Radiation-free multi-component rare earth tungsten electrode material and preparing method thereof

A multi-component composite, electrode material technology, used in welding/cutting media/materials, manufacturing tools, welding equipment, etc., can solve problems such as inability to fully exert performance, achieve good sintering effect, reduce cracking, and better performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

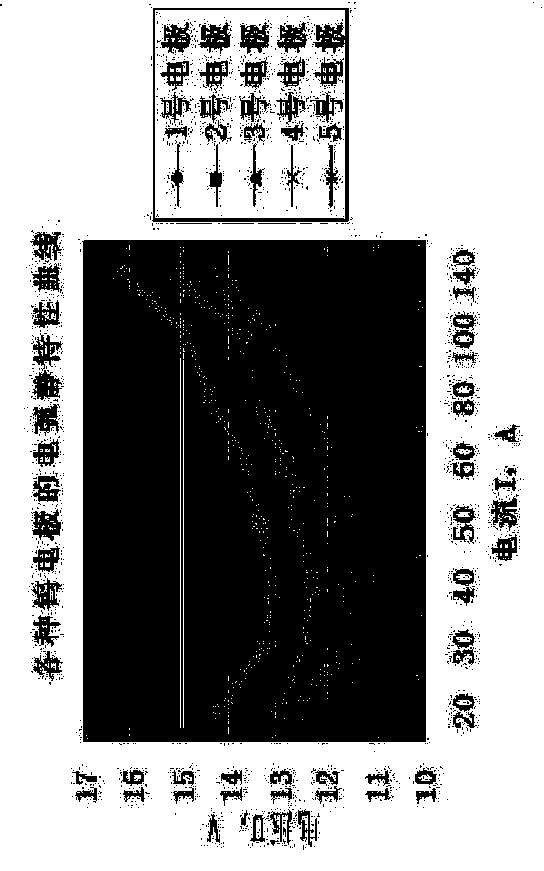

Image

Examples

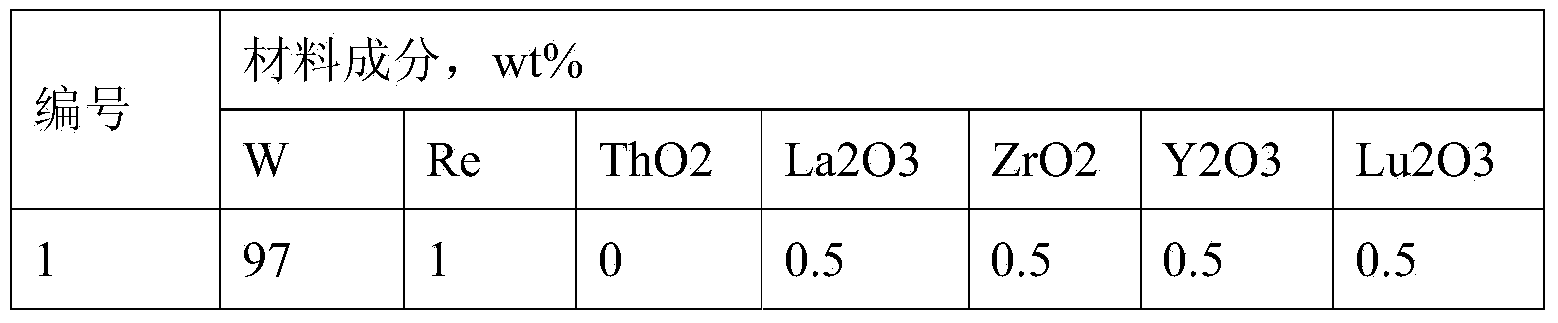

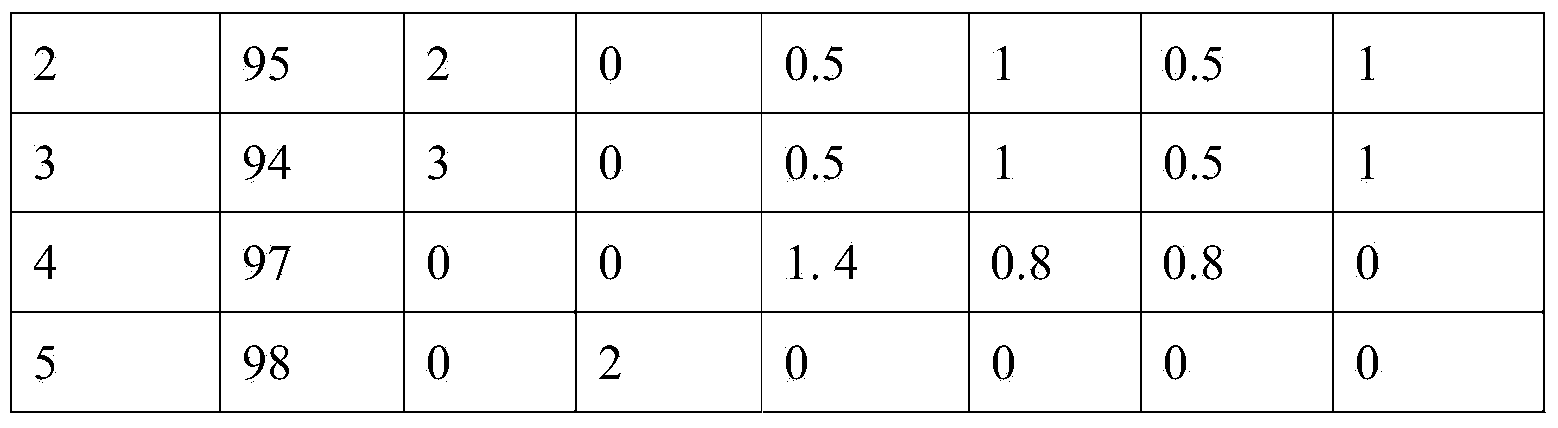

Embodiment 1

[0018] Weigh 19.93g of lanthanum nitrate, 26.13g of zirconium nitrate, 25.44g of yttrium nitrate, 14.28g of lutetium nitrate and 21.6g of ammonium rhenate powder, and configure it into a mixed solution, add 1834.8g of tungsten trioxide powder, stir well, heat and dry to obtain Mix the powder, reduce the mixed powder with hydrogen in a reduction furnace with a temperature of 400°C for 45 minutes, then reduce the mixed powder with hydrogen in a reduction furnace with a temperature of 700°C for 45 minutes, and reduce the mixed powder after two reductions Sieve and set aside. After the sieved mixed powder is fully stirred evenly, weigh 500g and fill it into a soft film bag, put the bag into a cold isostatic press and press it into a cylindrical billet weighing 500g, and the pressing pressure is set at 1000Kg / cm 2 . Pre-sinter the pressed billet under the protection of hydrogen, the sintering temperature is 1100°C, the loading capacity is 5 boats / boat, the sintering time is 30min,...

Embodiment 2

[0020] Weigh 19.93g of lanthanum nitrate, 26.13g of zirconium nitrate, 25.44g of yttrium nitrate, 14.28g of lutetium nitrate and 21.6g of ammonium rhenate powder, and configure it into a mixed solution, add 1834.8g of tungsten trioxide powder, stir well, heat and dry to obtain Mix the powder, reduce the mixed powder with hydrogen in a reduction furnace at a temperature of 500°C for 60 minutes, then reduce the mixed powder with hydrogen in a reduction furnace at a temperature of 800°C for 60 minutes, and reduce the mixed powder after two reductions Sieve and set aside. After the sieved mixed powder is fully stirred evenly, weigh 1000g and fill it into a soft film bag, put the bag into a cold isostatic press and press it into a cylindrical billet weighing 1000g, and the pressing pressure is set at 1500Kg / cm 2 . Pre-sinter the pressed billet under the protection of hydrogen, the sintering temperature is 1200°C, the loading capacity is 8 boats / boat, the sintering time is 50min, a...

Embodiment 3

[0022] Weigh 19.93g of lanthanum nitrate, 26.13g of zirconium nitrate, 25.44g of yttrium nitrate, 14.28g of lutetium nitrate and 21.6g of ammonium rhenate powder, and configure it into a mixed solution, add 1834.8g of tungsten trioxide powder, stir well, heat and dry to obtain Mix the powder, reduce the mixed powder with hydrogen in a reduction furnace at a temperature of 700°C for 75min, then reduce the mixed powder with hydrogen in a reduction furnace with a temperature of 1000°C for 75min, pass the mixed powder after twice reduction Sieve and set aside. After the sieved mixed powder is fully stirred evenly, weigh 2500g and fill it into a soft film bag, put the bag into a cold isostatic press and press it into a cylindrical billet weighing 2500g, and the pressing pressure is set at 3000Kg / cm 2 . Pre-sinter the pressed billets under the protection of hydrogen, the sintering temperature is 1300°C, the loading capacity is 10 boats / boat, the sintering time is 60min, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com