Fireproof heat preservation partition wall board and preparation method thereof

A technology for fire prevention, heat preservation and partition board, which is applied in ceramic products, other household appliances, building components, etc., can solve the problems of weakening the overall competitive advantage of lightweight partition boards, low mechanical performance test results, and poor surface density control. , to achieve the effect of shortening the construction period, low cost, and improving the degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment relates to the preparation of a fireproof and thermal insulation partition wall board.

Embodiment 11

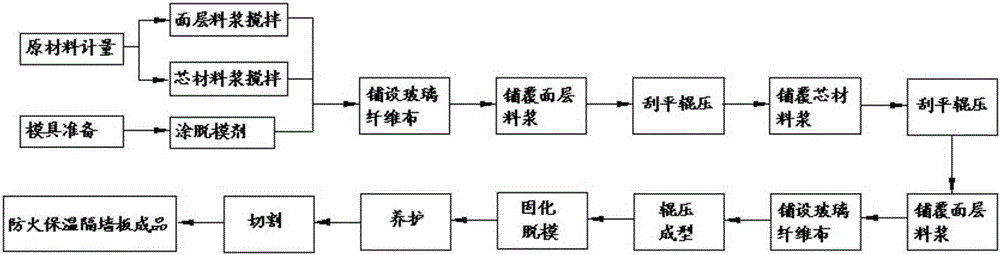

[0044] This embodiment relates to the preparation of a fireproof and thermal insulation partition wall board, comprising the following steps:

[0045] a. Pretreatment of the mold plate: select the mold plate, requiring that (1) the surface is smooth and smooth without pitting; (2) the thickness is consistent, and the thickness is generally required to reach 8 mm; (3) set the length and width specifications according to production needs, such as length 2.44 meters, width 1.22 (4) It has toughness, waterproof performance and non-deformability, and any plate that meets the above requirements can be used; clean the surface of the selected mold plate and wipe the mold release agent;

[0046] b1, prepare the surface layer slurry, the surface layer slurry includes the following weight raw materials:

[0047] 86kg of magnesium sulfate solution with a Baume degree of 22-30, 100kg of light-burned magnesium oxide, 2kg of potassium methyl silicate, 1kg of mortar concrete fiber short filam...

Embodiment 12

[0059] This embodiment relates to the preparation of a fireproof and thermal insulation partition wall board, comprising the following steps:

[0060] a. Pretreatment of the mold board: when selecting the mold board, it is required that (1) the surface is flat and smooth without pitting; (2) the thickness is consistent; (3) the length and width specifications are set according to the production needs; Any plate can be used; clean the surface of the selected mold plate and then wipe the release agent;

[0061] b1, prepare the surface layer slurry, the surface layer slurry includes the following weight raw materials:

[0062] 88kg of magnesium sulfate solution with a Baume degree of 22-30, 100kg of light-burned magnesium oxide, 3kg of potassium methyl silicate, 1.2kg of mortar concrete fiber short filaments, and 1kg of modifier;

[0063] Prepare a magnesium sulfate solution according to the production temperature 12 hours in advance, and age it for later use;

[0064] After mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com