Section steel anti-tilt tooling

A profile steel and anti-tilt technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve problems such as damage to the outer surface of angle steel and lower work efficiency of support plates, and achieve the effects of weight reduction, convenient operation, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

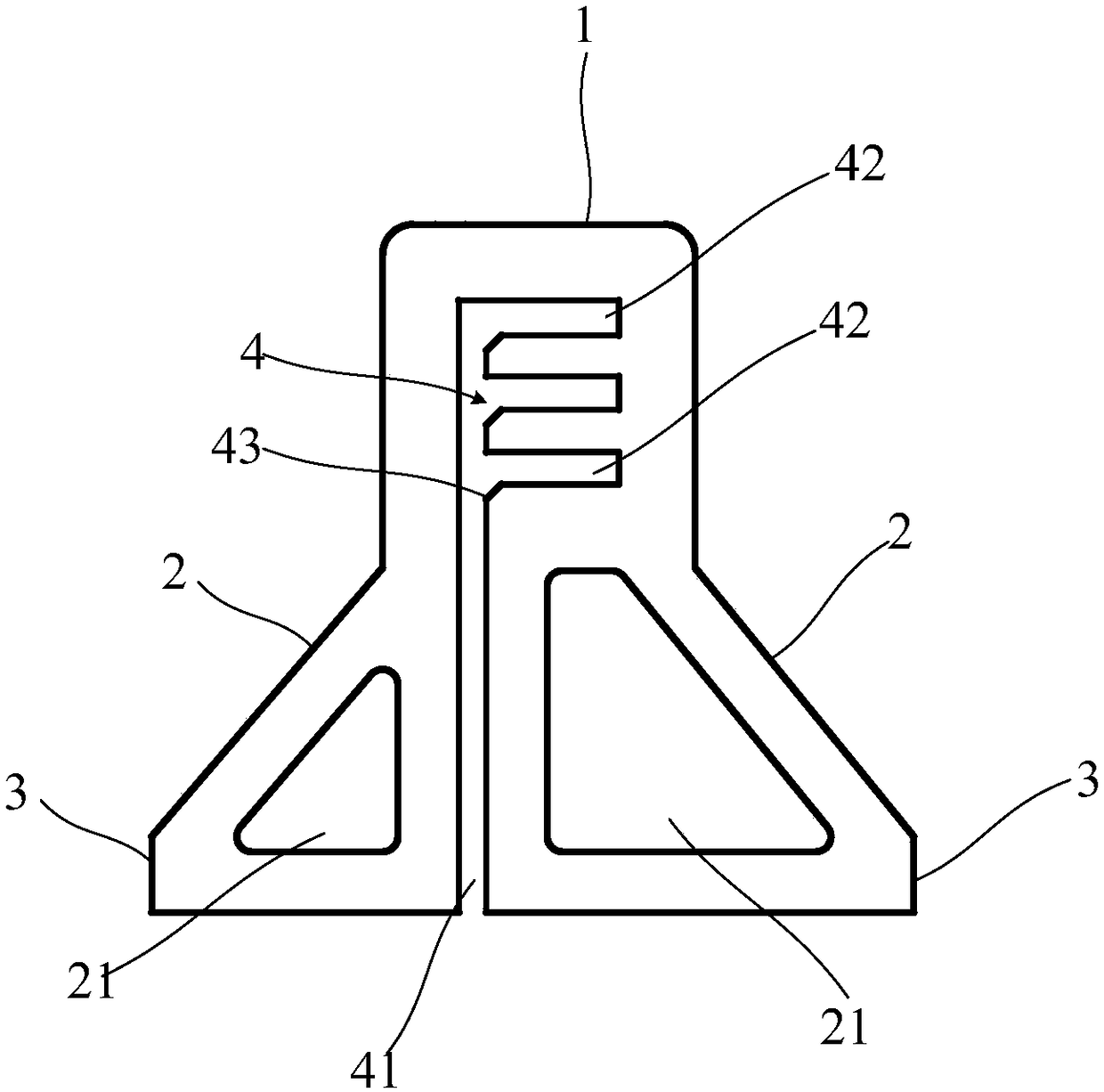

[0044] This embodiment provides a steel anti-tilt tooling, such as figure 1 As shown, the section steel anti-tilt tooling includes a vertical plate 1 , a support plate 2 and a foot 3 that can be erected.

[0045] The height direction of the riser 1 is kept perpendicular to the thickness direction of the riser 1, the riser 1 is provided with a receiving groove 4, the receiving groove runs through the riser 1 along the thickness direction of the riser 1, and the receiving groove 4 includes a first receiving groove 41 and The second accommodating groove 42, the first accommodating groove 41 extends upwards from the lower end of the riser 1, the second accommodating groove 42 and the first accommodating groove 41 are perpendicular to each other, and the second accommodating groove 42 and the first accommodating groove 41 are connected Yes, the second accommodating groove and the first accommodating groove form an L shape.

[0046] The accommodating groove 4 passes through one end...

Embodiment 2

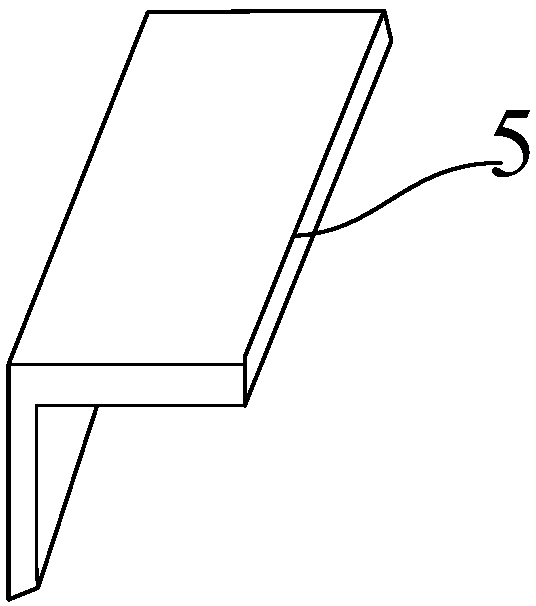

[0057] This embodiment provides a profiled steel anti-tilt tooling, the structure of the profiled steel anti-tilt tooling of this embodiment is roughly similar to the structure of the profiled steel anti-tilt tooling of Embodiment 1, the difference is that, as Figure 4 As shown, the second accommodating groove and the first accommodating groove form a T shape. When applied to angle steel, the T-shaped structure does not need to consider the placement direction of the angle steel, and can also adapt to more types of steel, so the T-shaped structure is more adaptable than the L-shaped structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com