Patents

Literature

52results about How to "No processing" patented technology

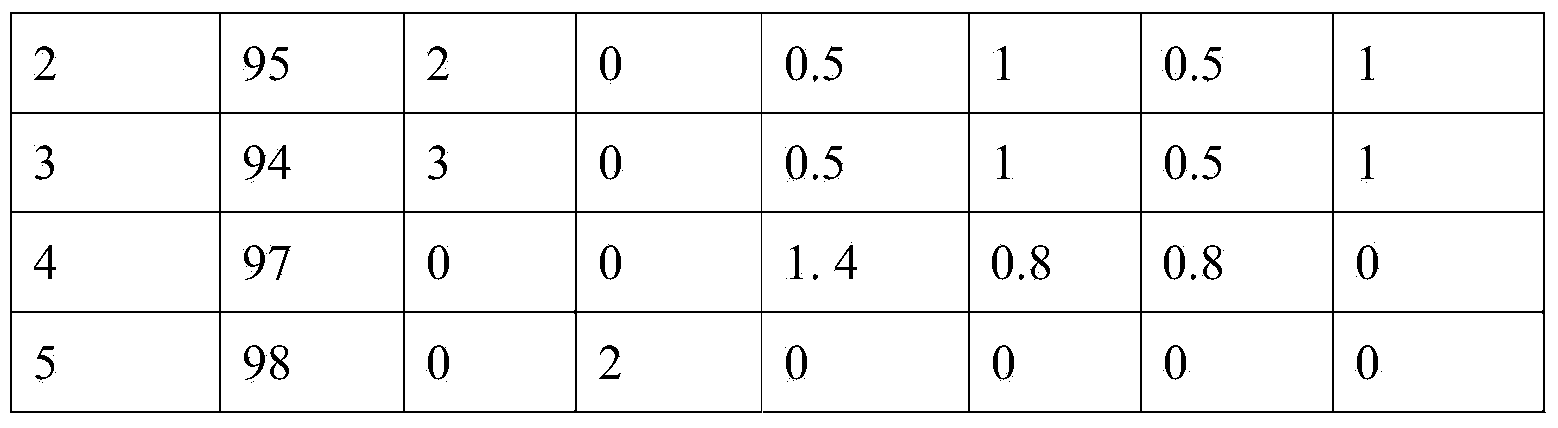

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

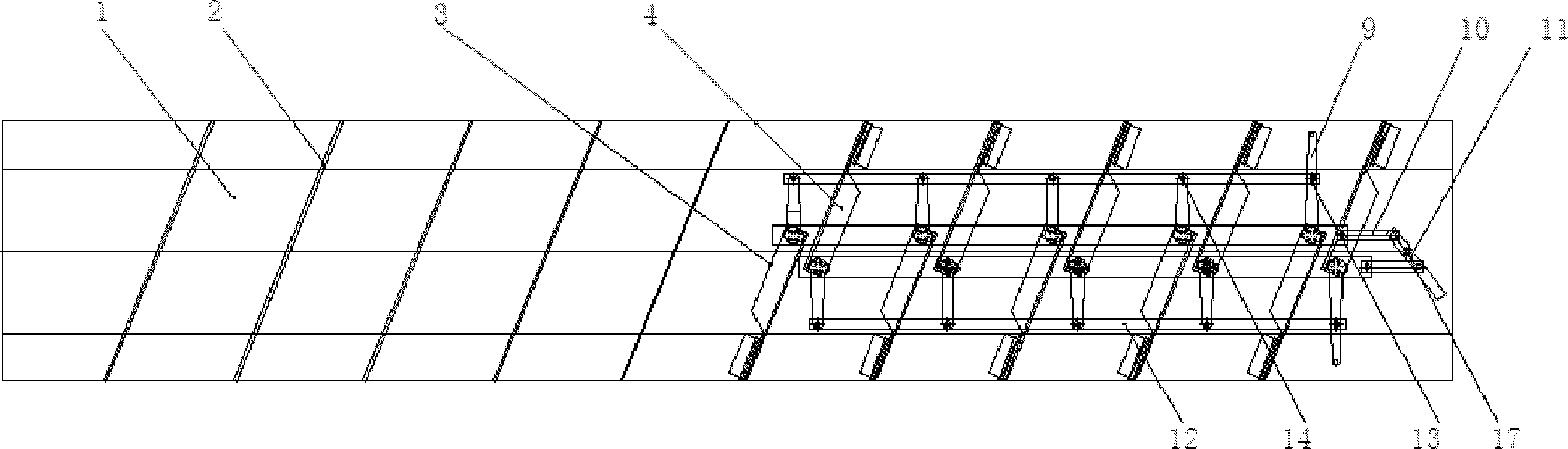

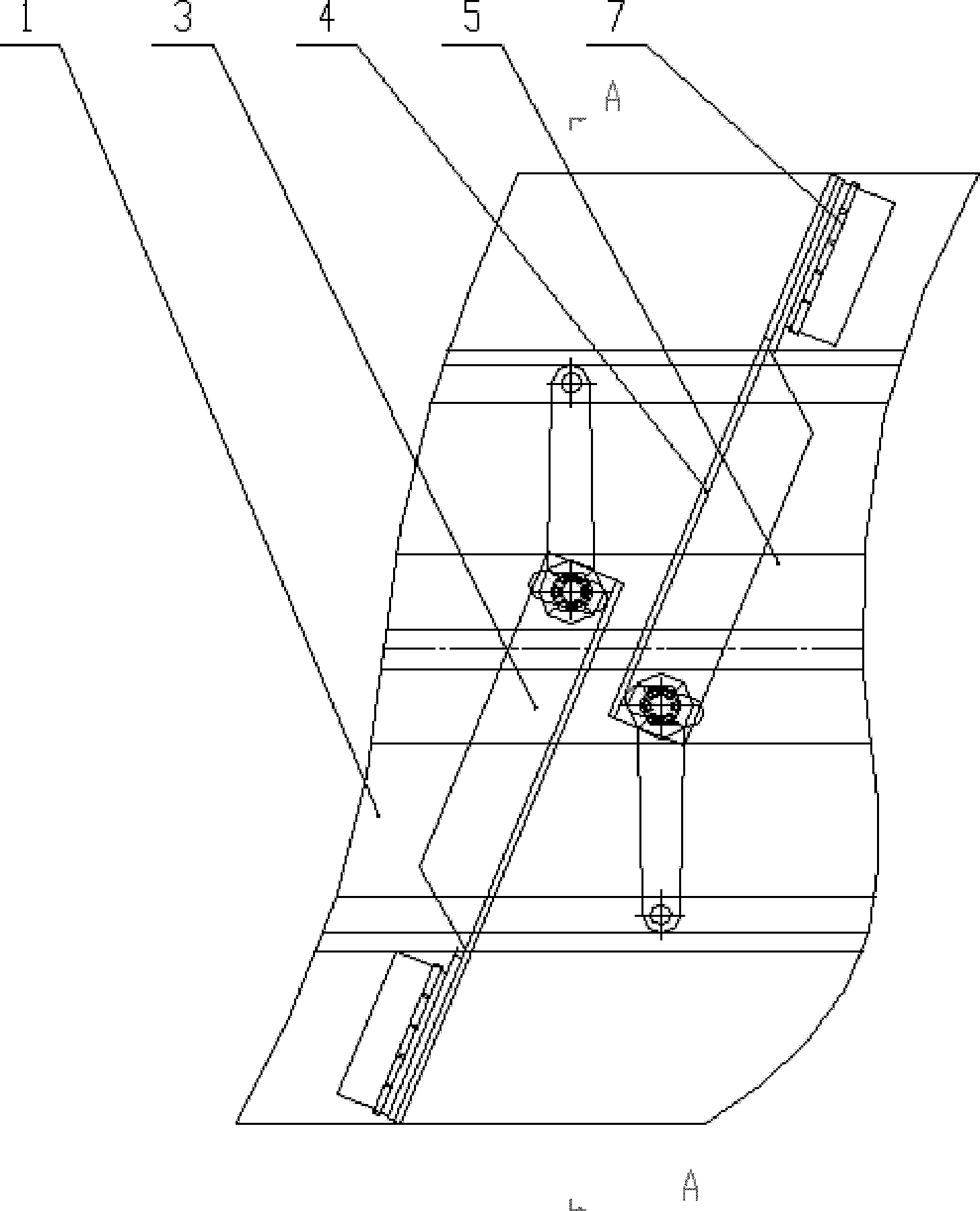

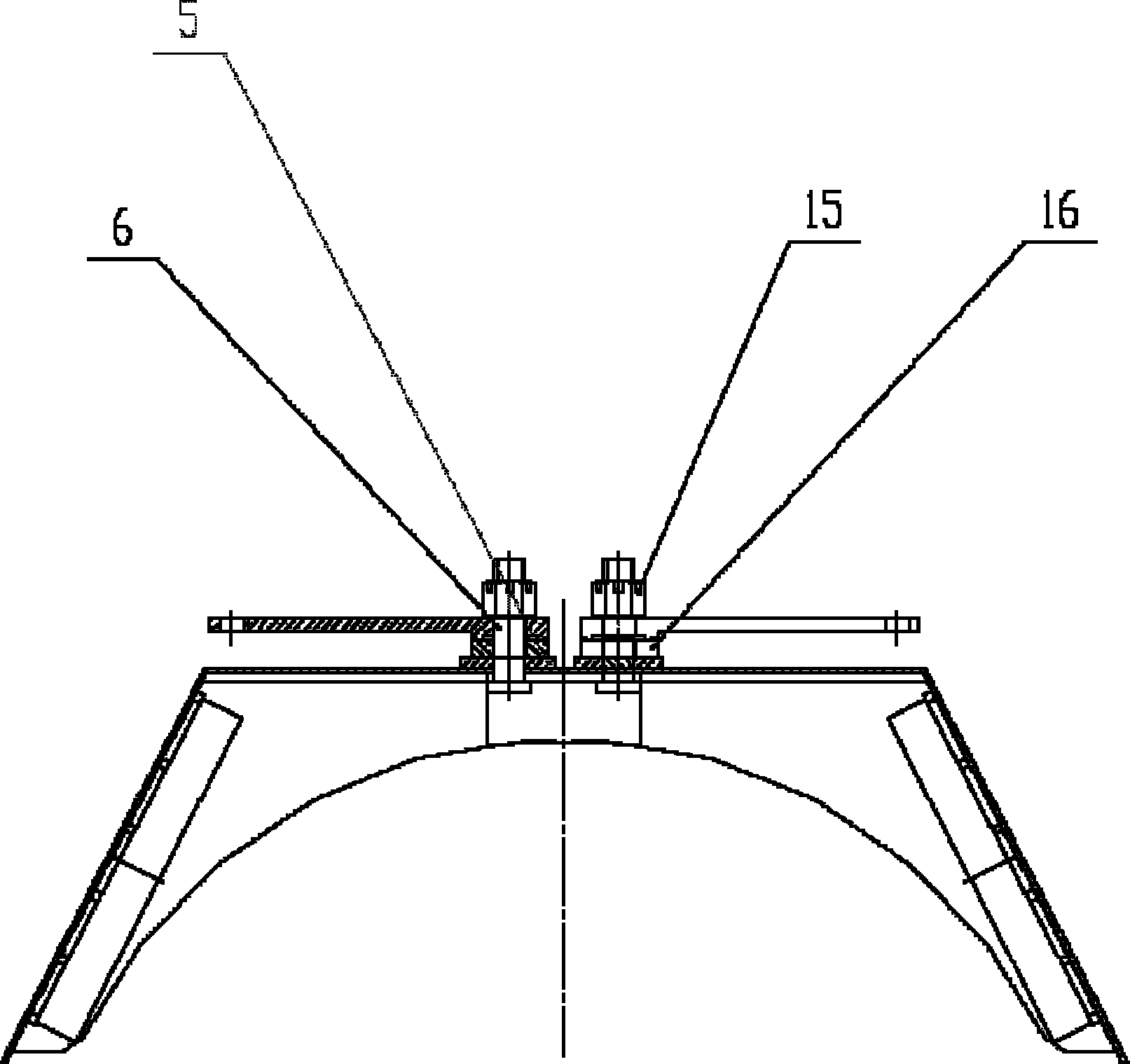

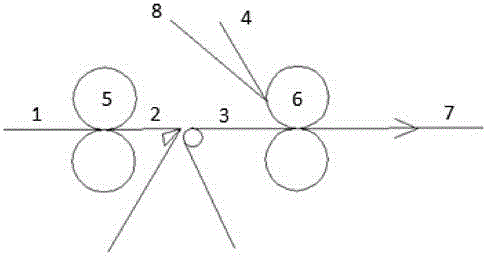

Tool and method for measuring deflection angle of airplane control surface

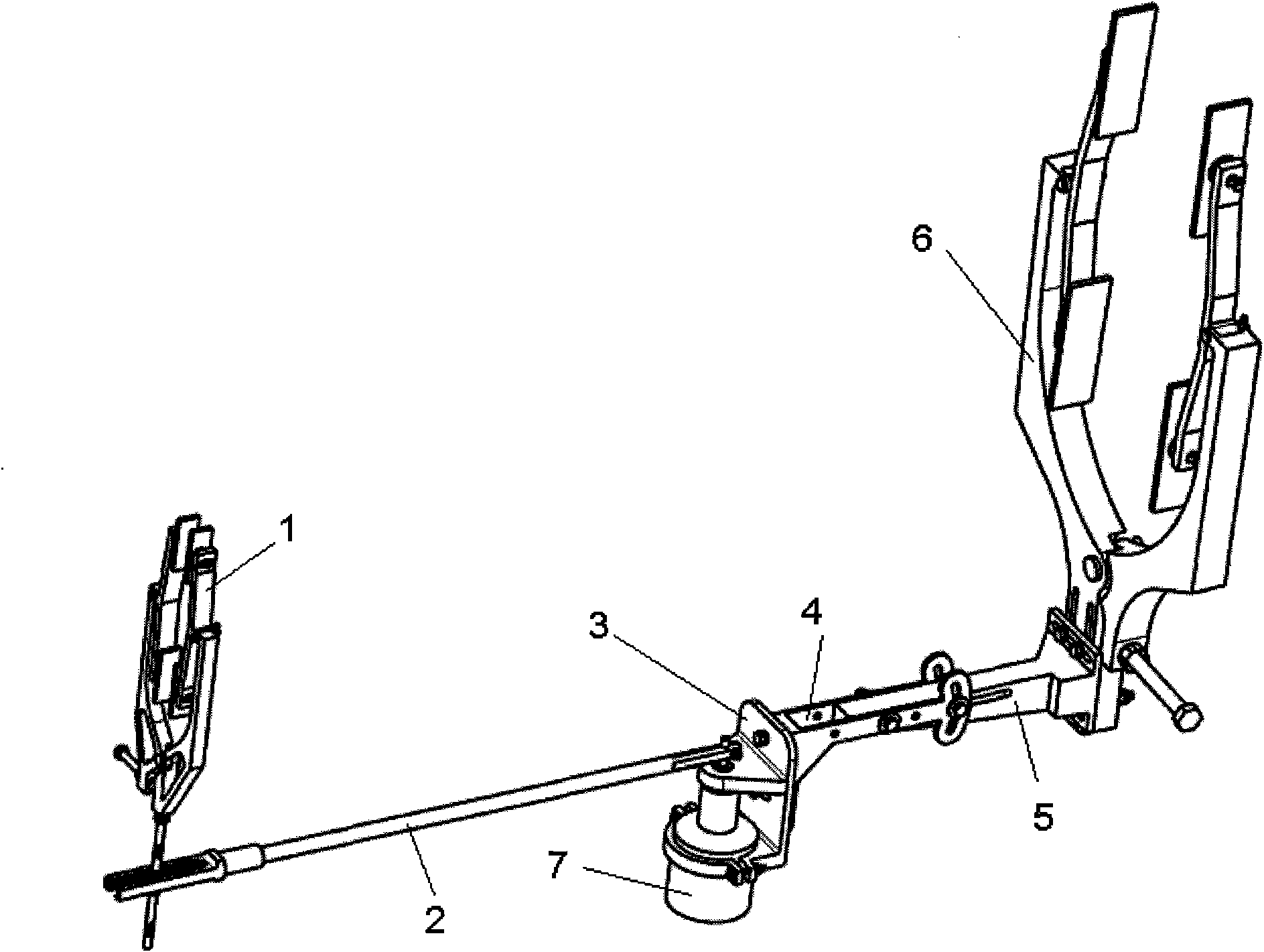

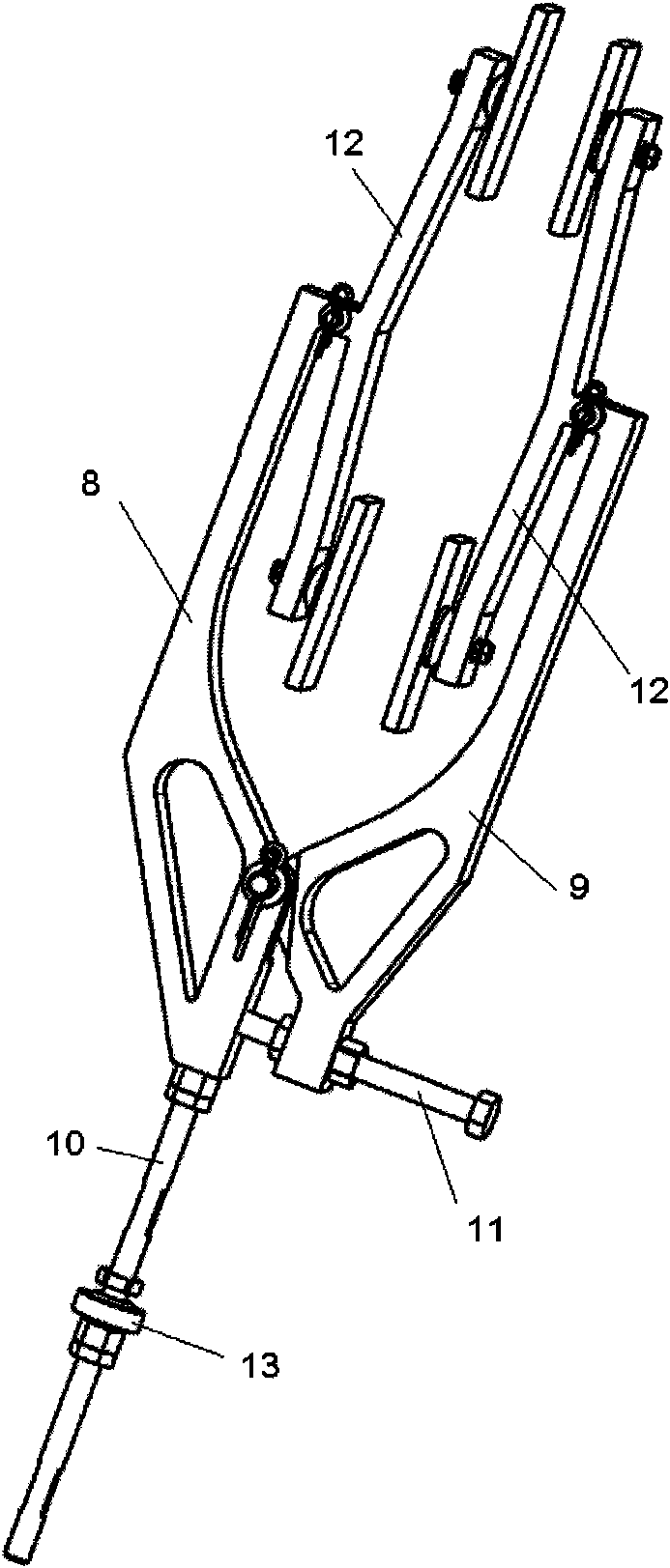

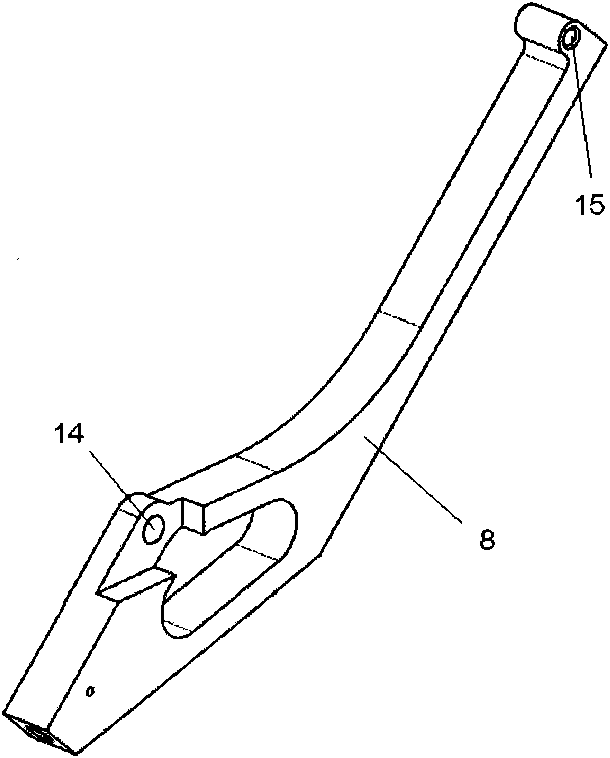

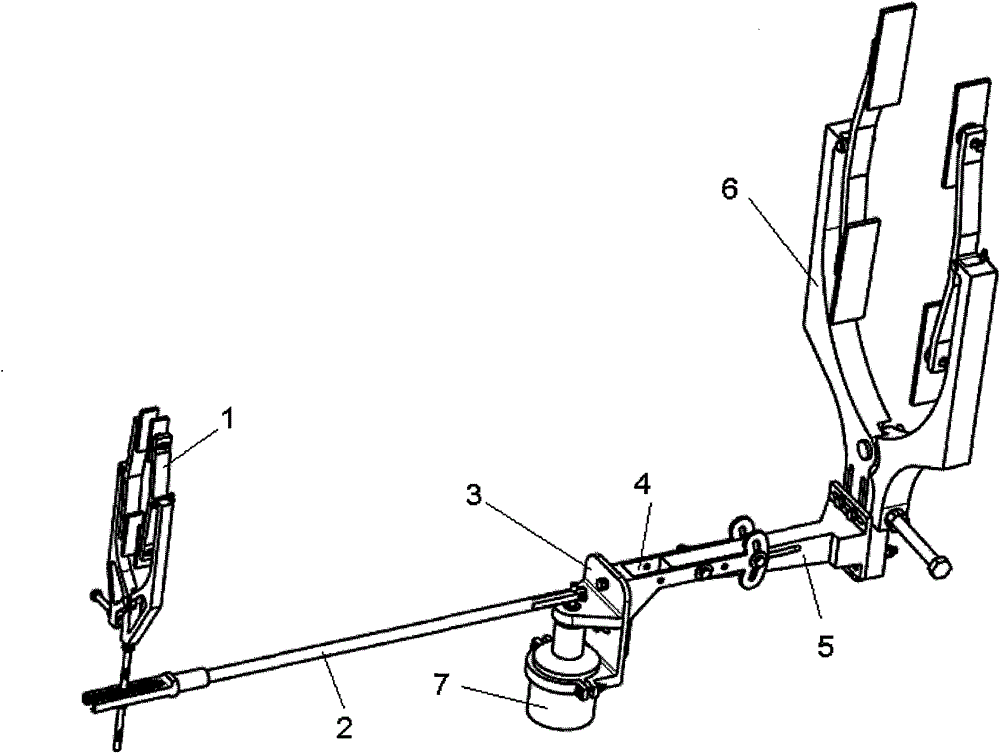

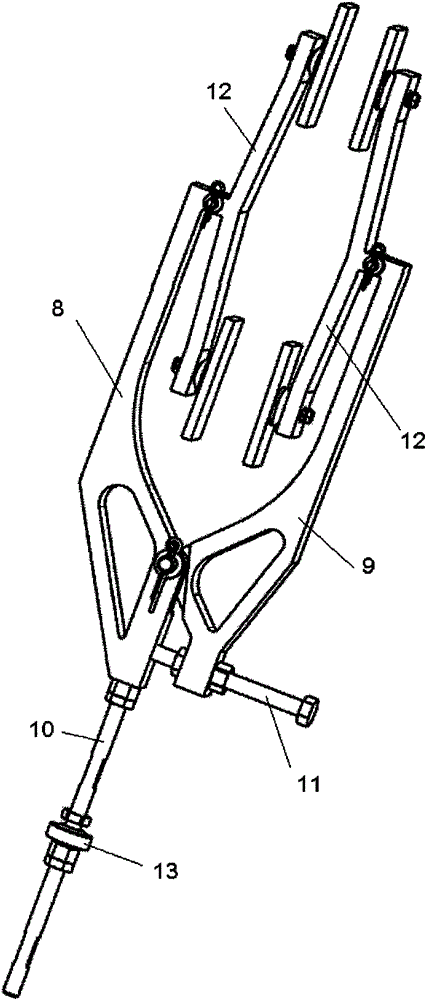

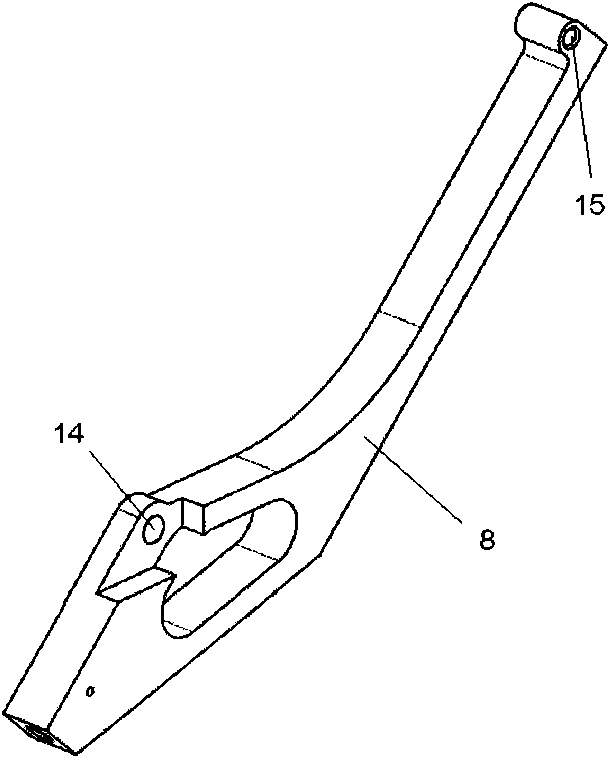

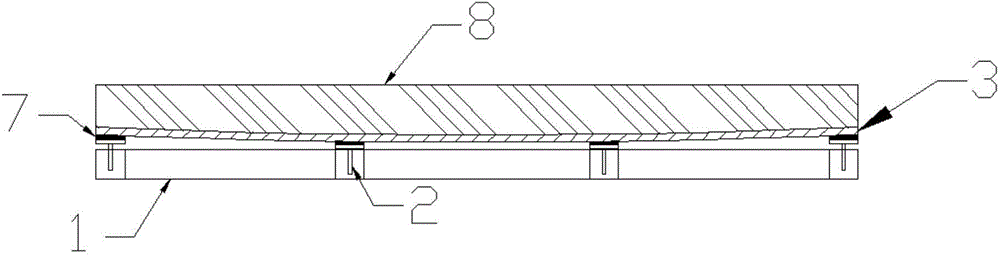

The invention discloses a tool and a method for measuring the deflection angle of an airplane control surface. The measuring tool comprises a control surface clip (1), a stabilizer clip (6), a brace rod (5), a regulating arm (4), a sensor support (3), an angular displacement sensor (7) and a forked rocker arm (2). The measuring process comprises the following steps: clamping the stabilizer clip (6) of the measuring tool to a force-bearing position of a vertical tail stabilizer (45), sequentially mounting the brace rod (5), the regulating arm (4), the sensor support (3), the angular displacement sensor (7) and the forked rocker arm (2) in place, clamping the control surface clip (1) to a force-bearing position of an upper rudder (46), and moving the angular displacement sensor (7) to a rotary shaft of the upper rudder (46) so as to measure the deflection angle of the control surface. The invention can be simultaneously used for measuring the deflection angle of the rudder or the elevator in the bench test or the ground built-in test of an airplane, can be directly used for measuring the deflection angle of the control surface without disassembling structural parts of the airframe, and is especially suitable for the condition that the deflection amount can not be educed for measurement by means of a link mechanism in case that the rotary shaft is arranged inside the envelope of the control surface.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

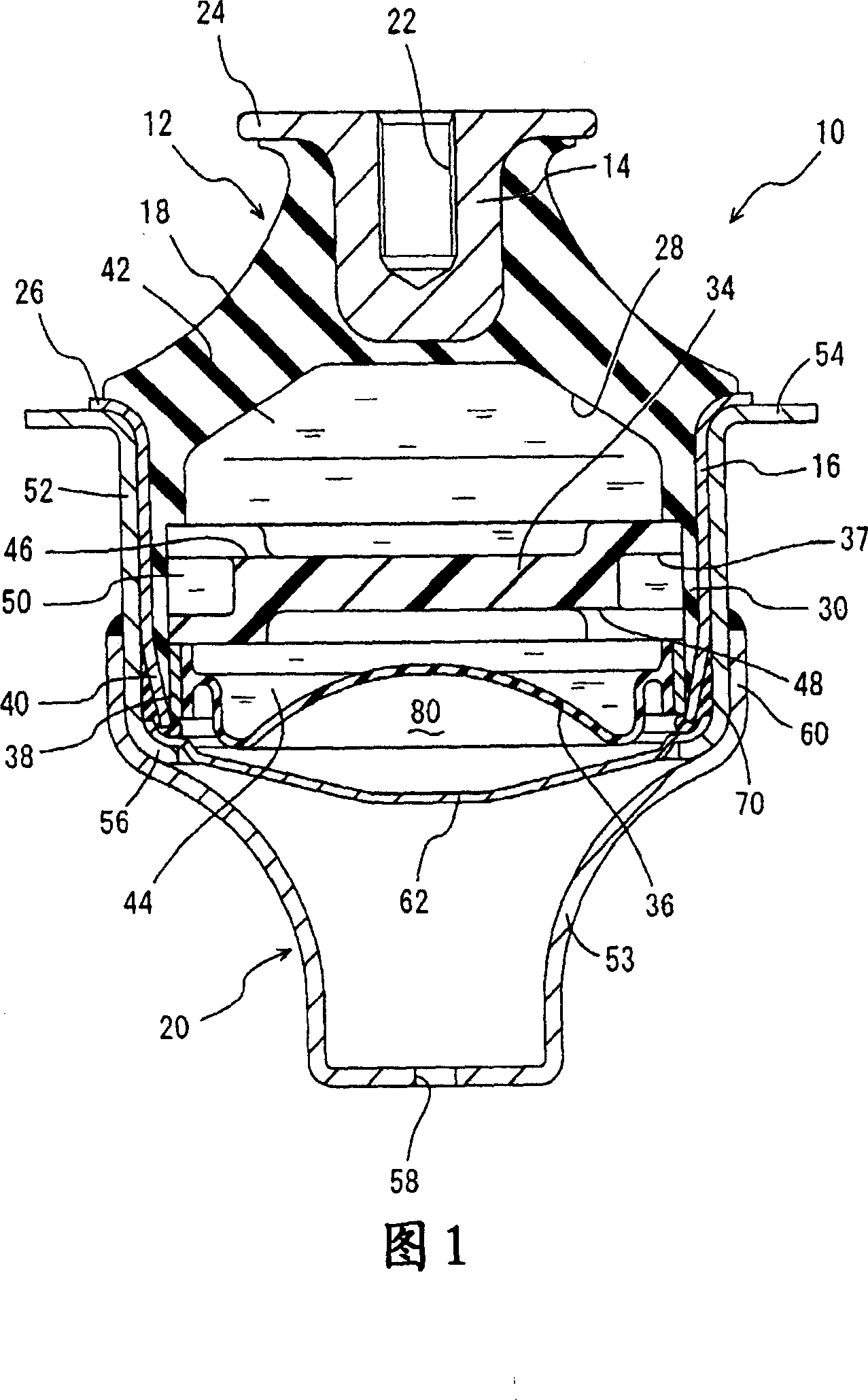

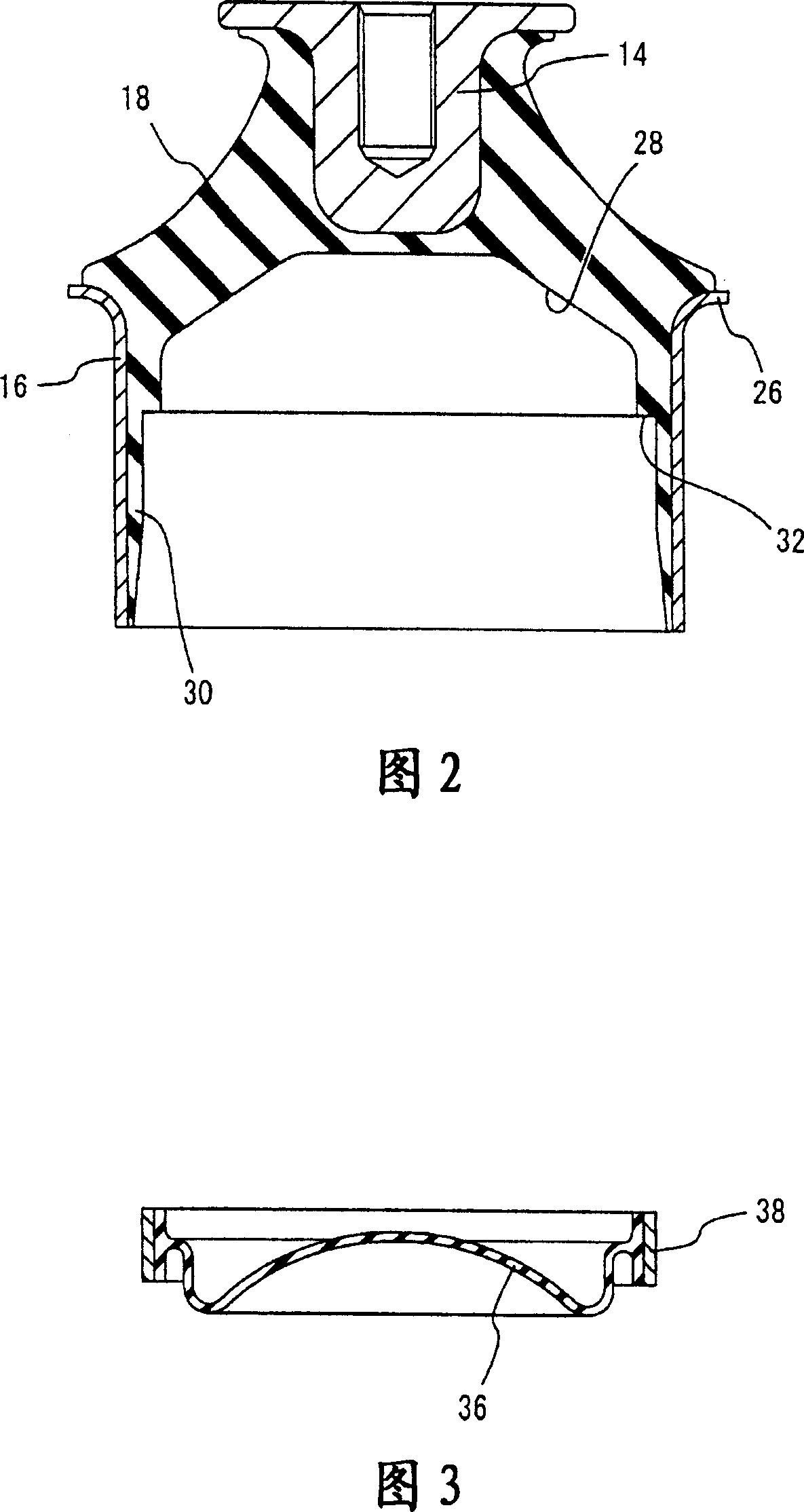

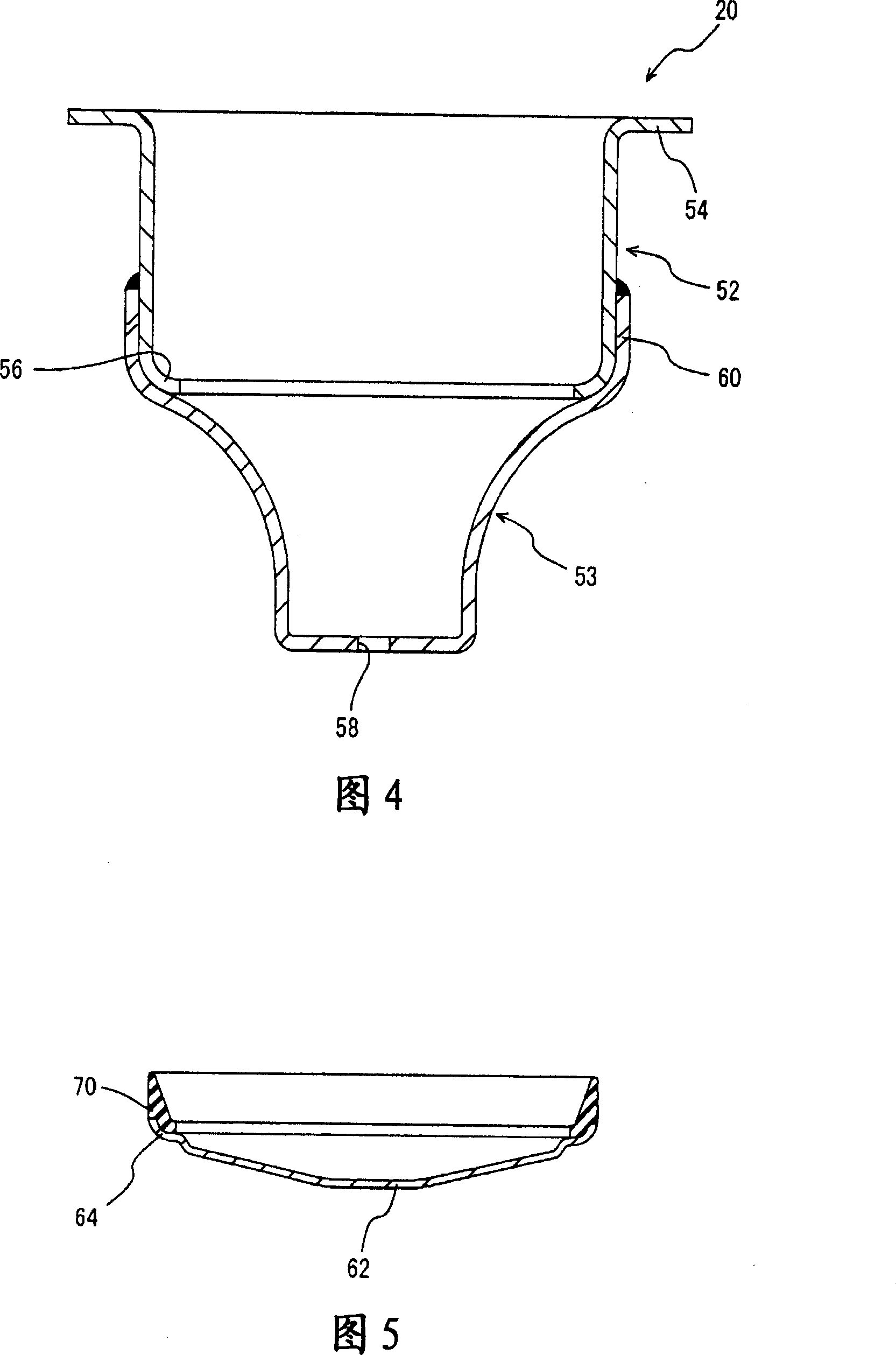

Fluid filled vibration damping device and method of producing the same

A fluid filled vibration damping device including an elastic body connecting a first and second mounting member, a pressure-receiving chamber defined by the elastic body and an equilibrium chamber defined by a flexible rubber film. The second mounting member is press fitted into a tubular holder member having an annular holding portion integrally formed at its lower end projecting radially inwardly. A cover plate member having an outside diameter smaller than an inside diameter of the holder member is disposed within the holder member with an outer peripheral portion is fixedly clamped by the second mounting member and the annular holding portion. A sealing rubber is disposed for fluid-tightly closing a gap formed between the clamped portion so that an tightly closed air chamber defined by the cover plate member is formed on a back side of the flexible rubber film.

Owner:SUMITOMO RIKO CO LTD

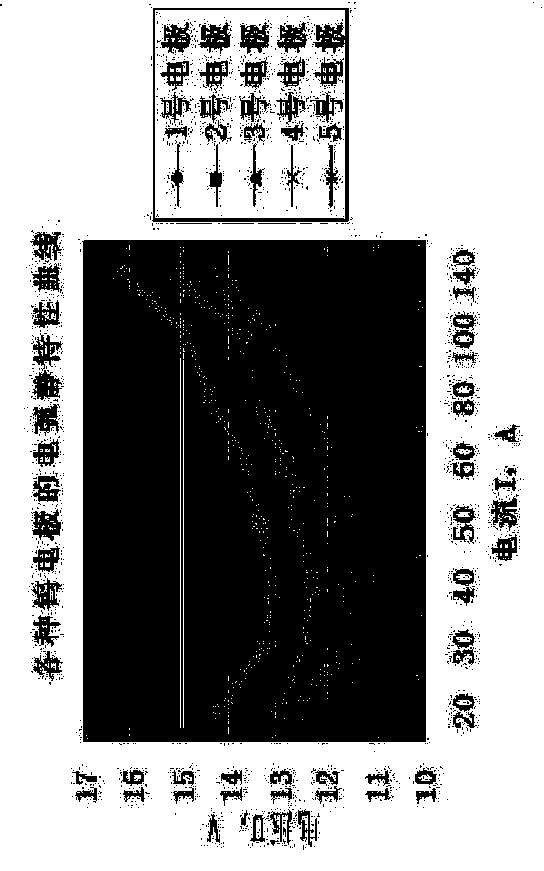

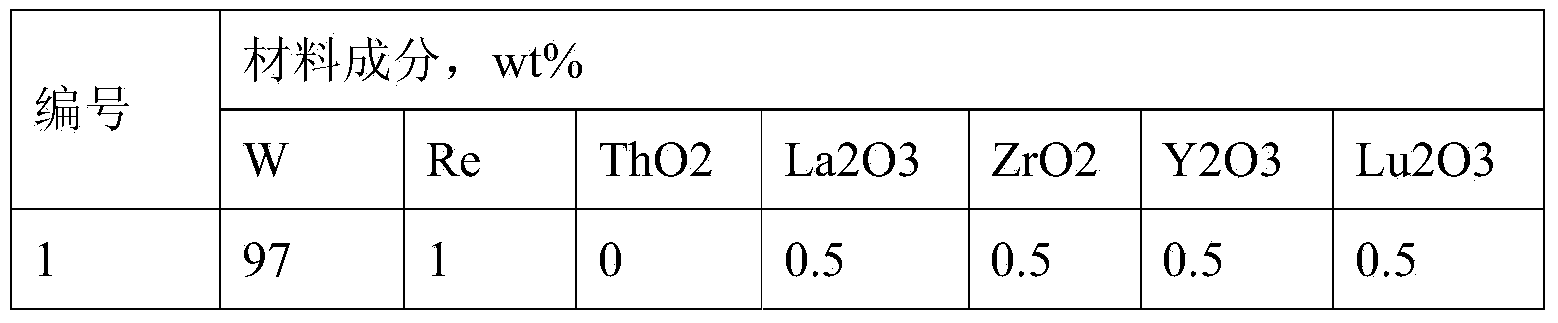

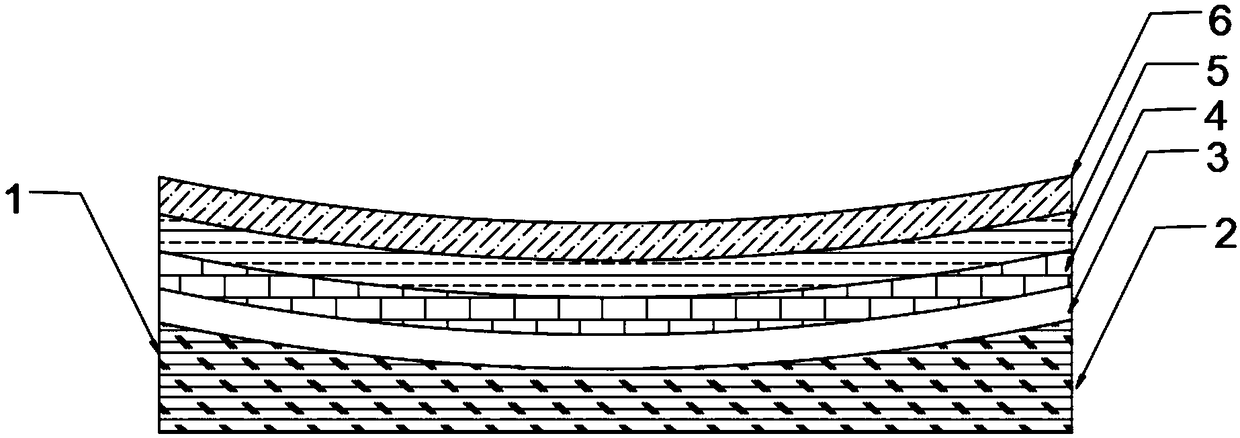

Radiation-free multi-component rare earth tungsten electrode material and preparing method thereof

InactiveCN103862196ARadiation-freeNo processingWelding/cutting media/materialsSoldering mediaRheniumRare earth

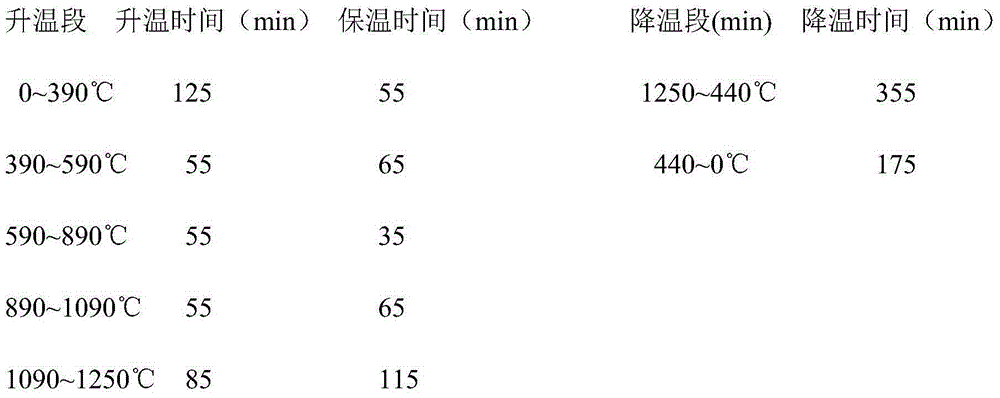

The invention discloses a radiation-free multi-component rare earth tungsten electrode material and a preparing method thereof. The radiation-free multi-component rare earth tungsten electrode material contains lanthanum oxide, zirconia, yttrium oxide, lutecia, rhenium and tungsten. The mass percent of each rare earth oxide in the material is 0.5-1.5%, the mass percent of the total quantity of the rare earth oxide in the material is 2-3%, the mass percent of alloy element rhenium in the material is 1-4%, and the balance is tungsten. The preparing method for the radiation-free multi-component rare earth tungsten electrode material comprises the procedures of solution disposition, drying, reduction, isostatic cool pressing, sintering, vertical melting, medium frequency induction annealing, B202 rotary forging, B201 rotary forging, drawing, straightening, cutting, polishing and grinding. The prepared radiation-free multi-component rare earth tungsten electrode material is easy to machine and better in use performances.

Owner:深圳市威勒科技股份有限公司

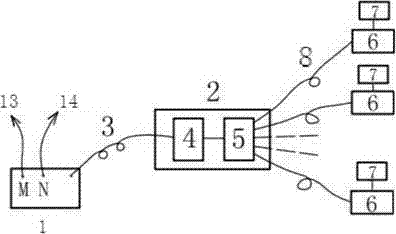

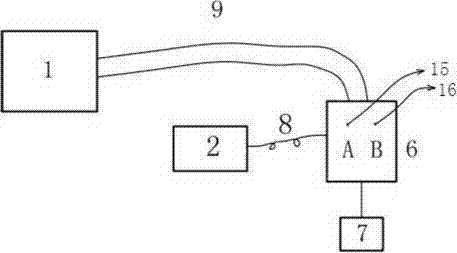

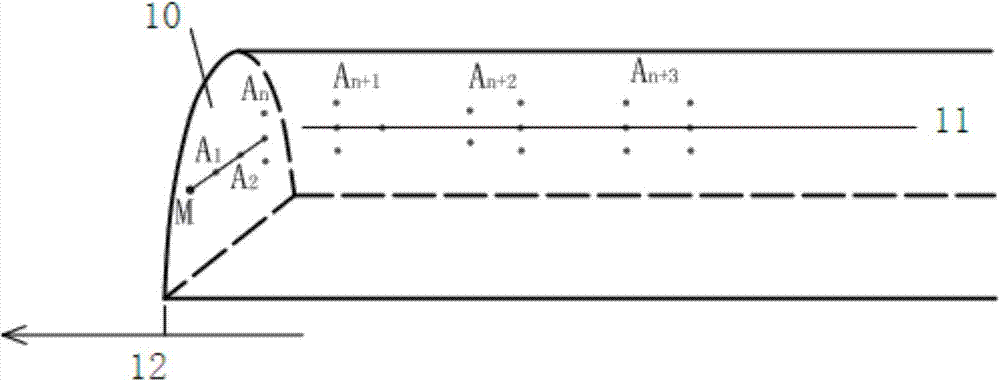

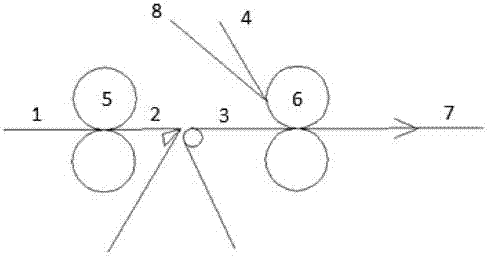

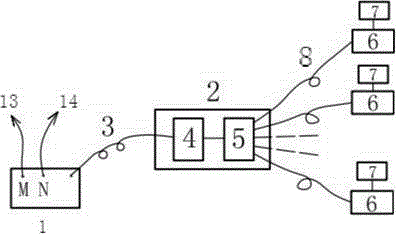

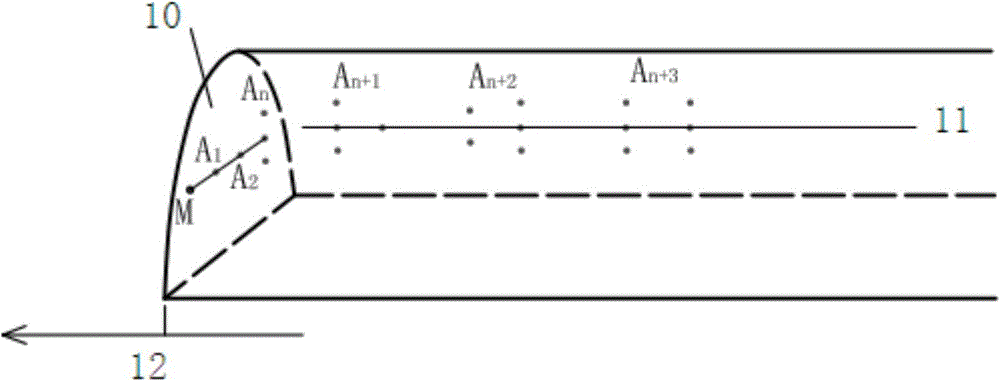

Electrical prospecting multi-electrode multi-power supply unit system and prospecting method thereof

ActiveCN103487836ALow powerEasy to implementElectric/magnetic detectionAcoustic wave reradiationPower flowPotential difference

The invention relates to an electrical prospecting multi-electrode multi-power supply unit system and a prospecting method thereof. The electrical prospecting multi-electrode multi-power supply unit system is characterized in that the numbers of power supply electrodes A and power supply electrodes B are both equal to the number of current emitting units; an emission controller comprises an emission current modulation controller and an emission delay controller which are mutually connected; a receiver is connected with the emission current modulation controller; each current emitting unit is connected with the emission delay controller, and each current emitting unit is connected with the receiver in a communicating way; the receiver is provided with terminals which are respectively used for connecting a measuring electrode M and a measuring electrode N and used for measuring the potential difference between the measuring electrode M and the measuring electrode N; each current emitting unit is respectively connected with the power supply electrodes A and the power supply electrodes B. According to the invention, the power supply current of the current emitting units is not more than 1 A, and the power supply voltage of the current emitting units is not more than 200 V; the current emitting units are low in power, easy to realize and safely used for a tunnel and arranged on a all-metal full-face tunnel boring machine.

Owner:钟世航

Vortex oscillator

ActiveCN103706275ALimited rotational movementSmooth revolutionShaking/oscillating/vibrating mixersEngineeringMixing effect

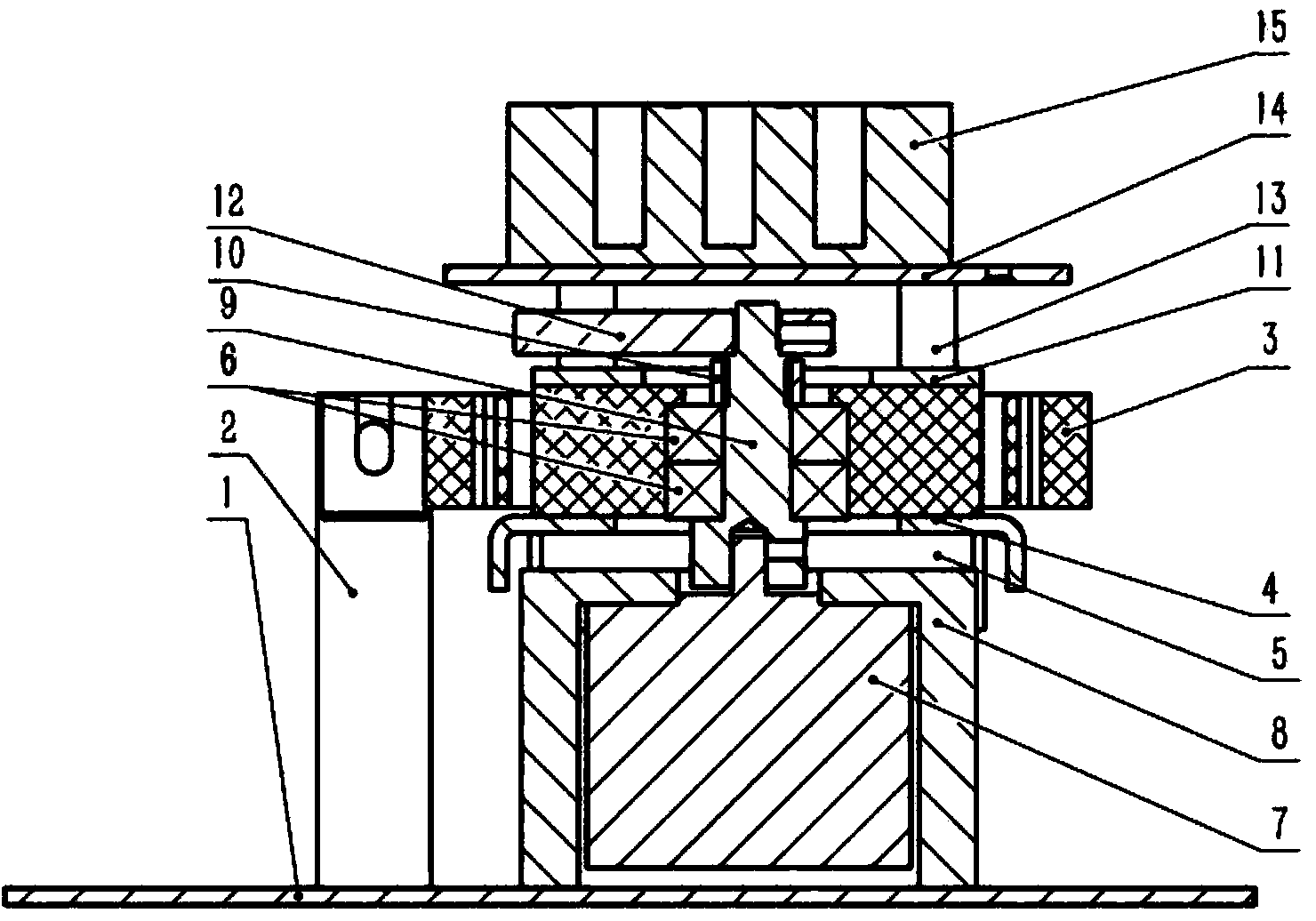

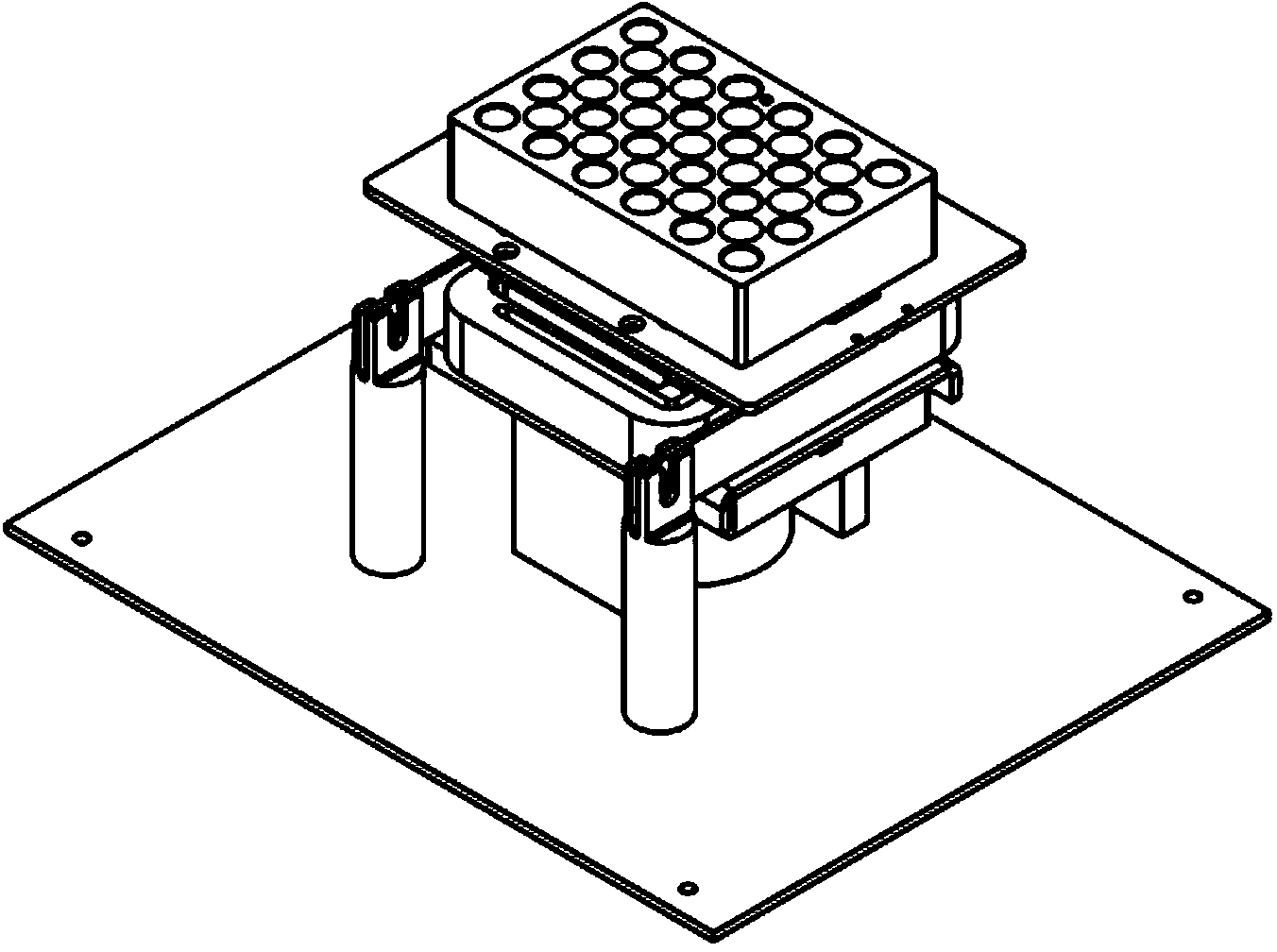

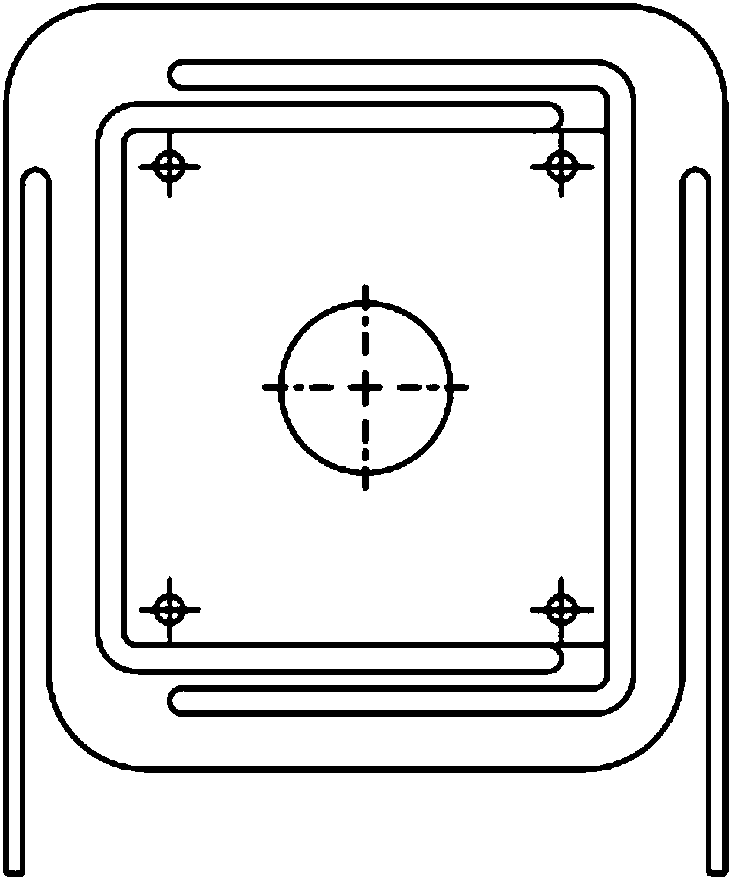

The invention relates to a vortex oscillator. A motor is fixed on a motor base, and a rotating shaft of the motor is in transmission connection with an eccentric shaft; a plastically deformable control support is mounted on the eccentric shaft through a bearing, and the plastically deformable control support and the eccentric shaft can rotate relative to each other; an upper support plate and a lower support plate are arranged above and below the plastically deformable control support respectively, an upper counterweight is arranged at the top end of the eccentric shaft, and a lower counterweight is arranged on the lower support plate; a sample block is arranged on a sample block support plate, and the sample block support plate is arranged on the upper support plate through an isolation column; the bottom of a pillar and the motor base are relatively fixed, and the top of the pillar is connected with the plastically deformable control support. The vortex oscillator provided by the invention can effectively limit the autorotation motion of the sample block and ensure the stable revolution motion of the sample block, and enables a reagent placed in a test tube in the sample block to produce a stable vortex so as to achieve an excellent uniform mixing effect.

Owner:北京达博创新科技开发有限公司

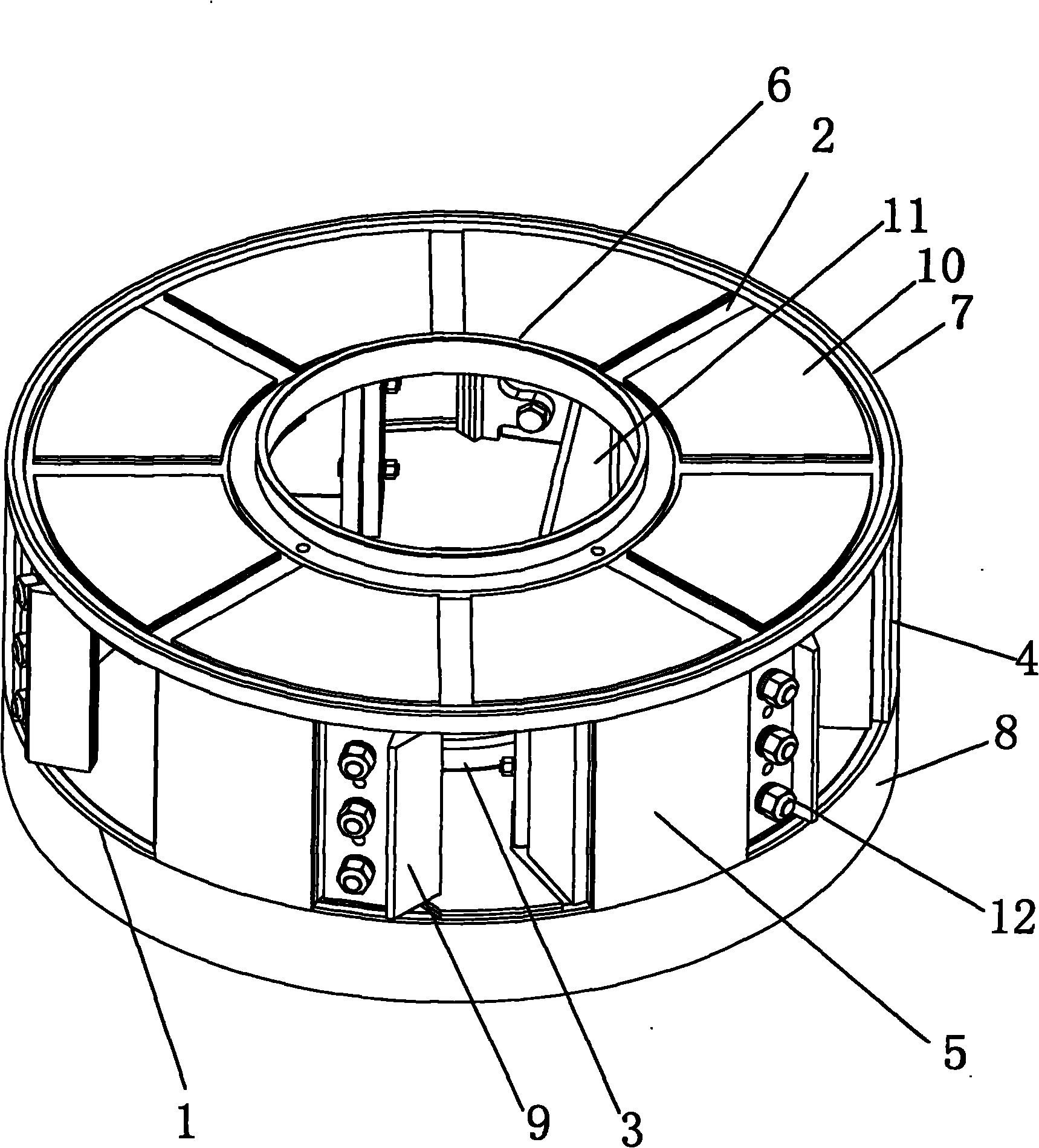

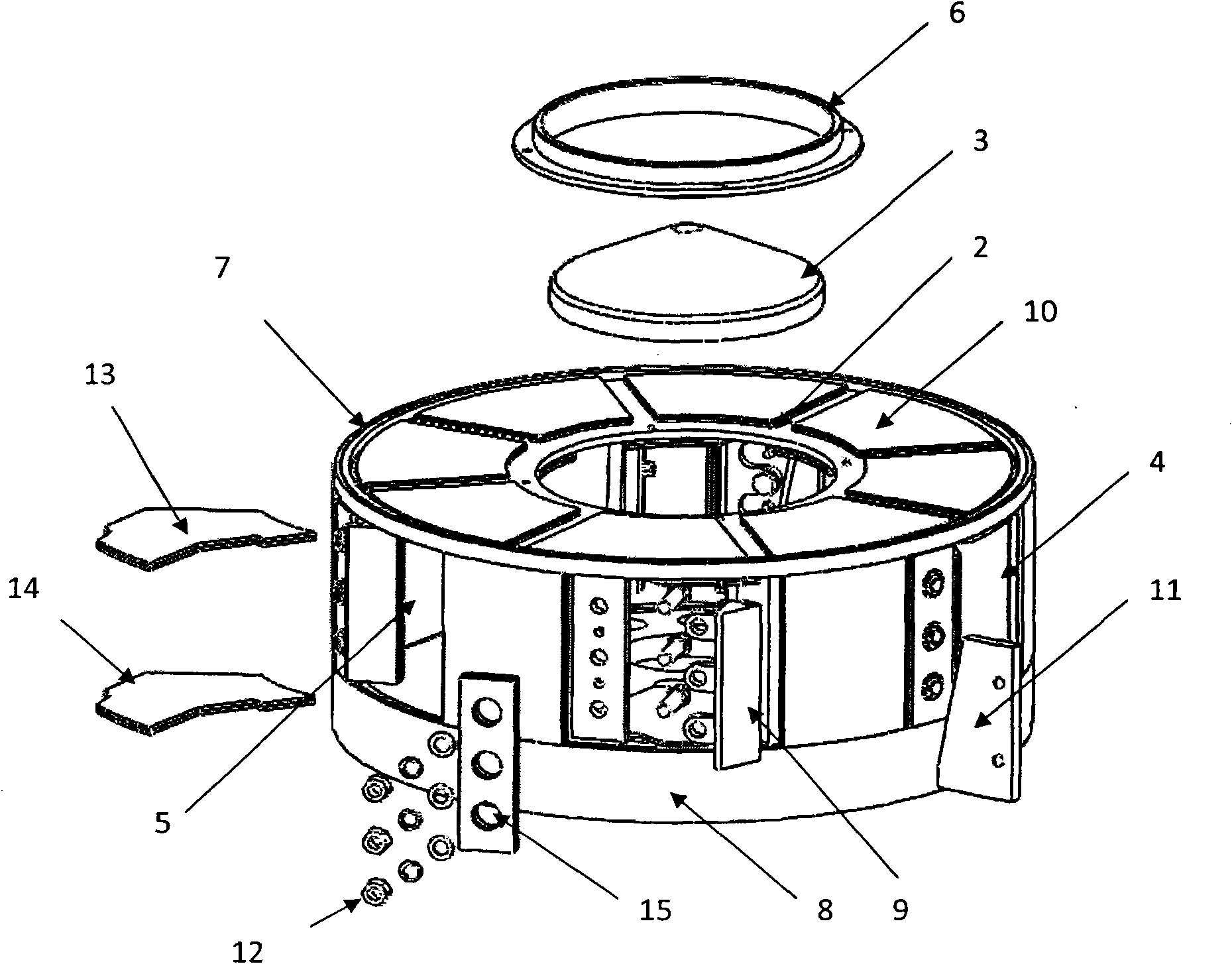

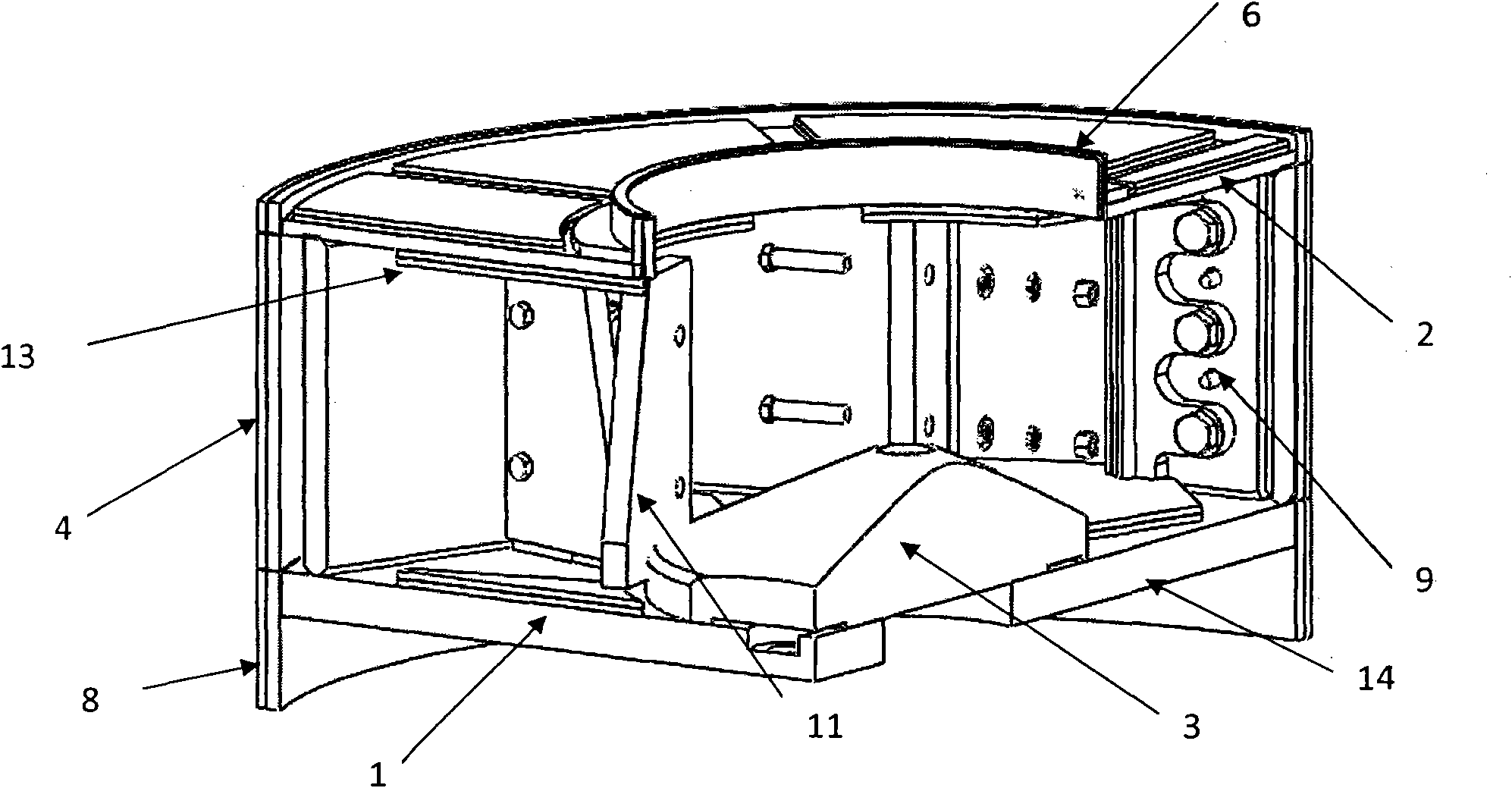

Structure type impeller breaker

The invention relates to a structure type impeller breaker, comprising a rotor; the structure type impeller breaker is characterized in that: the rotor comprises a bottom plate (1), a ring-shaped top plate (2), a material dividing cone (3) and a plurality of connection plates (4); the material dividing cone (3) is fixed on the bottom plate (1) by a fastening piece, the connection plates (4) are arranged between the bottom plate (1) and the ring-shaped top plate (2), and a material blowing opening (5) is formed between the adjacent connection plates (4); a discharging outlet protecting ring (6) is arranged at the center of the ring-shaped top plate (2), an upper protecting ring (7) is welded at the outer ring of the ring-shaped top plate (2), a lower protecting ring (8) is welded at the outer ring of the bottom plate (1), and a wear resistant material layer is arranged on the outer surface of the connection plate (4); a replaceable injection orifice lining plate (9) is arranged at the same sides of all material blowing openings (5), and an upper padding plate (13) and a lower padding plate (14) are respectively welded on the upper and lower surfaces of the material blowing opening (5). The structure type impeller breaker radically solves the difficult problem that a rotor wear-out part is hard to be used repeatedly after being worn out, a great amount of raw material can be saved and the cost is reduced.

Owner:NANJING ZHONGDA BUILDING MATERIAL EQUIP MFG

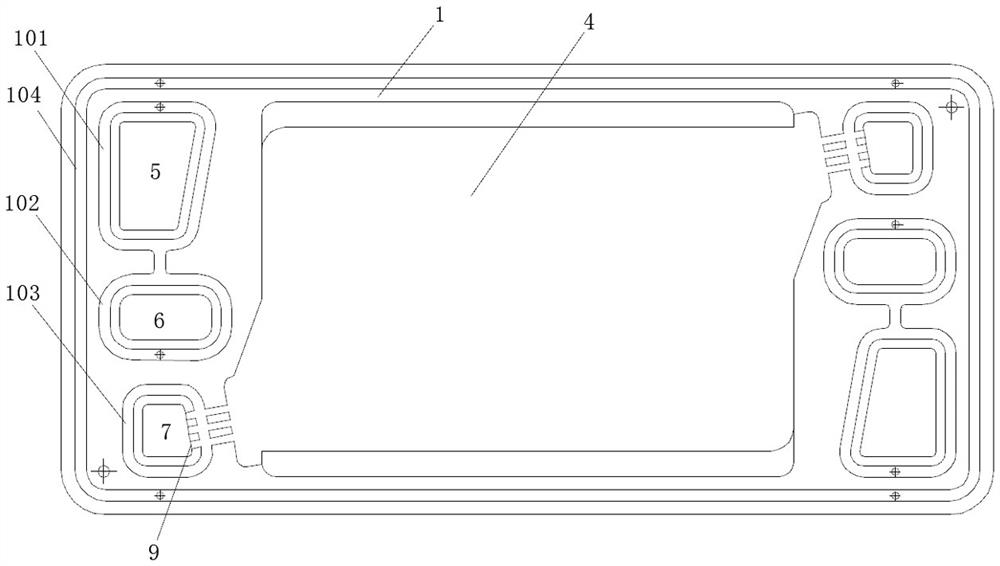

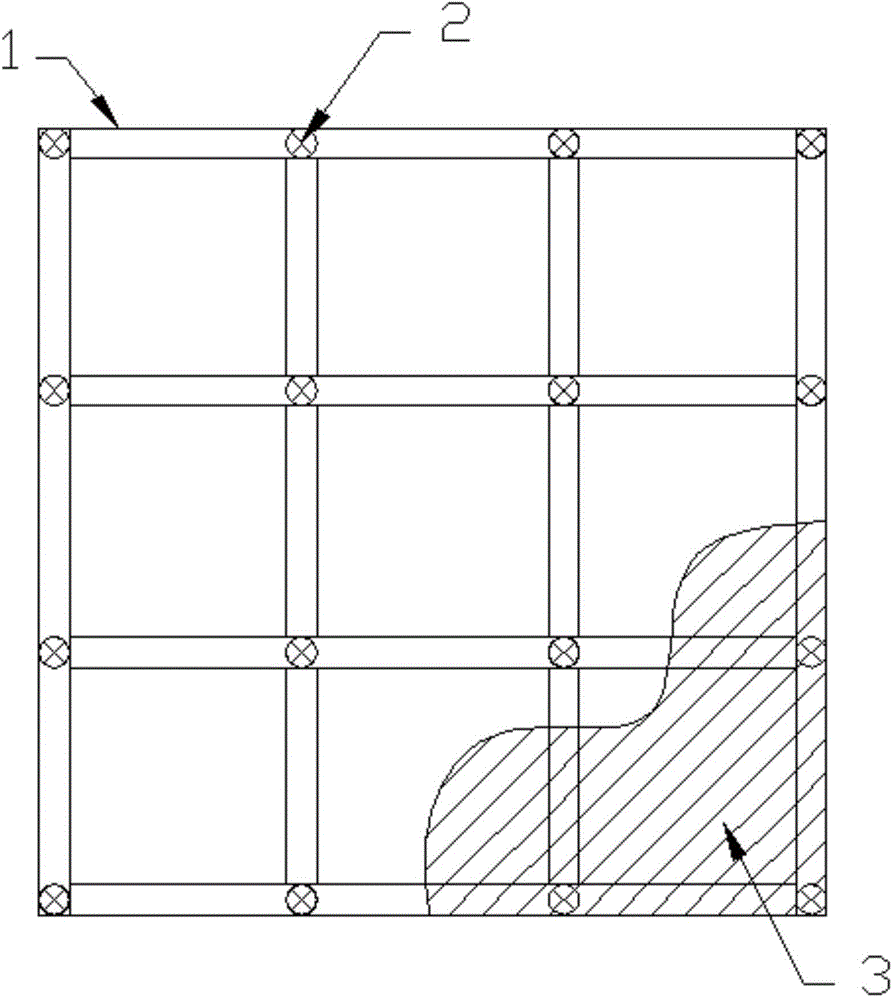

Splicing machining process for circular knife die cutting material

InactiveCN104260148AIncrease profitSimple processMetal working apparatusEngineeringMachining process

Disclosed is a splicing machining process for a circular knife die cutting material. The splicing machining process for the circular knife die cutting material includes the following steps that (1) preliminary longitudinal frames of a product are formed by die cutting, and the densely die cut preliminary longitudinal frames are widened to the design width; (2) preliminary transverse frames of the product cover another material strip in a fitting mode, the vertical interval of the upper and lower preliminary transverse frames is designed in a design height; (3) matched convex snap-in structures and concave snap-in structures are formed at two ends of the preliminary longitudinal frames and at corresponding positions of the preliminary transverse frames by die cutting; (4) the preliminary transverse frames and the preliminary longitudinal frames are spliced together in a covering mode, and the convex snap-in structures and the concave snap-in structures are spliced in a snap-in mode; (5) an inner frame and an outer frame of the product are formed by die cutting, and subsequent machining is performed. By means of the splicing machining process for the circular knife die cutting material, inner outline waste materials are not generated, the utilization rate of the die cutting material is increased, the process is simple, machining of complicated parts is absent, the usage is convenient, and producing costs are low.

Owner:DONGGUAN HUAMAO PRECISION MACHINERY TECH

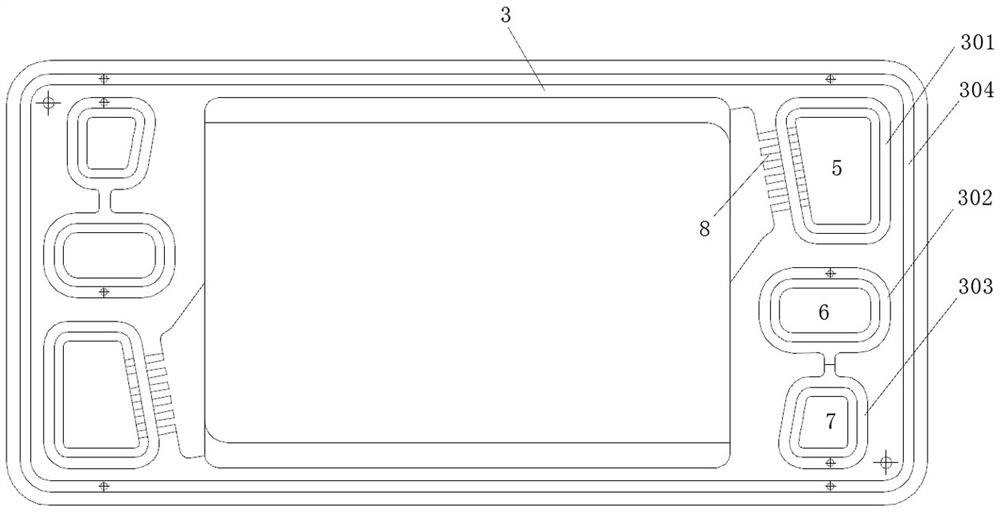

Sealing structure and sealing method of non-welded metal plate single battery

PendingCN112701315AReduce manufacturing costImprove yieldSealing/support meansStructural engineeringBattery cell

The invention relates to a sealing structure and a sealing method of a non-welded metal plate single cell, the sealing structure comprises a single cell formed by stacking an anode plate, a membrane electrode and a cathode plate together, an air main channel is communicated with a cathode flow field through an air side air inlet duct and a negative plate air side boss, and a hydrogen main channel is communicated with an anode flow field through a hydrogen side gas inlet duct by penetrating through a hydrogen side boss of an anode plate; the anode plate air side boss is communicated with the anode plate water side boss through a first channel, a first communication hole is formed in a membrane electrode frame between the anode plate water side boss and the cathode plate water side boss, and the cathode plate water side boss is communicated with the cathode plate hydrogen side boss through a second channel; and sealing rings are formed in the anode plate air side boss, the first channel, the anode plate water side boss, the cathode plate water side boss, the second channel and the cathode plate hydrogen side boss through integrated glue injection. The sealing structure and the sealing method are high in reliability, low in production cost and high in production efficiency.

Owner:FUJIAN YANAN ELECTRIC MACHINE

Magnetorheological chemical mechanical polishing solution used for SiC single crystal wafer and using method thereof

InactiveCN106281043ARealize continuous processingScratch freePolishing compositions with abrasivesMaterial removalSurface roughness

The invention provides a magnetorheological chemical mechanical polishing solution used for a SiC single crystal wafer and a using method thereof. A key formula of the magnetorheological chemical mechanical polishing solution is formed by a part A and a part B. The formula A comprises 3-10 wt% of abrasive particles, 5-30 wt% of magnetic particles, 1-10 wt% of dispersion stabilizer and base carrier liquid. The formula B comprises 1-30 wt% of oxidizing agent, 1-10 wt% of catalyst, 0.01-1 wt% of PH value modifier and base carrier liquid. By adoption of the magnetorheological chemical mechanical polishing solution, the formulas A and B can be used in a mixed mode or independently prior to processing according to different device and polishing requirements. The magnetorheological chemical mechanical polishing solution has the advantages that the surface roughness of the SiC single crystal wafer obtained after precision polishing processing, the material removal rate can reach 0.1-3.8 [mu]m / h, and the polishing finished surface is flat and smooth. A process for preparing the polishing solution is simple, and the magnetorheological chemical mechanical polishing solution is convenient to use and operate, low in cost and high in efficiency, can be used for processing the silicon surface and the carbon surface of the SiC single crystal wafer and have very high appcability and economic value.

Owner:GUANGDONG UNIV OF TECH

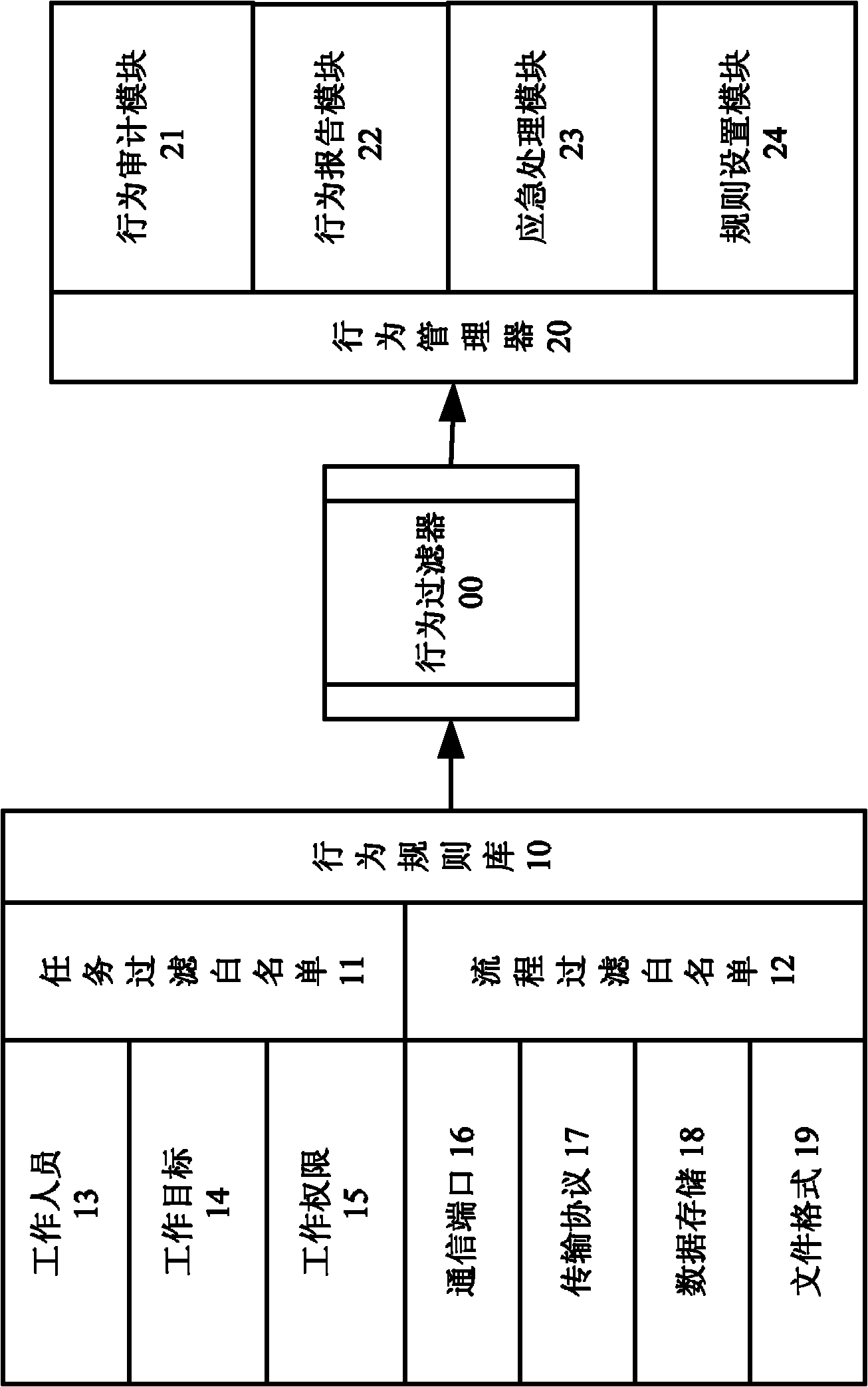

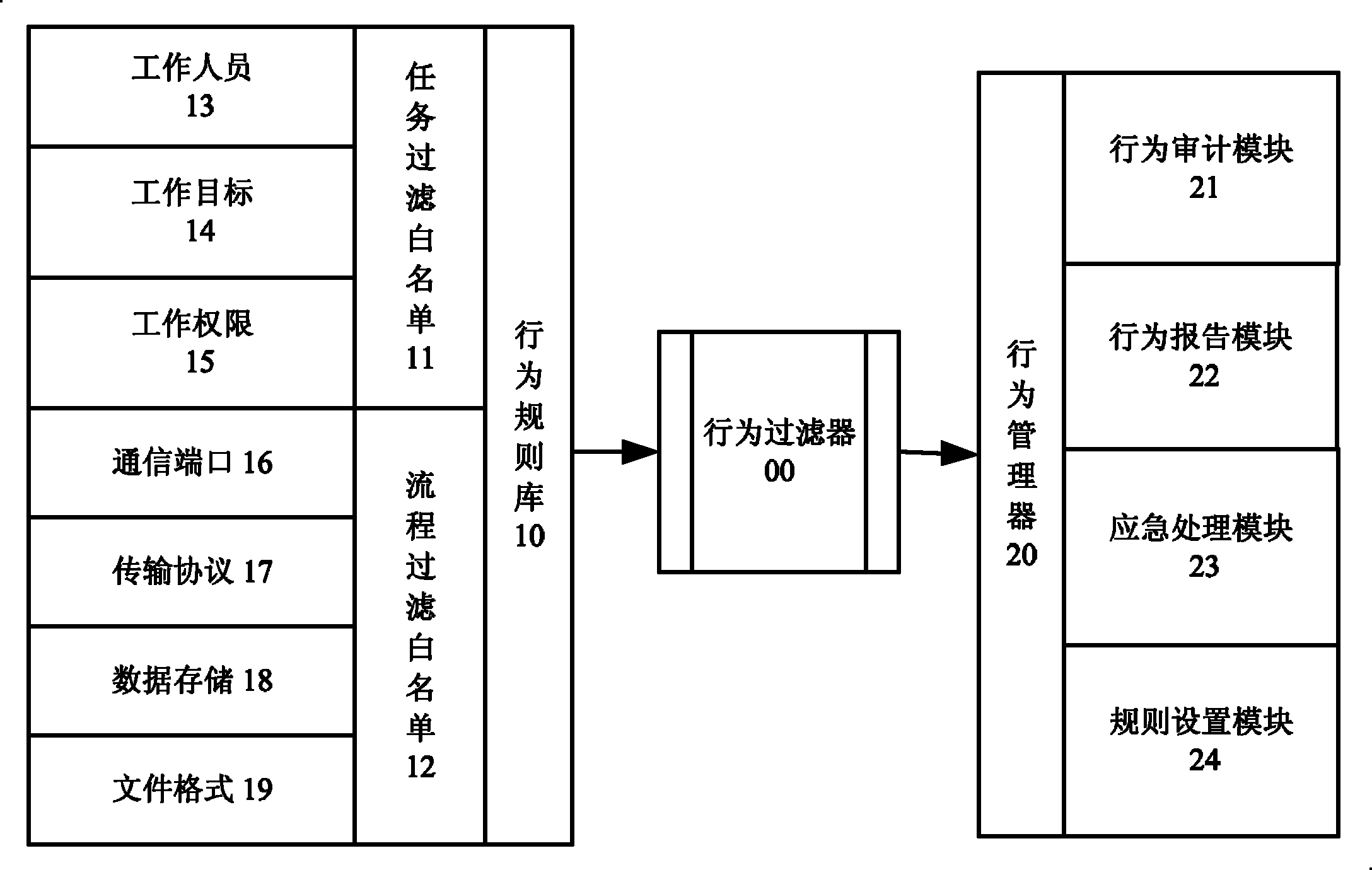

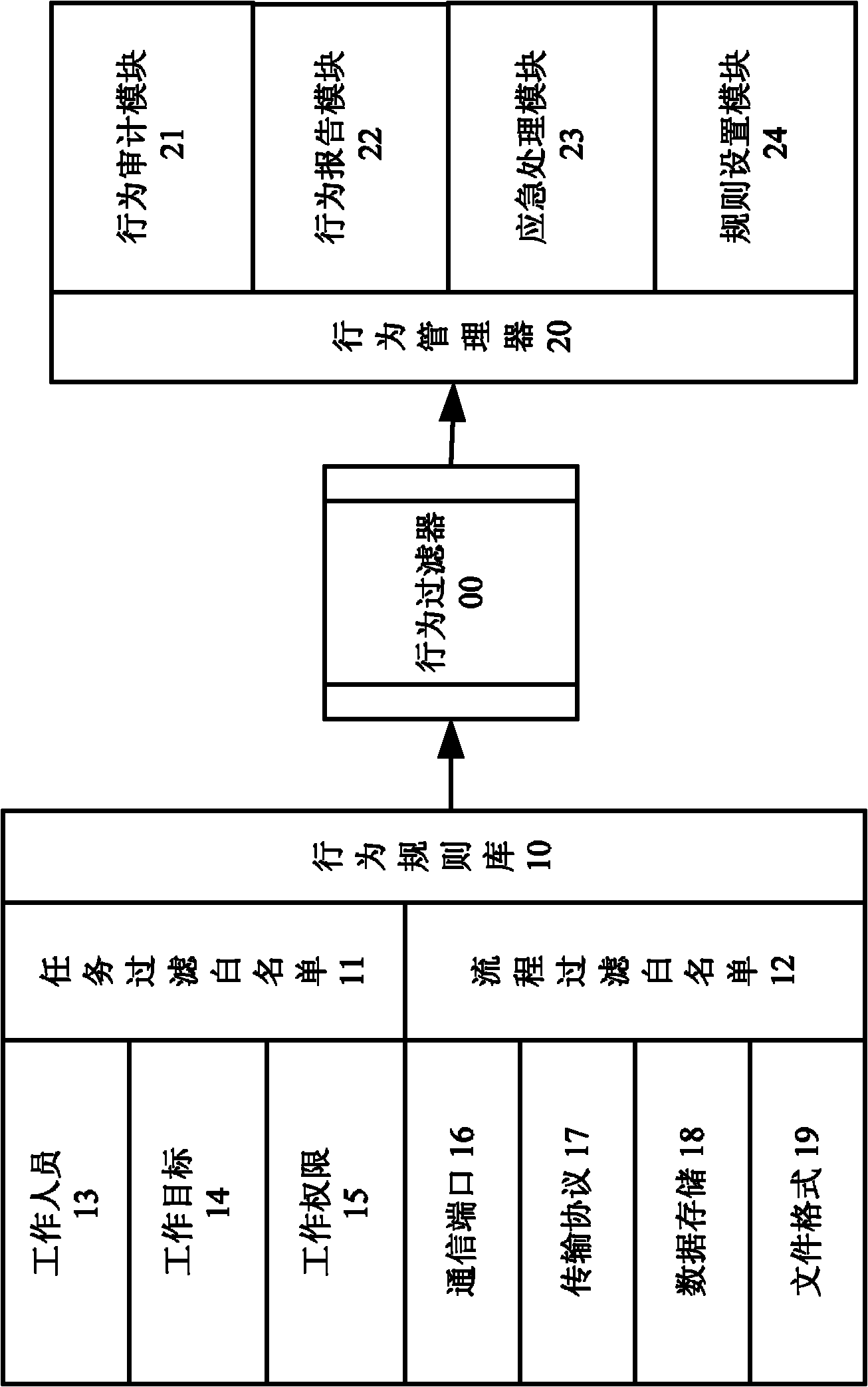

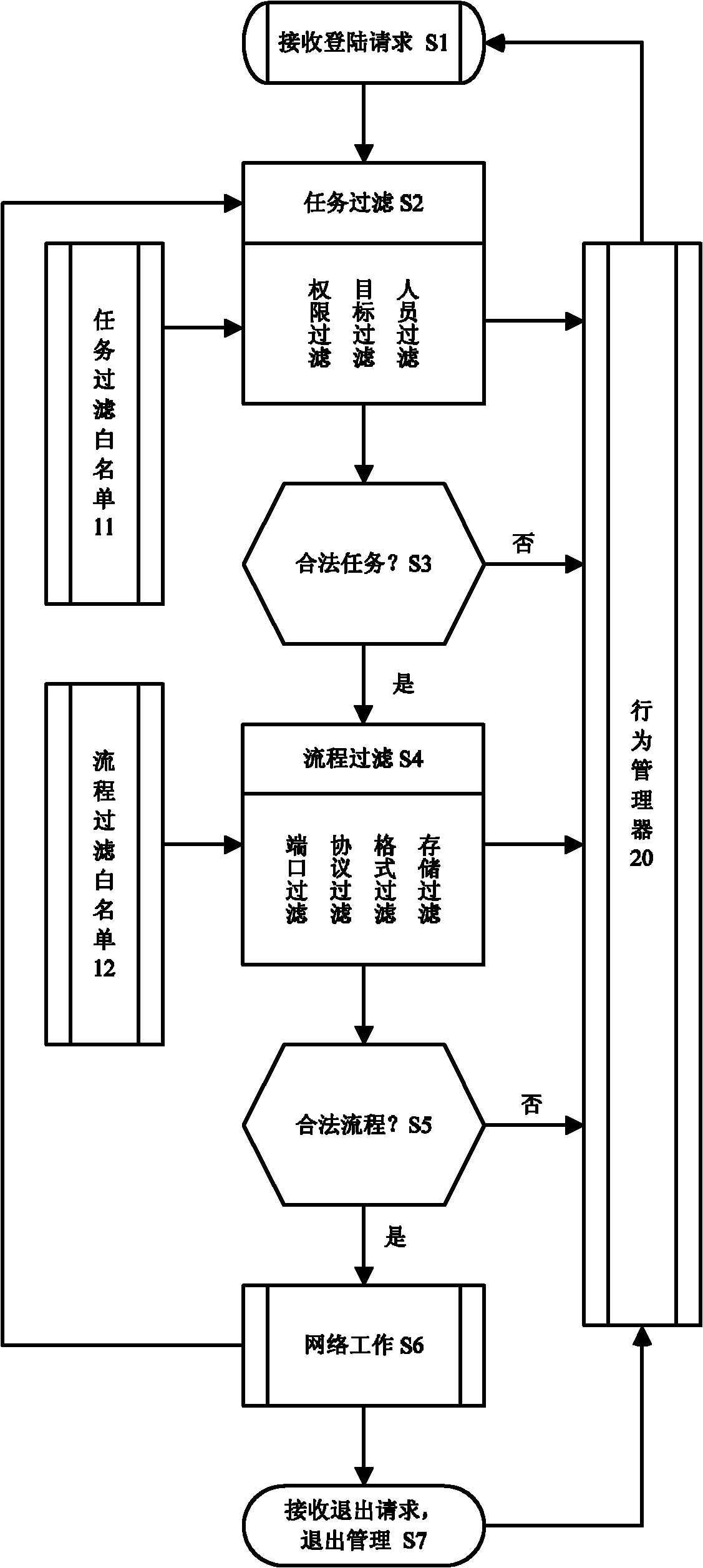

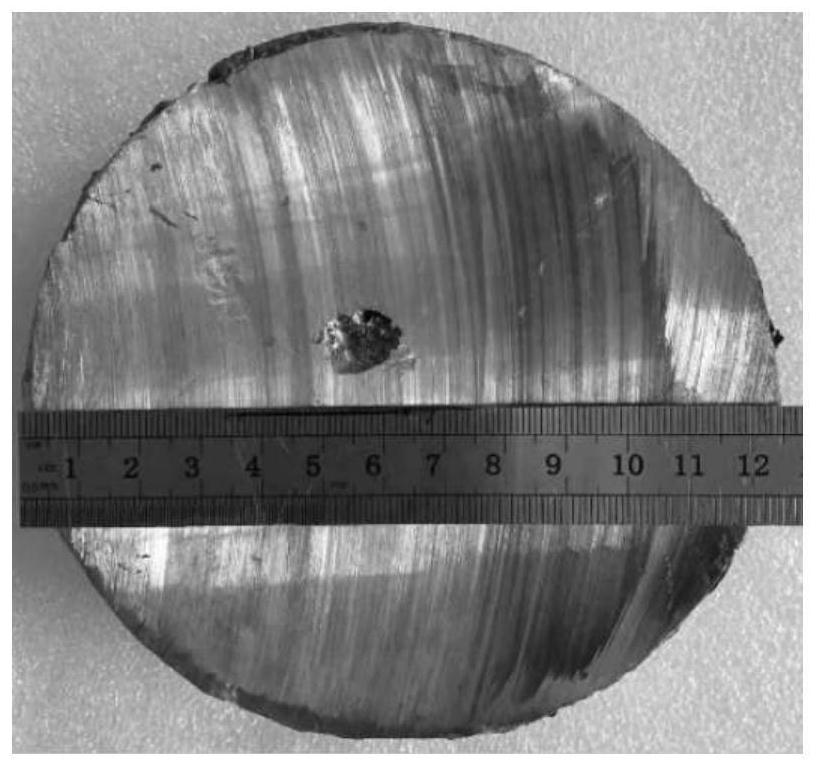

Job network behavior fire wall

The invention discloses a job network behavior fire wall, comprising a behavior rule base, a behavior manager and a behavior filter, wherein the behavior rule base is used for defining classification of the job task of document processing and defining the job flow of corresponding document processing; the behavior filter is used for monitoring and filtering the job network behaviors of the log-in users in real time, judging whether the job network behaviors are legal according to the behavior rule base and submitting the judgment result to the behavior manager; and the behavior manager dynamically manages the network jobs according to the judgment result. The fire wall precludes all the non-standard network jobs and document processing behaviors and satisfies the requirements of the job network for high security and reliability.

Owner:安徽天虹数码科技股份有限公司

Injection molding process of metal powder metallurgical workpiece

The invention discloses an injection molding process of a metal powder metallurgical workpiece. The injection molding process comprises the following steps that 1, injection molding is performed, namely injection molding is conducted on a mixture of metal powder and an organic binding agent by means of an injection molding machine to obtain an injection blank; 2, the organic binding agent is removed, namely the organic binding agent in the injection blank is removed by adopting a chemical or thermal decomposition method; 3, sintering is performed, namely the injection blank is sintered; 4, quenching is performed, namely quenching is performed in the CO2 atmosphere at the temperature of 900-1000 DEG C for 1.5-2.5 hours; 5, tempering is performed, namely tempering is performed at the temperature of 150-250 DEG C for 1-2 hours. The injection molding process is used for manufacturing the metal powder metallurgical workpiece high in surface hardness.

Owner:ZHONGSHAN YAOWEI POWDER UNIT CO LTD

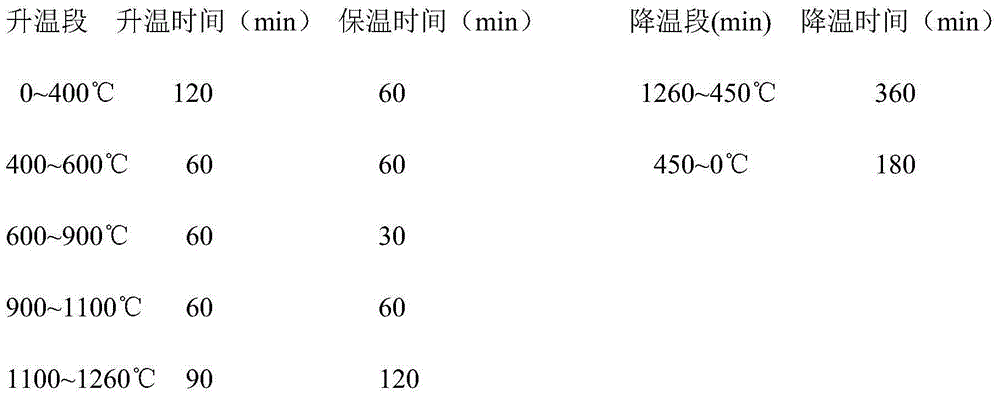

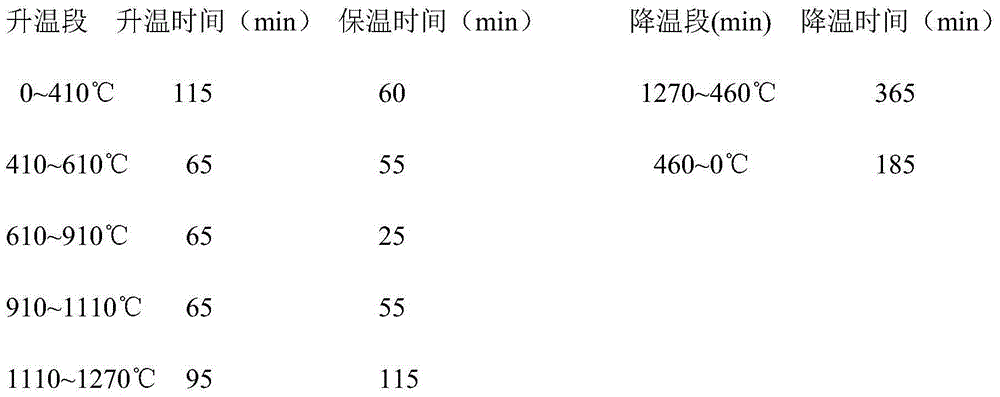

Preparation method of ceramic-metal composite material

InactiveCN110369706ACeramic high strengthImprove cooling effectTransportation and packagingMetal-working apparatusLaser cuttingCeramic metal

The invention discloses a preparation method of a ceramic-metal composite material. The preparation method comprises the following steps of (1), granulating, wherein 316L stainless steel powder, blackzirconia ceramic powder and a binder are mixed and granulated correspondingly to prepare a 316L stainless steel feeding material and a black zirconia ceramic feeding material; (2) forming, wherein the 316L stainless steel feeding material is subjected to injection molding, then a 316L stainless steel injection blank is cut to be in a required shape and size by a laser cutting machine, and the cutpart comprises a sprue; and the cut 316L injection blank is placed on a mold, and then the black zirconia ceramic feeding material is used for filling the part which is cut off by laser; (3) sintering, wherein catalytic degreasing and sintering are carried out on the ceramic and the metal injection blank; and (4), polishing, wherein the sintered ceramic-metal connecting part is ground and polished. The ceramic metal composite material prepared by the technical scheme has the characteristics of being high in ceramic strength, resistant to scratching, resistant to wearing, good in heat dissipation performance, almost free of signal shielding characteristics, good in metal ductility, resistant to falling and easy to machine.

Owner:SHANGHAI FUTURE HIGH-TECH CO LTD

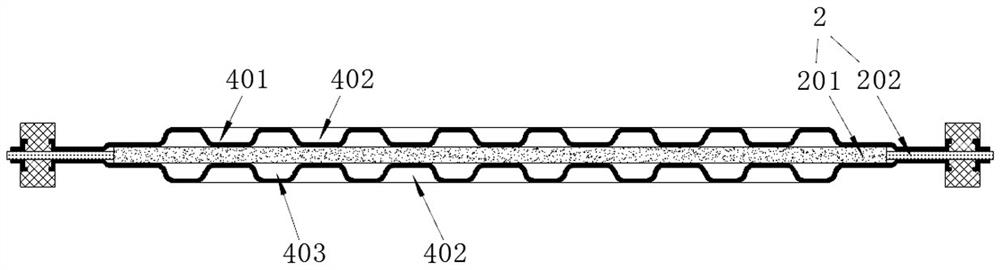

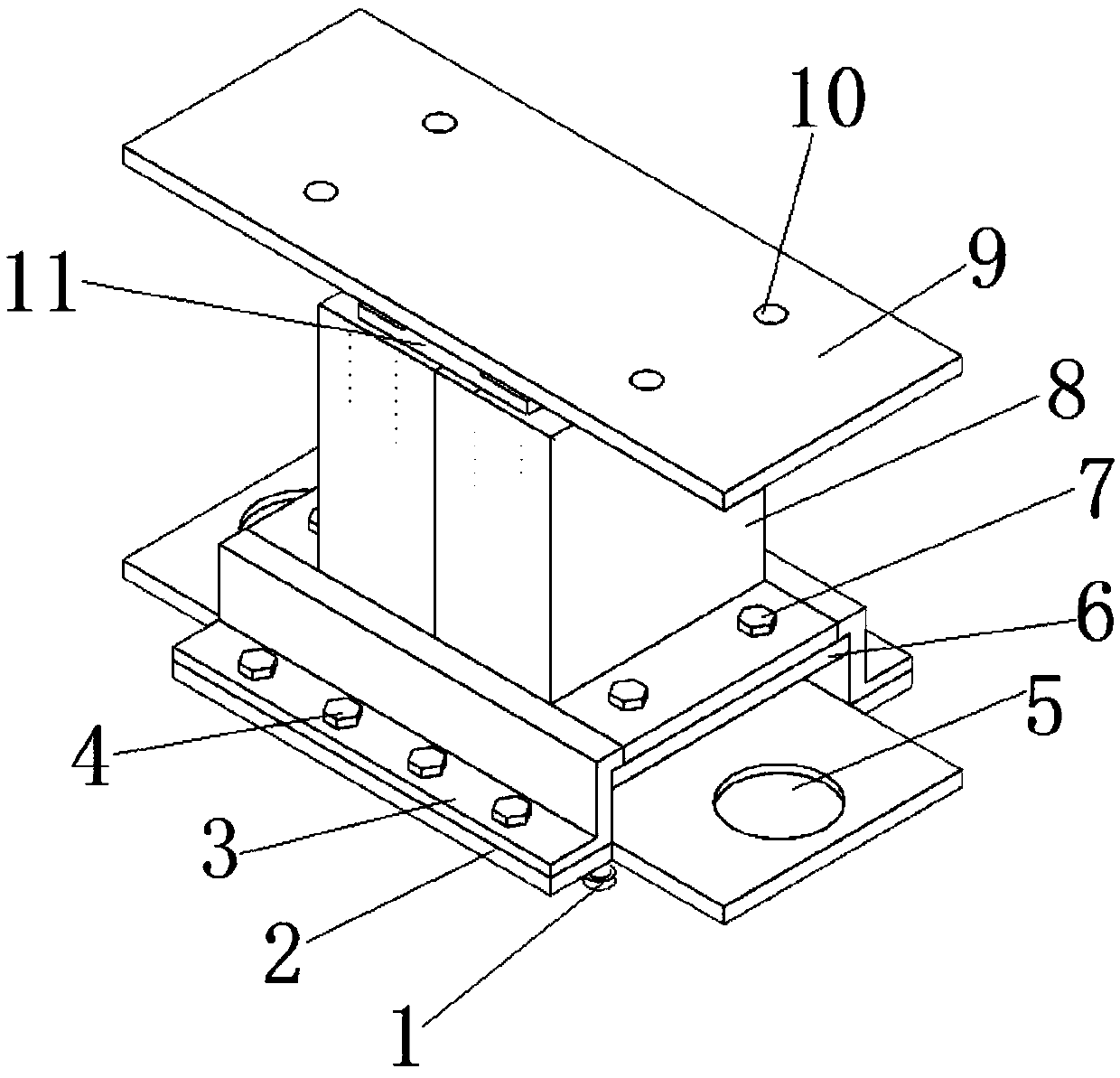

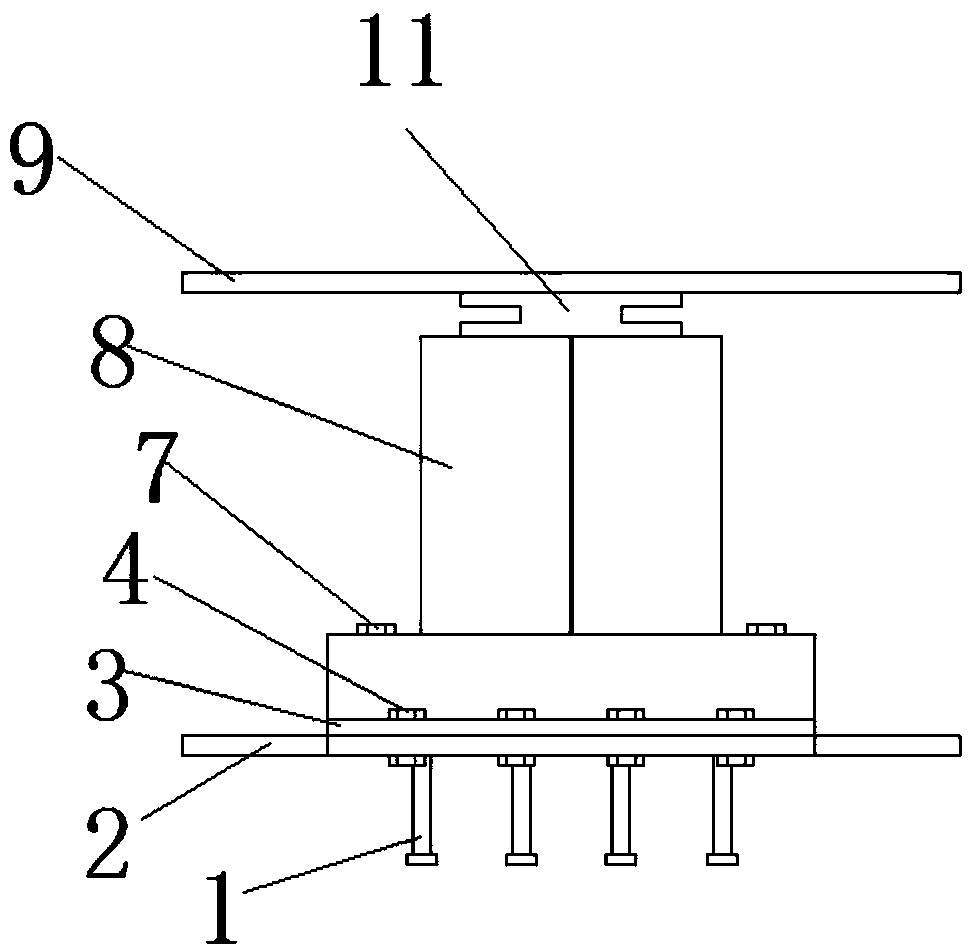

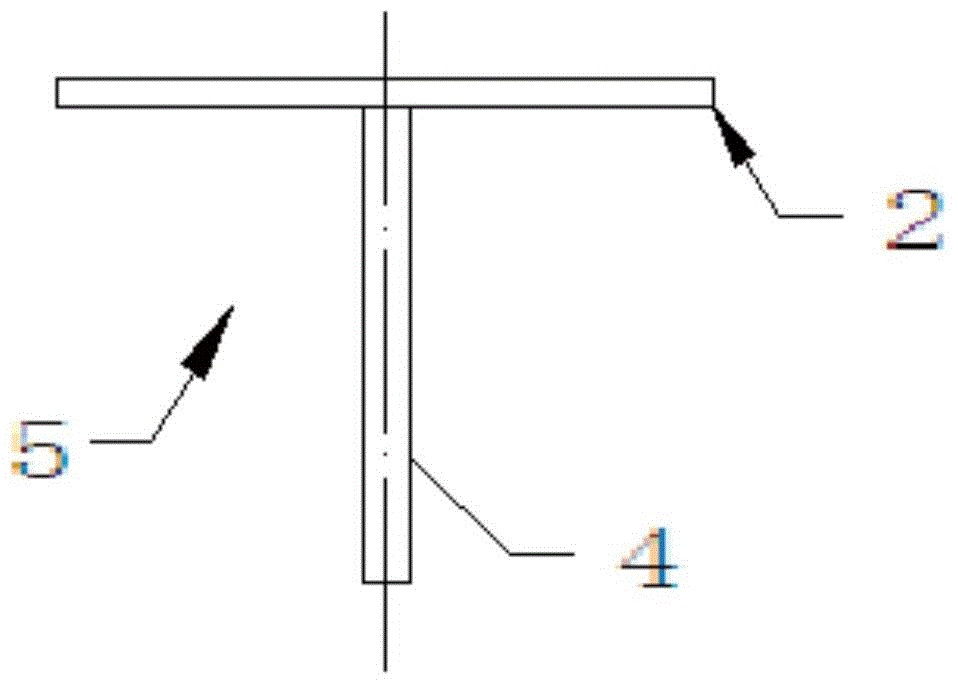

Shock insulation support with adjustable vertical height

InactiveCN108018950AGuaranteed deformation coordination abilitySolve the adjustmentProtective buildings/sheltersShock proofingSlide plateEngineering

Owner:XIAN UNIV OF TECH

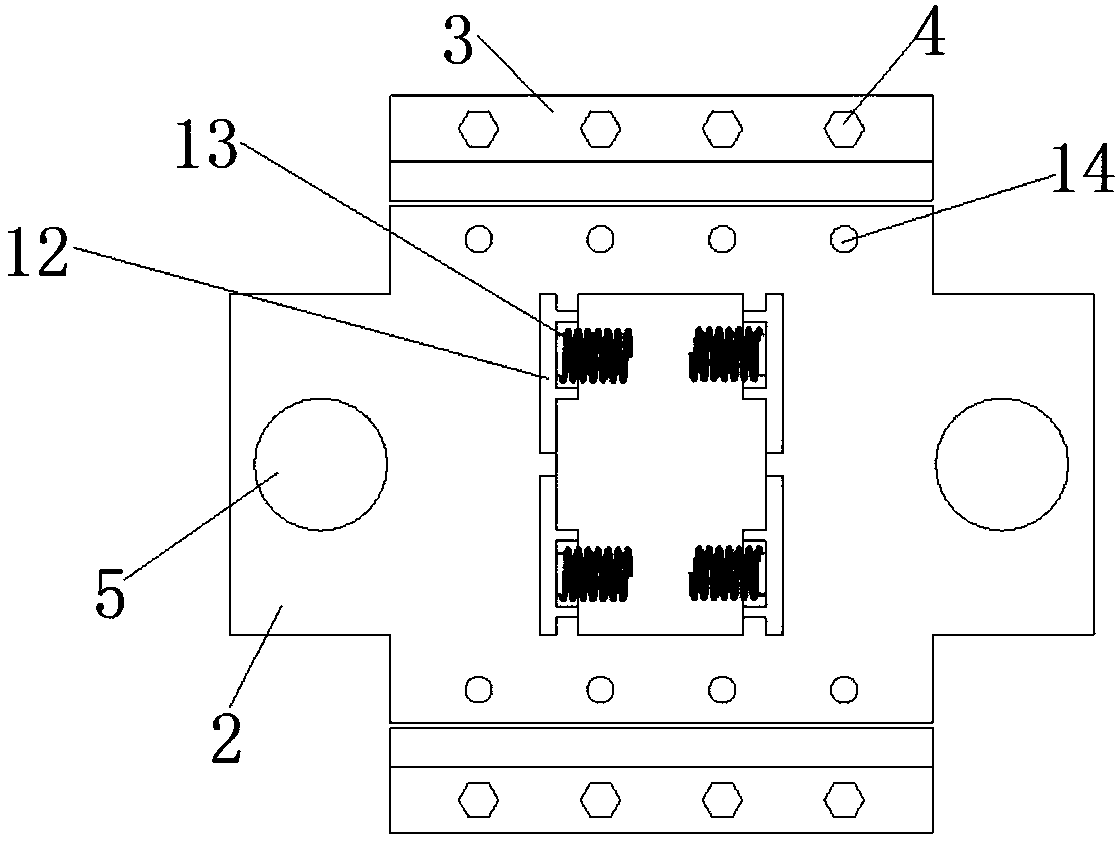

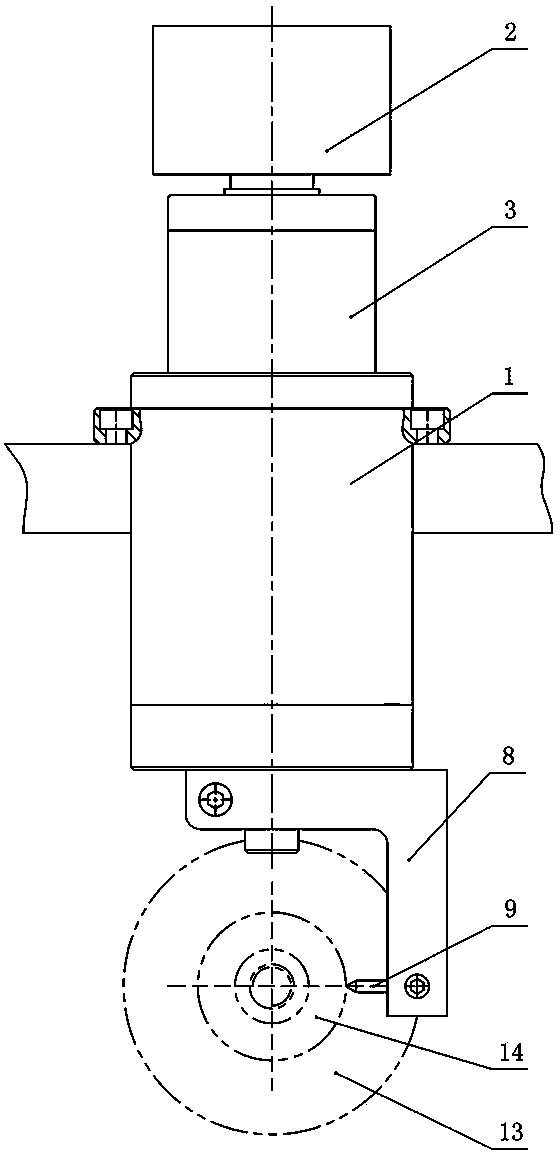

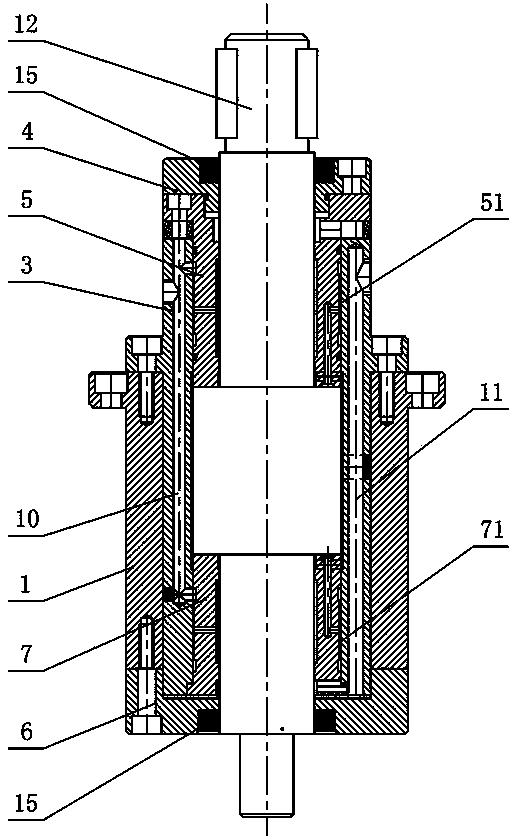

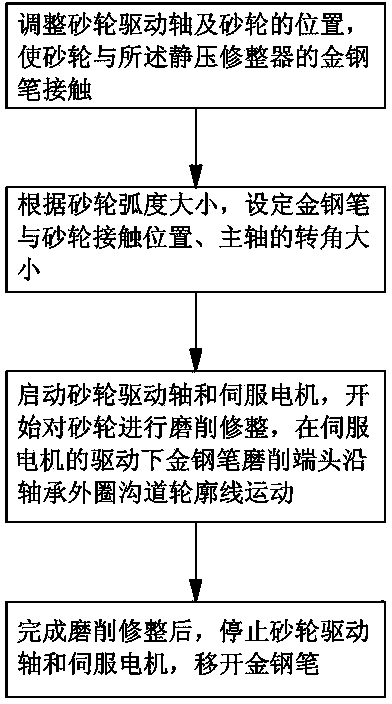

Static pressure dresser of super-grinding bearing outer ring raceway grinding wheel and dressing method

InactiveCN104070455AIncrease stiffnessGood vibration dampingAbrasive surface conditioning devicesEngineeringContact position

Provided are a static pressure dresser of a super-grinding bearing outer ring raceway grinding wheel and a dressing method. The dresser comprises a base sleeve, a servo motor, a sleeve, an upper end cover, an upper hydrostatic bearing, a lower end cover, a lower hydrostatic bearing, a pen chuck, a corundum pen and a spindle, wherein the sleeve is sleeved by the base sleeve, the spindle is sleeved by the sleeve, the upper end cover and the lower end cover are respectively arranged at the upper end and the lower end of the sleeve, the upper hydrostatic bearing and the lower hydrostatic bearing are supported between the spindle and the sleeve, the pen chuck is installed at the lower end of the spindle, the corundum pen is installed on the pen chuck, and the servo motor is connected with the upper end of the spindle. The dressing method comprises the steps of S1, enabling the grinding wheel to be in contact with the corundum pen of the static pressure dresser; S2, setting the contact position of the corundum pen and the grinding wheel and a rotating angle of the spindle; S3, starting a grinding wheel driving shaft and the servo motor and beginning to perform grinding trimming on the grinding wheel; S4, enabling the grinding wheel driving shaft and the servo motor to shut down after grinding trimming and moving away the corundum pen.

Owner:HUNAN HYDRO SPINDLE TECH +1

Tool and method for measuring deflection angle of airplane control surface

The invention discloses a tool and a method for measuring the deflection angle of an airplane control surface. The measuring tool comprises a control surface clip (1), a stabilizer clip (6), a brace rod (5), a regulating arm (4), a sensor support (3), an angular displacement sensor (7) and a forked rocker arm (2). The measuring process comprises the following steps: clamping the stabilizer clip (6) of the measuring tool to a force-bearing position of a vertical tail stabilizer (45), sequentially mounting the brace rod (5), the regulating arm (4), the sensor support (3), the angular displacement sensor (7) and the forked rocker arm (2) in place, clamping the control surface clip (1) to a force-bearing position of an upper rudder (46), and moving the angular displacement sensor (7) to a rotary shaft of the upper rudder (46) so as to measure the deflection angle of the control surface. The invention can be simultaneously used for measuring the deflection angle of the rudder or the elevator in the bench test or the ground built-in test of an airplane, can be directly used for measuring the deflection angle of the control surface without disassembling structural parts of the airframe, and is especially suitable for the condition that the deflection amount can not be educed for measurement by means of a link mechanism in case that the rotary shaft is arranged inside the envelope of the control surface.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

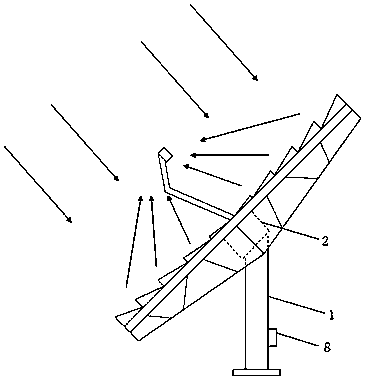

Curved surface reflector forming equipment and forming method thereof

InactiveCN104671649AReduce energy consumptionLow costGlass reforming apparatusProduction lineEngineering

The invention discloses curved surface reflector forming equipment which comprises a forming die, a frame and multiple fixing pieces, wherein the fixing pieces comprise top sheets and lower rod pieces which are fixedly connected with one another; fixing holes matched with the fixing pieces are formed in the frame; the heights of the lower rod pieces on the fixing pieces in the fixing holes can be adjusted; the forming die is opposite to the frame; the top sheets on the fixing pieces are aligned with the forming die; one surface of the forming die is a to-be-formed curved surface; and a to-be-processed mirror surface is positioned between the to-be-formed curved surface of the forming die and the top sheets on the fixing pieces. According to the equipment disclosed by the invention, a large production line of curved surface reflectors is not needed, and the equipment has the advantages of low energy consumption, low cost and convenience to process. The curved surface reflector forming equipment can be applied to forming groove-type and Fresnel type primary curved surface reflectors and forming tower-type and disc-type secondary curved surface reflectors.

Owner:中广核太阳能开发有限公司 +1

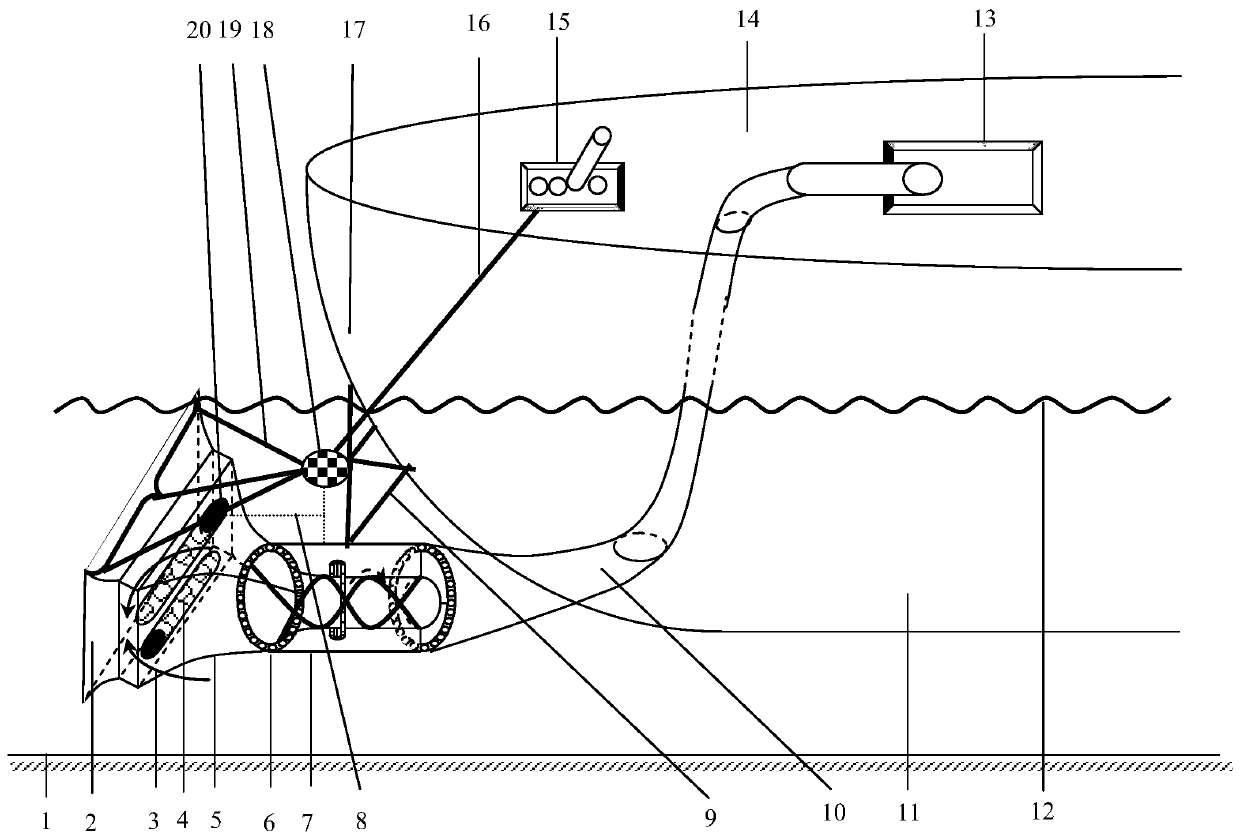

Mobile type automatic treating, suction and removing device for gathered floating substances in water areas

PendingCN110984103AEliminate hazardsAchieve mechanical propertiesWater cleaningWaterborne vesselsUnderwaterEnvironmental engineering

The invention discloses a mobile type automatic treating, suction and removing device for gathered floating substances in water areas and belongs to the field of environmental engineering and equipment. A proper removing ship is selected in a water area where water area floating substances are gathered, and a roll type underwater shredder and a submersible helicon-centrifugal pump are mounted on aship bow below the water surface through universal hinges and fixed connecting parts. The upper edge of a horn-shaped feeding port of the shredder is slightly higher than the water surface, and the direction of the feeding port can be freely adjusted through universal hinges and a control rod. Through active chasing of the removing ship, the floating substances are gathered at the feeding port ofthe underwater shredder and smoothly broken by a working roll. A reducing discharging port of the shredder is connected with an inlet of the submersible helicon-centrifugal pump through a high-pressure wired hose, so that the broken water area floating substances are conveyed to a material treatment or discharge device by the submersible helicon-centrifugal pump for following tretament or recycling. The device can actively and efficiently treat various types of gathered water area floating substances, is beneficial to protection and treatment of water area environments, and has broad application prospects.

Owner:DALIAN UNIV OF TECH

A multi-electrode and multiple power supply unit system for electrical exploration and its exploration method

ActiveCN103487836BLow powerEasy to implementElectric/magnetic detectionAcoustic wave reradiationPower flowPotential difference

A multi-electrode and multiple power supply unit system for electrical exploration and its exploration method, wherein in the system, the number of power supply electrodes A and B is equal to the number of current sending units; The current modulation controller and the transmission delay controller; the connection between the receiver and the transmission current modulation controller, and the connection between each current sending unit and the transmission delay controller; the connection between each current sending unit and the receiver Communication connection; the receiver is provided with terminals for connecting the measuring electrode M and the measuring electrode N respectively, and for measuring the potential difference between the measuring electrode M and the measuring electrode N; each current sending unit is respectively connected to the power supply electrode A And the corresponding power supply electrode B. The power supply current of the current transmitting unit of the present invention does not exceed 1A, and the power supply voltage does not exceed 200V. The power of each transmitting unit is small, easy to realize, safe to use in tunnels and installed on full-metal tunnel boring machines.

Owner:钟世航

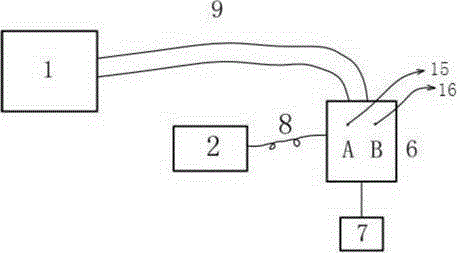

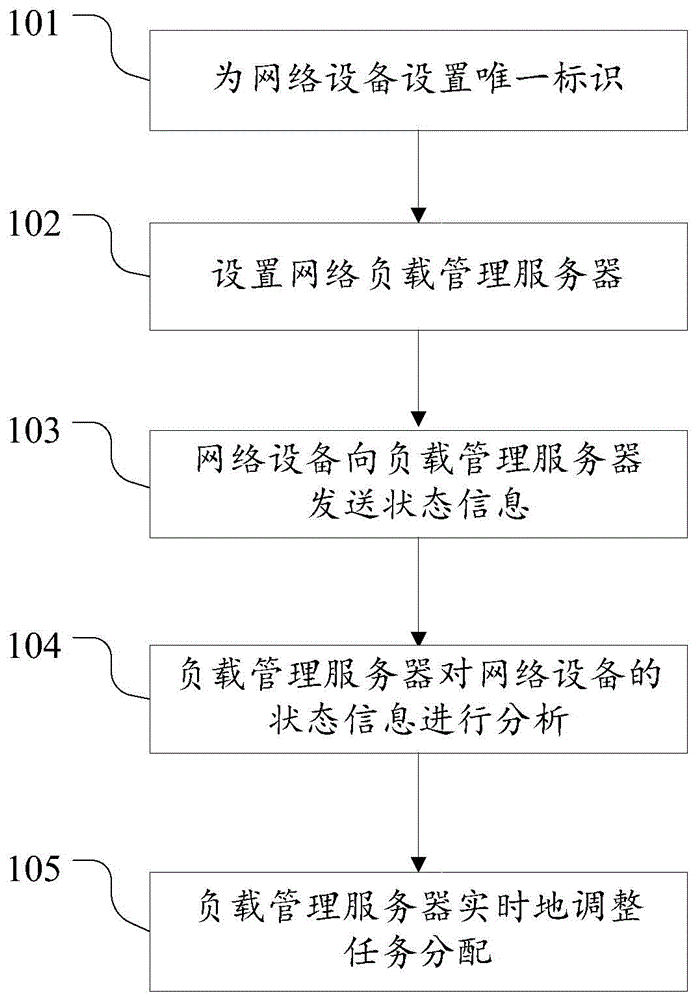

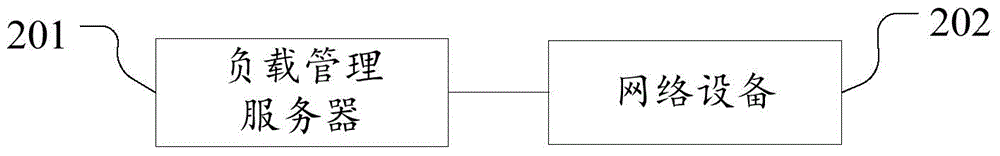

Network load balancing method and system

InactiveCN106302216AScalableImprove user experienceData switching networksStructure of Management InformationNetwork Load Balancing Services

The invention discloses a network load balancing method and system. The method comprises that each network device in the network is provided with a unique identification; a server is arranged to manage the network load; the network devices sends state information to the server; the server forms a complete topological structure diagram for the whole network, and concludes and analyzes the state information of the network devices; and according to a preset strategy, the server adjusts task distribution for the network devices in real time. The method can be used to establish high-efficiency and reliable network in lower cost, the network server resource and bandwidth resource in multi-server network configuration are utilized fully, user experience is improved, and the total service processing capability of the network is enhanced.

Owner:TVM BEIJING TECH

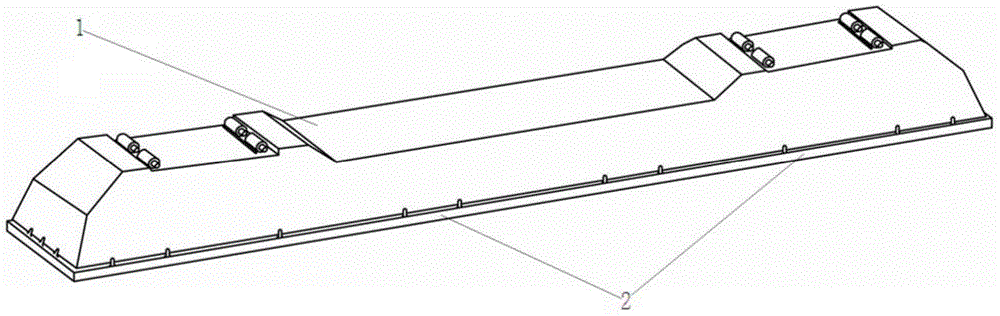

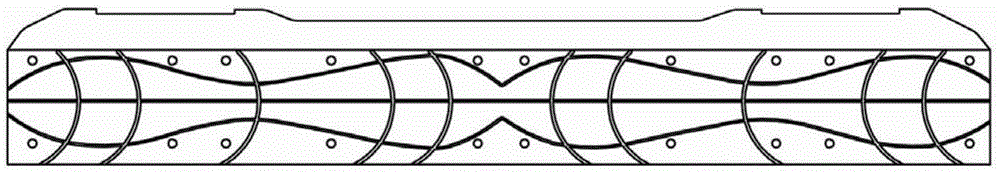

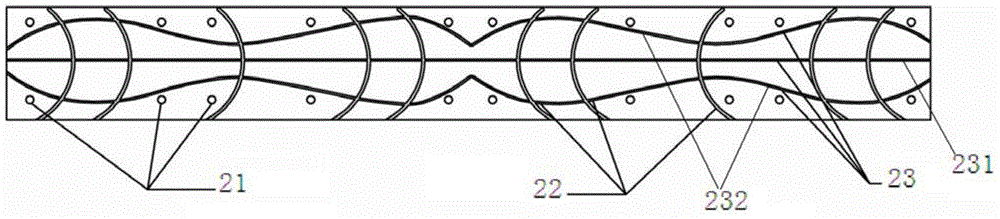

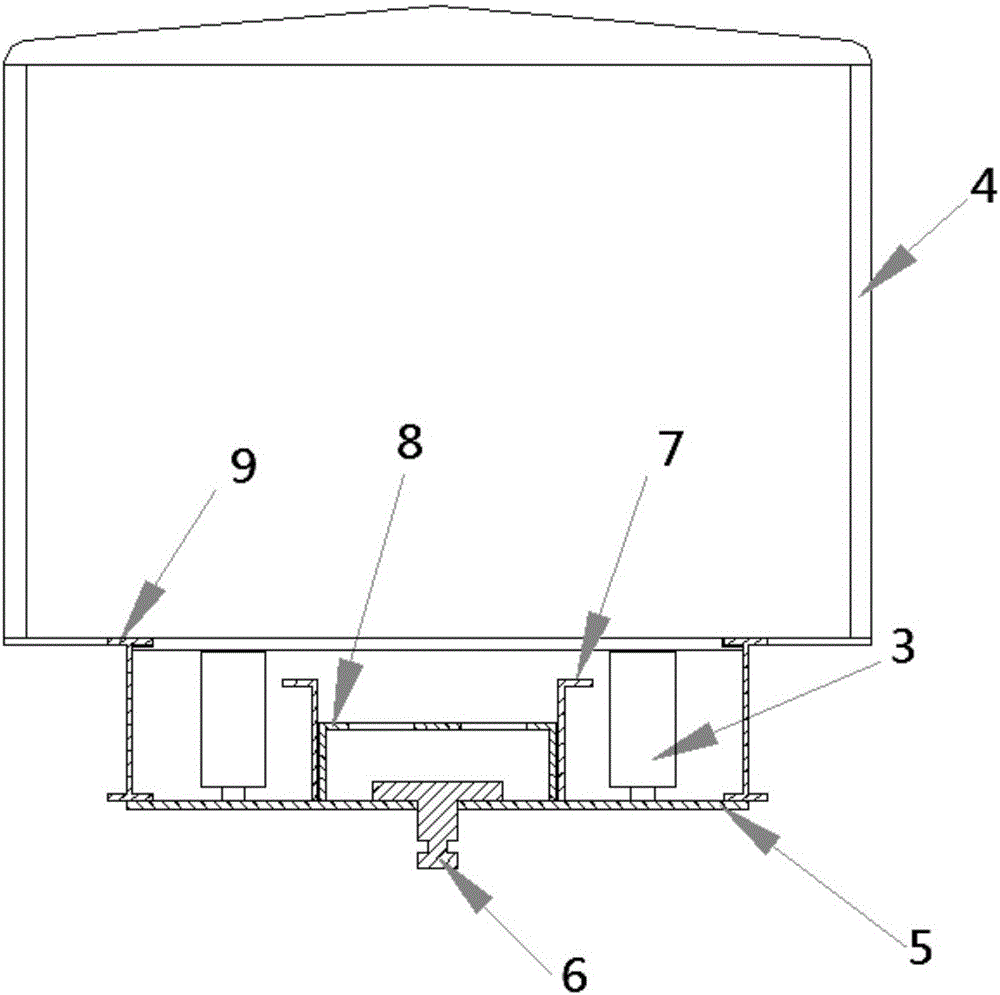

Adjustable threshing cylinder upper hood

The invention relates to an adjustable threshing cylinder upper hood which comprises a shell, at least two fixed spiral flow deflectors and at least two pairs of adjustable spiral flow deflectors. Each pair of adjustable spiral flow deflectors comprises a left adjustable spiral flow deflector and a right adjustable spiral flow deflector which are oppositely arranged; the adjustable threshing cylinder upper hood also comprises a sliding pin linkage rod, sliding pins, a connection hinge plate, flow deflector regulating rods, a flow deflector regulation and control rod, a flow deflector regulating linkage rod, hinge pins and locking blocks. In the invention, the angles of the left adjustable spiral flow deflectors and the right adjustable spiral flow deflectors can be regulated according to the types and the humidity conditions of harvested crops and the angular positions of the flow deflectors can be locked, so that the harvesting effect achieves the best state and firmness of equipment is improved.

Owner:潍坊速博世达农业装备有限公司

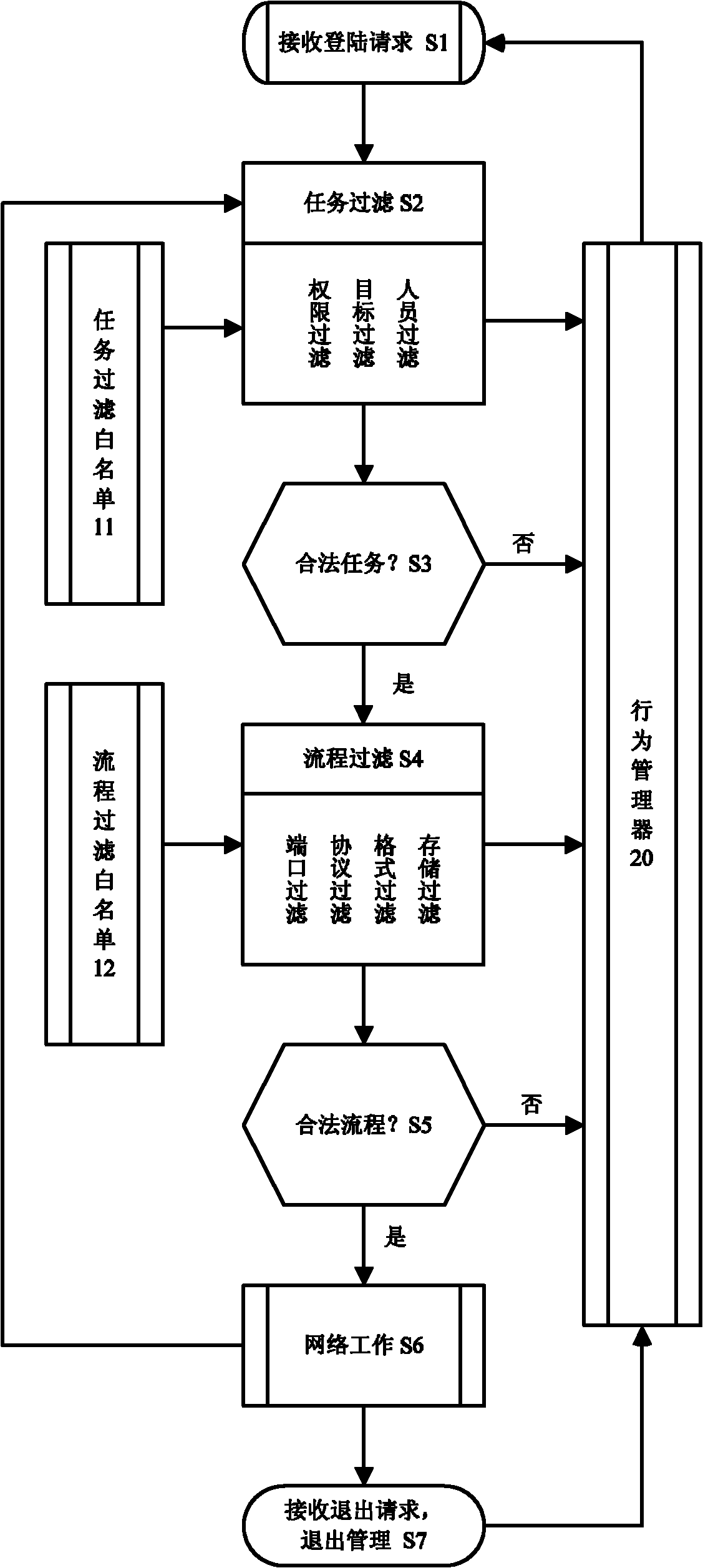

Behavior filtering method of job network behavior fire wall

The invention discloses a behavior filtering method of a job network behavior fire wall, which comprises the following steps of: receiving a login request of a login user, wherein the login request comprises a required job task; carrying out task filtration on the job task according to a task filtering white list; judging whether the job task subjected to the task filtration is a legal job task or not; carrying out process filtration on the legal job task; judging whether the legal job task subjected to the process filtration is a legal process or not; and providing network services for the job task with legal process so as to avoid all nonstandard network jobs and file processing behaviors and meet the requirements for high safety and high reliability of the job network.

Owner:安徽天虹数码科技股份有限公司

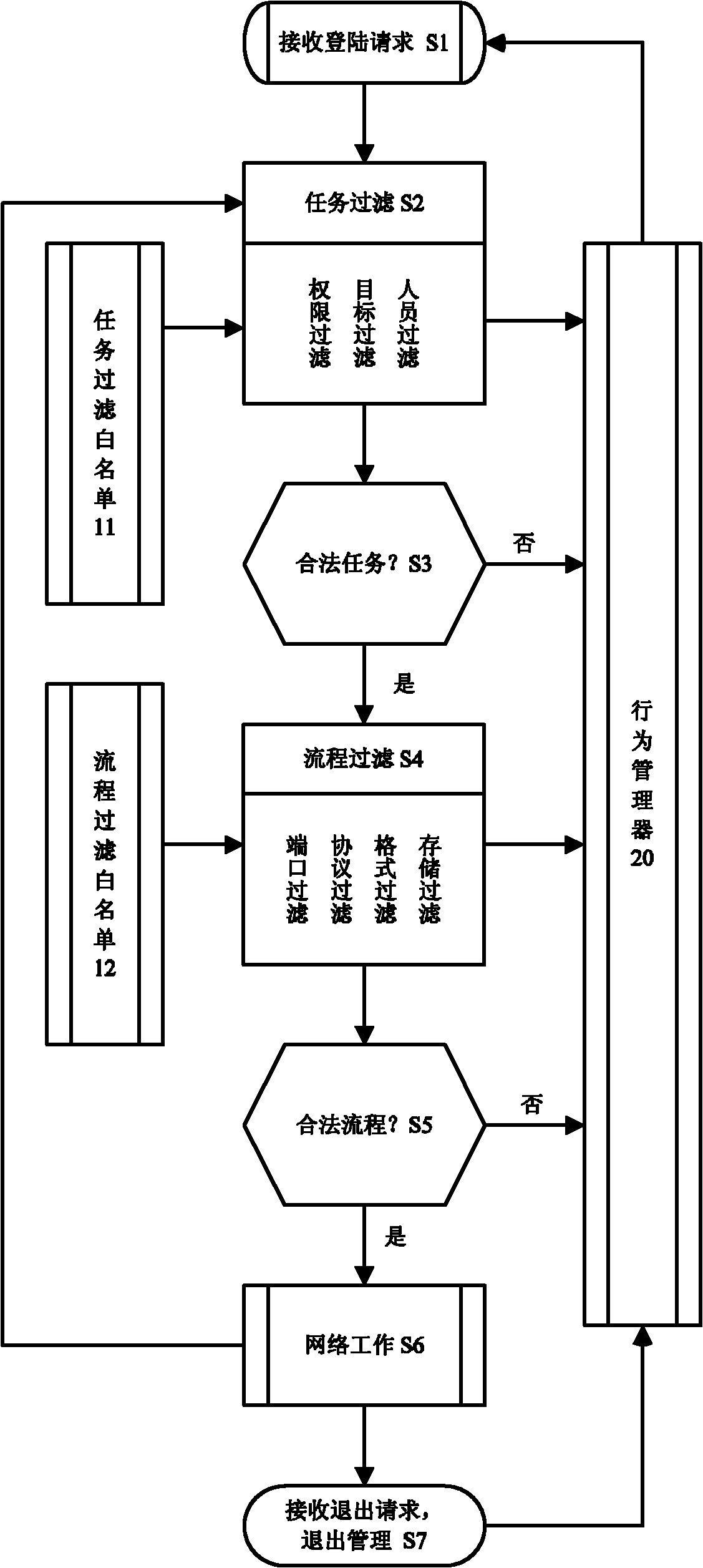

Concave curved-roof-surface waterproof structure and construction technology thereof

InactiveCN108979017AImprove performanceGood weather resistanceBuild-up roofsRoof covering insulationsEngineeringSteel frame

The invention relates to the technical field of building designing, in particular to a concave curved-roof-surface waterproof structure and a construction technology thereof. The concave curved-roof-surface waterproof structure comprises a waterproof structure body, a concrete layer is arranged at the bottom of the waterproof structure body, a waterproof layer is connected to the top face of the concrete layer, a heat preservation layer is arranged on the top face of the waterproof layer, a rigid waterproof layer is arranged on the top face of the heat preservation layer, and a house decorating layer is connected to the top face of the rigid waterproof layer. The construction technology of the waterproof structure body includes the following steps that steel is rolled, a steel frame is placed, concrete is poured, the top face of the concrete is poured into a concave curved structure after fine building, the waterproof layer is laid, the heat preservation layer is sprayed, concrete is poured, and the decorating layer is laid. According to the concave curved-roof-surface waterproof structure and the construction technology thereof, the waterproof layer is directly arranged on the concrete structure layer, construction is simple, the construction procedure is simple, and the waterproof effect of the curved roof surface is good.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

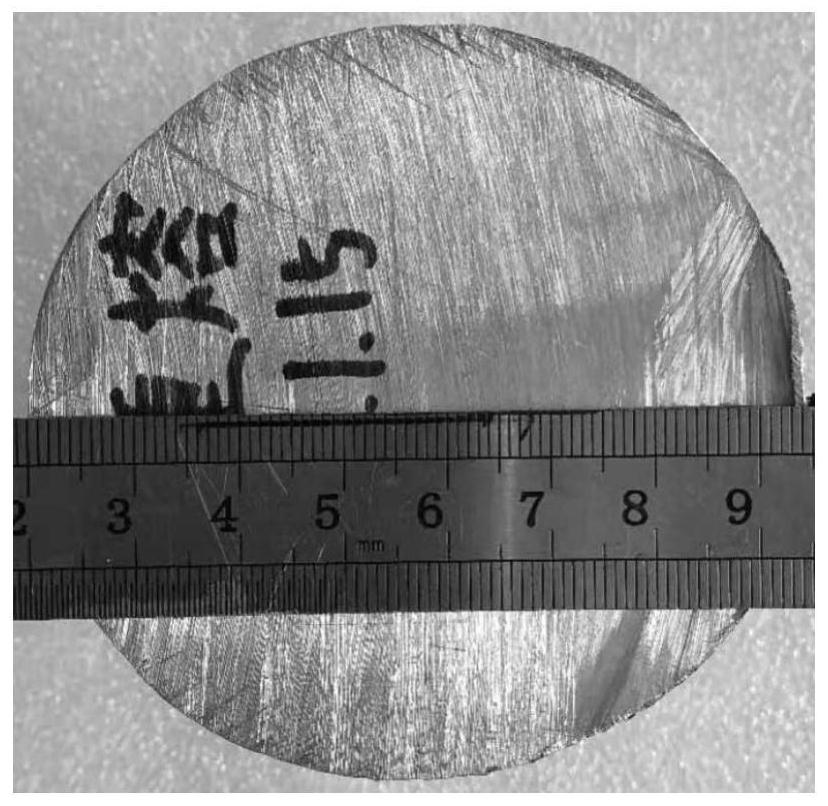

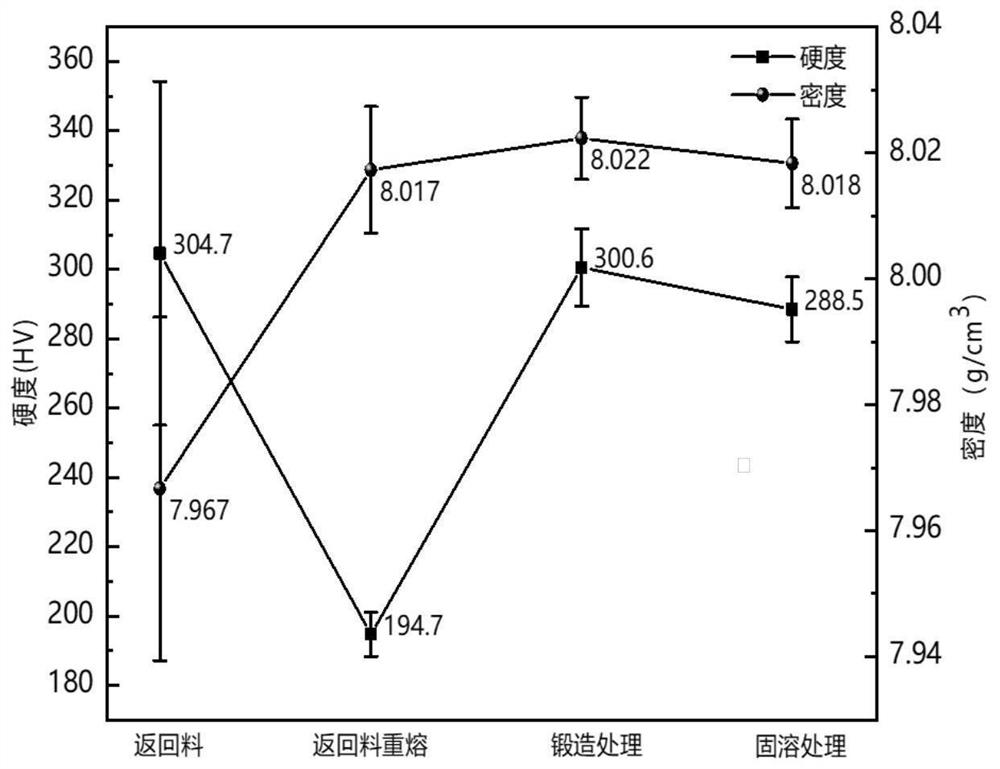

Short-process recycling method for return scraps

The invention relates to the technical field of resource recycling, in particular to a short-process recycling method for dead head return scraps. The recycling method for the dead head return scraps is characterized in that the return scraps are treated by a remelting-forging combined process. The recycling method for the dead head return scraps has the following advantages that (1) valuable metal elements in the return scraps can be recycled at a time, and the method has the advantages of being short in flow and simplified in process; (2) recycled return scrap alloys are high in quality and can be directly used as an alloy casting raw material, cyclic utilization is realized, and the recycling value is improved; (3) the method is relatively low in treatment cost; and (4) no other waste is generated, and industrial popularization and application are facilitated.

Owner:BEIJING UNIV OF TECH

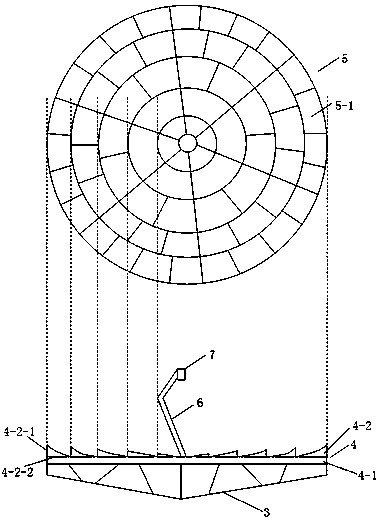

Novel disc type light collecting lens structure

PendingCN108036527ASimple production processReduce wind loadsSolar heating energySolar heat collector controllersOptoelectronicsL&D process

The invention belongs to the field of a disc type solar disc lens structure, in particular to a novel disc type light collecting lens structure. The novel disc type light collecting lens structure comprises an upright post, a rotary mechanism, a bracket, a backboard, a light collecting lens and a heat absorber; the upright post is connected with the backboard through the rotary mechanism; the rotary mechanism is used for driving the backboard to track the sunshine; the backboard comprises a circular base plate and a plurality of circle of lens bases which are fixed to the base plate; each lensbase is provided with an annular arc surface; the axial section of each annular arc surface is a part of a parabola; the light collecting lens consists of a plurality of lenses; the lenses are closely adhered to the annular arc surfaces; the annular arc surfaces can be used for gathering the incident light from a direction vertical to the base plate to a focus position by reflection of the lenses; and the focus and the heat absorber are at the same position. The light collecting lens of the novel disc type light collecting lens structure provided by the invention consists of different circlesof lenses which are arranged; the lens surfaces at each circle consist of a plurality of lens surfaces which are the same in shape and are closely arranged; the lenses at the same circle can be manufactured by using a same set of mold, so the production procedures are simplified, and the light collection efficiency is improved.

Owner:天津清芸主力能源科技有限公司

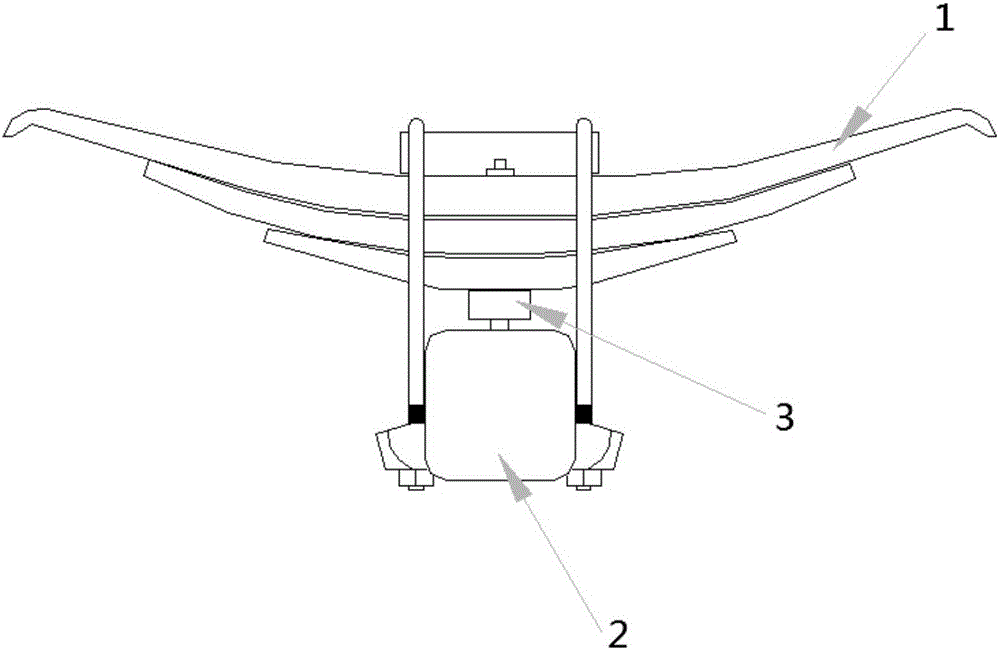

Sleeper with exchangeable sleeper pad

A sleeper with an exchangeable sleeper pad comprises a sleeper and an exchangeable sleeper pad matched with the sleeper. The bottom of the sleeper is fixedly applied to the exchangeable sleeper pad; one surface of the exchangeable sleeper pad connected with the bottom of the sleeper is provided with adherent projections, transverse spacing projections and longitudinal spacing projections; the adherent projections, transverse spacing projections and longitudinal spacing projections are respectively embedded into adherent grooves, transverse spacing grooves and longitudinal spacing grooves; and the transverse and longitudinal spacing projections are arc-shaped curve projections in different directions. Problems of railway ballast, road bed deformation, sleeper pad exchange and sleeper circulating use can be solved; and the transverse and longitudinal spacing projections are arc-shaped curve projections in different directions, so shear-bearing capacity of the transverse and longitudinal spacing projections can be increased.

Owner:北京宝曼国泰轨道技术有限公司

Novel axle automatic weighing device, vehicle applying same and weighing method

PendingCN106546309AMeet timelySimple structureSpecial purpose weighing apparatusAutomotive engineeringLoad cell

The invention relates to a novel axle automatic weighing device, a vehicle applying the same and a weighing method. The novel axle automatic weighing device comprises a suspension system, an axle and weighing sensors, and is characterized in that the suspension system transfers the gravity to the axle, and a part between the suspension system and the axle or the whole gravity transfer path is provided with the weighing sensors. The automatic weighing vehicle comprises the novel axle automatic weighing device. The novel axle automatic weighing device can realize weighing for the vehicle loading capacity at any time and any place, and satisfies the timeliness of weighing for the vehicle loading capacity. In addition, the novel axle automatic weighing device is simple in structure, free of processing of complicated parts, convenient to use and low in manufacturing cost.

Owner:罗公祥

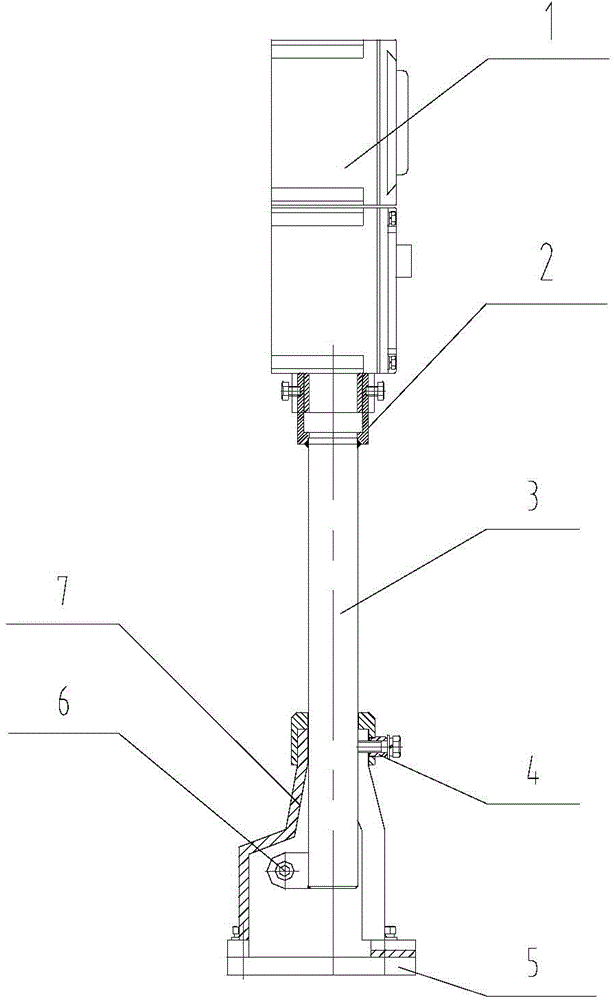

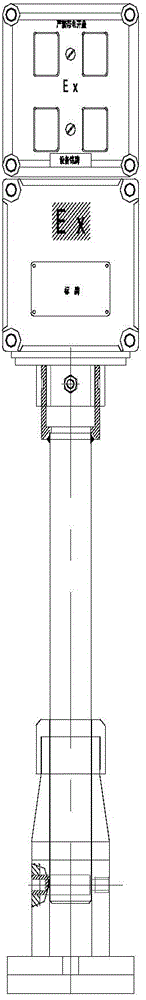

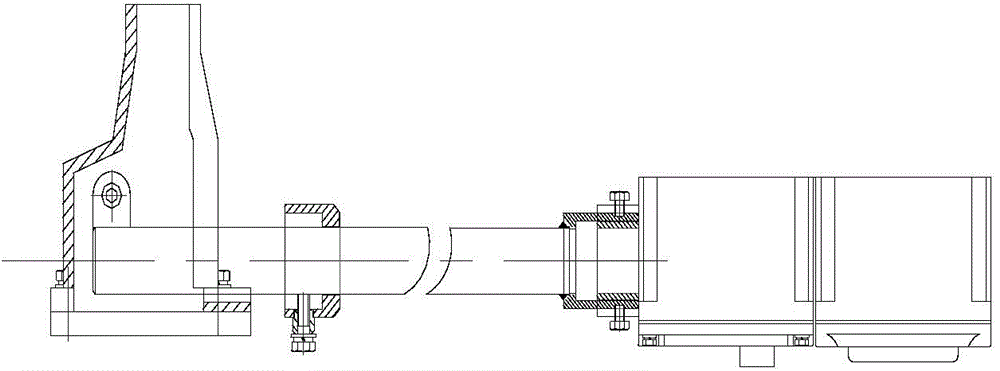

Explosion-suppression duplex double-control self-locking control operation column

The invention provides an explosion-suppression duplex double-control self-locking control operation column. The bottom of a supporting column is hinged with a locking pin. One side in the hinging rotation direction of the column is provided with a transverse placement gap. The supporting column rotates around the locking pin. The rotation lower limit of the supporting column is the position where the supporting column is transversely placed in the transverse placement gap, and the rotation upper limit is the position whether the supporting column is parallel with or superposed with a lamp base. An electric appliance control box is provided with two independent control buttons. Each control button independently control a set of electric power consumption equipment. Each control button is provided with an independent button screwdriver opening fork locking device. According to the explosion-suppression duplex double-control self-locking control operation column, the control power supplies of two sets of electric power consumption equipment can simultaneously enter a power supply wire inlet. In performing maintenance on a single set of equipment when control equipment fails, operation of the other set of equipment is not affected. The explosion-suppression duplex double-control self-locking control operation column can be placed in a transverse manner conveniently; and when a drilling machine finishes operation and is conveyed, the explosion-suppression duplex double-control self-locking control operation column can be placed to the transverse manner for conveying. According to the explosion-suppression duplex double-control self-locking control operation column, after mounting is finished, the orientation of the electric appliance control box can be conveniently rotated for adjustment.

Owner:CNPC BOHAI EQUIP MFG +2

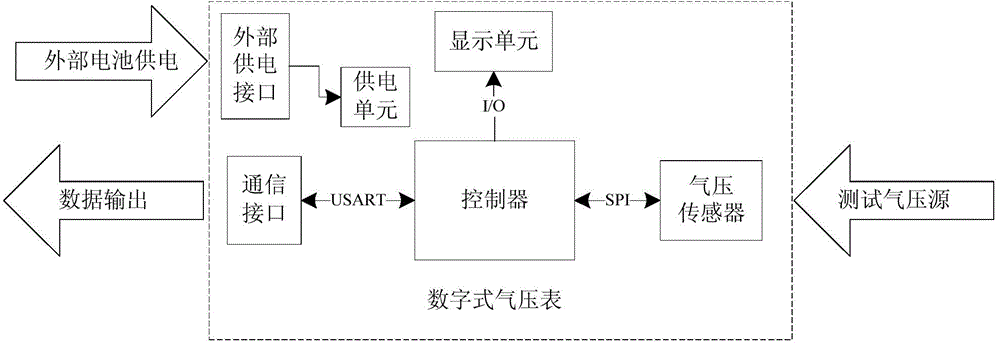

Multifunctional digital air pressure gauge

InactiveCN105091935AImprove test efficiencySimple and efficient operationMeasurement devicesCommunication interfaceEngineering

A multifunctional digital air pressure gauge includes a controller, a communication interface, an air pressure sensor, a power supply, a display unit, an external power source power supply interface and a test air pressure source interface; the controller is connected with the air pressure sensor, the communication interface and the display unit; the power supply unit supplies power to the controller, the communication interface, the air pressure sensor and the display unit; the power supply unit is also connected with the external power source power supply interface; and the air pressure sensor is connected with the test air pressure source interface. The multifunctional digital air pressure gauge provided by the invention can automatically test an air pressure value, corresponding altitude and a lifting speed value, is high in test efficiency, and is simple and convenient to operate; and can realize various detection functions of an air pressure differential pressure gauge, an air pressure altimeter and a lifting speed gauge at the same time, thereby expanding the range of application of the digital air pressure gauge, and improving the integration level of a system.

Owner:北京光徽德润航空技术有限公司

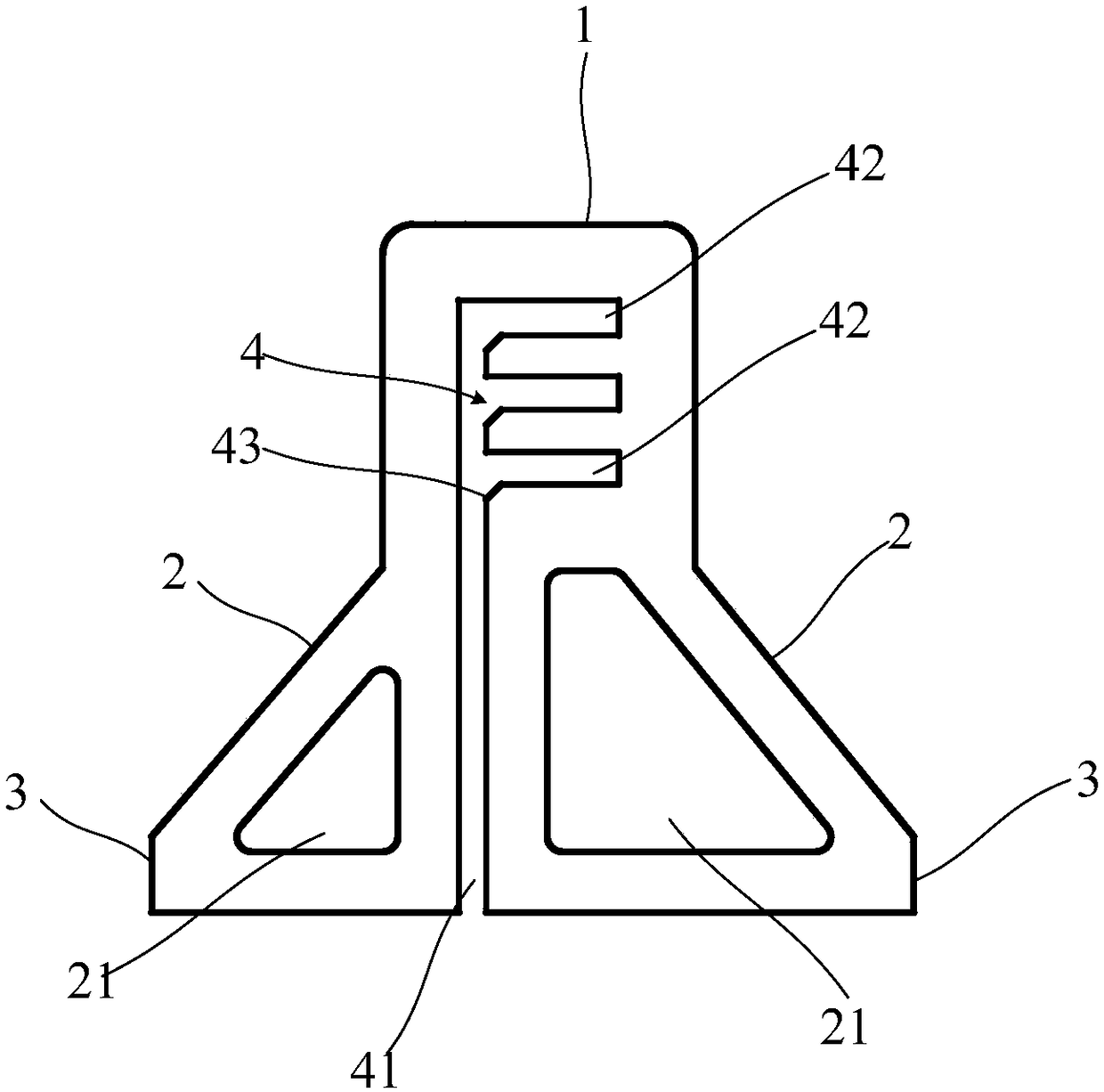

Section steel anti-tilt tooling

InactiveCN108161319AReduce weightStrong stabilityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineering

The invention discloses a section steel anti-tilt tooling. The tooling comprises a vertical plate capable of vertically setting, accommodation grooves are formed in the vertical plate, the accommodation grooves penetrate through the vertical plate in the thickness direction of the vertical plate, the accommodation grooves comprise a first accommodation groove, the first accommodation groove extends upwards from the lower end face of the vertical plate, the accommodation grooves further comprise a second accommodation groove, the second accommodation groove is perpendicular to the first accommodation groove and communicated with the first accommodation groove, and the accommodation grooves are formed for the section steels to penetrate through to constrain the section steels from tilting. According to the tooling, by forming two accommodation grooves which are communicated with each other in the vertical plate capable of vertically setting, the section steels can conveniently penetratethrough the accommodation grooves from one end faces of the section steels in the length direction of the section steels, so that tilting of the section steels is constrained, after the operation is completed, the vertical plate can be taken away from the section steels conveniently, the tooling is movably connected with the section steels, operation time can be reduced, the working efficiency isimproved, and outer surfaces of angle steels are not damaged.

Owner:SHANGHAI WAIGAOQIAO SHIP BUILDING CO LTD

A splicing process of circular knife die-cutting materials

InactiveCN104260148BWith asynchronous bonding functionIncrease profitMetal working apparatusEngineeringMachining process

Disclosed is a splicing machining process for a circular knife die cutting material. The splicing machining process for the circular knife die cutting material includes the following steps that (1) preliminary longitudinal frames of a product are formed by die cutting, and the densely die cut preliminary longitudinal frames are widened to the design width; (2) preliminary transverse frames of the product cover another material strip in a fitting mode, the vertical interval of the upper and lower preliminary transverse frames is designed in a design height; (3) matched convex snap-in structures and concave snap-in structures are formed at two ends of the preliminary longitudinal frames and at corresponding positions of the preliminary transverse frames by die cutting; (4) the preliminary transverse frames and the preliminary longitudinal frames are spliced together in a covering mode, and the convex snap-in structures and the concave snap-in structures are spliced in a snap-in mode; (5) an inner frame and an outer frame of the product are formed by die cutting, and subsequent machining is performed. By means of the splicing machining process for the circular knife die cutting material, inner outline waste materials are not generated, the utilization rate of the die cutting material is increased, the process is simple, machining of complicated parts is absent, the usage is convenient, and producing costs are low.

Owner:DONGGUAN HUAMAO PRECISION MACHINERY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com