Novel disc type light collecting lens structure

A concentrating mirror and dish-type technology, applied in the field of new dish-type concentrating mirror structure, can solve problems such as high requirements for on-site installation and debugging, additional cost of the control system, and additional loss of the dish mirror structure, and achieves easy cosine loss, small wind load, and The effect of easy production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that this invention is not limited by the specific embodiments.

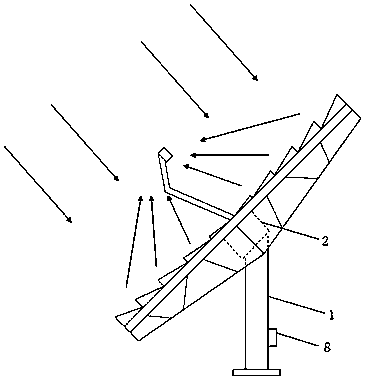

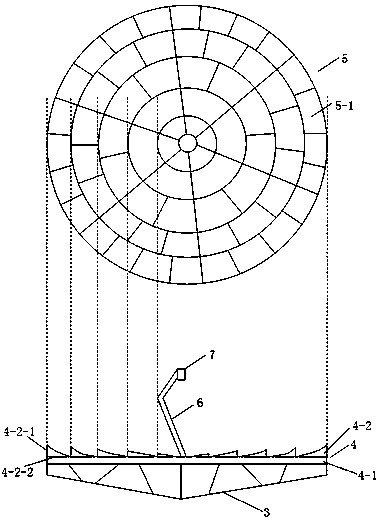

[0034] Such as figure 1 The heat absorption system of the condenser 5 includes a column 1, a back plate 4, a support arm 6, a heat sink 7, a motor, a rotary mechanism 2 and a control cabinet 8, and the center of the back plate 4 of the condenser 5 is installed on the column 1, extending from the column 1 Out of the support arm 6, the heat absorber 7 is installed on the top of the support arm 6. The angle and length of the support arm 6 are calculated so that the heat absorber 7 is located at the focal point of the specular reflection while minimizing the incident sunlight. During normal operation, the control cabinet 8 controls the slewing mechanism 2 to drive the condenser 5 to perform biaxial tracking of the sun in altitude and azimuth to ensure that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com