Clamping device for plate-shaped workpiece

A technology of clamping device and plate-shaped workpiece, which is applied in the direction of clamping device, positioning device, metal processing machine parts, etc., can solve the problems of easy crushing of the workpiece, large force on the workpiece, and asynchronous clamping between the two pressure plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

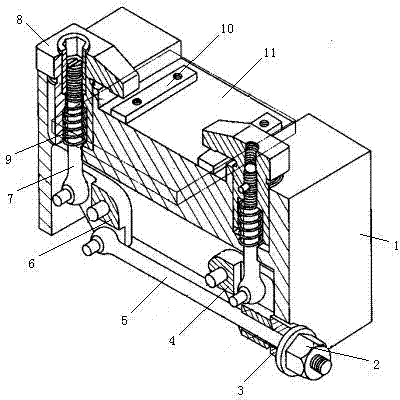

[0011] like figure 1 As shown, the clamping device for a plate-shaped workpiece includes two pressing plates, a transmission mechanism and a base 1 with a clamping table 11, and two elastic pads 10 are arranged on the holding table 11, wherein the two pressing plates It is the hook head pressure plate 8 that is arranged oppositely on both sides of the clamping table 11. The transmission mechanism includes a screw rod 5, a left turning block 6, a right turning block 4 and two transmission rods 7, and the transmission rod 7 is sleeved with a reset Spring 9, the upper end of return spring 9 is fixedly connected to the transmission rod 7, the lower end is supported on the base 1, the upper end of the transmission rod 7 is threaded with the hook head pressure plate 8, and the middle part of the left turning block 6 is hinged on a hook head pressure plate 8 below On the base 1, the upper part is hinged with the bottom end of a transmission rod 7, and the lower part is hinged with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com