Structure type impeller breaker

A crusher and structural technology, applied in grain processing and other directions, can solve problems such as waste of resources, save energy, reduce wear, and overcome the contradiction between strength and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

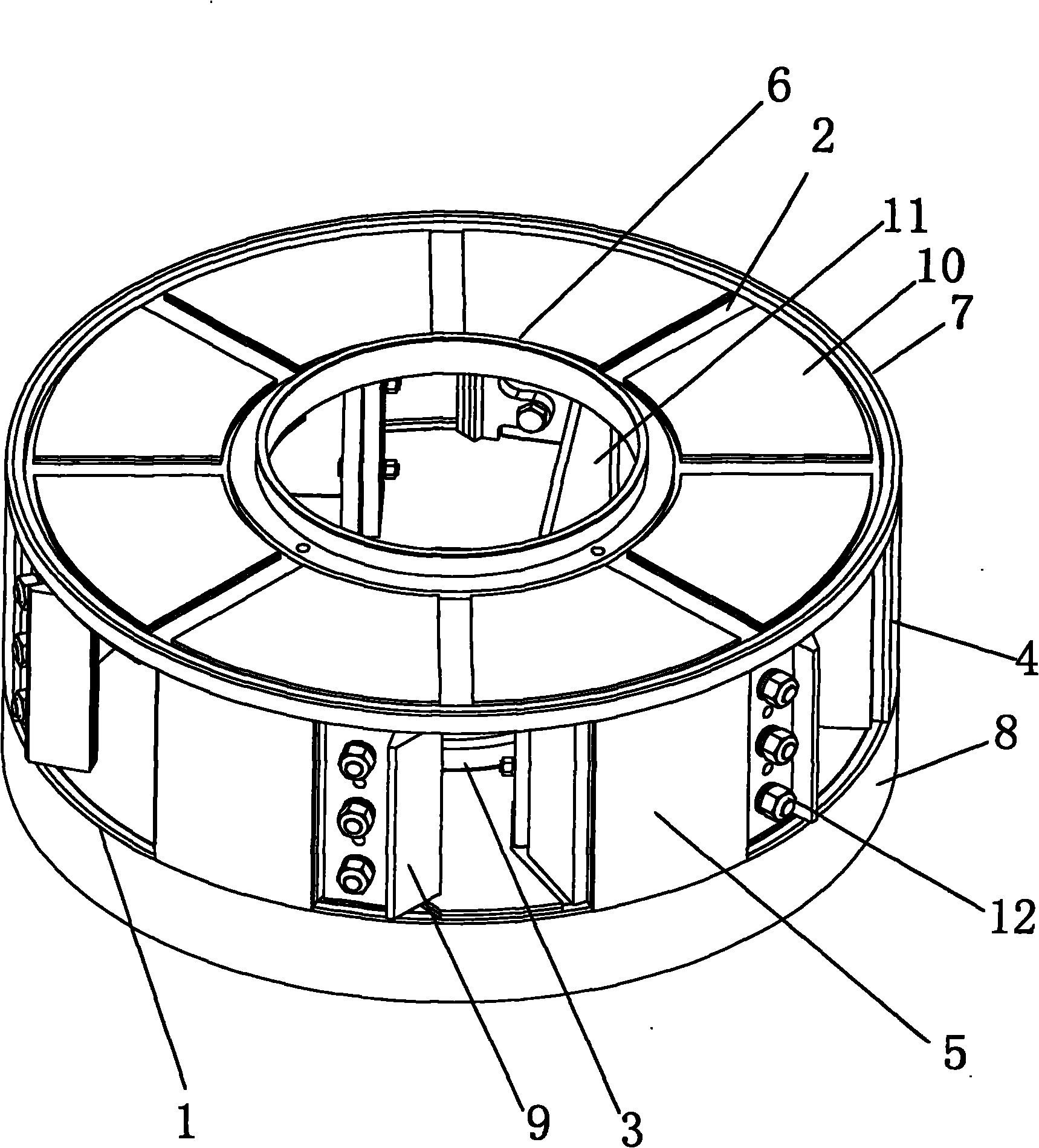

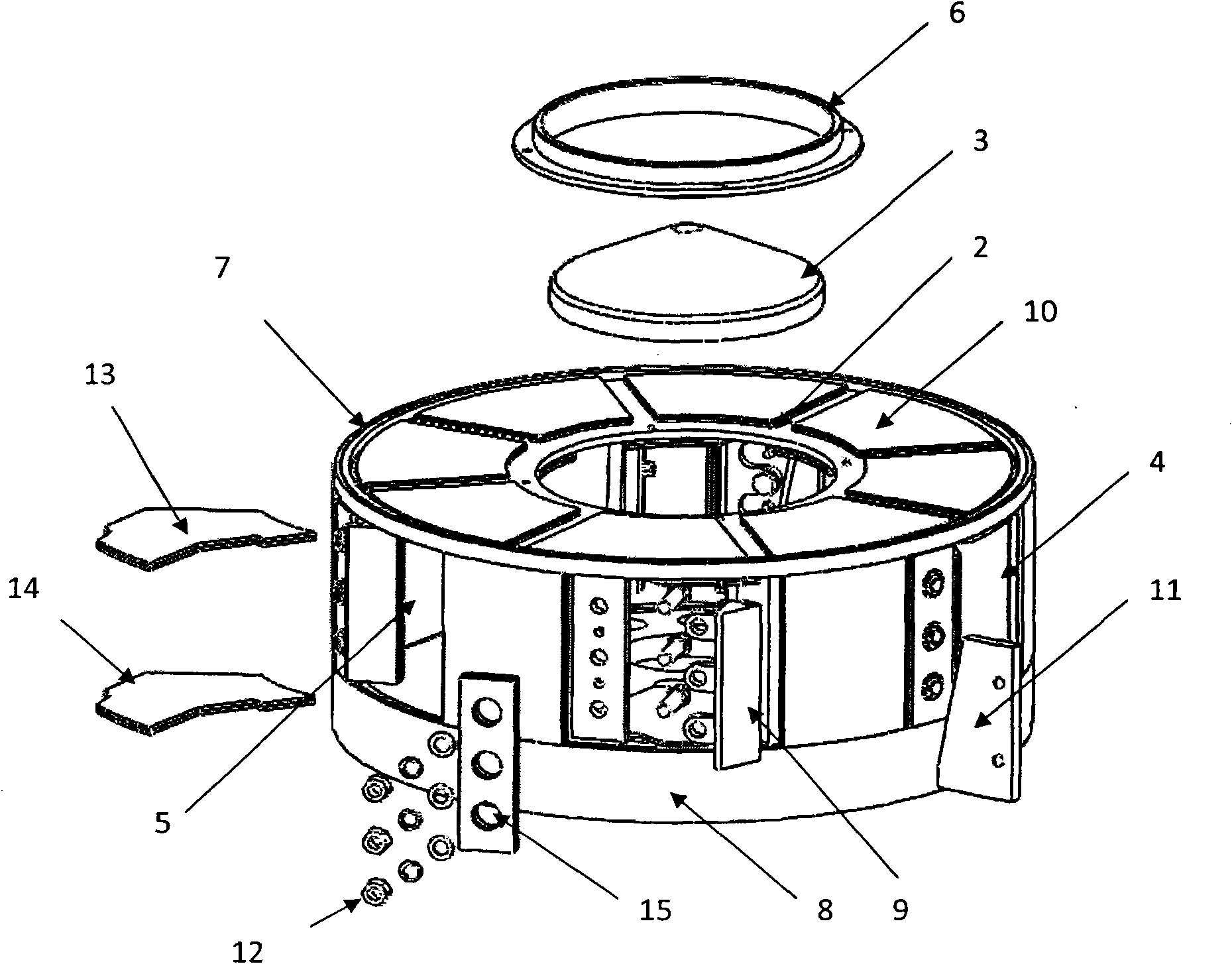

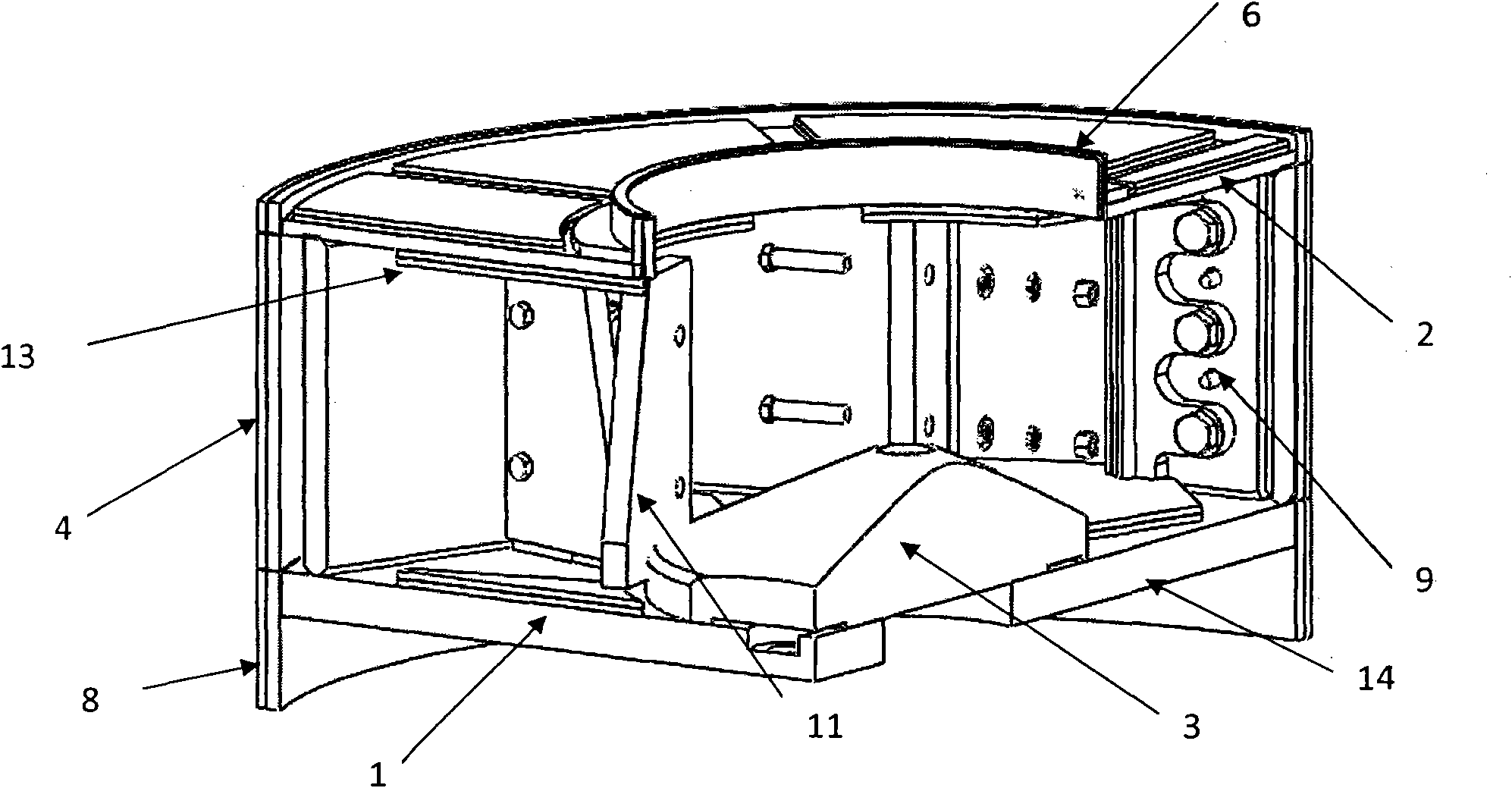

[0020] Such as figure 1 , 2 , 3 shown.

[0021] A structural rotor crusher, including a rotor, a steel cylinder, a drive device, a recovery device, etc., wherein the steel cylinder, drive device, recovery device, etc. Rotor, so the following focuses on the introduction of the rotor. The rotor of the present invention comprises a base plate 1, an annular top plate 2, a material distribution cone 3 and several connecting plates 4, and the material distribution cone 3 is fixed on the base plate 1 by fasteners, such as image 3 As shown, the material distribution cone 3 is a replaceable part, and the connecting plate 4 can be installed between the bottom plate 1 and the annular top plate 2 by welding, riveting or other mechanical processing methods, and a spray port is formed between adjacent connecting plates 4 5. A feeding bin is formed between the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com