Biaxial tension-shear test part with matrix fiber bundle and preparation method thereof

A technology of biaxial tensile shearing and matrix fiber, which is applied in the preparation of test samples, measuring devices, instruments, etc., to reduce the cost of experiments, simplify the installation process, and prevent torsion and slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0033] The preparation method of the biaxial tensile-shear test piece with matrix fiber bundle of the present invention comprises the following steps:

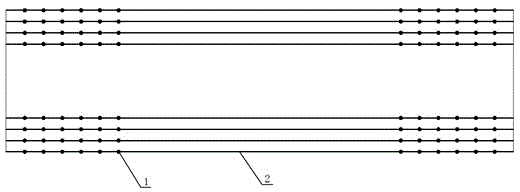

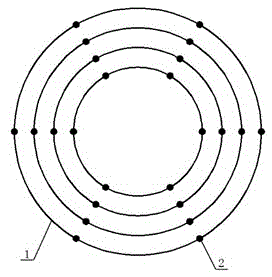

[0034] Step 1. In order to keep the prepared fiber bundle sample with matrix consistent with the shape of the woven composite material, and to make the fiber bundles distributed periodically, pull out the weft yarn in the middle part of the two-dimensional woven fiber cloth and only keep the warp yarn in the middle region of the fiber cloth 2 and fix the multi-layer extraction fiber cloth to the mold to deposit the matrix to make a round tube sample 5, such as figure 1 , figure 2 shown;

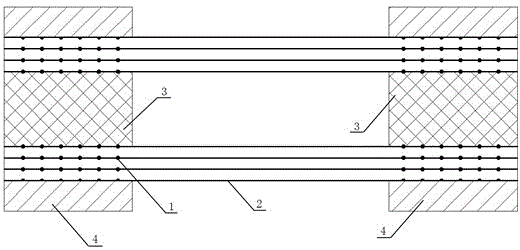

[0035] Step 2. Place the anti-crushing plug 3 made of high thermal expansion coefficient and high compressive stiffness material in an environment of 0°C to -10°C to make its volume smaller; the high therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com