Patents

Literature

70results about How to "Not easy to pinch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

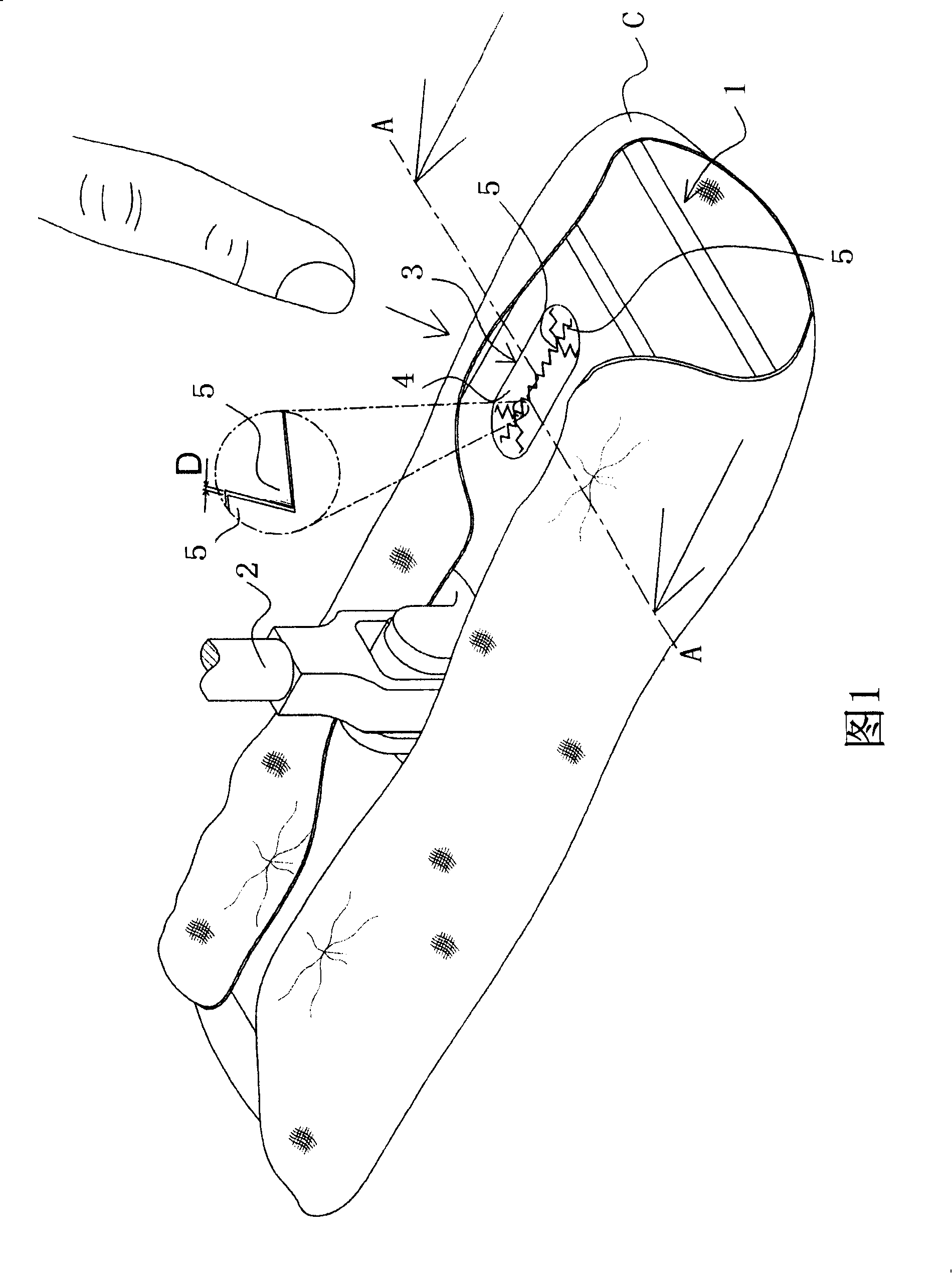

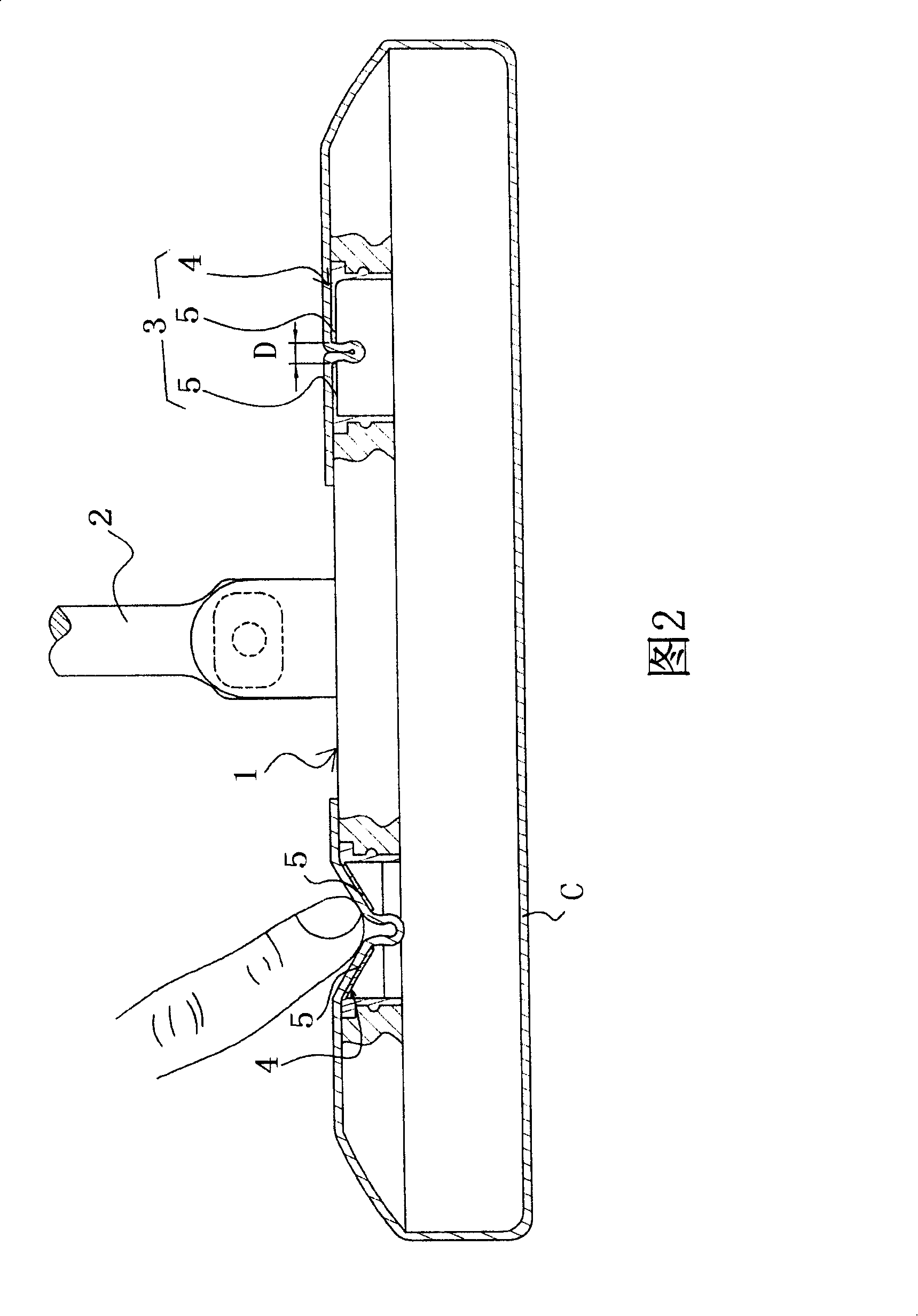

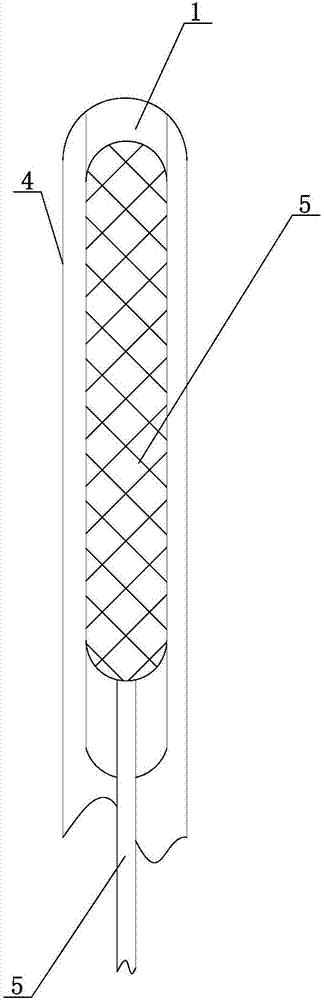

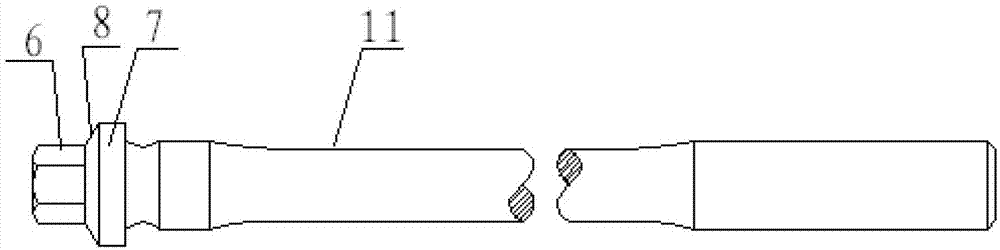

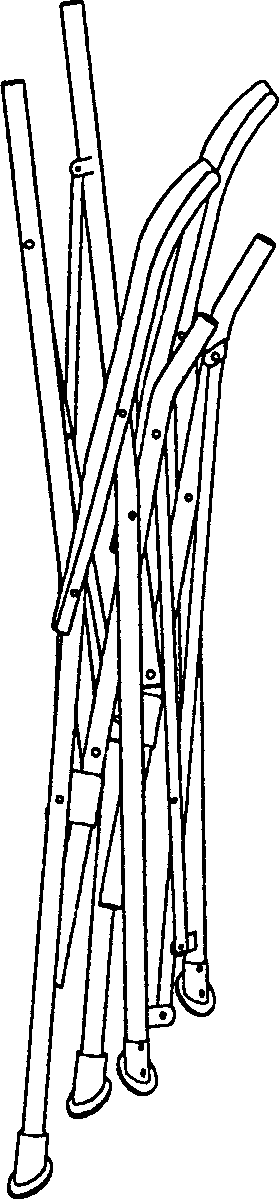

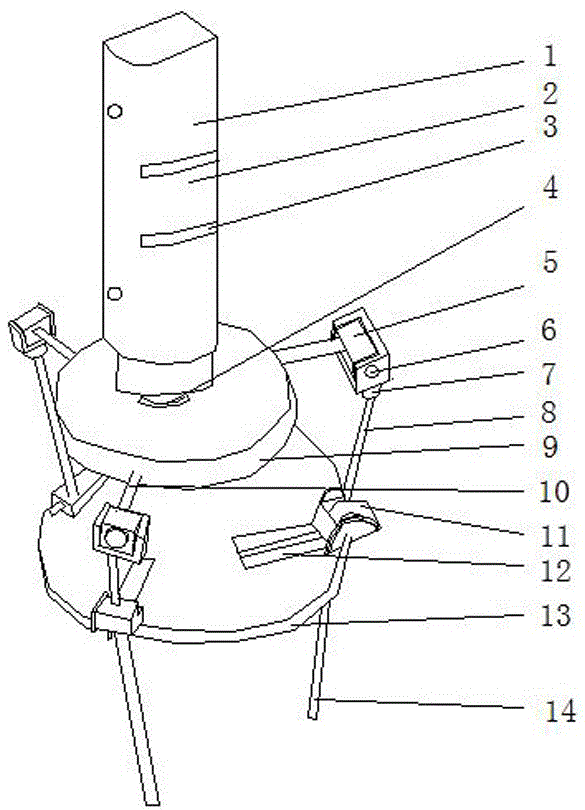

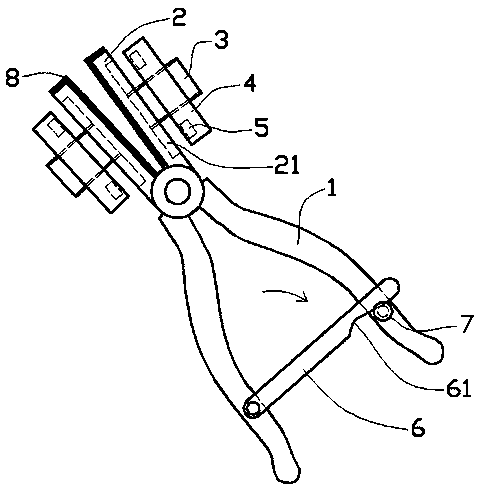

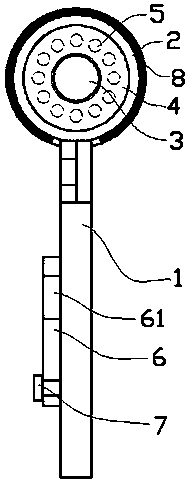

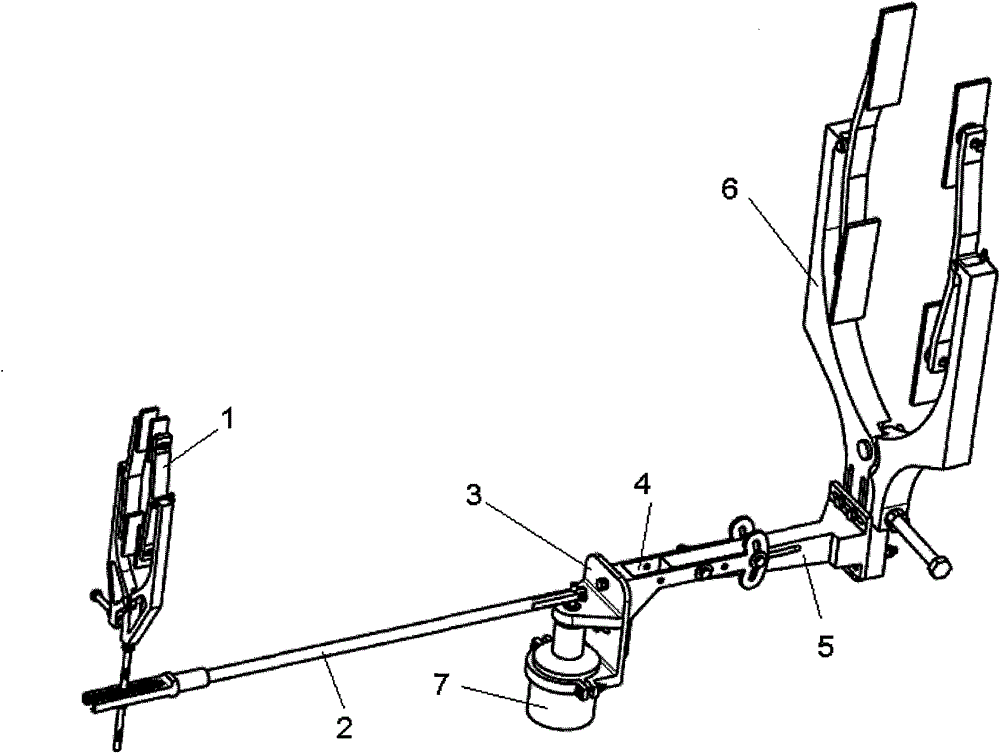

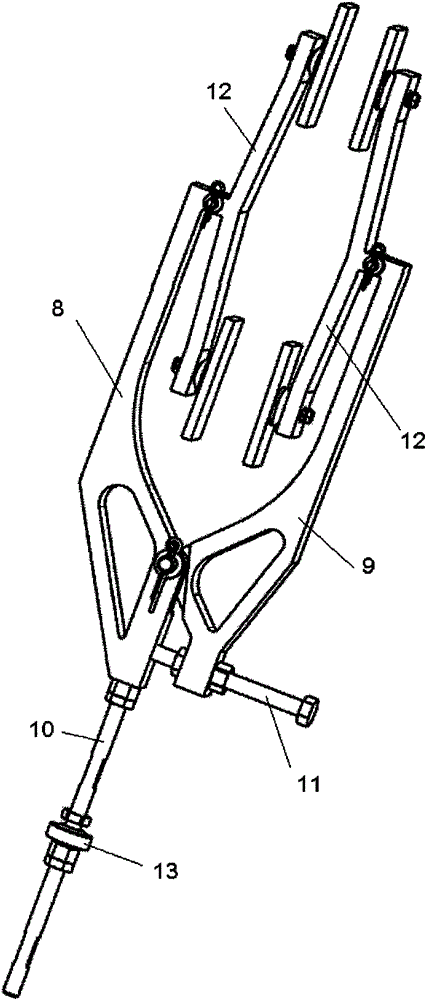

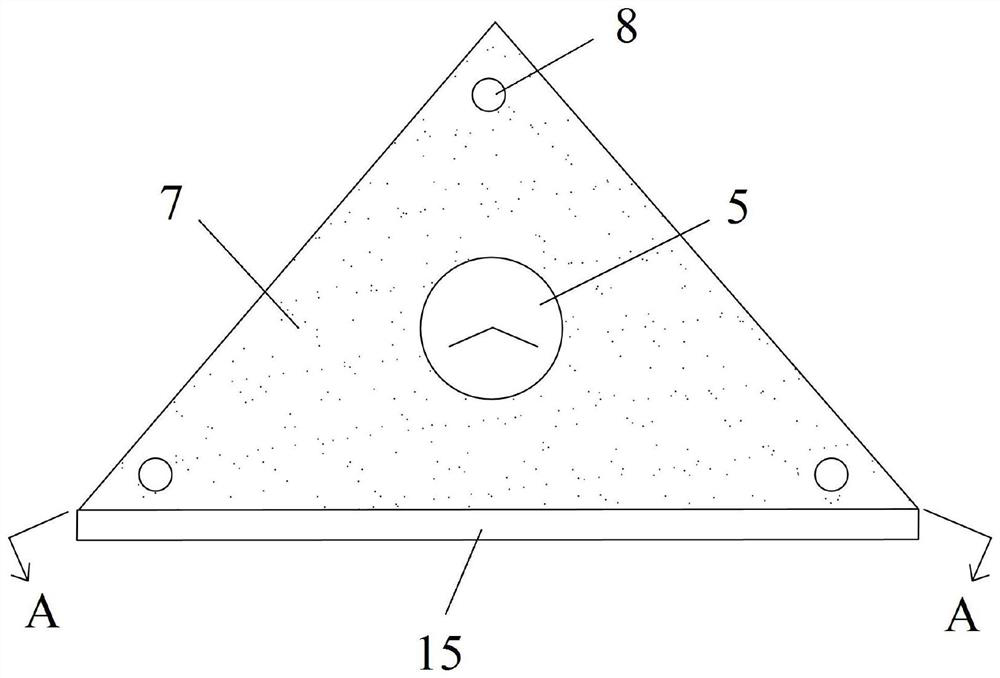

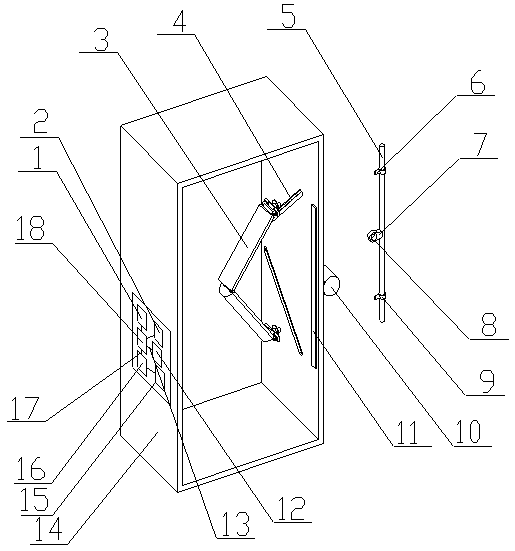

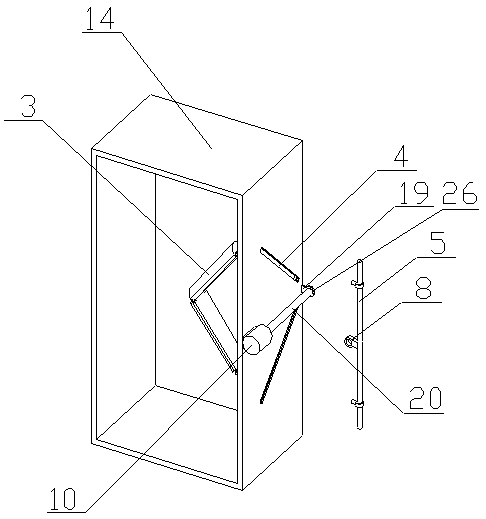

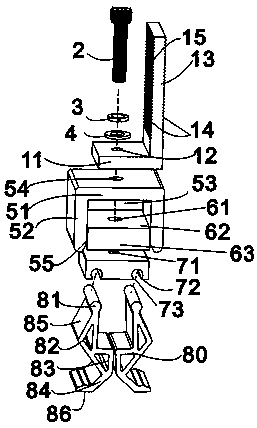

Tool and method for measuring deflection angle of airplane control surface

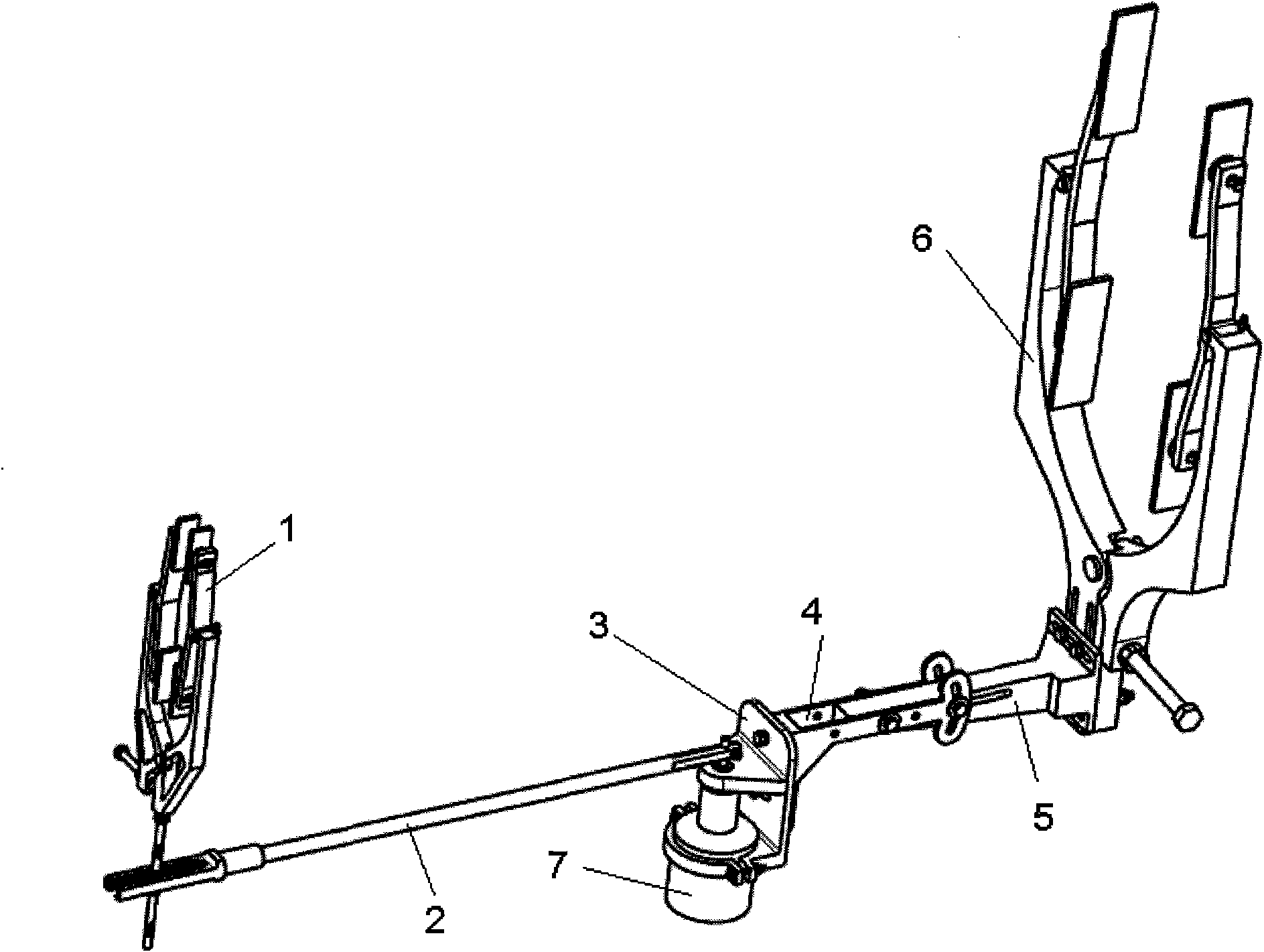

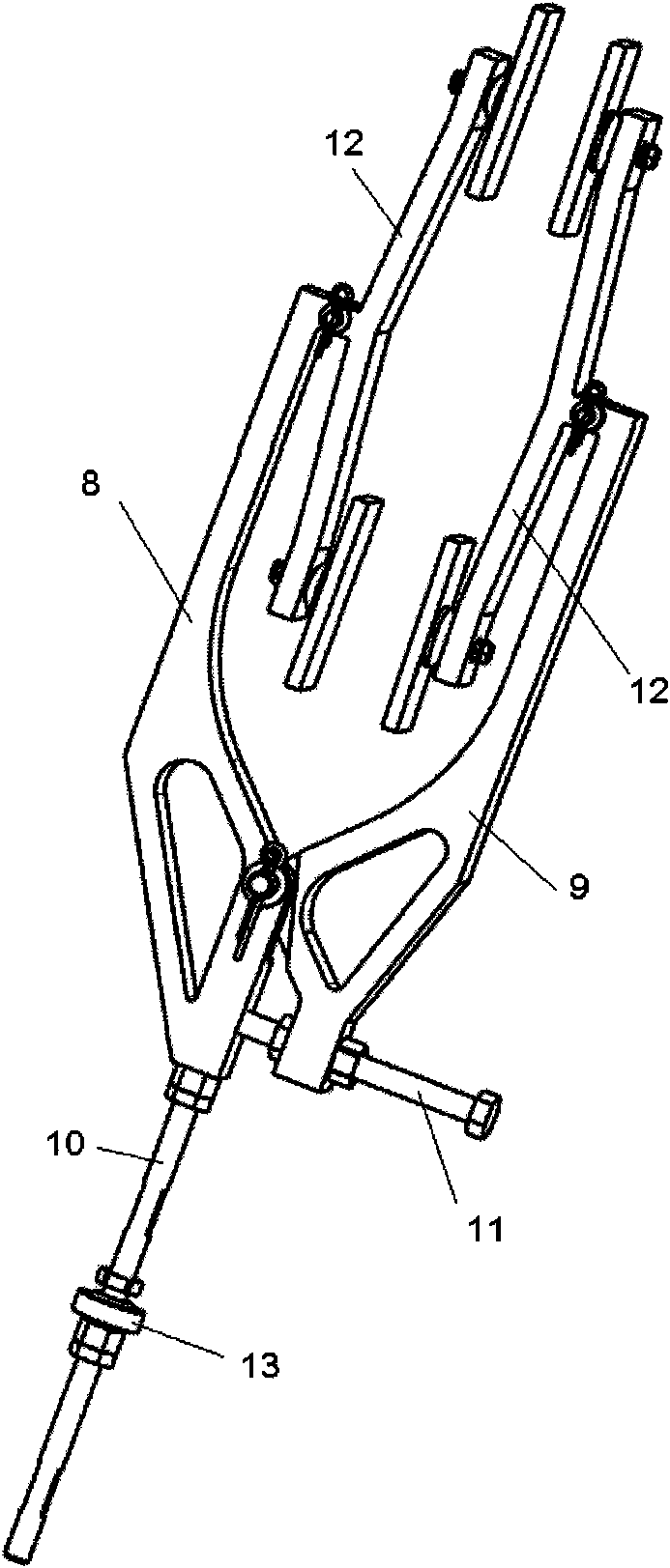

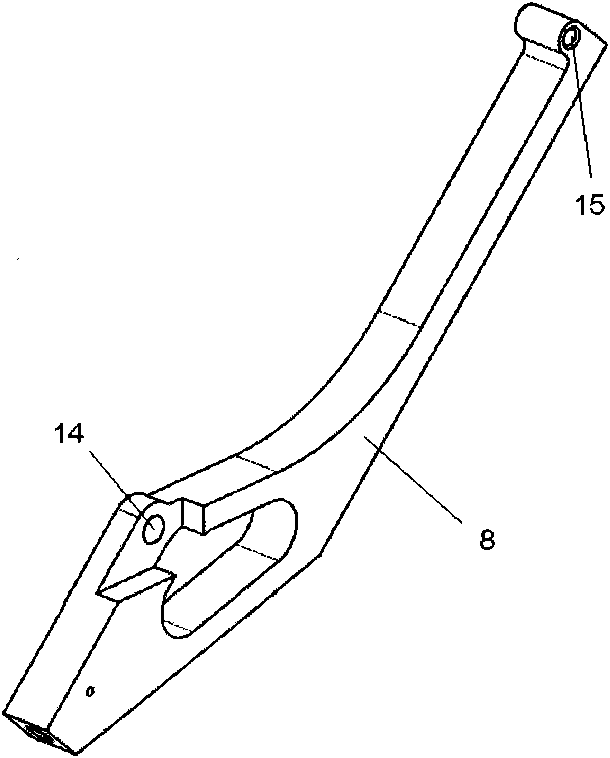

The invention discloses a tool and a method for measuring the deflection angle of an airplane control surface. The measuring tool comprises a control surface clip (1), a stabilizer clip (6), a brace rod (5), a regulating arm (4), a sensor support (3), an angular displacement sensor (7) and a forked rocker arm (2). The measuring process comprises the following steps: clamping the stabilizer clip (6) of the measuring tool to a force-bearing position of a vertical tail stabilizer (45), sequentially mounting the brace rod (5), the regulating arm (4), the sensor support (3), the angular displacement sensor (7) and the forked rocker arm (2) in place, clamping the control surface clip (1) to a force-bearing position of an upper rudder (46), and moving the angular displacement sensor (7) to a rotary shaft of the upper rudder (46) so as to measure the deflection angle of the control surface. The invention can be simultaneously used for measuring the deflection angle of the rudder or the elevator in the bench test or the ground built-in test of an airplane, can be directly used for measuring the deflection angle of the control surface without disassembling structural parts of the airframe, and is especially suitable for the condition that the deflection amount can not be educed for measurement by means of a link mechanism in case that the rotary shaft is arranged inside the envelope of the control surface.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

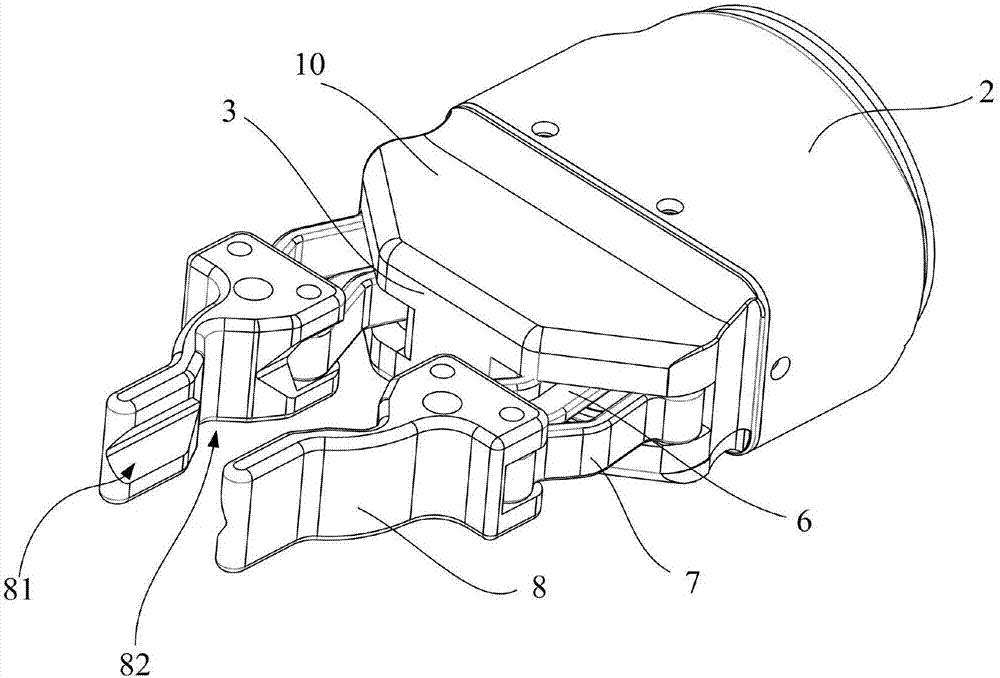

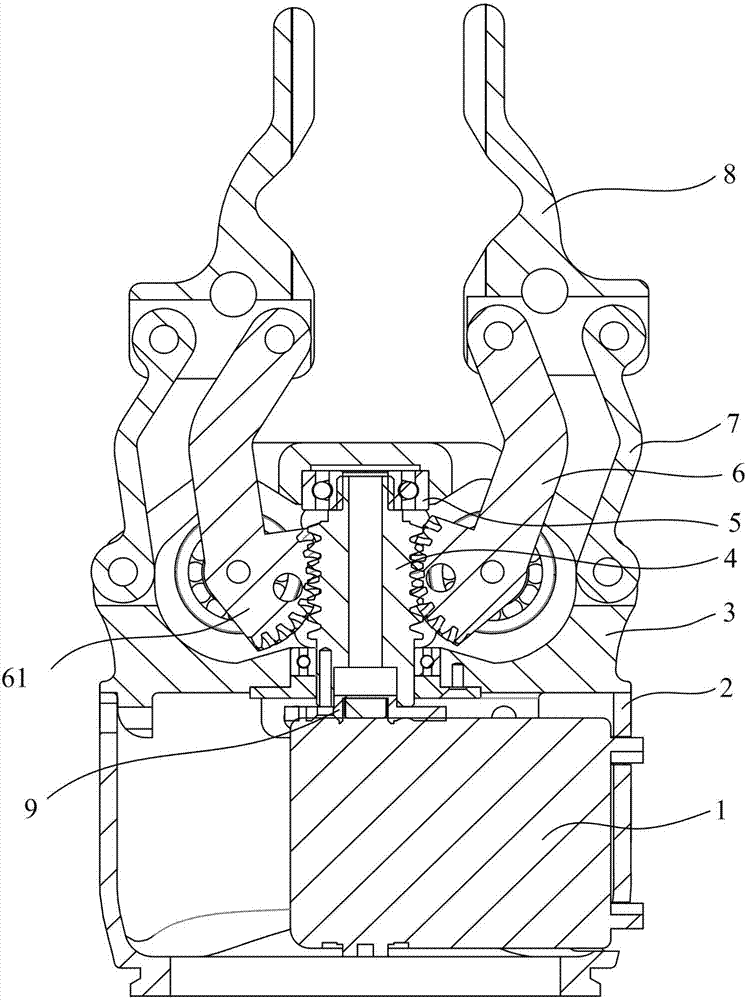

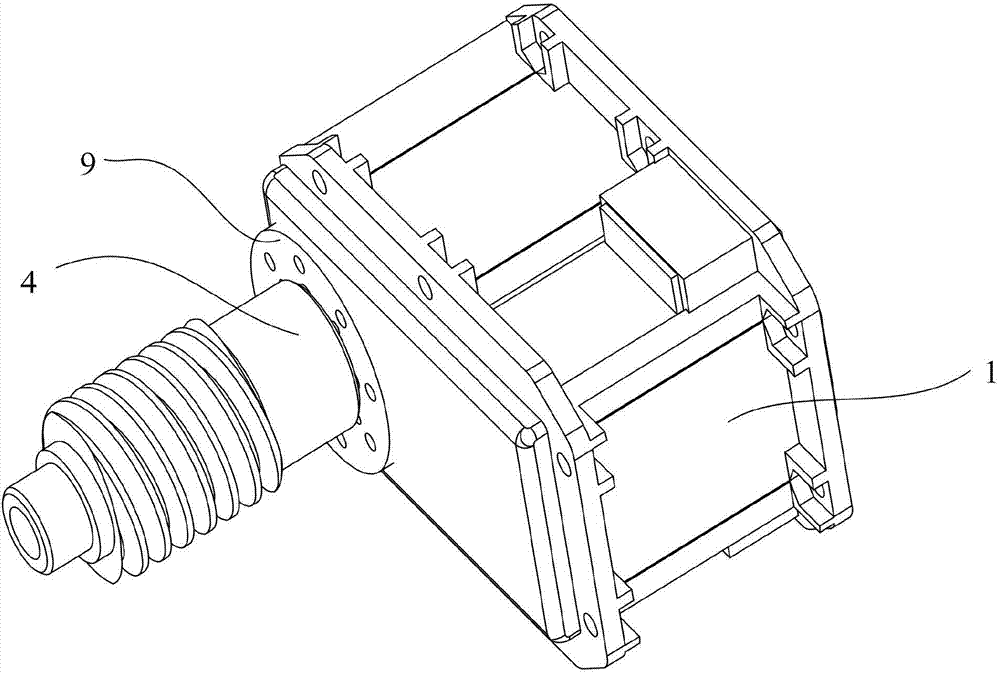

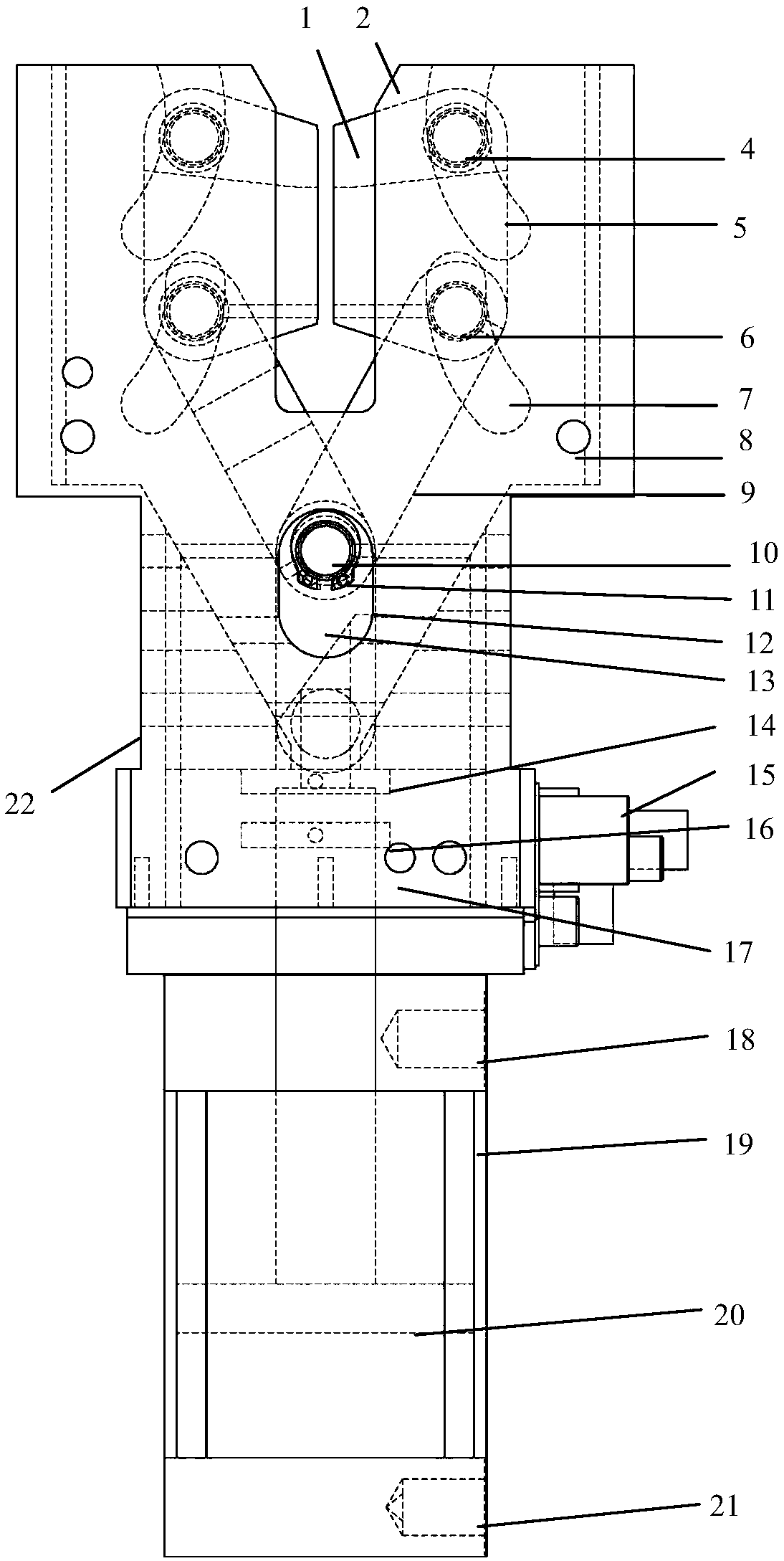

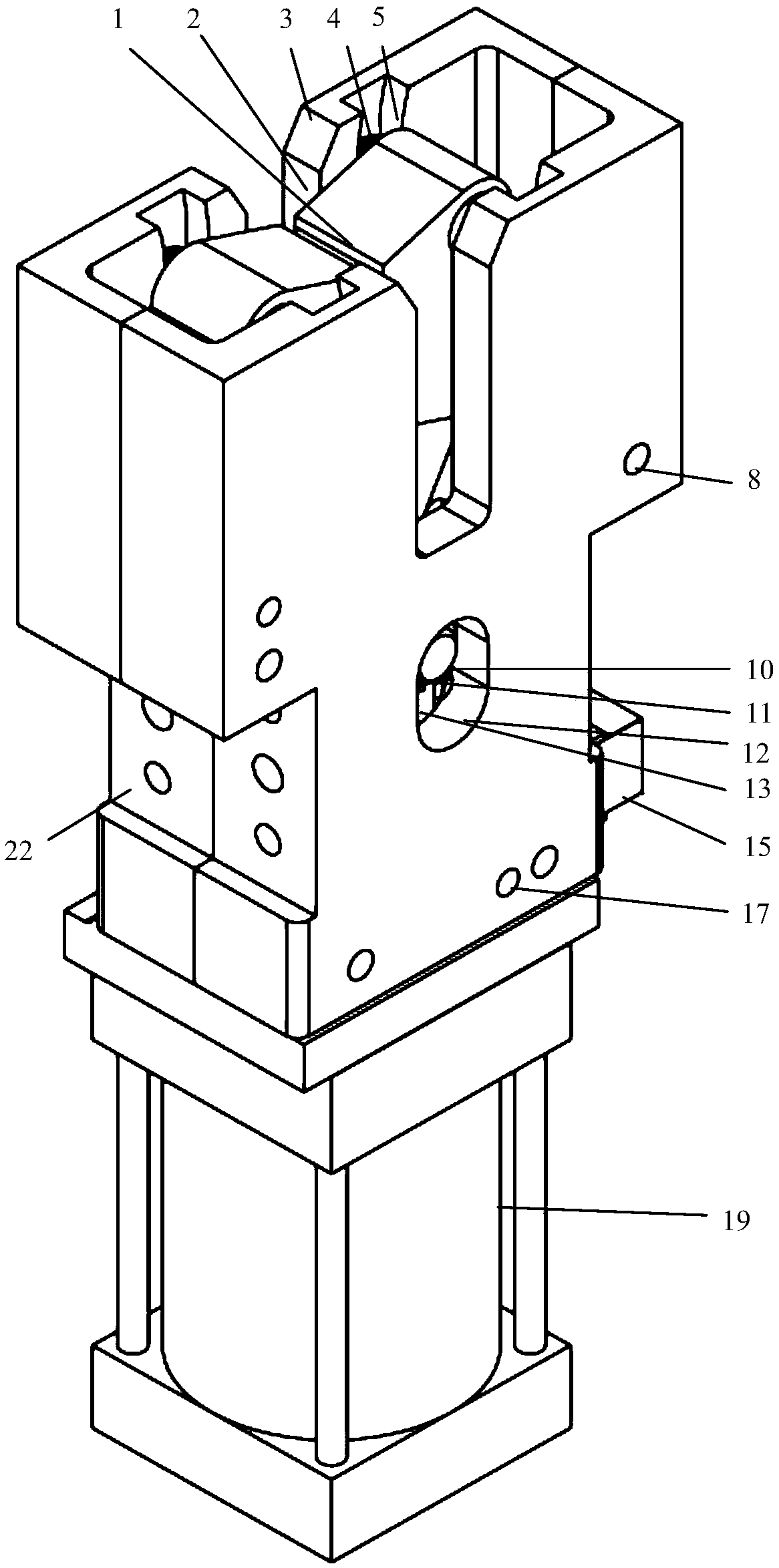

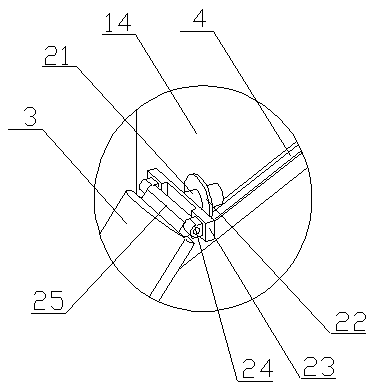

Robot end clamping module driven by steering engine

The invention discloses a robot end clamping module driven by a steering engine. The end clamping module comprises the drive steering engine capable of outputting power outwards. The power output end of the drive steering engine is connected with a steering engine output disc. The other end of the steering engine output disc is connected with one end of a worm arranged in an upper base and drives the worm to rotate forwards or backwards. A pair of drive clamping arms is further hinged into the upper base in a bilateral symmetry mode. The worm is in engaged transmission connection with the drive clamping arms, so that the drive clamping arms swing around the hinge center of the upper base. The clamping ends of the drive clamping arms can be reunited or separated. Compared with the prior art, the robot end clamping module driven by the steering engine has the advantages of being simple in structure, small in size, compact, flexible to operate and the like; control under conditions of various torque, speeds and positions can be achieved by controlling the steering engine motion mode; and a lower base is of a replaceable structure, and can cooperate with ends of different robots for operation quite conveniently, so that a work procedure needing to prevent workpieces from being damaged during clamping is efficiently completed.

Owner:GUANGDONG UNIV OF TECH

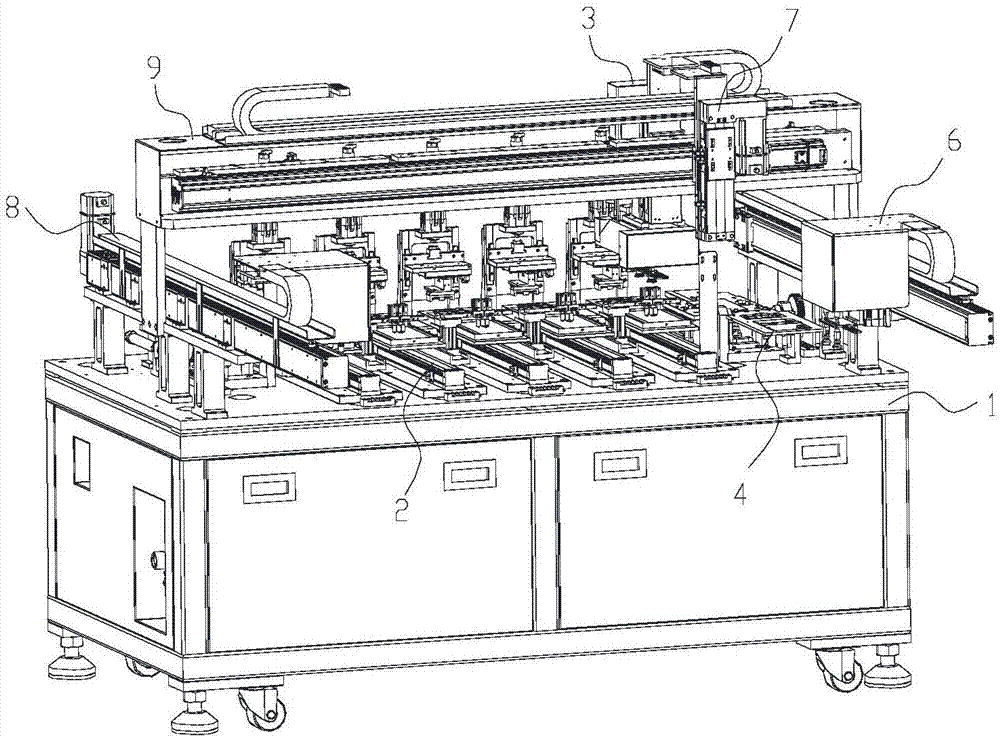

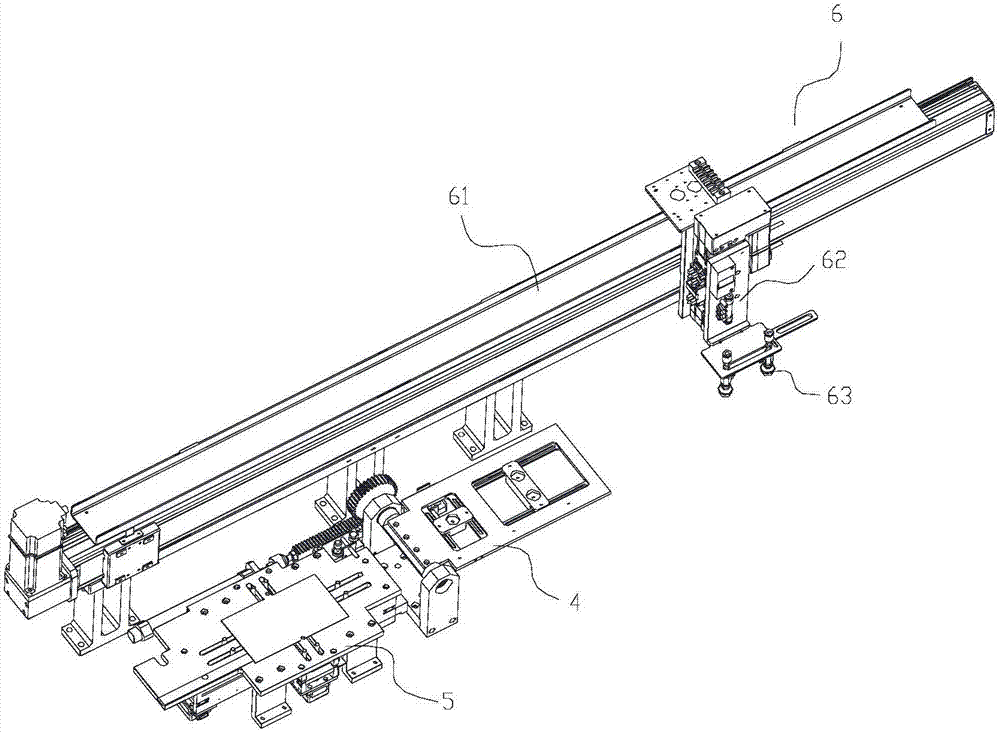

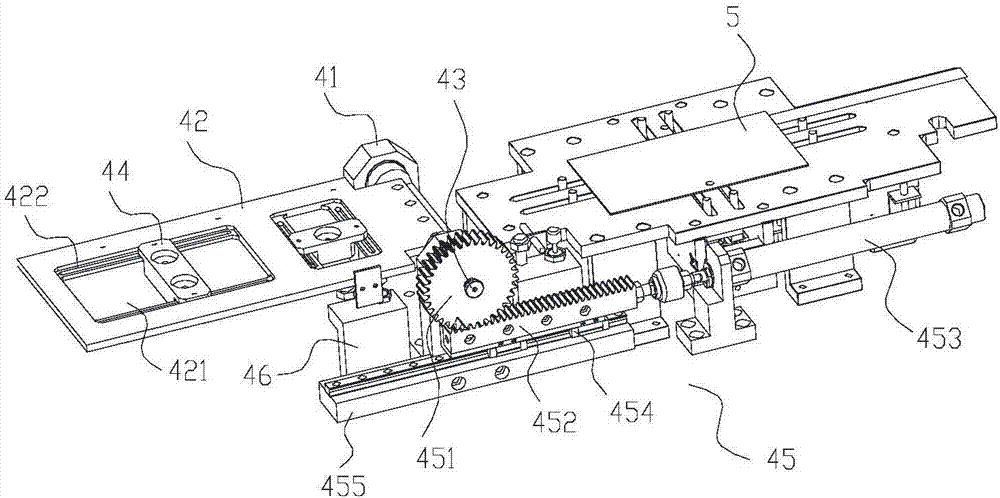

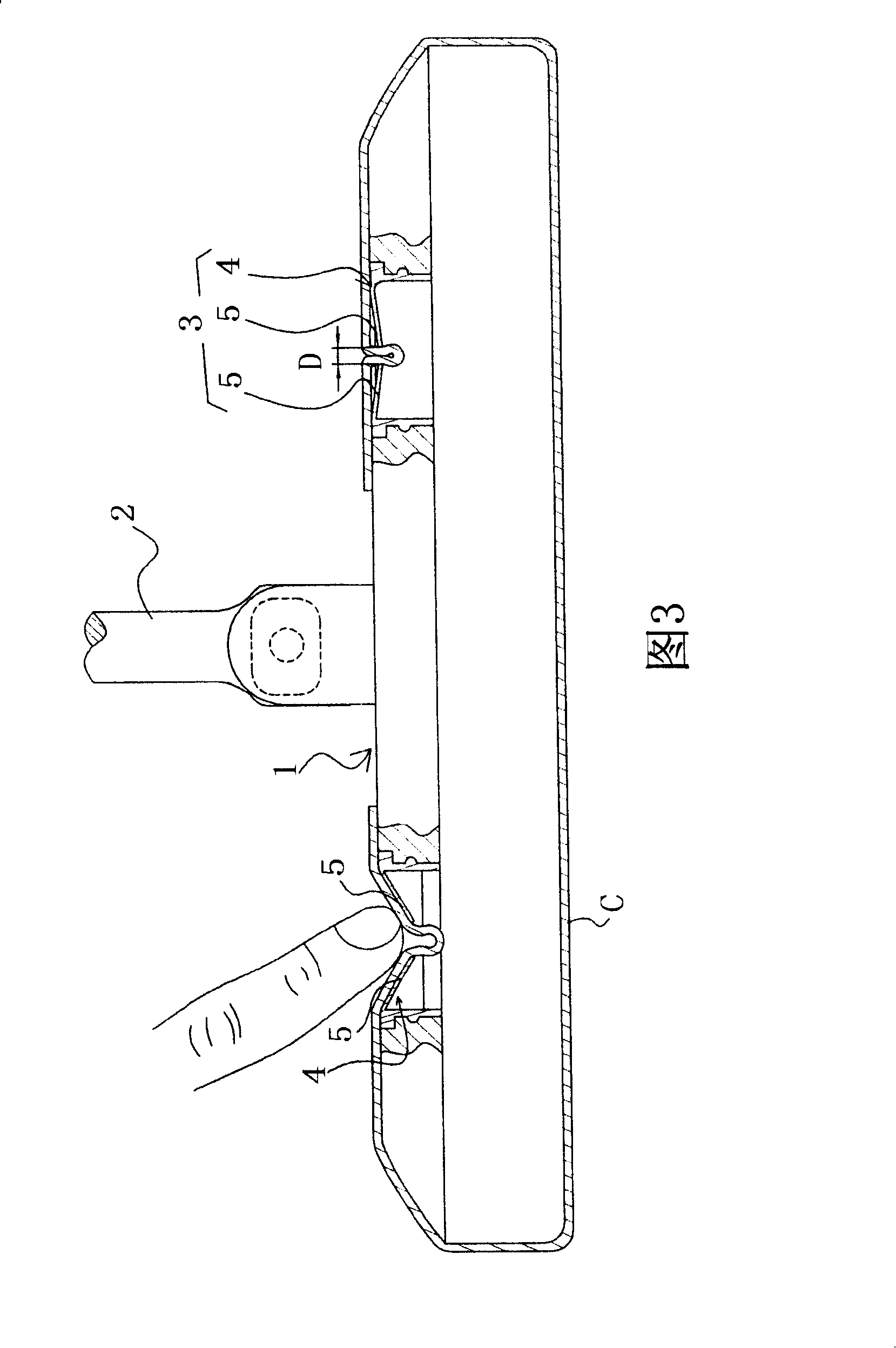

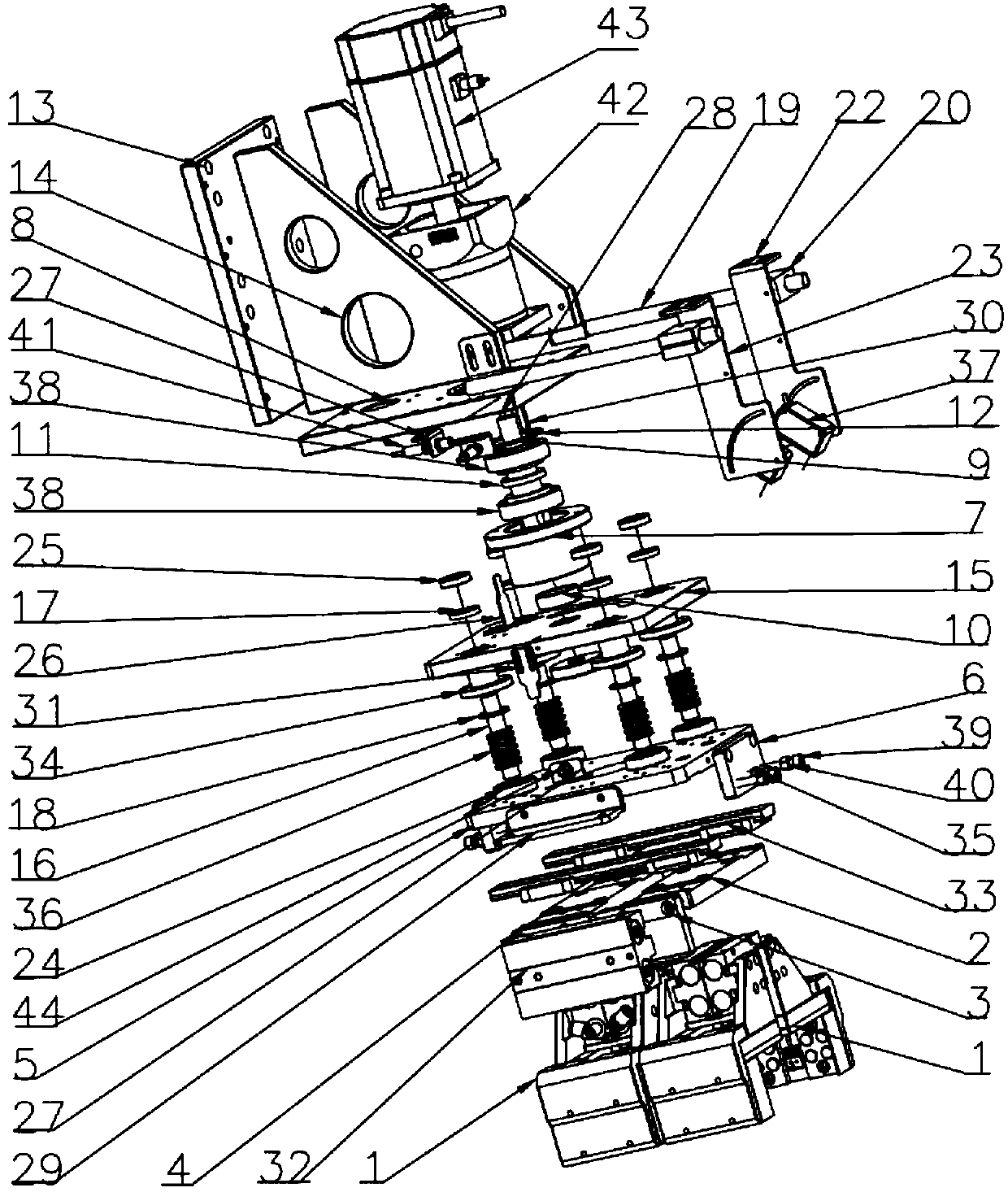

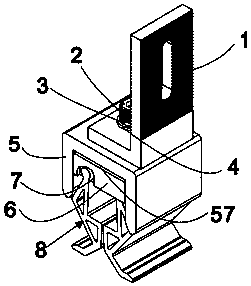

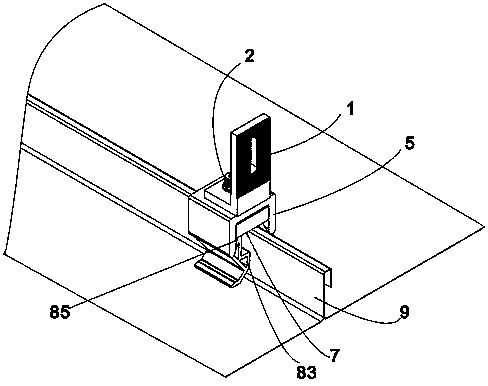

Test device and method for computer function of mobile phone screen connector

The invention discloses a test device and method for the computer function of a mobile phone screen connector. The test device comprises a machine body, a test tool, a positioning mechanism, a transfer mechanism and a discharging mechanism, wherein the test tool, the positioning mechanism, the transfer mechanism and the discharging mechanism are installed on the machine body. The test tool is provided with a detection station. A mobile phone screen connector of a to-be-tested mobile phone screen is subjected to adjustment and angle positioning to a required angle through the positioning mechanism so as to adapt to the detection station position, so that the crimping detection of the mobile phone screen connector is enabled to achieve precise positioning, the detection process is fast, the degree of automation is high, and the detection efficiency is high. The test device is simple and reasonable in structure, the usage is convenient, the space is saved, the application is stable, the cost performance is high, and the accurate positioning is achieved.

Owner:深圳眼千里科技有限公司

Clamping device for plate-shaped workpiece

InactiveCN103753296ANot easy to pinchIncrease contact surfaceWork clamping meansPositioning apparatusEngineeringMechanical engineering

Owner:CHONGQING TIANZHIDAO SCI & TECH DEV

Mop cleaning cloth fixing structure

Owner:杨雅箐

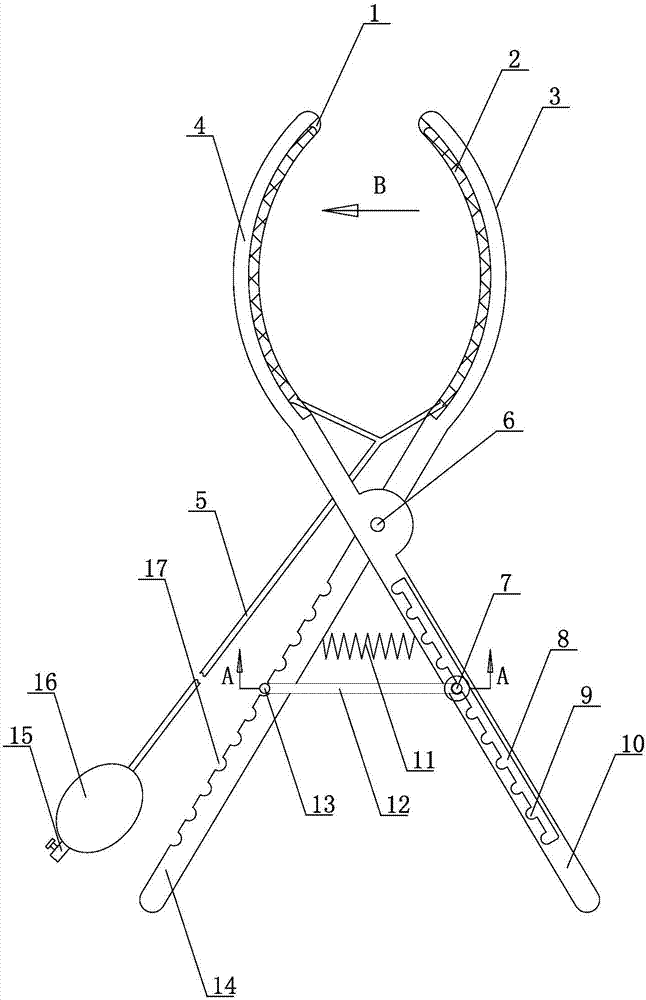

Midwifery forceps for gynecology and obstetrics

InactiveCN107411807AIncrease elasticityImprove buffering effectObstetrical instrumentsObstetric historyForceps

The invention discloses a midwifery forceps for gynecology and obstetrics. The midwifery forceps comprises a first clamp body and a second clamp body, a first clamp handle is fixedly connected with the end of the first clamp body, a second clamp handle is fixedly connected with the end of the second clamp body, the first clamp handle is connected with the second clamp handle in a hinged mode, grooves are formed in the inner walls of the first clamp body and the second clamp body, an inflatable airbag is embedded in each groove, a trachea is connected with the end of the inflatable airbag, an inflatable device is connected with the end of the trachea, a long groove is formed in the first clamp handle, several locating holes are uniformly distributed on the inner side of the long groove, several locking holes are uniformly distributed on the outer side of the second clamp handle, a sliding shaft is inserted in the locating holes, a locking rod is fixed on the top end of the sliding shaft, a locking shaft arranged vertically and downward facing is fixed on the top end of the locking rod, and a locking sleeve which can rotate along the locking shaft is connected with the locking shaft in a sleeving mode. The midwifery forceps for gynecology and obstetrics has the advantages that 1, the structure is simple, 2, the elasticity is good and the angle of the clamp bodies is conveniently locked.

Owner:济南富安机械设计有限公司

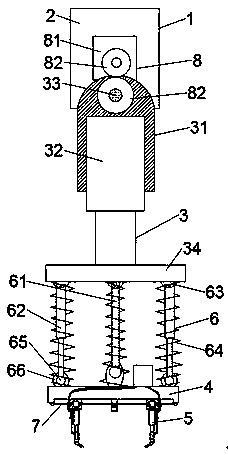

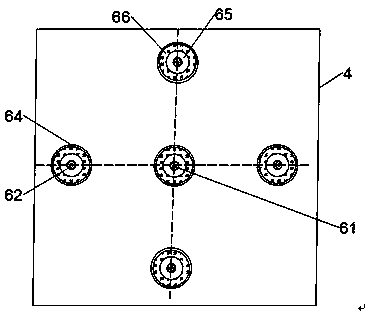

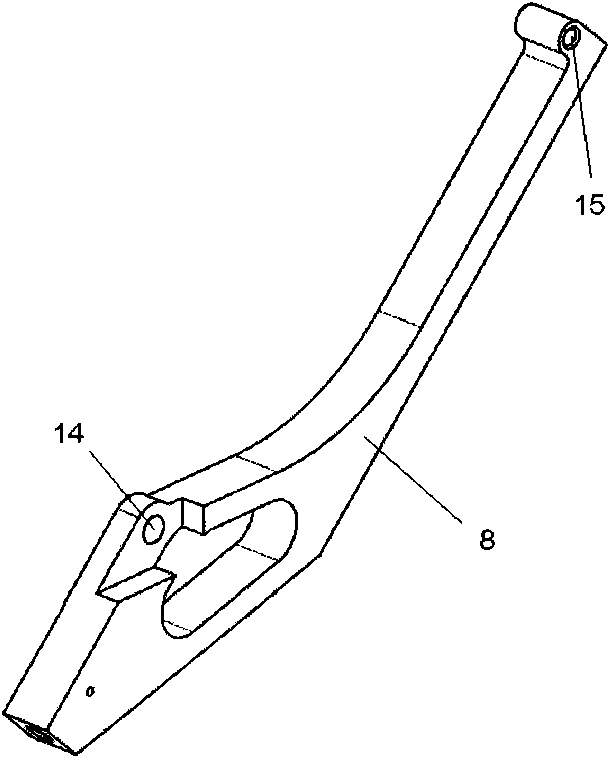

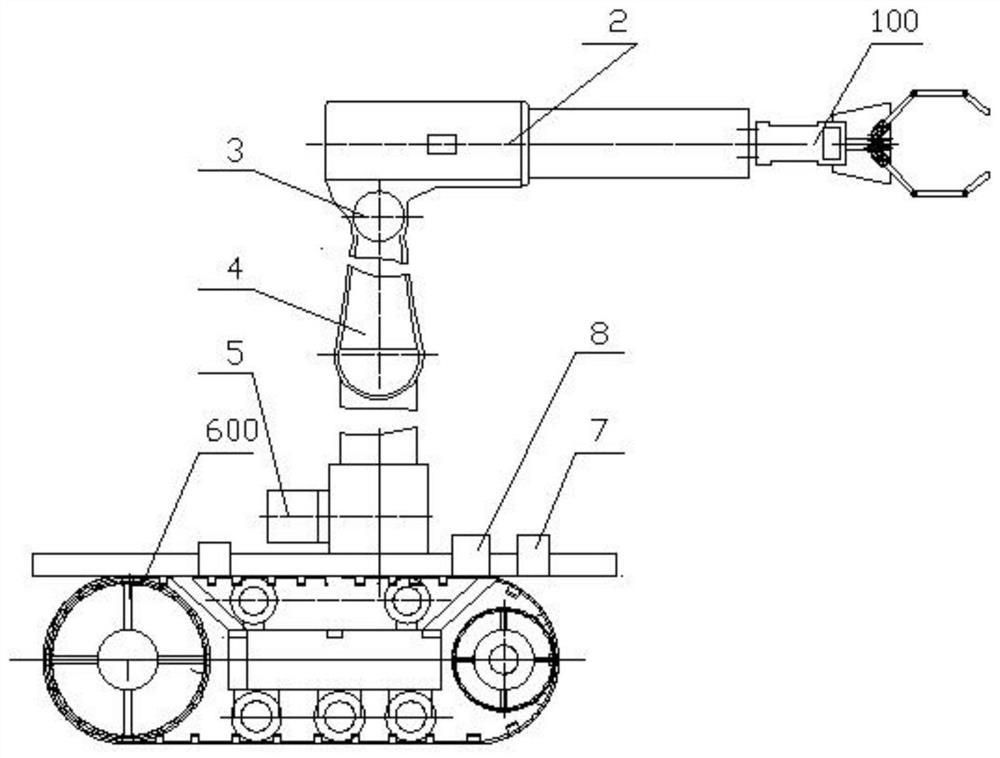

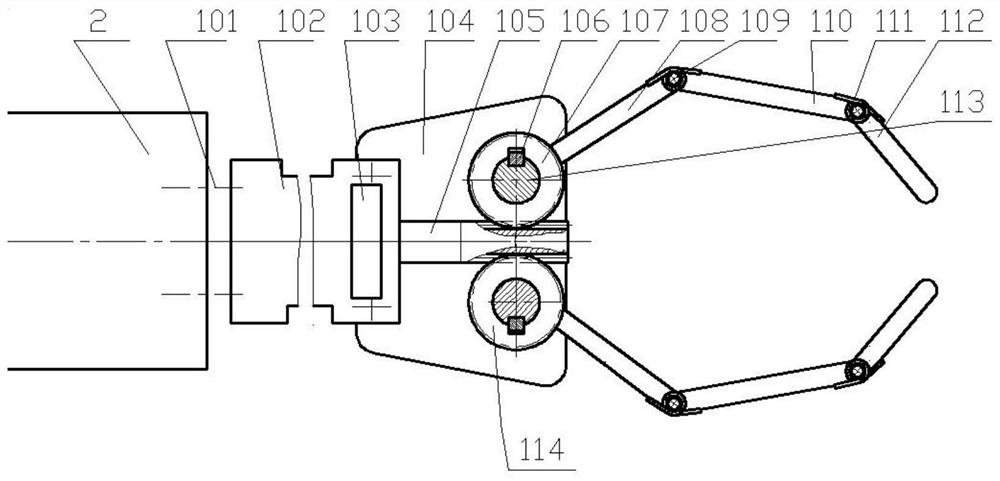

Intelligent material carrying mechanical arm and carrying method

InactiveCN109677905AIncrease the lengthIncrease the efficiency of grabbing materialsConveyor partsEngineeringManipulator

The invention discloses an intelligent material carrying mechanical arm and carrying method. The mechanical arm comprises a mechanical carrying hand, the mechanical carrying hand comprises a first supporting arm, a second extension arm, a mechanical palm and a four-finger grabbing device; the first supporting arm is connected with the second extension arm through a hinge shaft, the second extension arm is connected with the mechanical palm through a palm turning mechanism, and the bottom end of the mechanical palm is connected with the four-finger grabbing mechanism through a four-shaft synchronous driving mechanism. The method comprises the steps that a walking carrying trolley walks to the position nearby the material, the first supporting arm, the second extension arm, the mechanical palm and the four-finger grabbing device are matched, the material is grabbed, the trolley and the mechanical arm cooperate to convey the material to the designated position, the material is loosened, the mechanical arm returns to the grabbing point to continuously grab the material, an extension oil cylinder of the second extension arm can extend, the length of the mechanical arm is prolonged, themechanical grabbing ends can rapidly approach to the material, the material grabbing efficiency and accuracy are high, the structure is simple, the cost is low, the material is not prone to being damaged due to clamping, and the material transport is more stable and reliable.

Owner:盐城汇金科技信息咨询服务有限公司

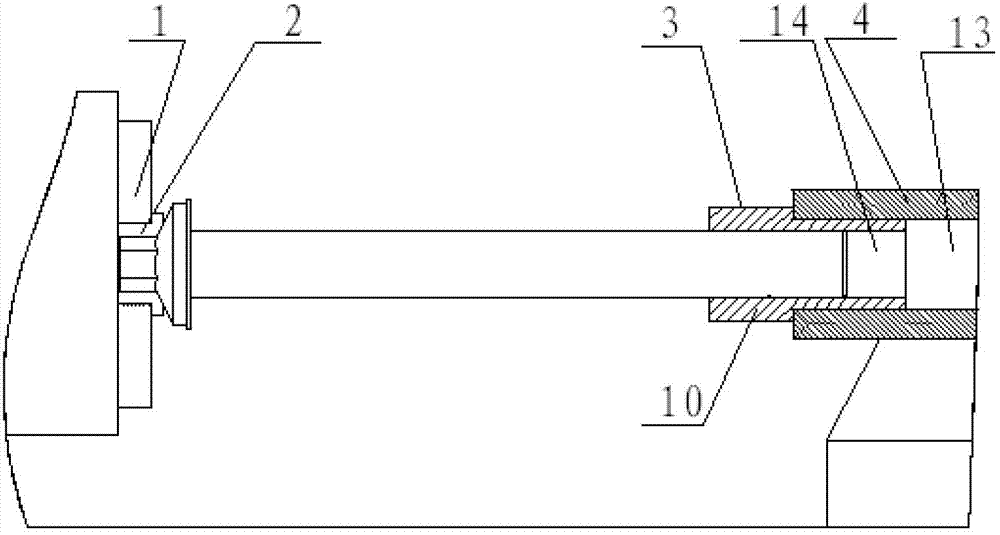

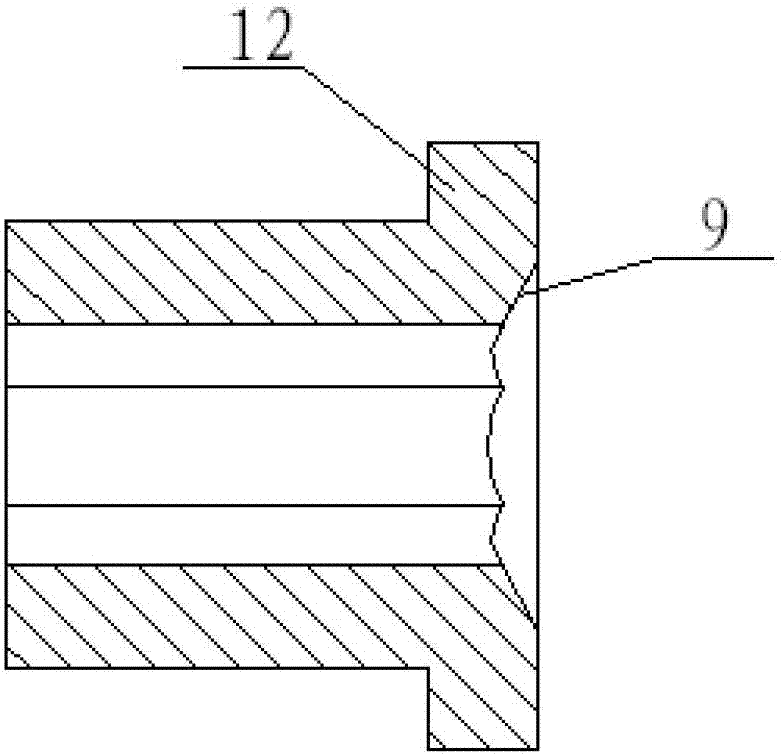

Turning machining method of flange bolt as well as positioning and clamping device for same

InactiveCN102773737ANot easy to pinchIncrease contact areaPositioning apparatusMetal-working holdersPrismTailstock

The invention provides a turning machining method of a flange bolt as well as a positioning and clamping device for the same, and aims at the defects in the prior art that the head part of a bolt is easy to clamp when a bolt bar of a thin and long bolt of a flange disc is machined. The clamping device comprises a clamping disc and inner polygonal sleeve sections on clamping disc claws; when the clamping disc claw is folded, an integral inner polygonal sleeve is formed by the inner polygonal sleeve sections; a free end of the inner polygonal sleeve is provided with an inner chamfer matched with a flange degree surface of the flange bolt; and the inner polygonal sleeve, the inner chamfer and the clamping disc are coaxial with a tailstock liner. The method adopts the device and takes the inner chamfer as a positioning standard of the head part of the bolt; and the method and the device disclosed by the invention are used for machining the flange bolt so that the contact area is enlarged in a clamping process and prism surfaces of a multi-angle flange disc flange are not easy to injure due to clamping.

Owner:浙江中航来宝精工科技有限公司

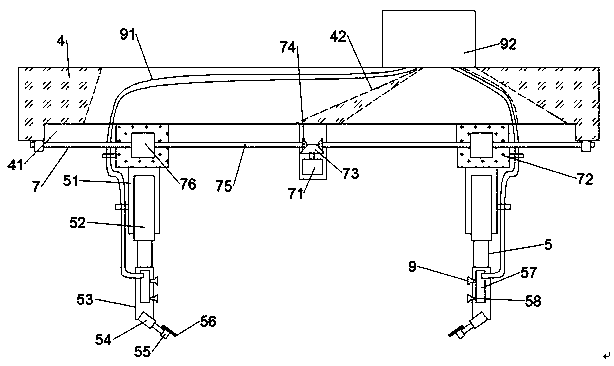

Puncture and aspiration system for thoracic surgery department

The invention discloses a puncture and aspiration system for a thoracic surgery department. The puncture and aspiration system comprises a bed board. Rollers are arranged at the bottom of the bed board. A through hole is formed in the bed board, a lifting electric stretchable rod running through the through hole is arrange below the bed board through a support, a fixing rod is arranged on the lifting electric stretchable rod, an arm supporting plate is arranged on the fixing rod, a sliding groove is formed in the fixing rod, a chest electric stretchable rod sliding up and down is arranged inside the sliding groove, a cushion block for supporting the chest is arranged on the chest electric stretchable rod, and a first electric stretchable rod driving the chest electric stretchable rod to move up and down is arranged below the arm supporting plate. The system can relieve the tired feeling of a patient, and the patient feels comfortable when rested on a base plate.

Owner:郑亚

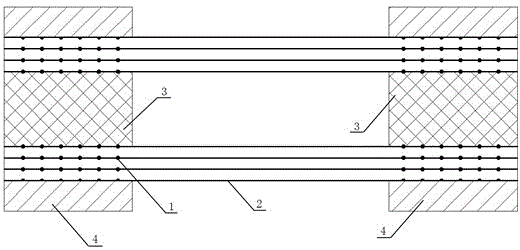

PVC decorative board film laminating and unwinding mechanism

The invention relates to a PVC decorative board film laminating and unwinding mechanism which comprises a bottom plate, a first bearing pedestal and a second bearing pedestal; the first bearing pedestal is fixedly arranged on the bottom plate; the second bearing pedestal is arranged on the bottom plate and can move along the bottom plate to be close to or far from the first bearing pedestal; shortshafts are rotationally arranged in the first bearing pedestal and the second bearing pedestal in a penetrating manner correspondingly; threads are formed in the peripheries of one ends, close to each other, of the two short shafts correspondingly; the peripheries of the ends, close to each other, of the two short shafts are connected with adjusting nuts correspondingly and are sleeved with elastic clamping plugs correspondingly; the elastic clamping plugs are located on one sides, which are close to each other, of the two adjusting nuts; a film roll is coaxially arranged between the two short shafts; and under the action of external force, the adjusting nuts are tightened, and the adjusting nuts can axially push the corresponding elastic clamping plugs to stretch into and elastically abut against hole locations of the corresponding ends of the film roll. The PVC decorative board film laminating and unwinding mechanism has the advantages that the PVC decorative board film laminating and unwinding mechanism is simple in structure and convenient in use and operation, rapid disassembly, assembly and replacement of the film roll is facilitated, the film roll is located accurately andthe clamping is relatively stable.

Owner:湖北银座新材料股份有限公司

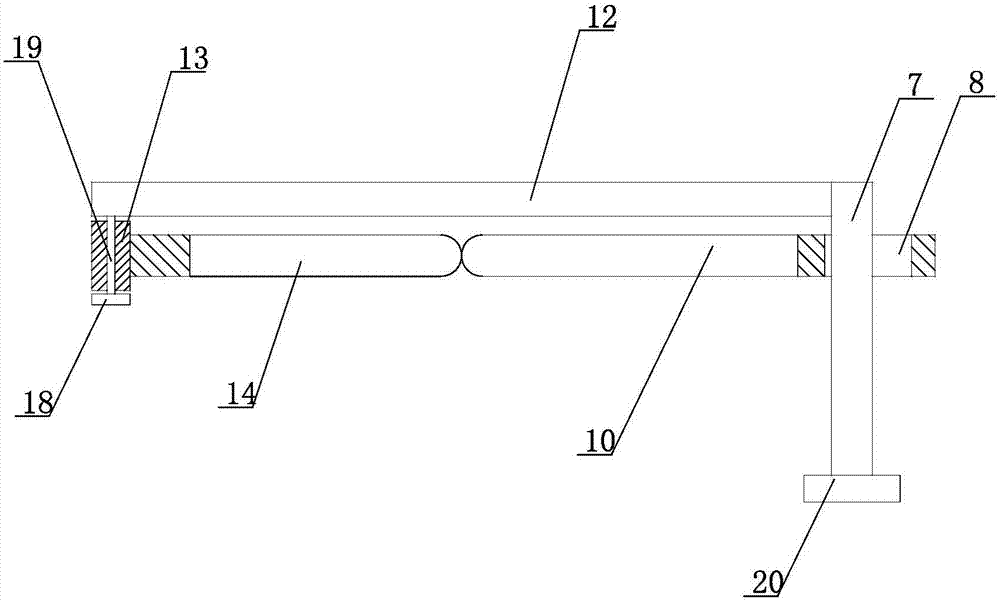

Biaxial tension-shear test part with matrix fiber bundle and preparation method thereof

ActiveCN104913969ANot easy to pinchCrush won'tPreparing sample for investigationStrength propertiesInterference fitFiber bundle

The invention discloses a biaxial tension-shear test part with a matrix fiber bundle. The biaxial tension-shear test part comprises a circular pipe sample and is characterized in that the circular pipe sample comprises a fiber cloth deposited matrix, the middle of the circular pipe sample is a test part, two ends of the circular pipe sample are fixing parts, a fiber cloth located at the test part of the circular pipe sample is a fiber structure which only contains warp yarn and does not contain weft yarn, conquassation-resistant plugs are in an interference fit relationship with the interiors of pipe cavities of the fixing parts of the circular pipe sample, and torque creep-resistant sleeves fixedly sleeve the peripheral surfaces of the fixing parts of the circular pipe sample. The biaxial tension-shear test part has the advantages of simple preparation processes, low experiment cost, good test part quality and difficult slipping.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

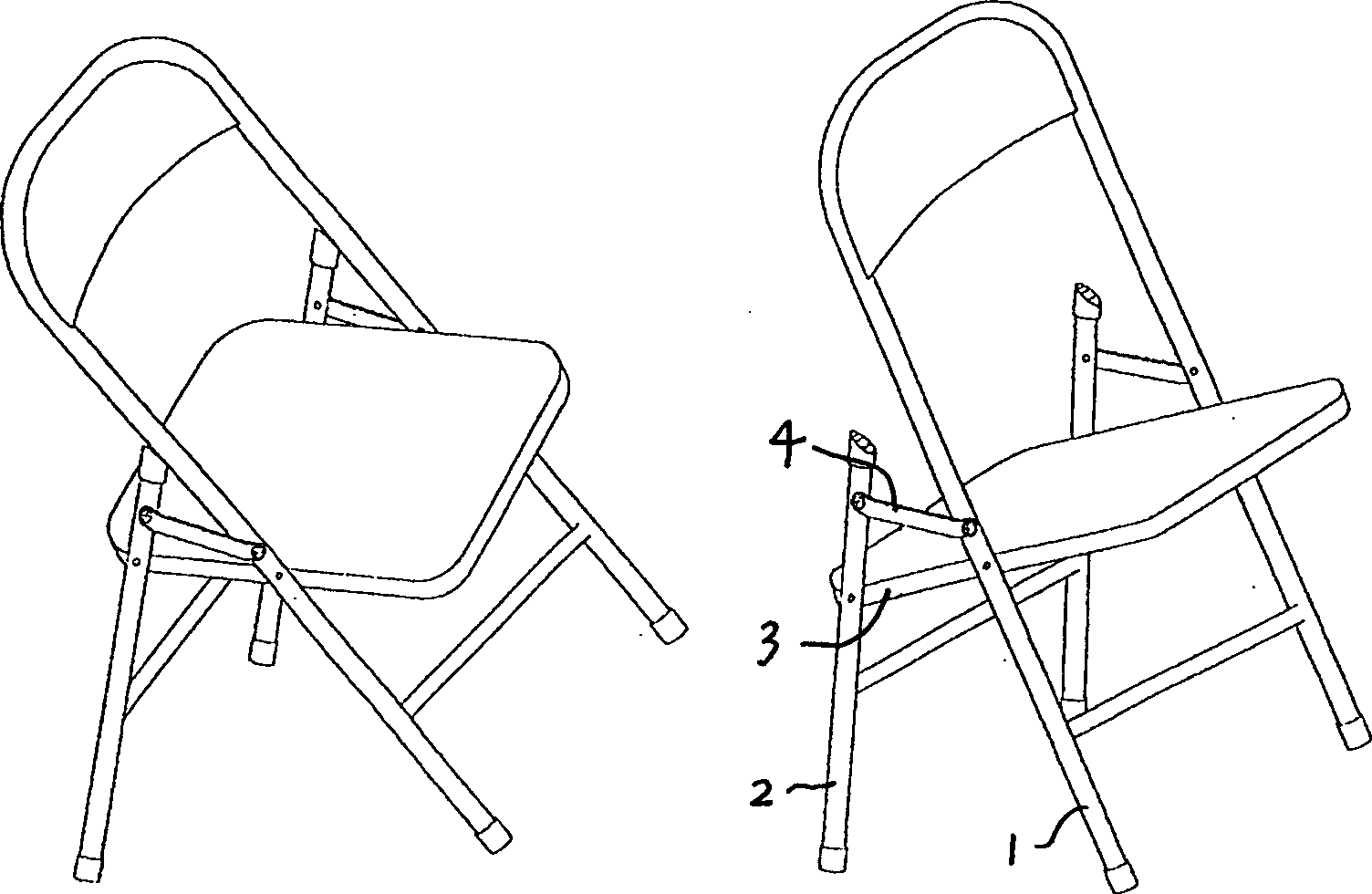

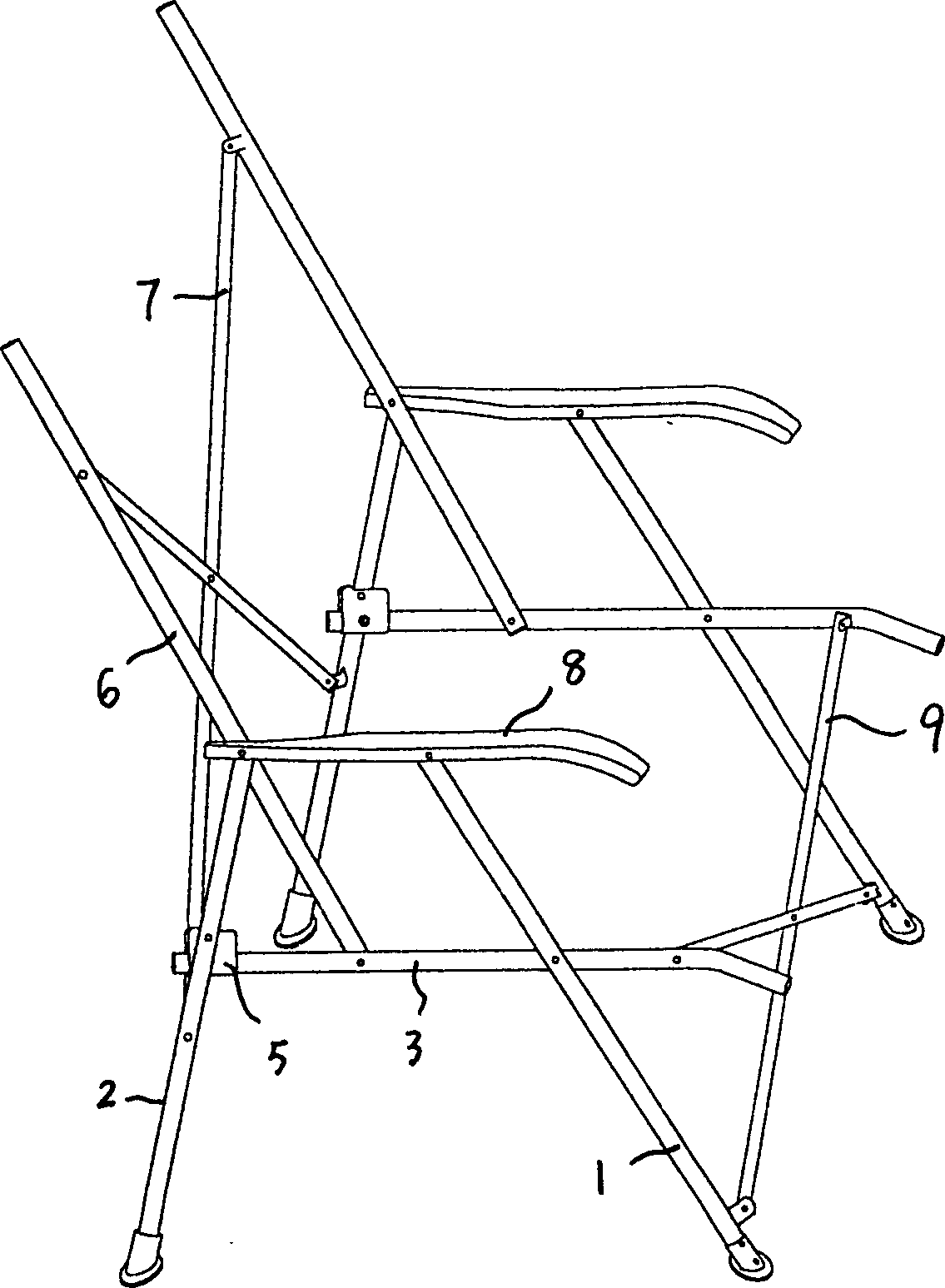

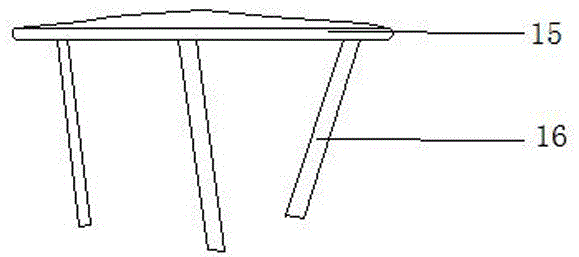

Foldable chair support

InactiveCN1500425ANot easy to pinchStabilized stateDismountable chairsFoldable chairsEngineeringSupport plane

Owner:邓鉴荣

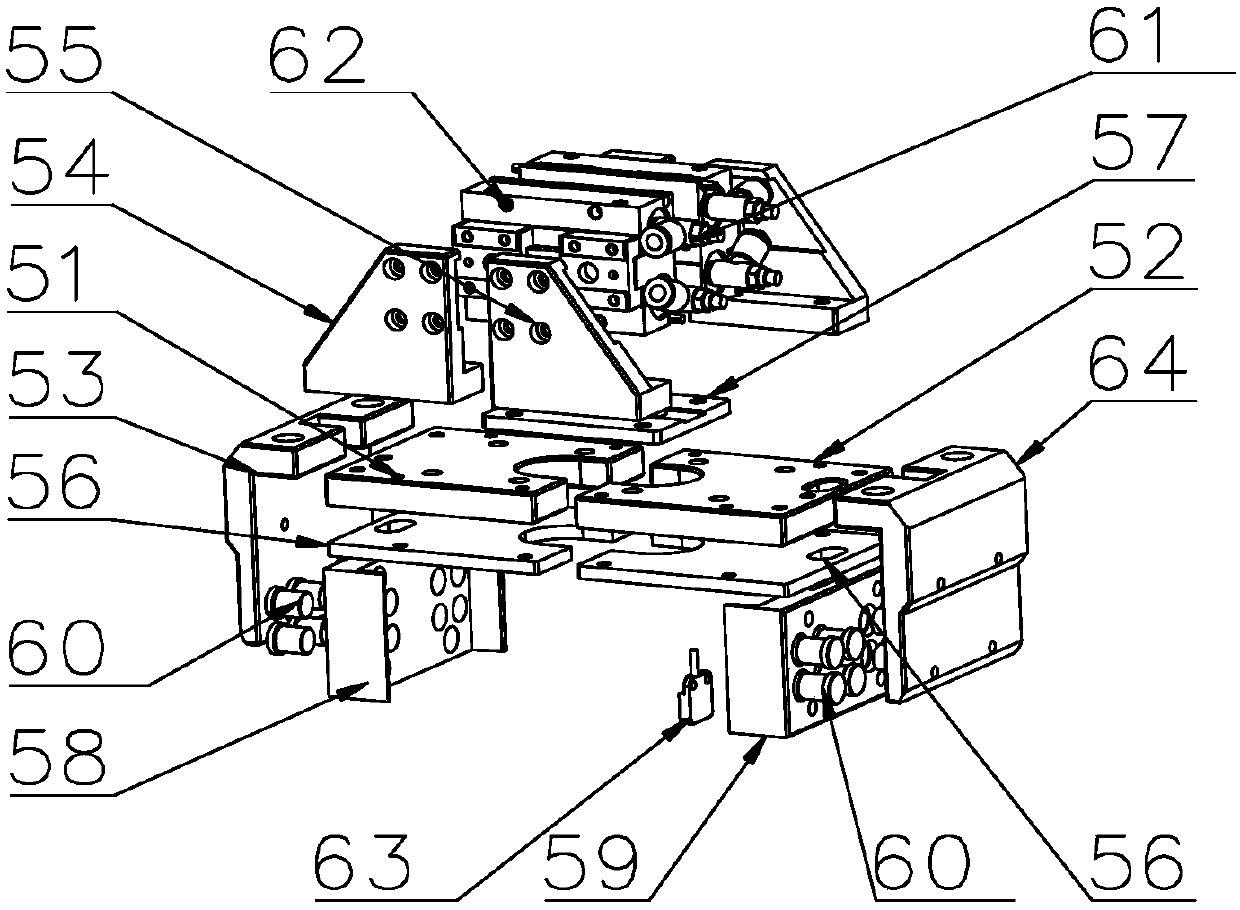

Mechanical arm of double gripper structure and control method of mechanical arm

PendingCN107738248AFulfil requirementsCompact structureProgramme-controlled manipulatorGripping headsManipulatorPneumatic gripper

The invention discloses a mechanical arm of a double gripper structure and a control method of the mechanical arm. The mechanical arm of the double gripper structure comprises a fixing mechanism, a rotating mechanism and a double pneumatic gripper structure. The fixing mechanism is used for fixing a mechanical arm body to a machine; the rotating mechanism is connected with the fixing mechanism andthe double pneumatic gripper structure; and the double pneumatic gripper structure is provided with two pneumatically-controlled pneumatic grippers. The mechanical arm of the double gripper structureand the control method of the mechanical arm are easy to implement, and efficiency of battery gripping can be remarkably improved.

Owner:深圳市精实机电科技有限公司

Plate shearing sliding groove type robot griper

ActiveCN108788291AReduce in quantityAchieve clampingGripping headsShearing machinesEngineeringMechanical engineering

The invention relates to a plate shearing sliding groove type robot gripper. The gripper comprises a shell, a sliding groove type clamping module, a position induction module and a driving module. Thesliding groove type clamping module and the position induction module are arranged in the shell. The lower end of the shell is connected with the driving module. The upper end of the shell is of a symmetrical clamping structure and is provided with arc-shaped sliding grooves and a middle sliding groove. The sliding groove type clamping module is connected with the shell through the sliding grooves. Compared with the prior art, the sliding groove type clamping module adopts the clamping structure comprising a sliding block, connecting rods and the sliding grooves; a cylinder drives the connecting rods through the sliding block to enable clamping fingers to move along the sliding grooves of the shell to implement clamping or loosening. The plate shearing sliding groove type robot gripper has the characteristics of having the automatic centering and positioning, power-enhanced clamping, parallel clamping, parallel loosening, bi-directional symmetrical clamping capabilities, is particularly suitable for the working conditions that an industrial robot grabs plates and the like and meets the requirements for flexible plate shearing production of the robot.

Owner:SHANGHAI LEADERSOFT INFORMATION TECH CO LTD

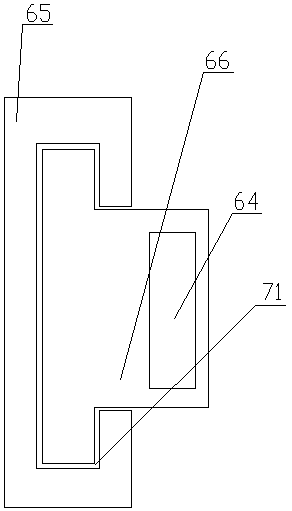

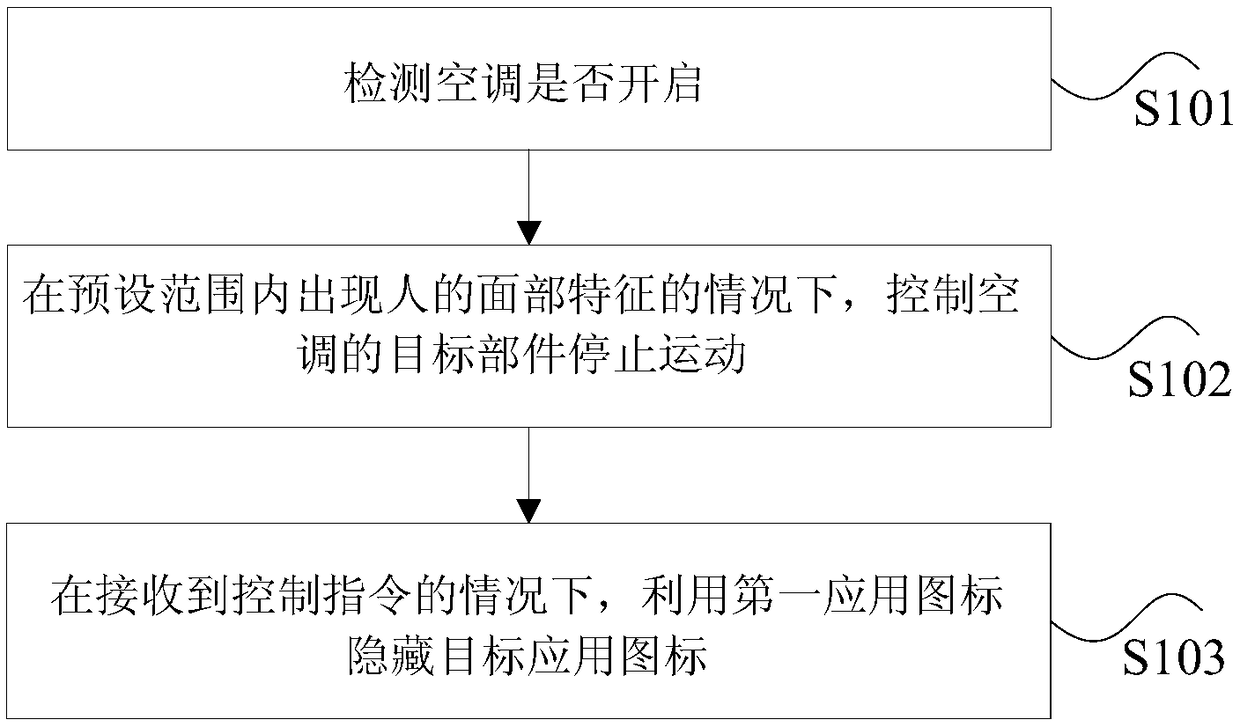

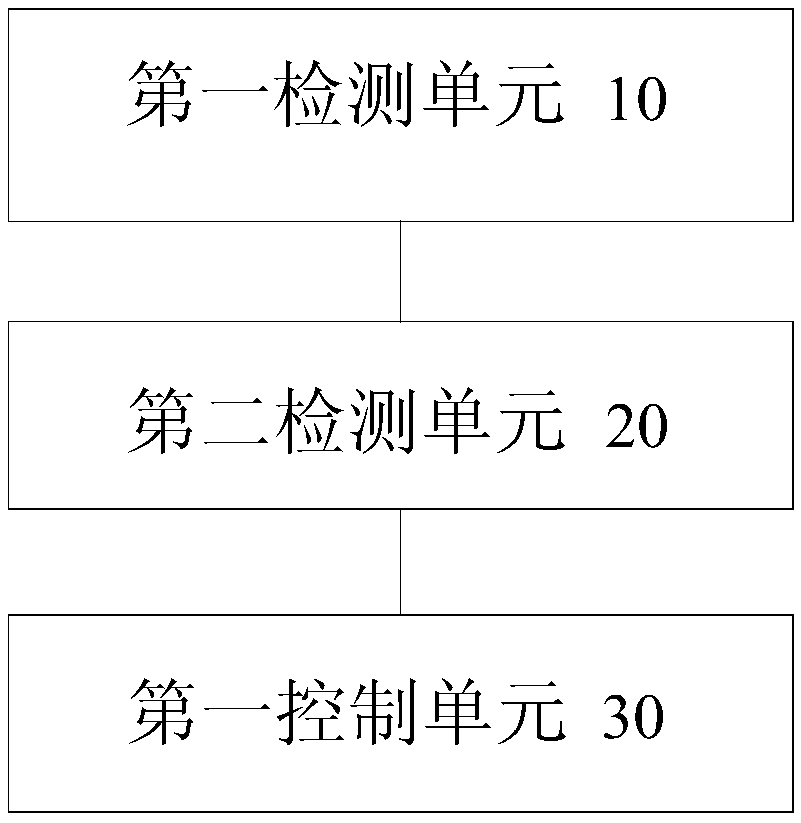

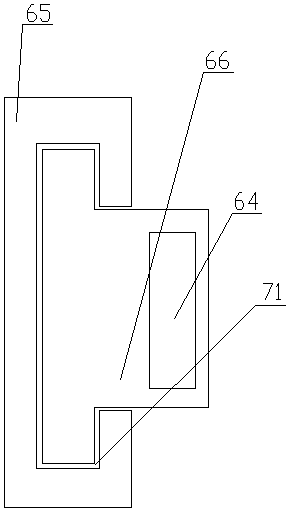

Method and device for control over air conditioner

InactiveCN108895626ASolve the problem of being easily pinched by the moving parts of the air conditionerEasy to be pinched by the moving parts of the air conditionerMechanical apparatusLighting and heating apparatusEngineering

Owner:GREE ELECTRIC APPLIANCES INC

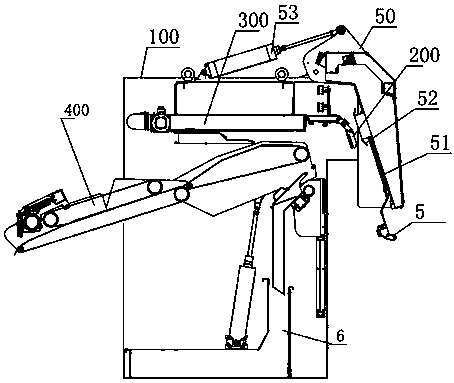

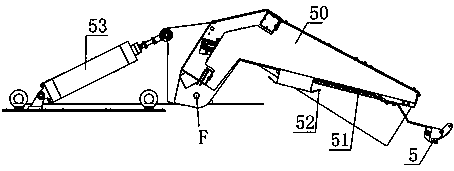

Transplanter end executor

InactiveCN106068843AProtection against falling etc.Promote circulationTransplantingSurface mountingArchitectural engineering

The invention discloses a transplanter end executor which comprises an executor body, a movable disc and a transplanting fixing pointer disc. An air tank is mounted right above the executor body, an air tank locking nut is arranged in the middle of the executor body, the movable disc is mounted in the middle of the executor body, sliders are arranged around the executor body, a scaling device is mounted below the executor body, a fixed disc is mounted right below the executor body, a fixed disc connecting rod is mounted in the middle of the executor body, a pin is mounted on the surface of each slider, and movable transplanting pointers are arranged around the lower surface of the transplanting fixing pointer disc. A groove is formed in the air tank, so that surface friction force of the air tank is increased, and air circulation is improved; the air tank locking nut is mounted below the air tank to fix the same, so that the circumstance that the air tank falls down in the process of construction due to serious vibration is prevented; the movable disc is mounted below the executor body, so that convenience is brought to pointer moving.

Owner:安徽富牧通生物科技有限公司

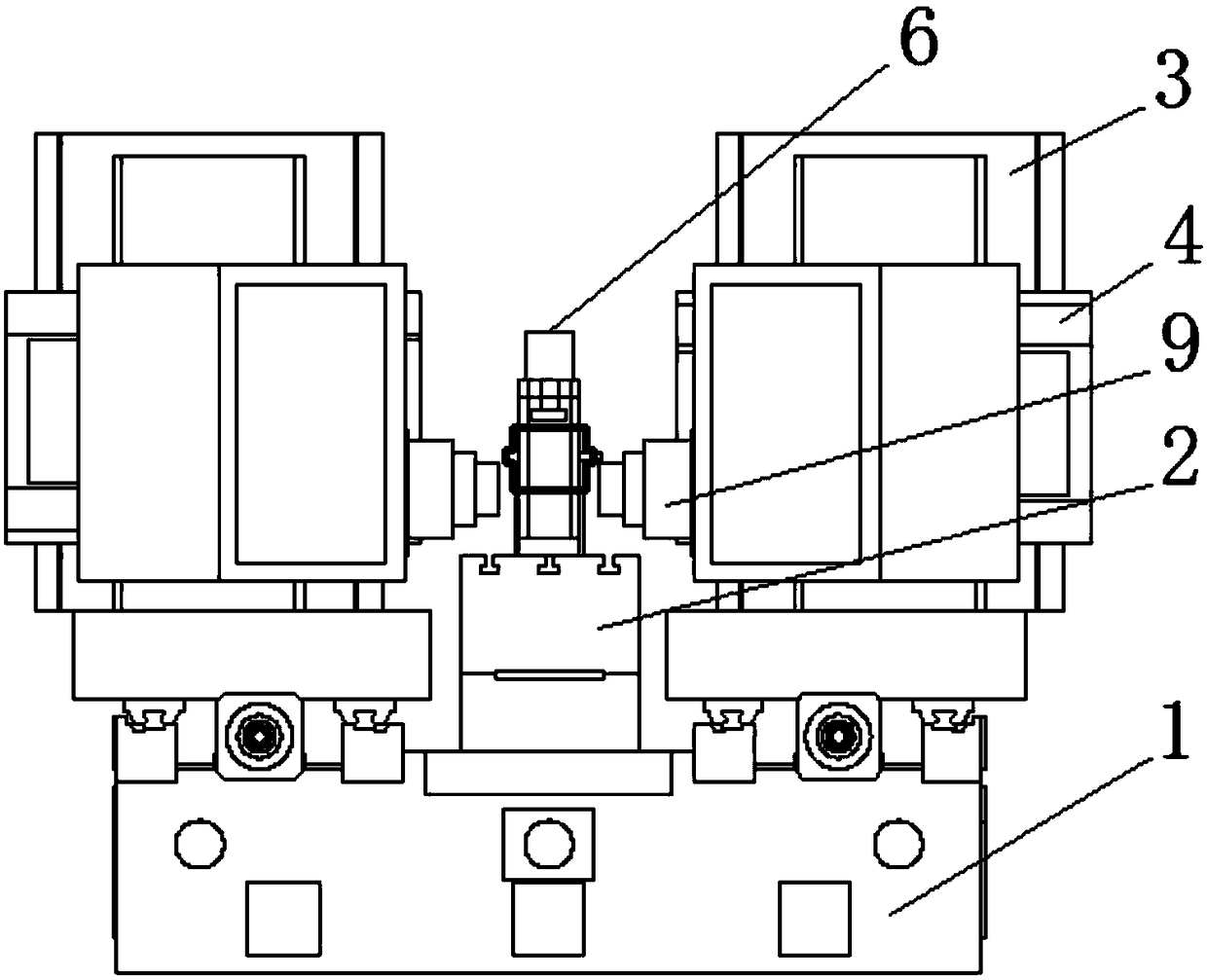

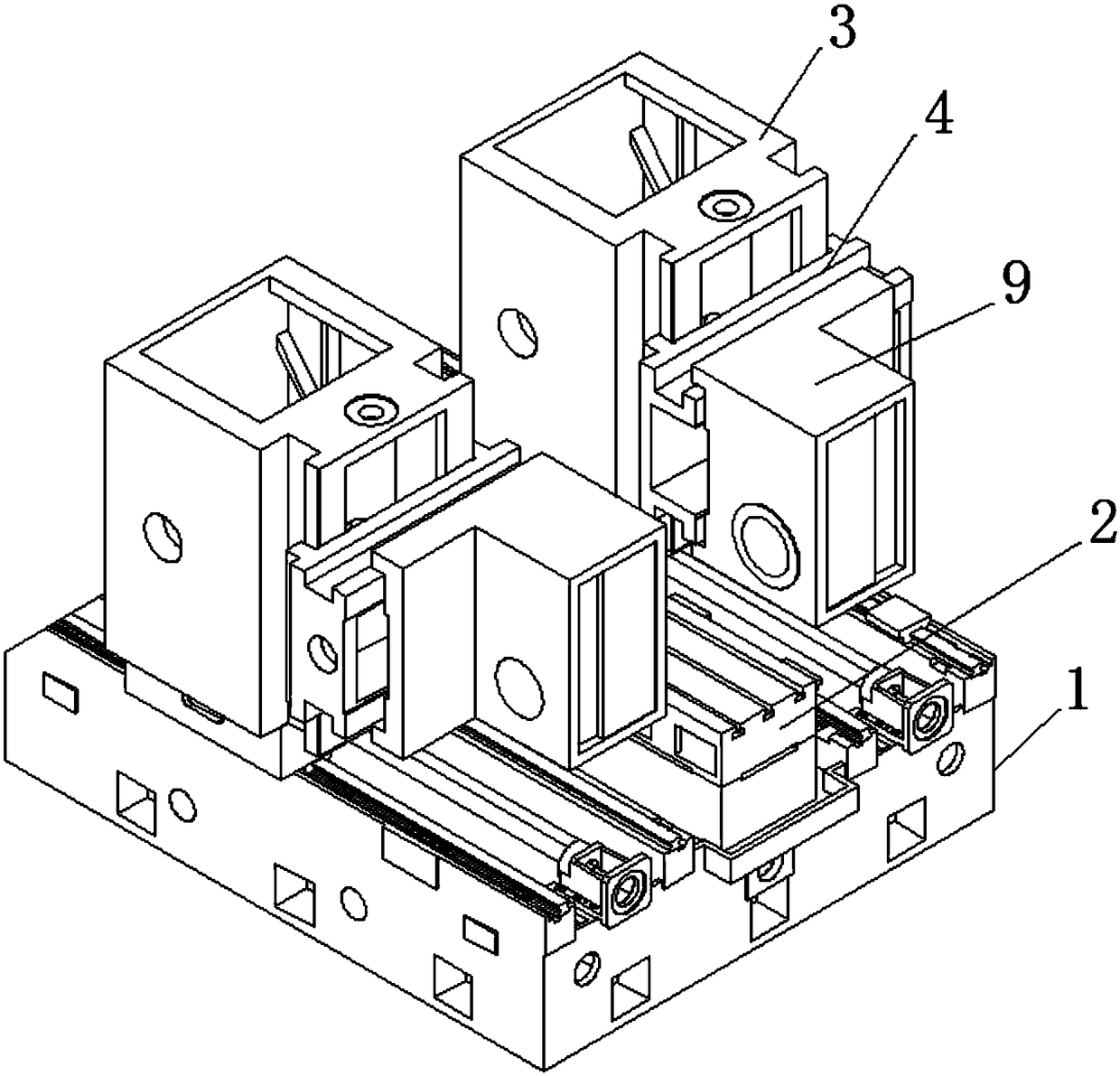

Double-surface milling machine tool with special three-direction fixing clamp

InactiveCN109226840ANot easy to moveImprove machining accuracyMilling machinesPositioning apparatusSlide plateEngineering

The invention discloses a double-surface milling machine tool with a special three-direction fixing clamp, and belongs to the field of machining equipment. The double-surface milling machine tool withthe special three-direction fixing clamp comprises a double-surface milling machine tool body, wherein a working bench is fixedly connected to the upper end of the double-surface milling machine toolbody; the left upper end and the right upper end of the double-surface milling machine tool body are respectively and fixedly connected with a vertical column; the two vertical columns are respectively positioned at two sides of the working bench; a sliding groove is dug at one end of each vertical column; main-shaft box sliding plates are connected to the sliding grooves in a sliding manner; main-shaft boxes are connected to the outer ends of the main-shaft box sliding plates in the sliding manner; the three-direction fixing clamp is arranged at the upper end of the working bench and comprises two side-direction clamping plates which are connected with the working bench in the sliding manner. The double-surface milling machine tool disclosed by the invention has the beneficial effects that the effect of clamping the upper part and the side surfaces of a workpiece can be realized, and the control on the up-down freedom degree and the left-right freedom degree of the workpiece is realized, so that the workpiece is not easy to move due to influence of cutting force and the machining accuracy of the workpiece is improved.

Owner:南通利联机床制造有限公司

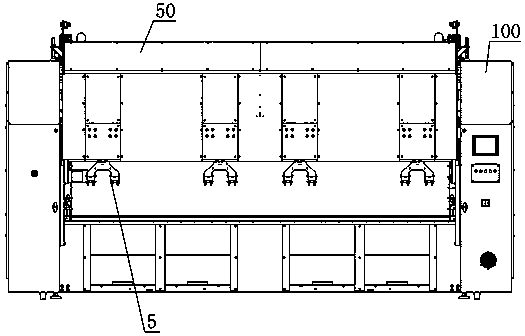

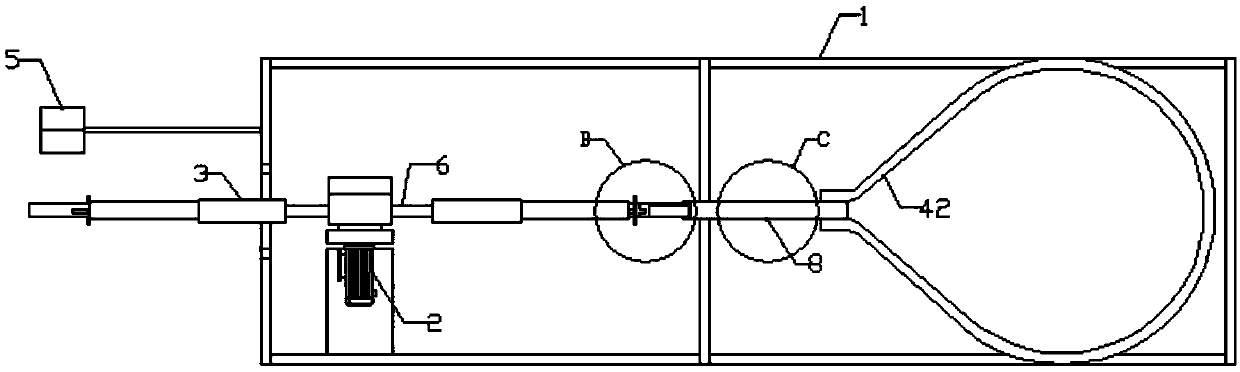

Linen spreading machine

The invention discloses a linen spreading machine. A linen spreading device, a linen receiving device and a linen conveying device are arranged at the upper end of a rack; the upper segment of a linenreceiving connecting plate is arranged on the part, on the front side of the linen spreading device, of the rack, one or more rodless air cylinders are vertically arranged on the inner side of the linen receiving connecting plate, and a pair of linen receiving manipulators are arranged on a moving part of each rodless air cylinder. The structure of the linen spreading device is that a linen spreading guide rail is horizontally arranged between a left side panel and a right side panel on the upper portion of the front end of the rack, one pair of linen spreading manipulators are movably arranged on the linen spreading guide rail, and the two linen spreading manipulators are driven by a first driving device; an air bag is arranged in a clamping opening of each linen spreading manipulator and communicated with an air source. When linen is conveyed, the linen spreading machine can keep a high flatness degree all the time.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

Magnetic force tongs device

The invention provides a magnetic force tongs device. The magnetic force tongs device comprises tong arms and tong heads which are respectively hinged pairwise, wherein the two tong heads are cake-shaped; thread heads are fixed to the circular faces of the outer sides of the tong heads in the vertical axial directions; magnetic force heads which can be rotated and advance and retreat are assembled on the thread heads; the magnetic force heads are cake-shaped; magnetic blocks which are arrayed in a circle are uniformly distributed in the magnetic force heads; the magnetic force surfaces of the magnetic blocks and the tongs planes of the tong heads are parallel; the different magnetism faces, which are provided with the magnetic blocks, of the two corresponding magnetic force heads are opposite. The magnetic force tongs device is mainly used for carrying out clamping operation on sheet-shaped objects; when the device clamps, the clamping force is constant by the magnetic force effect; meanwhile, the distance between the two magnetic force heads is adjusted, the magnitude of the clamping force is conveniently adjusted, and the objects cannot be easily damaged.

Owner:国网山东省电力公司临清市供电公司 +1

Tool and method for measuring deflection angle of airplane control surface

The invention discloses a tool and a method for measuring the deflection angle of an airplane control surface. The measuring tool comprises a control surface clip (1), a stabilizer clip (6), a brace rod (5), a regulating arm (4), a sensor support (3), an angular displacement sensor (7) and a forked rocker arm (2). The measuring process comprises the following steps: clamping the stabilizer clip (6) of the measuring tool to a force-bearing position of a vertical tail stabilizer (45), sequentially mounting the brace rod (5), the regulating arm (4), the sensor support (3), the angular displacement sensor (7) and the forked rocker arm (2) in place, clamping the control surface clip (1) to a force-bearing position of an upper rudder (46), and moving the angular displacement sensor (7) to a rotary shaft of the upper rudder (46) so as to measure the deflection angle of the control surface. The invention can be simultaneously used for measuring the deflection angle of the rudder or the elevator in the bench test or the ground built-in test of an airplane, can be directly used for measuring the deflection angle of the control surface without disassembling structural parts of the airframe, and is especially suitable for the condition that the deflection amount can not be educed for measurement by means of a link mechanism in case that the rotary shaft is arranged inside the envelope of the control surface.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

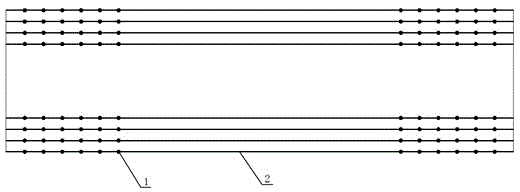

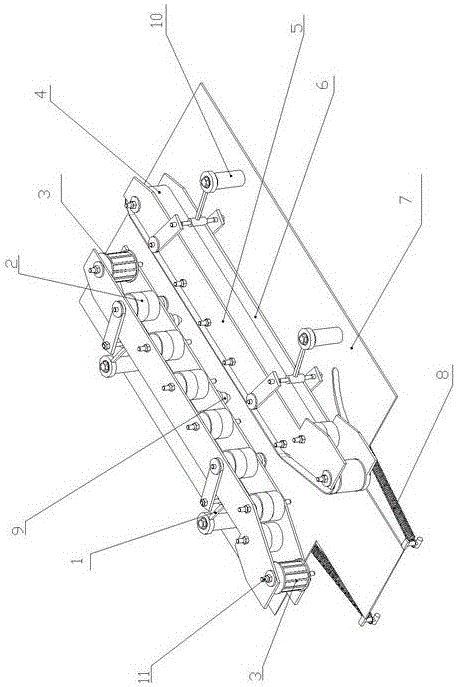

Conveying device of fully-automatic express carton packaging machine

The invention discloses a conveying device of a fully-automatic express carton packaging machine. The conveying device comprises frame connection rods, bearings, toothed belt wheels, toothed belts, an upper clamping plate, a lower clamping plate, a bottom plate, a spring, universal wheels, a rack and a drive shaft. Conveying devices at the two sides are symmetrical and both adopt a double-rocker mechanism respectively, and friction is generated by virtue of the extrusion of the conveying devices at the two sides to push cartons to move; and a spring is connected to the bottom of the belt wheel at the front end, and facilitates to clamp the cartons during conveying and return the cartons after the cartons pass through. The conveying device disclosed by the invention is capable of realizing smooth and reliable conveying for the folded cartons to a delivery port, and capable of realizing self-adaptive conveying for the cartons with different specifications. The conveying device is simple in structure and convenient to operate, enables the packaging machine to realize the adjustable widths of the conveyed cartons, and lowers the labour intensity of workers.

Owner:JILIN UNIV

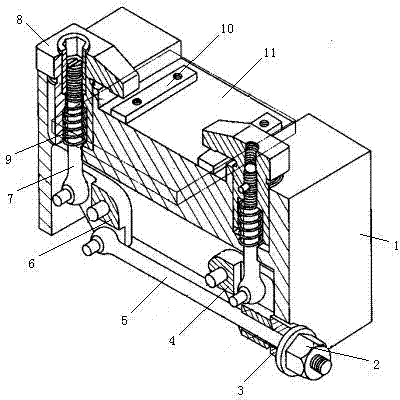

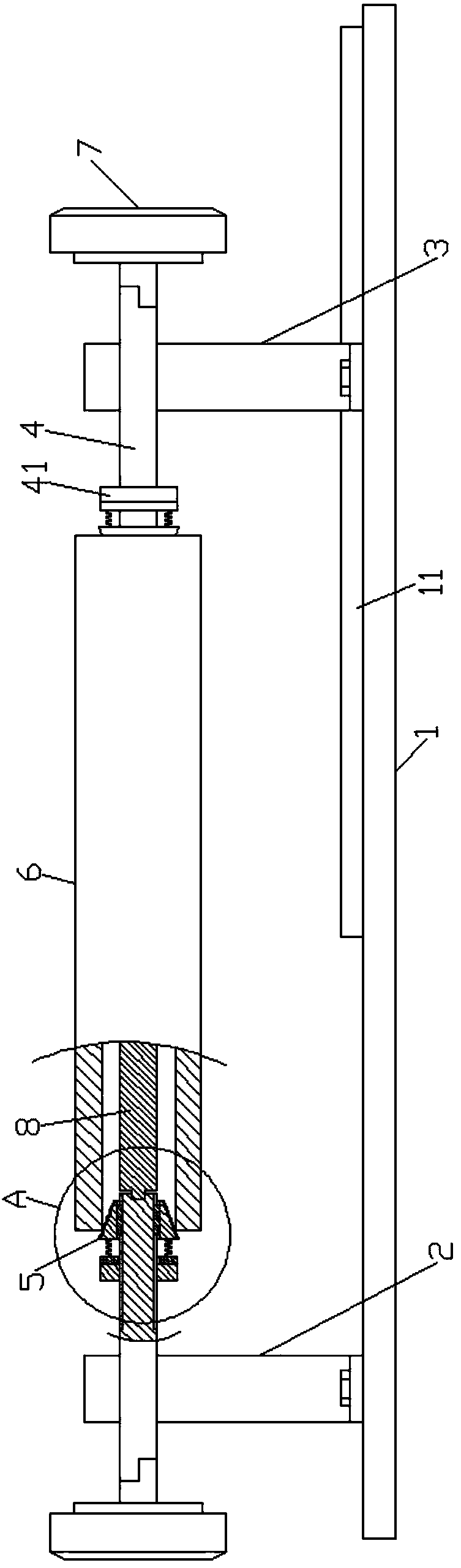

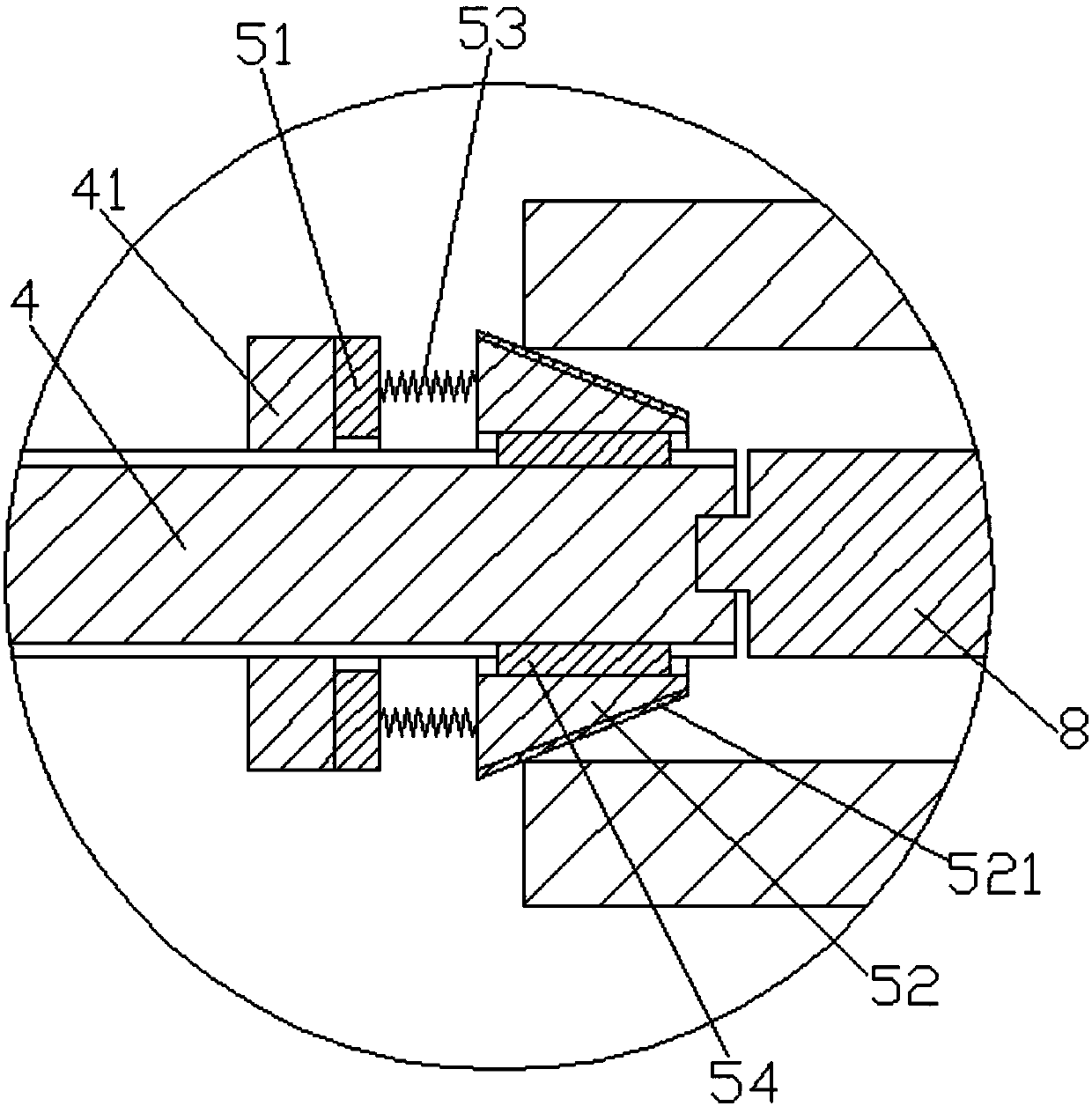

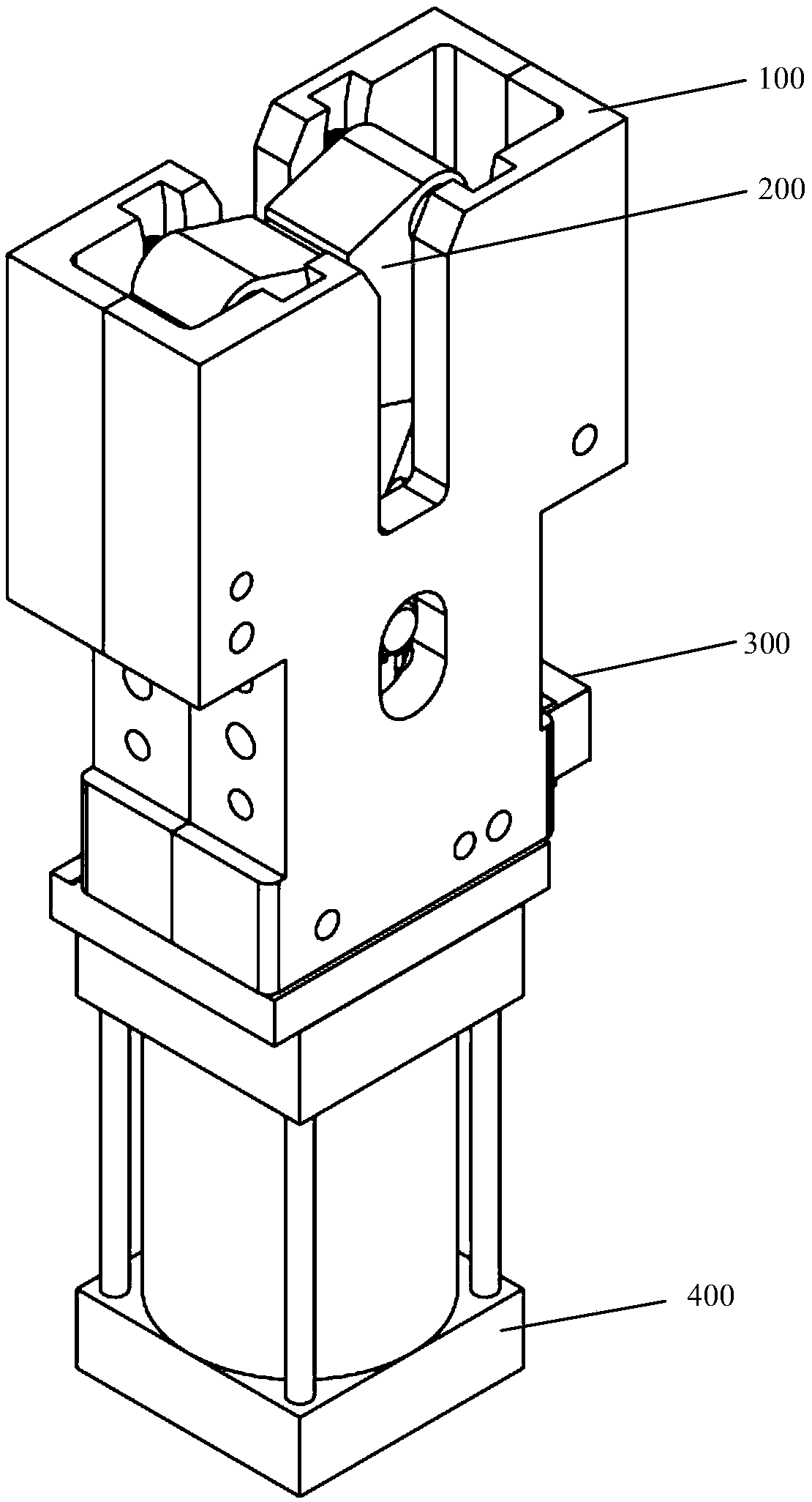

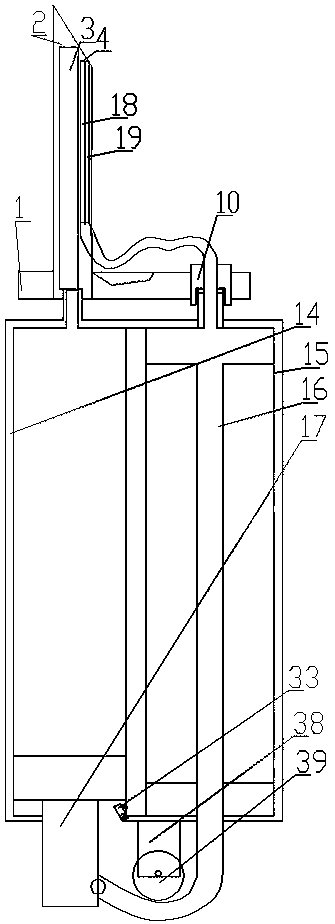

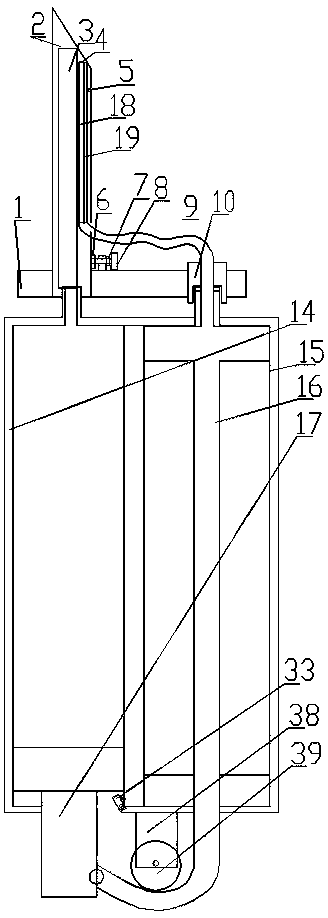

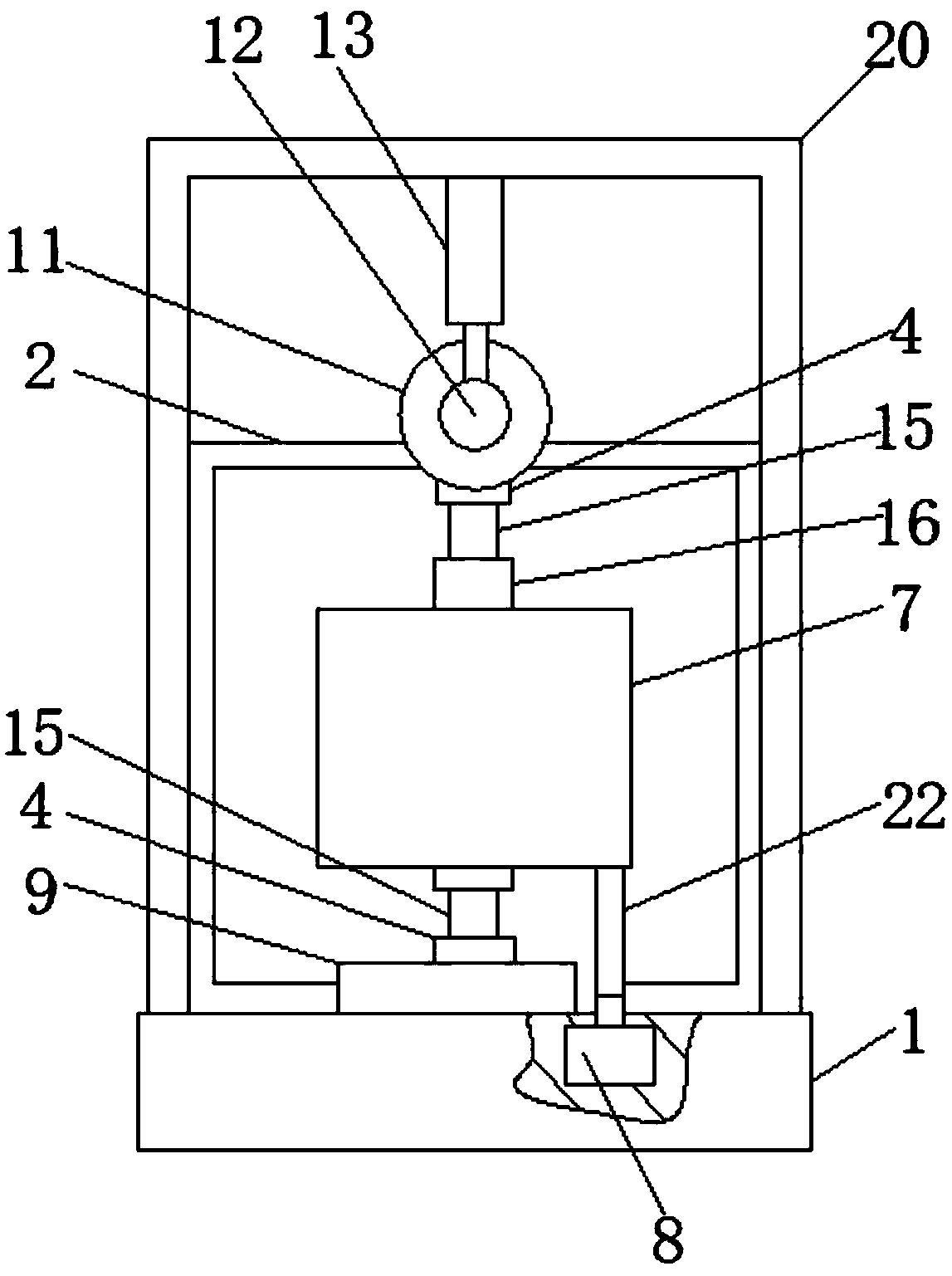

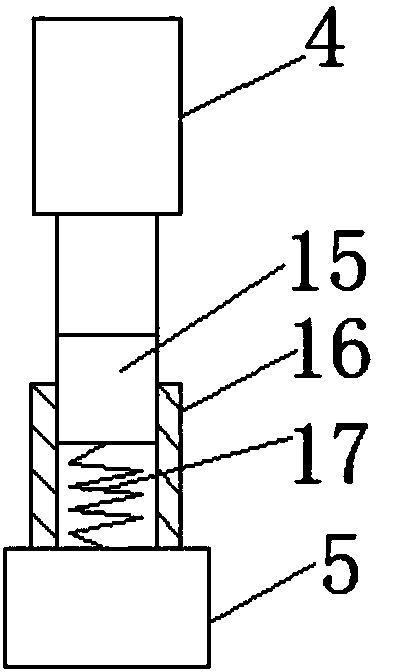

B-mode ultrasound operating bed suitable for weak patients

InactiveCN107789148AAvoid pinchingNot easy to pinchOperating tablesSurgical needlesB mode ultrasoundEngineering

The invention discloses a B-mode ultrasound operating bed suitable for weak patients. The bed comprises a bed board which is provided with rollers at the bottom, a through hole is formed in the bed board, a lifting electric telescopic rod which penetrates through the through hole is arranged under the bed board through a supporting frame, a fixing rod is arranged on the lifting electric telescopicrod, an arm supporting board is arranged on the fixing rod, a sliding groove is formed in the fixing rod, a chest electric telescopic rod which slides up and down is arranged in the sliding groove, acushion block used for supporting the chest is arranged on the chest electric telescopic rod, and a first electric telescopic rod which drives the chest electric telescopic rod to move up and down isarranged under the arm supporting board. The bed is capable of reducing fatigues for patients, and bending over the supporting board is comfortable.

Owner:郑亚

Electric suction negative pressure type glass cleaning tool

PendingCN111643003ANot easy to damageSmooth rotationWindow cleanersStructural engineeringMechanical engineering

The invention discloses an electric suction negative pressure type glass cleaning tool and relates to the technical field of cleaning appliances. The tool comprises a shell, a negative-pressure pump,a negative-pressure sucker, wiping cotton, a scraping strip, a rotary connecting assembly and a grab rail, wherein the negative-pressure pump is connected with the negative-pressure sucker; a throughhole is formed in the bottom face of the shell; the negative-pressure sucker extends out of the shell through the through hole; the wiping cotton is arranged on the outer side of the bottom face of the shell and arranged on the periphery of the negative-pressure sucker; the scraping strip is arranged on one side of the bottom face of the shell; and the top face of the shell is connected with the grab rail through the rotary connecting assembly. The electric suction negative pressure type glass cleaning tool provided by the invention can realize immediate wiping and scraping, is not easy to pinch hands and damage glass, improves the cleaning effect, and is convenient to control the direction.

Owner:南宫市品尚家居用品有限公司

Automatic interception safety-check door based on Internet of things

The invention relates to an automatic interception safety-check door based on the Internet of things, and discloses a safety-check door device which intercepts the inspected person by the longitudinally oblique linear sliding of two intercepting plates. The door is simple in structure, practical and convenient, is not easy to pinch the inspected person, and is good in use effect. The automatic interception safety-check door is characterized in that two sliding grooves are symmetrically opened on one side of the a body frame, the sliding grooves are obliquely placed, a driving motor is placed on one side of the main body frame, a supporting ring is placed on one side of the main body frame through a supporting rod and is positioned between the two sliding grooves, one end of a screw rod isconnected to a motor shaft of the driving motor, the other end of the screw rod is placed in the supporting ring, the screw rod is horizontally placed, a screw sleeve sleeves the screw rod, the middlepart of a transmission rod is connected with a screw sleeve through a connecting plate, two sliding sleeves are sleeved on the transmission rod and located at upper and lower sides of the screw sleeve respectively, one ends of connecting rods are placed on the sliding sleeves, two hollow rods penetrate the two sliding grooves, and one ends of the two hollow rods are sleeved on the two connectingrods.

Owner:安徽恒源煤电股份有限公司

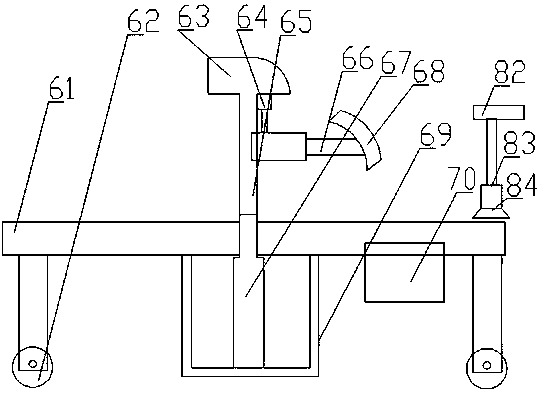

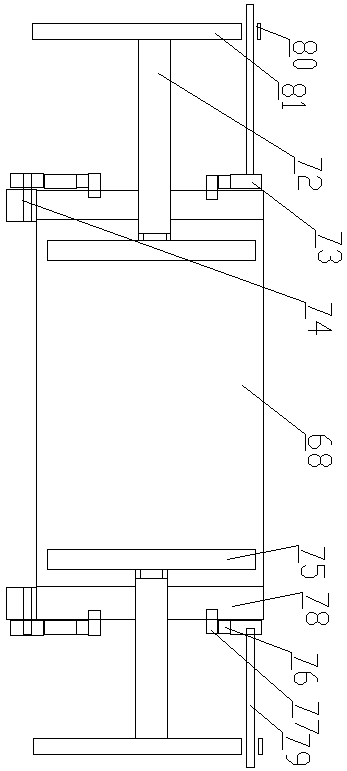

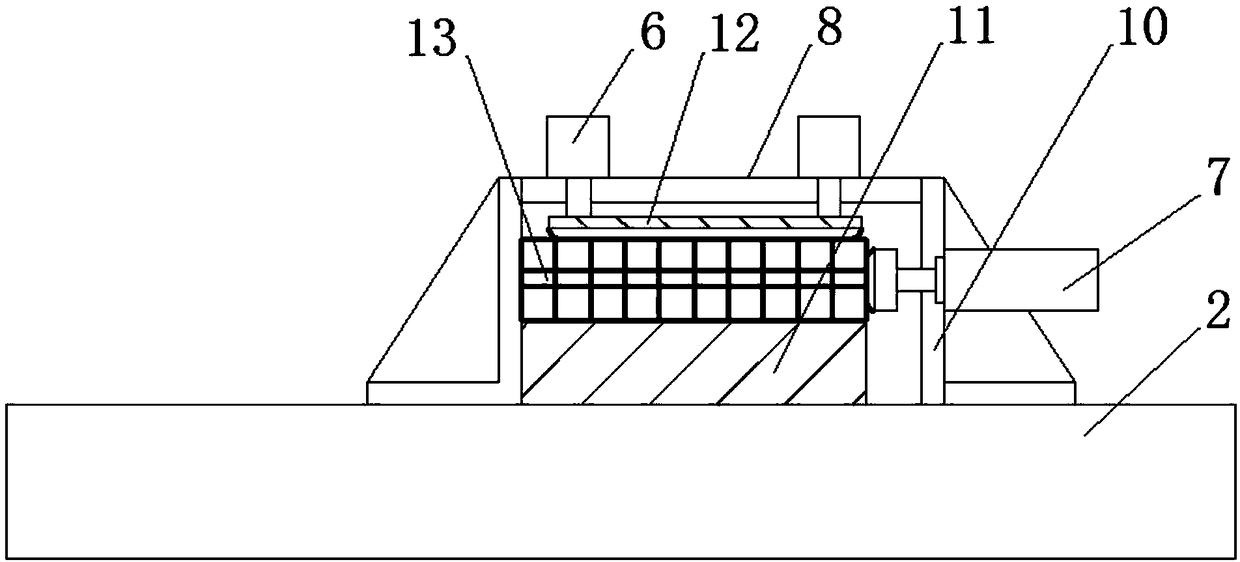

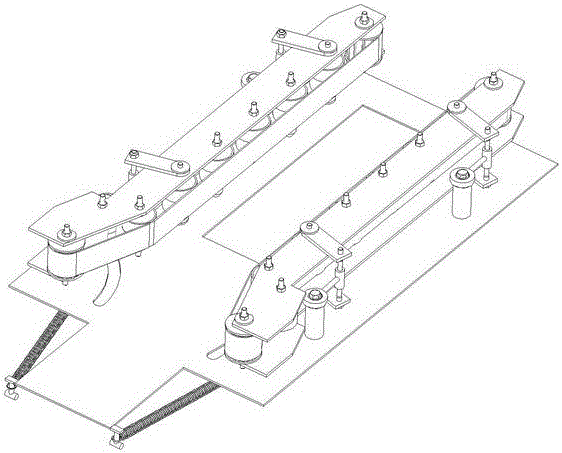

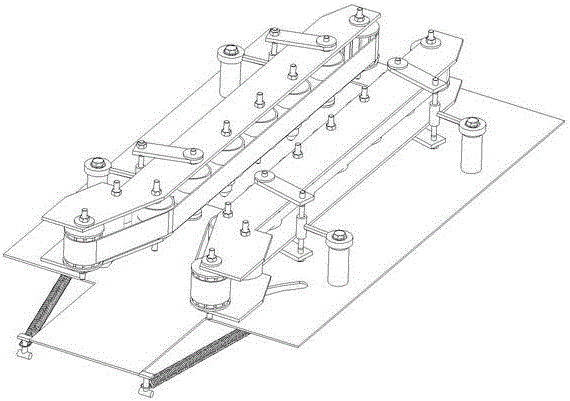

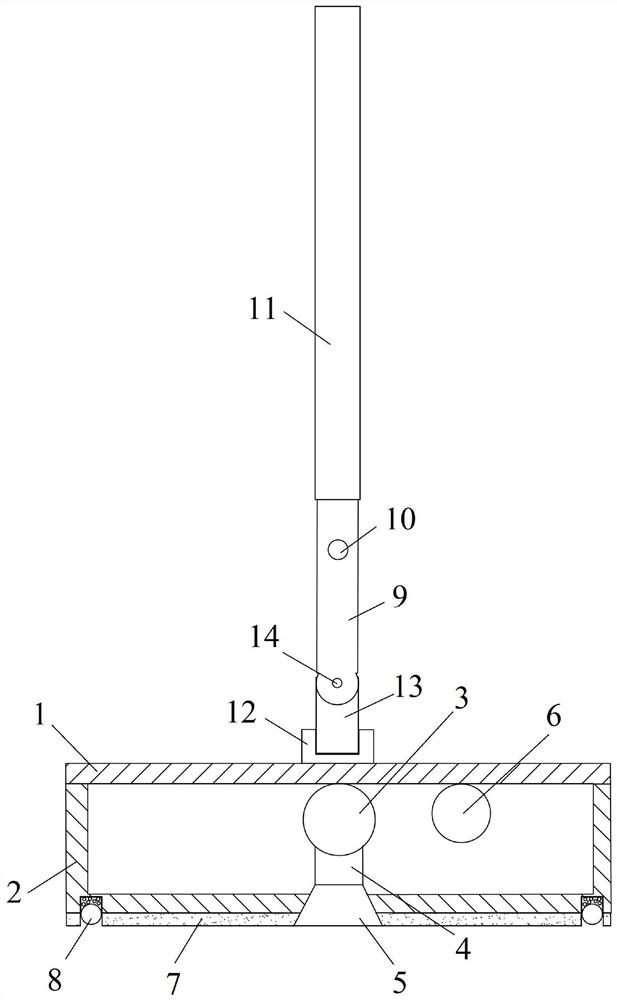

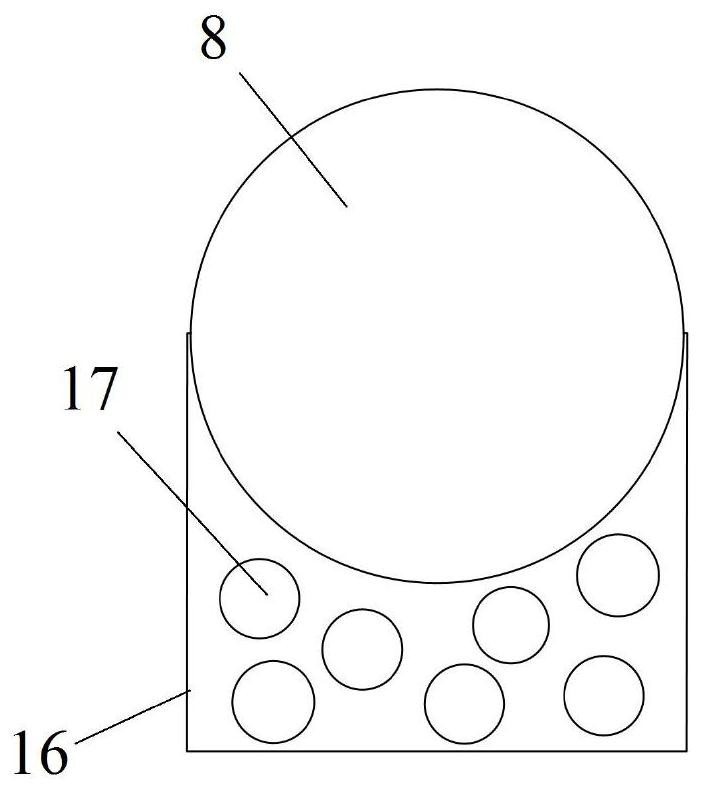

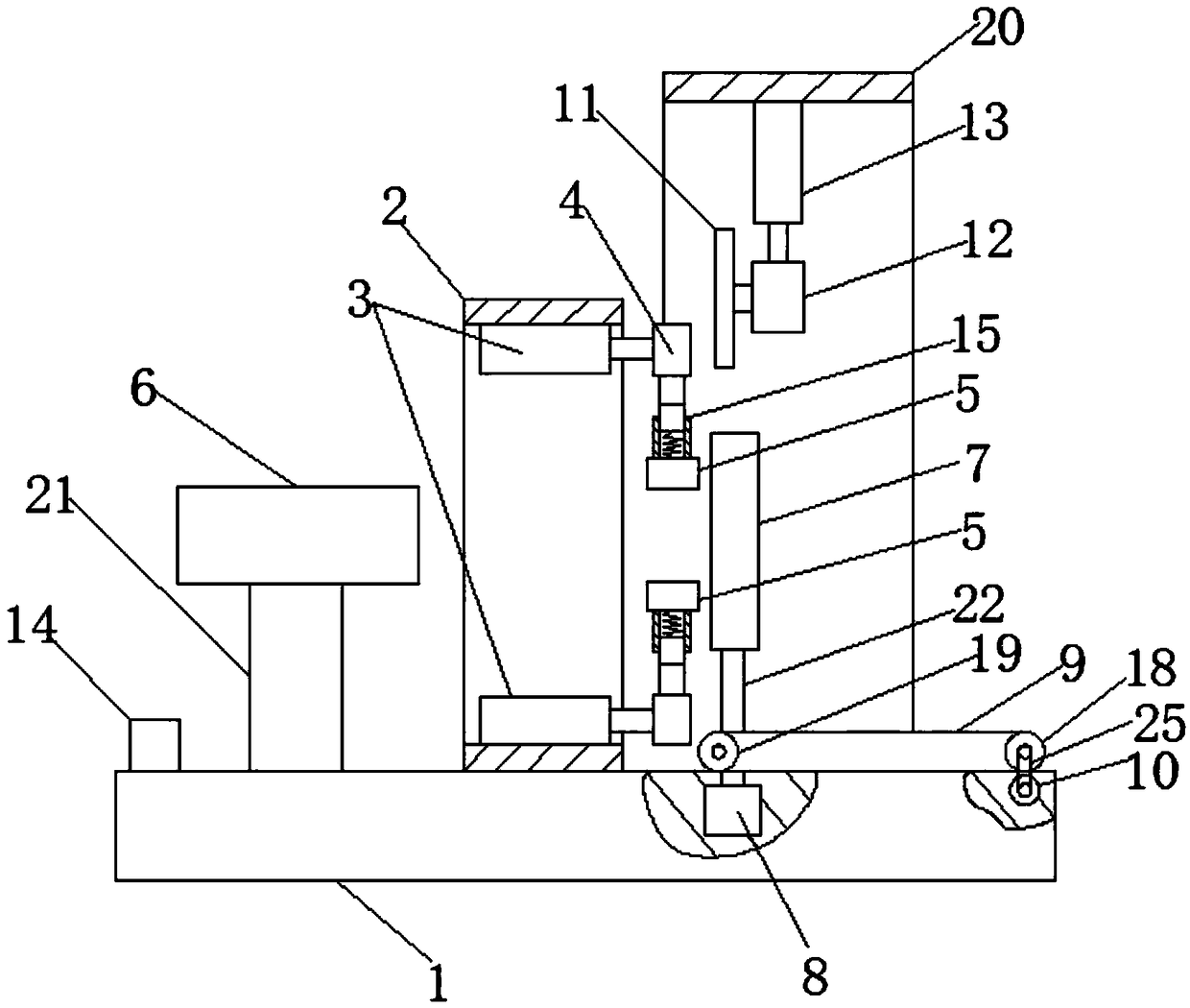

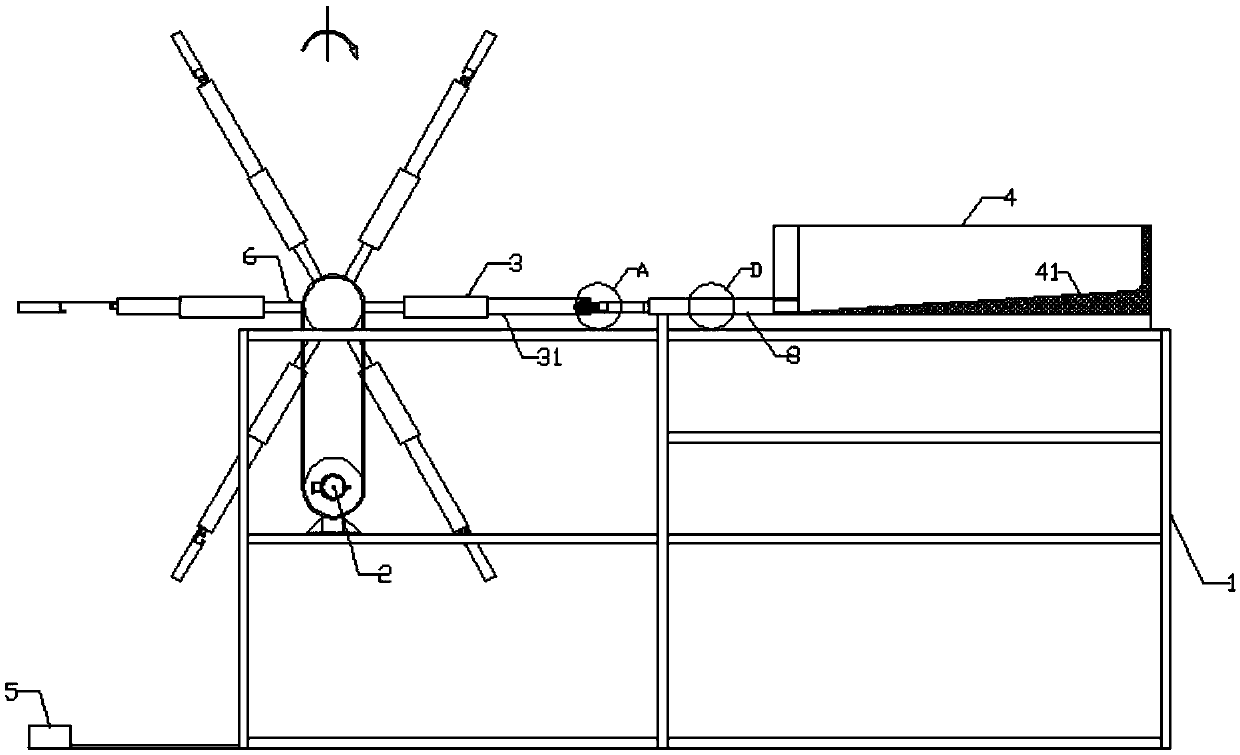

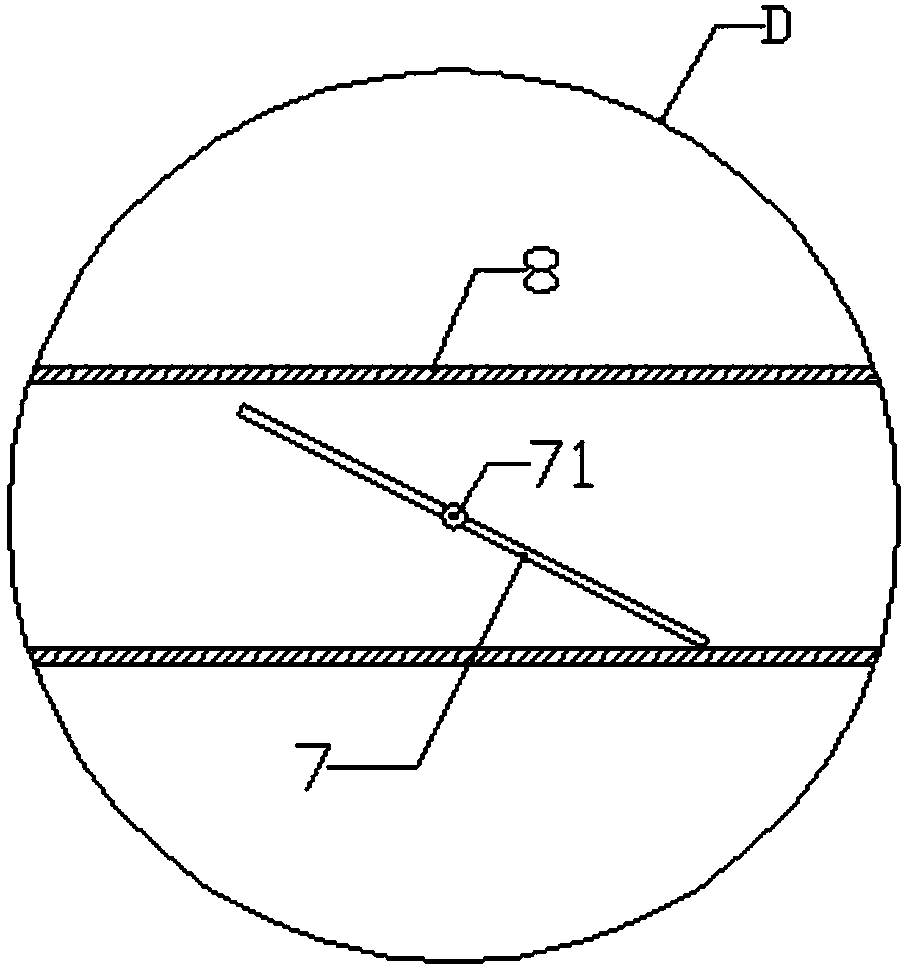

Clamping and conveying type raw bamboo sawing machine

InactiveCN108297182ANot easy to pinchReduce the chance of injuryCane mechanical workingCircular sawsHydraulic cylinderPulp and paper industry

The invention discloses a clamping and conveying type raw bamboo sawing machine. The machine comprises a bottom plate (1), and a square frame(2) is arranged in the middle of the bottom plate (1); theupper end and the lower end of the square frame (2) are correspondingly connected with first hydraulic cylinders (3), and the same sides of the two first hydraulic cylinders (3) are connected with second hydraulic cylinders (4) correspondingly; each second hydraulic cylinder (4) is connected with a clamping plate (5) correspondingly, a fixed cylinder (6) is arranged on one side of the square frame(2), and a baffle is arranged on the other side of the square frame (2); a conveyor belt (9) is arranged below the baffle (7), and a second motor (10) is connected to the conveyor belt (9); a saw blade (11) is arranged above the baffle (7), and the saw blade (11) is connected with a third motor (12) and a third hydraulic cylinder (13); and a controller (14) is arranged on the bottom plate (1). According to the machine, the operation is simpler and more convenient, the safety is improved, and the clamping and conveying type raw bamboo sawing machine has the advantages of being wide in application range, good in practicability, good in structural stability and good in clamping effect.

Owner:李华平

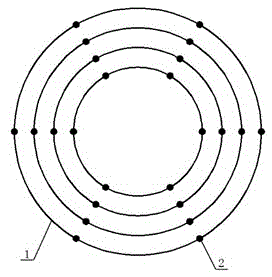

Clamping device applied to trimming arc surfaces of abrasive blocks of grinding wheel

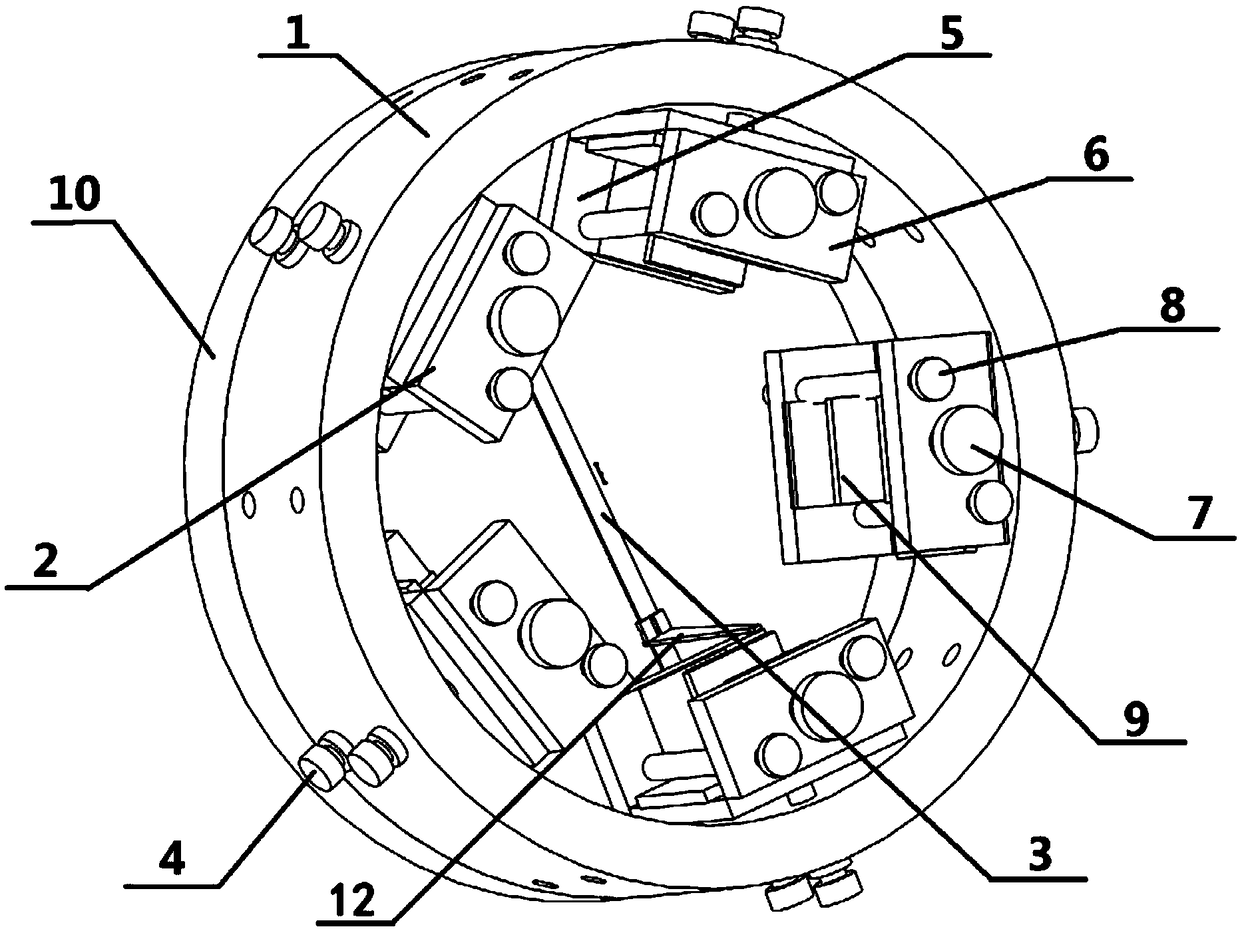

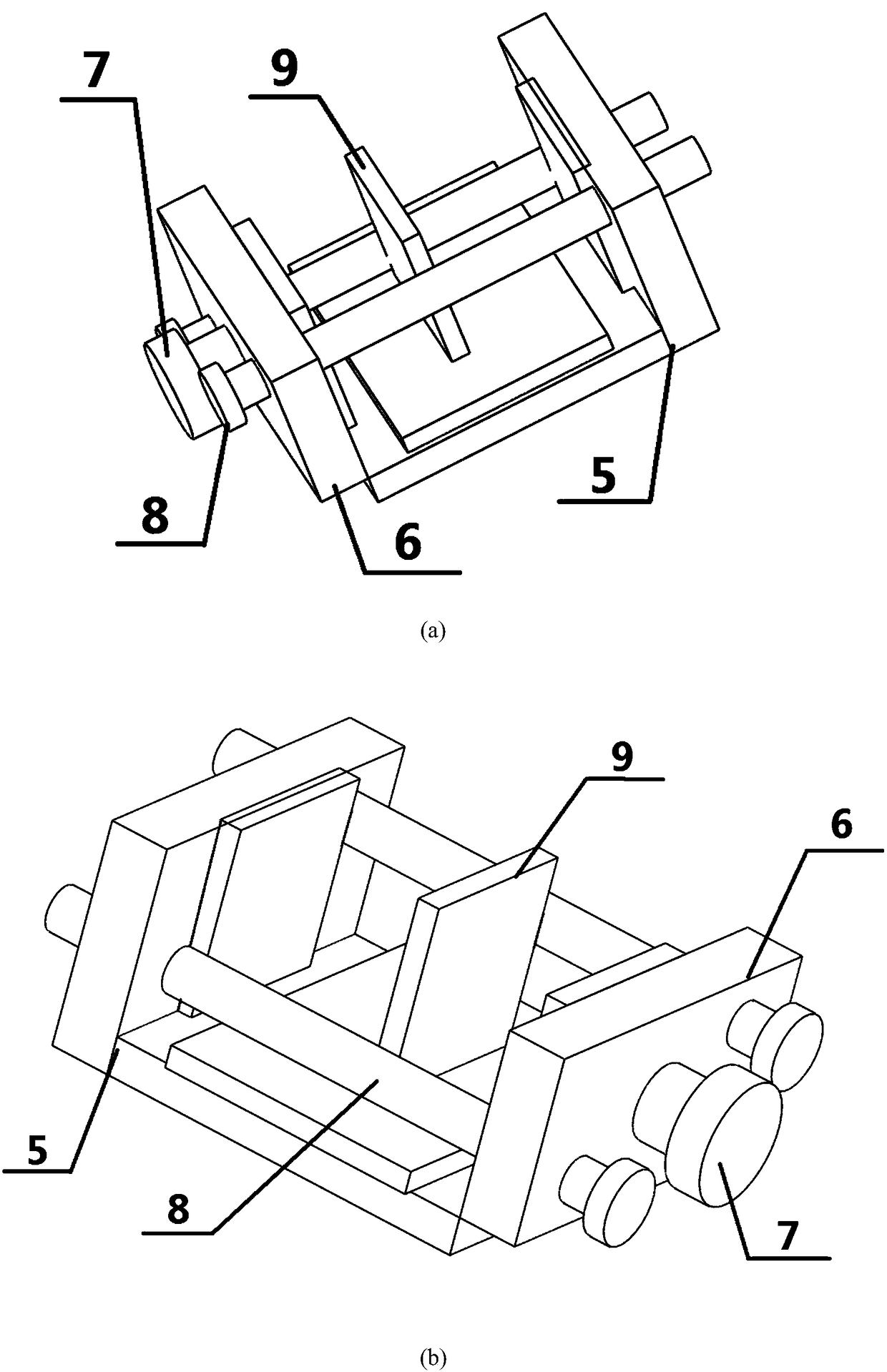

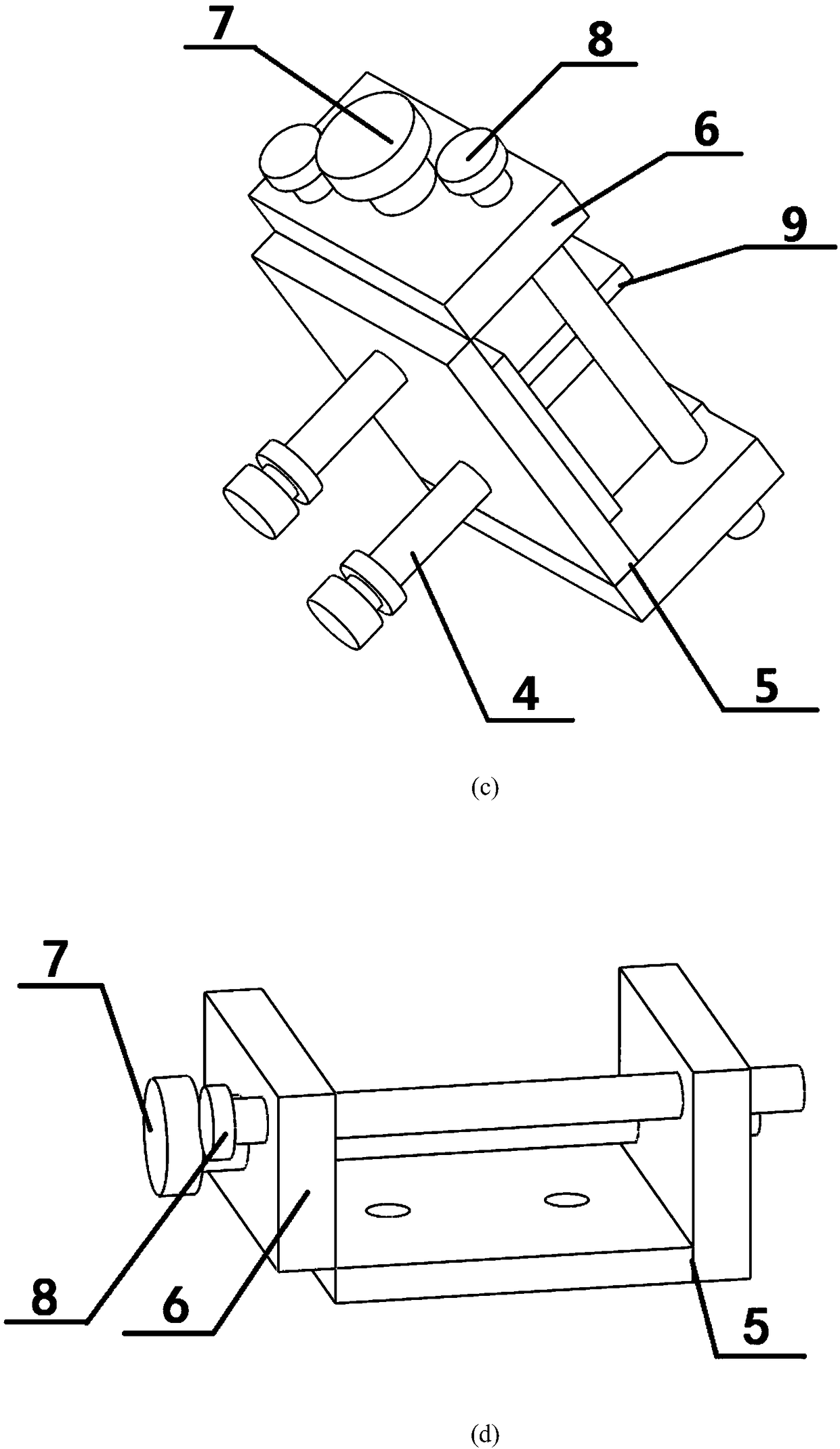

ActiveCN108687663ASimple structureEconomicalAbrasive surface conditioning devicesEngineeringMechanical engineering

The invention provides a clamping device applied to trimming the arc surfaces of abrasive blocks of a grinding wheel. The clamping device comprises a circular ring-shaped outer cover, and fixture bodies for clamping the circular arc-shaped abrasive blocks, wherein a plurality of fixture bodies are evenly distributed and connected onto the outer cover by adopting the circle center of the outer cover as the center. The fixture bodies comprise clamping front pressing plates, clamping rear bottom plates, connecting screws and clamping screws; the clamping front pressing plates and the clamping rear bottom plates are connected and fixed through the connecting screws; the circular arc-shaped abrasive blocks are clamped between the clamping front pressing plates and the clamping rear bottom plates; and the clamping forces of the clamping front pressing plates and the clamping rear bottom plates on the circular arc-shaped abrasive blocks are adjusted through the clamping screws. The clamping device provided by the invention is simple in structure, good in economical efficiency, convenient to install, and capable of effectively ensuring the yield and processing the abrasive blocks in largevolumes, so that the consistency of the abrasive blocks is high, and a favorable basis condition is provided for the next working procedure.

Owner:SHENYANG JIANZHU UNIVERSITY

Color steel tile fixture

PendingCN108071195AImprove stabilityLong-term use is stable and goodPhotovoltaic supportsSolar heating energyArchitectural engineering

Owner:SHANGHAI CHIKO SOLAR TECH

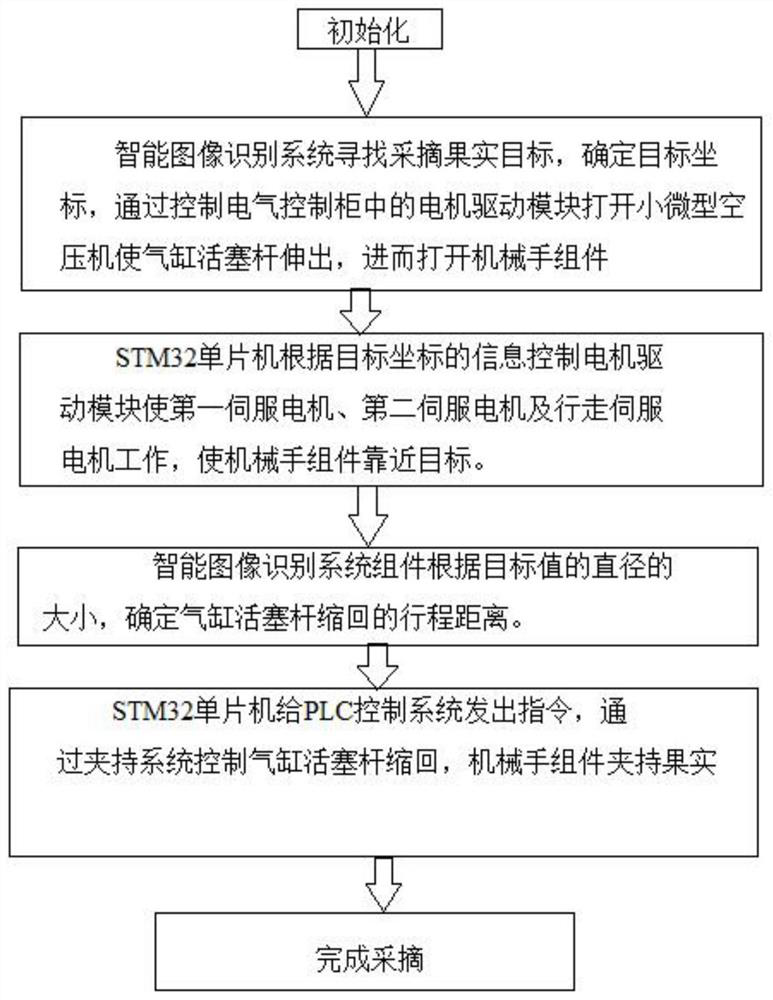

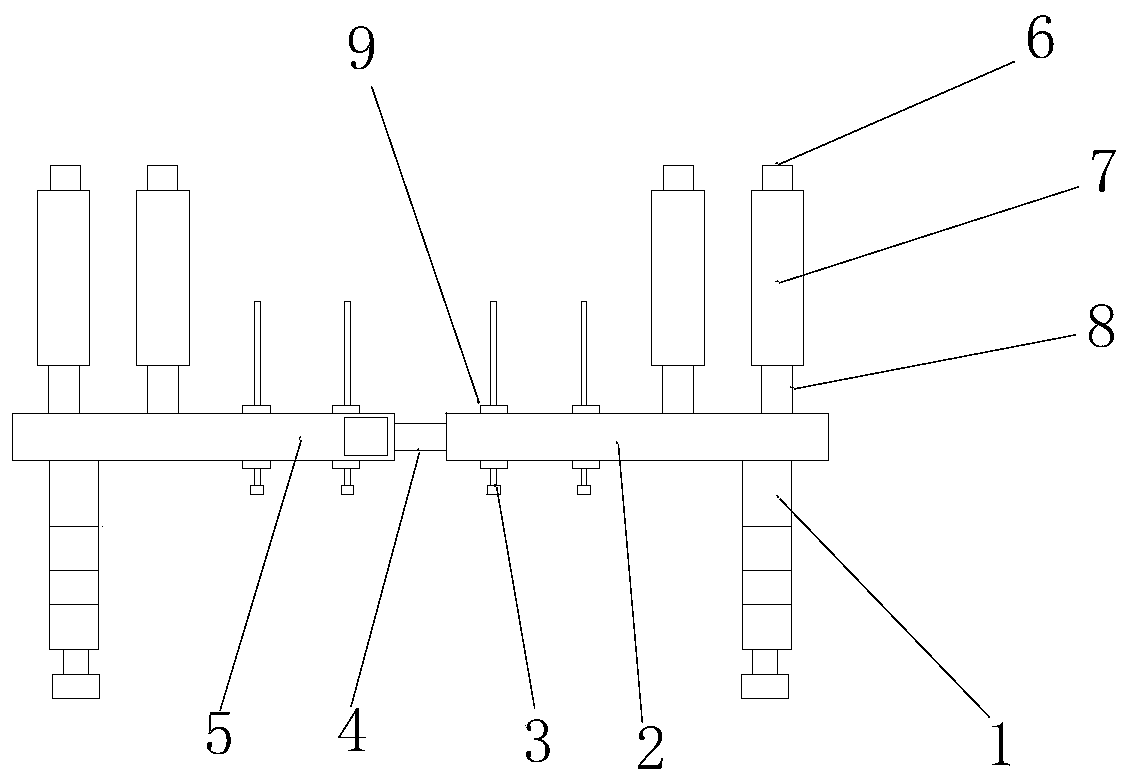

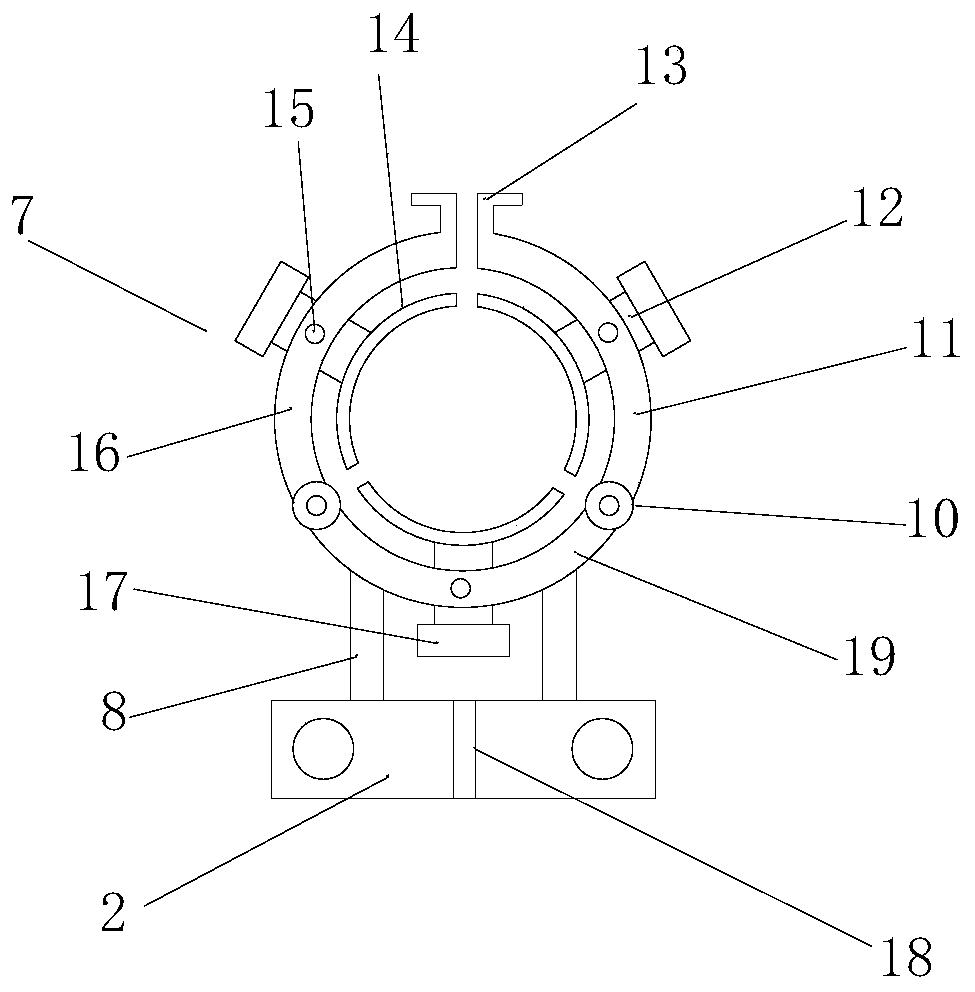

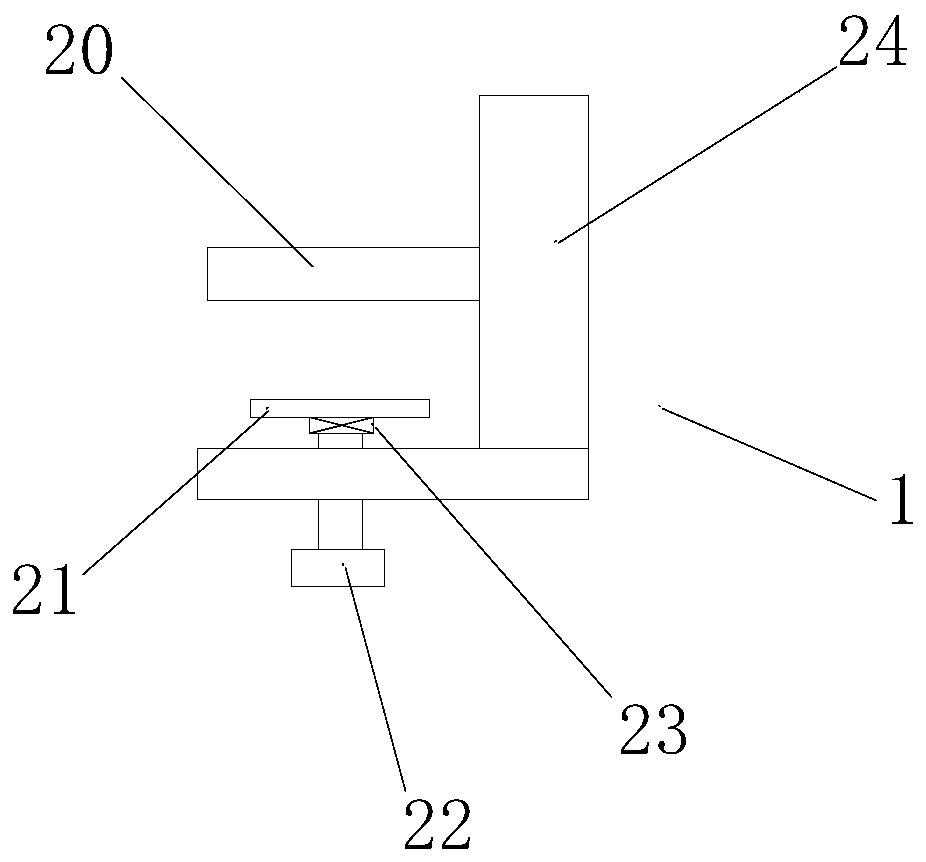

Fruit and vegetable picking robot device

InactiveCN113661834AEasy to findNot easy to pinchProgramme-controlled manipulatorGripping headsRobot handGear wheel

The invention discloses a fruit and vegetable picking robot device, and relates to the technical field of agricultural machinery. The fruit and vegetable picking robot device comprises a picking robot mechanical structure, and the picking robot mechanical structure comprises an intelligent mobile platform and a manipulator assembly; a mechanical arm assembly is arranged on the intelligent mobile platform; the manipulator assembly comprises an air cylinder, a supporting plate and two clamping jaws, the left end of the air cylinder is fixed to the mechanical arm assembly through a bolt, and the supporting plate is fixed to one side face of the right end of the air cylinder through a screw; the supporting plate is parallel to a piston rod of the air cylinder. the supporting plate is provided with two gear fixing shafts, and the gear fixing shafts are perpendicular to the supporting plate; the two gear fixing shafts are fixedly connected with a first gear and a second gear through flat keys correspondingly; the first gear and the second gear are respectively connected with the two clamping jaws; a rack is arranged at the front end of the piston rod. According to the fruit and vegetable picking robot device, an intelligent image recognition system assembly is arranged, so that fruit targets can be found conveniently, and fruits are not prone to being damaged by clamping.

Owner:YANCHENG INST OF IND TECH

External limb fixing frame special for orthopedic department

InactiveCN110338893AReasonable layoutIngenious structureExternal osteosynthesisOrthopedic departmentEngineering

The invention discloses an external limb fixing frame special for the orthopedic department. The external limb fixing frame comprises a first supporting plate and a second supporting plate which are symmetrically arranged at the two sides, the left end of the first supporting plate and the right end of the second supporting plate are connected through two lead screws, fixing legs are arranged at the lower side of the right end of the first supporting plate and the lower side of the left end of the second supporting plate respectively, two limb fixing rings are arranged at the upper side of theright end of the first supporting plate, and two limb fixing rings are arranged at the upper side of the left end of the second supporting plate. The external limb fixing frame is reasonable in layout and ingenious in structure, the whole device is fixed to a proper position through the fixing legs, then the limbs are supported through the two supporting plates, the four fixing rings are adoptedfor clamping the two ends of each required limb, then fixing nails penetrate through staggered bone at the two ends for after-position-correction fixation, and limiting screws are screwed up; meanwhile, a screw cover is adjusted to keep a proper distance between the two supporting plates, the requirement of limb fixation for the firmness and precision of the frame is met, and the operation is convenient.

Owner:FUJIAN PROVINCIAL HOSPITAL

Auxiliary processing equipment for lobsters

The invention discloses auxiliary processing equipment for lobsters, and relates to the field of processing of the lobsters. The auxiliary processing equipment comprises a cleaning device and a pretreatment device, wherein the cleaning device comprises a housing, and a roller and a cleaning pond are arranged in the housing; the pretreatment device comprises a pretreatment cavity, wherein a shrimpthrough passage is arranged on one side of the pretreatment cavity; and shrimp clamping devices are arranged at the outlet of the shrimp through passage; a shrimp clamping cavity is formed in each ofthe shrimp clamping devices, two second rotating shafts are arranged on two side walls of each of the shrimp clamping cavities, and fan-shaped regulating blocks are symmetrically arranged on each of the second rotating shafts; and a chock block is arranged on the outer side of each of the shrimp clamping cavities, and a spring block is arranged at the position close to the shrimp taking opening, of the chock block and is used for enabling the opening close to the shrimp taking opening, of the fan-shaped regulating block to be smaller than the opening away from the shrimp taking opening, of theregulating block. The lobsters can be thoroughly cleaned, and through the pretreatment equipment, the catgut of the lobsters can be convenient to remove, and the condition that people are hurt by lobsters through clamping can be effectively prevented.

Owner:张中跃

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com