melt type quick dry yellow pavement anti-slip paint, wherein ingredients in the paint has the weight ratio that hot melting kettles: granular calcium carbonate: calcium carbonate ultrafine micropowder: water-based paint quick dry agents is 300:10:5:6, and the hot melting kettle comprises the following ingredients in percentage by weight: 45 percent of acrylic resin, 20 percent of aggregate, 10 percent of plasticizers, 15 percent of pigment and 10 percent of fillings; and 2) the control speed edge lines are alternate by one dotted line and one full line and are in arrangement parallel to the lane cutting line, the length of the single speed control edge line is 0.4 to 2m, and the distance between the adjacent speed control edge lines is equal to the length of the speed control edge line. Through the arrangement of speed control edge lines, the optical flow rate and the edge rate of the visual perception of a driver are changed, the perception speed of the driver is accelerated, and the subjective acceleration consciousness is reduced, so the goal of speed limitation is reached.

Owner:WUHAN UNIV OF TECH

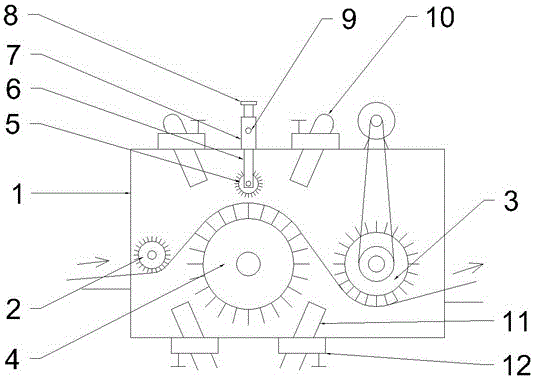

Non-woven carding dust-removing device

InactiveCN106498647AReduce output speedIncrease frictionMechanical cleaningPressure cleaningEngineeringNonwoven fabric

The invention provides a non-woven carding dust-removing device. The non-woven carding dust-removing device comprises a dust-removing box, wherein a cloth inlet is formed in one end of the dust-removing box and a cloth outlet is formed in the other end of the dust-removing box; a cloth inlet steering roller is arranged at the cloth inlet and in the dust-removing box; a cloth outlet steering roller is arranged at the cloth outlet and in the dust-removing box; a carding roller is arranged in the dust-removing box; a cloth pressing roller is arranged over the roller surface of the carding roller and is arranged at the bottom of an adjusting shaft; an upper dust-absorbing pipe is arranged on each of the two sides of the cloth pressing roller; the upper dust-absorbing pipe passes through the top of the dust-removing box and extends to be above the carding roller; a lower dust-absorbing pipe is arranged below the carding roller and in the dust-removing box. By adoption of the scheme, the non-woven carding dust-removing device has a simple structure, good speed-controlling effect and low use cost and can remove dust.

Owner:湖州盛世杰制衣有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com